A Multi-MOx Sensor Approach to Measure Oxidizing and Reducing Gases †

Abstract

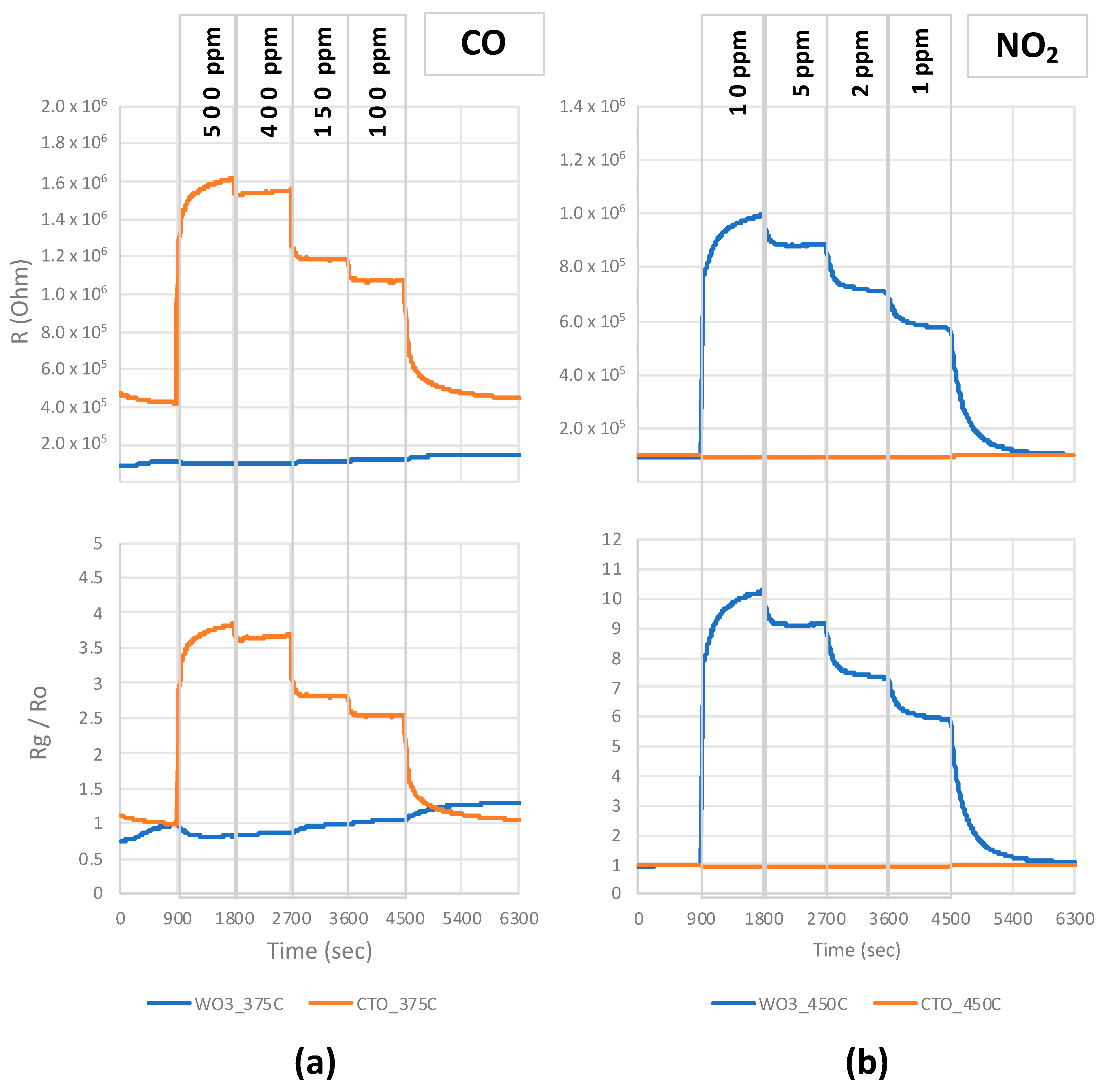

:- p-type CTO (titanium-doped chromium trioxide), a ternary oxide which provides a stable baseline, minimal humidity interference and high sensitivity to reducing gases such as CO, and

- n-type WO3, a binary oxide with excellent sensitivity to oxidizing gases such as NO2 and O3.

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Danesh, E.; Dudeney, R.; Tsang, J.-H.; Blackman, C.; Covington, J.; Smith, P.; Saffell, J. A Multi-MOx Sensor Approach to Measure Oxidizing and Reducing Gases. Proceedings 2019, 14, 50. https://doi.org/10.3390/proceedings2019014050

Danesh E, Dudeney R, Tsang J-H, Blackman C, Covington J, Smith P, Saffell J. A Multi-MOx Sensor Approach to Measure Oxidizing and Reducing Gases. Proceedings. 2019; 14(1):50. https://doi.org/10.3390/proceedings2019014050

Chicago/Turabian StyleDanesh, Ehsan, Richard Dudeney, Jone-Him Tsang, Chris Blackman, James Covington, Peter Smith, and John Saffell. 2019. "A Multi-MOx Sensor Approach to Measure Oxidizing and Reducing Gases" Proceedings 14, no. 1: 50. https://doi.org/10.3390/proceedings2019014050

APA StyleDanesh, E., Dudeney, R., Tsang, J.-H., Blackman, C., Covington, J., Smith, P., & Saffell, J. (2019). A Multi-MOx Sensor Approach to Measure Oxidizing and Reducing Gases. Proceedings, 14(1), 50. https://doi.org/10.3390/proceedings2019014050