The increased consumption of fossil fuels has led to scientific interest in establishing a hydrogen-based infrastructure. Currently, there are a few different electrolysis technologies for H2 production: (i) PEM, (ii) alkaline (AFC) and (iii) solid oxide (SOEC). PEM electrolysis uses a hydrated polymer membrane, with an operating temperature window of 45–85 °C and reaching power capacities of >500 kWs. AFC electrolysis uses a caustic solution as an electrolyte with operating temperatures in the range of 65–220 °C and can also reach high power capacities. Finally, SOEC units use a ceramic electrolyte with an operating temperature of 600–1000 °C and power capacities that can reach several MWs (including thermal exploitation). In terms of costs, PEM and AFC are currently the most economical and flexible solutions.

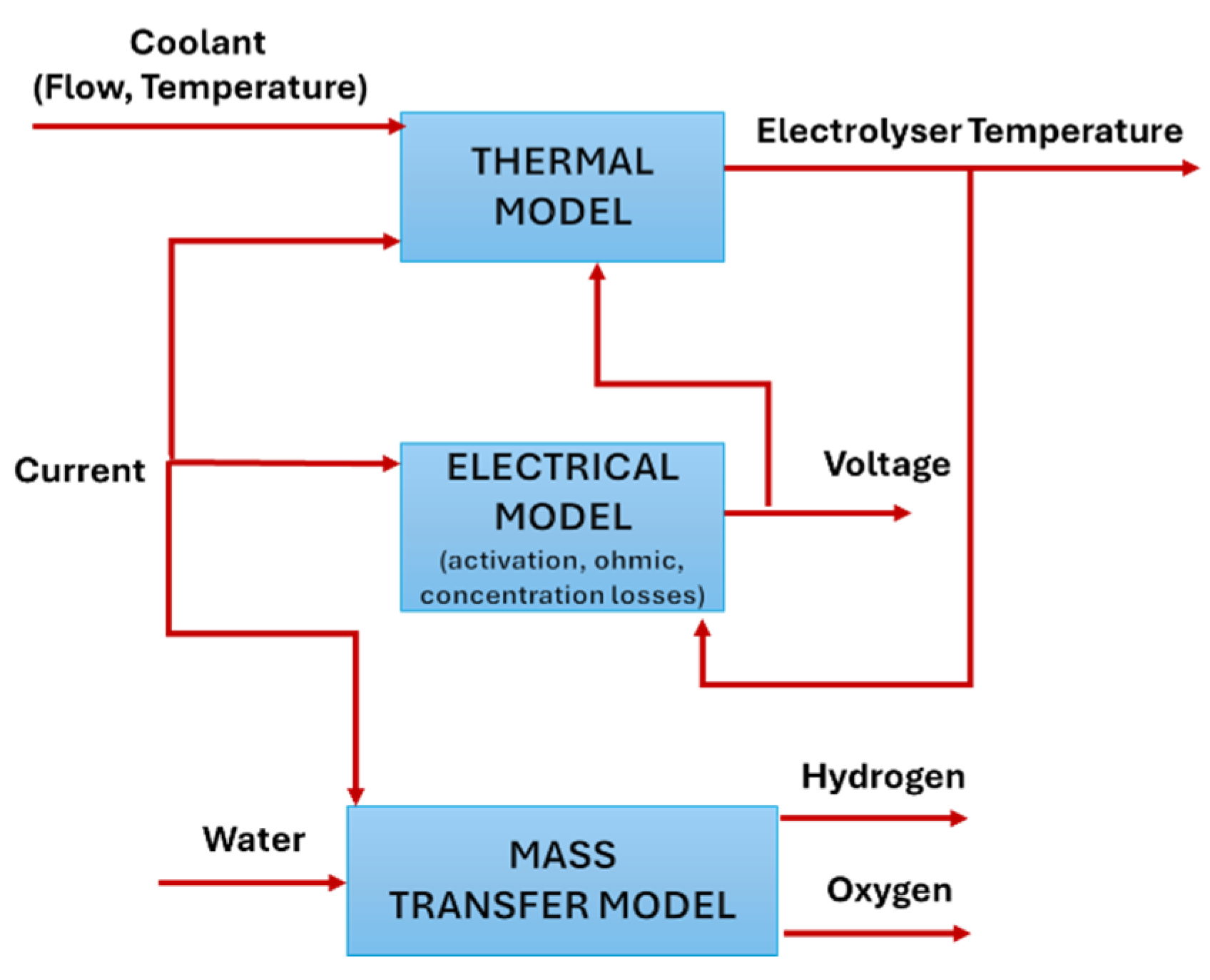

The aim of this study is the dynamic modeling and control of an electrolysis system. The modeling module is based on submodels that use a combination of electrochemical, thermal, and mass transport equations to fully describe the system operation (see

Figure 1). The electrical model takes as input the electrolyzer temperature and the applied current for the voltage calculation. In the mass transfer model, the molar flows/concentrations of water, hydrogen and air (oxygen and nitrogen) are based on the provided electric current. Finally, the thermal model simulates the dynamics of heat and temperature variations as it is provided by the V-I electric model and the applied cooling utilities.

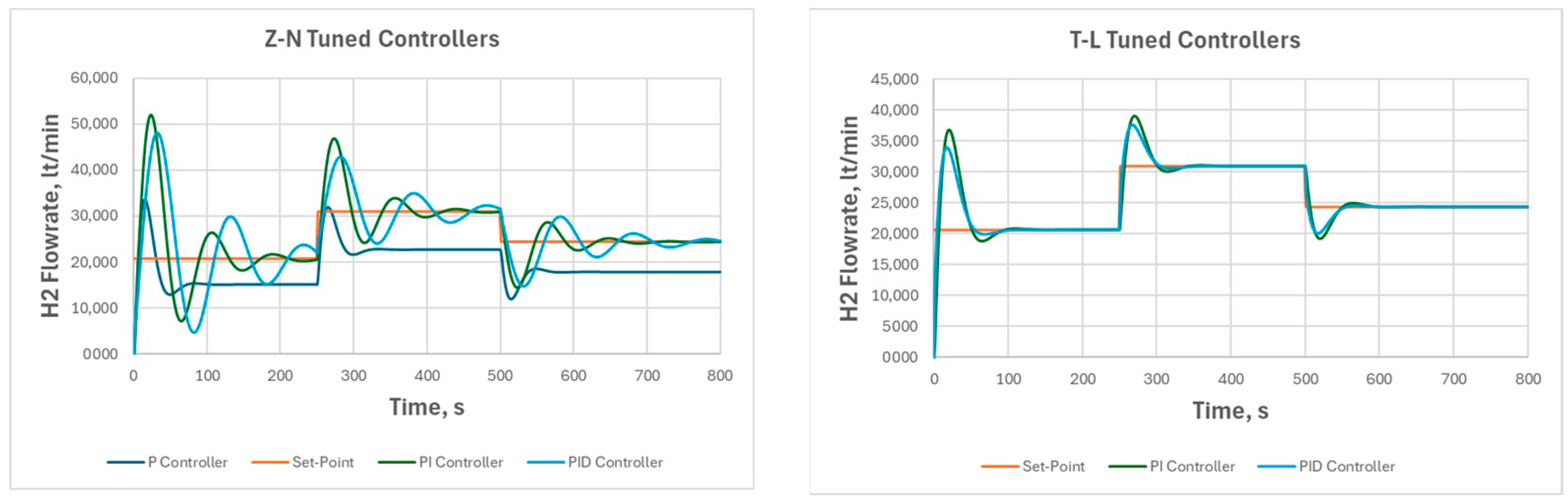

Feedback controllers have been designed for the (a) regulation of hydrogen production by manipulating the applied electric current and (b) regulation of the temperature by the manipulation of a coolant flowrate. Conventional P/PI/PID controllers, model-based controllers and optimal controllers are evaluated towards enhanced disturbance rejection and set-point tracking. Performance criteria such as ISE, IAE, ITAE and ITSE will be evaluated for the best controller selection, also based on low power consumption and high efficiency. Regarding the process control requirements for such a complicated system, this study designed feedback PID controllers (tuned via Ziegler-Nichols/Z-N and Tyreus-Luyben/T-L methodologies). Based on preliminary simulation scenarios it was found that T-L tuned PID controllers presented an exceptional performance as they incorporated reduced overshoot and oscillations along with a fast settling time. The manipulated variable was the imposed current to the electrolyzer. A sample of results is shown in

Figure 2 as follows.

Author Contributions

Conceptualization, S.D. and D.I.; methodology, All Authors; software, S.D., V.P. and D.I.; validation, S.D., V.P. and D.I.; formal analysis, All Authors; investigation, S.D., V.P. and D.I.; data curation, S.D., V.P. and D.I.; writing—original draft preparation, S.D. and D.I.; writing—review and editing, S.D. and D.I.; visualization, all Authors; supervision, all Authors; project administration, all Authors. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).