Analysis and Reliability Study of Luminescent Materials for White Lighting †

Abstract

:1. Introduction

2. Methods

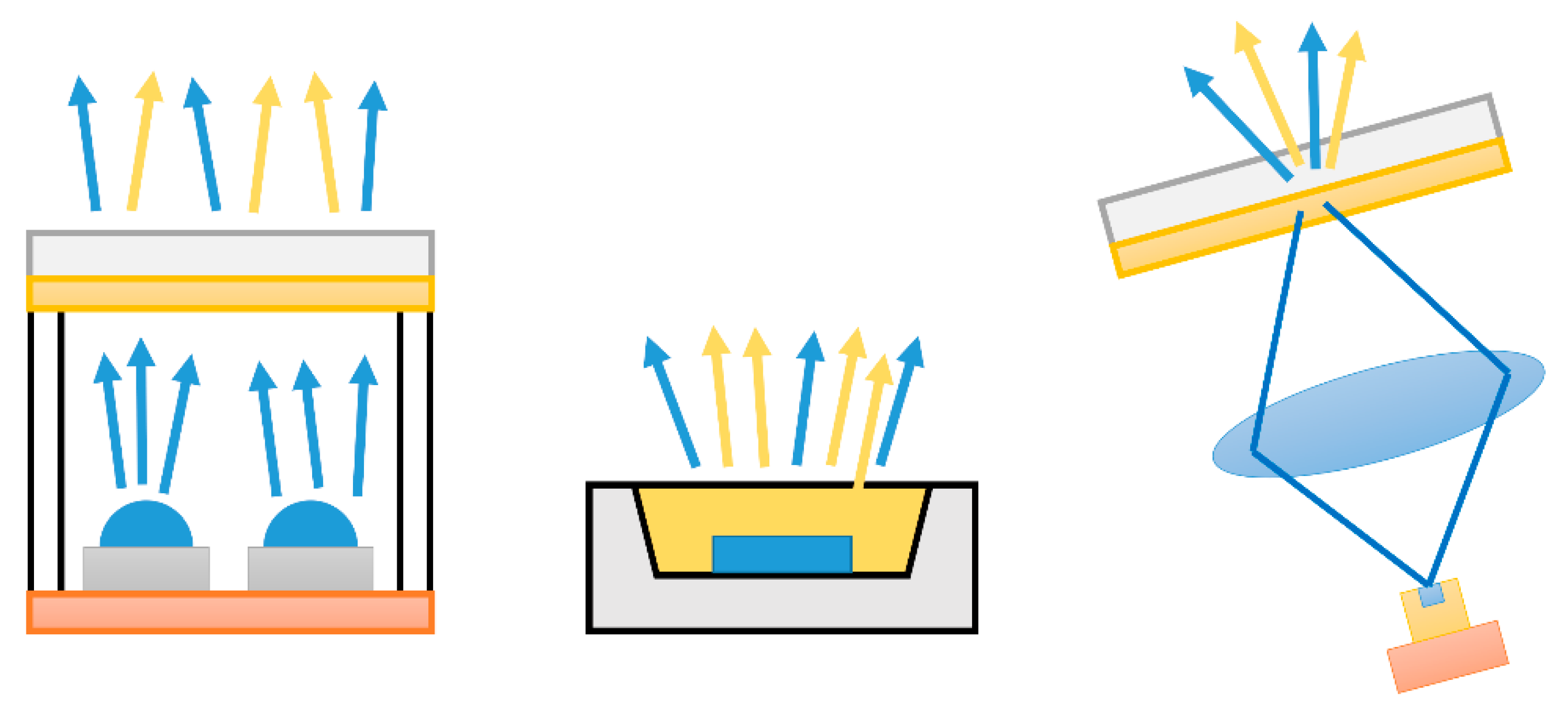

2.1. Remote Phosphors for LED Application

2.2. Silicone-Encapsulated Phosphors in Mid-Power LEDs

2.3. Phosphors for Laser Applications

3. Results and Discussion

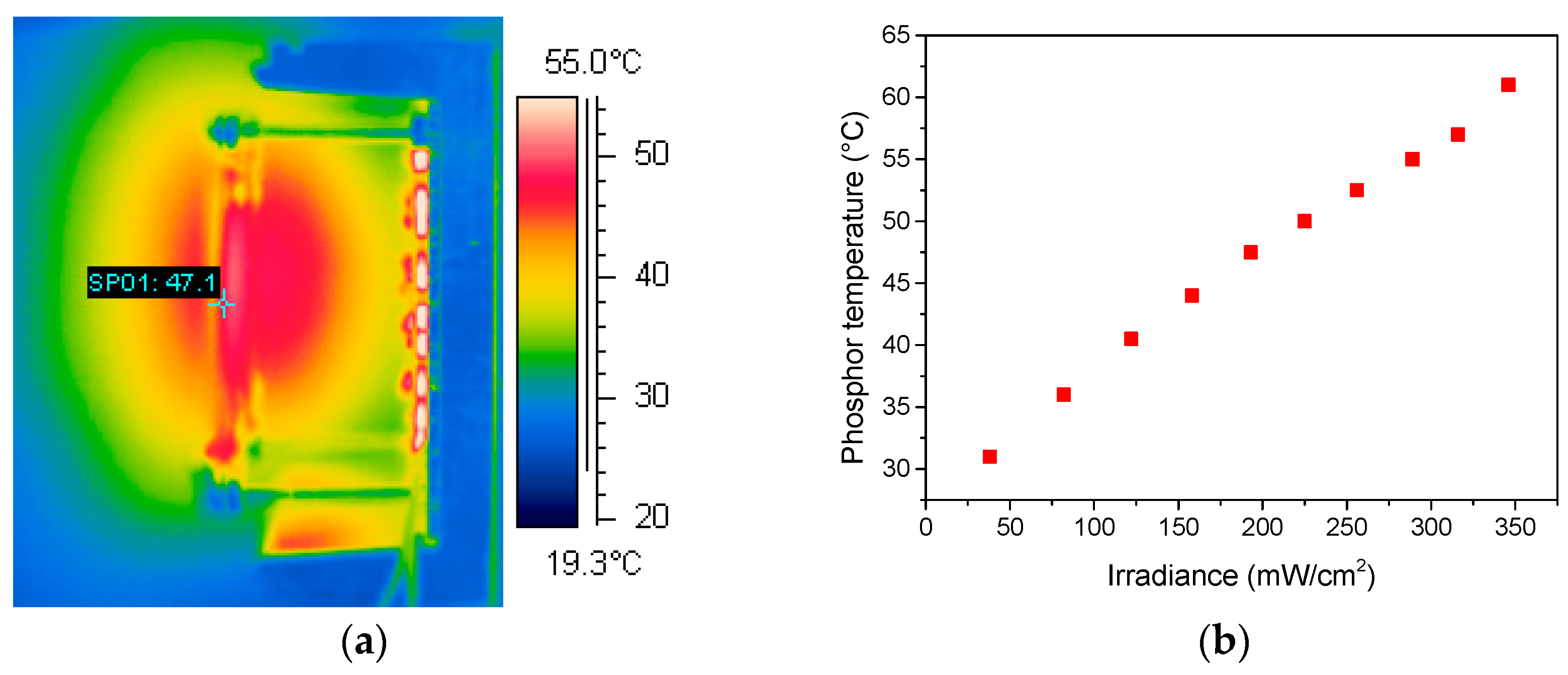

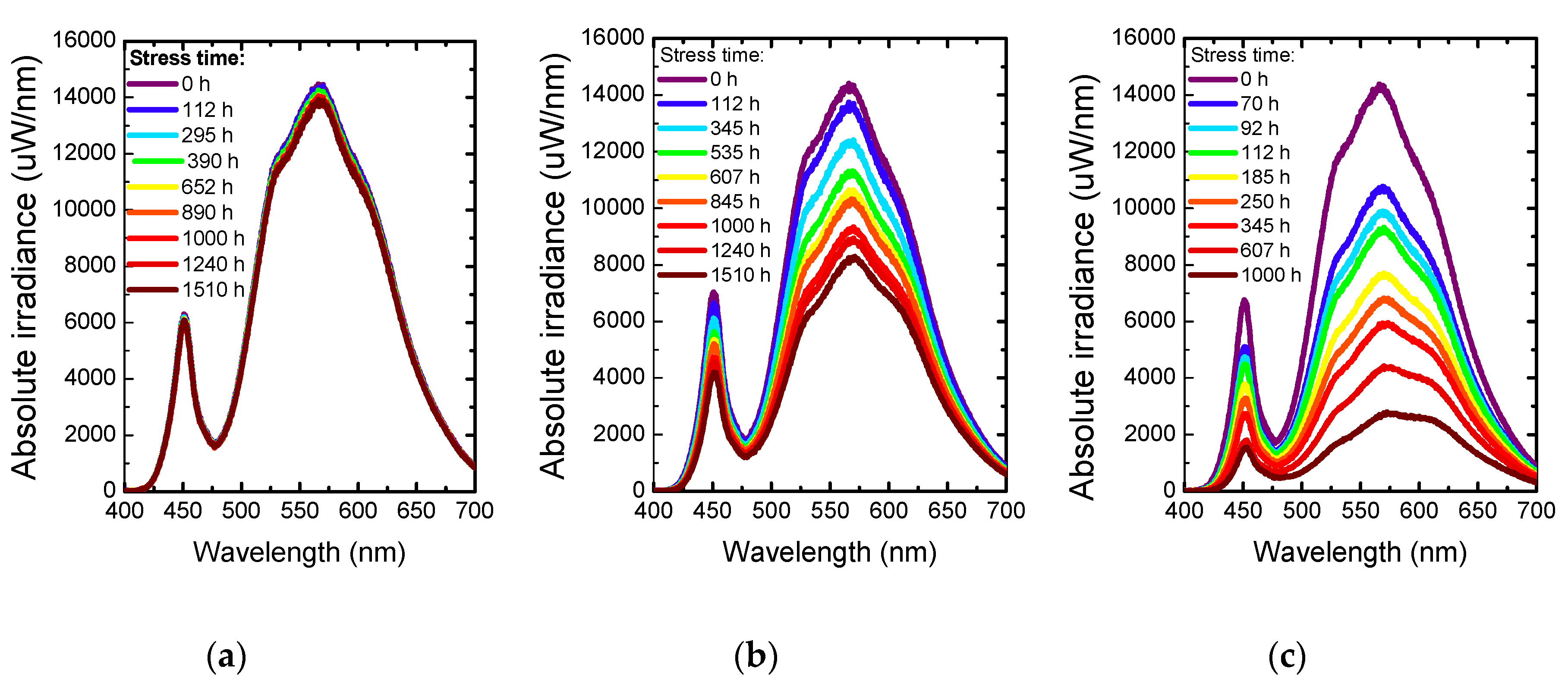

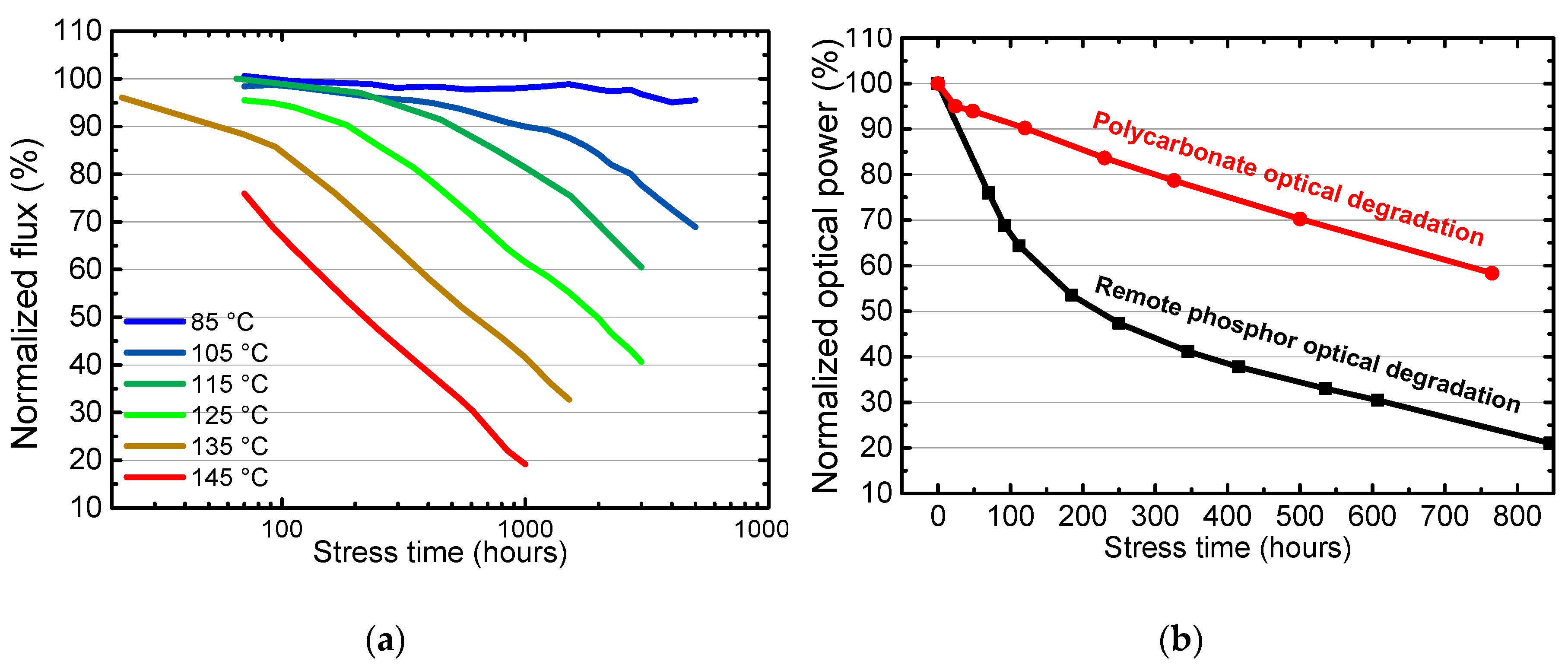

3.1. Remote Phosphors for LED Application

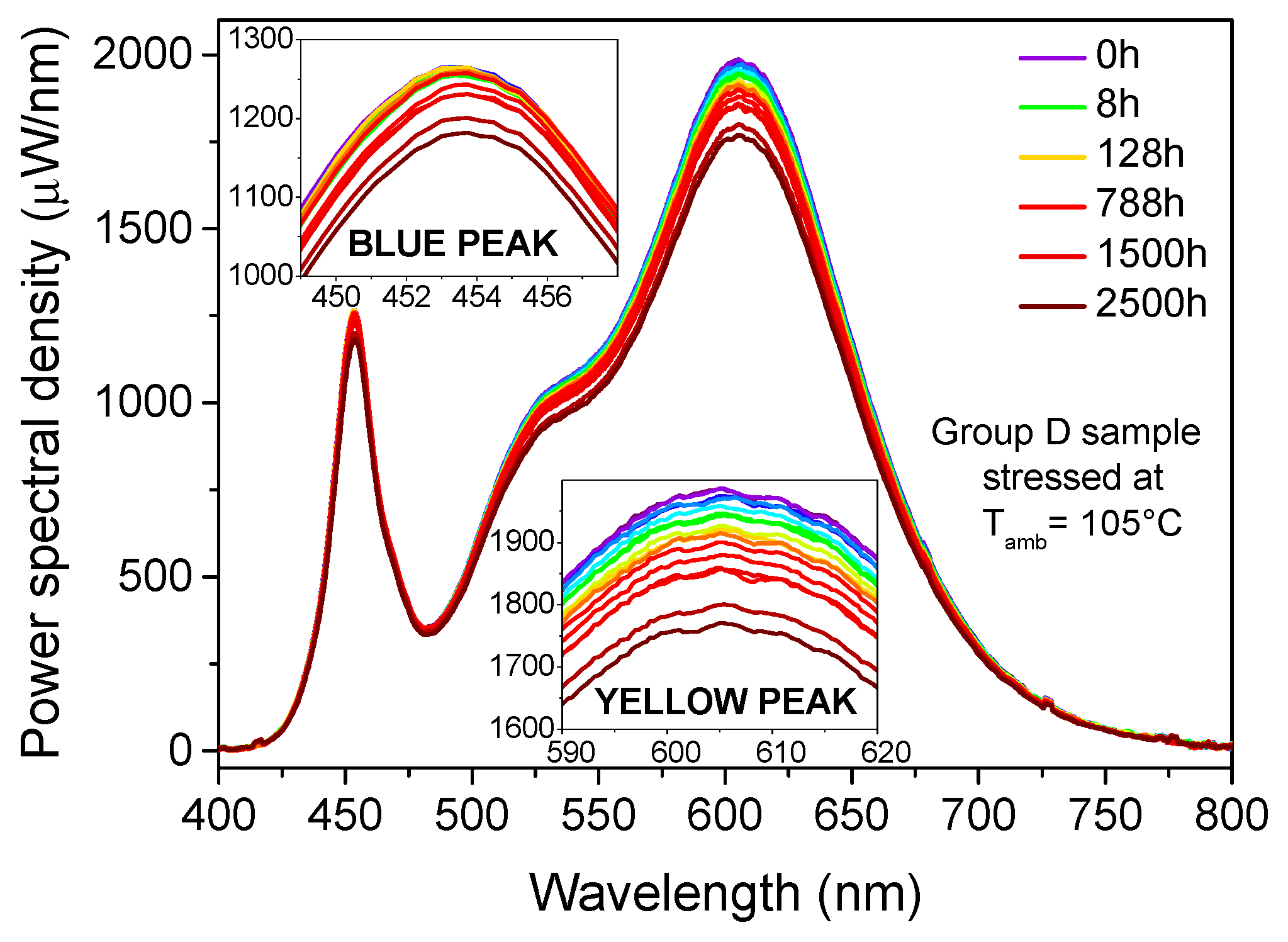

3.2. Silicone-Encapsulated Phosphors in Mid-Power LEDs

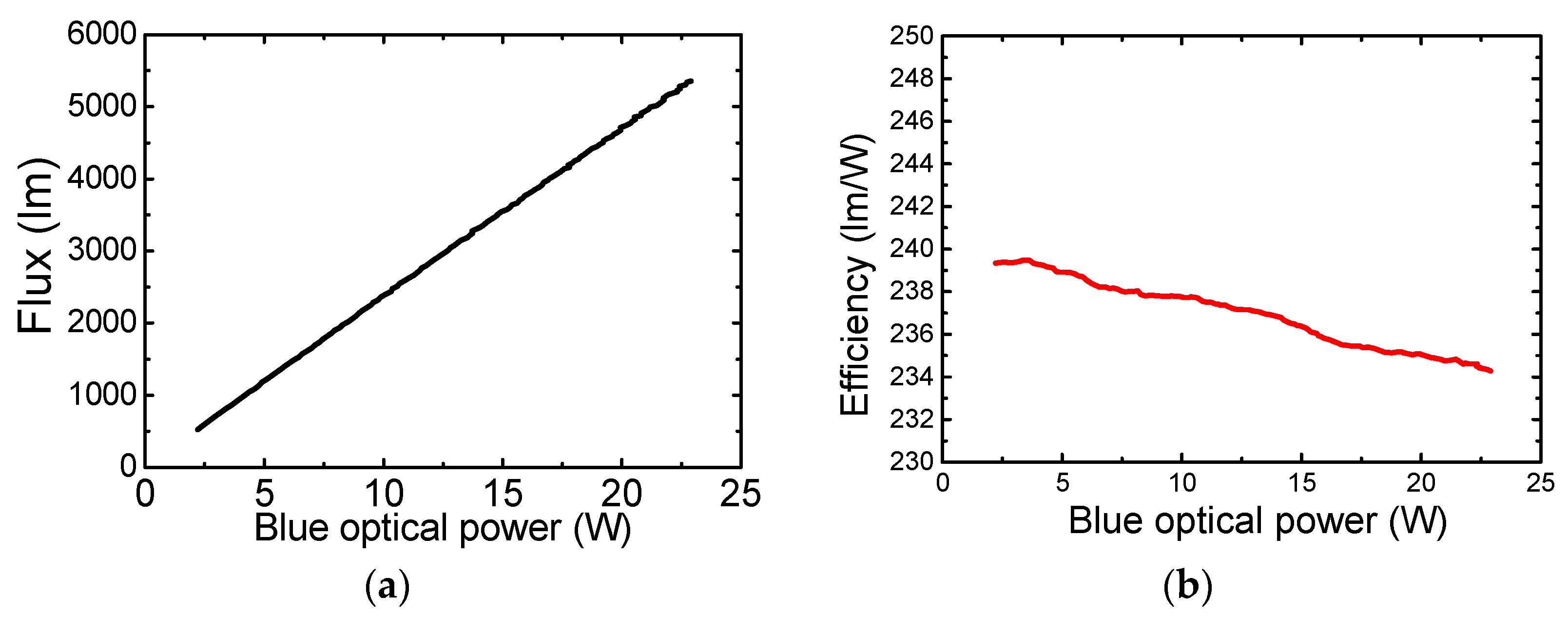

3.3. Phosphors for Laser Applications

4. Conclusions

References

- Trevisanello, L.; De Zuani, F.; Meneghini, M.; Trivellin, N.; Zanoni, E.; Meneghesso, G. Thermally activated degradation and package instabilities of low flux LEDS. In Proceedings of the IEEE International Reliability Physics Symposium, Montreal, QC, Canada, 26–30 April 2009; pp. 98–103. [Google Scholar]

- Kim, J.K.; Luo, H.; Schubert, E.F.; Cho, J.; Sone, C.; Park, Y. Strongly Enhanced Phosphor Efficiency in GaInN White Light-Emitting Diodes Using Remote Phosphor Configuration and Diffuse Reflector Cup. Jpn. J. Appl. Phys. 2005, 44, L649. [Google Scholar] [CrossRef]

- Dal Lago, M.; Meneghini, M.; Trivellin, N.; Mura, G.; Vanzi, M.; Meneghesso, M.; Zanoni, E. Phosphors for LED-based light sources: Thermal properties and reliability issues. Microelectron. Reliab. 2012, 52, 2164–2167. [Google Scholar] [CrossRef]

- Bachmann, V.; Ronda, C.; Meijerink, A. Temperature Quenching of Yellow Ce3+ Luminescence in YAG:Ce. Chem. Mater. 2009, 21, 2077–2084. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Trivellin, N.; Meneghini, M.; Buffolo, M.; Meneghesso, G.; Zanoni, E. Analysis and Reliability Study of Luminescent Materials for White Lighting. Proceedings 2018, 2, 1158. https://doi.org/10.3390/ecms2018-05233

Trivellin N, Meneghini M, Buffolo M, Meneghesso G, Zanoni E. Analysis and Reliability Study of Luminescent Materials for White Lighting. Proceedings. 2018; 2(17):1158. https://doi.org/10.3390/ecms2018-05233

Chicago/Turabian StyleTrivellin, Nicola, Matteo Meneghini, Matteo Buffolo, Gaudenzio Meneghesso, and Enrico Zanoni. 2018. "Analysis and Reliability Study of Luminescent Materials for White Lighting" Proceedings 2, no. 17: 1158. https://doi.org/10.3390/ecms2018-05233

APA StyleTrivellin, N., Meneghini, M., Buffolo, M., Meneghesso, G., & Zanoni, E. (2018). Analysis and Reliability Study of Luminescent Materials for White Lighting. Proceedings, 2(17), 1158. https://doi.org/10.3390/ecms2018-05233