Cover Thickness Prediction for Steel Inside Concrete by Sub-Terahertz Wave Using Deep Learning †

Abstract

1. Introduction

2. Outline of Experiments and Analyses

2.1. Experimental Procedures

2.2. Measurement Methods

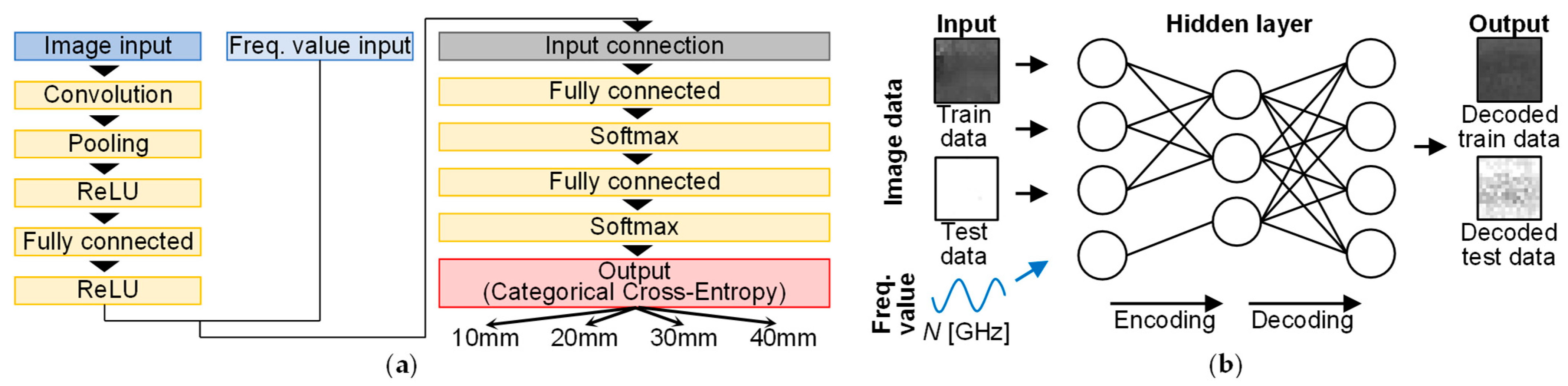

2.3. Structure of Deep Learning Model

3. Results and Discussion

3.1. Measurement Results from Sub-THz Waves

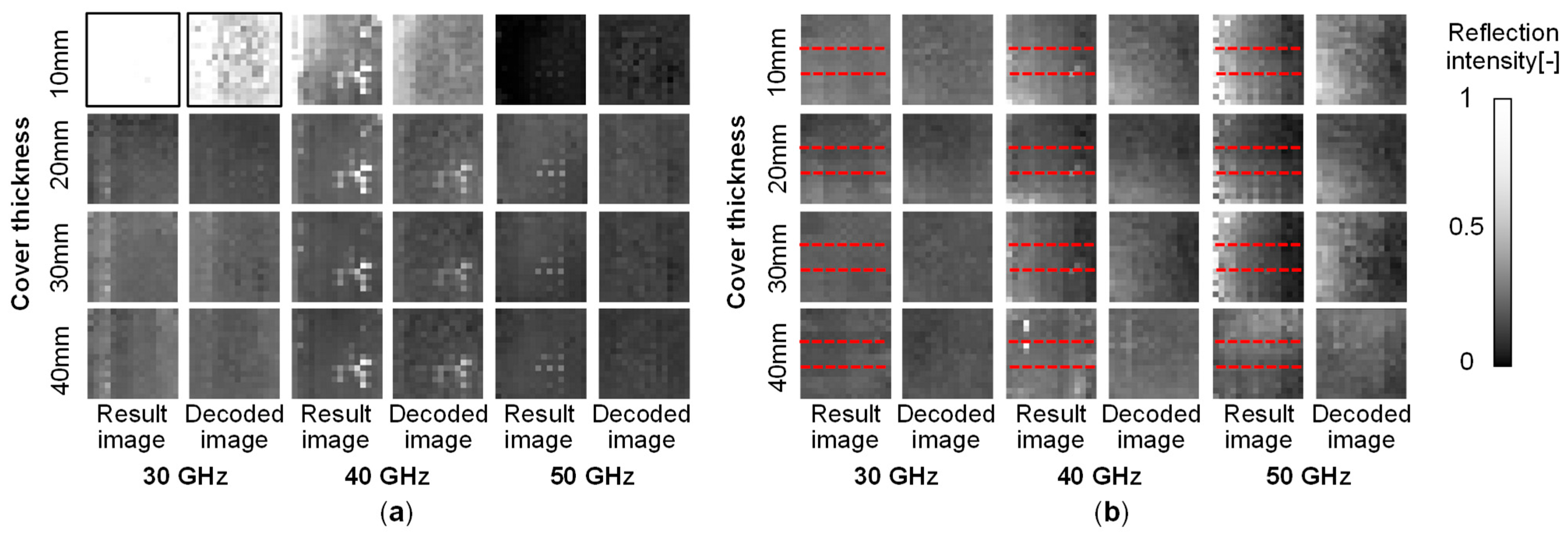

3.2. Results from Supervised Deep Learning

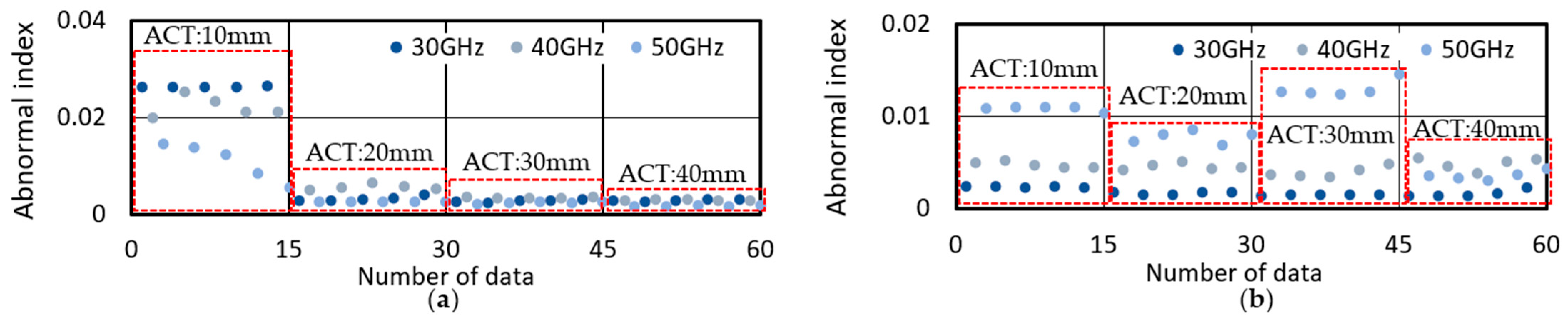

3.3. Results from Unsupervised Deep Learning

4. Conclusions

- (1)

- The cover thickness of steel plates in concrete can be accurately predicted and classified using both supervised and unsupervised deep learning.

- (2)

- Supervised learning accurately predicts rebar in concrete up to a 20 mm cover thickness, but this accuracy declines at 30 mm and 40 mm.

- (3)

- Unsupervised deep learning enables clustering of the cover thickness of rebar in concrete.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, Z.; Yoon, J.; Zhang, R.; Rajabipour, F.; Srubar, W.V., III; Dabo, I.; Radlińska, A. Machine learning in concrete science: Applications, challenges, and best practices. npj Comput. Mater. 2022, 8, 127. [Google Scholar] [CrossRef]

- Ansari, S.S.; Ansari, H.; Khateeb, A.; Ibrahim, S.M. Comparative study of machine learning models for predicting the compressive strength of concrete using Non-Destructive Testing methods. Mater. Today Proc. 2024; in press. [Google Scholar] [CrossRef]

- Tanabe, T.; Oyama, Y. THz non-destructive visualization of disconnection and corrosion status cover with opaque insulator. IEEJ Trans. Electron. 2019, 139, 149–153. [Google Scholar] [CrossRef]

- Kobayashi, C.; Nishiwaki, T.; Tanabe, T.; Oohashi, T.; Hamasaki, H.; Hikishima, S.; Tanaka, A.; Arita, K.; Fujii, S.; Sato, D.; et al. Non-destructive testing of reinforced concrete structures using sub-terahertz reflected waves. Dev. Built. 2024, 18, 100423. [Google Scholar] [CrossRef]

| Amount of Data | Supervised Deep Learning | Unsupervised Deep Learning | ||

|---|---|---|---|---|

| Train | Test | Train | Test | |

| Steel plate specimen | 1260 | 420 | 315 | 420 |

| Rebar specimen | 1680 | 420 | 315 | 420 |

| Amount of Data | PCT from Steel Plate Specimen | PCT from Rebar Specimen | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 20 | 30 | 40 | Recall | 10 | 20 | 30 | 40 | Recall | ||

| ACT | 10 | 104 | 0 | 1 | 0 | 0.99 | 101 | 0 | 0 | 4 | 0.96 |

| 20 | 1 | 96 | 2 | 6 | 0.91 | 9 | 96 | 0 | 0 | 0.91 | |

| 30 | 0 | 1 | 100 | 4 | 0.95 | 13 | 17 | 42 | 33 | 0.40 | |

| 40 | 0 | 16 | 12 | 77 | 0.73 | 28 | 8 | 49 | 20 | 0.19 | |

| Precision | 0.99 | 0.85 | 0.87 | 0.89 | 0.67 | 0.79 | 0.46 | 0.35 | |||

| F-score | 0.99 | 0.88 | 0.91 | 0.80 | 0.79 | 0.85 | 0.43 | 0.25 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koyama, K.; Nishiwaki, T.; Hashimoto, K. Cover Thickness Prediction for Steel Inside Concrete by Sub-Terahertz Wave Using Deep Learning. Proceedings 2025, 129, 40. https://doi.org/10.3390/proceedings2025129040

Koyama K, Nishiwaki T, Hashimoto K. Cover Thickness Prediction for Steel Inside Concrete by Sub-Terahertz Wave Using Deep Learning. Proceedings. 2025; 129(1):40. https://doi.org/10.3390/proceedings2025129040

Chicago/Turabian StyleKoyama, Ken, Tomoya Nishiwaki, and Katsufumi Hashimoto. 2025. "Cover Thickness Prediction for Steel Inside Concrete by Sub-Terahertz Wave Using Deep Learning" Proceedings 129, no. 1: 40. https://doi.org/10.3390/proceedings2025129040

APA StyleKoyama, K., Nishiwaki, T., & Hashimoto, K. (2025). Cover Thickness Prediction for Steel Inside Concrete by Sub-Terahertz Wave Using Deep Learning. Proceedings, 129(1), 40. https://doi.org/10.3390/proceedings2025129040