3.1. MPO

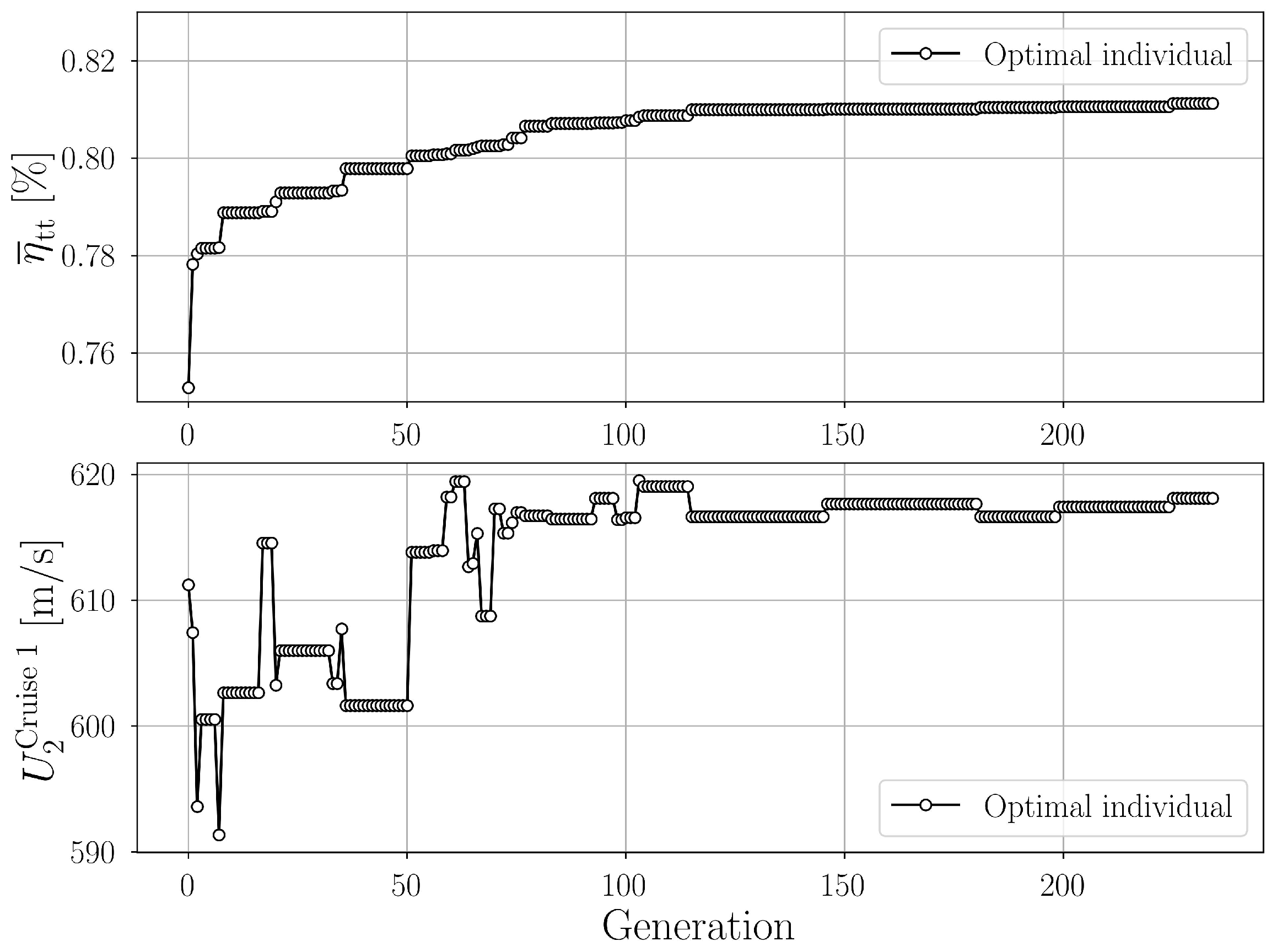

Figure 5 shows the convergence history of the MPO, presenting the value of average total-to-total efficiency,

(

16) (top), and the value of the blade peripheral speed for the second operating point (bottom) for the best-fitness individual of each generation. A continuous increase in the objective function is detected throughout the optimization history, until convergence is reached at an average efficiency value of ≈81%. At the same time, the values of the blade peripheral speed at the second operating point (Cruise 1) show that the constraint is active, and that the optimizer is capable of maintaining its value below the requested maximum (620 m/s).

Interestingly, during the optimization process, both

and

were active optimization variables as confirmed by

Figure 6, which shows their change through the optimization history. Both

and

converge towards the higher end of the range defined by their bounds, without reaching their upper bounds.

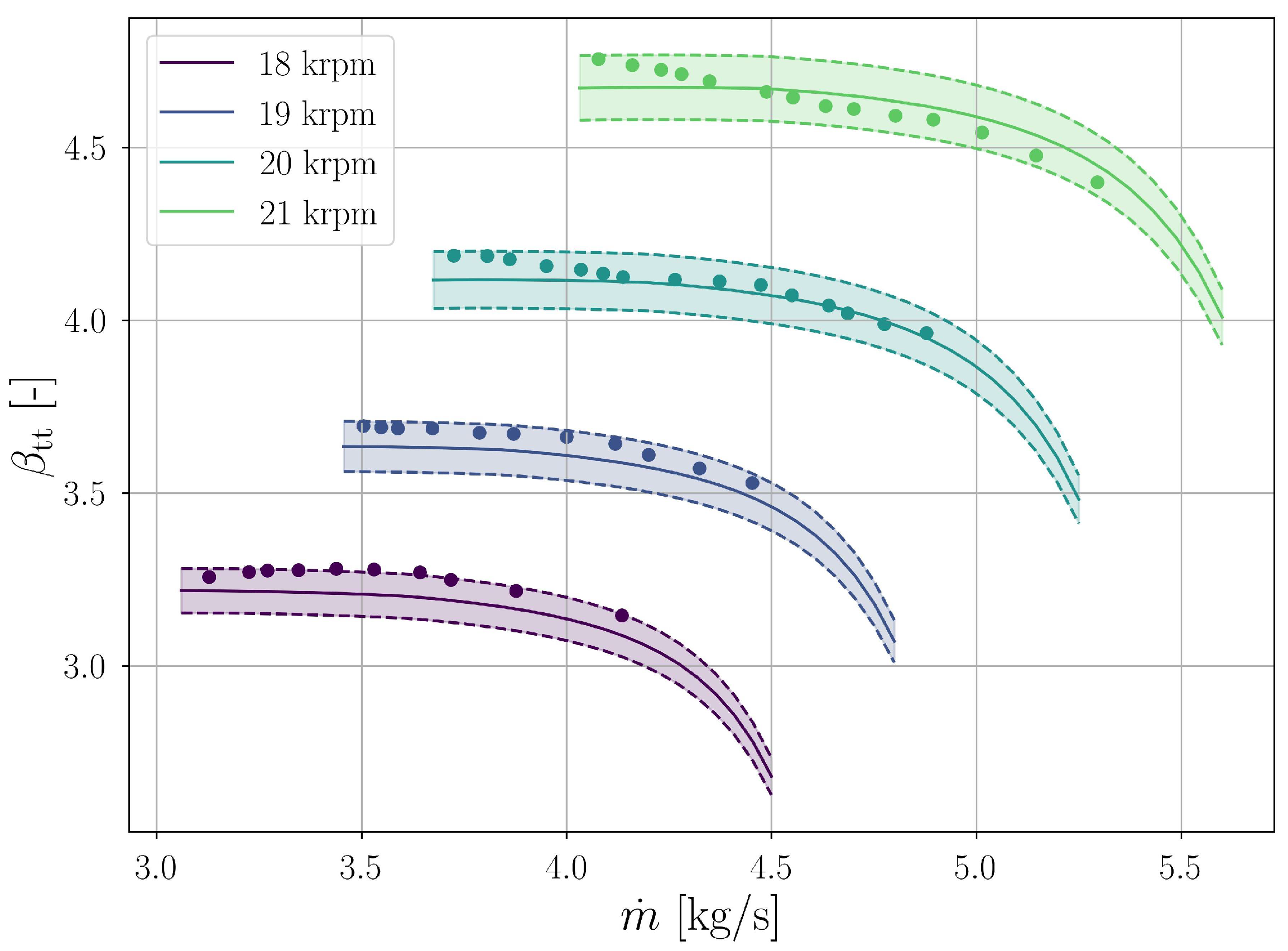

The corrected map of the optimal MPOed compressor, is shown in

Figure 7, together with the superposition of the design point marked by a star

, and the specified OPs, marked by triangle

, square

and circle

. While the speedline recalculation procedure was active during the optimization process, only the original speedlines used for the initial compressor map discretization are displayed for clarity. Furthermore, the corrected mass flow rate axis is scaled by the required mass flow rate at Ground point to preserve the confidentiality of the design.

Notably, all the points specified as optimization targets (despite remarkably different mass flow rate and pressure ratio values) fall well within the compressor map. Furthermore, all of them reach the desired pressure ratio

specified in

Table 3.

3.2. SPO

The non-dominated solutions at the last generation from the SPO test case are presented in

Figure 8. Being that the two optimization objectives (

and

) are conflicting, a typical Pareto front arises, represented by black symbols and a solid line.

To compare the results of the MPO and SPO optimizations, all non-dominated solutions obtained in the SPO, were post-processed by means of the multi-point evaluation procedure described in

Section 2.2. In this regard, it is worth recalling that the SPO does not involve any metric associated to the performance at the target OPs, as only the design speedline is involved in the SPO.

The multi-point evaluation post-processing of the SPO shows that out of the 80 non-dominated solutions defining the Pareto front in

Figure 8, 68 designs were able to deliver the required

at the three OPs. However, only 11 design candidates featured no constraint violation, while the other 37 showed a negligible cumulated constraint violation, Equation (

26), with respect to the values listed in

Table 3. The remaining solutions were either unable to reach the required targets, or unable to process a range of mass flow rate values wide enough to incorporate all the OPs:

3.3. SPO-CG

Figure 8 also shows the non-dominated solutions of the SPO-CG optimization, red triangles and solid line. Similarly to the SPO case, the SPO-CG non-dominated solutions have been post-processed by means of the multi-point evaluation procedure described previously.

The results of the multi-point evaluation show that out of the 80 non-dominated solutions, only 3 designs met the specified constraints, and another 17 showed a negligible cumulated constraints violation with respect to the values listed in

Table 3. The remaining solutions were, also in this case, either unable to meet the required constraints, or unable to accommodate a range of mass flow rate values wide enough to incorporate all the OPs.

One should also notice that, in comparison to the SPO case, a considerably smaller number of SPO-CG optimal designs are capable of meeting the multi-point design requirements at the 3 OPs. Finally, the comparison of the Pareto fronts of the single-point optimizations highlights that the SPO Pareto front dominates the SPO-CG optimal solutions. These results further suggest the effectiveness of the automatic design point selection method.

3.4. Comparison of the Optimal Solutions

The constraint and efficiency values obtained for the three optimal solutions (MPO, SPO and SPO-CG) at the various operating points are collected in

Table 4. While in the multi-point optimization case (MPO), a single optimal solution was computed, a set of non-dominated solutions was obtained for each single-point optimization (SPO and SPO-CG). In these two cases, the optimal solution was therefore selected by choosing the highest

(computed adopting the same weights used for the MPO,

), among the designs that did not violate the constraints.

For confidentiality reasons, the

values are not disclosed, whereas only the change with respect to the target value is presented (

27). Therefore, a positive value indicates that the constraint has been met:

Results show that the MPO compressor features values above 80% at all OPs. The SPOed design exhibits slightly lower values at Ground and Cruise 1 OPs, and a comparable value at Cruise 2. In contrast, the SPO-CG optimal solution presents the lowest efficiency values at the three OPs. Furthermore, it must be noted that the SPO-CG solution provides a at the Ground OP that is 2% larger than the required value, which causes an unnecessary excess of power demand. These results support the conclusion that the MPO method provides globally larger efficiency values at the various OPs, and also allows to identify a suitable design point. The latter observation is also confirmed by the multi-point analysis performed on the SPO and SPO-CG Pareto fronts. Particularly, this analysis shows better performance for the SPO compressor, which was optimized at the same design point found by the MPO.

In

Table 5, a comparison between the design variables of the optimal single-point cases against the MPO case is provided. First of all, the SPO and the optimal MPO solutions feature a different set of design variables (as highlighted by the first column in

Table 5), despite the two solutions featuring the same design point. This difference in design variables explains the higher performance offered by the MPO design. Secondly, the largest differences between the three designs lay in the design variables controlling the shape of the diffuser pinch. In both single-point optimization cases, a more enhanced pinch is required as a result of the greater value of

. This occurrence could be explained by the slightly larger absolute flow angle at the diffuser inlet

required by the SPO and SPO-CG cases. In contrast, the two single-point optimized designs show an opposite requirement in the location of the pinch. In the SPO case, the pinch occurs much more upstream (at lower

) than in the MPO design, while it occurs further downstream (at higher

) for the SPO-CG case.

While the MPO strategy proved to be superior in terms of achievable efficiency, constraints management at the various operating points, and design point selection, it also entails a larger computational cost. First of all, only the design speedline is required by the single-point method, instead, the MPO method requires the calculation of the full compressor map. Increasing the number of speedlines used for the compressor map discretization increases the accuracy, at the expense of computational cost. In the present work, six speedlines are used. However, this parameter may be application dependent, as a larger (or lower) number of speedlines may be necessary for operating points further away from (or closer to) each other.

Moreover, an additional step is required by the MPO method for the multi-point evaluation, although of modest computational cost in comparison to the map calculation. The computational cost associated to the multi-point evaluation scales with the number of operating points provided. The accuracy of the multi-point evaluation can be increased via the recalculation of the speedline corresponding to the estimated rotational speed at step 2, Equation (

4) of

Section 2.2. In this regard, it should be highlighted that a better trade-off between the number of speedlines used for the compressor map calculation and the speedline recalculation may exist, although this is deemed beyond the scope of the work.

Finally, when the automatic design point selection method is employed, two additional design variables are introduced. In turn, this may require a larger population size, leading to a longer evaluation time per generation.

In the present work, the computational time of the MPO with automatic design point selection method and speedline recalculation, performed on 21 cores for 230 generations of 100 individuals each is 51.8 h. This corresponds to an average computational time of ≈13.5 min/generation, equal to 8.10 s/individual. In contrast, the computational time of the SPO case is 1.66 min/generation, equal to 1.25 s/individual.