Battery Housing for Electric Vehicles, a Durability Assessment Review

Abstract

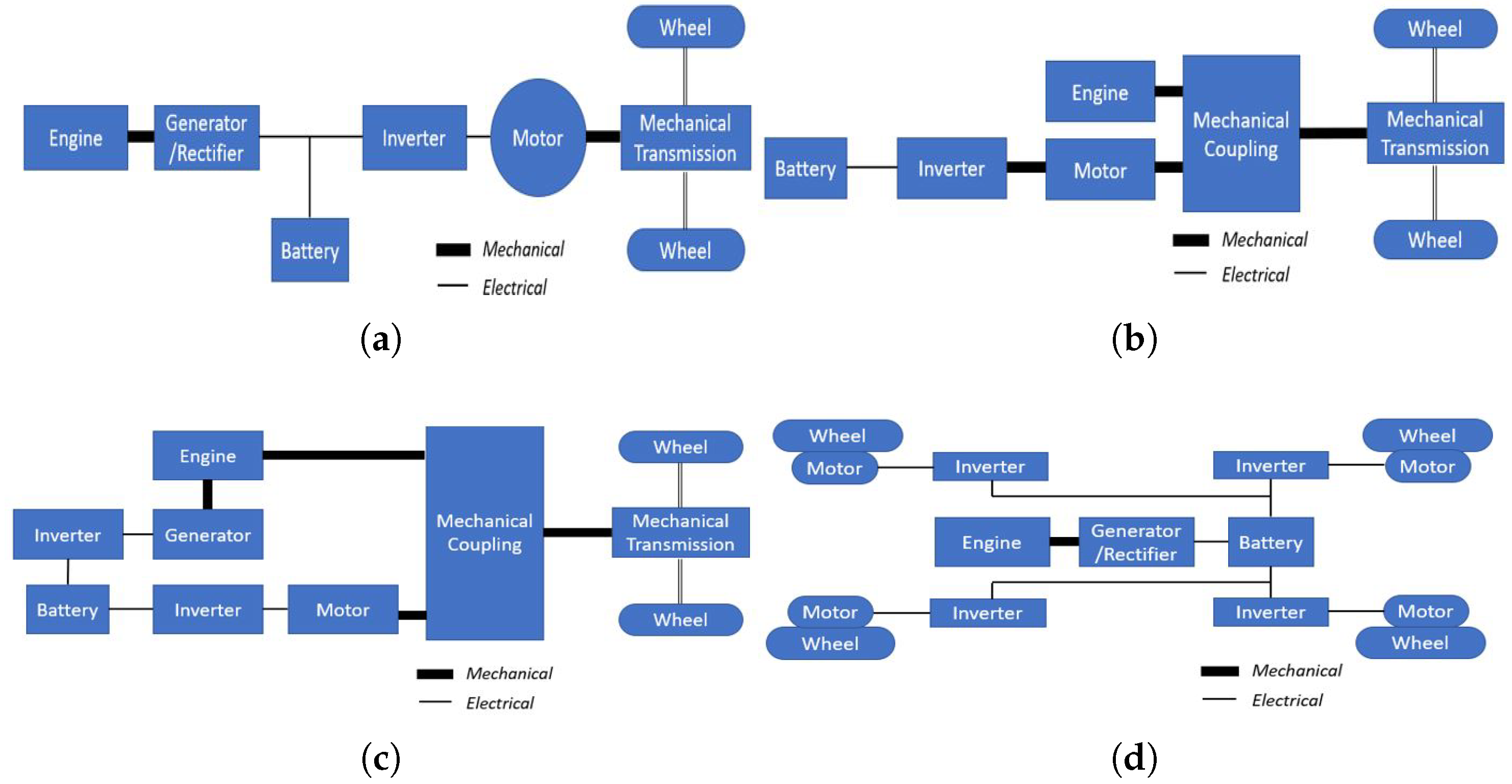

1. Introduction

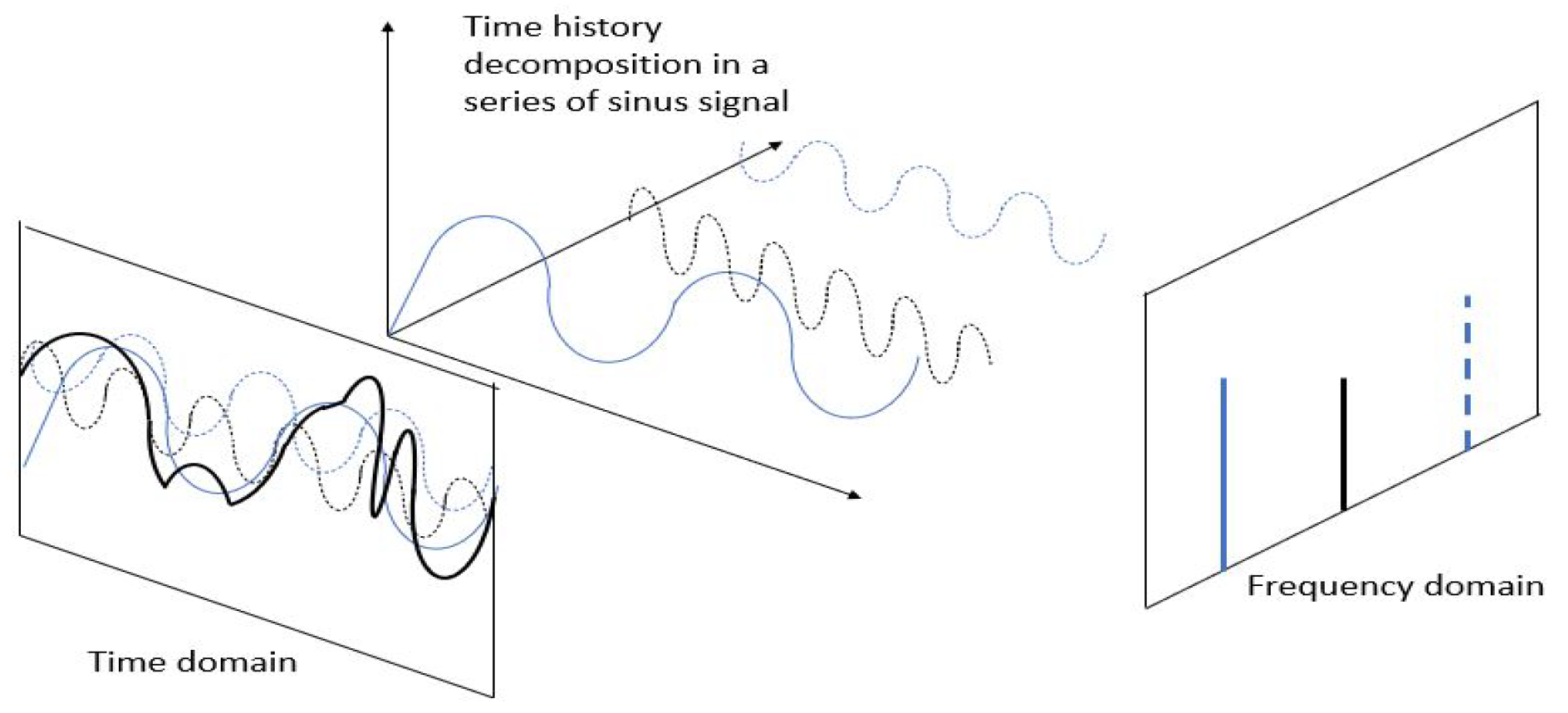

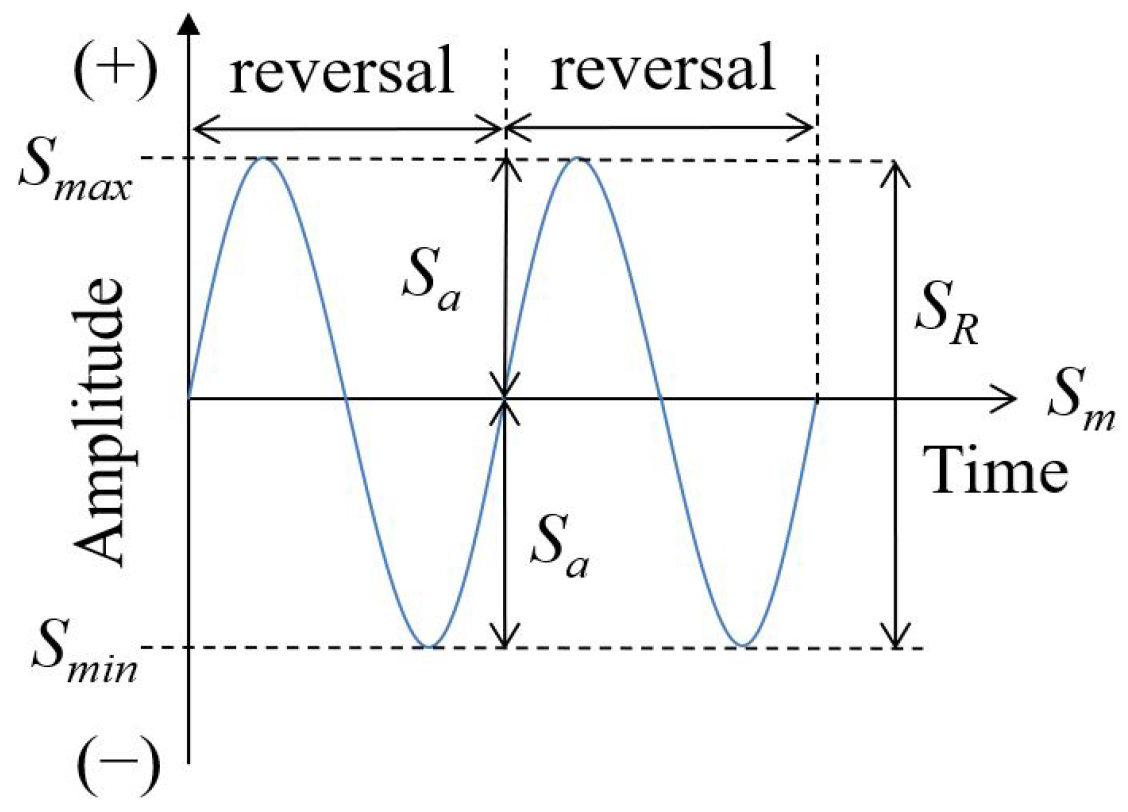

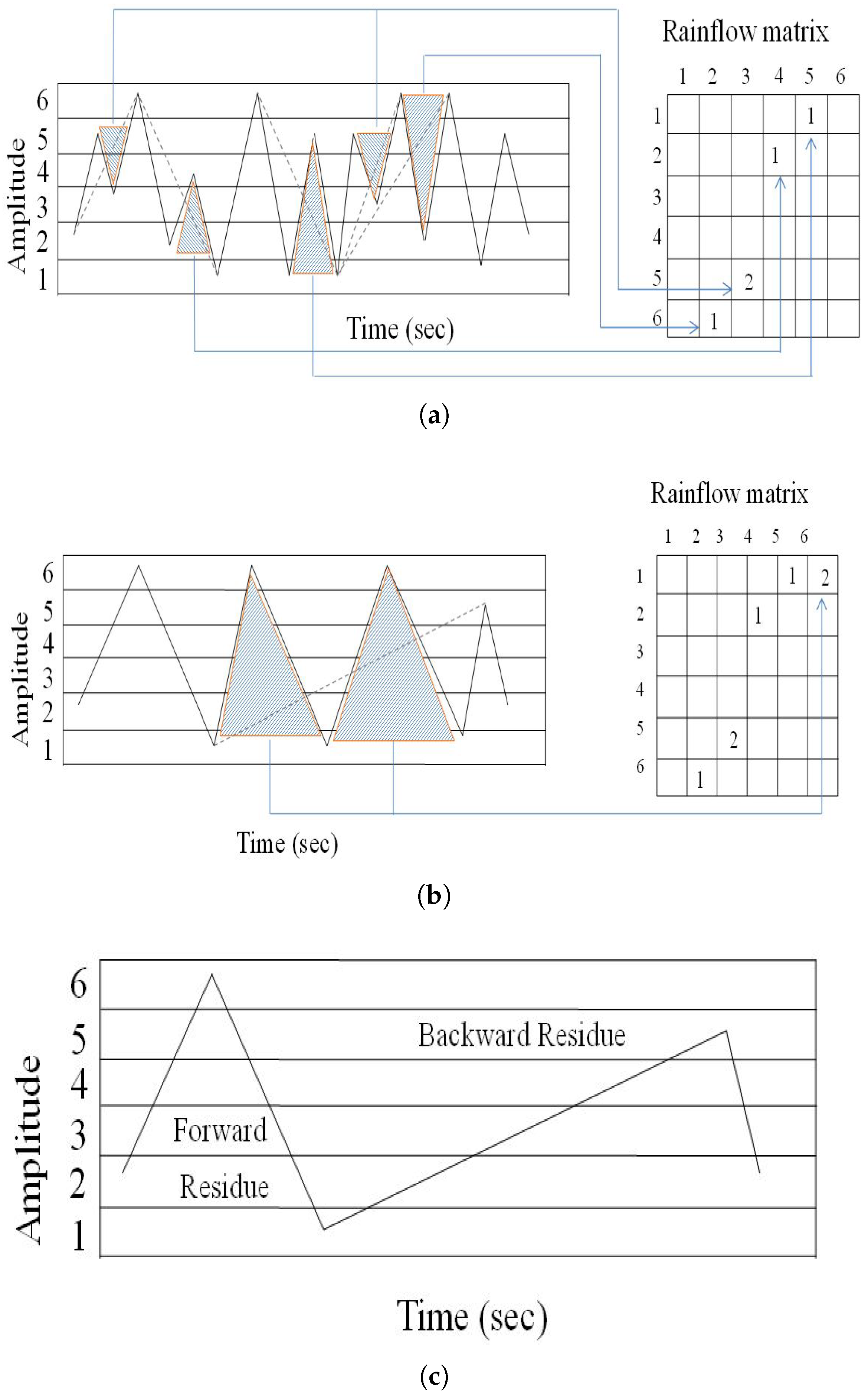

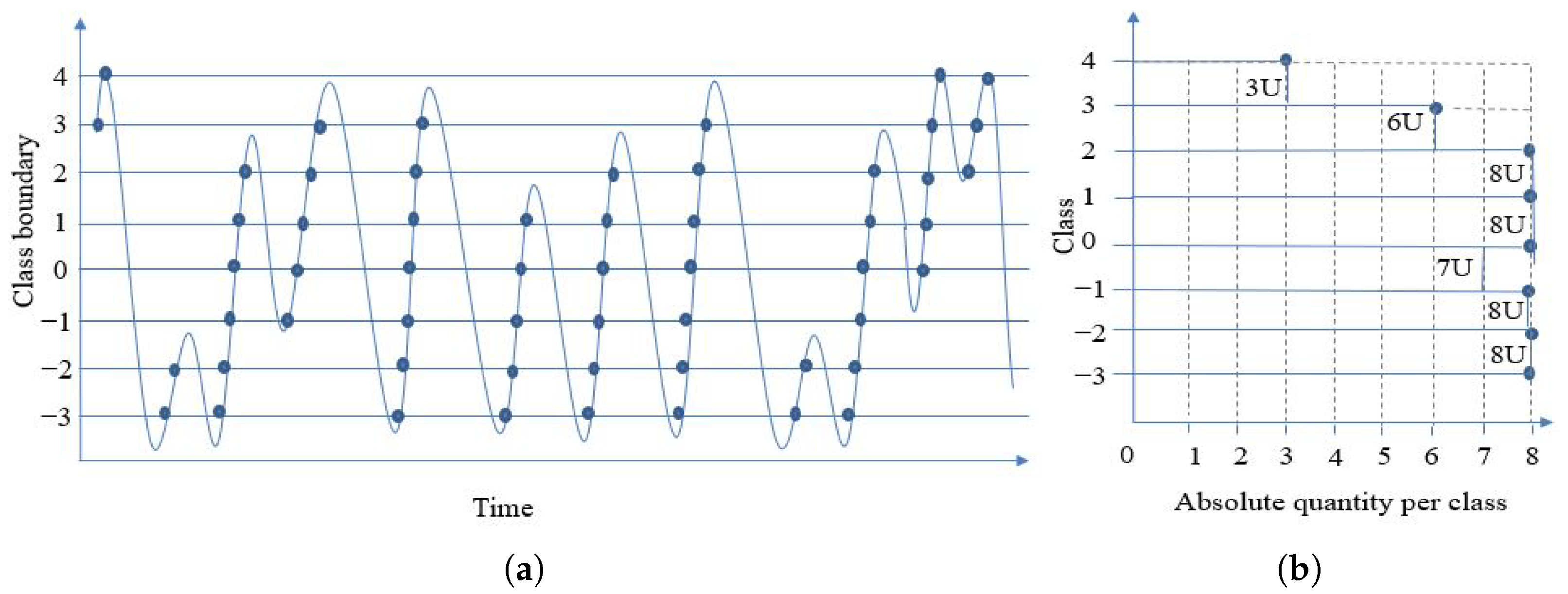

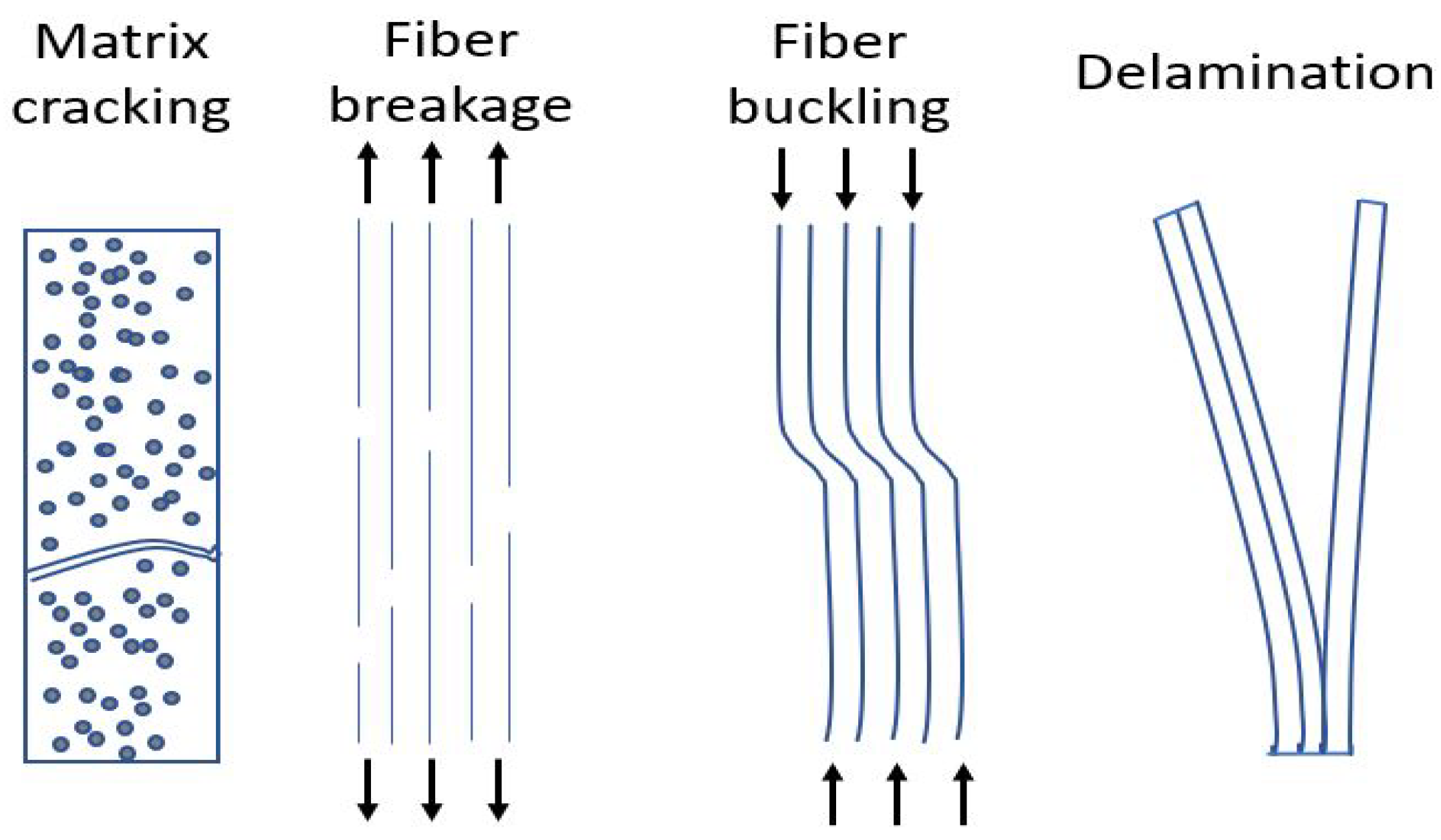

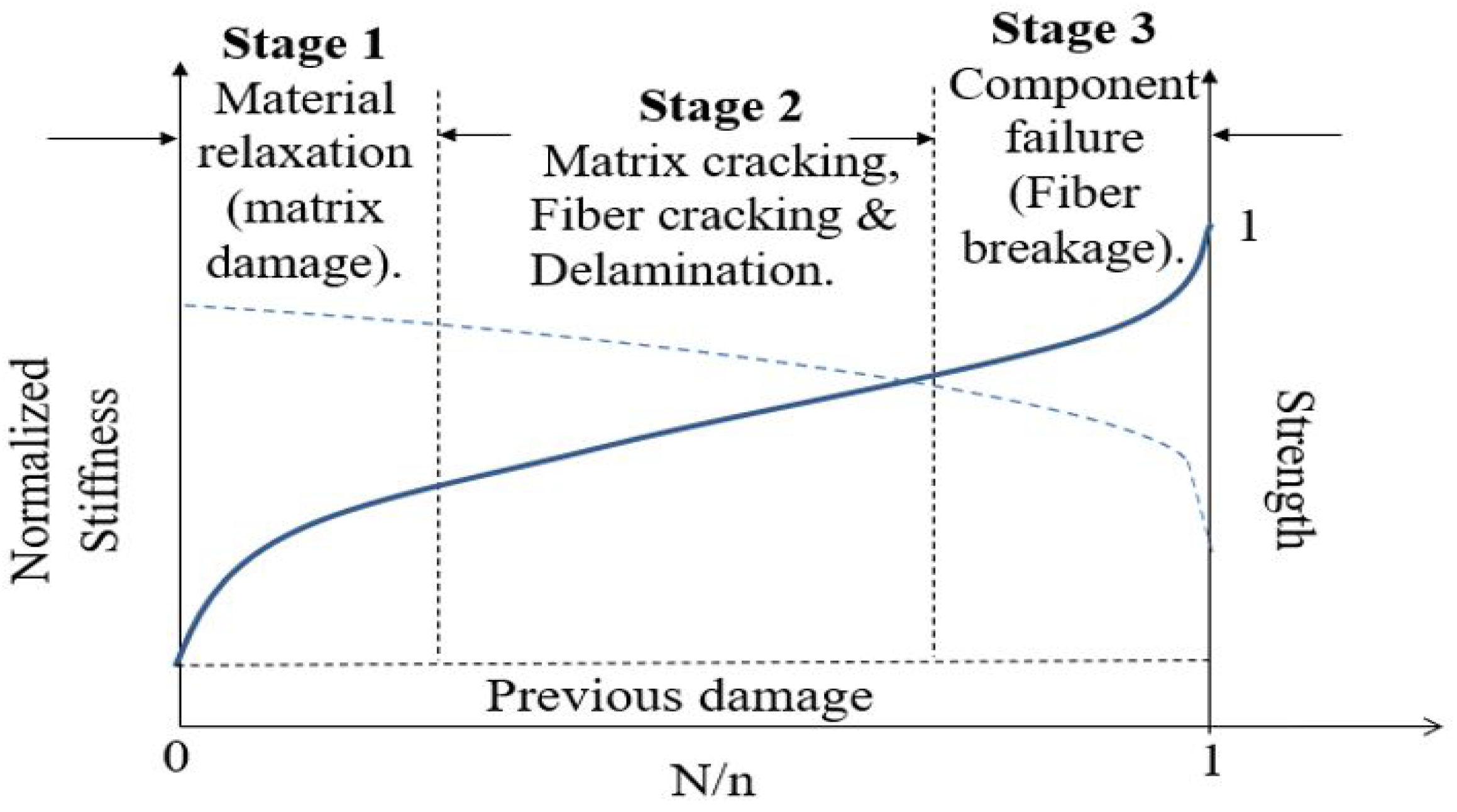

2. Battery Housing

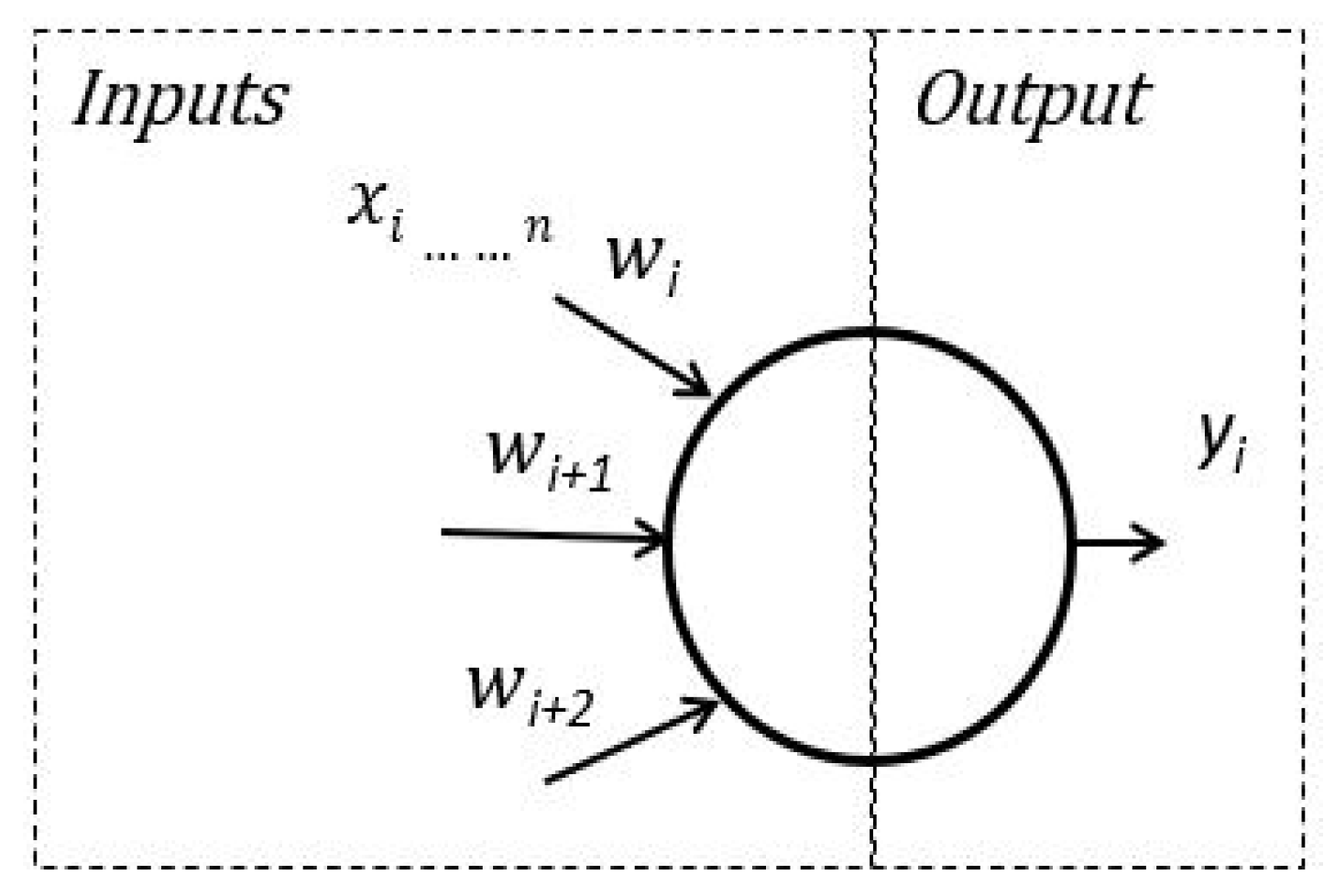

3. Fatigue in Composites

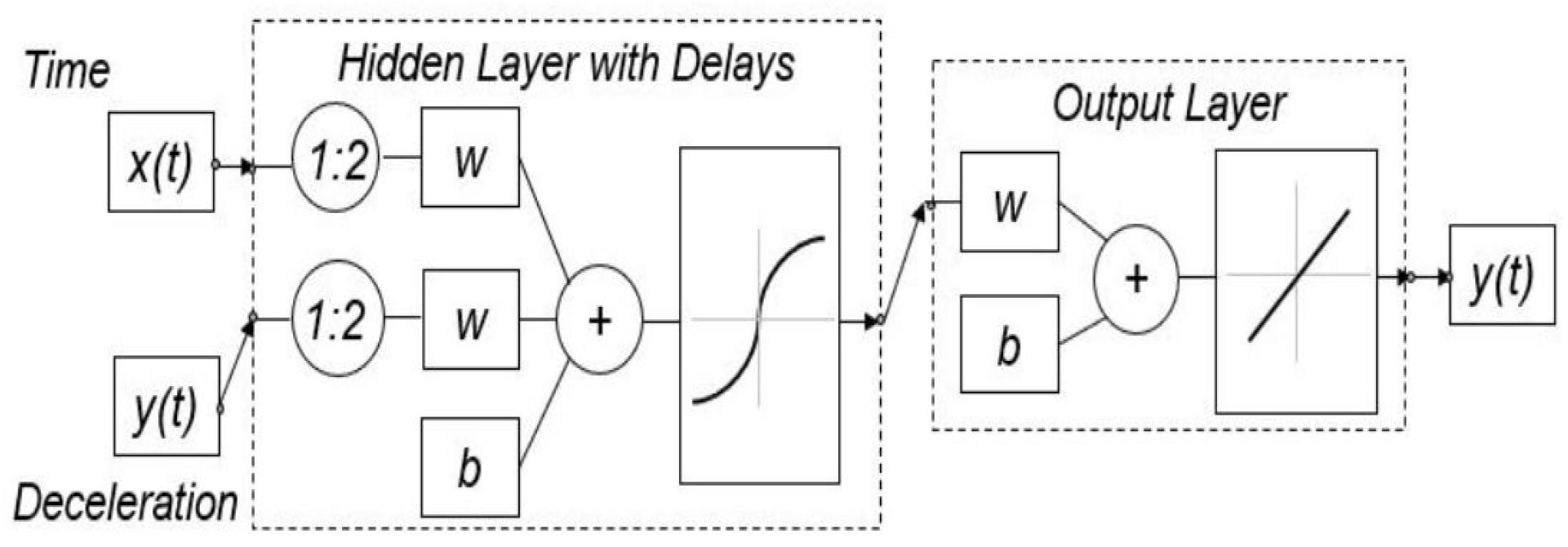

4. Neural Networks in Fatigue Life Prediction

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ahmadi, P. Environmental impacts and behavioral drivers of deep decarbonization for transportation through electric vehicles. J. Clean. Prod. 2019, 225, 1209–1219. [Google Scholar] [CrossRef]

- Delogu, M.; Zanchi, L.; Dattilo, C.A.; Pierini, M. Innovative composites and hybrid materials for electric vehicles lightweight design in a sustainability perspective. Mater. Today Commun. 2017, 13, 192–209. [Google Scholar] [CrossRef]

- Machacek, D.T.; Yasar, N.O.; Huber, T.; Onder, C.H. Energy management of hydrogen hybrid electric vehicles—A potential analysis. Int. J. Hydrogen Energy 2024, 58, 1–13. [Google Scholar] [CrossRef]

- Roper, S.W.K.; Kim, I.Y. Integrated topology and packaging optimization for conceptual-level electric vehicle chassis design via the component-existence method. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2023, 237, 2118–2131. [Google Scholar] [CrossRef]

- Zhang, S.; Xiong, R.; Cao, J. Battery durability and longevity based power management for plug-in hybrid electric vehicle with hybrid energy storage system. Appl. Energy 2016, 179, 316–328. [Google Scholar] [CrossRef]

- Liu, Y.; Liao, Y.G.; Lai, M.C. Fuel economy improvement and emission reduction of 48 V mild hybrid electric vehicles with P0, P1, and P2 architectures with lithium battery cell experimental data. Adv. Mech. Eng. 2021, 13, 16878140211036022. [Google Scholar] [CrossRef]

- Sabri, M.; Danapalasingam, K.A.; Rahmat, M.F. A review on hybrid electric vehicles architecture and energy management strategies. Renew. Sustain. Energy Rev. 2016, 53, 1433–1442. [Google Scholar] [CrossRef]

- Nabi, M.N.; Ray, B.; Rashid, F.; Al Hussam, W.; Muyeen, S. Parametric analysis and prediction of energy consumption of electric vehicles using machine learning. J. Energy Storage 2023, 72, 108226. [Google Scholar] [CrossRef]

- Veza, I.; Asy’ari, M.Z.; Idris, M.; Epin, V.; Fattah, I.R.; Spraggon, M. Electric vehicle (EV) and driving towards sustainability: Comparison between EV, HEV, PHEV, and ICE vehicles to achieve net zero emissions by 2050 from EV. Alex. Eng. J. 2023, 82, 459–467. [Google Scholar] [CrossRef]

- Boretti, A. The perspective of hybrid electric hydrogen propulsion systems. Int. J. Hydrogen Energy 2024, 50, 857–868. [Google Scholar] [CrossRef]

- Gasco, F.; Feraboli, P. Manufacturability of composite laminates with integrated thin film Li-ion batteries. J. Compos. Mater. 2014, 48, 899–910. [Google Scholar] [CrossRef]

- Wang, W.; Yang, S.; Lin, C.; Shen, W.; Lu, G.; Li, Y.; Zhang, J. Investigation of mechanical property of cylindrical lithium-ion batteries under dynamic loadings. J. Power Sources 2020, 451, 227749. [Google Scholar] [CrossRef]

- Xiong, Y.; Pan, Y.; Wu, L.; Liu, B. Effective weight-reduction-and crashworthiness-analysis of a vehicle’s battery-pack system via orthogonal experimental design and response surface methodology. Eng. Fail. Anal. 2021, 128, 105635. [Google Scholar] [CrossRef]

- Taghavifar, H. The influence of different fuels and injection methods of RCCI and DCI in hybrid ICE-Battery vehicle performance. Fuel 2023, 340, 127467. [Google Scholar] [CrossRef]

- Arat, H.T. Alternative fuelled hybrid electric vehicle (AF-HEV) with hydrogen enriched internal combustion engine. Int. J. Hydrogen Energy 2019, 44, 19005–19016. [Google Scholar] [CrossRef]

- Shah, R.; Mittal, V.; Matsil, E.; Rosenkranz, A. Magnesium-ion batteries for electric vehicles: Current trends and future perspectives. Adv. Mech. Eng. 2021, 13, 16878140211003398. [Google Scholar] [CrossRef]

- Pejman, R.; Gorman, J.; Najafi, A.R. Multi-physics design of a new battery packaging for electric vehicles utilizing multifunctional composites. Compos. Part B Eng. 2022, 237, 109810. [Google Scholar] [CrossRef]

- Pan, Y.; Xiong, Y.; Wu, L.; Diao, K.; Guo, W. Lightweight design of an automotive battery-pack enclosure via advanced high-strength steels and size optimization. Int. J. Automot. Technol. 2021, 22, 1279–1290. [Google Scholar] [CrossRef]

- Buidin, T.I.C.; Mariasiu, F. Battery thermal management systems: Current status and design approach of cooling technologies. Energies 2021, 14, 4879. [Google Scholar] [CrossRef]

- Li, W.; Zhou, Y.; Zhang, H.; Tang, X. A review on battery thermal management for new energy vehicles. Energies 2023, 16, 4845. [Google Scholar] [CrossRef]

- Chan, C.K.; Chung, C.H.; Raman, J. Optimizing Thermal Management System in Electric Vehicle Battery Packs for Sustainable Transportation. Sustainability 2023, 15, 11822. [Google Scholar] [CrossRef]

- Chen, K.; Yang, L.; Chen, Y.; Wu, B.; Song, M. Efficient Design of Battery Thermal Management Systems for Improving Cooling Performance and Reducing Pressure Drop. Energies 2024, 17, 2275. [Google Scholar] [CrossRef]

- Zhang, F.; Zhai, L.; Zhang, L.; Yi, M.; Du, B.; Li, S. A novel hybrid battery thermal management system with fins added on and between liquid cooling channels in composite phase change materials. Appl. Therm. Eng. 2022, 207, 118198. [Google Scholar] [CrossRef]

- Deng, J.; Huang, Q.; Li, X.; Zhang, G.; Li, C.; Li, S. Influence mechanism of battery thermal management with flexible flame retardant composite phase change materials by temperature aging. Renew. Energy 2024, 222, 119922. [Google Scholar] [CrossRef]

- Huang, Y.H.; Cheng, W.L.; Zhao, R. Thermal management of Li-ion battery pack with the application of flexible form-stable composite phase change materials. Energy Convers. Manag. 2019, 182, 9–20. [Google Scholar] [CrossRef]

- Tang, Z.; Feng, R.; Huang, P.; Bai, Z.; Wang, Q. Modeling analysis on the cooling efficiency of composite phase change material-heat pipe coupling system in battery pack. J. Loss Prev. Process Ind. 2022, 78, 104829. [Google Scholar] [CrossRef]

- Luo, J.; Zou, D.; Wang, Y.; Wang, S.; Huang, L. Battery thermal management systems (BTMs) based on phase change material (PCM): A comprehensive review. Chem. Eng. J. 2022, 430, 132741. [Google Scholar] [CrossRef]

- Zhang, J.; Li, X.; Zhang, G.; Wu, H.; Rao, Z.; Guo, J.; Zhou, D. Experimental investigation of the flame retardant and form-stable composite phase change materials for a power battery thermal management system. J. Power Sources 2020, 480, 229116. [Google Scholar] [CrossRef]

- Sun, Z.; Guo, Y.; Zhang, C.; Whitehouse, J.; Zhou, Q.; Xu, H.; Wang, C. Experimental study of battery passive thermal management system using copper foam-based phase change materials. Int. J. Thermofluids 2023, 17, 100255. [Google Scholar] [CrossRef]

- Schmolke, T.; Teutenberg, D.; Meschut, G. Development of a test method for investigating the leak tightness of hybrid joined battery housing connections. Int. J. Adhes. Adhes. 2022, 117, 103171. [Google Scholar] [CrossRef]

- Arora, S.; Shen, W.; Kapoor, A. Review of mechanical design and strategic placement technique of a robust battery pack for electric vehicles. Renew. Sustain. Energy Rev. 2016, 60, 1319–1331. [Google Scholar] [CrossRef]

- Lee, P.Y.; Park, S.; Cho, I.; Kim, J. Vibration-based degradation effect in rechargeable lithium ion batteries having different cathode materials for railway vehicle application. Eng. Fail. Anal. 2021, 124, 105334. [Google Scholar] [CrossRef]

- Shui, L.; Chen, F.; Garg, A.; Peng, X.; Bao, N.; Zhang, J. Design optimization of battery pack enclosure for electric vehicle. Struct. Multidiscip. Optim. 2018, 58, 331–347. [Google Scholar] [CrossRef]

- Li, H.; Peng, W.; Yang, X.; Chen, H.; Sun, J.; Wang, Q. Full-Scale Experimental Study on the Combustion Behavior of Lithium Ion Battery Pack Used for Electric Vehicle. Fire Technol. 2020, 56, 2545–2564. [Google Scholar] [CrossRef]

- Zhu, J.; Wierzbicki, T.; Li, W. A review of safety-focused mechanical modeling of commercial lithium-ion batteries. J. Power Sources 2018, 378, 153–168. [Google Scholar] [CrossRef]

- Zhang, X.; Xiong, Y.; Pan, Y.; Du, H.; Liu, B. Crushing stress and vibration fatigue-life optimization of a battery-pack system. Struct. Multidiscip. Optim. 2023, 66, 48. [Google Scholar] [CrossRef]

- Wang, W.; Dai, S.; Zhao, W.; Wang, C.; Ma, T. Design optimization of a novel negative Poisson’s ratio non-module battery pack system considering crashworthiness and heat dissipation. Compos. Struct. 2021, 275, 114458. [Google Scholar] [CrossRef]

- Yang, Y.; Xu, X.; Zhang, Y.; Hu, H.; Li, C. Synergy analysis on the heat dissipation performance of a battery pack under air cooling. Ionics 2020, 26, 5575–5584. [Google Scholar] [CrossRef]

- Krüger, C.; Spohr, S.; Merdivan, D.; Urban, P. Avoiding structural redundancies between the vehicle body and the battery housing based on a functional integration approach. Automot. Engine Technol. 2022, 7, 197–208. [Google Scholar] [CrossRef]

- Xu, C.; Weng, L.; Ji, L.; Zhou, J. An analytical model for the fracture behavior of the flexible lithium-ion batteries under bending deformation. Eur. J. Mech.-A/Solids 2019, 73, 47–56. [Google Scholar] [CrossRef]

- Yang, Y.; Boom, R.; Irion, B.; van Heerden, D.J.; Kuiper, P.; de Wit, H. Recycling of composite materials. Chem. Eng. Process. Process Intensif. 2012, 51, 53–68. [Google Scholar] [CrossRef]

- Coren, F.; Stelzer, P.S.; Reinbacher, D.; Ellersdorfer, C.; Fischer, P.; Major, Z. Dynamic failure and crash simulation of carbon fiber sheet moulding compound (CF-SMC). Automot. Engine Technol. 2021, 6, 63–77. [Google Scholar] [CrossRef]

- Schuh, G.; Bergweiler, G.; Fiedler, F.; Koltermann, M. Flexible Production Concept of a Low-Cost Battery Pack Housing for Electric Vehicles. In Proceedings of the 53rd CIRP Conference on Manufacturing Systems 2020, Chicago, IL, USA, 1–3 July 2020; Volume 93, pp. 137–142. [Google Scholar]

- Sglcarbon. Battery Cases for Electric Cars. Available online: https://www.sglcarbon.com/en/markets-solutions/applications/battery-cases/# (accessed on 3 July 2024).

- Kautex. Pentatonic Battery Enclosures. Available online: https://www.kautex.com/en/mobility/battery-enclosures (accessed on 3 July 2024).

- Syensqo. Battery Pack. Available online: https://www.syensqo.com/en/solutions-market/batteries/battery-pack (accessed on 3 July 2024).

- Plasticstoday. Composites Drive Battery Lightweighting in EVs. Available online: https://www.plasticstoday.com/automotive-mobility/composites-drive-battery-lightweighting-in-evs (accessed on 3 July 2024).

- IDTechEx. Materials for Electric Vehicle Battery Cells and Packs 2023–2033. Available online: https://www.idtechex.com/en/research-report/materials-for-electric-vehicle-battery-cells-and-packs-2023-2033/936 (accessed on 3 July 2024).

- BCP. Composite Panel Solutions for Electric Vehicle Battery Systems. Available online: https://bespokecompositepanels.com/sectors/ev-battery-housing-plate/ (accessed on 3 July 2024).

- Huntsman. Battery Housing. Available online: https://www.huntsman-transportation.com/EN/applications/applications-for-composites/battery-housing.html (accessed on 3 July 2024).

- Gültekin, E.; Yahşi, M. Dynamic compression and impact analyses of the lattice structures for battery safety. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2023, 237, 930–940. [Google Scholar]

- Höhne, C.C.; Blaess, P.; Ilinzeer, S.; Griesbaum, P. New approach for electric vehicle composite battery housings: Electromagnetic shielding and flame retardancy of PUR/UP-based sheet moulding compound. Compos. Part A Appl. Sci. Manuf. 2023, 167, 107404. [Google Scholar]

- Kwon, Y.I.; Lim, E.; Song, Y.S. Simulation of injection-compression molding for thin and large battery housing. Curr. Appl. Phys. 2018, 18, 1451–1457. [Google Scholar]

- Lee, S.; Shin, D.; Kim, G.; Ji, W. Numerical model for compression molding process of hybridly laminated thermoplastic composites based on anisotropic rheology. Compos. Part C Open Access 2022, 7, 100215. [Google Scholar] [CrossRef]

- Shan, L.; Tan, C.; Shen, X.; Ramesh, S.; Zarei, M.; Kolahchi, R.; Hajmohammad, M. The effects of nano-additives on the mechanical, impact, vibration, and buckling/post-buckling properties of composites: A review. J. Mater. Res. Technol. 2023, 24, 7570–7598. [Google Scholar] [CrossRef]

- Lizama-Camara, Y.; Pinna, C.; Lu, Z.; Blagdon, M. Effect of the injection moulding fibre orientation distribution on the fatigue life of short glass fibre reinforced plastics for automotive applications. Procedia CIRP 2019, 85, 255–260. [Google Scholar] [CrossRef]

- Carraro, P.A.; Maragoni, L.; Quaresimin, M. Characterisation and analysis of transverse crack-induced delamination in cross-ply composite laminates under fatigue loadings. Int. J. Fatigue 2019, 129, 105217. [Google Scholar] [CrossRef]

- Zhou, T.; Jiang, S.; Han, T.; Zhu, S.P.; Cai, Y. A physically consistent framework for fatigue life prediction using probabilistic physics-informed neural network. Int. J. Fatigue 2023, 166, 107234. [Google Scholar] [CrossRef]

- Halamka, J.; Bartošák, M.; Španiel, M. Using hybrid physics-informed neural networks to predict lifetime under multiaxial fatigue loading. Eng. Fract. Mech. 2023, 289, 109351. [Google Scholar] [CrossRef]

- Guo, Y.E.; Shang, D.G.; Cai, D.; Jin, T.; Li, D.H. Fatigue life prediction considering temperature effect for carbon fibre reinforced composites under variable amplitude loading. Int. J. Fatigue 2023, 168, 107442. [Google Scholar] [CrossRef]

- Tao, C.; Qiu, J.; Yao, W.; Ji, H. A novel method for fatigue delamination simulation in composite laminates. Compos. Sci. Technol. 2016, 128, 104–115. [Google Scholar] [CrossRef]

- Kulkarni, S.S.; Hale, F.; Taufique, M.; Soulami, A.; Devanathan, R. Investigation of Crashworthiness of Carbon Fiber-Based Electric Vehicle Battery Enclosure Using Finite Element Analysis. Appl. Compos. Mater. 2023, 30, 1689–1715. [Google Scholar] [CrossRef]

- Rajiv, B.; Kalos, P.; Pantawane, P.; Chougule, V.; Chavan, V. Classification of damages in composite material using multi-support vector machine. J. Inst. Eng. (India) Ser. C 2022, 103, 655–661. [Google Scholar] [CrossRef]

- Jimenez, M. Accelerated fatigue test in mechanical components. In Contact and Fracture Mechanics; IntechOpen: London, UK, 2018; pp. 253–273. [Google Scholar]

- Harris, B. Fatigue in Composites: Science and Technology of the Fatigue Response of Fibre-Reinforced Plastics; CRC Press LLC: Boca Raton, FL, USA, 2003. [Google Scholar]

- Zhang, B.; Shi, D.; Liu, C.; Hao, W.; Yang, X. Physics-informed machine learning with high-throughput design module for evaluating rupture life and guiding design of oxide/oxide ceramic matrix composites. Ceram. Int. 2023, 49, 34945–34957. [Google Scholar] [CrossRef]

- Zhao, L.; Shan, M.; Hong, H.; Qi, D.; Zhang, J.; Hu, N. A residual strain model for progressive fatigue damage analysis of composite structures. Compos. Struct. 2017, 169, 69–78. [Google Scholar] [CrossRef]

- D’Amore, A.; Grassia, L. Phenomenological approach to the study of hierarchical damage mechanisms in composite materials subjected to fatigue loadings. Compos. Struct. 2017, 175, 1–6. [Google Scholar] [CrossRef]

- Suzuki, T.; Mahfuz, H.; Takanashi, M. A new stiffness degradation model for fatigue life prediction of GFRPs under random loading. Int. J. Fatigue 2019, 119, 220–228. [Google Scholar] [CrossRef]

- Jimenez-Martinez, M.; Varela-Soriano, J.; De La Trinidad-Rendon, J.S.; Torres-Cedillo, S.G.; Cortés-Pérez, J.; Coca-Gonzalez, M. Fatigue Analysis of Printed Composites of Onyx and Kevlar. J. Compos. Sci. 2023, 8, 12. [Google Scholar] [CrossRef]

- Niaki, S.A.; Haghighat, E.; Campbell, T.; Poursartip, A.; Vaziri, R. Physics-informed neural network for modelling the thermochemical curing process of composite-tool systems during manufacture. Comput. Methods Appl. Mech. Eng. 2021, 384, 113959. [Google Scholar] [CrossRef]

- Kennedy, C.R.; Brádaigh, C.M.Ó.; Leen, S.B. A multiaxial fatigue damage model for fibre reinforced polymer composites. Compos. Struct. 2013, 106, 201–210. [Google Scholar] [CrossRef]

- Lian, W.; Yao, W. Fatigue life prediction of composite laminates by FEA simulation method. Int. J. Fatigue 2010, 32, 123–133. [Google Scholar] [CrossRef]

- Mohammadi, B.; Shokrieh, M.; Jamali, M.; Mahmoudi, A.; Fazlali, B. Damage-entropy model for fatigue life evaluation of off-axis unidirectional composites. Compos. Struct. 2021, 270, 114100. [Google Scholar] [CrossRef]

- Dong, H.; Li, Z.; Wang, J.; Karihaloo, B. A new fatigue failure theory for multidirectional fiber-reinforced composite laminates with arbitrary stacking sequence. Int. J. Fatigue 2016, 87, 294–300. [Google Scholar] [CrossRef]

- Llobet, J.; Maimí, P.; Mayugo, J.; Essa, Y.; de la Escalera, F.M. A fatigue damage and residual strength model for unidirectional carbon/epoxy composites under on-axis tension-tension loadings. Int. J. Fatigue 2017, 103, 508–515. [Google Scholar] [CrossRef]

- Liu, C.; Xu, X.; Wu, J.; Zhu, H.; Wang, C. Deep transfer learning-based damage detection of composite structures by fusing monitoring data with physical mechanism. Eng. Appl. Artif. Intell. 2023, 123, 106245. [Google Scholar] [CrossRef]

- Plets, J.; Bouckaert, Q.; Ahmed, B.; De Waele, W.; Hectors, K. Neural network based fatigue lifetime prediction of metals subjected to block loading. Int. J. Fatigue 2024, 183, 108283. [Google Scholar] [CrossRef]

- Oliveira, G.A.B.; Cardoso, R.A.; Júnior, R.C.S.F.; Doca, T.; Araújo, J.A. On the generalization capability of artificial neural networks used to estimate fretting fatigue life. Tribol. Int. 2024, 192, 109222. [Google Scholar] [CrossRef]

- Gao, J.; Heng, F.; Yuan, Y.; Liu, Y. A novel machine learning method for multiaxial fatigue life prediction: Improved adaptive neuro-fuzzy inference system. Int. J. Fatigue 2024, 178, 108007. [Google Scholar] [CrossRef]

- Tao, C.; Zhang, C.; Hongli, J.; Qiu, J. Neural cohesive model for delamination simulation in composite laminates under cyclic loadings. Int. J. Fatigue 2022, 164, 107123. [Google Scholar] [CrossRef]

- Baisthakur, S.; Fitzgerald, B. Physics-Informed Neural Network surrogate model for bypassing Blade Element Momentum theory in wind turbine aerodynamic load estimation. Renew. Energy 2024, 224, 120122. [Google Scholar] [CrossRef]

- Fernández, J.; Chiachío, J.; Barros, J.; Chiachío, M.; Kulkarni, C.S. Physics-guided recurrent neural network trained with approximate Bayesian computation: A case study on structural response prognostics. Reliab. Eng. Syst. Saf. 2024, 243, 109822. [Google Scholar] [CrossRef]

- He, G.; Zhao, Y.; Yan, C. Uncertainty quantification in multiaxial fatigue life prediction using Bayesian neural networks. Eng. Fract. Mech. 2024, 298, 109961. [Google Scholar] [CrossRef]

- Li, C.; Yang, H.; Suo, Z.; Tang, J. Fatigue-Resistant elastomers. J. Mech. Phys. Solids 2020, 134, 103751. [Google Scholar] [CrossRef]

- Zhu, S.; Zhang, Y.; Zhu, B.; Zhang, J.; He, Y.; Xu, W. High cycle fatigue life prediction of titanium alloys based on a novel deep learning approach. Int. J. Fatigue 2024, 182, 108206. [Google Scholar] [CrossRef]

- Han, S.; Khatir, S.; Wang, C.; Wahab, M.A. An improved Artificial Neural Network for the direct prediction of fretting fatigue crack initiation lifetime. Tribol. Int. 2023, 183, 108411. [Google Scholar] [CrossRef]

- Tognan, A.; Patanè, A.; Laurenti, L.; Salvati, E. A Bayesian defect-based physics-guided neural network model for probabilistic fatigue endurance limit evaluation. Comput. Methods Appl. Mech. Eng. 2024, 418, 116521. [Google Scholar] [CrossRef]

- Salvati, E.; Tognan, A.; Laurenti, L.; Pelegatti, M.; De Bona, F. A defect-based physics-informed machine learning framework for fatigue finite life prediction in additive manufacturing. Mater. Des. 2022, 222, 111089. [Google Scholar] [CrossRef]

- Monaco, E.; Rautela, M.; Gopalakrishnan, S.; Ricci, F. Machine learning algorithms for delaminations detection on composites panels by wave propagation signals analysis: Review, experiences and results. Prog. Aerosp. Sci. 2024, 146, 100994. [Google Scholar] [CrossRef]

- Moradi, M.; Gul, F.C.; Zarouchas, D. A Novel machine learning model to design historical-independent health indicators for composite structures. Compos. Part B Eng. 2024, 275, 111328. [Google Scholar] [CrossRef]

- Zhang, X.; Xiong, Y.; Pan, Y.; Xu, D.; Kawsar, I.; Liu, B.; Hou, L. Deep-learning-based inverse structural design of a battery-pack system. Reliab. Eng. Syst. Saf. 2023, 238, 109464. [Google Scholar] [CrossRef]

- Helwing, R.; Hülsbusch, D.; Walther, F. Deep learning method for analysis and segmentation of fatigue damage in X-ray computed tomography data for fiber-reinforced polymers. Compos. Sci. Technol. 2022, 230, 109781. [Google Scholar] [CrossRef]

- Gholizadeh, S.; Leman, Z.; Baharudin, B. State-of-the-art ensemble learning and unsupervised learning in fatigue crack recognition of glass fiber reinforced polyester composite (GFRP) using acoustic emission. Ultrasonics 2023, 132, 106998. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Pan, Y.; Xiong, Y.; Zhang, Y.; Tang, M.; Dai, W.; Liu, B.; Hou, L. Deep learning-based vibration stress and fatigue-life prediction of a battery-pack system. Appl. Energy 2024, 357, 122481. [Google Scholar] [CrossRef]

- Xu, X.; Liu, C. Physics-guided deep learning for damage detection in CFRP composite structures. Compos. Struct. 2024, 331, 117889. [Google Scholar] [CrossRef]

- Tao, C.; Zhang, C.; Ji, H.; Qiu, J. Fatigue damage characterization for composite laminates using deep learning and laser ultrasonic. Compos. Part B Eng. 2021, 216, 108816. [Google Scholar] [CrossRef]

- Kolodziejczyk, F.; Mortazavi, B.; Rabczuk, T.; Zhuang, X. Machine learning assisted multiscale modeling of composite phase change materials for Li-ion batteries’ thermal management. Int. J. Heat Mass Transf. 2021, 172, 121199. [Google Scholar] [CrossRef]

- Srivastava, V.; Basu, B.; Prabhu, N. Application of Machine Learning (ML)-based multi-classifications to identify corrosion fatigue cracking phenomena in Naval steel weldments. Mater. Today Commun. 2024, 39, 108591. [Google Scholar] [CrossRef]

- Sepasdar, R.; Karpatne, A.; Shakiba, M. A data-driven approach to full-field nonlinear stress distribution and failure pattern prediction in composites using deep learning. Comput. Methods Appl. Mech. Eng. 2022, 397, 115126. [Google Scholar] [CrossRef]

- Cristiani, D.; Falcetelli, F.; Yue, N.; Sbarufatti, C.; Di Sante, R.; Zarouchas, D.; Giglio, M. Strain-based delamination prediction in fatigue loaded CFRP coupon specimens by deep learning and static loading data. Compos. Part B Eng. 2022, 241, 110020. [Google Scholar] [CrossRef]

- Moradi, M.; Broer, A.; Chiachío, J.; Benedictus, R.; Loutas, T.H.; Zarouchas, D. Intelligent health indicator construction for prognostics of composite structures utilizing a semi-supervised deep neural network and SHM data. Eng. Appl. Artif. Intell. 2023, 117, 105502. [Google Scholar] [CrossRef]

- Yan, C.; Vescovini, R.; Dozio, L. A framework based on physics-informed neural networks and extreme learning for the analysis of composite structures. Comput. Struct. 2022, 265, 106761. [Google Scholar] [CrossRef]

- Zhang, Z.; Gu, G.X. Physics-informed deep learning for digital materials. Theor. Appl. Mech. Lett. 2021, 11, 100220. [Google Scholar] [CrossRef]

- He, G.; Zhao, Y.; Yan, C. MFLP-PINN: A physics-informed neural network for multiaxial fatigue life prediction. Eur. J. Mech.-A/Solids 2023, 98, 104889. [Google Scholar] [CrossRef]

- Jimenez-Martinez, M.; Alfaro-Ponce, M. Effects of synthetic data applied to artificial neural networks for fatigue life prediction in nodular cast iron. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 10. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jimenez-Martinez, M.; Valencia-Sánchez, J.L.; Torres-Cedillo, S.G.; Cortés-Pérez, J. Battery Housing for Electric Vehicles, a Durability Assessment Review. Designs 2024, 8, 113. https://doi.org/10.3390/designs8060113

Jimenez-Martinez M, Valencia-Sánchez JL, Torres-Cedillo SG, Cortés-Pérez J. Battery Housing for Electric Vehicles, a Durability Assessment Review. Designs. 2024; 8(6):113. https://doi.org/10.3390/designs8060113

Chicago/Turabian StyleJimenez-Martinez, Moises, José Luis Valencia-Sánchez, Sergio G. Torres-Cedillo, and Jacinto Cortés-Pérez. 2024. "Battery Housing for Electric Vehicles, a Durability Assessment Review" Designs 8, no. 6: 113. https://doi.org/10.3390/designs8060113

APA StyleJimenez-Martinez, M., Valencia-Sánchez, J. L., Torres-Cedillo, S. G., & Cortés-Pérez, J. (2024). Battery Housing for Electric Vehicles, a Durability Assessment Review. Designs, 8(6), 113. https://doi.org/10.3390/designs8060113