Investigating Hydrofracture Evolution of Quasi-Brittle Material Using a Post-Peak Control Technique Associated with Speckle-Shearing Interferometry †

Abstract

:1. Introduction

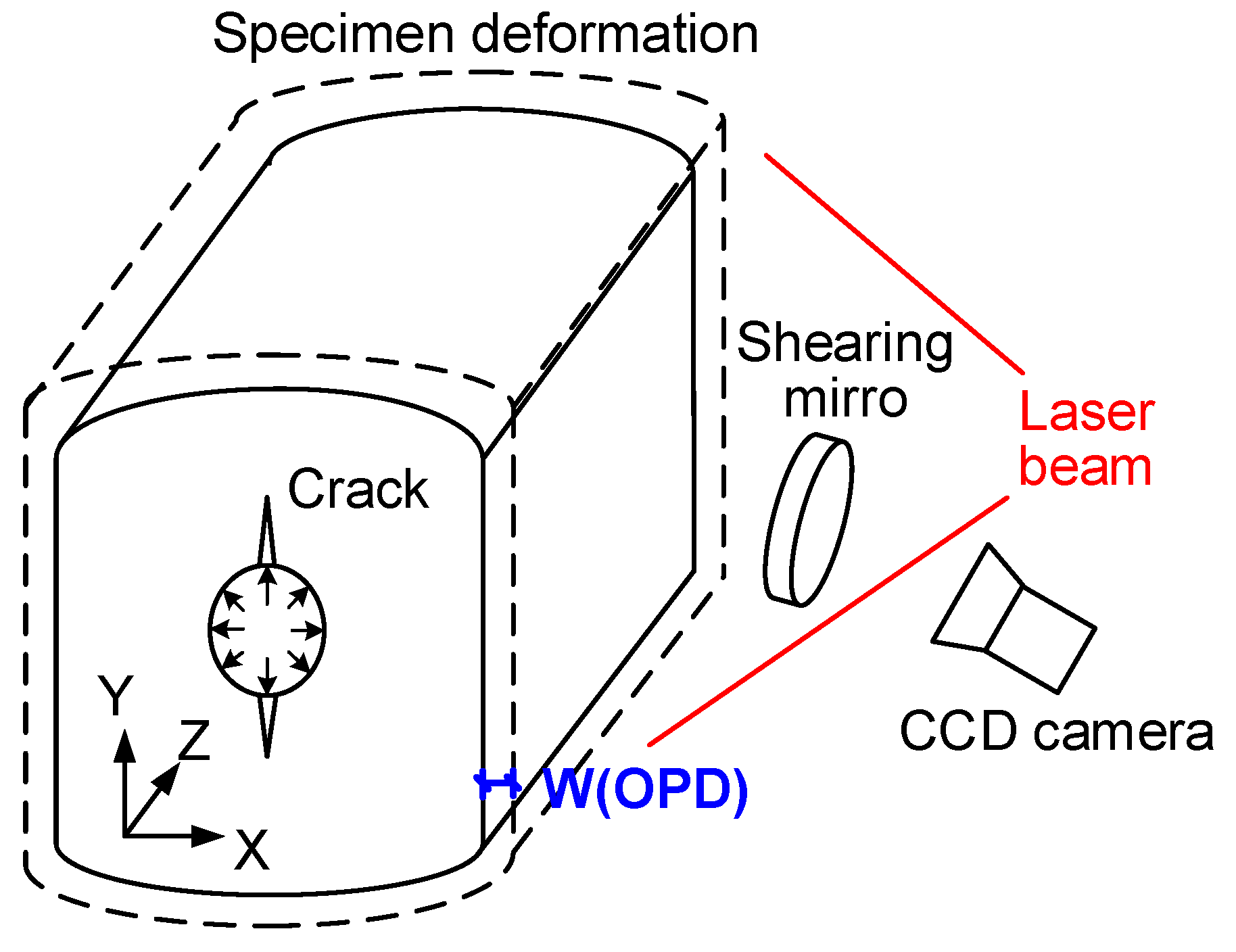

2. Speckle-Shearing Interferometry

3. Test material and Specimen Preparation

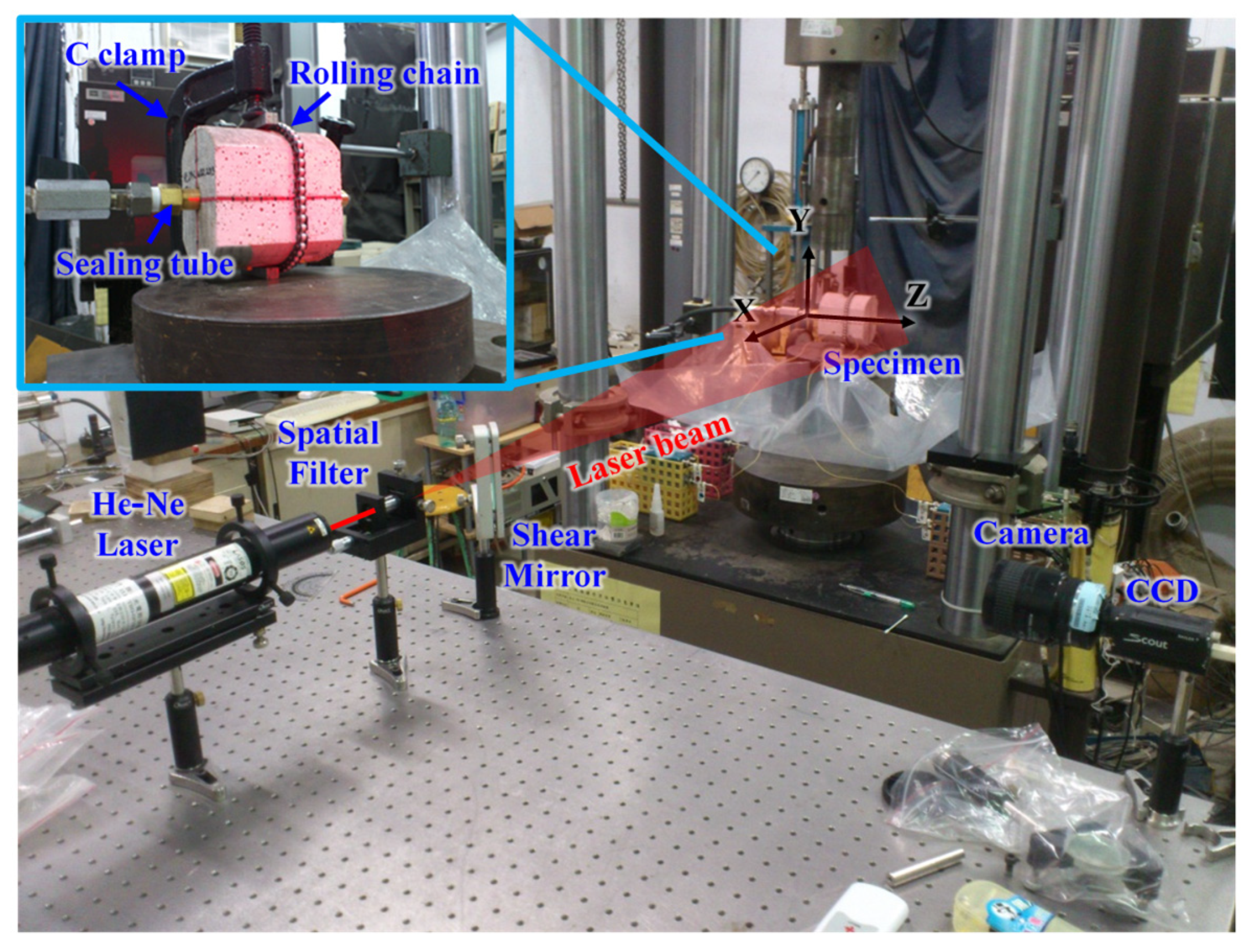

4. Experimental Setup of Hydraulic Fracture and SSI

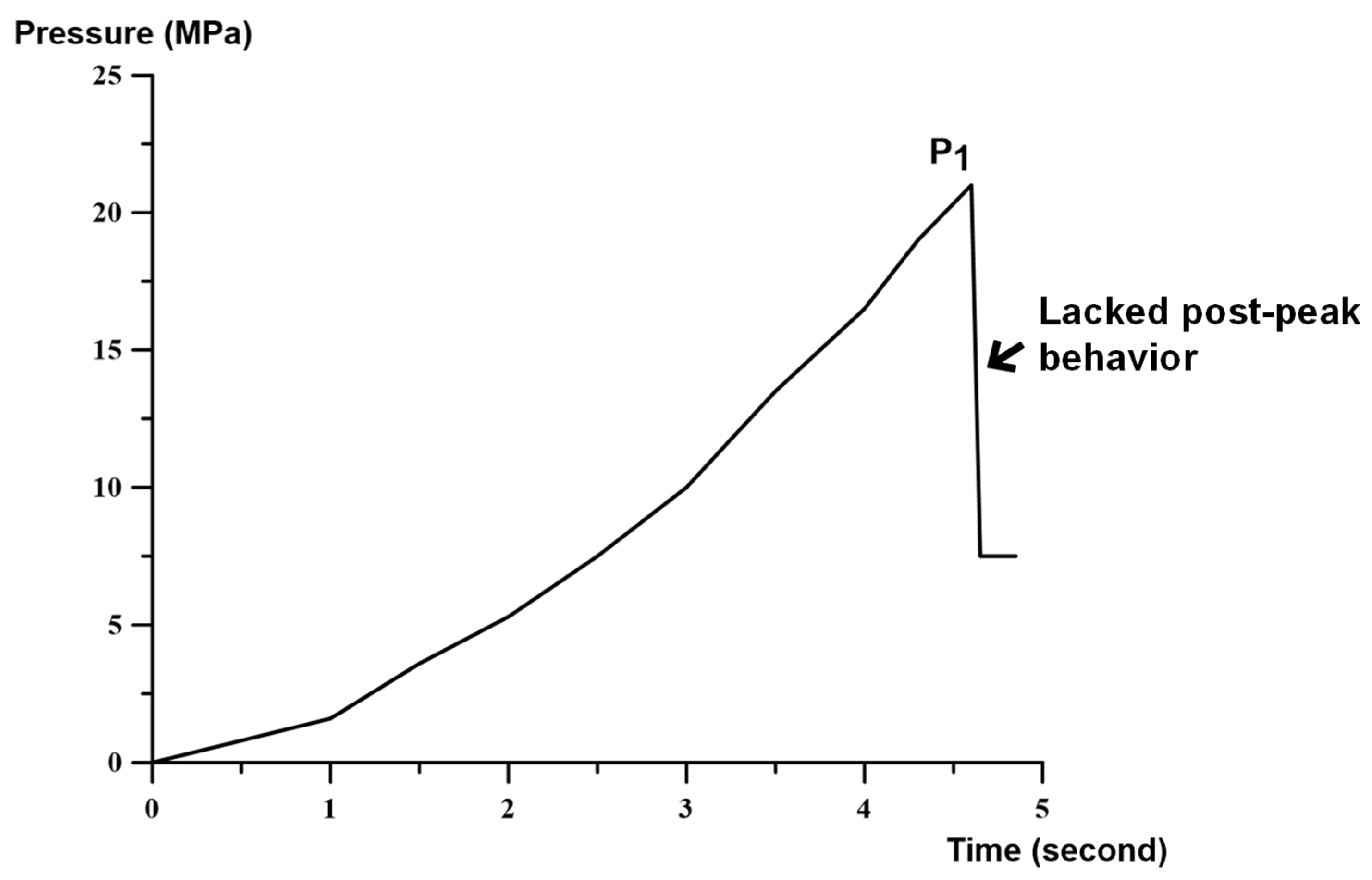

4.1. Hydraulic Fracture Apparatus with Post-Peak Control System

4.2. Optical Equipment

5. Results and Discussion

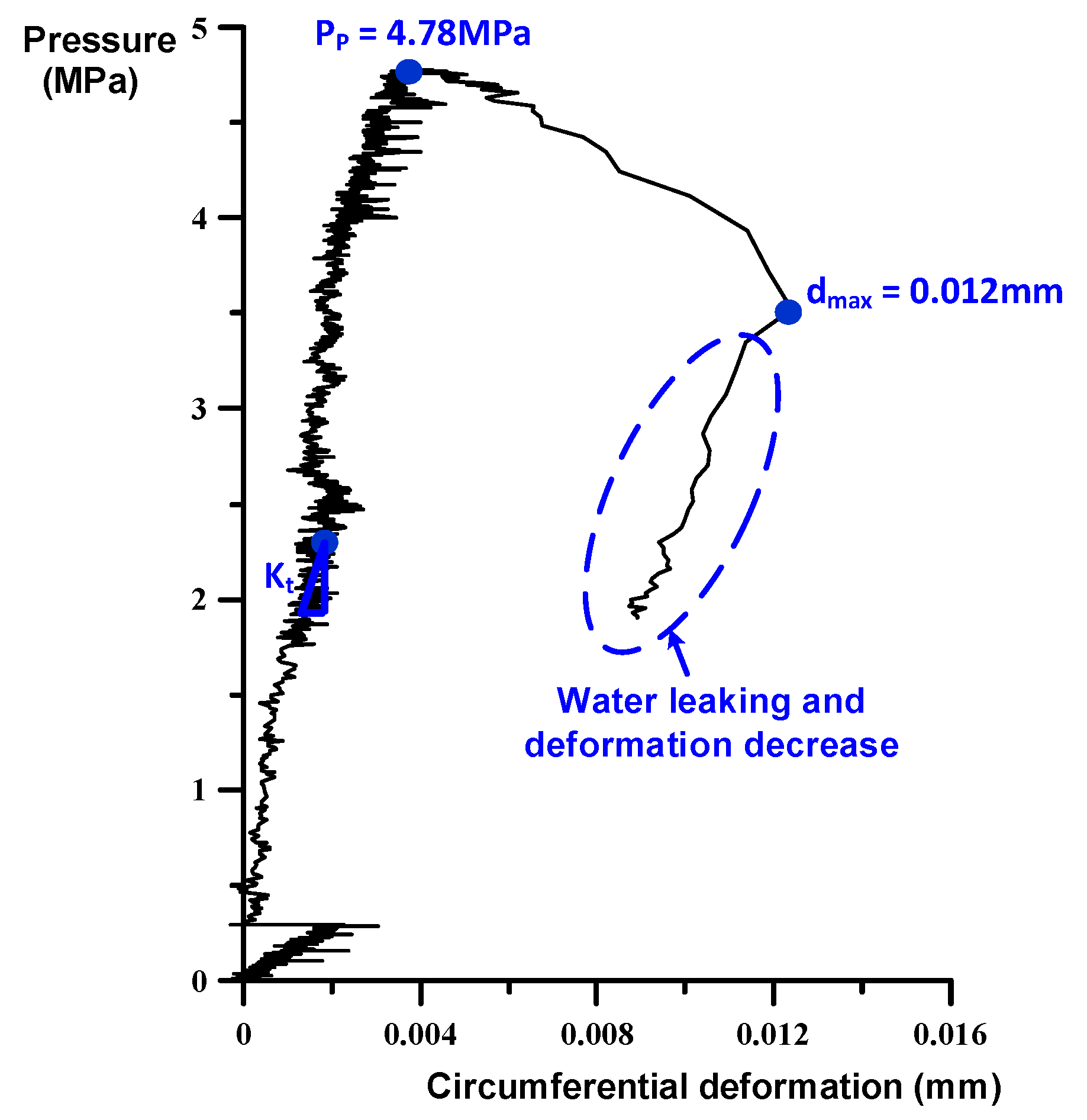

5.1. Entire Loading Curve

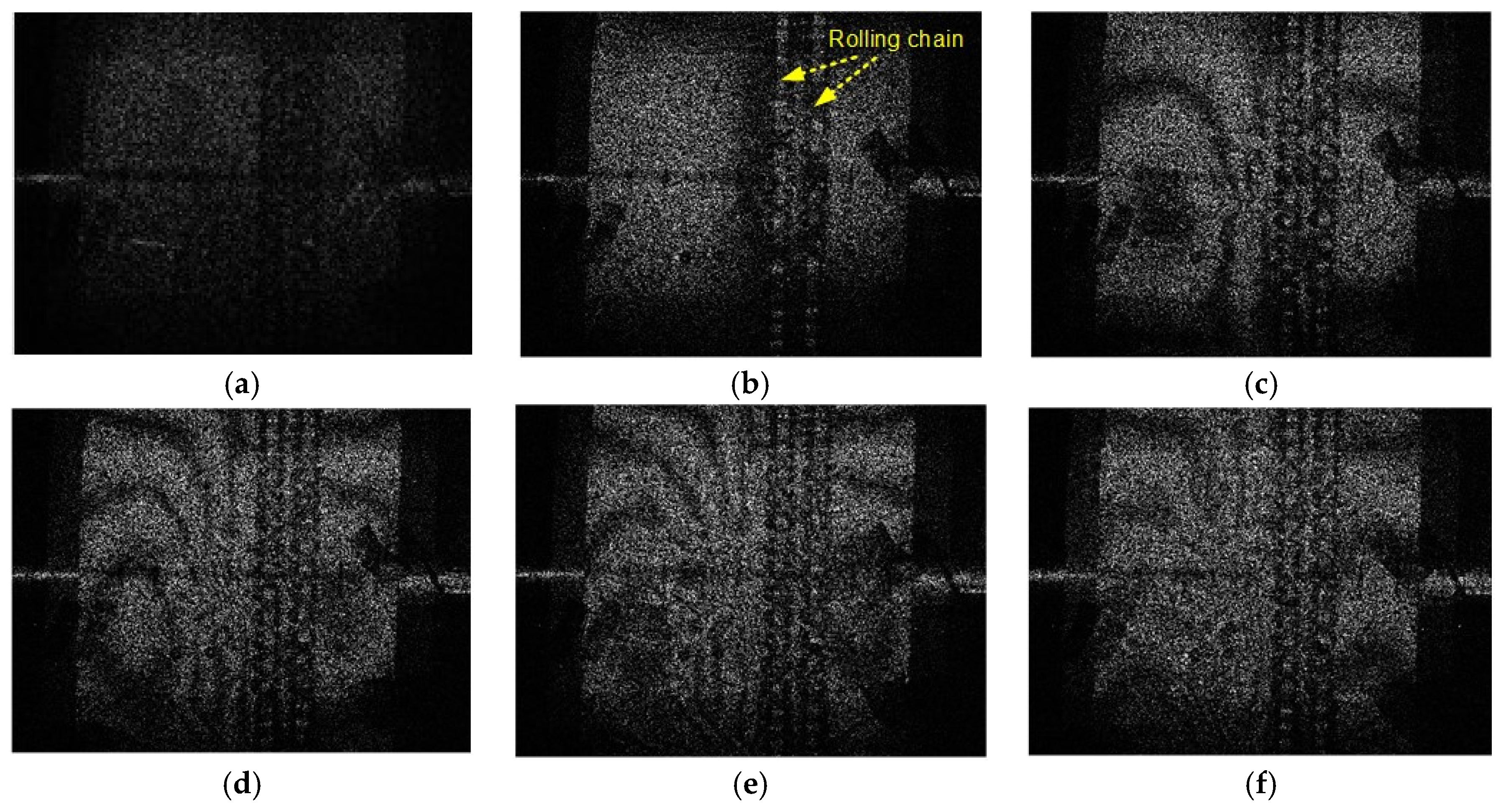

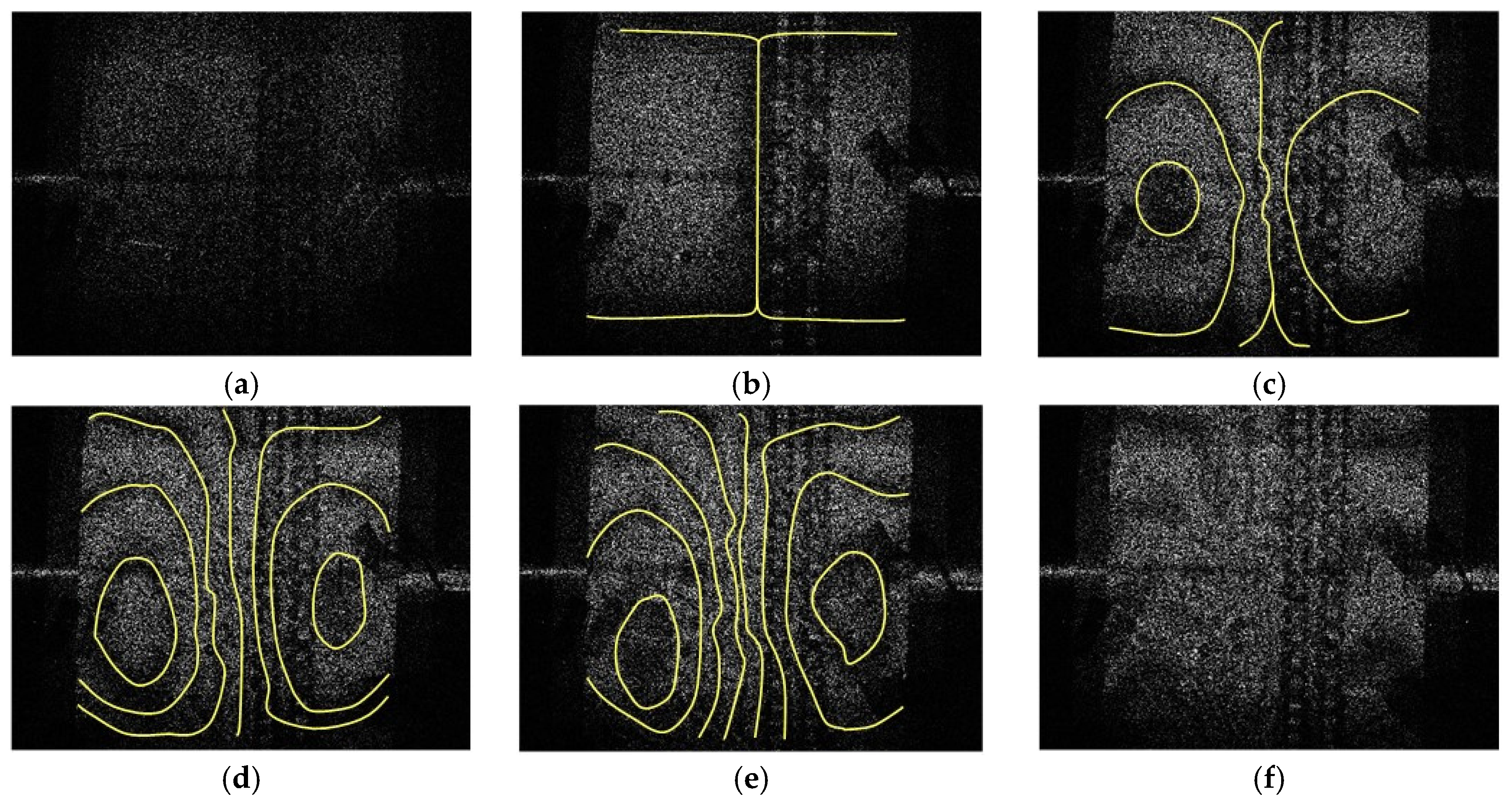

5.2. Fringe Pattern Evolution

Author Contributions

Acknowledgments

References

- Wu, R. Some Fundamental Mechanisms of Hydraulic Fracturing. Ph.D. Dissertation, Georgia Institute of Technology, Atlanta, GA, USA, 17 November 2005. [Google Scholar]

- Chen, L.-H.; Chen, W.-C.; Chen, Y.-C.; Benyamin, L.; Li, A.-J. Investigation of Hydraulic Fracture Propagation Using a Post-peak Control System Coupled with Acoustic Emission. Rock Mech. Rock Eng. 2015, 48, 1233–1248. [Google Scholar] [CrossRef]

- Bunger, A.P.; Gordeliy, E.; Detournay, E. Comparison between Laboratory Experiments and Coupled Simulations of Saucer-shaped Hydraulic Fractures in Homogeneous Brittle-elastic Solids. J. Mech. Phys. Solids 2013, 61, 1636–1654. [Google Scholar] [CrossRef]

- Guo, T.; Zhang, S.; Qu, Z.; Zhou, T.; Xiao, Y.; Gao, J. Experimental Study of Hydraulic Fracturing for Shale by Stimulated Reservoir Volume. Fuel 2014, 128, 373–380. [Google Scholar] [CrossRef]

- Liu, P.; Ju, Y.; Ranjith, P.G.; Zheng, Z.; Chen, J. Experimental Investigation of the Effects of Heterogeneity and Geostress Difference on the 3D Growth and Distribution of Hydrofracturing Cracks in Unconventional Reservoir Rocks. J. Nat. Gas Sci. Eng. 2016, 35, 541–554. [Google Scholar] [CrossRef]

- Yushi, Z.; Shicheng, Z.; Tong, Z.; Xiang, Z. Experimental Investigation into Hydraulic Fracture Network Propagation in Gas Shales using CT Scanning Technology. Rock Mech. Rock Eng. 2015, 49, 33–45. [Google Scholar] [CrossRef]

- Butters, J.N.; Leendertz, J.A. Holographic and Video Techniques Applied to Engineering Measurement. Meas. Control 1971, 4, 349–354. [Google Scholar] [CrossRef]

- Leendertz, J.A.; Butters, J.N. An Image-shearing Speckle-pattern Interferometer for Measuring Bending Moments. J. Phys. E Sci. Instrum. 1973, 6, 1107. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, W.-C.; Chen, L.-H.; Lin, S.-T.; Chen, Y.-C. Investigating Hydrofracture Evolution of Quasi-Brittle Material Using a Post-Peak Control Technique Associated with Speckle-Shearing Interferometry. Proceedings 2018, 2, 452. https://doi.org/10.3390/ICEM18-05326

Chen W-C, Chen L-H, Lin S-T, Chen Y-C. Investigating Hydrofracture Evolution of Quasi-Brittle Material Using a Post-Peak Control Technique Associated with Speckle-Shearing Interferometry. Proceedings. 2018; 2(8):452. https://doi.org/10.3390/ICEM18-05326

Chicago/Turabian StyleChen, Wei-Chih, Li-Hsien Chen, Shyh-Tsong Lin, and Yao-Chung Chen. 2018. "Investigating Hydrofracture Evolution of Quasi-Brittle Material Using a Post-Peak Control Technique Associated with Speckle-Shearing Interferometry" Proceedings 2, no. 8: 452. https://doi.org/10.3390/ICEM18-05326

APA StyleChen, W.-C., Chen, L.-H., Lin, S.-T., & Chen, Y.-C. (2018). Investigating Hydrofracture Evolution of Quasi-Brittle Material Using a Post-Peak Control Technique Associated with Speckle-Shearing Interferometry. Proceedings, 2(8), 452. https://doi.org/10.3390/ICEM18-05326