SnO2-Pd as a Gate Material for the Capacitor Type Gas Sensor †

Abstract

:1. Introduction

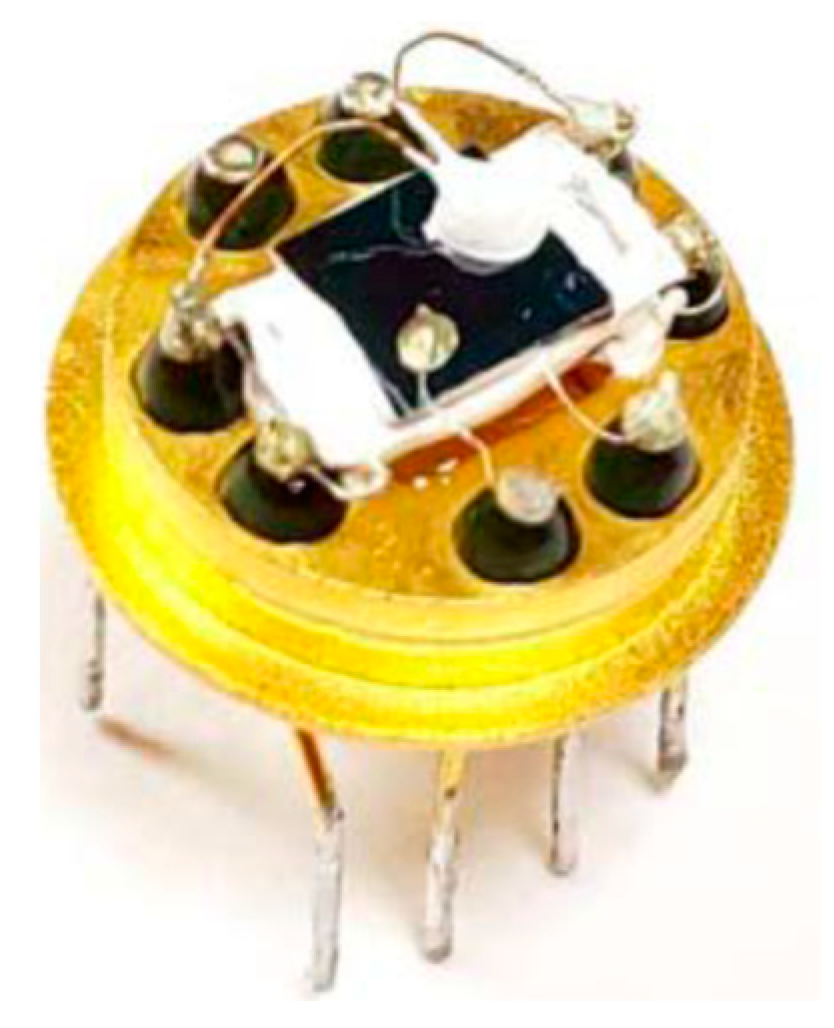

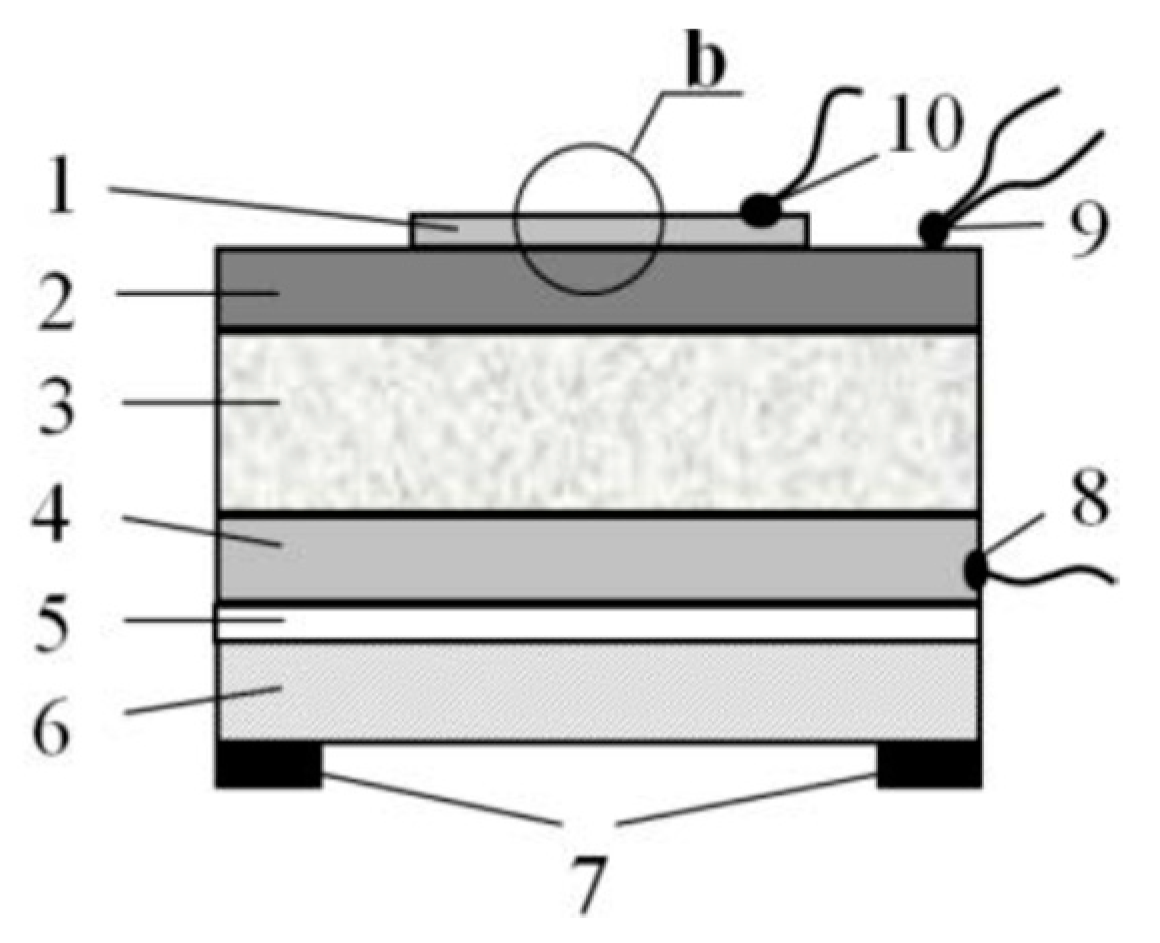

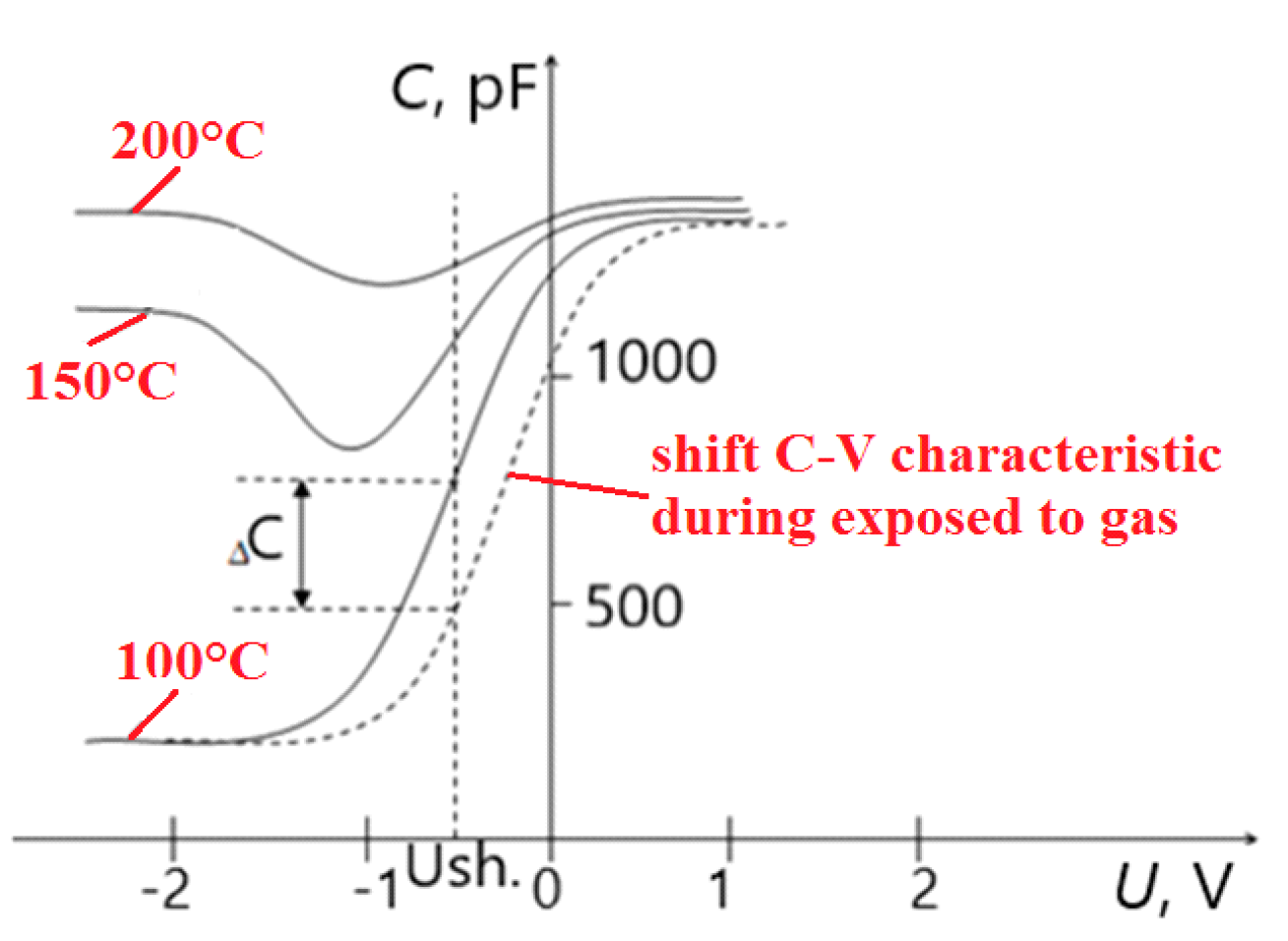

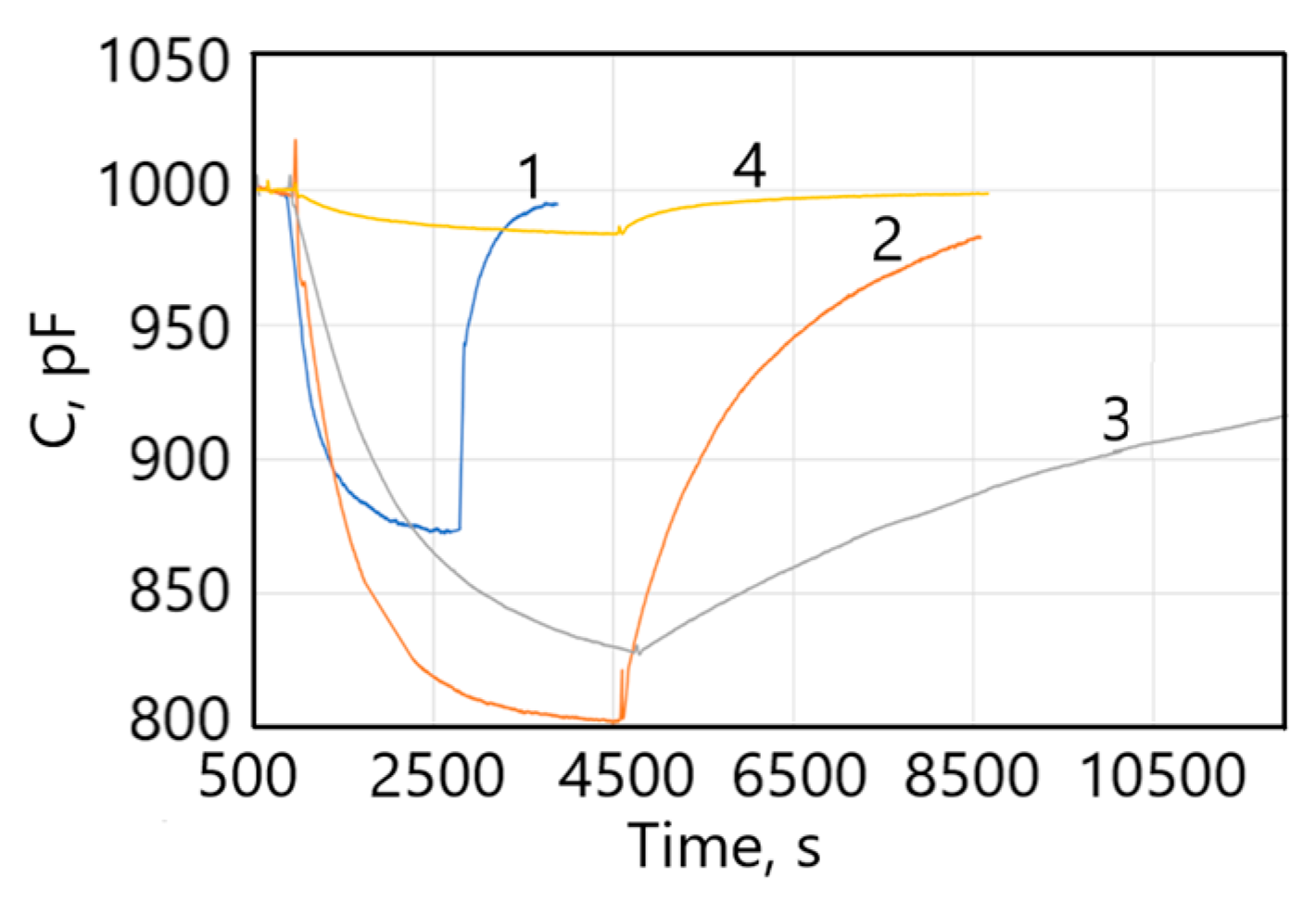

2. Experimental

Funding

Conflicts of Interest

References

- Shivaraman, M.S.; Lundström, I.; Svensson, C.; Hammarsten, H. Hydrogen sensitivity of palladium-thin-oxide-silicon schottky barriers. Electron. Lett. 1976, 12, 483–484. [Google Scholar] [CrossRef]

- Fogelberg, J.; Dannetun, H.; Lundström, I.; Petersson, L.-G. A hydrogen sensitive palladium metal-oxide-semiconductor device as sensor for dissociating NO in H2-atmospheres. Vacuum 1990, 41, 705–708. [Google Scholar] [CrossRef]

- Zhovannik, E.V.; Nikolaev, I.N.; Stavkin, D.G.; Shevlyuga, V.M.; Imamov, R.M.; Lomov, A.A. Studies of transient region between laser-deposited palladium and (111)Si. Kristallografiya 1996, 41, 935–939. [Google Scholar]

- Samotaev, N.; Litvinov, A.; Etrekova, M. Improving Detection Chlorine by Field Effect Gas Sensor with Using Temperature Pulse Mode. In Proceedings of the IMCS 2018, Vienna, Austria, 15–19 July 2018; pp. 474–475. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Samotaev, N.; Oblov, K.; Litvinov, A.; Etrekova, M. SnO2-Pd as a Gate Material for the Capacitor Type Gas Sensor. Proceedings 2019, 14, 10. https://doi.org/10.3390/proceedings2019014010

Samotaev N, Oblov K, Litvinov A, Etrekova M. SnO2-Pd as a Gate Material for the Capacitor Type Gas Sensor. Proceedings. 2019; 14(1):10. https://doi.org/10.3390/proceedings2019014010

Chicago/Turabian StyleSamotaev, Nikolay, Konstantin Oblov, Arthur Litvinov, and Maya Etrekova. 2019. "SnO2-Pd as a Gate Material for the Capacitor Type Gas Sensor" Proceedings 14, no. 1: 10. https://doi.org/10.3390/proceedings2019014010

APA StyleSamotaev, N., Oblov, K., Litvinov, A., & Etrekova, M. (2019). SnO2-Pd as a Gate Material for the Capacitor Type Gas Sensor. Proceedings, 14(1), 10. https://doi.org/10.3390/proceedings2019014010