1. Introduction

Thermal diffusivity is one of the most representative thermal properties of materials, and its evaluation is important in many scientific and industrial fields. The laser flash method [

1,

2], periodic heat method [

3] and temperature wave method [

4] are standard methods to measure thermal diffusivity. The aim of the laser flush method is to evaluate thermal diffusivity by applying a short thermal pulse to the entire front surface of a material and observing the temperature variation on the rear surface. The periodic heat method and the temperature wave method evaluate thermal properties by analyzing the phase response of thermal waves generated by periodic heating. Both methods typically measure the phase difference between the front and rear surfaces of the sample to determine thermal diffusivity and thermal conductivity. However, these methods have the limitation that the specimen must be cut out if the rear surface of the sample is not accessible, which is not nondestructive. A recent study [

5] has proposed a more practical method for identifying thermal diffusivity by measuring temperature variation in the material surface using a combination of laser spot and step heating. Nevertheless, this method requires the thickness of the sample to be known in advance. In this study, a method to accurately and efficiently identify thermal diffusivity by pulse-step laser-spot heating is established even when the specimen thickness is unknown.

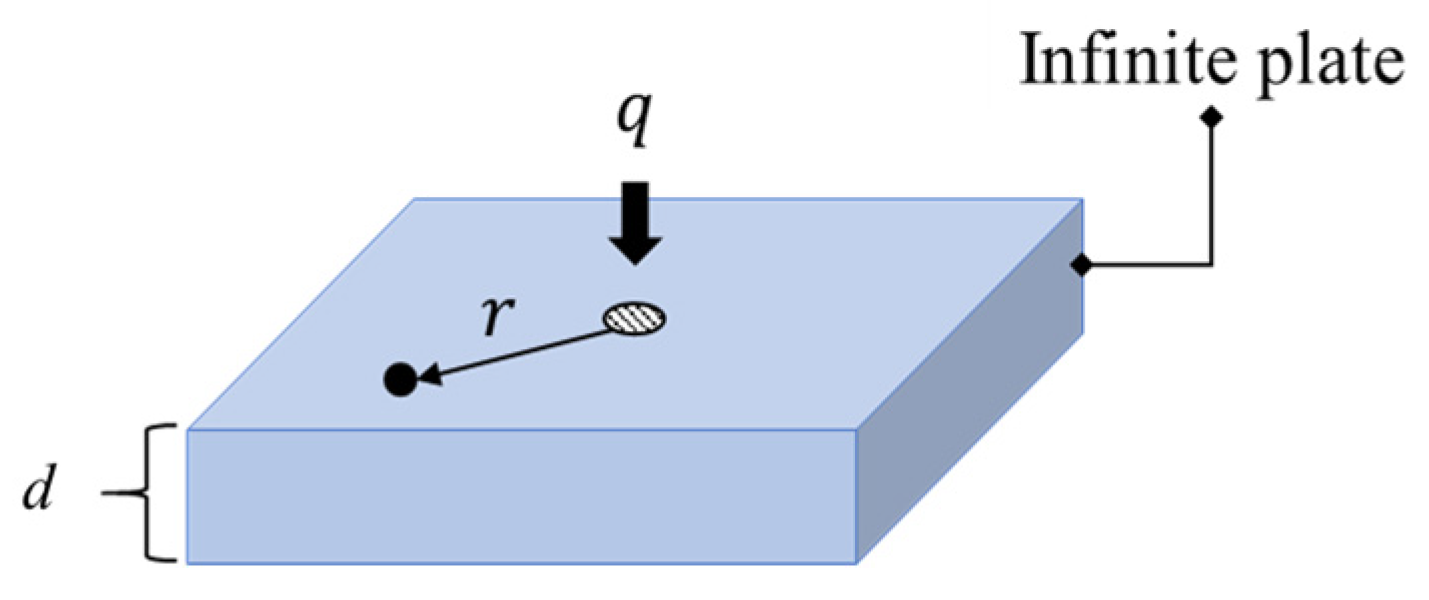

2. Solution for Temperature Variation

Assume that an infinite flat plate is subjected to step heating at a point from time

t = 0 to

t =

t1 as shown in

Figure 1. The heat flux is expressed as

The theoretical solution for the surface temperature variation

T(

r,

t) at a distance

r from the heating point is given as [

6,

7]

Here k is the thermal conductivity, d is the thickness, and α is the thermal diffusivity of the plate. In addition, x and y indicate the position of the temperature measurement point, and x0, y0 indicate the position of the heating point.

By applying Equation (2) in the fitting process to the surface temperature data obtained at various times and positions using the IR camera, it is possible to simultaneously identify the unknown parameters: thermal diffusivity α, thickness d, and the heating point position x0 and y0. If the thickness and heating position are known in advance, thermal diffusivity may be identified with higher accuracy due to the reduction in unknown parameters.

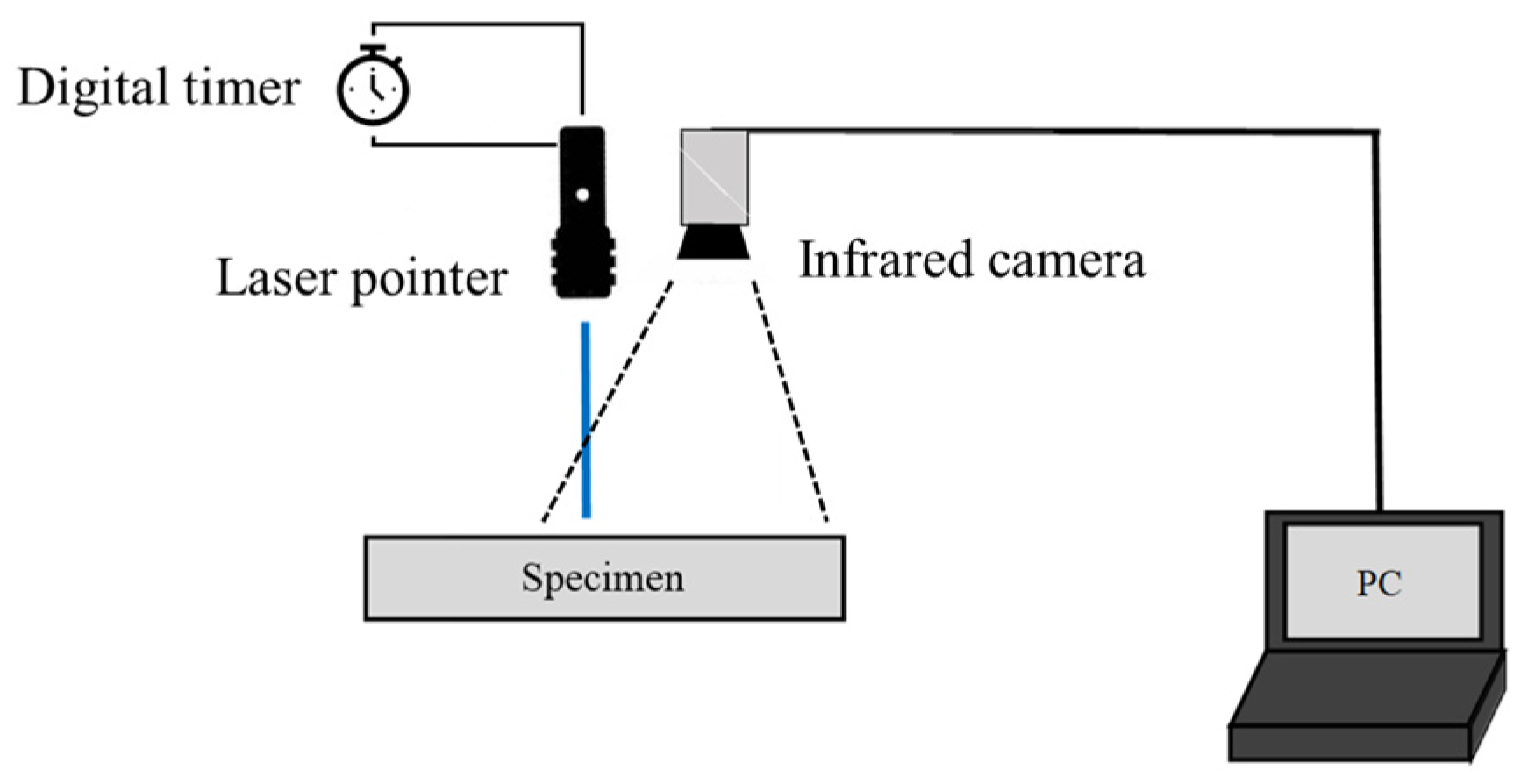

3. Experimental Method

The experiment was carried out as illustrated in

Figure 2. A laser beam (HTRLASER, Yiwu, China) was irradiated to the specimen, and surface temperature data was obtained by IR camera (Optris, Berlin, Germany). The heating period was precisely controlled using a digital timer (Omron, Kyoto, Japan). A ceramic plate (NISHIMURA ADVANCED CERAMICS CO.,LTD, Kyoto, Japan) made of alumina was used as a specimen. Experimental parameters are summarized in

Table 1.

4. Results

Table 2 shows the identification results of thermal diffusivity and thickness in the case when the heating position is known. The time and radius data range used for the identification was determined to minimize the influence of error factors such as laser spot diameter and noise. These results indicate that, when the thickness is unknown, step heating (

t1 = 50 s) leads to smaller identification errors in both thermal diffusivity and thickness, whereas pulse-step heating (

t1 = 10 s) results in a larger error in thickness identification.

Table 3 shows the identification results of thermal diffusivity in the case when the thickness and the heating position are known. The accuracy of thermal diffusivity identification is improved in both methods compared to

Table 2, with a particularly significant improvement observed in the case of pulse-step heating. These results indicate that stopping the heating midway slightly improves the accuracy.

5. Discussion

When the thickness is known, the pulse-step method yields slightly higher accuracy. This is considered to be due to the increased sensitivity of thermal diffusivity during fitting by using both the heating and cooling process. On the other hand, when the thickness is unknown, the accuracy of thermal diffusivity identification by the pulse-step method becomes inferior to that by the step method, and the accuracy of thickness identification is significantly decreased. This is considered to be because the thermal effect from the rear surface is not sufficiently reflected to the surface temperature. In fact, considering the thermal diffusion length shown below, the minimum time

t′ at which the influence of the rear surface appears to the surface temperature is 13 s after the start of heating in this experiment.

In summary, the results suggest that the pulse-step method, when the plate thickness is known, and the step method, when the thickness is unknown, enable more accurate identification of thermal diffusivity. To improve the accuracy of thermal diffusivity and thickness estimation in pulse-step heating, it is necessary to increase the heating time and sufficiently utilize the data range beyond 13 s after the start of heating.

6. Conclusions

A method to simultaneously identify the thermal diffusivity, thickness and heating point position by a laser spot heating technique was developed. Experiments were conducted to verify the method.

It has been shown that both the step heating and the pulse-step heating methods provided accurate identification of thermal diffusivity when the thickness is known in advance. In the case when the thickness is unknown, the step heating method resulted in higher accuracy than the pulse-step heating method. This is attributed to the need for sufficient heating and appropriate selection of the data range used for fitting, in order to capture the influence of the rear surface on the surface temperature.

Author Contributions

Conceptualization, S.T.; methodology, S.T.; software, S.T.; validation, S.T., S.T.; formal analysis, S.T.; investigation, S.T.; resources, S.T.; data curation, S.T.; writing—original draft preparation, S.T.; writing—review and editing, S.T.; visualization, Y.K.; methodology, H.I.; project administration, S.T.; funding acquisition, S.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research was conducted as a joint research project between Institute of Science Tokyo (formerly Tokyo Institute of Technology) and Panasonic Connect Co., Ltd.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The datasets presented in this article are not readily available because the research is currently ongoing. Requests to access the datasets should be directed to the authors.

Acknowledgments

The authors appreciate the support of Yousuke Irie from Panasonic Connect Co., Ltd., for providing test specimens and related assistance.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Sheindlin, M.; Halton, D.; Musella, M.; Ronchi, C. Advances in the use of laser-flash techniques for thermal diffusivity measurement. Rev. Sci. Instrum. 1998, 69, 1426–1436. [Google Scholar] [CrossRef]

- Baba, T.; Ono, A. Improvement of the laser flash method to reduce uncertainty in thermal diffusivity measurements. Meas. Sci. Technol. 2001, 12, 2046–2057. [Google Scholar] [CrossRef]

- Boudenne, A.; Ibos, L.; Gehin, E.; Candau, Y. A simultaneous characterization of thermal conductivity and diffusivity of polymer materials by a periodic method. J. Phys. D Appl. Phys. 2004, 37, 132–139. [Google Scholar] [CrossRef]

- Tomokiyo, A.; Okada, T. Determination of Thermal Diffusivity by the Temperature Wave Method. Jpn. J. Appl. Phys. 1968, 7, 128–135. [Google Scholar] [CrossRef]

- Salazar, A.; Colom, M.; Mendioroz, A. Laser-spot step-heating thermography to measure the thermal diffusivity of solids. Int. J. Therm. Sci. 2021, 170, 107124. [Google Scholar] [CrossRef]

- Carslaw, H.S.; Jaeger, J.C. Conduction of Heat in Solids; Clarendon Press Oxford: Oxford, UK, 1959; pp. 92–112. [Google Scholar] [CrossRef]

- Brugger, K. Exact Solutions for the Temperature Rise in a Laser-Heated Slab. J. Appl. Phys. 1972, 43, 573–583. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).