Effect of Mistuning and Blade Passing Frequencies on a Turbine’s Integral Mode Blade Vibration Detection Using a Pulsation Probe †

Abstract

1. Introduction

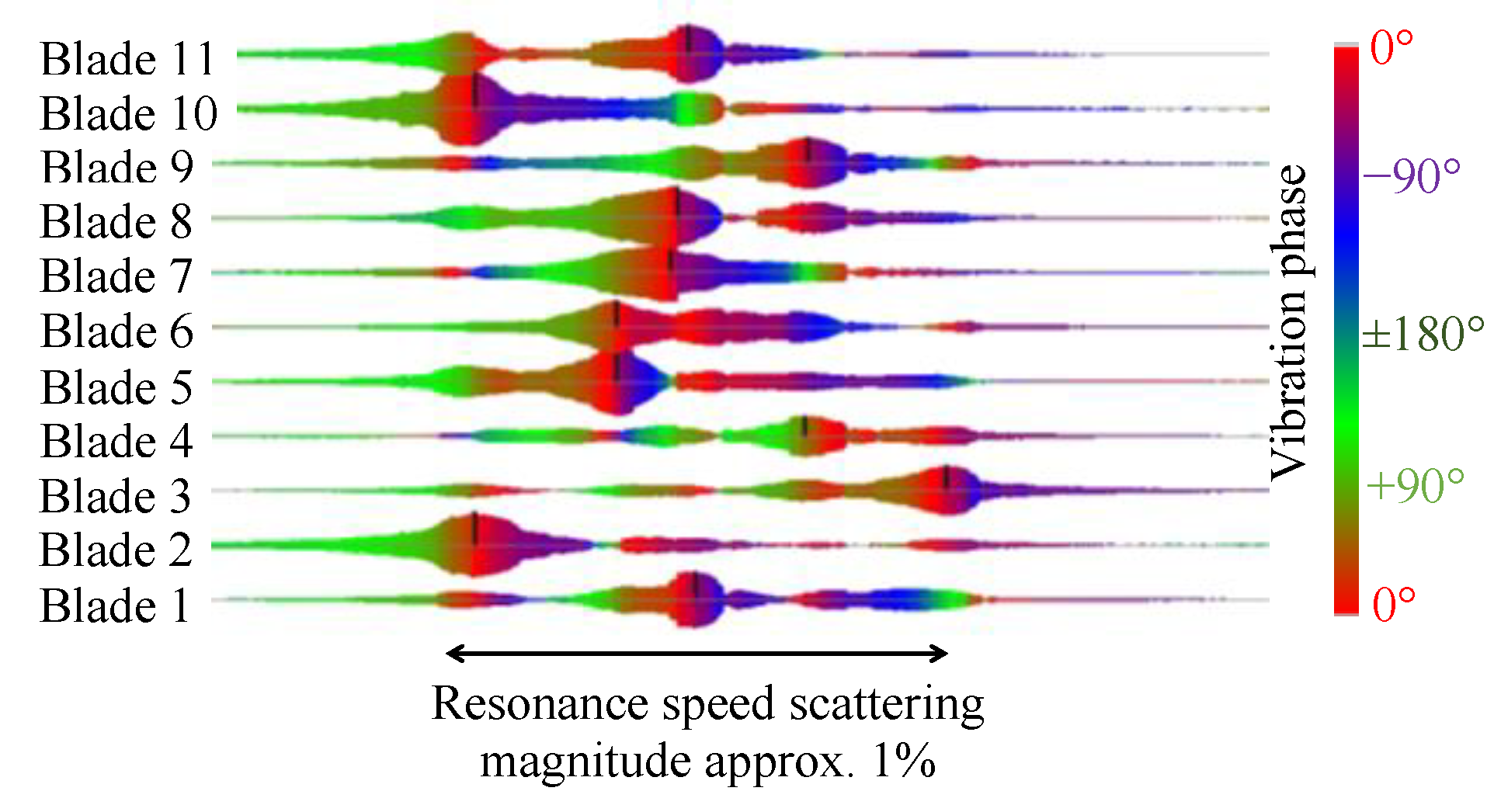

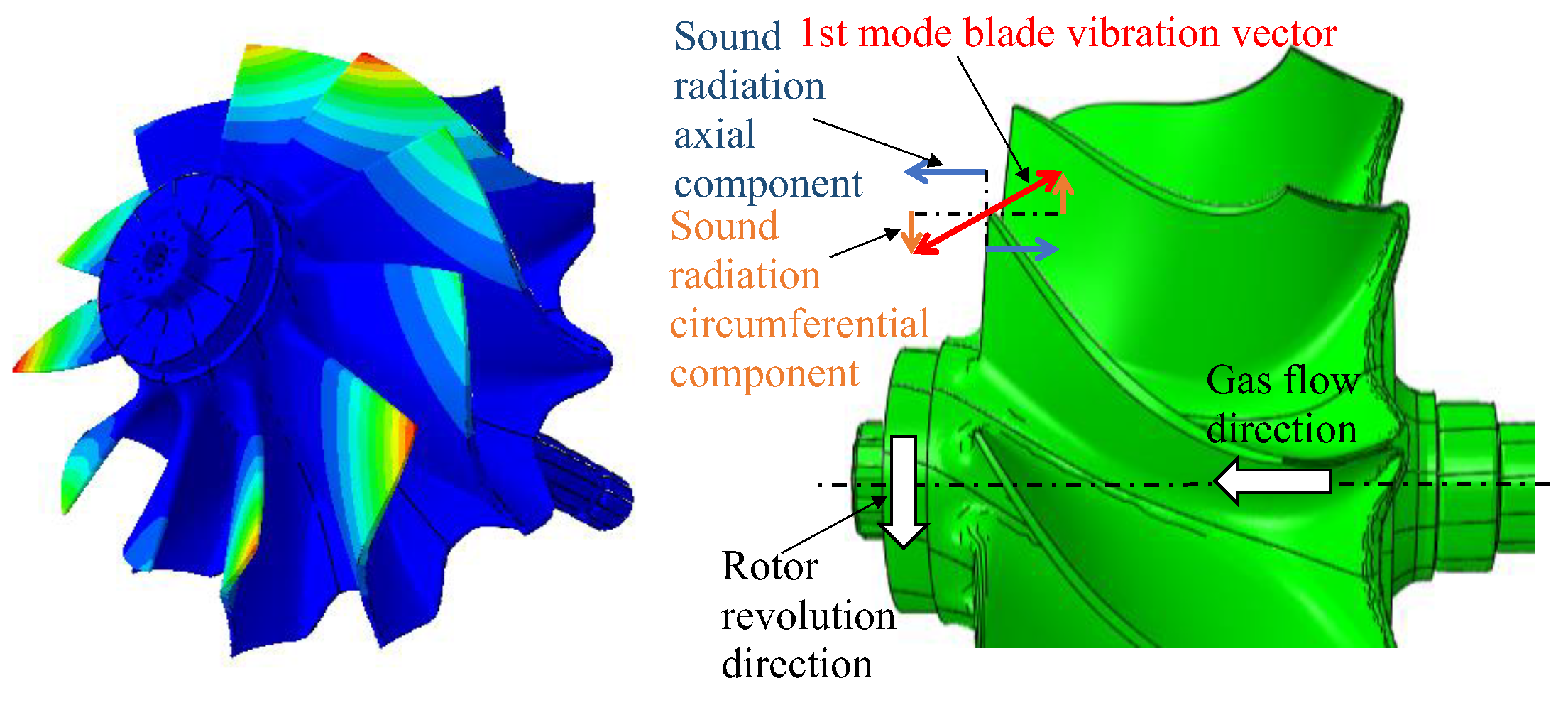

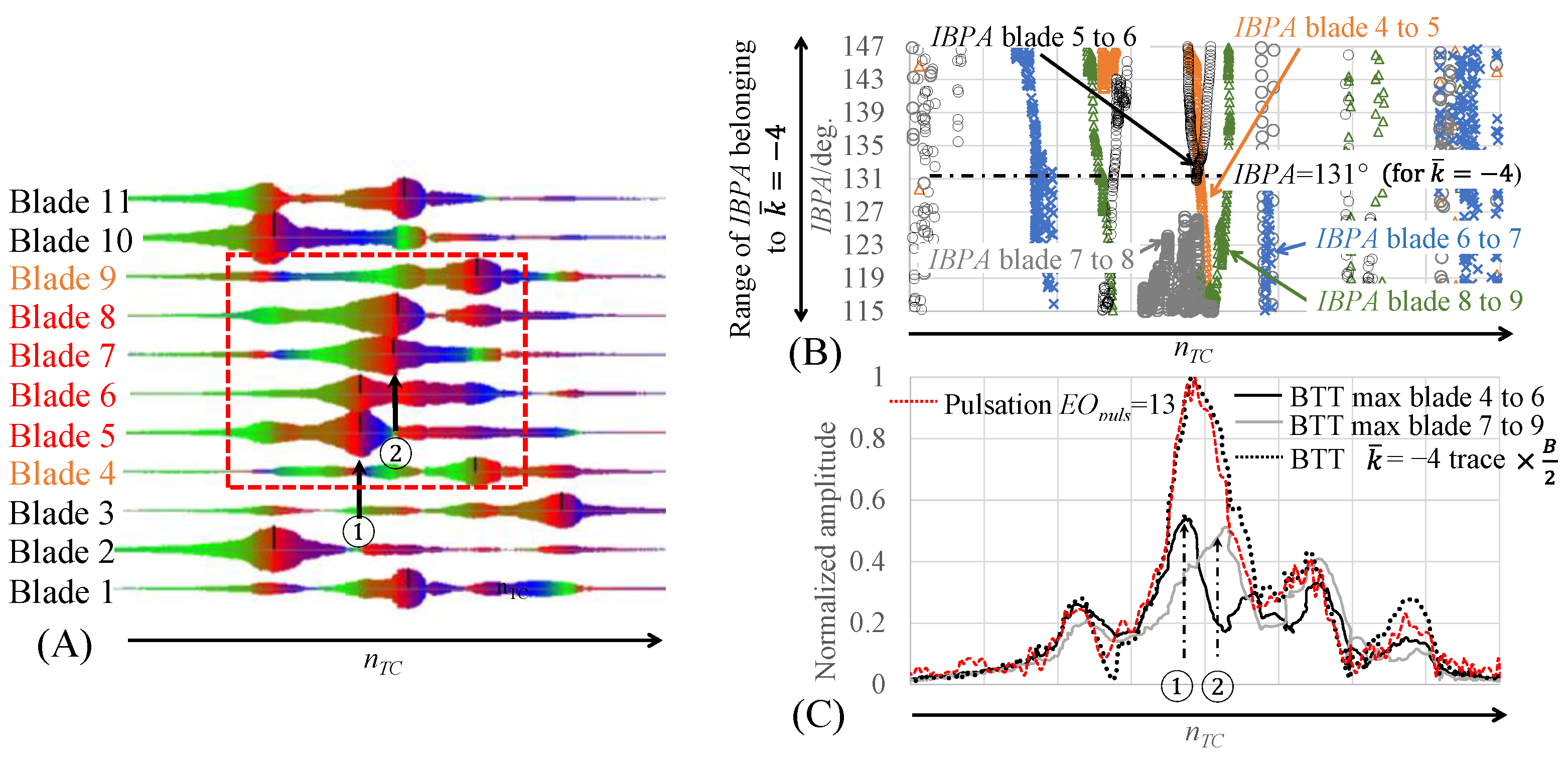

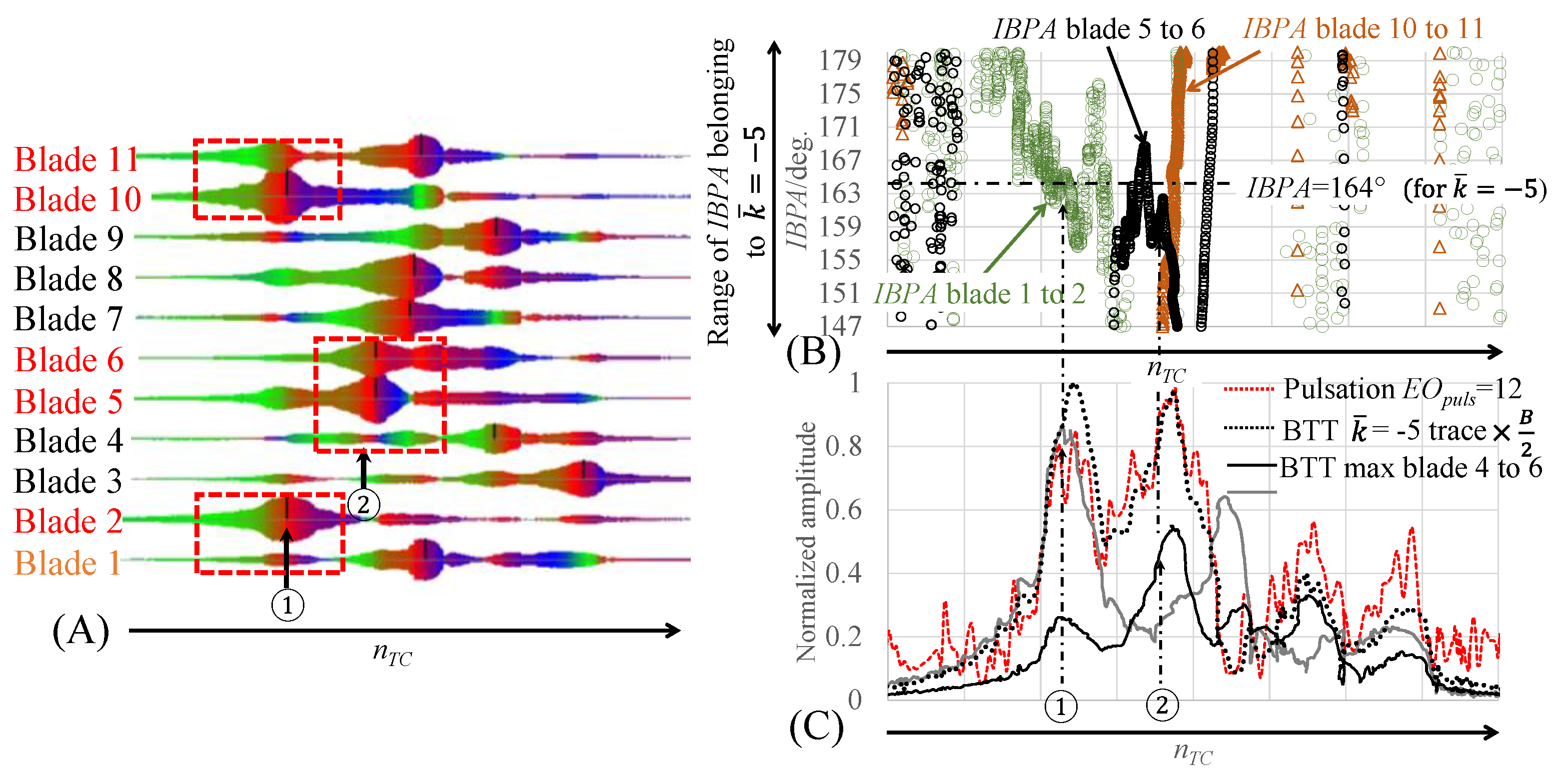

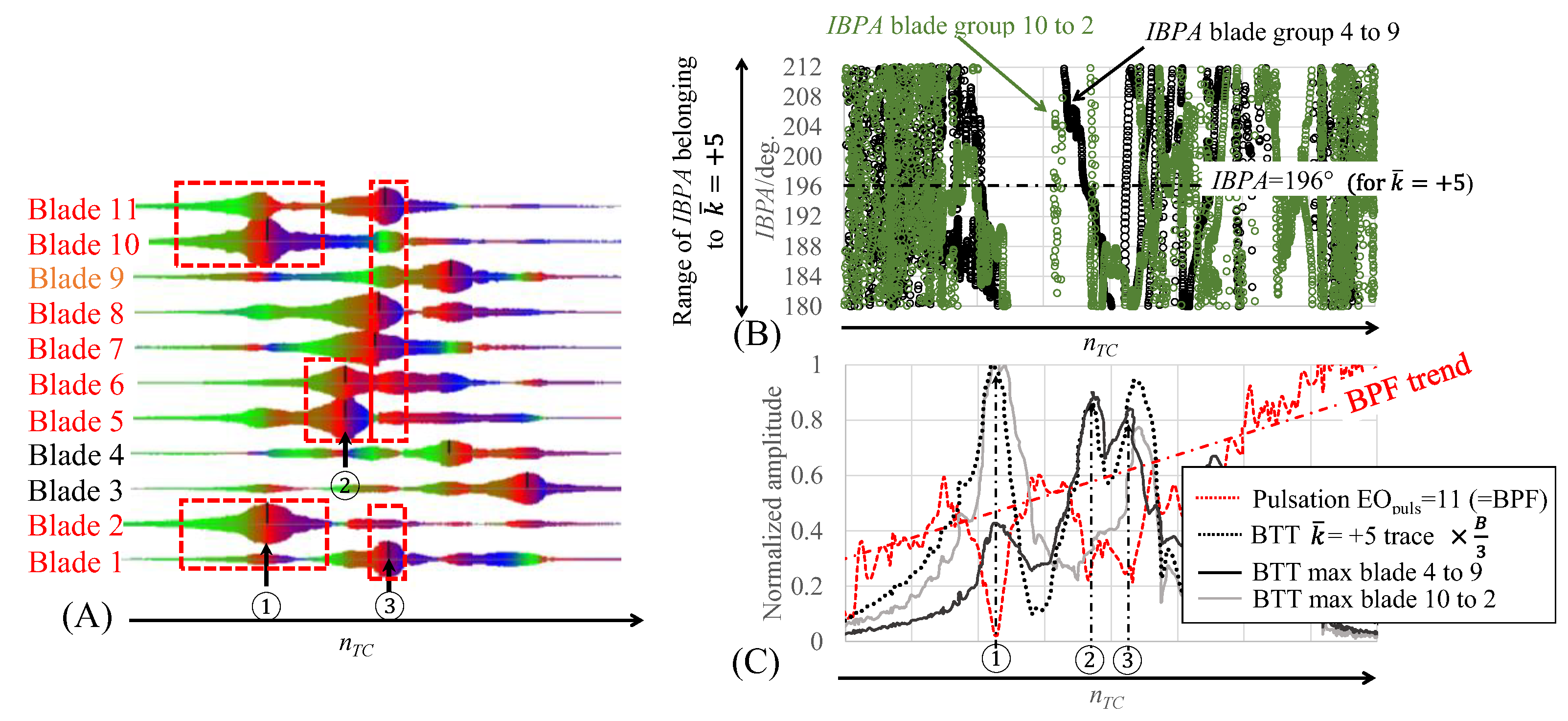

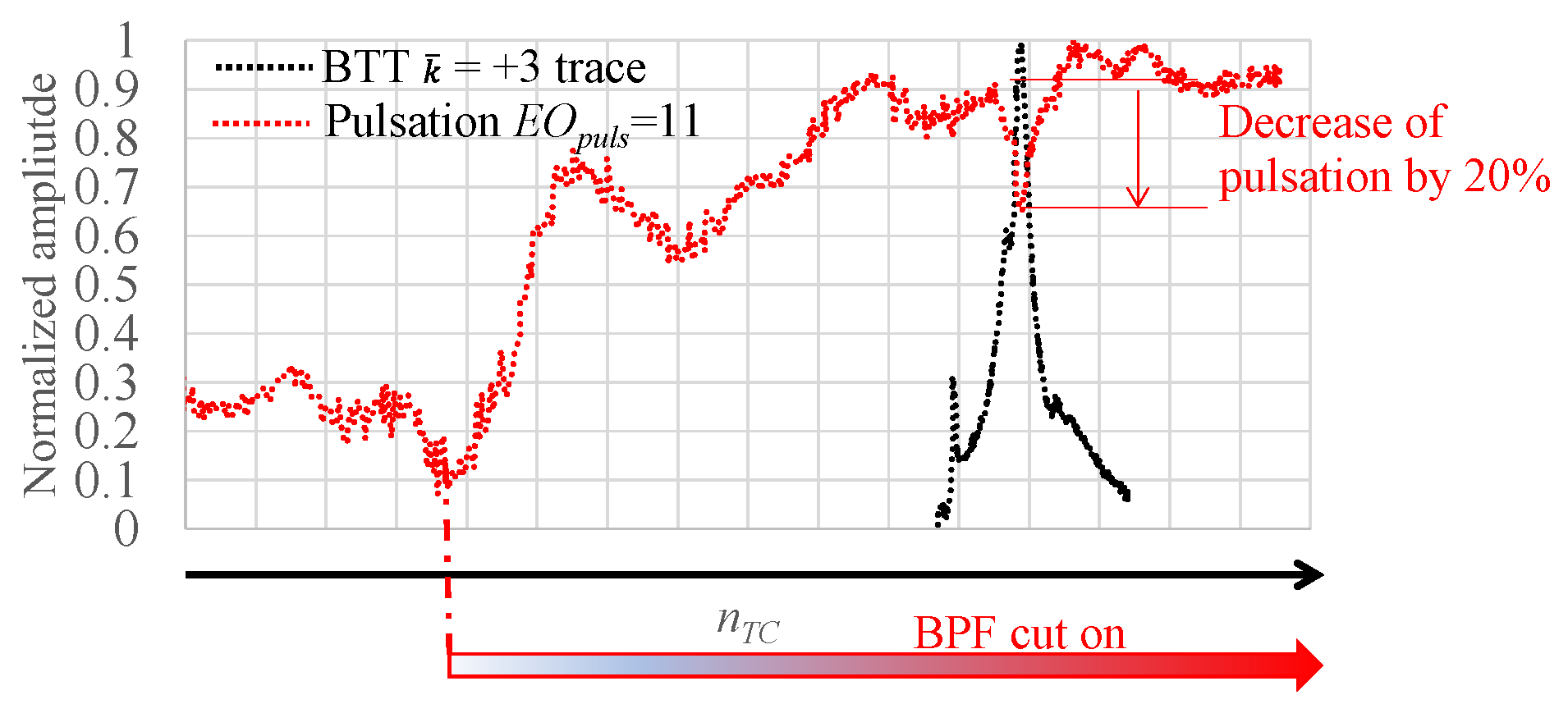

2. Theoretical Discussion

2.1. The Criterium for the Propagation of Circumferential Mode in the Axial Direction

“In order that the pressure field of a spinning lobed pattern propagates in the duct (i.e., axial direction), the circumferential Mach number at which it sweeps the annulus walls must equal or exceed unity.”[5]

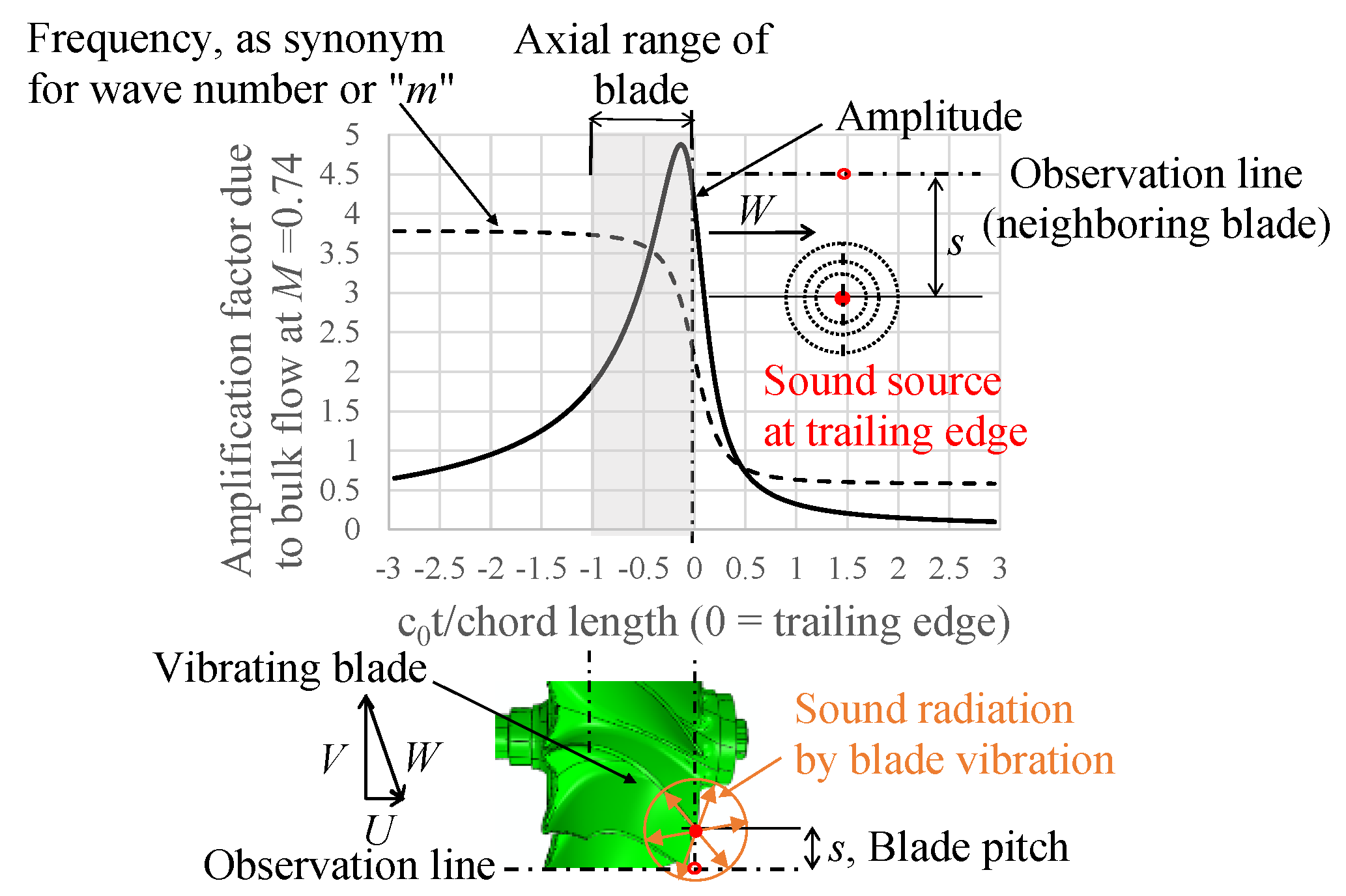

2.2. Effect of Subsonic Bulk Flow on Airborne Acoustic Radiation Amplitude and Wave Number

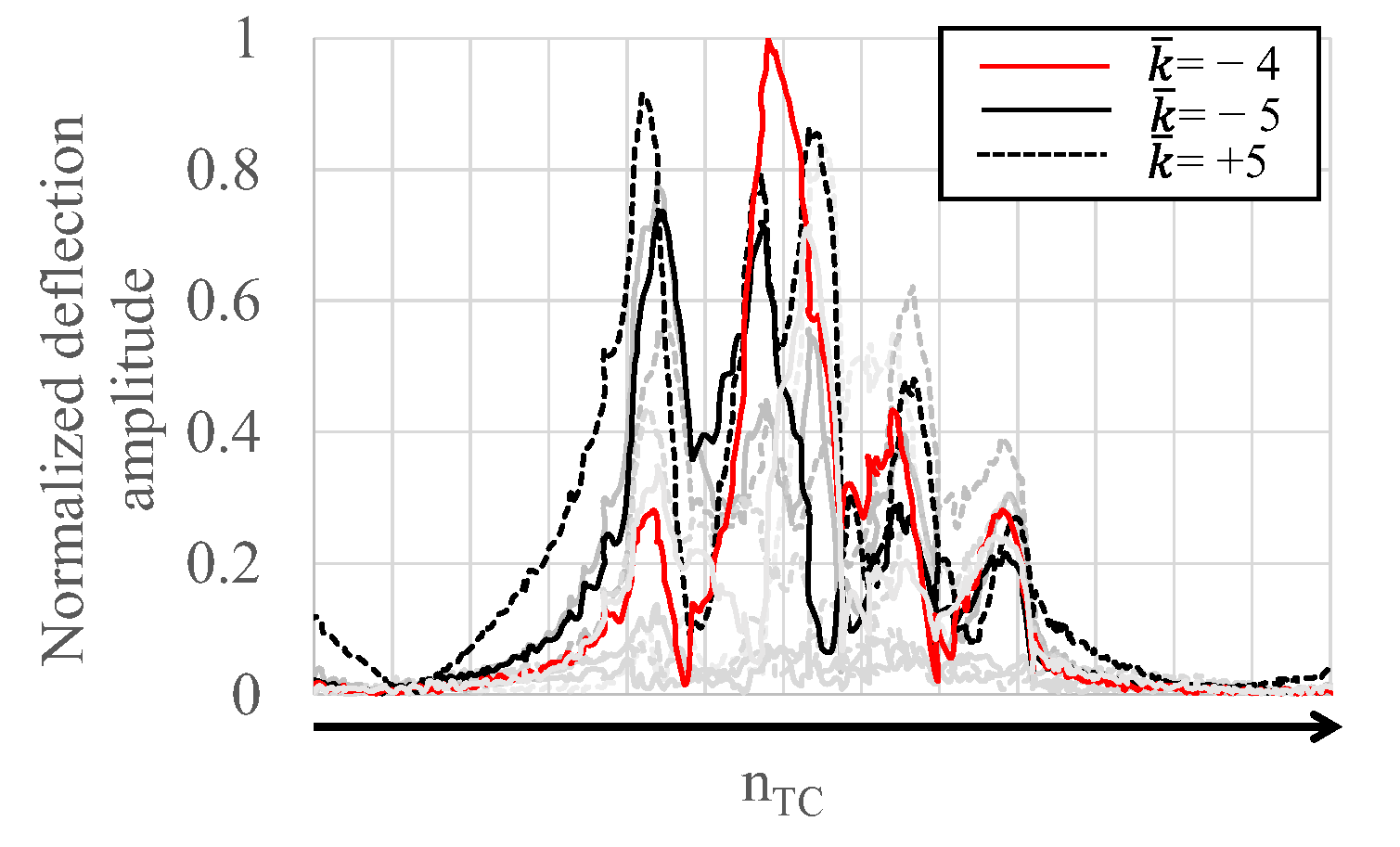

3. Experimental Results and Discussion

4. Conclusions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| BPF | blade passing frequency |

| BTT | blade tip timing measurement |

| EO | excitation or engine order in rotating frame of reference (low EO refers up to EO = 10, excitation originates from geometrical irregularities of casing and/or nozzle ring) |

| EOpuls | excitation or engine order in stationary frame of reference (excitation order detected by pulsation sensor installed on stator side |

| HCF | high cyclic fatigue |

| HFO | heavy fuel oil |

| IBPA | inter-blade phase angle |

| ND | nodal diameter (synonym for cyclic symmetrical mode) |

| LSMF | least square model fit used in BTT data analysis |

| NR | nozzle ring |

| B | turbine blade count |

| M | Mach number |

| U | axial bulk flow velocity |

| V | |

| W | relative bulk flow velocity |

| co | sound velocity |

| cs | circumferential mode sweep velocity |

| i | natural number |

| k | for odd number blade count |

| circumferential mode index | |

| m | airborne acoustic wave number between two blades |

| nTC | rotor revolution frequency |

| r | outer radius at the blade trailing edge |

| ω | blade vibration frequency |

| axial wave number defined by Equation (1) | |

| global wave number between two blades defined by Equation (2) |

References

- Ando, T. Pulsation and Vibration Measurement on Stator Side for Turbocharger Blade Vibration Monitoring. Int. J. Turbomach. Propuls. Power 2020, 5, 11. [Google Scholar] [CrossRef]

- Mengle, V.G. Acoustic spectra and detection of vibrating rotor blades including row-to-row interference. In Proceedings of the AIAA 13th Aeroacoustics Conference, Tallahassee, FL, USA, 22–24 October 1990. [Google Scholar]

- Kurkov, A.P. Flutter Spectral Measurements Using Stationary Pressure Transducers. J. Eng. Power. 1981, 103, 461–467. [Google Scholar] [CrossRef][Green Version]

- Kurkov, A.P. Formulation of Blade Flutter Spectral Analyses in Stationary Reference Frame; NASA TP-2296; NASA: Washington, DC, USA, 1984.

- Tyler, J.M.; Sofrin, T.G. Axial Flow Compressor Noise Studies; S.A.E. International Transactions: Warrendale, PA, USA, 1962; Volume 70, pp. 309–332. [Google Scholar]

- Zhao, F.; Nipkau, J.; Vahdati, M. Influence of Acoustic Reflection on Flutter Stability of an Embedded Blade Row. In Proceedings of the ETC11, Madrid, Spain, 23–27 March 2015. [Google Scholar]

- Hanamura, Y.; Tanaka, H. A simplified Method to Measure Unsteady Forces Acting on the Vibrating Blades in Cascade. Bull. JSME 1980, 23, 880–887. [Google Scholar] [CrossRef]

- Morse, P.M.; Ingard, K.U. Theoretical Acoustics. Chapter 11; Princeton University Press: Princeton, NJ, USA, 1987; ISBN 0-691-02401-4. [Google Scholar]

- Agilis Measurement Systems. 2022. Available online: https://agilismeasurementsystems.com/ (accessed on 7 January 2022).

- Müller, T.R.; Vogt, D.M.; Vogel, K.; Phillipsen, B.A. Influence of Interflow Interaction on the Aerodynamic Damping of an Axial Turbine Stage. In Proceedings of the ASME Turbo Expo 2018, Lillestrøm, Norway, 11–15 June 2018. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY-NC-ND) license (http://creativecommons.org/licenses/by-nc-nd/4.0/).

Share and Cite

Ando, T. Effect of Mistuning and Blade Passing Frequencies on a Turbine’s Integral Mode Blade Vibration Detection Using a Pulsation Probe. Int. J. Turbomach. Propuls. Power 2023, 8, 37. https://doi.org/10.3390/ijtpp8040037

Ando T. Effect of Mistuning and Blade Passing Frequencies on a Turbine’s Integral Mode Blade Vibration Detection Using a Pulsation Probe. International Journal of Turbomachinery, Propulsion and Power. 2023; 8(4):37. https://doi.org/10.3390/ijtpp8040037

Chicago/Turabian StyleAndo, Takashi. 2023. "Effect of Mistuning and Blade Passing Frequencies on a Turbine’s Integral Mode Blade Vibration Detection Using a Pulsation Probe" International Journal of Turbomachinery, Propulsion and Power 8, no. 4: 37. https://doi.org/10.3390/ijtpp8040037

APA StyleAndo, T. (2023). Effect of Mistuning and Blade Passing Frequencies on a Turbine’s Integral Mode Blade Vibration Detection Using a Pulsation Probe. International Journal of Turbomachinery, Propulsion and Power, 8(4), 37. https://doi.org/10.3390/ijtpp8040037