Non-Contact Detection of Steel Corrosion Using Sub-Terahertz Waves †

Abstract

1. Introduction

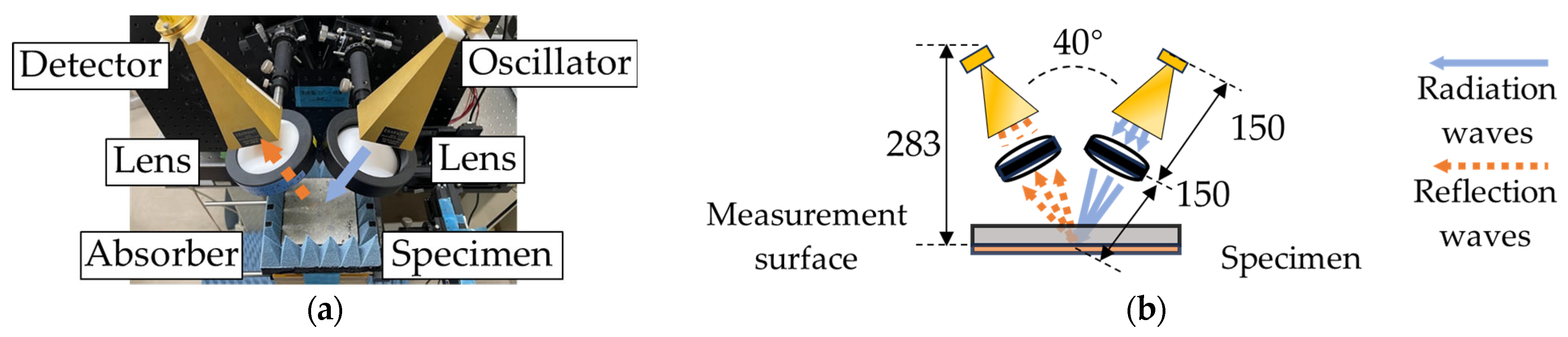

2. Measurement Methods and Materials

2.1. Outline of Experiments

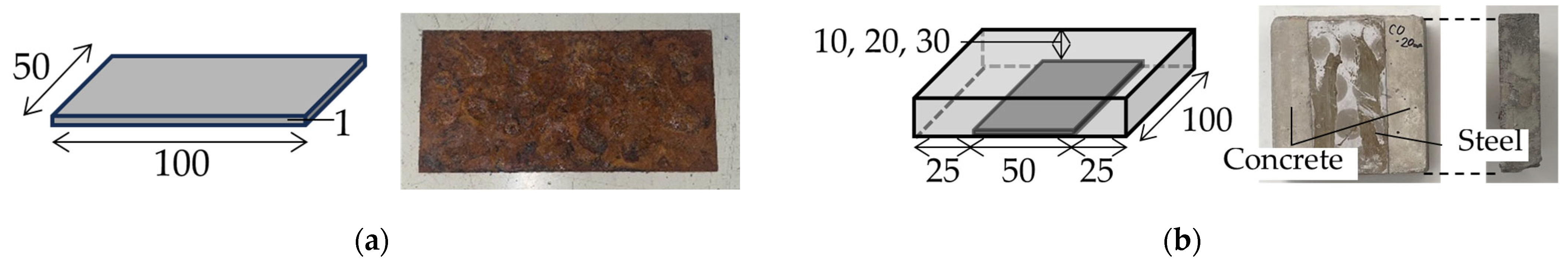

2.2. Materials

3. Results and Discussion

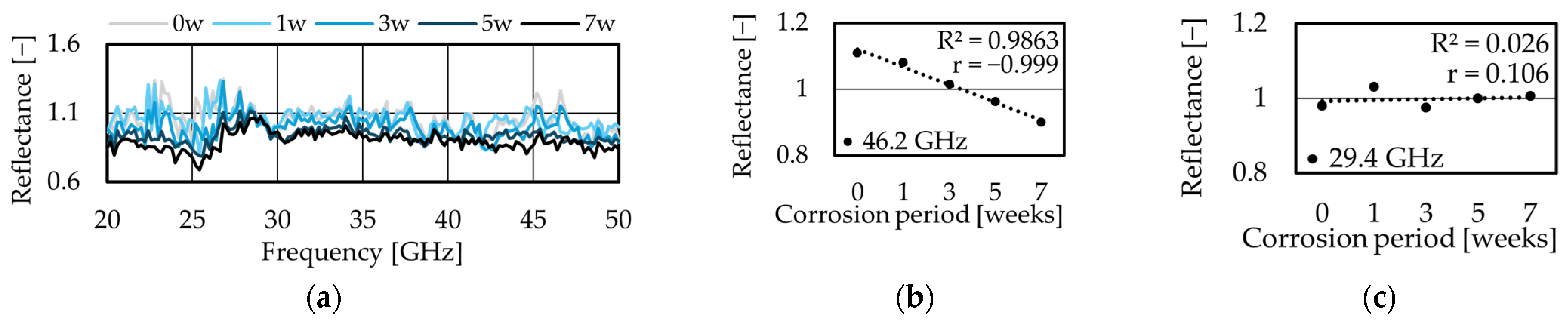

3.1. Reflection of Steel Specimens

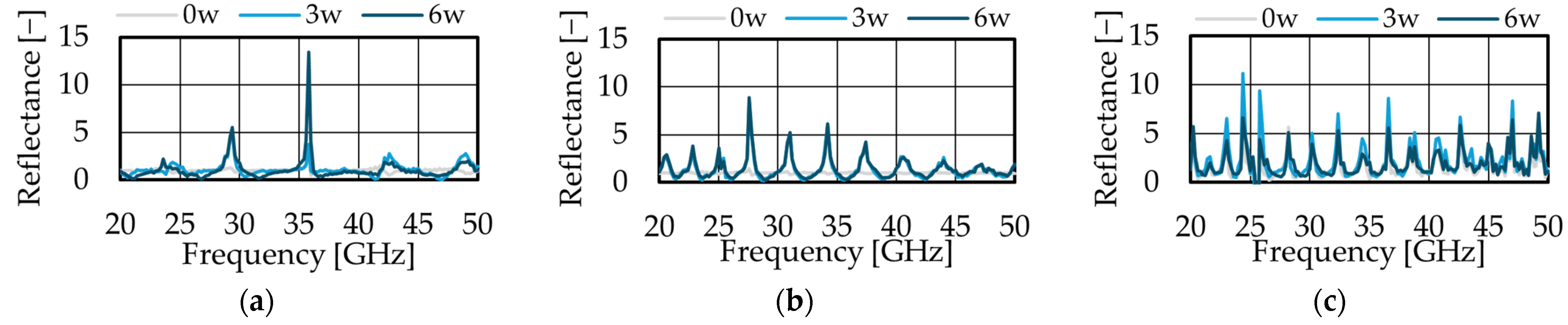

3.2. Detection of Steel Corrosion Inside Concrete

4. Conclusions

- (1)

- The reflectance spectra of steel specimens were measured using frequencies ranging from 20 to 50 GHz, and a decrease in reflectance due to corrosion was observed at many frequencies.

- (2)

- Measurements of steel-embedded specimens revealed periodic increases in reflectance associated with corrosion. Comparison with uncorroded embedded specimens indicated that corrosion could be detected in steel plates with up to 20 mm covered.

- (3)

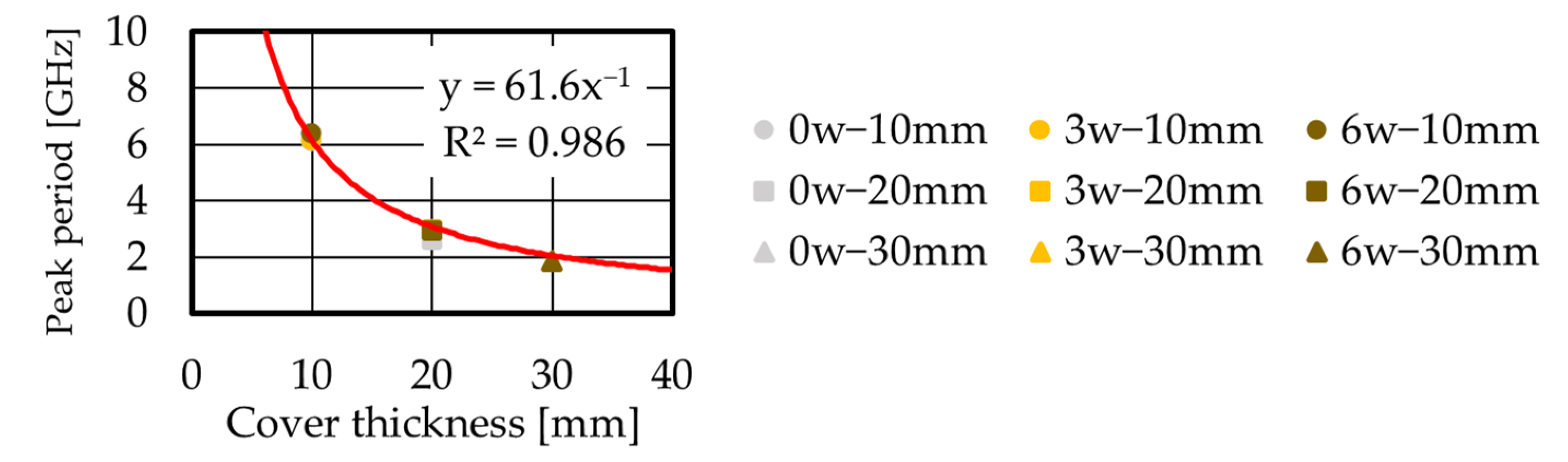

- It was shown that the spacing between reflectance peaks can be used to estimate cover thicknesses of 10, 20, and 30 mm.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ghosh, D.; Kumar, R.; Ganguli, A.; Mukherjee, A. Nondestructive Evaluation of Rebar Corrosion–Induced Damage in Concrete through Ultrasonic Imaging. J. Mater. Civ. Eng. 2020, 32, 04020294. [Google Scholar] [CrossRef]

- Cotič, P.; Kolarič, D.; Bosiljkov, V.B.; Bosiljkov, V.; Jagličić, Z. Determination of the applicability and limits of void and delamination detection in concrete structures using infrared thermography. NDT&E Int. 2015, 74, 87–93. [Google Scholar] [CrossRef]

- Omar, T.; Nehdi, M.L. Remote sensing of concrete bridge decks using unmanned aerial vehicle infrared thermography. Autom. Constr. 2017, 83, 360–371. [Google Scholar] [CrossRef]

- Tanaka, A.; Arita, K.; Kobayashi, C.; Nishiwaki, T.; Tanabe, T.; Fujii, S. Fundamental Properties of Sub-THz Reflected Waves for Water Content Estimation of Reinforced Concrete Structures. Buildings 2024, 14, 1076. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kurashina, R.; Kobayashi, C.; Nishiwaki, T.; Tanaka, A.; Tanabe, T.; Hamasaki, H.; Sato, D.; Arita, K. Non-Contact Detection of Steel Corrosion Using Sub-Terahertz Waves. Proceedings 2025, 129, 32. https://doi.org/10.3390/proceedings2025129032

Kurashina R, Kobayashi C, Nishiwaki T, Tanaka A, Tanabe T, Hamasaki H, Sato D, Arita K. Non-Contact Detection of Steel Corrosion Using Sub-Terahertz Waves. Proceedings. 2025; 129(1):32. https://doi.org/10.3390/proceedings2025129032

Chicago/Turabian StyleKurashina, Riku, Chihiro Kobayashi, Tomoya Nishiwaki, Akio Tanaka, Tadao Tanabe, Hitoshi Hamasaki, Daisuke Sato, and Koji Arita. 2025. "Non-Contact Detection of Steel Corrosion Using Sub-Terahertz Waves" Proceedings 129, no. 1: 32. https://doi.org/10.3390/proceedings2025129032

APA StyleKurashina, R., Kobayashi, C., Nishiwaki, T., Tanaka, A., Tanabe, T., Hamasaki, H., Sato, D., & Arita, K. (2025). Non-Contact Detection of Steel Corrosion Using Sub-Terahertz Waves. Proceedings, 129(1), 32. https://doi.org/10.3390/proceedings2025129032