Conceptual Design and Evaluation of Windshield Displays for Excavators

Abstract

:1. Introduction

- RQ1.

- What kind of information do operators need to know in order to perform safe operations?

- RQ2.

- What commercially available technologies can be used to present information near line of sight and what are their limitations?

- RQ3.

- How should the supportive information be visualized based on the chosen technology and the currently performed operation?

- RQ4.

- How do excavator operators perceive the proposed visualization approach?

2. Related Work

3. Methods

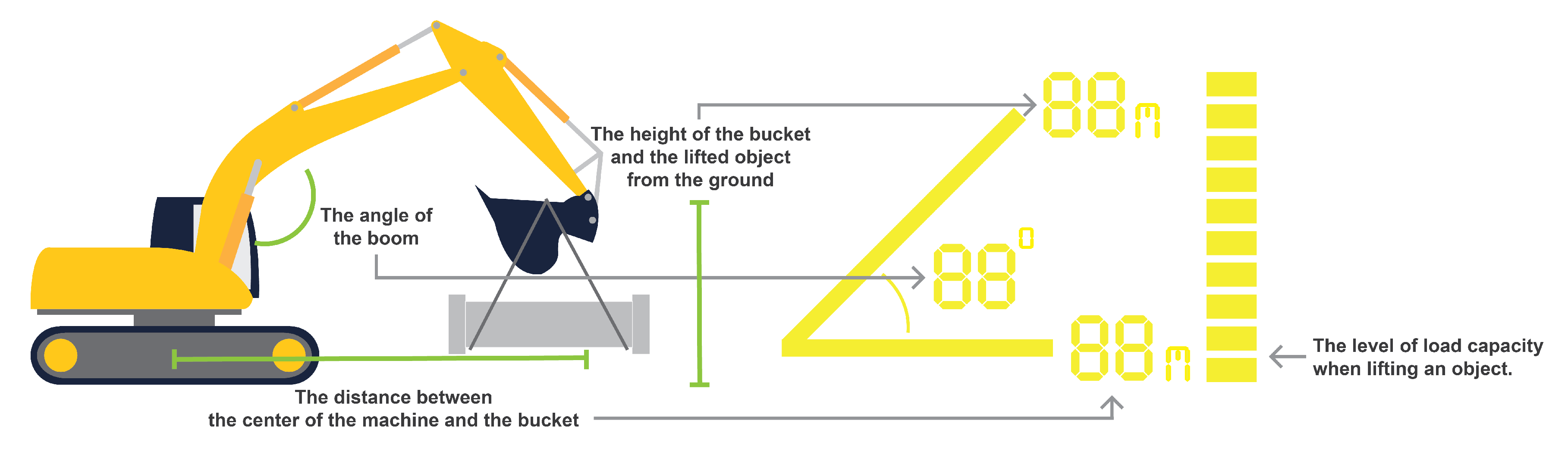

3.1. Using Safety Guidelines to Find which Information Is Important for Safe Operations

3.2. Reviewing Commercially Available Technologies for Presenting Information Near Line of Sight

3.3. Conducting a Design Workshop to Generate Visualization Ideas

3.3.1. Proximity Warning

3.3.2. Balance-Related Information

3.3.3. Undercarriage Direction

3.3.4. Relative Load Capacity

3.3.5. Generic Warning Sign

3.4. Interviewing Operators to Get Their Feedback

4. Results

4.1. Comments on the Proximity Warning

4.2. Comments on the Balance-Related Information

4.3. Comments on the Undercarriage Direction

4.4. Comments on the Relative Load Capacity

4.5. Comments on the Generic Warning Sign

4.6. Information Placement on the Windshield

5. Discussion

6. Future Work

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hughes, K.; Jiang, X. Using discrete event simulation to model excavator operator performance. Hum. Factors Ergon. Manuf. Serv. Ind. 2010, 20, 408–423. [Google Scholar] [CrossRef]

- Kazan, E.; Usmen, M.A. Worker safety and injury severity analysis of earthmoving equipment accidents. J. Saf. Res. 2018, 65, 73–81. [Google Scholar] [CrossRef] [PubMed]

- Jo, B.W.; Lee, Y.S.; Kim, J.H.; Kim, D.K.; Choi, P.H. Proximity Warning and Excavator Control System for Prevention of Collision Accidents. Sustainability 2017, 9, 1488. [Google Scholar] [CrossRef] [Green Version]

- Wallmyr, M.; Sitompul, T.A.; Holstein, T.; Lindell, R. Evaluating Mixed Reality Notifications to Support Excavator Operator Awareness. In Human-Computer Interaction—INTERACT 2019-17th IFIP TC 13 International Conference, Proceedings, Part I; Springer: Cham, Switzerland, 2019; pp. 743–762. [Google Scholar] [CrossRef]

- Wallmyr, M. Seeing Through the Eyes of Heavy Vehicle Operators. In Human-Computer Interaction—INTERACT 2017; Springer: Cham, Switzerland, 2017; pp. 263–282. [Google Scholar] [CrossRef] [Green Version]

- Kress, B.; Victorien, R.; Meyrueis, P. Digital combiner achieves low cost and high reliability for head-up display applications. SPIE Newsroom 2009. [Google Scholar] [CrossRef]

- Haeuslschmid, R.; Pfleging, B.; Alt, F. A Design Space to Support the Development of Windshield Applications for the Car. In Proceedings of the 2016 CHI Conference on Human Factors in Computing Systems, San Jose, CA, USA, 7–12 May 2016; ACM: New York, NY, USA, 2016; pp. 5076–5091. [Google Scholar] [CrossRef]

- Sitompul, T.A.; Wallmyr, M. Using Augmented Reality to Improve Productivity and Safety for Heavy Machinery Operators: State of the Art. In Proceedings of the 17th International Conference on Virtual-Reality Continuum and Its Applications in Industry, Brisbane, Australia, 17–20 December 2019; ACM: New York, NY, USA, 2019; pp. 8:1–8:9. [Google Scholar] [CrossRef] [Green Version]

- Vessey, I.; Galletta, D. Cognitive Fit: An Empirical Study of Information Acquisition. Inf. Syst. Res. 1991, 2, 63–84. [Google Scholar] [CrossRef]

- Nuamah, J.K.; Seong, Y.; Jiang, S.; Park, E.; Mountjoy, D. Evaluating effectiveness of information visualizations using cognitive fit theory: A neuroergonomics approach. Appl. Ergon. 2020, 88, 103173. [Google Scholar] [CrossRef] [PubMed]

- Endsley, M.R.; Jones, D.G. Designing for Situation Awareness: An Approach to User-Centered Design, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar] [CrossRef]

- Fang, Y.; Cho, Y.K. Effectiveness Analysis from a Cognitive Perspective for a Real-Time Safety Assistance System for Mobile Crane Lifting Operations. J. Constr. Eng. Manag. 2017, 143, 05016025:1–05016025:11. [Google Scholar] [CrossRef]

- Akyeampong, J.; Udoka, S.; Caruso, G.; Bordegoni, M. Evaluation of hydraulic excavator Human–Machine Interface concepts using NASA TLX. Int. J. Ind. Ergon. 2014, 44, 374–382. [Google Scholar] [CrossRef]

- Fang, Y.; Cho, Y.K.; Durso, F.; Seo, J. Assessment of operator’s situation awareness for smart operation of mobile cranes. Autom. Constr. 2018, 85, 65–75. [Google Scholar] [CrossRef]

- Santana-Fernández, J.; Gil, J.G.; Del-Pozo-San-Cirilo, L. Design and Implementation of a GPS Guidance System for Agricultural Tractors Using Augmented Reality Technology. Sensors 2010, 10, 10435–10447. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Palonen, T.; Hyyti, H.; Visala, A. Augmented Reality in Forest Machine Cabin. IFAC-PapersOnLine 2017, 50, 5410–5417. [Google Scholar] [CrossRef]

- Rakauskas, M.E.; Ward, N.J.; Gorjestani, A.R.; Shankwitz, C.R.; Donath, M. Evaluation of a DGPS Driver Assistive System for Snowplows and Emergency Vehicles. In International Conference of Traffic and Transport Psychology; Elsevier: Nottingham, UK, 2005; pp. 257–272. [Google Scholar]

- Englund, M.; Lundström, H.; Brunberg, T.; Löfgren, B. Utvärdering av Head-Up Display för Visning av Apteringsinformation i Slutavverkning; Technical Report; Skogforsk: Uppsala, Sweden, 2015. [Google Scholar]

- Kvalberg, J.L. Head-Up Display in Driller and Crane Cabin. Master’s Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2010. [Google Scholar]

- Strategic Forum for Construction. Lifting Operations with Excavators; Construction Plant-hire Association: London, UK, 2008. [Google Scholar]

- Occupational Safety and Health Branch. Code of Practice on Safe Use of Excavators; Labour Department: Hong Kong, China, 2005. [Google Scholar]

- Health and Safety Executive. The Safe Use of Vehicles on Construction Sites; HSE Books: Sudbury, UK, 2009. [Google Scholar]

- CITB Construction Skills. Health and Safety Advice for Plant Operators; CITB Northern Ireland: Crumlin, UK, 2016. [Google Scholar]

- Segura, Á.; Moreno, A.; Brunetti, G.; Henn, T. Interaction and Ergonomics Issues in the Development of a Mixed Reality Construction Machinery Simulator for Safety Training. In Proceedings of the International Conference on Ergonomics and Health Aspects of Work with Computers, Beijing, China, 22–27 July 2007; Springer: Berlin/Heidelberg, Germany, 2007; pp. 290–299. [Google Scholar]

- Tretten, P.; Gärling, A.; Nilsson, R.; Larsson, T.C. An On-Road Study of Head-Up Display: Preferred Location and Acceptance Levels. Proc. Hum. Factors Ergon. Soc. Annu. Meet. 2011, 55, 1914–1918. [Google Scholar] [CrossRef] [Green Version]

- Abileah, A.; Harkonen, K.; Pakkala, A.; Smid, G. Transparent Electroluminescent (EL) Displays; Technical Report; Planar Systems: Beaverton, OR, USA, 2008. [Google Scholar]

- Snyder, C. Paper Prototyping: The Fast and Easy Way to Design and Refine User Interfaces; Morgan Kaufmann Publishers: San Francisco, CA, USA, 2003. [Google Scholar]

- Beaudouin-Lafon, M.; Mackay, W.E. Prototyping tools and techniques. In Human-Computer Interaction: Development Process; Sears, A., Jacko, J.A., Eds.; CRC Press: Boca Raton, FL, USA, 2009; Chapter 7; pp. 121–144. [Google Scholar]

- Schneider, S.; Buchholz, B.; Moir, S.; Virji, M.A. An Ergonomic Assessment of an Operating Engineer: A Pilot Study of Excavator Use. Appl. Occup. Environ. Hyg. 1997, 12, 23–27. [Google Scholar] [CrossRef]

- Cann, A.P.; Salmoni, A.W.; Vi, P.; Eger, T.R. An Exploratory Study of Whole-Body Vibration Exposure and Dose While Operating Heavy Equipment in the Construction Industry. Appl. Occup. Environ. Hyg. 2003, 18, 999–1005. [Google Scholar] [CrossRef] [PubMed]

- Osafo-Benoah, B.; Jiang, S. Empirical Investigation of Conflict and Interference within Haptic Controlled Human-Excavator Interface. In Advances in Usability Evaluation Part I, 1st ed.; Soares, M., Rebelo, F., Eds.; CRC Press: Boca Raton, FL, USA, 2019; Chapter 5; pp. 42–51. [Google Scholar]

- Osafo-Yeboah, B.; Jiang, S.; Delpish, R.; Jiang, Z.; Ntuen, C. Empirical study to investigate the range of force feedback necessary for best operator performance in a haptic controlled excavator interface. Int. J. Ind. Ergon. 2013, 43, 197–202. [Google Scholar] [CrossRef]

- Morosi, F.; Rossoni, M.; Caruso, G. Coordinated control paradigm for hydraulic excavator with haptic device. Autom. Constr. 2019, 105, 102848. [Google Scholar] [CrossRef]

- Desai, Y.; Davis, D.; Jiang, S.; Ward, A. The Effect of Auditory Cues on Haptic-Controlled Excavator Operator Performance. In Proceedings of the IIE Annual Conference Proceedings, Montreal, QC, Canada, 31 May–3 June 2014; IIE: Norcross, GA, USA, 2014; pp. 825–832. [Google Scholar]

- Topliss, B.H.; Pampel, S.M.; Burnett, G.; Gabbard, J.L. Evaluating Head-Up Displays across Windshield Locations. In Proceedings of the 11th International Conference on Automotive User Interfaces and Interactive Vehicular Applications, Utrecht, The Netherlands, 21–25 September 2019; ACM: New York, NY, USA, 2019; pp. 244–253. [Google Scholar] [CrossRef]

| No | Age | Status | Experience | Excavator Sizes | Knowledge on Head-Up Displays |

|---|---|---|---|---|---|

| 1 | 22 years old | Professional | 5 years | 14–65 tonnes | Has tried one in a car |

| 2 | 40 years old | Professional | 2 years | 1.5–75 tonnes | Has tried one in a car |

| 3 | 43 years old | Professional | 5 years | 5–25 tonnes | Has no knowledge |

| 4 | 53 years old | Hobbyist | 11 years | 1.1 tonnes | Has tried one in a car |

| 5 | 58 years old | Professional | 34 years | 14 tonnes | Has seen one, but never tried |

| 6 | 64 years old | Professional | 50 years | 1.5–95 tonnes | Has seen one, but never tried |

| 7 | 39 years old | Professional | 5 years | 1.5–30 tonnes | Has tried one in a car |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sitompul, T.A.; Wallmyr, M.; Lindell, R. Conceptual Design and Evaluation of Windshield Displays for Excavators. Multimodal Technol. Interact. 2020, 4, 86. https://doi.org/10.3390/mti4040086

Sitompul TA, Wallmyr M, Lindell R. Conceptual Design and Evaluation of Windshield Displays for Excavators. Multimodal Technologies and Interaction. 2020; 4(4):86. https://doi.org/10.3390/mti4040086

Chicago/Turabian StyleSitompul, Taufik Akbar, Markus Wallmyr, and Rikard Lindell. 2020. "Conceptual Design and Evaluation of Windshield Displays for Excavators" Multimodal Technologies and Interaction 4, no. 4: 86. https://doi.org/10.3390/mti4040086

APA StyleSitompul, T. A., Wallmyr, M., & Lindell, R. (2020). Conceptual Design and Evaluation of Windshield Displays for Excavators. Multimodal Technologies and Interaction, 4(4), 86. https://doi.org/10.3390/mti4040086