Abstract

In this contribution we present a highly miniaturized device that integrates a photoactive material with a highly efficient LED light source. This so-called micro light plate configuration (µLP) allows for maximizing the irradiance impinging on the photoactive material, with a minimum power consumption, excellent uniformity and accurate control of the illumination. We demonstrate that, with the µLP approach, very efficient low power gas sensors can be built, and provide a detailed analysis of the rationales behind such improvement, as well as a quantitative model and a set of design rules to implement it in further integrated applications. As a demonstrator, we will describe a NO2 gas sensor operating in the part per billion range (ppb) with microwatt (µW) power consumption. These are the best figures reported to date in conductometric metal-oxides (MOX) sensors operated with light (instead of heat) at room temperature.

1. Motivation

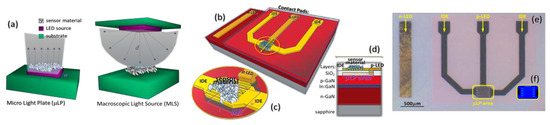

Conventional conductometric MOX-based gas sensors operate at relatively high temperatures (few hundred °C) to activate the interaction between the target gas molecules and the sensor material. This leads to important power needs, with values of ~10 mW for the most optimized/miniaturized “micro-hot-plate” configurations [1]. Light is known as an alternative path to achieve such activation [2], but most implementations to date are bulky and based on discrete components, lacking power efficiency and optimized irradiance/response ratios (Figure 1a). Here, we present the new “micro-light-plate” (µLP) approach [2]: a sensor configuration built around a miniaturized LED (Figure 1a). This represents one of the few efforts made to date to produce wafer-scale integrated illuminated sensors [3,4], and the one rendering the best performances, by more than 3 orders of magnitude (from tens of mW to tens of µW) [5].

Figure 1.

(a) Comparison between the Micro Light Plate (µLP) proposed in this work and the conventional light spreading scenario (Macroscopic Light Source). (b) Schematic view of the µLP devices. (c) Detailed view of the µLP area containing the active LED region, the IDEs, and the sensor material. (d) Cross section of the device structure across the µLP area. (a–d) Adapted from Ref. [2], with the permission of AIP Publishing. (e) Optical microscopy image of the actual µLP devices as fabricated, and (f) with the LED lit on.

2. Methods

In the µLP (Figure 1b–d), the sensor material is placed directly on top of a planar LED structure (InGaN, 455 nm peak emission), only separated by a few hundred nanometers (350 nm) to insulate it electrically (SiO2). Consequently, almost all the light emitted by the LED impinges on the sensor MOX, allowing for very well controlled, uniform and high irradiances, with reduced electrical power consumption. For demonstration purposes, the sensor material we choose were ZnO nanoparticles deposited on the µLP on top of a pair of Interdigitated Electrodes (IDE) made of Au (Figure 1b–f). Theory showed that, in order to achieve an optimum performance in terms of power consumption, the LED emission area must match the area of the sensor material (in size and shape). In our case, the active area was a rectangle of 190 µm × 250 µm.

3. Results

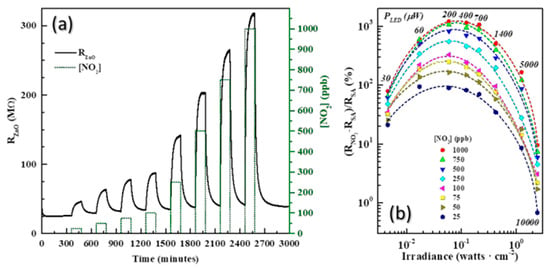

Figure 2a shows an example of the resistance records measured in the presence of NO2 in increasing concentrations, from 25 ppb to 1 ppm. Figure 2b summarizes the responses obtained under different irradiance levels, showing a complex bell-shaped response that is fully explained by the balance between the adsorption and desorption of oxidizing molecules from the surface by the action of the impinging photons [6]. Remarkably, at the lowest concentrations investigated, responses above 20% were obtained, with just 30 µW of electrical power applied to the LED in the µLP. At the optimum irradiance levels, peak responses of more than 90% to 25 ppb were found. In these conditions, with a noise-to-signal level of 3%, even concentrations below 1 ppb could theoretically be detected.

Figure 2.

(a) Resistance record of the response to NO2 and (b) summary of the responses obtained under different irradiance levels (and thus power consumption). Electrical power applied to the LED at each irradiance level is indicated in italics labels. Lines corresponds to qualitative fittings to existing models in the literature [6]. Data taken from Ref. [5].

References

- Elmi, I.; Zampolli, S.; Cozzani, E.; Mancarella, F.; Cardinali, G.C. Development of ultra-low-power consumption MOX sensors with ppb-level VOC detection capabilities for emerging applications. Sens. Actuators B Chem. 2008, 135, 342. [Google Scholar] [CrossRef]

- Prades, J.D.; Wasisto, H.S.; Markiewicz, N.; Cané, C.; Fabrega, C.; Waag, A.; Casals, O.; Gràcia, I. Micro light plates for low-power photoactivated (gas) sensors. Appl. Phys. Lett. 2019, 114, 053508. [Google Scholar]

- Espid, E.; Taghipour, F. UV-LED Photo-activated Chemical Gas Sensors: A Review. Crit. Rev. Solid State Mater. Sci. 2017, 42, 416. [Google Scholar] [CrossRef]

- Wang, C.Y.; Cimalla, V.; Kups, T.; Röhlig, C.C.; Stauden, T.; Ambacher, O.; Kunzer, M.; Passow, T.; Schirmacher, W.; Pletschen, W.; et al. Integration of In2O3 nanoparticle based ozone sensors with GaInN/GaN light emitting diodes. Appl. Phys. Lett. 2007, 91, 1. [Google Scholar] [CrossRef]

- Casals, O.; Markiewicz, N.; Fabrega, C.; Gracia, I.; Cané, C.; Wasisto, H.S.; Waag, A.; Prades, J.D. A Parts Per Billion (ppb) Sensor for NO2 with Microwatt (μW) Power Requirements based on Micro Light Plates. ACS Sens. 2019, 4, 822. [Google Scholar] [CrossRef] [PubMed]

- Prades, J.D.; Jimenez-Diaz, R.; Manzanares, M.; Hernandez-Ramirez, F.; Cirera, A.; Romano-Rodriguez, A.; Mathur, S.; Morante, J.R. A model for the response towards oxidizing gases of photoactivated sensors based on individual SnO2 nanowires. Phys. Chem. Chem. Phys. 2009, 11, 10881. [Google Scholar] [CrossRef] [PubMed]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).