Ultra-High Sensitive (Ppt) Gas Sensor Based on the Pulse Heating Using MEMS Technique †

1. Introduction

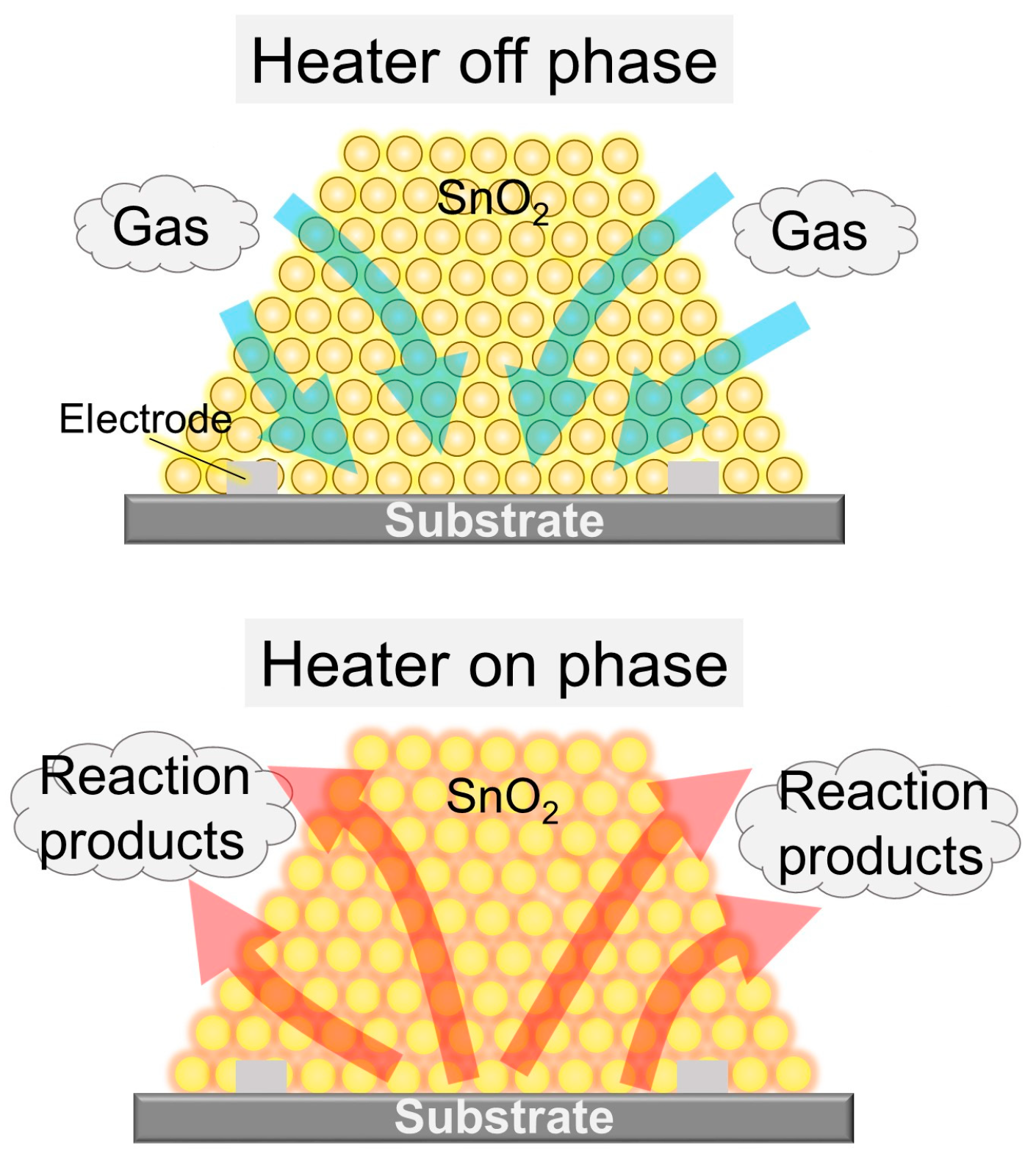

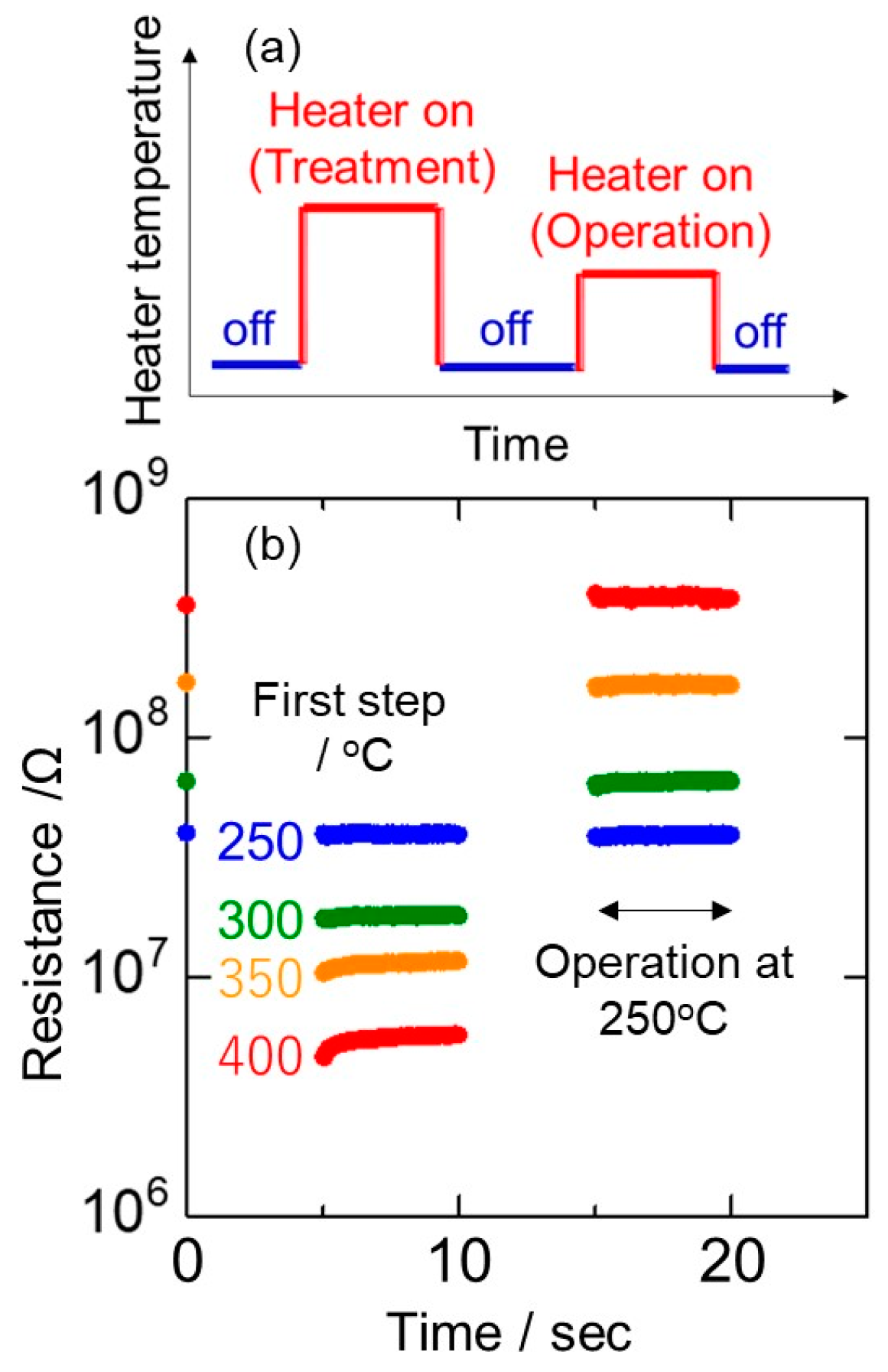

2. Gas Detection Using Monotonic Pulse-Driving Mode

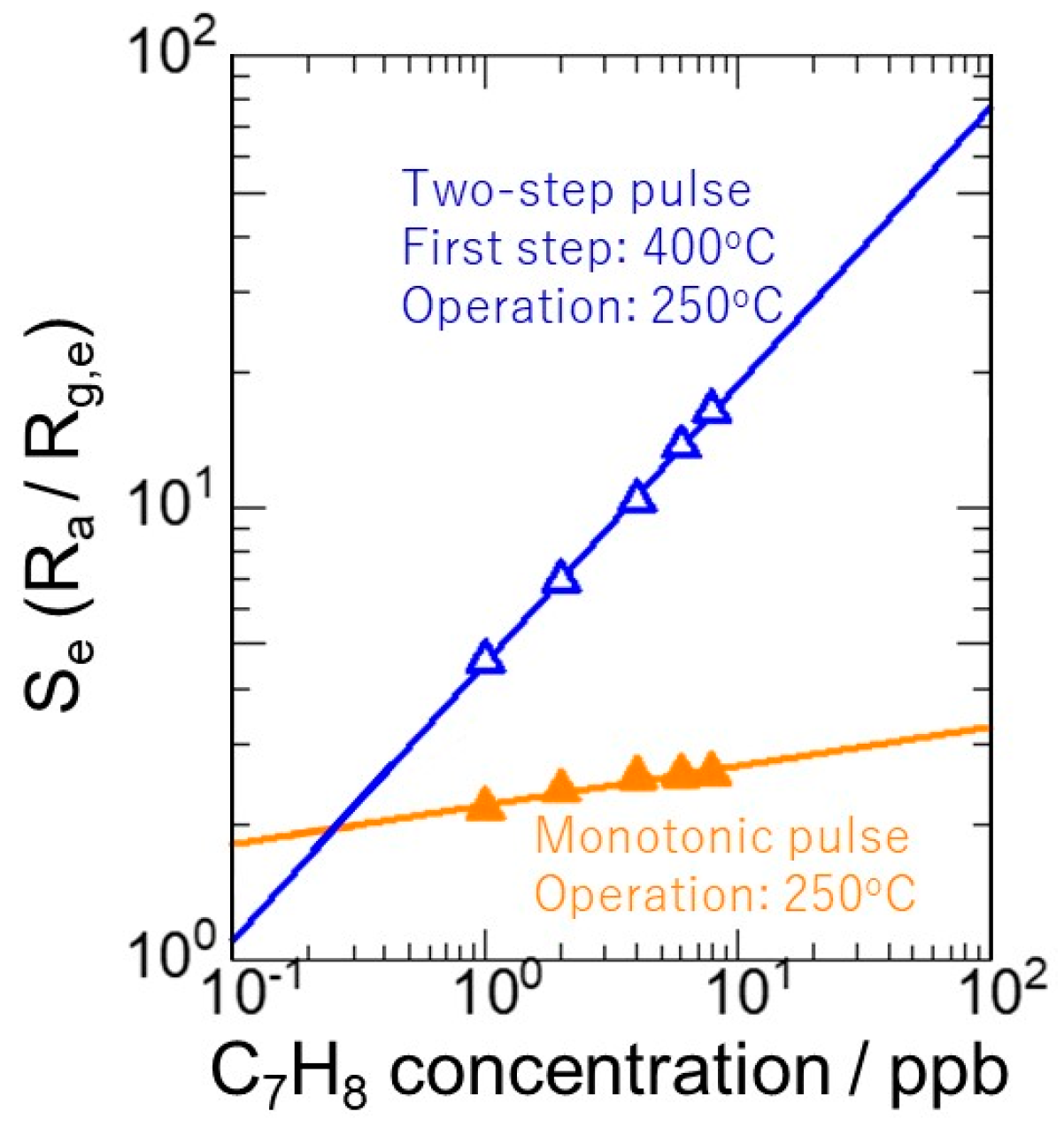

3. Two-Step Pulse-Driving Mode for Gas Detection

References

- Suematsu, K.; Shin, Y.; Ma, N.; Oyama, T.; Sasaki, M.; Yuasa, M.; Kida, T.; Shimanoe, K. Pulse-Driven Micro Gas Sensor Fitted with Clustered Pd/SnO2 Nanoparticles. Anal. Chem. 2015, 87, 8407–8415. [Google Scholar] [CrossRef] [PubMed]

- Suematsu, K.; Harano, W.; Oyama, T.; Shin, Y.; Watanabe, K.; Shimanoe, K. Pulse-Driven Semiconductor Gas Sensors Toward ppt Level Toluene Detection. Anal. Chem. 2018, 90, 11219–11223. [Google Scholar] [CrossRef] [PubMed]

- Suematsu, K.; Yuasa, M.; Kida, T.; Yamazoe, N.; Shimanoe, K. Determination of Oxygen Adsorption Species on SnO2: Exact Analysis of Gas Sensing Properties Using a Sample Gas Pretreatment System. J. Electrochem. Soc. 2014, 161, B123–B128. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suematsu, K.; Harano, W.; Hiroyama, Y.; Watanabe, K.; Shimanoe, K. Ultra-High Sensitive (Ppt) Gas Sensor Based on the Pulse Heating Using MEMS Technique. Proceedings 2019, 14, 24. https://doi.org/10.3390/proceedings2019014024

Suematsu K, Harano W, Hiroyama Y, Watanabe K, Shimanoe K. Ultra-High Sensitive (Ppt) Gas Sensor Based on the Pulse Heating Using MEMS Technique. Proceedings. 2019; 14(1):24. https://doi.org/10.3390/proceedings2019014024

Chicago/Turabian StyleSuematsu, Koichi, Wataru Harano, Yuki Hiroyama, Ken Watanabe, and Kengo Shimanoe. 2019. "Ultra-High Sensitive (Ppt) Gas Sensor Based on the Pulse Heating Using MEMS Technique" Proceedings 14, no. 1: 24. https://doi.org/10.3390/proceedings2019014024

APA StyleSuematsu, K., Harano, W., Hiroyama, Y., Watanabe, K., & Shimanoe, K. (2019). Ultra-High Sensitive (Ppt) Gas Sensor Based on the Pulse Heating Using MEMS Technique. Proceedings, 14(1), 24. https://doi.org/10.3390/proceedings2019014024