Investigation on the Microstructure and Micro-Mechanical Properties of Thermal-Sprayed NiCoCrAlY High Entropy Alloy Coating

Abstract

1. Introduction

2. Experimental Section

2.1. Deposition and Characterization of the Coating

2.2. Micro-Pillar Fabrication and Stress–Strain Calculation

3. Results and Discussion

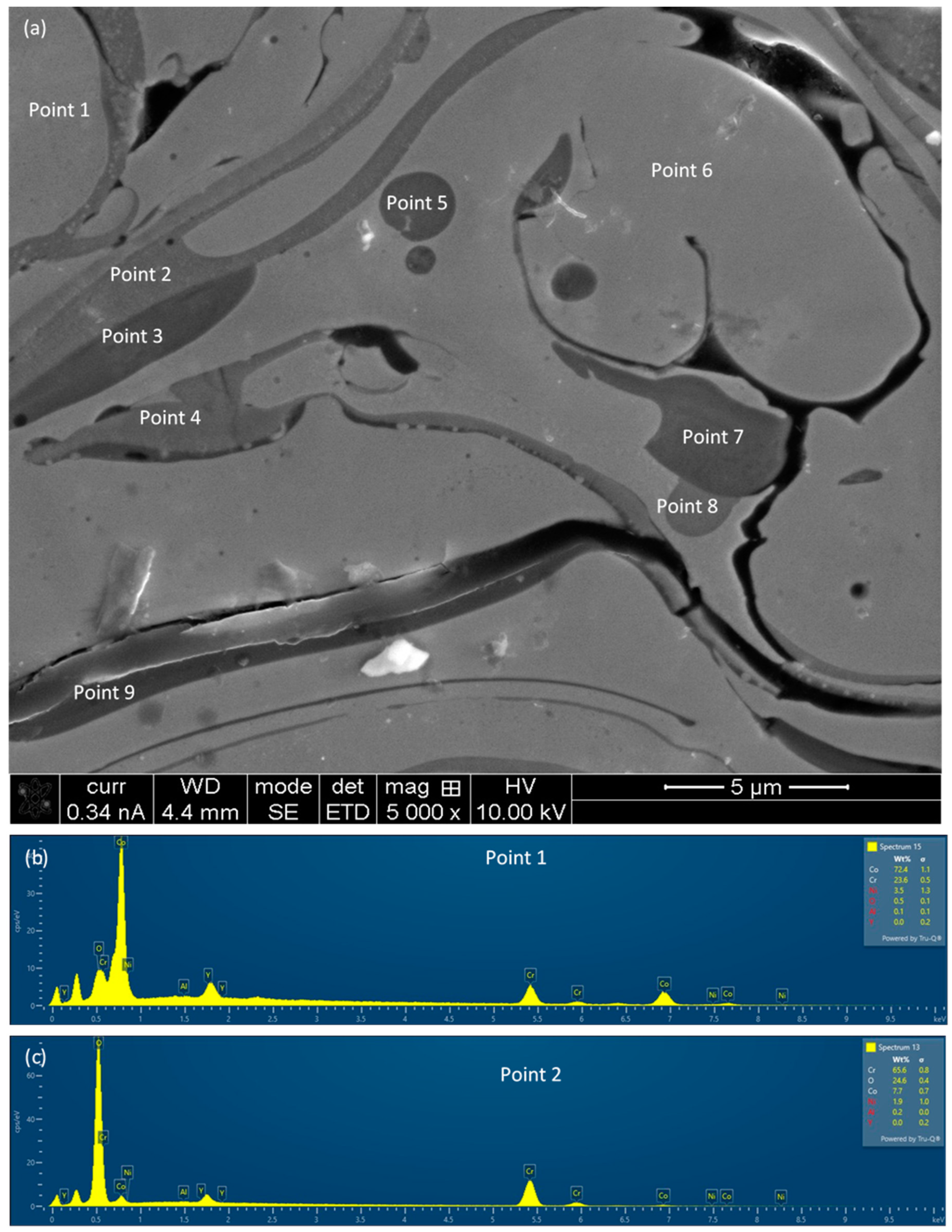

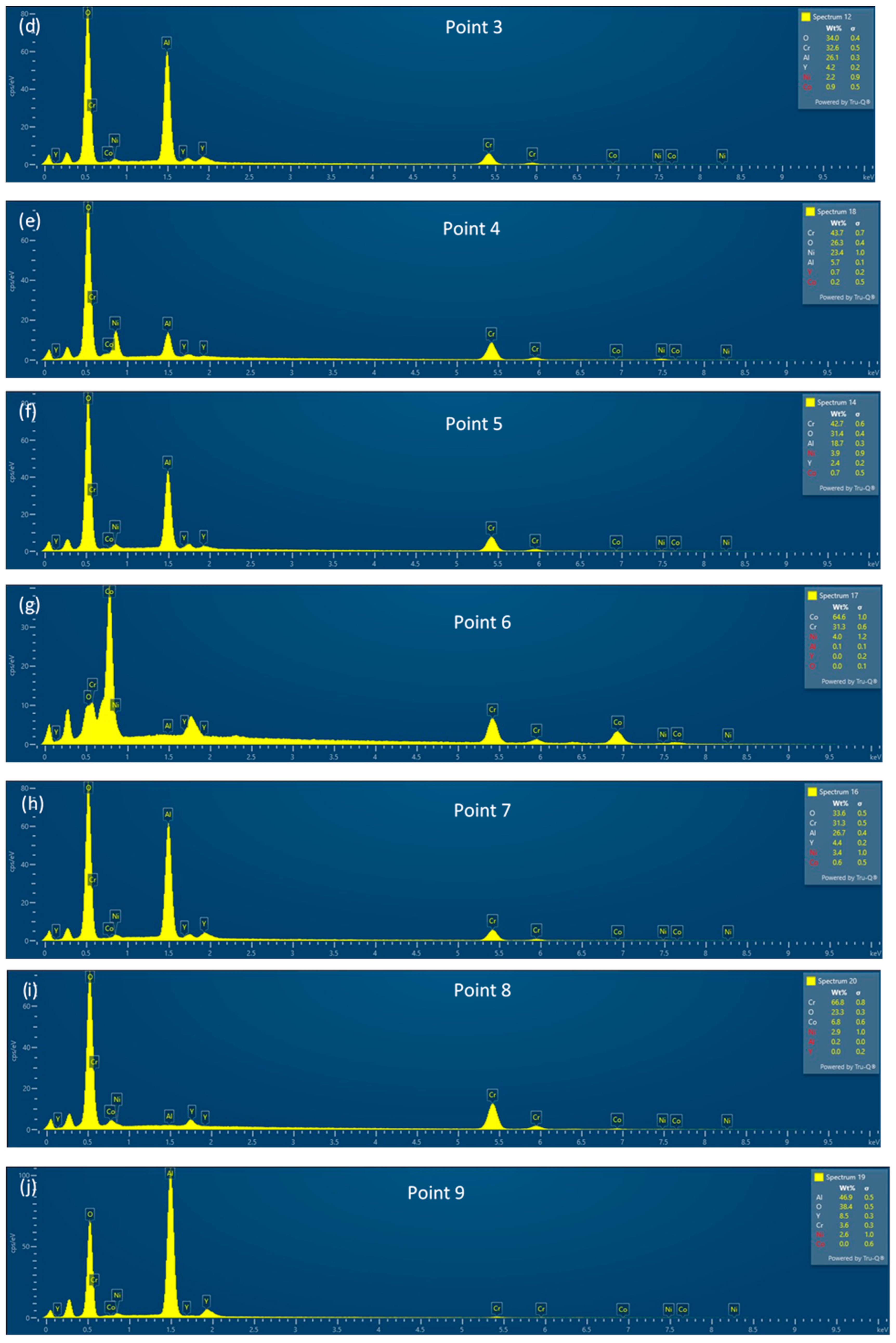

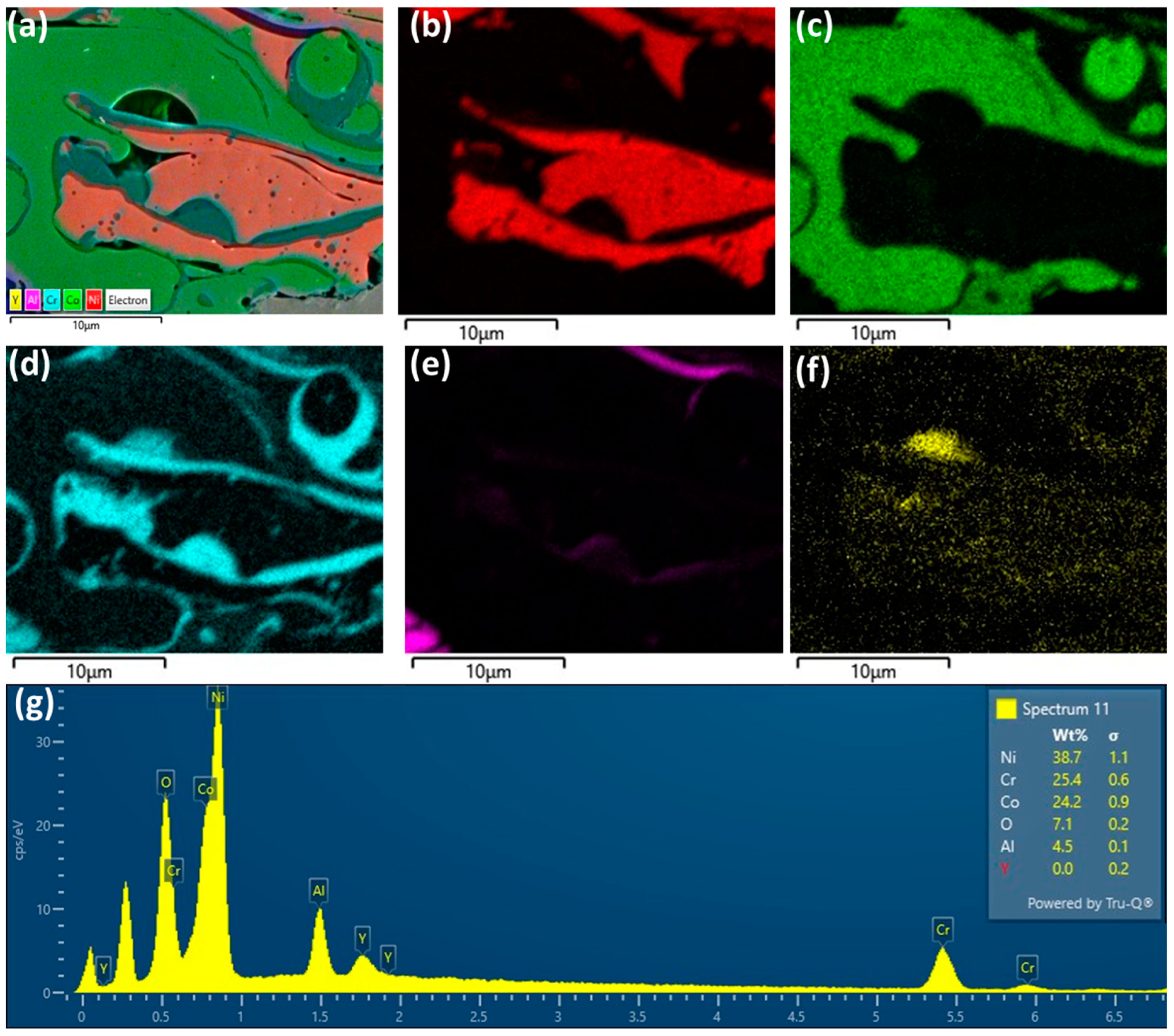

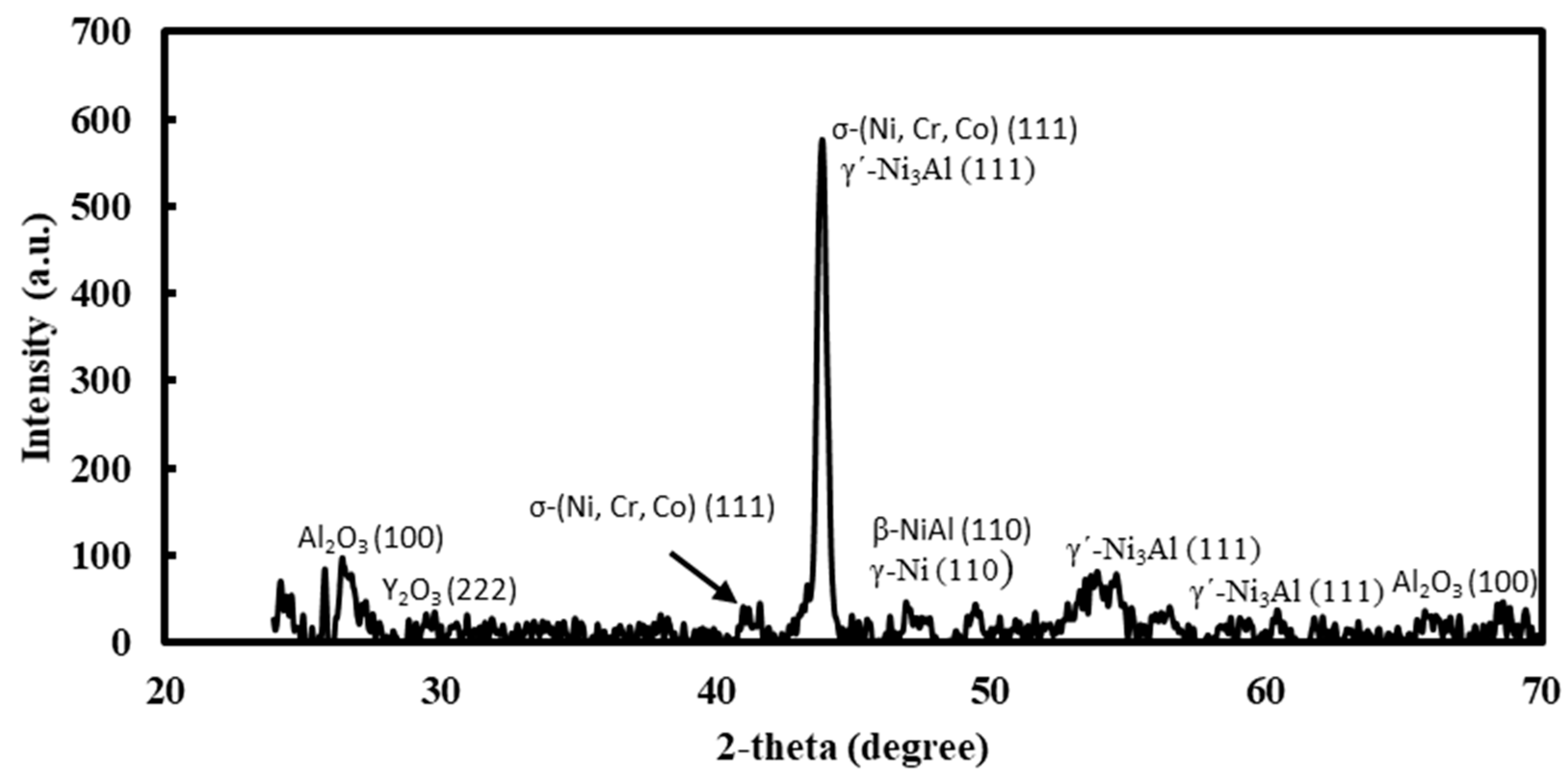

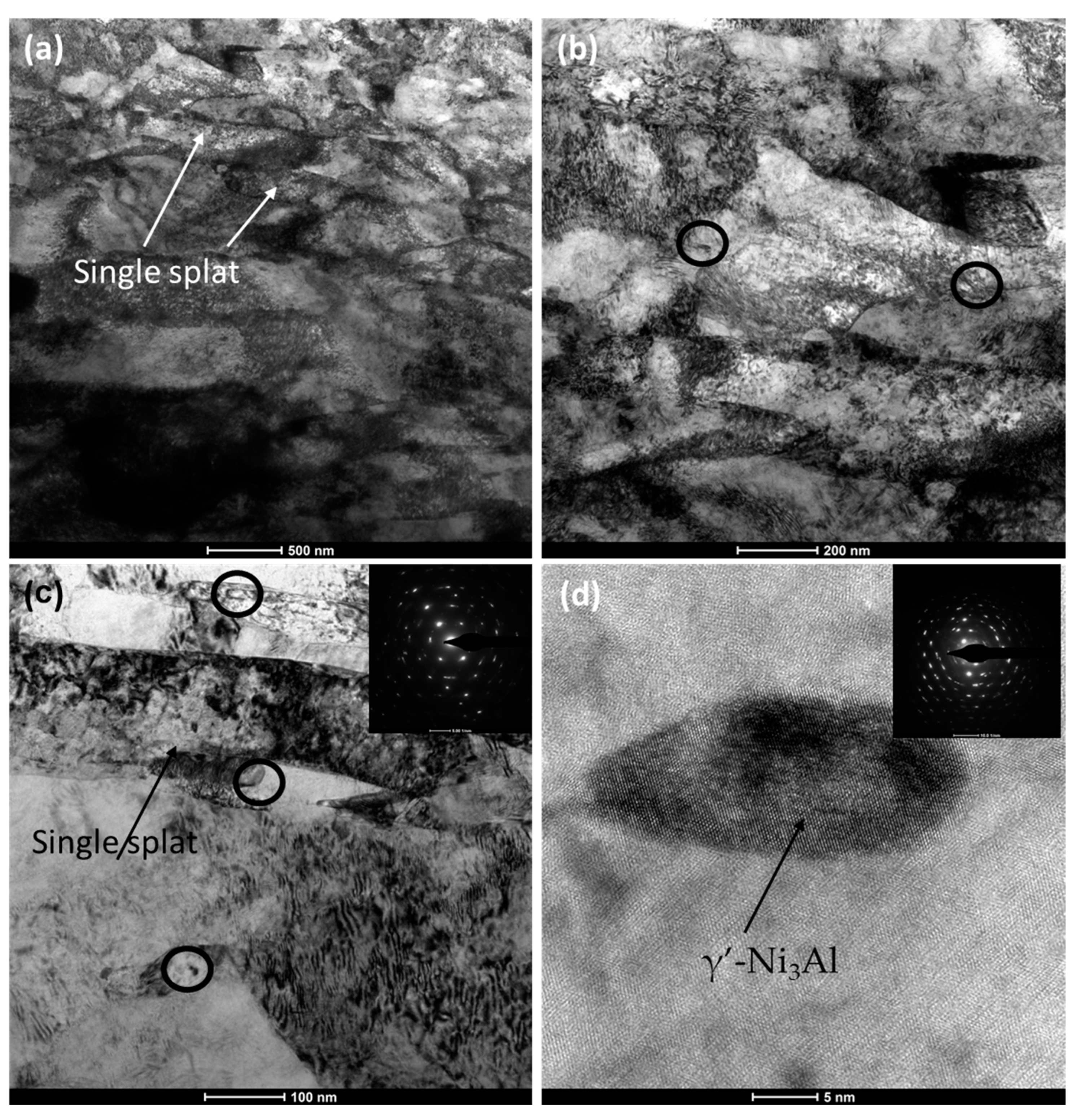

3.1. Coating Characterization

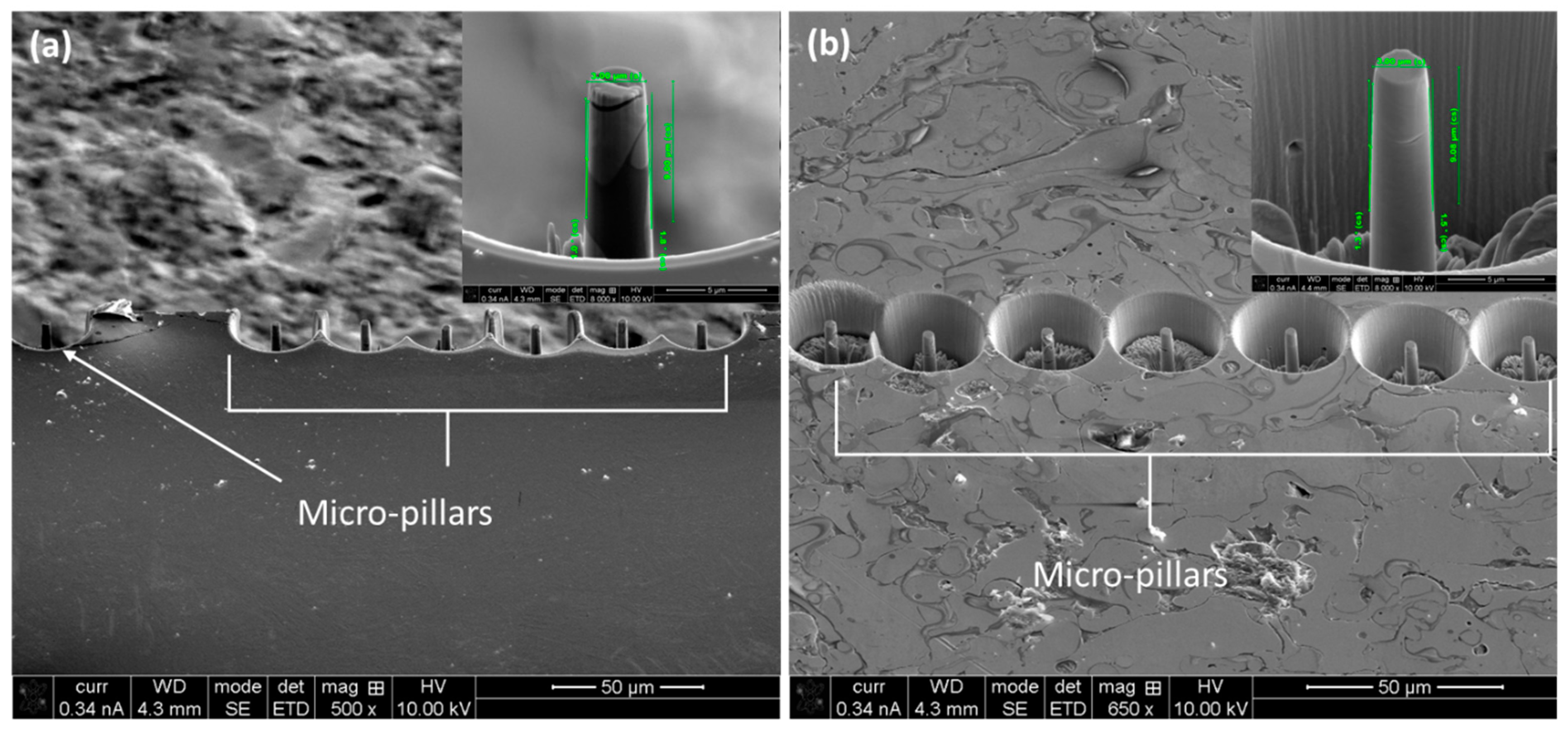

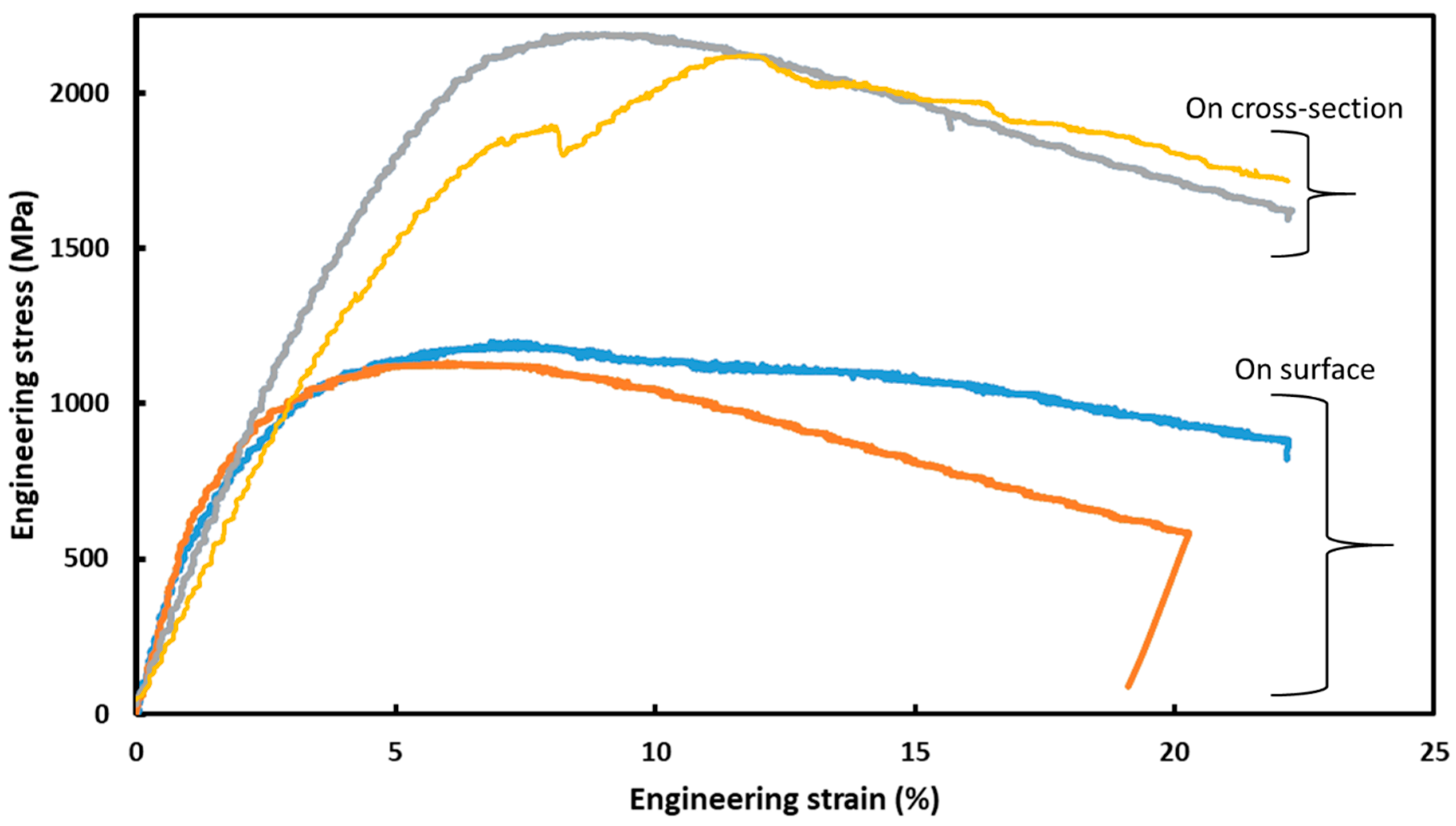

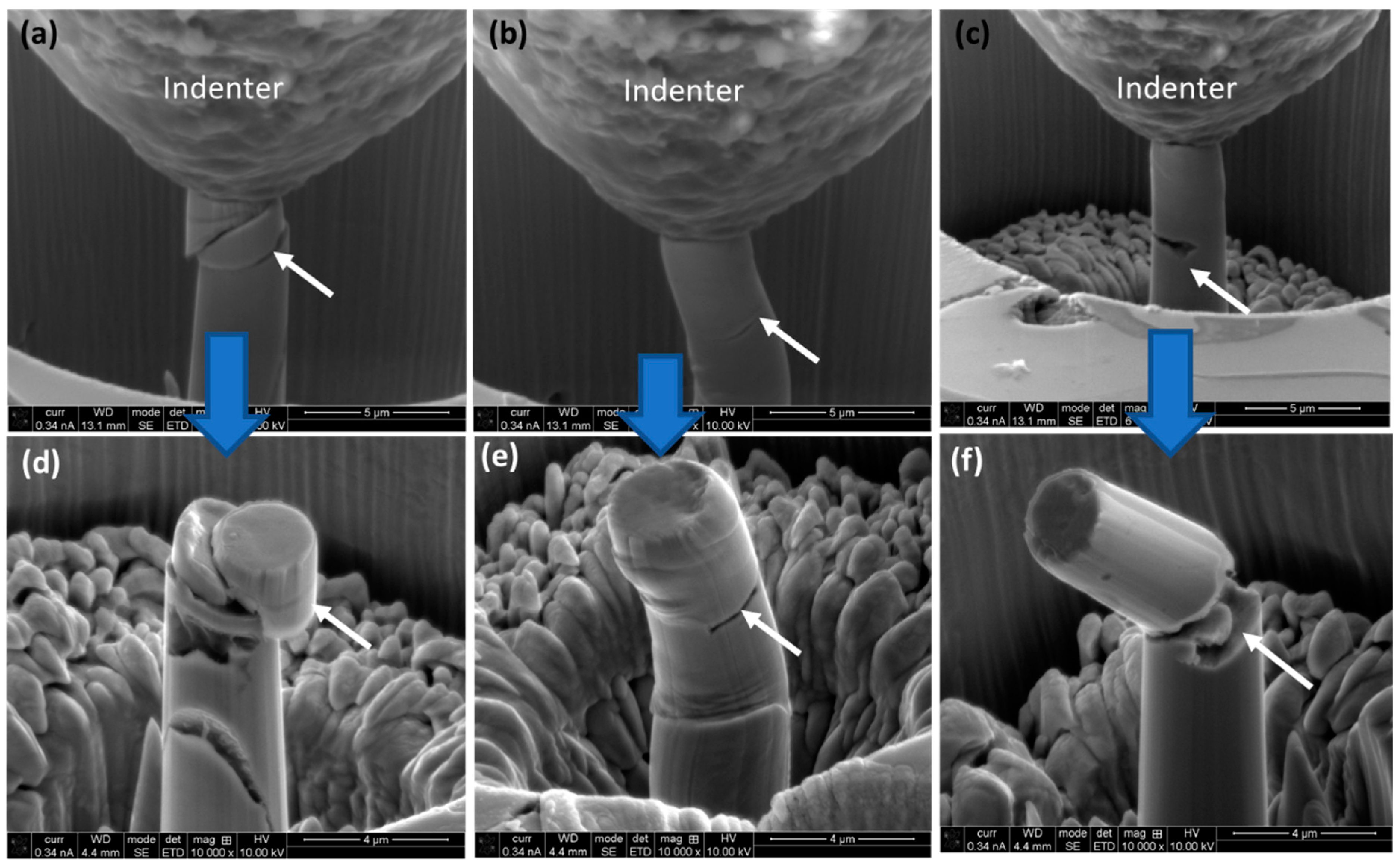

3.2. In Situ Micro-Pillars Compression

3.3. Analysis of Deformed Micro-Pillars

3.4. Deformation Mechanisms

4. Conclusions

- APS-deposited NiCoCrAlY HEA coating attained metallurgical bonding with the substrate, and the as-deposited coating thickness was about 300 μm, with limited porosity (<1%). The coating structure revealed representative lamellar-like structure that are characteristics of thermal-deposited coating, which consisted of the Ni (γ-Ni) matrix solid solution and secondary phase, like β–NiAl, together with the precipitates fine α–Cr and γ′–Ni3Al intermetallics.

- The strength and modulus of elasticity of the coating was higher in the cross-sectional direction (1.27 ± 0.10 MPa of yield strength and 2.19 ± 0.10 GPa of compressive strength), than that of the planar direction (0.85 ± 0.09 MPa of yield strength and 1.20 ± 0.08 GPa of compressive strength). The striking difference was due to the presence of the secondary/intermetallic phases in the micro-pillar, together with that of the loading direction with respect to the splat boundaries orientation.

- The deformation of the coating took place as a result of the wrinkle and slip/shear bands formation once the mechanical loading exceeded the strength of the material.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Padture, N.P.; Gell, M.; Jordan, E.H. Thermal barrier coatings for gas-turbine engine applications. Science 2002, 296, 280–284. [Google Scholar] [CrossRef] [PubMed]

- Beele, W.; Marijnissen, G.; Van Lieshout, A. The evolution of thermal barrier coatings—Status and upcoming solutions for today’s key issues. Surf. Coat. Technol. 1999, 120, 61–67. [Google Scholar] [CrossRef]

- Cao, X.; Vassen, R.; Stöver, D. Ceramic materials for thermal barrier coatings. J. Eur. Ceram. Soc. 2004, 24, 1–10. [Google Scholar] [CrossRef]

- Hao, E.; An, Y.; Zhao, X.; Zhou, H.; Chen, J. NiCoCrAlYTa coatings on nickel-base superalloy substrate: Deposition by high velocity oxy-fuel spraying as well as investigation of mechanical properties and wear resistance in relation to heat-treatment duration. Appl. Surf. Sci. 2018, 462, 194–206. [Google Scholar] [CrossRef]

- Smialek, J.L.; Miller, R.A. Revisiting the birth of 7YSZ thermal barrier coatings: Stephan Stecura. Coatings 2018, 8, 255. [Google Scholar] [CrossRef]

- Haynes, J. Elevated Temperature Coatings: Science and Technology; TMS: Warrendale, PA, USA, 1999; pp. 185–196. [Google Scholar]

- Kim, J.; Pyeon, J.; Kim, B.-G.; Khadaa, T.; Choi, H.; Zhe, L.; Dube, T.; Zhang, J.; Yang, B.-i.; Jung, Y.-g. Oxidation Behavior of NiCoCrAlY Coatings Deposited by Vacuum Plasma Spraying and High-Velocity Oxygen Fuel Processes. Coatings 2023, 13, 319. [Google Scholar] [CrossRef]

- Schulz, U.; Leyens, C.; Fritscher, K.; Peters, M.; Saruhan-Brings, B.; Lavigne, O.; Dorvaux, J.-M.; Poulain, M.; Mévrel, R.; Caliez, M. Some recent trends in research and technology of advanced thermal barrier coatings. Aerosp. Sci. Technol. 2003, 7, 73–80. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, C.; Li, J.; Ding, G.; Duan, L. Fabrication and characterization of ITO thin film resistance temperature detector. Vacuum 2017, 140, 121–125. [Google Scholar] [CrossRef]

- Bates, B.; Witman, J.; Zhang, Y. Electrolytic co-deposition of Ni-CrAlY composite coatings using different deposition configurations. Mater. Manuf. Process. 2016, 31, 1232–1237. [Google Scholar] [CrossRef]

- Tancret, F.; Bhadeshia, H.; MacKay, D. Design of a creep resistant nickel base superalloy for power plant applications: Part 1-Mechanical properties modelling. Mater. Sci. Technol. 2003, 19, 283–290. [Google Scholar] [CrossRef]

- Marginean, G.; Utu, D. Cyclic oxidation behaviour of different treated CoNiCrAlY coatings. Appl. Surf. Sci. 2012, 258, 8307–8311. [Google Scholar] [CrossRef]

- Nijdam, T.; Kwakernaak, C.; Sloof, W. The effects of alloy microstructure refinement on the short-term thermal oxidation of NiCoCrAlY alloys. Metall. Mater. Trans. A 2006, 37, 683–693. [Google Scholar] [CrossRef]

- Kim, D.; Shin, I.; Koo, J.; Kim, S.; Seo, D.; Kim, J.; Seok, C. Quantitative analysis on the depletion rate of β-NiAl phases in MCrAlY coating. J. Mech. Sci. Technol. 2014, 28, 513–519. [Google Scholar] [CrossRef]

- Toscano, J.; Vaβen, R.; Gil, A.; Subanovic, M.; Naumenko, D.; Singheiser, L.; Quadakkers, W. Parameters affecting TGO growth and adherence on MCrAlY-bond coats for TBC’s. Surf. Coat. Technol. 2006, 201, 3906–3910. [Google Scholar] [CrossRef]

- Wang, B.; Gong, J.; Sun, C.; Huang, R.; Wen, L. The behavior of MCrAlY coatings on Ni3Al-base superalloy. Mater. Sci. Eng. A 2003, 357, 39–44. [Google Scholar] [CrossRef]

- Hou, X.; Zhang, C.; Wang, F.; Ding, G. Fabrication and characterization of NiCoCrAlY coating deposited on nickel-based superalloy substrates. Vacuum 2018, 155, 55–59. [Google Scholar] [CrossRef]

- Gudmundsson, B.; Jacobson, B.; Gruner, H. The influence of substrate temperature on the microstructure and hardness of vacuum-plasma-sprayed Co–Ni–Cr–Al–Si–Zr–Y and Co–Ni–Cr–Al–Y alloys. Mater. Sci. Eng. A 1989, 108, 105–115. [Google Scholar] [CrossRef]

- Noguchi, K.; Nishida, M.; Chiba, A. Transmission electron microscopy of low pressure plasma sprayed CoNiCrAlY coating. Scr. Mater. 1996, 35, 1359–1364. [Google Scholar] [CrossRef]

- Basak, A.; Matteazzi, P.; Vardavoulias, M.; Celis, J.-P. Corrosion–wear behaviour of thermal sprayed nanostructured FeCu/WC–Co coatings. Wear 2006, 261, 1042–1050. [Google Scholar] [CrossRef]

- Basak, A.K.; Celis, J.-P.; Vardavoulias, M.; Matteazzi, P. Effect of nanostructuring and Al alloying on friction and wear behaviour of thermal sprayed WC–Co coatings. Surf. Coat. Technol. 2012, 206, 3508–3516. [Google Scholar] [CrossRef]

- Hou, G.; An, Y.; Zhao, X.; Zhou, H.; Chen, J. Effect of alumina dispersion on oxidation behavior as well as friction and wear behavior of HVOF-sprayed CoCrAlYTaCSi coating at elevated temperature up to 1000 C. Acta Mater. 2015, 95, 164–175. [Google Scholar] [CrossRef]

- Zhang, L.-w.; Lu, L.; Wang, L.; Ning, X.-j.; Wang, Q.-s.; Wang, R.-x. Microstructural characteristics and oxidation behavior of low-pressure cold-sprayed CoNiCrAlY coatings. J. Therm. Spray Technol. 2017, 26, 1565–1572. [Google Scholar] [CrossRef]

- Brandl, W.; Toma, D.; Krüger, J.; Grabke, H.; Matthäus, G. The oxidation behaviour of HVOF thermal-sprayed MCrAlY coatings. Surf. Coat. Technol. 1997, 94, 21–26. [Google Scholar] [CrossRef]

- Tang, F.; Ajdelsztajn, L.; Schoenung, J.M. Characterization of oxide scales formed on HVOF NiCrAlY coatings with various oxygen contents introduced during thermal spraying. Scr. Mater. 2004, 51, 25–29. [Google Scholar] [CrossRef]

- Lee, C.; Kim, H.; Choi, H.; Ahn, H. Phase transformation and bond coat oxidation behavior of plasma-sprayed zirconia thermal barrier coating. Surf. Coat. Technol. 2000, 124, 1–12. [Google Scholar] [CrossRef]

- Kawakita, J.; Kuroda, S.; Fukushima, T.; Kodama, T. Development of dense corrosion resistant coatings by an improved HVOF spraying process. Sci. Technol. Adv. Mater. 2003, 4, 281–289. [Google Scholar] [CrossRef][Green Version]

- Radhika, N.; Noble, N.; Adediran, A.A. Electrochemical and hot corrosion behaviour of annealed AlCoCrFeNi HEA coating over steel. Sci. Rep. 2024, 14, 5652. [Google Scholar] [CrossRef] [PubMed]

- Noble, N.; Radhika, N.; Sathishkumar, M.; Basak, A. Slurry erosion behaviour of AlCoCrFeNi high entropy alloy coating prepared by atmospheric plasma spraying. Trans. IMF 2024, 1–8. [Google Scholar] [CrossRef]

- Basak, A.; Pramanik, A.; Prakash, C. Deformation and strengthening of SiC reinforced Al-MMCs during in-situ micro-pillar compression. Mater. Sci. Eng. A 2019, 763, 138141. [Google Scholar] [CrossRef]

- Tabbakh, T.; Alshihri, S.; Basak, A.; Kurdi, A. Strength of a 3D printed Al 7068 alloy under micro-pillar compression. Met. Mater. Int. 2022, 28, 2706–2718. [Google Scholar] [CrossRef]

- Kurdi, A.; Basak, A. Deformation of electrodeposited gradient Co/Sn multilayered coatings under micro-pillar compression. Eng. Fract. Mech. 2018, 204, 138–146. [Google Scholar] [CrossRef]

- Catto, F.; Gabriel, A.; Bolfarini, C.; Kiminami, C.S.; Afonso, C.R.M. Rapid solidification and laser cladding of gas atomized Ni-Nb-Sn bulk metallic glass. In Materials Science Forum; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2017; pp. 311–316. [Google Scholar]

- Falcón, J.C.P.; Echeverria, A.; Afonso, C.R.; Carrullo, J.C.Z.; Borrás, V.A. Microstructure assessment at high temperature in NiCoCrAlY overlay coating obtained by laser metal deposition. J. Mater. Res. Technol. 2019, 8, 1761–1772. [Google Scholar] [CrossRef]

- Kiener, D.; Motz, C.; Dehm, G. Micro-compression testing: A critical discussion of experimental constraints. Mater. Sci. Eng. A 2009, 505, 79–87. [Google Scholar] [CrossRef]

- Girault, B.; Schneider, A.S.; Frick, C.P.; Arzt, E. Strength effects in micropillars of a dispersion strengthened superalloy. Adv. Eng. Mater. 2010, 12, 385–388. [Google Scholar] [CrossRef]

- Tang, J.; Bai, Y.; Zhang, J.; Liu, K.; Liu, X.; Zhang, P.; Wang, Y.; Zhang, L.; Liang, G.; Gao, Y. Microstructural design and oxidation resistance of CoNiCrAlY alloy coatings in thermal barrier coating system. J. Alloys Compd. 2016, 688, 729–741. [Google Scholar] [CrossRef]

- Liang, J.; Wei, H.; Hou, G.; Zheng, Q.; Sun, X.; Guan, H.; Hu, Z. Thermal stability of phases in a NiCoCrAlY coating alloy. J. Mater. Res. 2008, 23, 2264–2274. [Google Scholar] [CrossRef]

- Yuan, K.; Peng, R.L.; Li, X.-H.; Johansson, S. Hot corrosion behavior of HVOF-sprayed CoNiCrAlYSi coatings in a sulphate environment. Vacuum 2015, 122, 47–53. [Google Scholar] [CrossRef]

- Huntz, A. Influence of active elements on the oxidation mechanism of M–Cr–Al alloys. Mater. Sci. Eng. 1987, 87, 251–260. [Google Scholar] [CrossRef]

- Stott, F.; Wood, G. Growth and adhesion of oxide scales on Al2O3-forming alloys and coatings. Mater. Sci. Eng. 1987, 87, 267–274. [Google Scholar] [CrossRef]

- Smeggil, J. Some comments on the role of yttrium in protective oxide scale adherence. Mater. Sci. Eng. 1987, 87, 261–265. [Google Scholar] [CrossRef]

- Volenik, K.; Novak, V.; Dubský, J.; Chraska, P.; Neufuss, K. Properties of alloy steel coatings oxidized during plasma spraying. Mater. Sci. Eng. A 1997, 234, 493–496. [Google Scholar] [CrossRef]

- Buschow, K. Encyclopedia of Materials: Science and Technology; Elsevier: Amsterdam, The Netehrlands, 2001. [Google Scholar]

- Basak, A.; Celis, J.-P.; Ponthiaux, P.; Wenger, F.; Vardavoulias, M.; Matteazzi, P. Effect of nanostructuring and Al alloying on corrosion behaviour of thermal sprayed WC–Co coatings. Mater. Sci. Eng. A 2012, 558, 377–385. [Google Scholar] [CrossRef]

- Basak, A.; Achanta, S.; De Bonte, M.; Celis, J.-P.; Vardavoulias, M.; Matteazzi, P. Effect of Al and Cr addition on tribological behaviour of HVOF and APS nanostructured WC–Co coatings. Trans. IMF 2007, 85, 310–315. [Google Scholar] [CrossRef]

- Basak, A.; Achanta, S.; Celis, J.-P.; Vardavoulias, M.; Matteazzi, P. Structure and mechanical properties of plasma sprayed nanostructured alumina and FeCuAl–alumina cermet coatings. Surf. Coat. Technol. 2008, 202, 2368–2373. [Google Scholar] [CrossRef]

- Misra, A.; Hirth, J.; Hoagland, R. Length-scale-dependent deformation mechanisms in incoherent metallic multilayered composites. Acta Mater. 2005, 53, 4817–4824. [Google Scholar] [CrossRef]

- Wang, J.; Stanford, N. Investigation of precipitate hardening of slip and twinning in Mg5% Zn by micropillar compression. Acta Mater. 2015, 100, 53–63. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, G.; Lei, S.; Niu, J.; Sun, J. Transition from homogeneous-like to shear-band deformation in nanolayered crystalline Cu/amorphous Cu–Zr micropillars: Intrinsic vs. extrinsic size effect. Acta Mater. 2012, 60, 7183–7196. [Google Scholar] [CrossRef]

| NiCoCrAlY Coating | Yield Strength (σy), MPa | Ultimate Compressive Strength (σUCS), GPa | Elastic Modulus (E), MPa |

|---|---|---|---|

| Planar direction | 0.85 ± 0.09 | 1.20 ± 0.08 | 331.04 ± 29.87 |

| Cross-sectional direction | 1.27 ± 0.10 | 2.19 ± 0.10 | 340.24 ± 31.47 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Basak, A.K.; Radhika, N.; Prakash, C.; Pramanik, A. Investigation on the Microstructure and Micro-Mechanical Properties of Thermal-Sprayed NiCoCrAlY High Entropy Alloy Coating. Designs 2024, 8, 37. https://doi.org/10.3390/designs8020037

Basak AK, Radhika N, Prakash C, Pramanik A. Investigation on the Microstructure and Micro-Mechanical Properties of Thermal-Sprayed NiCoCrAlY High Entropy Alloy Coating. Designs. 2024; 8(2):37. https://doi.org/10.3390/designs8020037

Chicago/Turabian StyleBasak, Animesh Kumar, Nachimuthu Radhika, Chander Prakash, and Alokesh Pramanik. 2024. "Investigation on the Microstructure and Micro-Mechanical Properties of Thermal-Sprayed NiCoCrAlY High Entropy Alloy Coating" Designs 8, no. 2: 37. https://doi.org/10.3390/designs8020037

APA StyleBasak, A. K., Radhika, N., Prakash, C., & Pramanik, A. (2024). Investigation on the Microstructure and Micro-Mechanical Properties of Thermal-Sprayed NiCoCrAlY High Entropy Alloy Coating. Designs, 8(2), 37. https://doi.org/10.3390/designs8020037