Abstract

Modular precast construction is a methodological approach to reduce environmental impacts and increase productivity when building with concrete. Constructions are segmented into similar precast concrete elements, prefabricated with integrated quality control, and assembled just-in-sequence on site. Due to the automatised prefabrication, inaccuracies are minimised and the use of high-performance materials is enabled. As a result, the construction process is accelerated, and the modules can be designed to be lightweight and resource-efficient. This contribution presents the fundamentals of modular constructions made from precast concrete components. Then, to elaborate the requirements of a contemporary modular precast construction, the historic developments are described. Further, concepts and technical processes–comprehensible to non-expert readers–are introduced to formalise the discussion about the current state-of-the-art methods. Three case studies treating ongoing research are introduced and related to the conceptual fundamentals. The research is evaluated with regard to current barriers and future directions. In conclusion, modular precast construction is able to reduce emissions and increase productivity in the sector if researchers and firms coordinate the development of suitable technologies that bring value to critical stakeholders.

1. Introduction

1.1. Motivation

The demand for construction has been increasing steadily for decades because of the global growth of the population and economy. According to forecasts, the Earth’s population will increase by about 2 billion by the year 2050 [1]. This corresponds to the entire world population of 1930. Approximately the same amount of infrastructure that existed at that time will have to be built within the next 30 years—in addition to the maintenance and replacement construction of existing structures [2]. High-rise buildings [3,4,5] exhibit the potential to overcome this demand for new housing and can be designed to be resource-efficient [6,7] and are particularly suitable for modular construction [8,9]. Yet, the construction industry already causes about 38% of global CO2 emissions [10]. With (reinforced) concrete as the most used building material worldwide, cement production alone accounts for 7–8% of CO2 emissions [11], making it the largest single global emitter among all materials used by humans. The situation is similar with regards to the demand for the raw materials of concrete, such as water, sand, and gravel, which has been increasing continuously for years, disproportionately to the likewise increasing world population. Already, 85% of mineral raw materials are used for construction [12].

To achieve climate neutrality targets by 2050 (in Europe) and a limitation of global warming below 2 °C or 1.5 °C by 2100, compared to the preindustrial age [13], a drastic reduction in emissions is necessary. Yet, in the concrete industry there are several fields of action that offer an opportunity for this: first, the energetic optimisation of raw material production by optimising the concrete mixture and the production processes; second, the adjustment of the design strategies of buildings, their systems, and elements to improve structural efficiency, e.g., using structural optimisation [14]; and third, the optimisation of the fabrication and construction process [15]. In contrast to the current practice of on-site construction, industrialised prefabrication allows for increased quality management, optimised material flows with reduced waste, and significantly minimised disruptions in the adjoining traffic networks by decreasing the construction time on-site. The combination of modular design methods and industrialised production also makes it possible to improve the resilience of precast structural systems, enabling their adaptability to new functional requirements, the reuse of building stock, and the minimisation of demolition costs at the end of life.

1.2. Research Goal and Outline

Due to the above-mentioned potential benefits, the use of modular construction principles in architecture, engineering, and construction (AEC) has many historic priors and has received strongly growing interest in recent years. However, the vast majority of projects in the precast sector are still conducted in a conventional manner, without systematic consideration of cross-project scale and rationalisation effects. Many existing studies tried to improve the situation, yet they focus on selected fields and disciplines, for example, digital configurators [16], interfaces [17], production technology [18], or modularisation strategies [19,20]. However, due to the extremely diverse range of disciplines and fields of specialisation that contribute to modular and automated construction, there is a need for a uniform language and clear vocabulary that enables effective cooperation and equal understanding between the various disciplines. The authors of this paper collaborate in a multidisciplinary research program involving, amongst others, the fields of architecture, computational design, structural engineering, and production engineering and have thus gathered experience in overcoming the barriers of interdisciplinary communication.

The goal of this article is to qualitatively review and discuss the research needs for a new generation of individual modular precast systems while maintaining the benefits of cross-project scale effects. This goal is based on the assumption that it is conceptually and technologically feasible to overcome the seeming contradiction between geometric uniformity and modularity. Therefore, this article reviews historic priors in Section 2 with their contemporary achievements and restrictions. Section 3 and Section 4 revise the commonly implied meanings of related concepts and terminology. In addition, the concepts are extended considering particularly the contemporary possibilities of digital design and fabrication. Section 5 condenses the findings of Section 3 and Section 4 by treating three case studies of ongoing, fundamental research projects. Thereby, the conceptual possibility of individualised modular precast is shown and technological barriers are revealed. Section 6 discusses the findings of the preceding sections. In Section 7, key learnings are concluded and future research directions recommended.

2. Modularisation in Construction and Precast Building Systems —A Historical Perspective

The historical development of modular concepts and systems of prefabricated concrete structures is closely linked to the industrialisation of the construction industry during the 19th and 20th centuries. By the first decade of the 20th century, both in Europe and the US, concepts of prefabrication were applied to concrete construction, first at the scale of single elements and later at the level of building systems.

The following sub-sections provide insight into the historical developments and outline the main periods informing the current state of modular precast construction. The analysis thereby focuses on the USA, Europe, and the UdSSR. The analysis of these periods fosters an understanding of the requirements that modularisation and fabrication methods for precast concrete structures must address to advance future systems and module definitions.

2.1. Early Precast Systems and Modularisation Concepts—From Element to System

At the end of the 19th century, various patents were filed for individual structural precast elements, such as beams and columns by Francois Coignet (1854) [21] or precast slabs and wall panels by W.H. Lascelles (1875) [22].

In 1891, Coignet’s use of precast reinforced concrete beams in the Biarritz Casino [23], followed by Hennebique’s introduction of room-sized modules in the Singleman Houses in 1896 [24] and John Alexander Brodie’s application of factory-made concrete panels in Liverpool’s Eldon Street Mass Housing project around 1905 [25], marked significant early developments in prefabricated housing construction.

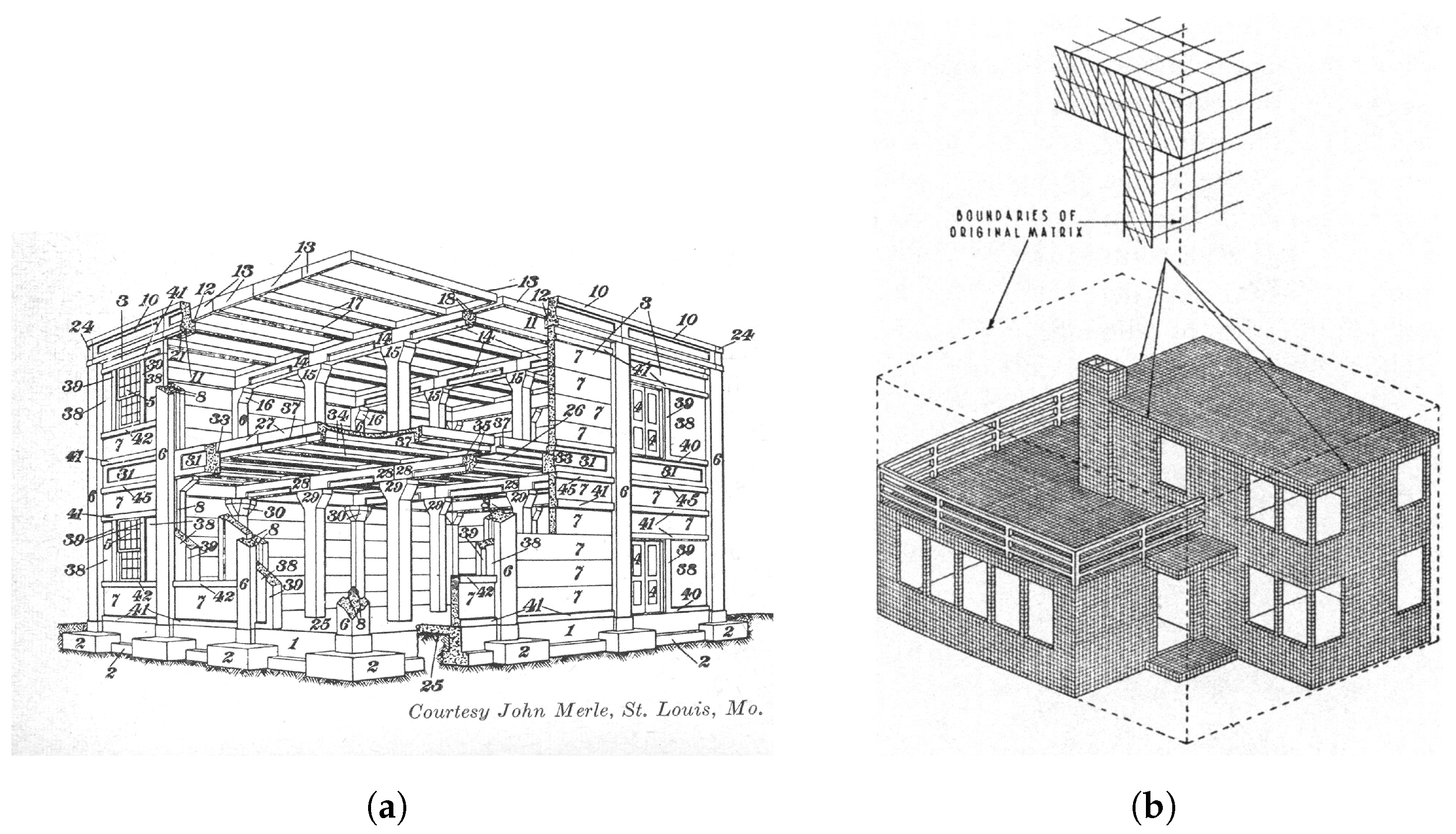

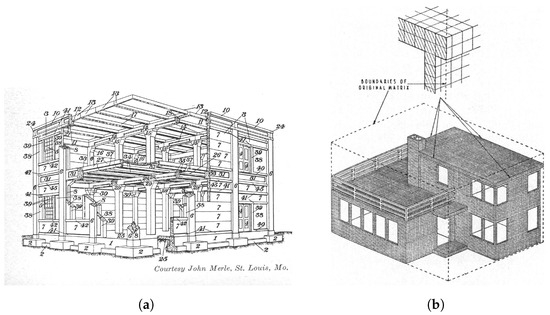

In the early 1910s, according to their inventors, the “Ransome Unit System” and “Unit Structural Concrete Method” were touted as revolutionary in precast construction, claiming to offer a 20% cost reduction and faster installation than traditional in situ methods (Figure 1a) [21]. Influenced by Fordist and Taylorist principles, early 20th-century modernist architects like Gropius advocated for prefabricated components and rationalised housing, envisioning “industrial assembly factories” for on-site assembly, emphasising that the goal is not repetition but the “individual house off the shelf” [26,27].

Figure 1.

Early modular open systems in theory and practice of construction: (a) the Conzelmann’s patented “Unit Structural Concrete Method”, 1912 [21]; (b) the Bemis cubical 4-inch module, 1936 [28].

From the beginning of modular construction, architects employed a great deal of creativity to individualise and customise structures while relying on standardised, mass-produced building elements. One of the first definitions of the term “modularity” cited in the Oxford English Dictionary (OED) originates directly from developments in the construction industry in the 1930s. The OED defines the word “module” as “a length chosen as the basis for the dimensions of the parts of a building, esp. one to be constructed from prefabricated components” and identifies the origin of this definition in the book The Evolving House, Vol. III [28] by the American industrialist and architect Albert Farwell Bemis from 1936 (Figure 1b). Bemis proposed a cubic four-inch building module as the basis for the standardisation of all kinds of building components and as a starting point for the fundamental reorganisation of the building industry towards the design and production of buildings based on one open system. The core idea to use parts with standard dimensions to coordinate architectural elements provides the foundation for another definition the OED gives, which describes a module as “a component of a larger or more complex system”. Here, concepts of standardisation and interchangeability have replaced size, measurement, and proportion as the core characteristics of modularity [29].

Frank Lloyd Wright’s Usonian Automatic Building System, introduced in the 1950s, offered a standardised kit of parts on a two-foot-square grid, yet its strict tolerances limited its application to a few projects [30]. Throughout the early 20th century, the construction industry’s focus on individual projects and the high costs of R&D meant that open modular systems were rarely implemented beyond theoretical models [31]. This reflected a fundamental misalignment with the economies of scale that modular construction required, contrasting sharply with the bespoke nature and variable demands of the construction reality, where customisation and site-specific adaptations often took precedence.

2.2. The Second Half of the 20th Century—Mass Production and Standardisation

After the Second World War, standardisation was considered a promising solution to fulfil the urgent need for new buildings [32]. Therefore, the period between 1945 and 1970 was often considered the Mass Production and Standardisation Period, marked by the rise of closed modular systems for housing reconstruction in Europe and Southeast Asia, aiming to optimise costs and speed but limiting the interchangeability of components across different systems [23].

One of the most utilised systems was the I-464 housing system, often described as a refined version of the Camus system, developed in 1951 by the French automotive engineer Raymond Camus [33]. While there was little difference in the function and production of both systems, the Camus system lost much of its popularity from the 1960s onwards. This was mainly due to high transportation costs, making prefabrication only profitable within a small radius around a prefabrication plant, and a greater demand by architects for a variety of forms to suit different sites and circumstances. While the state-owned factories in the USSR were less directly dependent on the wants and needs of a consumer market, Camus faced difficulties in finding enough orders to operate his factories at full load, forcing their closure by the mid-1960s [34].

As an exemplar of versatility in prefabrication, the Variel System, devised by Fritz Stucky in 1958, heralded a departure from rigid panelisation, enabling multidimensional assembly for structures as diverse as schools and high-rises, achieving a global reach before succumbing to the shifting tides of the construction industry [35,36,37,38]. According to Hernández, this general decline in the usage of precast systems marks the start of a new phase characterised by rethinking the design of precast building systems [23]. He describes the time between 1970 and 1985 as the beginning of the “Open Prefabrication Period” when firms started to produce more systems with several compatible components and prioritised flexible component assembly over large-scale modules. Hernandez claims that industrialised construction with high rigidity systems is now practically out of sight in developed countries [23], and modular construction seeks to address the growing demand for individualised projects. The utilisation of highly differentiated building elements does not only address aesthetic concerns but also forms the foundation for more material-efficient and material-specific constructions from precast concrete elements [39].

2.3. Modular Precast Construction in the 21st Century—Automation and Individualisation

From 1985 onward, the digitisation of the industry began, including the appearance and spread of computer-aided design (CAD) systems for creating electronic product data and programmable logic controller (PLC) systems for the control of automated machines. The labour force needed to produce mass customised modular precast elements could be significantly lowered [40]. For standardised elements with high repetition rates, a full CAD to computer-aided manufacturing (CAM) interface could soon be achieved [41]. Modules with adaptable measures could be manufactured while maintaining an economy of scale. Building Information Modelling (BIM) systems with programmable, algorithmic design logic and CAM interfaces were documented as early as 2004 [42].

The continued technological advancement and incorporation of digital planning alongside production processes are poised to significantly enhance the scale, efficiency, and manageability of product complexity within the precast industry [43,44,45]. The increasing lack of labour forces, the need to create affordable housing in metropolitan regions, and the foreseeable high demand for the renovation of old infrastructure underline the necessity to further advance automation processes in precast construction [46]. The evolution towards higher ecological standards and CO2 pricing policies is fostering a shift towards more intricately designed, shape-optimised, and quality-controlled precast elements with minimal tolerances [14,47,48].

This trend is exemplified in the case studies discussed in Section 5 that intensely apply these methods. The following Section 3 and Section 4 describe the variety of the historic systems in generic concepts and vocabulary that however leave the flexibility to consider modules and modular systems in the sense of mass customised individuality.

3. Conceptual Fundamentals of Modular Construction

3.1. Specification of Generic Concepts

It is difficult for non-experts to orient themselves in modular construction by studying example projects and abstract concepts as commonly encountered in fundamental teaching books or scientific publications. The following sections, therefore, explains concepts and definitions of modular construction in a comprehensible manner.

3.2. Modularity

According to what Fine [49] calls the three-dimensional modularity concept, modularity can be directed toward a product, process, or supply chain. An overlap of these three perspectives is also possible. The focus of this paper is on product modularity, and this definition is commonly implied in modular precast construction. Product modularity can be understood as the ordering concept, and its essential characteristic is decoupling relationships between subsystems in a system [29]. An example would be decoupling a column from a beam or decoupling a room to another in a high-rise building.

A further aspect is that modularity implies the schematisation of components to a class of standardised subsystems that are repeatedly used in the same or across different design projects [19]. A column module used in a building is designed and used according to a standard followed for other columns of the same type, and the type can be reused in other projects. The generic term “standardisation” in the context of modularisation refers to activities allowing scale effects and rationalisation for many design projects where the standardised modules are employed. The process of developing this standard or scheme of exchangeable modules is referred to as modularisation.

3.3. Modularisation

Modularisation is the activity of decomposing a technical system according to various requirements into modules and elaborating their standardised interfaces and rules of assembly [50]. Thus, modularisation involves the standardisation of subsystems into a scheme or “catalogue” of modules and their allowable connectivity. Different fundamental approaches to modularisation exist in theory, such as platform architectures for cars or PC mainboards. In architecture and construction, sectional modularity prevails, mostly referred to as construction kit approaches. Kit developers commonly aim to create modular systems that cover the required range of configurable (or customisable) product variants while using the smallest possible number of modules [51,52].

Modularisation happens on a merely schematic level. Adapting the modular system schemes for tangible (project) designs is called mass customisation [53,54]. Any final design generated via mass customisation builds on the abstracting modularisation that logically reduced a range of designs to a set of exhaustively defined modules and their interfaces.

3.4. Modular System

The modular system results from an iterative, very complex, time- and cost-intensive modularisation process. It consists of an exhaustive, standardised description of modules and interfaces and specifications of their assembly logic applicable for mass customisation. Modular systems can be characterised according to various criteria. The most important criterion is a system’s adaptability (or variability) regarding different project situations. This criterion ensures the acceptability of systems to clients and determines the potential scale effects. Adaptability is reached by interchangeability or a meaningful combination of modules [55,56] during the mass customisation process.

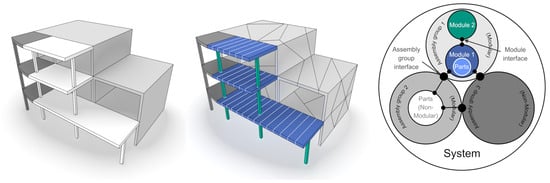

Modular systems mainly consist of modules and their interfaces that are explained in the following, using the high-rise building in Figure 2 as an example.

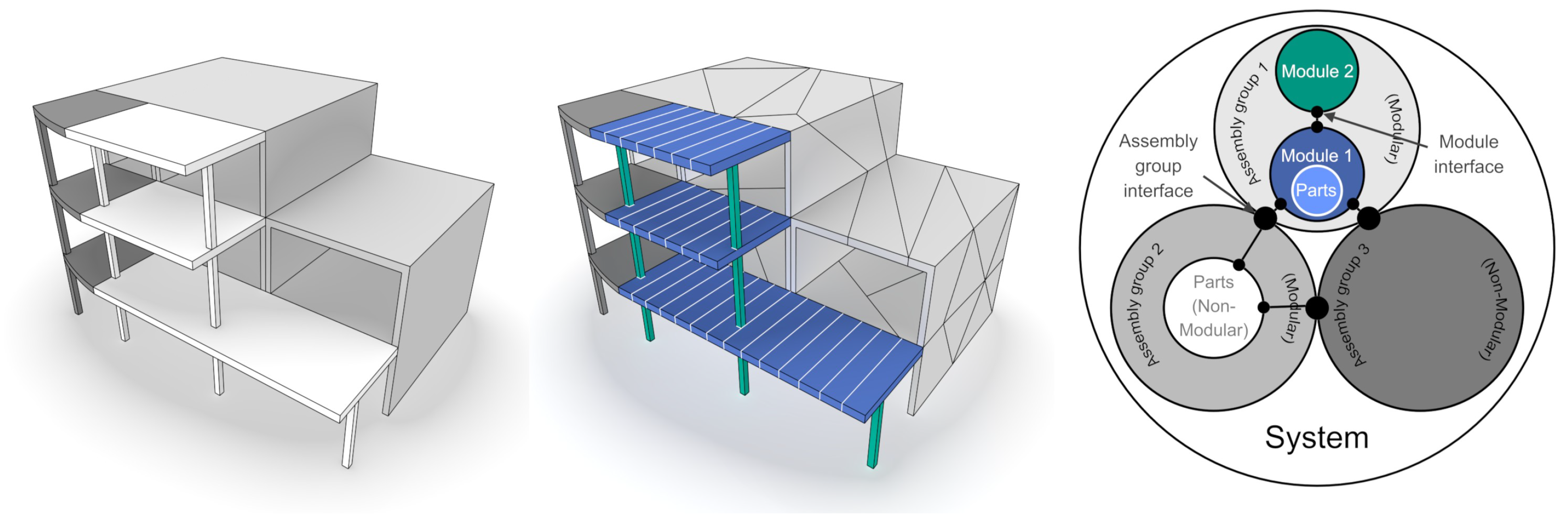

Figure 2.

Example of a non-modular, hierarchically organised (left) and hybrid modular building (centre) with exemplary interconnections and dependencies of modules, non-modular parts, and assembly groups forming the (structural) systems (right).

3.5. Module

Researchers agree that a module is characterised by standardisation and exchangeability as a member of a larger system [51,52]. A module does not necessarily describe an atomic entity but can also mean a set of (modular or non-modular) components and be exchangeable as a modular assembly group. For example, an assembly group forming a room can be categorised as a module even if it also consists of subordinate modules or non-modular parts. Figure 2 shows this on a high-rise building where assembly groups can be built up from modular or non-modular beams and slabs or segmented or monolithic slabs and walls.

In contrast to post-war modular precast construction, digital design and fabrication makes it technologically feasible to parametrise module shapes for better system adaptability while ensuring scale effects in planning and execution. Digitally controlled machines can cast and reinforce concrete components, such as beams and columns, of the same type, e.g., with equal outer dimensions. Based on the digital models of both the components and machines, different reinforcement patterns or installation parts can be integrated without an adaptation of hardware and software systems. Independent of variable parameters, the standardisation and exchangeability of modules are the key characteristics of modularity. Modular interfaces enable exchangeability by decoupling modules from one another.

3.6. Modular Interfaces

Interfaces are characterised by enabling the discrete exchange of materials, energy, or information [55,56], potentially decoupling exchangeable modular subsystems [19]. In modular construction, interfaces are commonly understood as energy transmitters, for the mechanical transfer of moments or axial or shear forces. Modular precast interfaces must seamlessly transfer forces between components to ensure the overall function of the module’s higher-level systems. Modular precast interfaces must also be strictly standardised to enable the exchangeability of modules. Further essential requirements are quick and tolerance-sensitive assembly [47], destruction-free disassembly, and durability. Therefore, interface design plays a vital role in the development of modular systems since geometric and mechanical uncertainties can lead to increased initial structural deformations, time-consuming reworking of individual modules, or no force transmission and, thus, the failure of the entire system.

3.7. Mass Customisation

Relying on exhaustively standardised and described modular systems, a variety of individualised projects can be designed and executed, exploiting scale effects and rationalised processes. In mechanical engineering, a classic example is the customisation of a car, by varying the modular car chair set variant or shell color. In construction, customisation is generally not possible, since buildings are mostly unique. Exceptions are, for example, room modules with different building services. However, the customisation takes place without causing the demand for individualised design and execution processes. In AEC, the high geometric adaptability of systems is a unique, very important requirement, for example, when a bridge system needs to cover a range of bridge spans. It must be handled accordingly by flexible algorithmic mass customisation and planning methods.

4. Process-Related Fundamentals of Modular Precast Construction

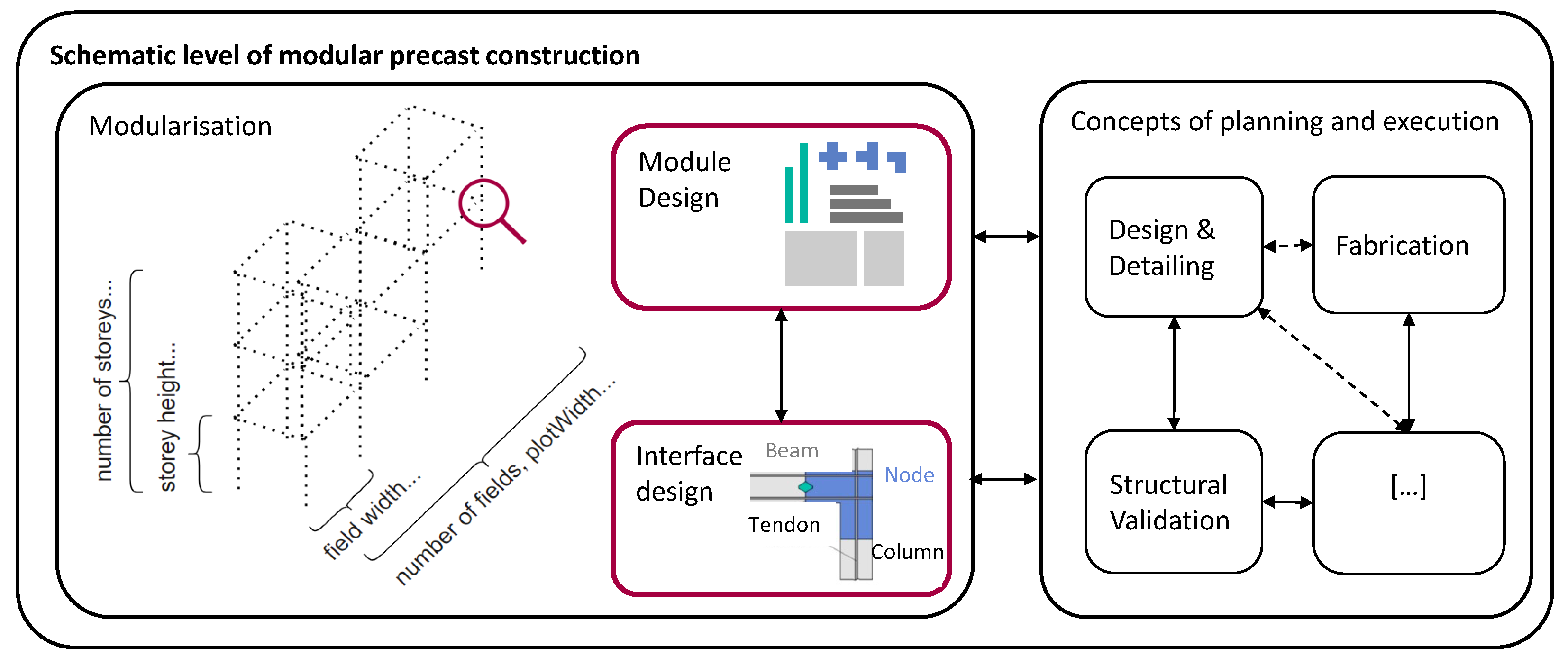

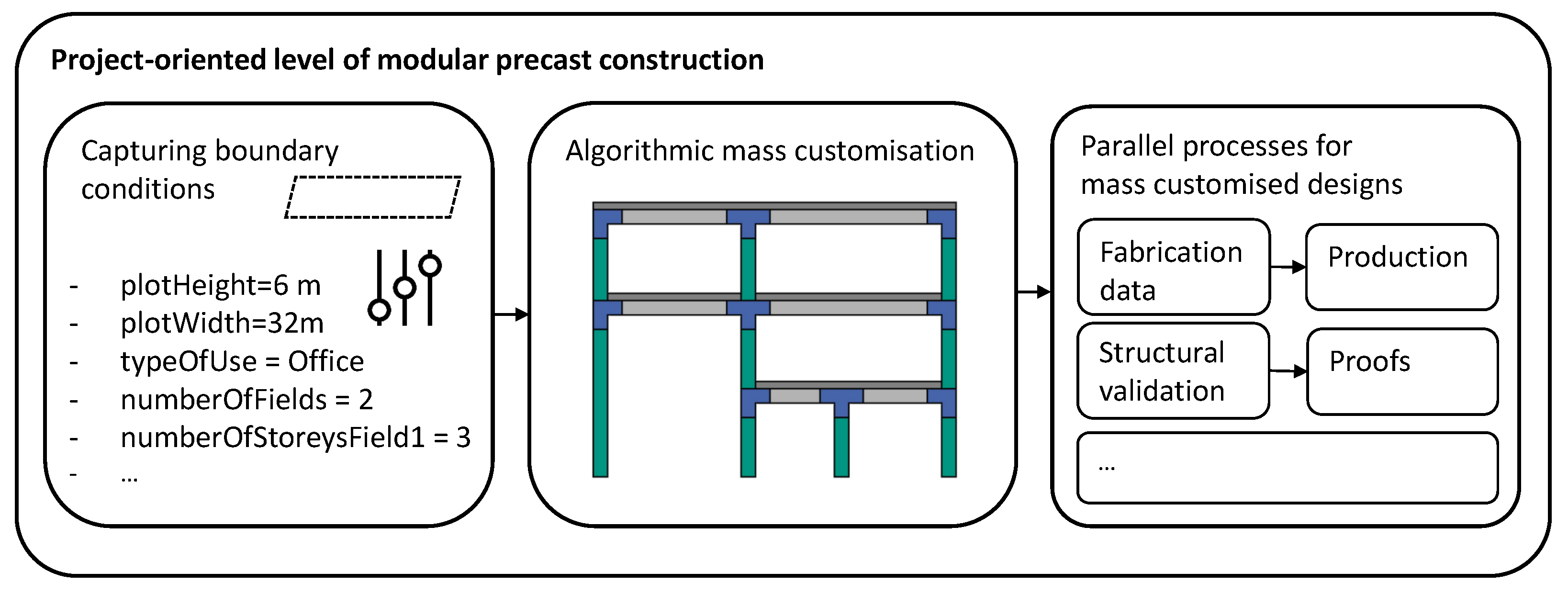

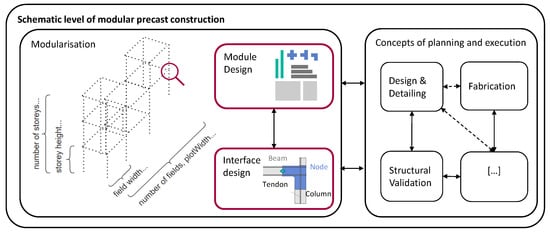

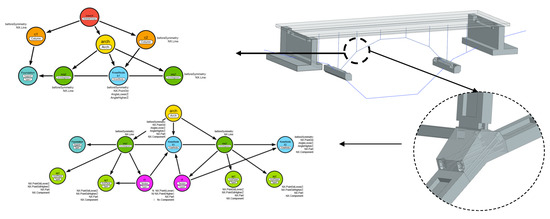

The basic concepts defined and explained in the previous section are embedded in a process-related view in the following. For this purpose, the construction kit for skeleton structures documented in [57] is used exemplarily. The technical process map is divided into a schematic level and a project-oriented level, represented in Figure 3 and Figure 4. The process map is explained and discussed in the following, indicating methodological guidelines and challenges to be considered, in particular, for modular precast construction. They mainly consist of methods for modularisation, which include the design of both the modules and the interfaces and concepts of planning and execution, which go beyond the approaches of unique, in situ construction (Figure 3).

Figure 3.

Key scheme-level processes for modular design.

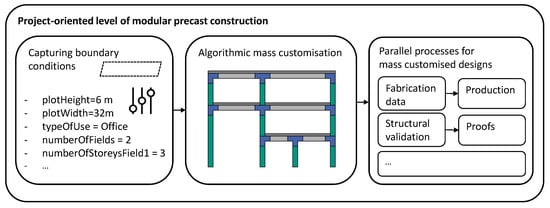

Figure 4.

Key project-level processes for modular design.

4.1. Scheme-Level Processes

4.1.1. Modularisation

As Figure 3 shows, on a schematic level of modular precast construction, the modularisation of the system is the initial and coordinating process. Instead of considering an individual building project, a modular design team should schematically decompose the system, such as a high-rise building, within certain design limits (e.g., the plot shape, width, floor height, etc.), into a finite set of standardised modules. In Figure 3, the modules are defined as columns, beams, nodes, or plates, with exhaustively defined cross-sections, structural behaviour, interfaces, and similar attributes. This standardisation (or schematisation) is the basis for an economy of scale for the design and realisation of many structures. The result of modularisation is the modular system and can be documented in informal, document-based forms like a catalogue [58]. In mechanical engineering, graphical, model-based languages stemming from systems engineering are also used for documentation [51].

Modularisation is a very complex, interdisciplinary process with multicriteria goals. As depicted in Figure 3 (right), all related planning and execution processes (e.g., design, detailing, and fabrication) and problems encountered need to be considered. Only by iteratively improving the modularisation of a construction kit can engineers consider all different functional requirements. It is recommendable to start by developing the first iteration of the construction kit that meets the architectural requirements with an intense consideration of structural validity. In comparison to conventional concrete structures, modular precast structures require focusing on challenges related to modular interface design for precast structures. Steel or timber construction has a long history of designing modular interfaces, whereas modular precast construction can rely on a smaller body of knowledge and experience to find solutions for dry, low-tolerance interfaces.

4.1.2. Modular Interface Design

During modularisation, the iterative process of interface design occurs mainly parallel with or sometimes sequentially to module detailing. As soon as a set of modules and their desired connectivity have been defined in a first iteration, the interfaces’ requirements and different working principles can be compiled. The two most critical requirement types in the design of modular precast elements are the load-bearing capacity [59] and geometrical tolerance [18,47,57].

In structuring the design process, the Zwicky morphological matrix provides methodological help in organising the compilation of requirements and operating principles [60]. To differentiate structural requirements on an interface, engineers can further specify them according to the type of load (tension, compression, bending, shear) and the spatial extension (punctual, linear, surface). The working principles can be further detailed according to the material used (concrete, steel, wood, etc.) and the type of load transfer mechanism (contact, inlay, post-tensioning). Designers can find economically feasible working principles in the catalogues of firms specialised in precast interface technology. If standardised, commercially available solutions do not fit, designers can consult scientific publications on reference precast buildings to develop custom solutions. This often applies to complex details in the design of bridges, where off-the-shelf interface solutions developed mainly for high-rise buildings are often insufficient. For this, a variety of reference bridges with different structural systems and details can be investigated (see, for example, a hybrid segmental bridge presented in [61]).

4.1.3. Adaptable Concepts of Planning and Execution of Construction Work

Modularisation is developed by harmonising architecture requirements and other domains, such as structural engineering or the execution of construction work. Only in a multidisciplinary ensemble is it feasible to develop a modularisation approach that allows for a rationalised conduction of many projects. The key concept to be developed in the first iteration is the concept for design and detailing, i.e., the concept of the mass customisation logic offered to the project clients. Applied to the example in Figure 4, this means an exhaustive standardisation of ways to limit and parametrise the response to changing project conditions. In the exemplary context of a high-rise housing system, modularisation needs to define how to design in the case of different layouts of a high-rise building with a particular gridding logic, a certain number of spans and storeys, facade variants to choos, and so forth. There are no standards on how to document such design decision logic. Architects may document the logic in a natural language or, more formally, by illustrating various examples of the kits’ use. An illustration of the latter strategy is procided by Winter [54], who developed and illustrated an adaptable modular design concept that could meet the normatives for social housing in Germany. Adaptable design and mass customisation is commonly not a single-step process but is usually split into a multiscale, level-of-detail process, as some examples show for high-rise buildings [16,53].

Based on the design and detailing concept, specialist planners develop suitable concepts for dependent and influencing design and execution processes. Such concepts do not differ fundamentally from those that engineers develop for non-modular projects. For example, a structural validation concept must still outline different types of proofs to be met and formulate analytical model requirements to conduct member force calculations and relate them to proofs. However, the main difference in modular construction lies in the potential to build upon standardisation and scale effects. Thus, decision makers can consider more elaborated, automated, and tailored solutions for potential implementation. Concrete examples are the development of modular system-specific, model-based architectures for structural validation, smart fabrication chains, or streamlined methods for the scheduling and documentation of construction processes. Any of those mentioned fields involves various technologies, is subject to specialised research, and cannot be discussed in the scope of this work. The key is that modular construction offers significantly improved possibilities to transfer research and technology into AEC practice.

4.2. Project-Level Processes

Modularisation allows many individualised construction projects to be executed with the same modules, arrangement logic, and downstream processes while maintaining scale effects. Thereby, the individualised modular project starts by capturing project boundary conditions and channeling them into the mass customisation process, as shown in Figure 4. The following subsections explain the details on this specific level of abstraction.

4.2.1. Mass Customisation

Mass customisation is the process of concretising the adaptable modular system to a specific project. The project planners rely on an exhaustive modularisation and a design and detailing concept on the schematic level (cf. Figure 3, top). Generally, it is possible to conduct the process of mass customisation manually using CAD tools. However, for efficiency reasons, parametrised algorithms reacting to the project boundary conditions and the designer’s input are commonly developed to channel the design process (Figure 4, bottom). Many examples of such configurators exist, typically building upon fundamental BIM technology combined with streamlined user interaction and a suitable semantic modelling strategy. Examples related to high-rise buildings can be found in [16,53], and a bridge design approach is documented in [58].

It is important to note that mass customisation is not a purely technological challenge. The architecture and implementation of customisation logic or software is commonly a very business-related process. Any company developing and digitising a mass customisation process must be aware of the contractor models, project structures, and interfaces it implies, which restrict the type of clients and the collaboration with other planners that a company developing the modular system can have [54]. In Germany and many other European countries there is a traditional separation between the planning and execution of construction work. It is currently hard to predict how contractor models will develop in the future. A desirable guideline is to decouple the mentioned processes and build upon open standards and interfaces in the project-specific planning processes.

4.2.2. Execution of Downstream Processes

Depending on a mass customised design, engineers conduct downstream processes such as structural validation. As shown in the technical map in Figure 4 (bottom), commonly, even parallel processes can be applied in contrast to non-modular projects. On the schematic level, modularisation implies prevalidating the modularisation for all relevant domains and coordinating the different domains to define a viable scheme in different dimensions. Thanks to a successful modularisation, planners must not identify fundamental problems with the mass customised project design while conducting planning processes subsequent to the kit-compliant design and detailing.

The automation of the different types of downstream processes, depending on adaptable concepts on the scheme level, is complex in implementation and involves dedicated technologies that cannot be discussed in the scope of this paper. However, it is essential to underline that standardisation and scale effects significantly simplify research and development in this setting. For example, BIM-based workflows in non-modular projects often do not yet exploit parametric modelling strategies or the full potential of model-based interoperability. In the particular setting of modular construction, significant improvements may be made.

This section elaborated the conceptual possibility of having modules and modular systems with individuality and geometric variability, based on the concepts and terminology defined. The next section discusses three case studies of ongoing research that follow this goal and points out key technological issues to be overcome.

5. Case Studies of Ongoing Research

5.1. Skeleton System

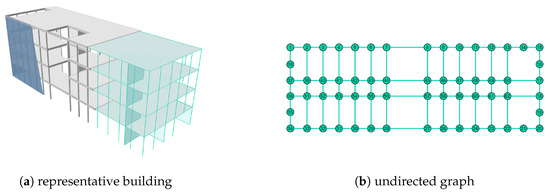

The first research project, conducted at the Karlsruhe Institute of Technology, focuses on modularisation methodology and interface technology concerning structural performance and assembly tolerances [57]. Section 4 as well as Figure 3 and Figure 4 already introduced the construction kit investigated in that research. It includes modules for segmented columns and beams as well as node-modules connecting them.

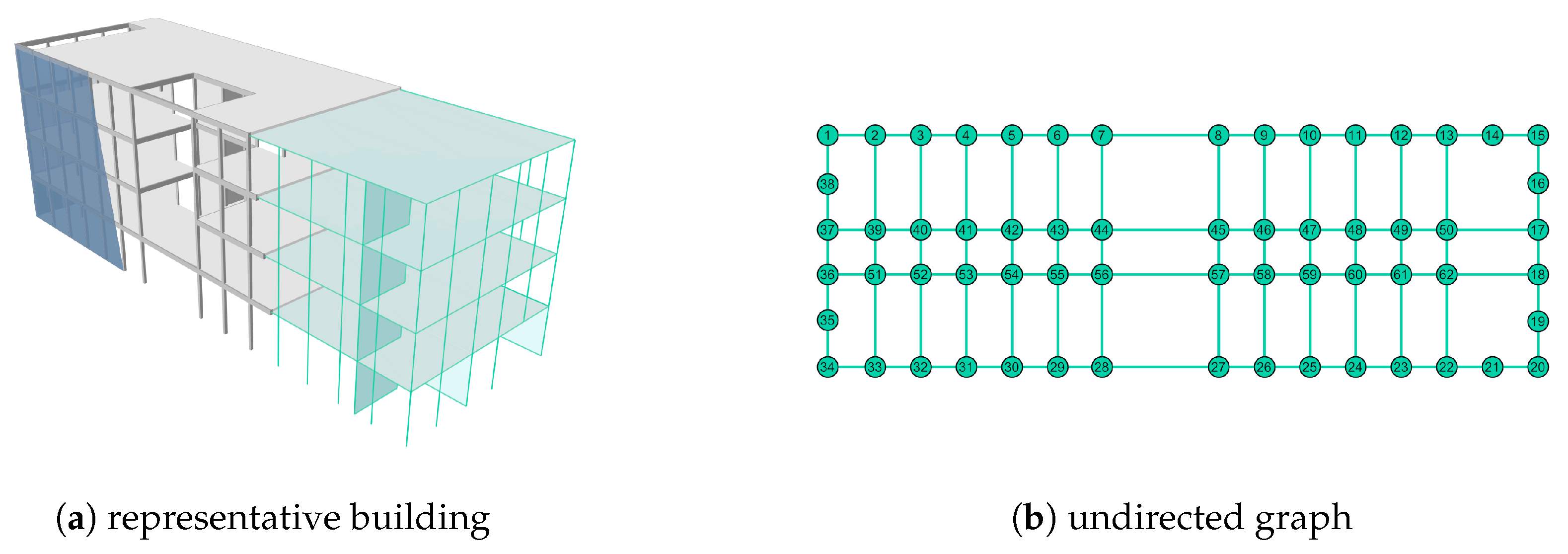

Figure 5 shows a representation of an exemplary building (a) and the transfer of the ground floor plan into a digital representation. The digital representation of the building is based on an undirected graph (b).

Figure 5.

Selection of buildings and digital representation.

The nodes of the graph represent nodes of the supporting structure. They are labelled in ascending order so that they are clearly assigned with their digital representation. The connections represent the topological links between the structural nodes in the building but not the number of components to realise the link. The distances between the nodes of the building can be derived from the digital representation, and the nodes are to be connected with beam modules. The aim of optimising the module characteristics is to achieve a minimum of internal diversity (minimal number of different beams and columns) with a high degree of external diversity (realisation of as many buildings as possible). In terms of classic optimisation problems [62], the design variables are the number of predefined modules with different dimensions or lengths, respectively. With respect to the the objective function, i.e., a minimum number of different module types (here represented by their length), a minimum number of different lengths is chosen to minimise the internal diversity of the modular system. In addition, the objective function was expanded to prioritize components that are as long as possible while simultaneously possessessing a low weight. This reduces the number of joints in the building and, furthermore, leads to a reduction in assembly and transport costs.

Two different optimisation algorithms were derived to solve the optimisation problem. One was an evolutionary algorithm and the other a specialised optimisation algorithm for mixed-integer optimisation problems (e.g., branch-and-cut). It was observed that both algorithms found the same optimum, yet the mixed-integer optimisation approach converges faster so it is considered more suitable for the present optimisation problem. The result of the optimisation is a set of different lengths that can be used to construct not only the building shown in Figure 5 but also all other chosen reference buildings in this study. The different identified dimensions and their occurrences form the optimal construction kit. Three reference buildings with three to seven storeys were chosen for the optimisation: two residential buildings and one administrative building with column spacing of up to 7 m, storey heights of up to 4 m, and areas of the ground floor of not more than approx. 4000 m2. Rectangular cross-sections of the components with edge lengths of 30 cm, 45 cm, and 60 cm were chosen to represent all links or components of the reference buildings. For the lengths of the building components, practical increments of 5 cm were chosen. The calculations showed that components with a length of 1.35 m have the highest occurrence regardless of the cross-sectional dimensions. A component with a length of 1.35 m therefore represents the ideal module of the construction kit.

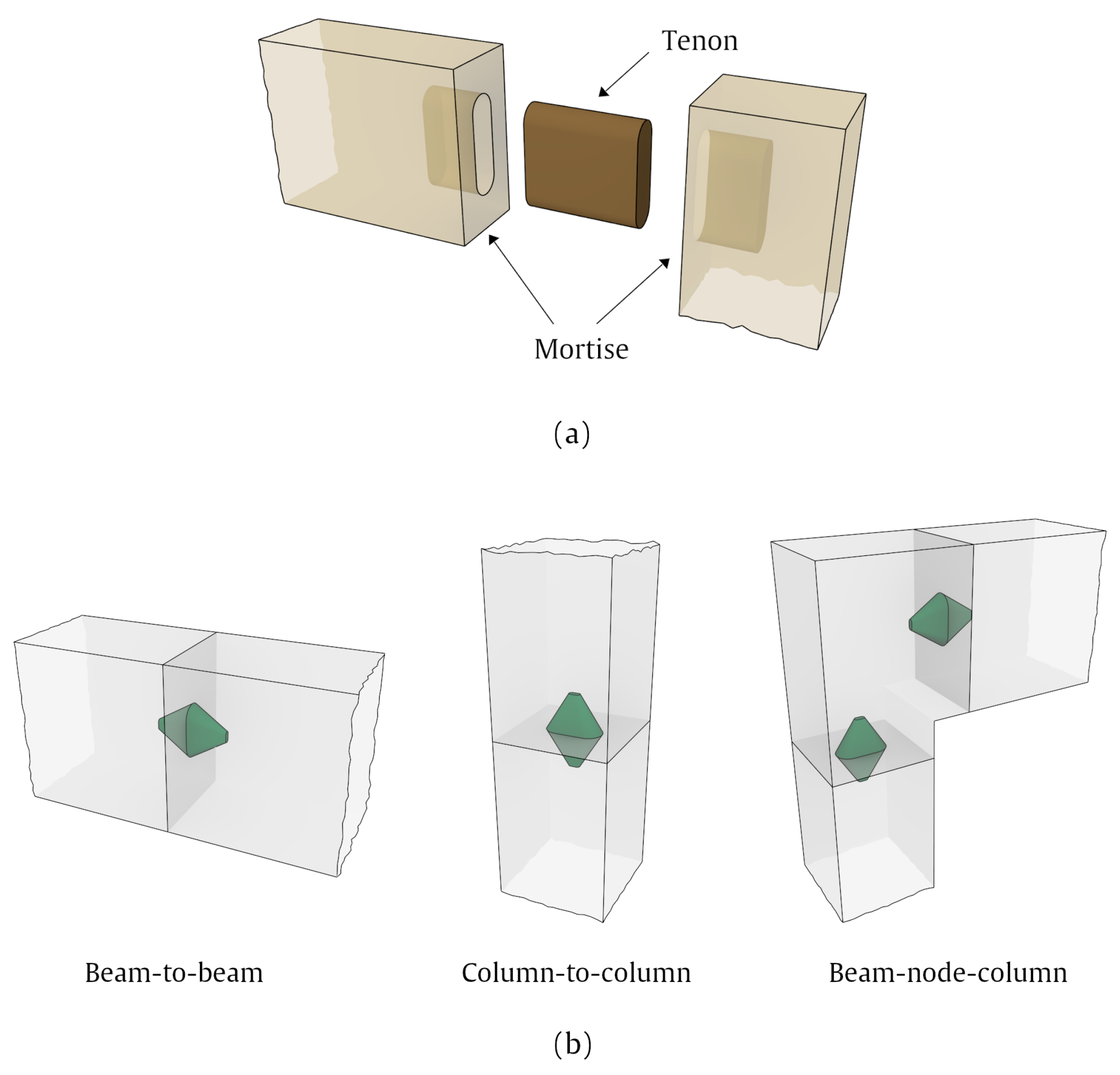

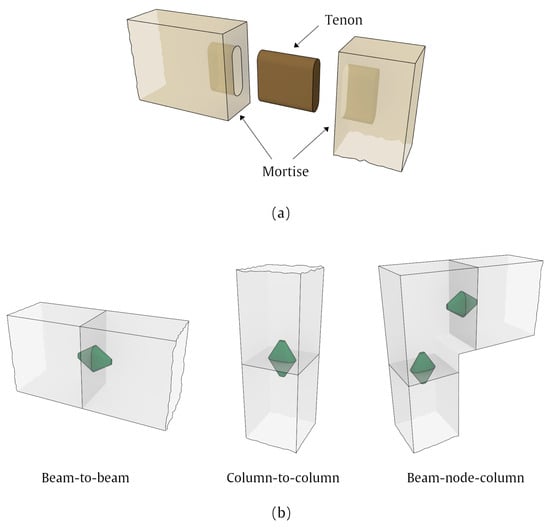

Besides optimisation-based methods for the modularisation process of skeleton structures, the research project also investigates improved interface technology for the modular beams and columns of the derived construction kit. Within the conceptual design of interfaces, the force transmission between joined modules and the simultaneous alignment or centring of the connected components were identified as essential conditions for an interface between 1D reinforced concrete components. In an initial study, a loose mortise and tenon joint adapted from timber construction (Figure 6a) was analysed in detail. A hybrid connection consisting of a double-conical steel connector between adjacent concrete components was used for this purpose. Figure 6b shows the design of the connection and its various applications.

Figure 6.

Dry and low-tolerance precast interface technology investigated at the Karlsruhe Institute of Technology [57]: (a) loose mortise and tenon joint in timber construction; (b) applications in concrete construction.

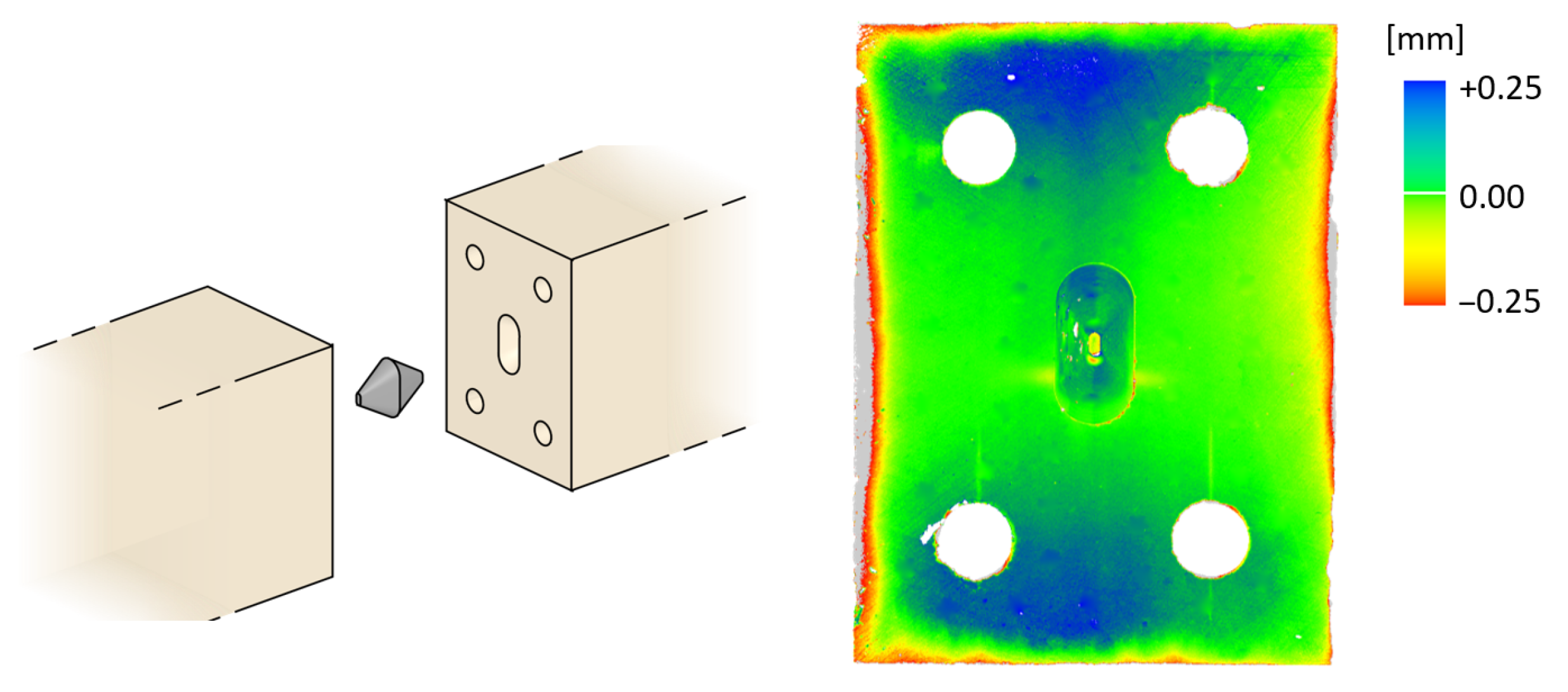

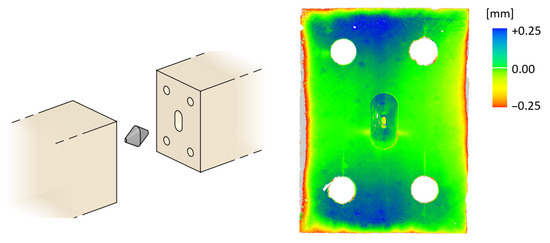

During the further development of this initially conceptualised interface, two aspects had to be investigated: first, the production of recesses with complex geometry in the concrete components and, second, an appropriate reinforcement pattern at the joints.

For the integration of recesses into the concrete components, 3D-printed molds made of plastic were identified as a suitable formwork inlays. Figure 7 shows this recess in the surface of a concrete component as conceptual design (left) and a heat map of the joint surface (right). Four tubes are provided for post-tensioning. At the overall surface of the joint, maximum shape deviations of approx. ±0.25 mm result. For the area of the recesses, the deviations correspond to only approx. ±0.1 mm. These small deviations in shape ensure that the load-bearing elements can be assembled quickly and precisely without great technical effort. The centring of the connector element and therefore modules could be proven during the assembly for experimental tests of the shear load capacity.

Figure 7.

Shape deviation of the recess in the concrete component for the positioning of the connecting element.

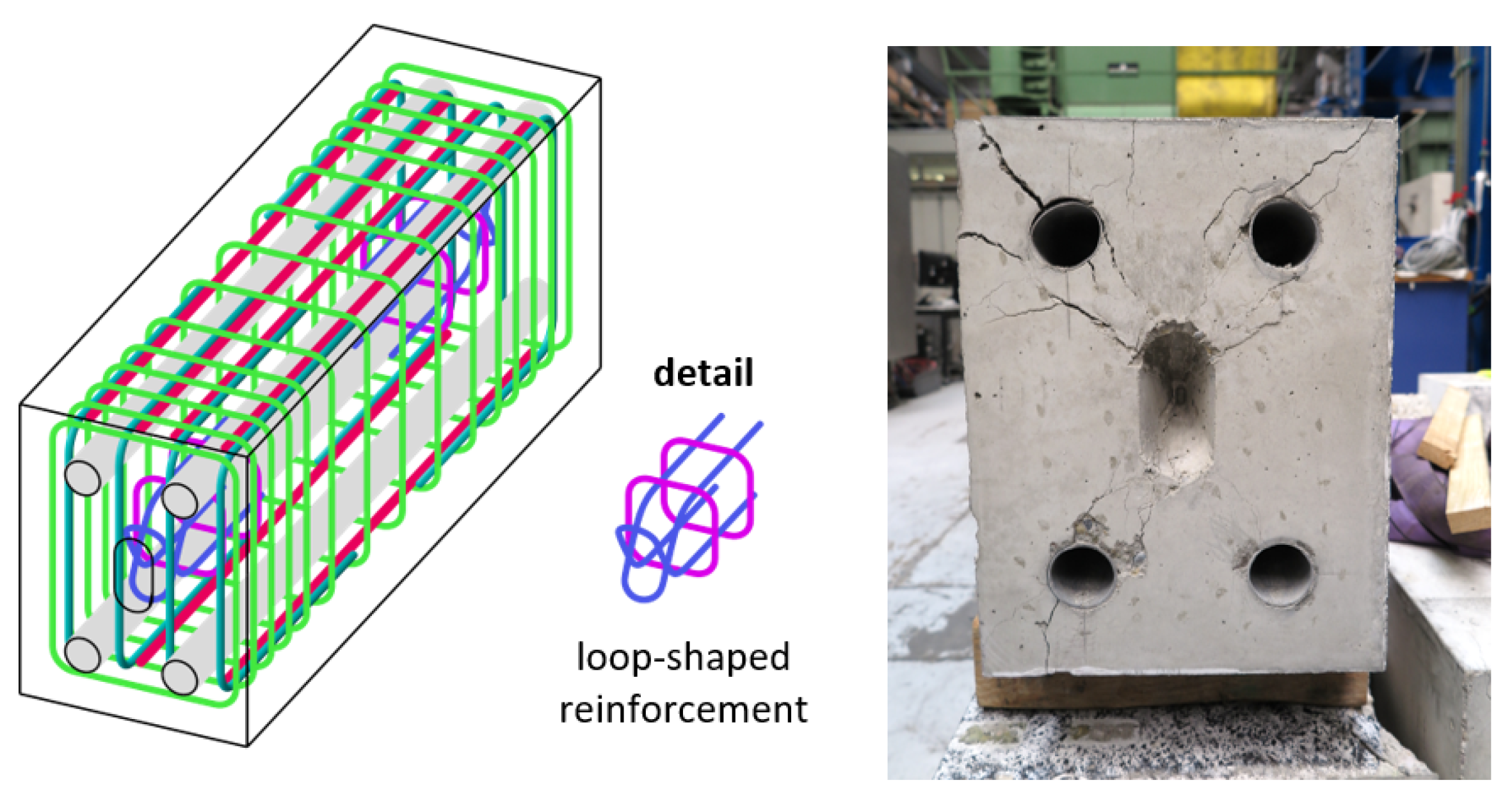

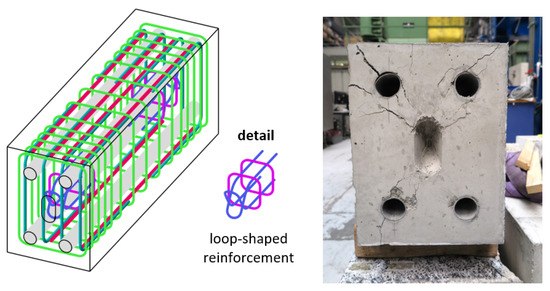

Figure 8 shows the reinforcement layout of the load-bearing elements with the detail of the area surrounding the recess of the concrete component. A loop-shaped reinforcement pattern was derived to withstand splitting tensile forces in the area of the recess and to ensure the ductile behaviour of the concrete component under shear loading.

Figure 8.

Reinforcement layout and crack distribution on a surface after the application of shear.

The experimental investigations were carried out on components made from concrete with a compressive strength of 64 MPa and reinforcement steel with a yield strength of 500 MPa. The load-deformation behaviour shows a load-bearing capacity of the connection under a pure shear load of approx. 400 kN for concrete components with a cross-section of 300 mm × 400 mm. During the experimental investigations, there was no preload applied on the cross-section, and therefore no frictional force was transmitted by the contact surfaces. The shear force was transmitted purely by the interlocking effect of the connecting element. The first results of numerical simulations confirm the ductile behaviour of the joint under the shear load. In further investigations, other geometries for interfaces between concrete modules and connectors will be analysed.

Due to the relevance and complexity of the interface design for modular structures, a related research project from TU Berlin in the authors’ research network investigates dimensioning models for interlocking shear profiles of precast beams [17,59].

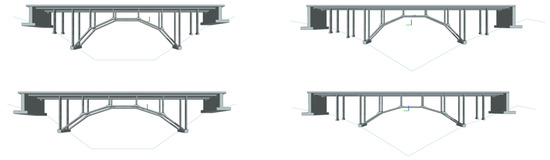

5.2. Arch Bridge System

The second case study stems from a research project at the Technical University Munich that predominantly focuses on the mass customisation of bridges using semantic modelling and BIM technology [58].

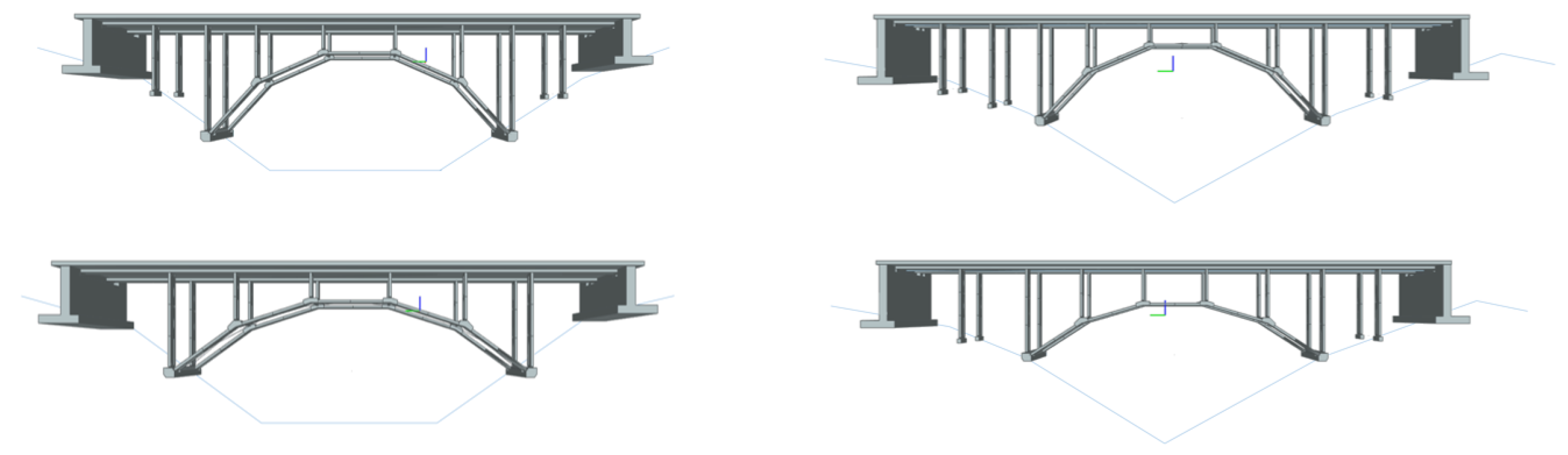

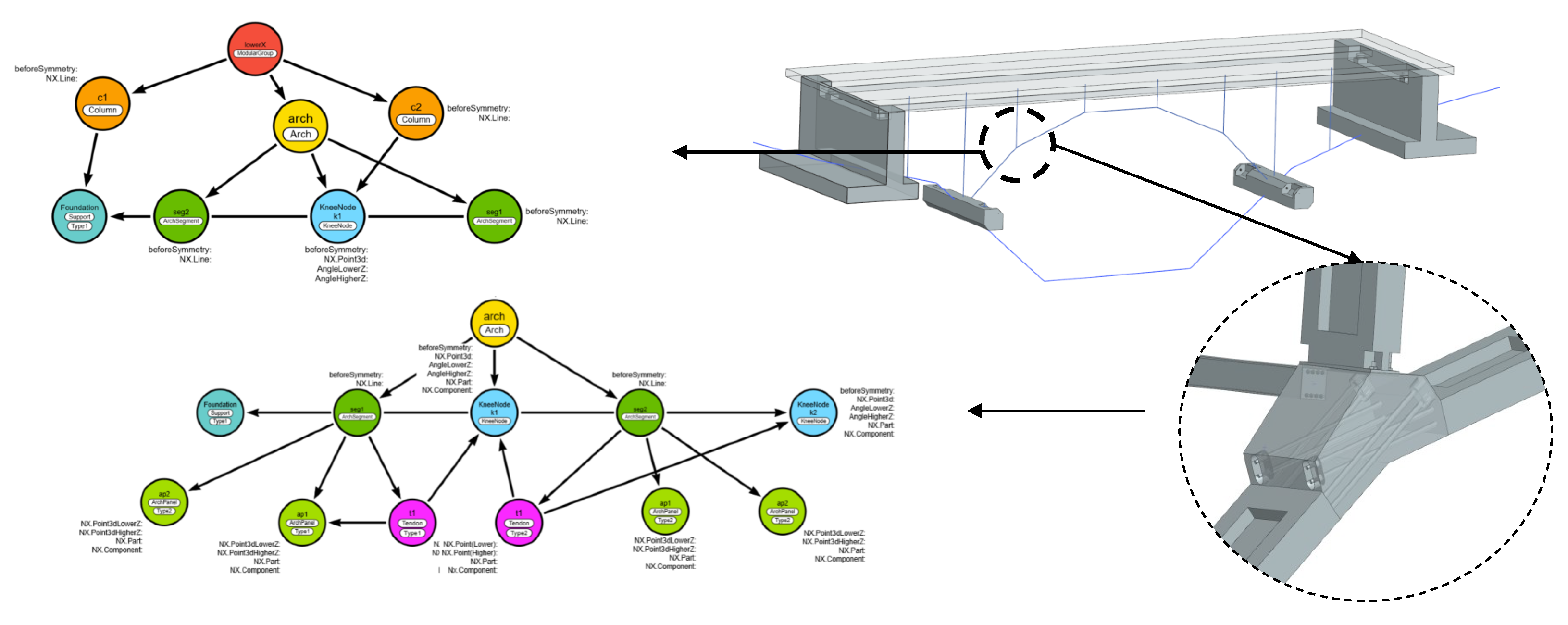

A modularisation method for an arch bridge was developed as a necessary preparatory work, considering the architectural requirements of variable topography. In detail, the modularisation treats the bridge substructure and foundations. The system utilises simple, panel-like modules with side lengths ranging from 2.0 to 3.5 m. In parallel, additive manufacturing using ultra-high-performance concrete (UHPC) is being investigated [63]. To cover the various interfaces, such as support and joining situations, seven module variants of this panel module were derived, mainly varying due to different interface specifications, for example, the varying placement of prestressing, plug connections, and inlay parts. The design of the system is discussed more in detail in [64]. All module variants, foundations, and superstructure elements were modelled as parametrised, schematic parts in a product modelling software to be used as building blocks of an algorithmic mass customisation process. The researchers developed a model-based, two-step design process. In the first step, alignment and topography are imported, and a steering sketch is fitted between those elements within certain architectural constraints. In the second step, the algorithm processes the steering sketch to generate and place all project-specific components, including inlay components such as plugs and tendons. Figure 9 shows the variability of the modular bridge system for different topographies and parameters. Based on the predefined modules, algorithmic mass customisation allows for an efficient and high-quality model generation in a few seconds [58].

Figure 9.

Variability of modular arch bridge system and algorithmic mass customisation approach [58].

The study shows the technological complexity of enabling individualised modular design for geometrically complex, adaptable systems. A complex planning process that depends on many project-specific circumstances needs to be subdivided into a standardised, sequential process with incremental design model scales. In every detail scale, the operative planners need to accept the range of parametric design decisions and be able to cope with the individuality of the different projects to allow the generation of a sustainable and well engineered solution.

For an illustration of such model scales, Figure 10 shows an exemplary bridge model in lower and higher levels of detail and the corresponding snippets of the digital representation on the left. The information complexity engineers need to handle algorithmically rises significantly in detailed design phases. Still, firms should invest effort in digital planning support. The case study underlines that the quality of design can be assured by algorithmic processes. This is particularly important when firms need to offer individuality while maintaining standardisation or need to plan projects with high constructive and geometric complexity.

Figure 10.

Design model generation in levels of detail with increasing information complexity [58].

The next section discusses an individualised modular precast system for double-curved shell structures, whereby a stronger focus is set on geometric issues in design and the coupling of digital design and fabrication.

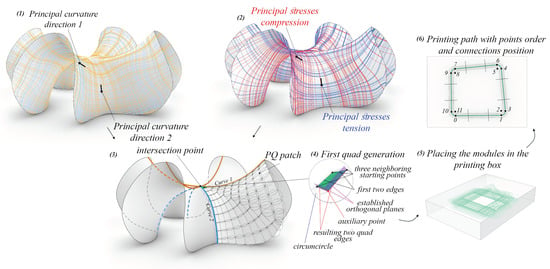

5.3. Double-Curved Shell Systems

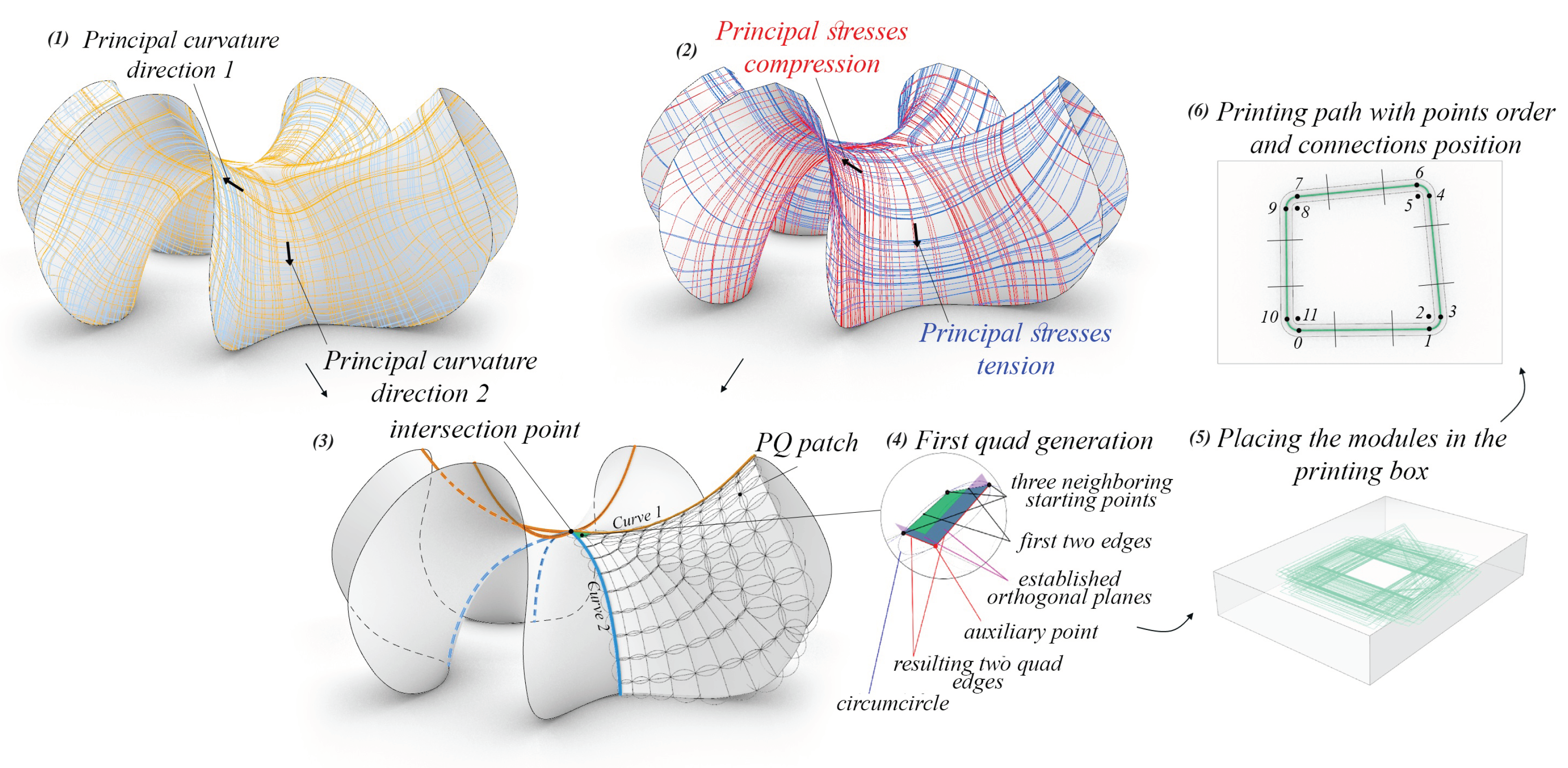

This case study from a research project conducted at TU Dresden focuses on mass customising modular, filigree, segmented shells’ coupling and validating design with an additive manufacturing process [65]. The shells are generically applicable for constructions requiring larger spans and free areas, such as aesthetic roofs or pavilion buildings.

For the shells, currently, only two module types are introduced during modularisation: one for outer modules ensuring the stable supporting of the shell and a second type for inner modules connected to four other modules in the shell network. As related interface technology, the researchers investigate several plug- and cable-based connection variants that differ in implications on production technology and materials used. The related mass customisation process starts by adapting a parametric NURBS surface. The customisation is constrained to four slightly adaptable shell shapes with optimal properties regarding design and statics, such as self-supporting arc systems or a shell with a minimal surface-to-volume relation. The shell dimensions currently investigated range between 7.80 and 11 m, while the laboratory scale of the modules ranges from 0.34 to 0.98 m in edge length. Figure 11 shows the mass customisation process for one shape variant of the shell that follows an organic “flower” shape.

Figure 11.

Mass customisation of a shell with complex geometry using pq-meshes.

The semi-automatic mass customisation process builds on the pq-mesh algorithm [66] that considers maximal geometric uniformity. An optimisation of the joint orientation parallel to the principal stresses in the shells is added as a second optimisation criterion. The necessary parameters to instantiate and orient all modules for the detailing of modules are computationally derived from the pq-mesh. For the given design model, the generation of fabrication information is also the subject of the research project, currently via the machine data-oriented programming language g-code [65]. The data exchange involves all data required for the developed additive manufacturing process, such as the description of the printing path of the thickened edges, the infill and textile reinforcement, the drilling position, the diameter, and the depth.

Like the second case study, the discussed research project investigates and illustrates modularisation strategies for load-bearing structures with very complex shapes. Equally, the elaboration of suitable algorithmic mass customisation methods enables an acceleration of planning processes and conceptually allows high-quality models to be derived for downstream applications. The basic coupling of design to fabrication and the digital fabrication processes are relatively mature in this research. Detailed structural considerations of interfaces and load transfer are likely to pose challenges.

6. Discussion

Modular precast construction has a long history, with many attempts since the advent of reinforced concrete. However, many companies investing in modular systems did not succeed or last due to economic performance issues or evolving architectural needs. In the 21st century, advancements in digital design and fabrication have improved the potential of modular systems. These advancements enable more personalised, adaptable, and aesthetically pleasing designs while maintaining efficiency in planning and building. Therefore, the authors are convinced that the productivity and sustainability of concrete construction will significantly increase with a higher share of modular precast construction. Modular constructions are also seen as one of the key factors to meet the global demand for housing and infrastructure.

Non-experts face the challenge of orienting themselves in the field of modular construction. The agreement on a consistent terminology, which has been brought together from the different definitions from architecture, civil engineering, mechanical engineering, computer science, and mathematics, allows for collaborative work on solving problems. Vital concepts and vocabularies were explained and embedded in a process-oriented view of modular precast construction. The case studies highlighted the methodological complexity of developing valid modularisation strategies that meet architectural requirements. Further, they underlined the need to develop more mature and flexible modular precast interface technology and methods of algorithmic mass customisation to control the high geometric and semantic complexity of modular construction systems. Hence, the design is steered by both the assembly and manufacturing, also known as Design for Manufacturing and Assembly (DfMA) [67]. In AEC, DfMA aims to minimise the number of building elements or joints, optimising the components in material and shape and streamlining processes. Thereby, high costs and low productivity are avoided. Then, the material consumption and CO2 emissions from both the structure and the manufacturing process are also minimised.

The academic research presented in the case studies focuses on detailed technical challenges and engineering methods. Yet, the framework presented provided a superordinate orientation by contextualising these research questions as part of a more extensive, interdisciplinary development.

The article leveraged an improved understanding of how modular precast construction with a high aesthetic and environmental performance can be brought to scale. Beyond the academic and technological perspective, companies must seek clients’ acceptance by considering viable contractor models and project structures. Open systems and distributed project planning and execution may increase the acceptance of critical stakeholders in the sector. Modular precast construction is a promising way to significantly increase the sustainability and productivity of construction planning and execution. This is only possible if researchers and firms in the AEC sector account for the technological and process-oriented challenges.

7. Conclusions

This article shows the historical development of modular construction from mostly closed systems, which often only result in similar, unaesthetic structures, to open systems that enable different types of unique buildings using standardised, individual modules. The case studies of current fundamental research projects shown vary between modular skeleton buildings, bridges, and shells, all of which are based on the same terminology. The key findings are as follows:

- In reflecting on the historical development of modular construction, an evolution is observed from the inflexibility of closed systems to open and individualised systems. This transition illustrates a significant industry shift, moving from uniform mass production towards the potential of mass customisation to allow architectural diversity while ensuring scale effects. While full automation in modular construction remains a developing frontier, the current trajectory suggests a future where digital and automated methodologies play a pivotal role in meeting the dynamic demands for sustainable and versatile buildings.

- Efficient production requires suitable modularisation methods that either modularise structures into identical modules or, conversely, build up structures from a set of standardised modules. Structural optimisation and data-oriented or mathematical methods (e.g., using NURBS) are appropriate for this purpose. The results are construction kits for structures that are suitable for mass customisation.

- From production must also be integrated into the modularisation methods. Restricting the module variability helps to limit the variety of developed construction kits. For example, the restriction to plane modules for shell structures takes into account the manufacturability complexity of non-planar baseplates when using additive manufacturing methods [68].

- The connection of load-bearing modules is of major importance. The development of interfaces must be considered throughout the entire engineering process during the development of modular construction. Future research needs to focus on the conversion and dismantling of modular buildings during the use and end of life, making it particularly important to develop detachable connections. Thereby, researchers should aim to prolong the service lives of modular buildings and weigh off proposed measures by means of LCA methods.

- Following the principles of DfMA, modular construction can essentially reduce CO2 emissions. For the global goal of carbon neutrality, the resuse of modular components [69] in future structures must be integrated in DfMA, e.g., via disassembly strategies and detachable interfaces of modules.

- A holistic digital representation of modular buildings is necessary to automate planning and prolong the life cycle of modular systems. The digital representation should combine design, production, and assembly data. The continuous expansion of digital planning support plays a major role and should include LCA and monitoring concepts. If industry-wide data standards can be introduced, digital tools can support engineers to manage consistently construction kits in the planning phase and a great number of modular projects in the use phase. In order to establish common digital standards, collaborators rely particularly on precise and consistent terminology.

Author Contributions

Conceptualisation, L.K., D.K., A.M. (Agemar Manny), D.S., M.R., R.R., Z.T., T.T. and J.S.; methodology, L.K., D.K., A.M. (Agemar Manny), D.S., M.R., and P.F.; software, validation, formal analysis, investigation, resources, and data curation: not applicable to research methodology; writing—original draft preparation, L.K., D.K., A.M. (Agemar Manny), D.S., M.R., Z.T., T.T., J.S., and P.F.; writing—review and editing, P.F., A.B., L.B., L.S., A.S., A.M. (Achim Menges), M.S, A.A., D.L., K.-U.B., and P.M.; visualisation, A.M. (Agemar Manny), L.K, D.K, D.S., M.R., Z.T., and P.F.; supervision, P.F., A.B., L.B., L.S., A.S., A.M. (Achim Menges), M.S., A.A., D.L., K.-U.B., and P.M.; project administration, D.K., L.K., M.R., P.F., and P.M.; funding acquisition, P.F., A.B., L.B., L.S., A.S., A.M. (Achim Menges), M.S., A.A., D.L., K.-U.B., and P.M. All authors have read and agreed to the published version of this manuscript.

Funding

The authors thank the German Research Foundation (DFG) for the financial support of the projects with the grant numbers 424070949, 423969184, 423935790, 423987937, 424057211, 423942391, 423942547, and 423957563, which are part of the Priority Program 2187 “Adaptive modularized constructions made in a flux”.

Data Availability Statement

The data presented in the studies are available on request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- United Nations, Department of Economic and Social Affairs, Population Division. World Population Prospects; United Nations: New York, NY, USA, 2019.

- Sobek, W. Die Zukunft des Leichtbaus: Herausforderungen und mögliche Entwicklungen. Bautechnik 2015, 92, 879–882. [Google Scholar] [CrossRef]

- Charmpis, D.C.; Komodromos, P.; Phocas, M.C. Optimized earthquake response of multi-storey buildings with seismic isolation at various elevations. Earthq. Eng. Struct. Dyn. 2012, 41, 2289–2310. [Google Scholar] [CrossRef]

- Forcellini, D.; Kalfas, K.N. Inter-story seismic isolation for high-rise buildings. Eng. Struct. 2023, 275, 115175. [Google Scholar] [CrossRef]

- Wang, S.J.; Hwang, J.S.; Chang, K.C.; Lin, M.H.; Lee, B.H. Analytical and experimental studies on midstory isolated buildings with modal coupling effect. Earthq. Eng. Struct. Dyn. 2013, 42, 201–219. [Google Scholar] [CrossRef]

- Weidner, S.; Bechmann, R.; Sobek, W. Why urban mining is inevitable: Analyzing the resource consumption of urban structures. In Structures and Architecture a Viable Urban Perspective? CRC Press: Boca Raton, FL, USA, 2022; pp. 947–954. [Google Scholar]

- Bechmann, R.; Weidner, S. Reducing the Carbon Emissions of High-Rise Structures from the Very Beginning. CTBUH J. 2021, 4, 30–35. [Google Scholar]

- Thai, H.T.; Ngo, T.; Uy, B. A review on modular construction for high-rise buildings. In Structures; Elsevier: Amsterdam, The Netherlands, 2020; Volume 28, pp. 1265–1290. [Google Scholar]

- Lawson, R.M.; Ogden, R.G.; Bergin, R. Application of modular construction in high-rise buildings. J. Archit. Eng. 2012, 18, 148–154. [Google Scholar] [CrossRef]

- Haist, M.; Bergmeister, K.; Curbach, M.; Forman, P.; Gaganelis, G.; Gerlach, J.; Mark, P.; Moffatt, J.; Müller, C.; Müller, H.S.; et al. Nachhaltig konstruieren und bauen mit Beton. In BetonKalender 2022; Bergmeister, K., Fingerloos, F., Wörner, J.D., Eds.; Wiley: Hoboken, NJ, USA, 2022; Volume 17672, pp. 421–531. [Google Scholar] [CrossRef]

- Board, S.N.E. Concrete needs to lose its colossal carbon footprint. Nature 2021, 597, 593–594. [Google Scholar] [CrossRef]

- UNEP. Sand and Sustainability: Finding New Solutions for Environmental Governance of Global Sand Resources; WebPage; United Nations Environment Programme: Geneva, Switzerland, 2019; Available online: https://wedocs.unep.org/20.500.11822/28163 (accessed on 30 October 2023).

- United Nations. Paris Agreement, in Report of the Conference of the Parties to the United Nations Framework Convention on Climate Change (21st Session); WebPage; United Nations: Geneva, Switzerland, 2016. Available online: https://unfccc.int/resource/docs/2015/cop21/eng/10.pdf (accessed on 30 October 2023).

- Gaganelis, G.; Mark, P.; Forman, P. Optimization Aided Design: Reinforced Concrete, 1st ed.; Ernst & Sohn: Berlin, Germany, 2022. [Google Scholar]

- Forman, P.; Glock, C.; Mark, P. Fast-track construction – motivation, history & concepts [in German]. Beton Stahlbetonbau 2021, 116, 2–11. [Google Scholar] [CrossRef]

- Gan, V.J. BIM-based graph data model for automatic generative design of modular buildings. Autom. Constr. 2022, 134, 104062. [Google Scholar] [CrossRef]

- Rettinger, M.; Guhathakurta, J.; Gänz, P.; Simon, S.; Hückler, A. Assessment of Prestressed Dry Joints by X-ray Computed Tomography. In Proceedings of the 14th fib International PhD Symposium in Civil Engineering, Rome, Italy, 5–7 September 2022; pp. 337–344. [Google Scholar]

- Stindt, J.; Forman, P.; Lanza, G.; Mark, P. Geometric evaluation and optimization of module arrangement in load bearing structures–Towards adaptive manufacturing in civil engineering. Bautechnik 2021, 98, 662–670. [Google Scholar] [CrossRef]

- Krause, D.; Gebhardt, N. Methodische Entwicklung Modularer Produktfamilien; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar] [CrossRef]

- Shafiee, S.; Piroozfar, P.; Hvam, L.; Farr, E.; Huang, G.; Pan, W.; Kudsk, A.; Rasmussen, J.; Korell, M. Modularisation strategies in the AEC industry: A comparative analysis. Archit. Eng. Des. Manag. 2020, 16, 270–292. [Google Scholar] [CrossRef]

- Staib, G.; Dörrhöfer, A.; Rosenthal, M.J. Components and Systems: Modular Construction: Design, Structure, New Technologies/Staib, Dörrhöfer, Rosenthal; Birkhäuser: Basel, Switzerland, 2008. [Google Scholar]

- Sutherland, J.; Humm, D.; Chrimes, M. (Eds.) Historic Concrete: The Background to Appraisal; Thomas Telford Publishing: London, UK, 2001. [Google Scholar] [CrossRef]

- Fernández-Ordóñez Hernández, D. Early Developments of Concrete Prefabrication. In High Tech Concrete: Where Technology and Engineering Meet; Hordijk, D.A., Luković, M., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 2795–2801. [Google Scholar] [CrossRef]

- Steinle, A.; Bachmann, H.; Tillmann, M.; Thrift, P. Precast Concrete Structures, 2nd ed.; Ernst & Sohn: Berlin, Germany, 2019. [Google Scholar]

- Johnson, D.L. On Frank Lloyd Wright’s Concrete Adobe; Routledge: London, UK, 2016. [Google Scholar] [CrossRef]

- Seelow, A. The Construction Kit and the Assembly Line—Walter Gropius’ Concepts for Rationalizing Architecture. Arts 2018, 7, 95. [Google Scholar] [CrossRef]

- Guillén, M. The Taylorized Beauty of the Mechanical: Scientific Management and the Rise of Modernist Architecture. Adm. Sci. Q. 2007, 52, 492–496. [Google Scholar] [CrossRef]

- Bemis, A.F. The Evolving House; The Technology Press, Massachusetts Institute of Technology: Cambridge, MA, USA, 1936; Volume iii. [Google Scholar]

- Russell, A.L. Modularity: An Interdisciplinary History of an Ordering Concept. Inf. Cult. 2012, 47, 257–287. [Google Scholar] [CrossRef]

- Morse-Fortier, L.J. From Frank Lloyd Wrights Usionan Automatic Building System: Lessons and Limitations in a lost Paradigm. J. Archit. Plan. Res. 1994, 11, 274–293. [Google Scholar]

- Herbert, G. The Dream of the Factory-Made House; The MIT Press: Cambridge, MA, USA, 1984. [Google Scholar] [CrossRef]

- Garcia, R.G. Concrete Meccanos: Precast Constructions after the Second World War in the Netherlands. Nuts Bolts Constr. Hist. 2017, 3, 421–429. [Google Scholar]

- Erofeev, N. The I-464 housing delivery system: A tool for urban modernisation in the socialist world and beyond. Fabrications 2019, 29, 207–230. [Google Scholar] [CrossRef]

- Bullock, N. 4000 dwellings from a Paris factory: Le procédé Camus and state sponsorship of industrialised housing in the 1950s. Archit. Res. Q. 2009, 13, 59–72. [Google Scholar] [CrossRef]

- Wouters, I.; Van de Voorde, S.; De Kooning, E. 3D Variel modules in precast concrete in Belgium (1969–1981): The work of Fritz Stucky and Willy Van Der Meeren. In Proceedings of the 10th International Conference on Structural Analysis of Historical Constructions, Leuven, Belgium, 13–15 September 2016; Van Balen, K., Verstrynge, E., Eds.; CRC Press/Balkema (Taylor and Francis Group): Boca Raton, FL, USA, 2016; pp. 953–960. [Google Scholar]

- Zarecor, K.E. The local history of an international type: The structural panel building in Czechoslovakia. Home Cult. 2010, 7, 217–235. [Google Scholar] [CrossRef]

- Jenatsch, G.M.; Krucker, B. Werk Serie—Fritz Stucky, Architekt und Unternehmer; GTA Verlag: Zürich, Switzerland, 2006. [Google Scholar]

- Stucky, F.; Meuli, R. Mehrfamilienhaus nach System Elcon: Architekten: Fritz Stucky und Rudolf Meuli, Zug, Switzerland. 1966. Available online: https://www.e-periodica.ch/digbib/view?pid=wbw-002:1966:53::2321 (accessed on 30 October 2023).

- Stieler, D.; Schwinn, T.; Menges, A. Volumetric intersections: Modularization approaches for freeform prefab concrete construction. Civ. Eng. Des. 2022, 4, 3–13. [Google Scholar] [CrossRef]

- Prilhofer, C. The History of Precast Concrete Elements. WebPage. 2023. Available online: https://www.prilhofer.com/precast-history (accessed on 30 October 2023).

- Elliott, K.S.; Hamid, Z.A. (Eds.) Modernisation, Mechanisation and Industrialisation of Concrete Structures; Wiley Blackwell: Chichester, UK, 2017. [Google Scholar] [CrossRef]

- Sacks, R.; Eastman, C.M.; Lee, G. Parametric 3D modeling in building construction with examples from precast concrete. Autom. Constr. 2004, 13, 291–312. [Google Scholar] [CrossRef]

- Kosse, S.; Vogt, O.; Wolf, M.; König, M.; Gerhard, D. Digital Twin Framework for Enabling Serial Construction. Front. Built Environ. 2022, 8. [Google Scholar] [CrossRef]

- Kosse, S.; Forman, P.; Stindt, J.; Hoppe, J.; König, M.; Mark, P. Industry 4.0 Enabled Modular Precast Concrete Components: A Case Study. In Proceedings of the International RILEM Conference on Synergising Expertise towards Sustainability and Robustness of Cement-based Materials and Concrete Structures, Milos, Greece, 14–16 June 2023; Jędrzejewska, A., Kanavaris, F., Azenha, M., Benboudjema, F., Schlicke, D., Eds.; Springer Nature Switzerland: Cham, Switzerland, 2023; Volume 43, pp. 229–240. [Google Scholar] [CrossRef]

- Zhao, X.; Zayed, T.; Yumin, N. Comparative analysis of modular construction practices in mainland China, Hong Kong and Singapore. J. Clean. Prod. 2020, 245, 118861. [Google Scholar] [CrossRef]

- Mark, P.; Lanza, G.; Lordick, D.; Albers, A.; König, M.; Borrmann, A.; Stempniewski, L.; Forman, P.; Frey, A.M.; Renz, R.; et al. Industrializing precast productions. Civ. Eng. Des. 2021, 3, 87–98. [Google Scholar] [CrossRef]

- Forman, P.; Mark, P. Production tolerances of precast concrete components for modular construction. Beton Stahlbetonbau 2022, 117, 286–295. [Google Scholar] [CrossRef]

- Forman, P.; Penkert, S.; Kämper, C.; Stallmann, T.; Mark, P.; Schnell, J. A survey of solar concrete shell collectors for parabolic troughs. Renew. Sustain. Energy Rev. 2020, 134, 110331. [Google Scholar] [CrossRef]

- Fine, C.H. Clockspeed: Winning Industry Control in the Age of Temporary Advantage; Perseus Books: Reading, UK, 1998. [Google Scholar]

- Baldwin, C.Y.; Clark, K.B. Design Rules: The Power of Modularity; MIT Press: Cambridge, UK, 2014. [Google Scholar] [CrossRef]

- Albers, A.; Scherer, H.; Bursac, N.; Rachenkova, G. Model Based Systems Engineering in Construction Kit Development–Two Case Studies. Procedia CIRP 2015, 36, 129–134. [Google Scholar] [CrossRef][Green Version]

- Lindemann, U.; Maurer, M. Entwicklung und Strukturplanung individualisierter Produkte. In Individualisierte Produkte; Lindemann, U., Reichwald, R., Zäh, M., Eds.; VDI-Buch, Springer: Berlin/Heidelberg, Germany, 2006; pp. 41–62. [Google Scholar] [CrossRef]

- Cao, J.; Bucher, D.F.; Hall, D.M.; Lessing, J. Cross-phase product configurator for modular buildings using kit-of-parts. Autom. Constr. 2021, 123, 103437. [Google Scholar] [CrossRef]

- Winter, S. Bauen mit Weitblick: Systembaukasten für den Industrialisierten Sozialen Wohnungsbau: Abschlussbericht Forschungsvorhaben. 2018. Available online: https://www.zukunftbau.de/projekte/forschungsfoerderung/1008187-1555 (accessed on 30 October 2023).

- Scalice, R.K.; de Andrade, L.F.S.; Forcellini, F.A. A Design Methodology for Module Interfaces. In Collaborative Product and Service Life Cycle Management for a Sustainable World; Springer: London, UK, 2008; pp. 297–304. [Google Scholar] [CrossRef]

- Miller, T.D.; Elgard, P. Design for Integration in Manufacturing: Proceedings of the Thirteenth IPS Research Seminar, Fuglsø, Denmark, 20–21 April 1998; Department of Production Aalborg University: Aalborg, Denmark, 1998. [Google Scholar]

- Manny, A.; Stempniewski, L.; Albers, A.; Simons, K. Conceptual design and investigation of an innovative joint for the rapid and precise assembly of precast UHPC elements. Eng. Struct. 2022, 265, 114454. [Google Scholar] [CrossRef]

- Kolbeck, L.; Vilgertshofer, S.; Borrmann, A. Graph-based mass customisation of modular precast bridge systems -Methodology for kit development and algorithmic design. In Proceedings of the 30th workshop of the European Group for Intelligent Computing in Engineering. European Group for Intelligent Computing in Engineering, London, UK, 4–7 July 2023. [Google Scholar]

- Rettinger, M.; Lounis, A.; Hückler, A.; Schlaich, M. Druckversuche zur Ermittlung der Tragfähigkeit von ebenen und feinverzahnten Trockenfugen für modulare Segmentbrücken. Beton Stahlbetonbau 2023, 118, 662–675. [Google Scholar] [CrossRef]

- Zwicky, F. The Morphological Approach to Discovery, Invention, Research and Construction. In New Methods of Thought and Procedure; Zwicky, F., Wilson, A.G., Eds.; Springer: Berlin/Heidelberg, Germany, 1967; pp. 273–297. [Google Scholar] [CrossRef]

- Berndorfer, C. Hybride Bahnbrücke Bögl–wenn Innovation in Serie geht. Beton Stahlbetonbau 2021, 116, 73–78. [Google Scholar] [CrossRef]

- Bhatti, M.A. Practical Optimization Methods: With Mathematica® Applications; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Kolbeck, L.; Auer, D.; Fischer, O.; Vilgertshofer, S.; Borrmann, A. Modulare Brückenbauwerke aus carbon-faserbewehrtem Ultrahochleistungsbeton – Graph-basierter Entwurf und trajektoriensensitive Fertigung. Beton Stahlbetonbau 2021, 116, 24–33. [Google Scholar] [CrossRef]

- Rettinger, M.; Prziwarzinski, A.; Meyer, M.; Kolbeck, L.; Tošić, Z.; Hueckler, A.; Lordick, D.; Borrmann, A.; Haist, M.; Lohaus, L.; et al. Modulare Fußgängerbrücken aus seriell hergestellten Betonfertigteilen – Entwürfe aus dem DFG-Schwerpunktprogramm 2187. Beton Stahlbetonbau 2023, 118, 56. [Google Scholar] [CrossRef]

- Tošić, Z.; Eichenauer, M.F.; Ivaniuk, E.; Lordick, D.; Krasić, S.; Mechtcherine, V. Design and optimization of free-form surfaces for modular concrete 3D printing. Autom. Constr. 2022, 141, 104432. [Google Scholar] [CrossRef]

- Pottmann, H.; Schiftner, A.; Bo, P.; Schmiedhofer, H.; Wang, W.; Baldassini, N.; Wallner, J. Freeform surfaces from single curved panels. ACM Trans. Graph. 2008, 27, 1–10. [Google Scholar] [CrossRef]

- Gao, S.; Jin, R.; Lu, W. Design for manufacture and assembly in construction: A review. Build. Res. Inf. 2023, 118, 538–550. [Google Scholar] [CrossRef]

- Xiao, J.; Ji, G.; Zhang, Y.; Ma, G.; Mechtcherine, V.; Pan, J.; Wang, L.; Ding, T.; Duan, Z.; Du, S. Large-scale 3D printing concrete technology: Current status and future opportunities. Cem. Concr. Compos. 2021, 122, 104115. [Google Scholar] [CrossRef]

- Brütting, J.; Senatore, G.; Fivet, C. Form follows availability–Designing structures through reuse. J. Int. Assoc. Shell Spat. Struct. 2019, 60, 257–265. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).