Investigation on the Crashworthiness Performance of Thin-Walled Multi-Cell PLA 3D-Printed Tubes: A Multi-Parameter Analysis

Abstract

:1. Introduction

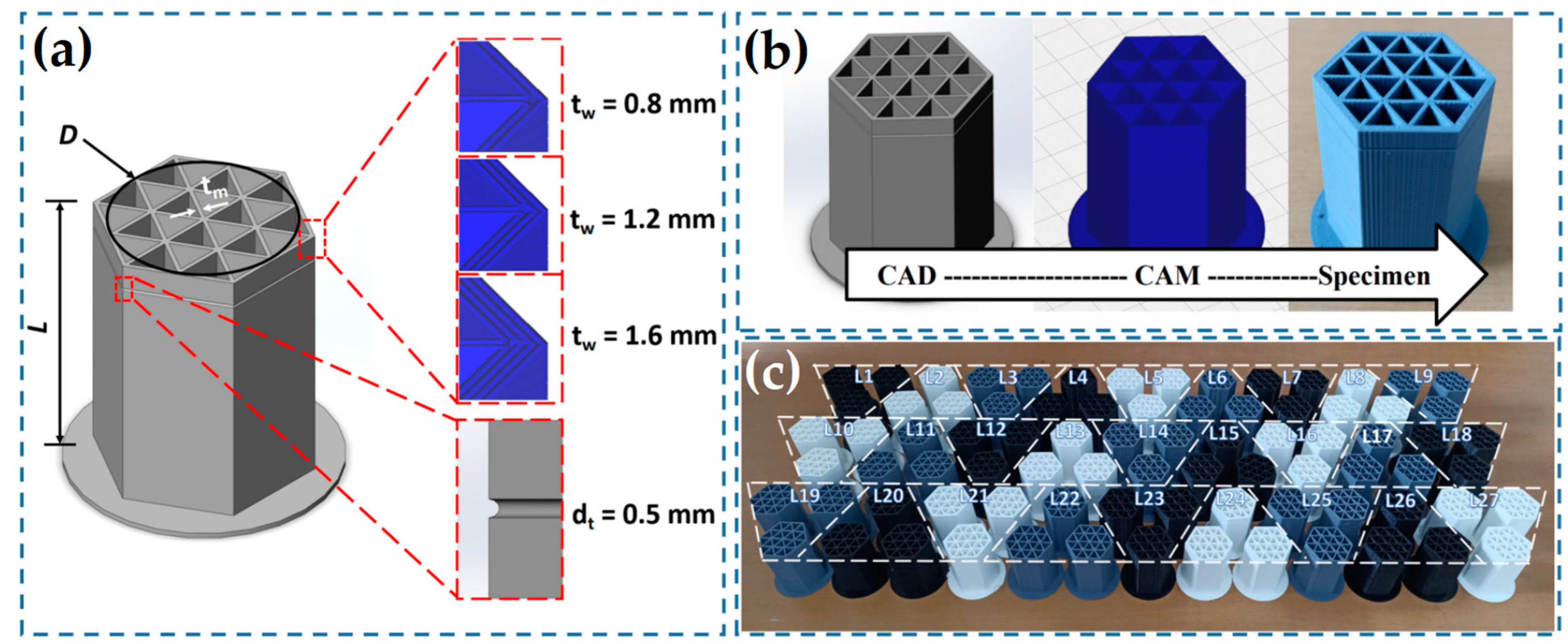

2. Experimental Procedure

2.1. Materials and Processing

2.2. Experimental Methods

2.3. Determination of Optimal Printing Parameters

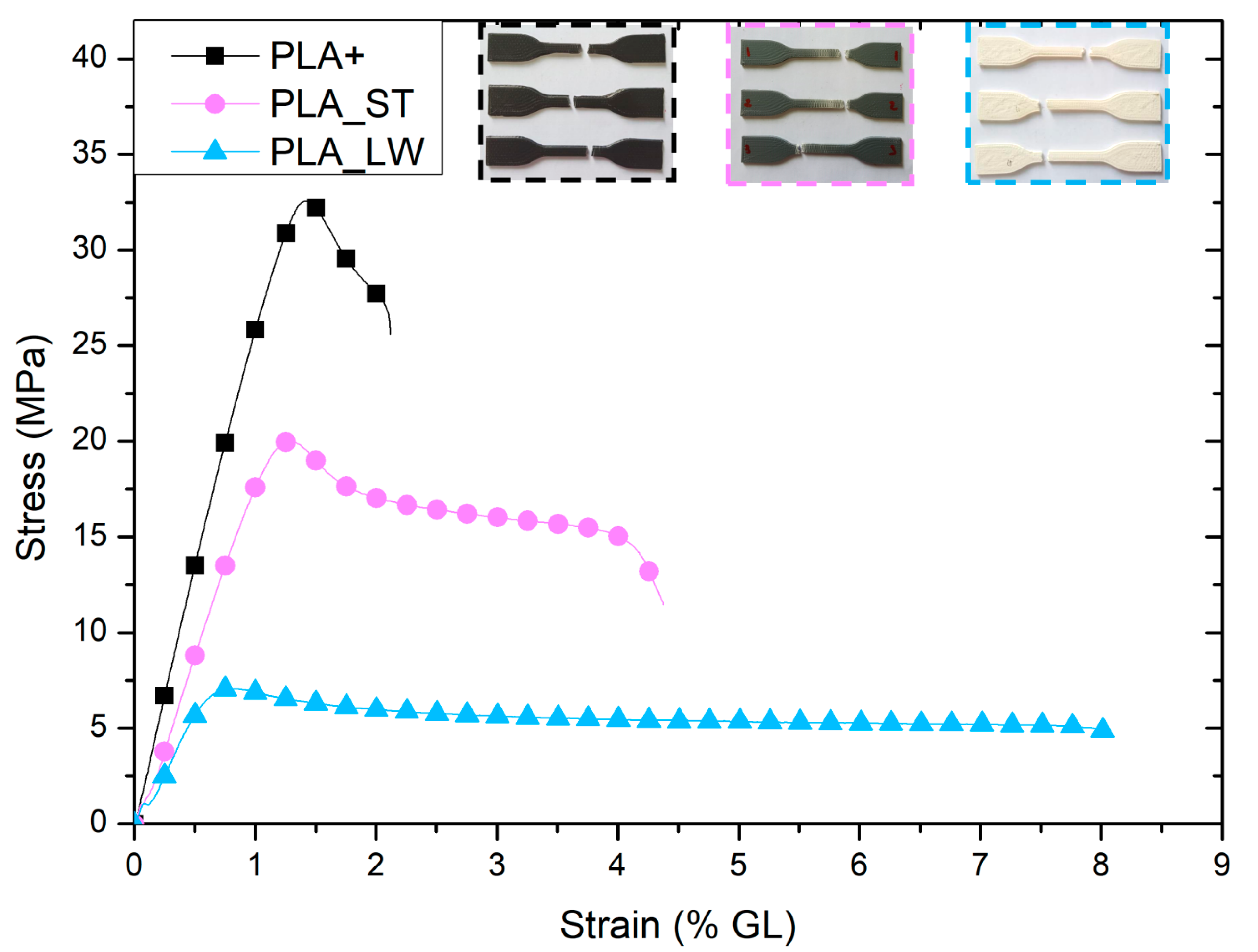

2.4. Tensile Properties

2.5. Crashworthiness Performance

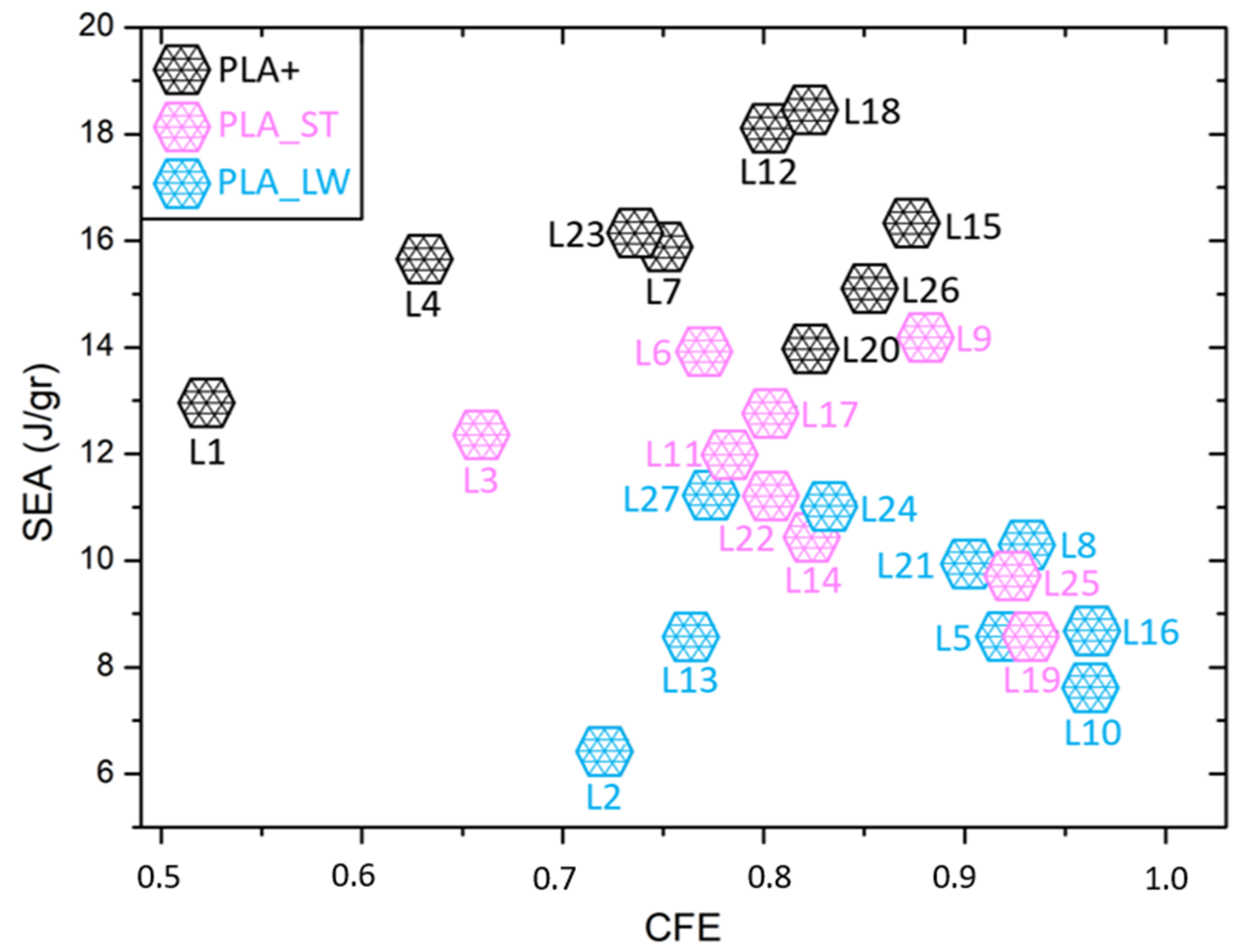

3. Results and Discussion

3.1. Mechanical Characterization of PLA Series

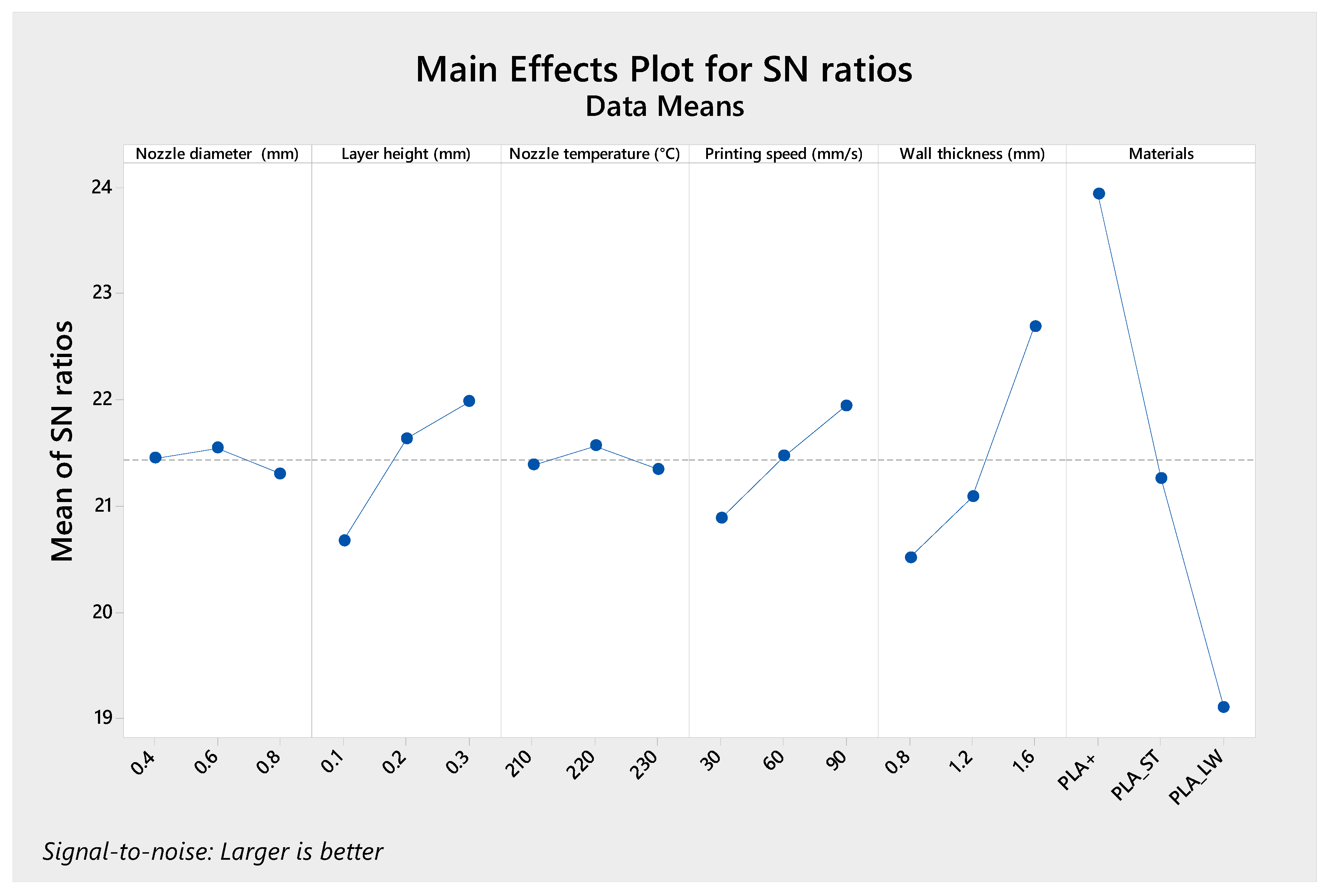

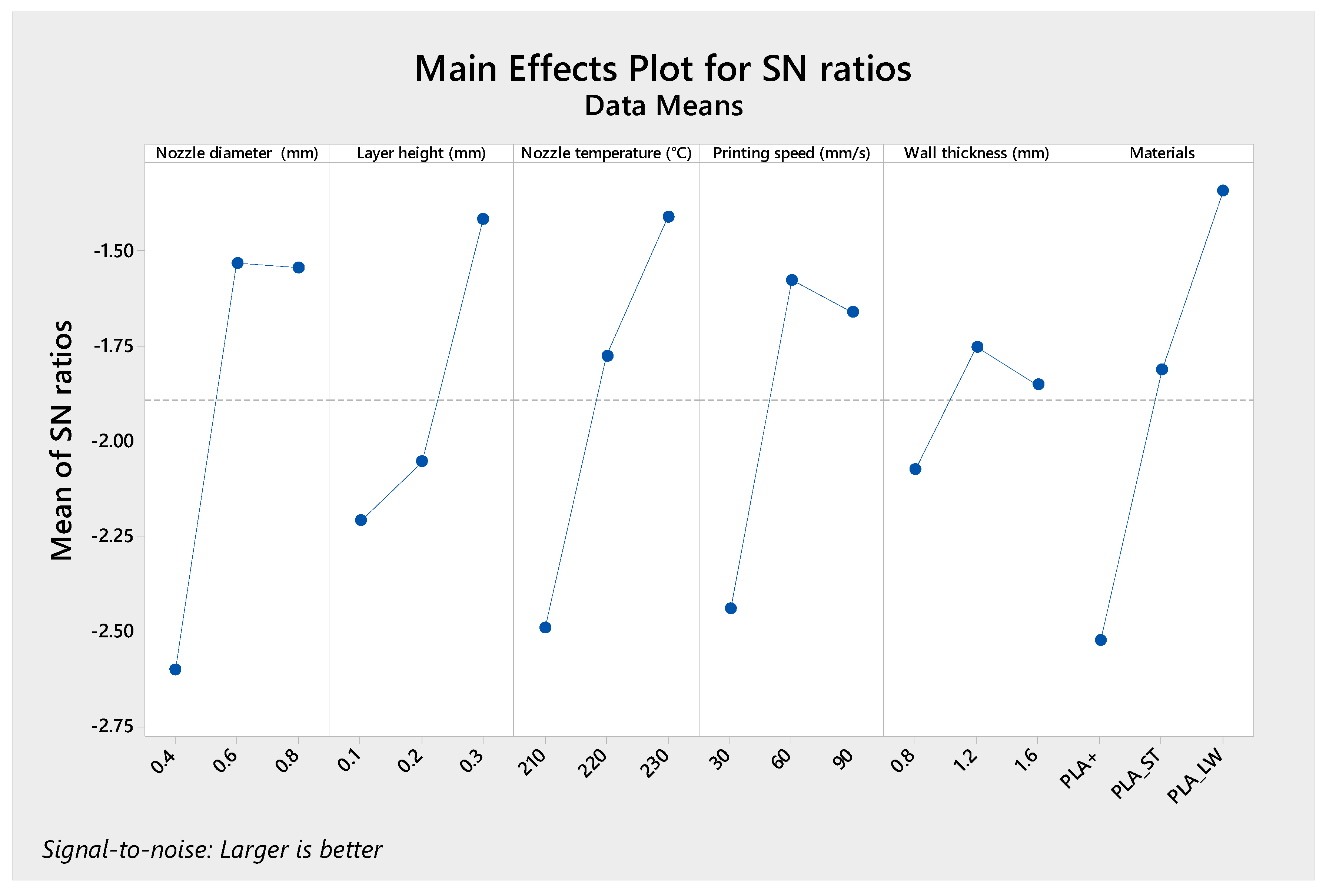

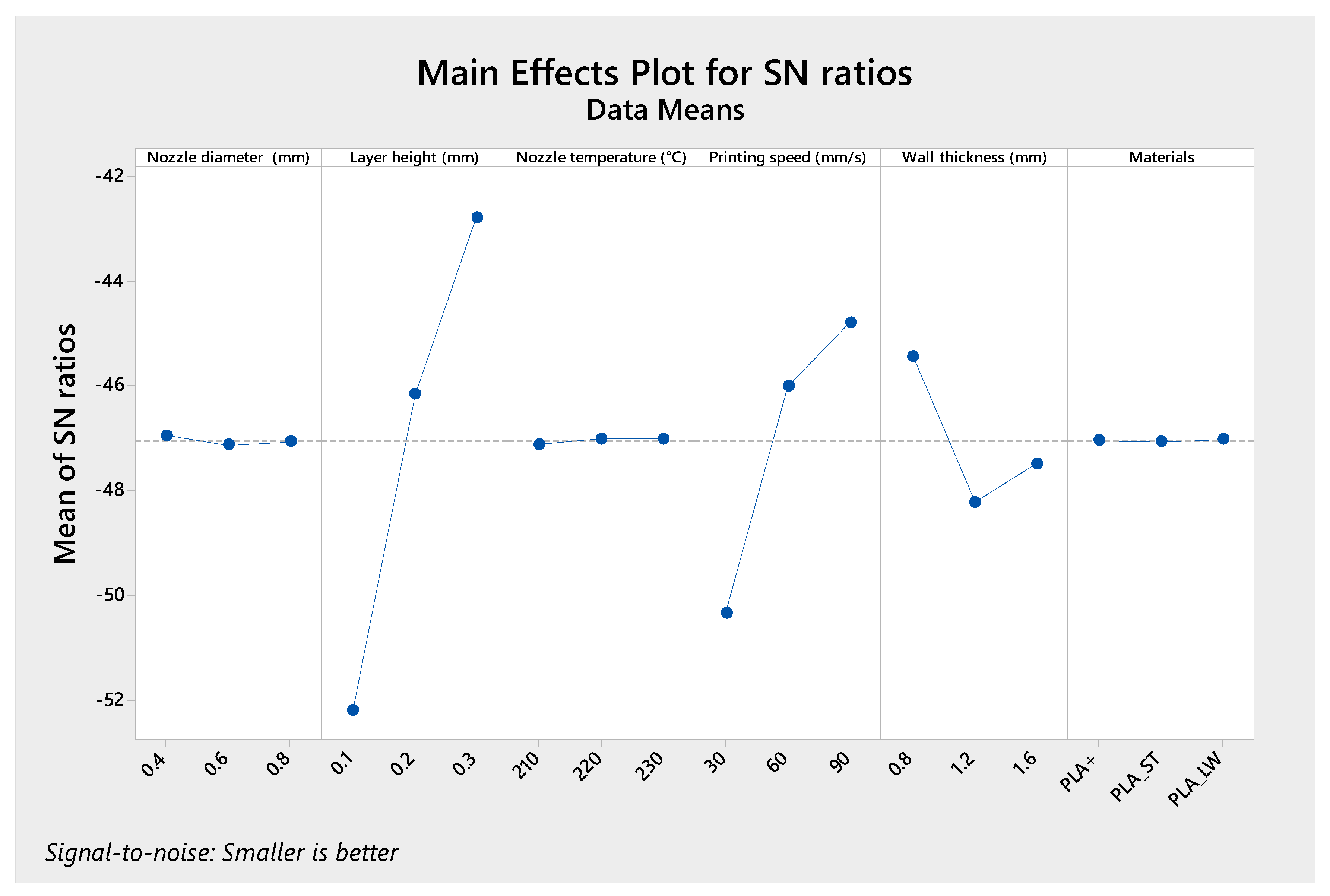

3.2. Analysis of S/N Ratio for Crashworthiness Performance

3.3. Analysis of Variance

3.4. Regression Analysis

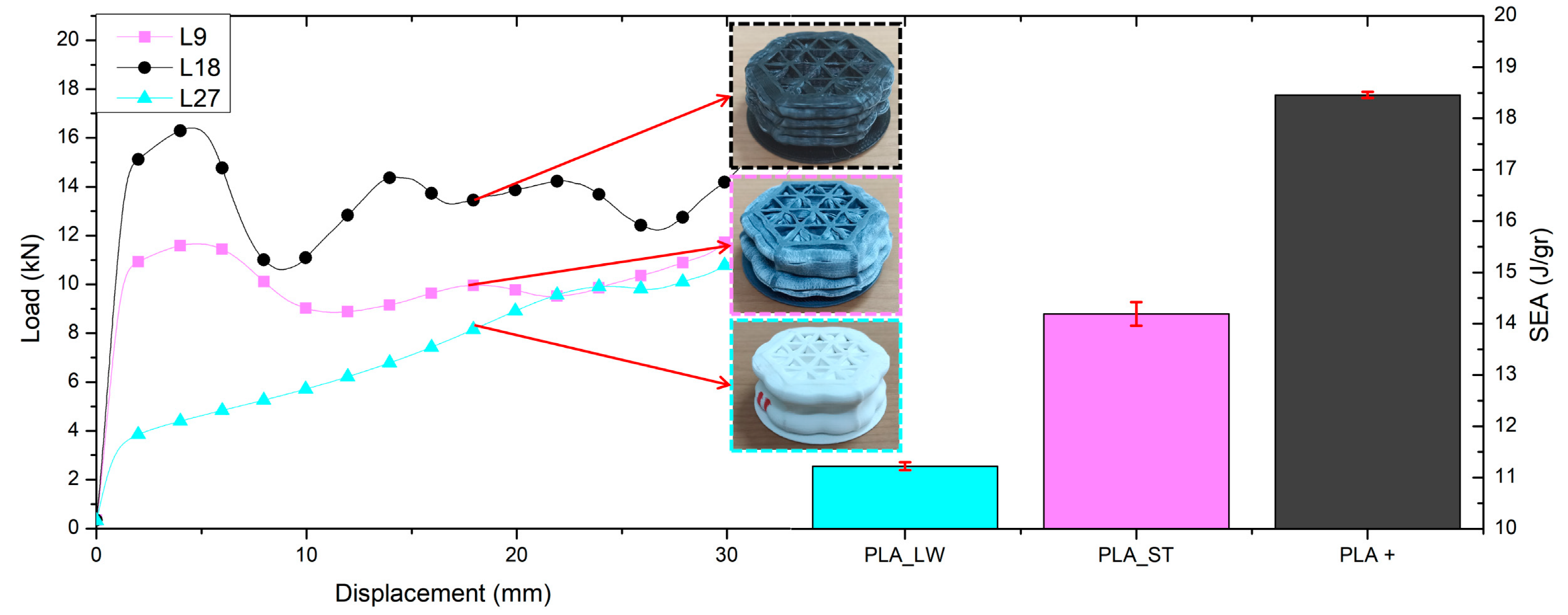

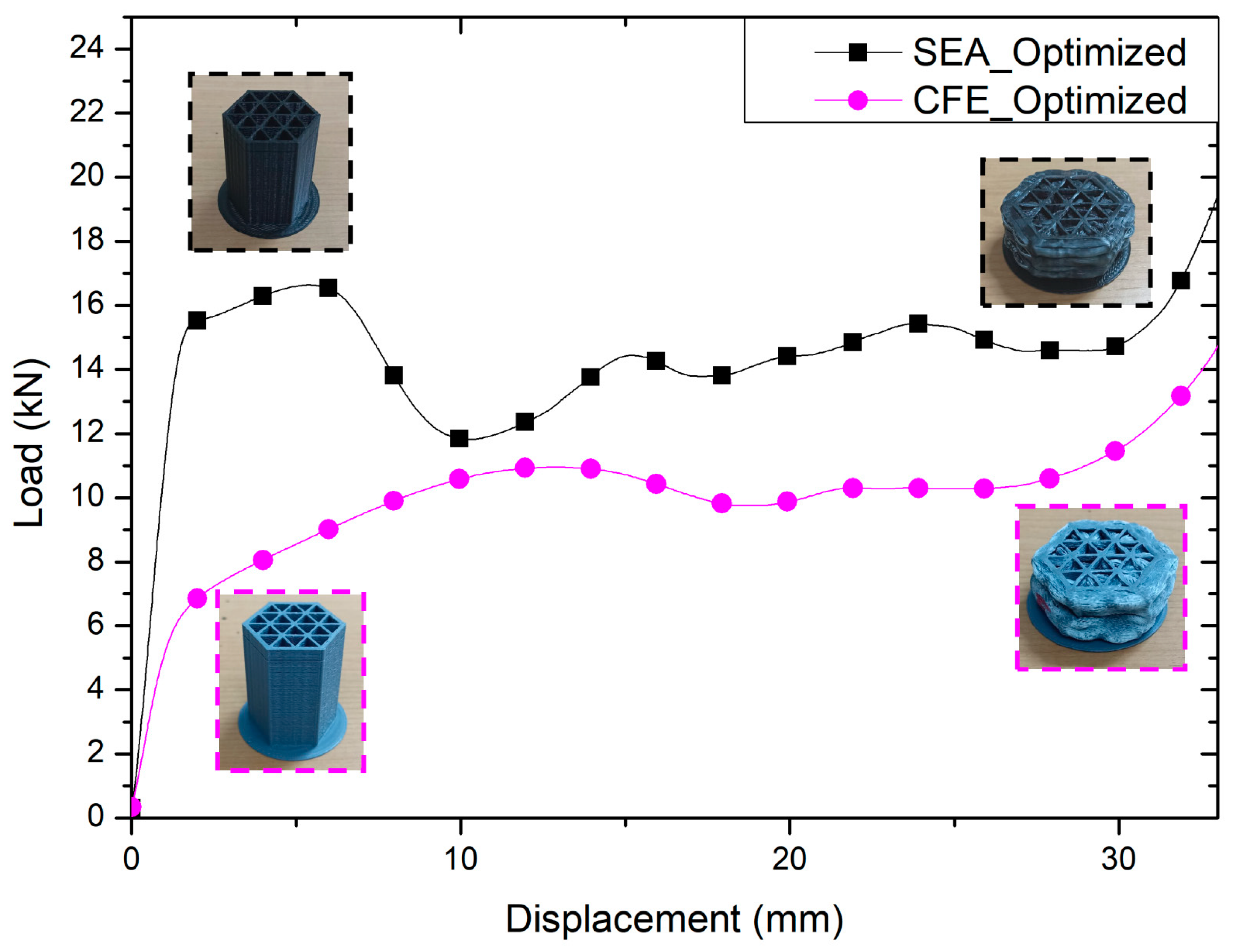

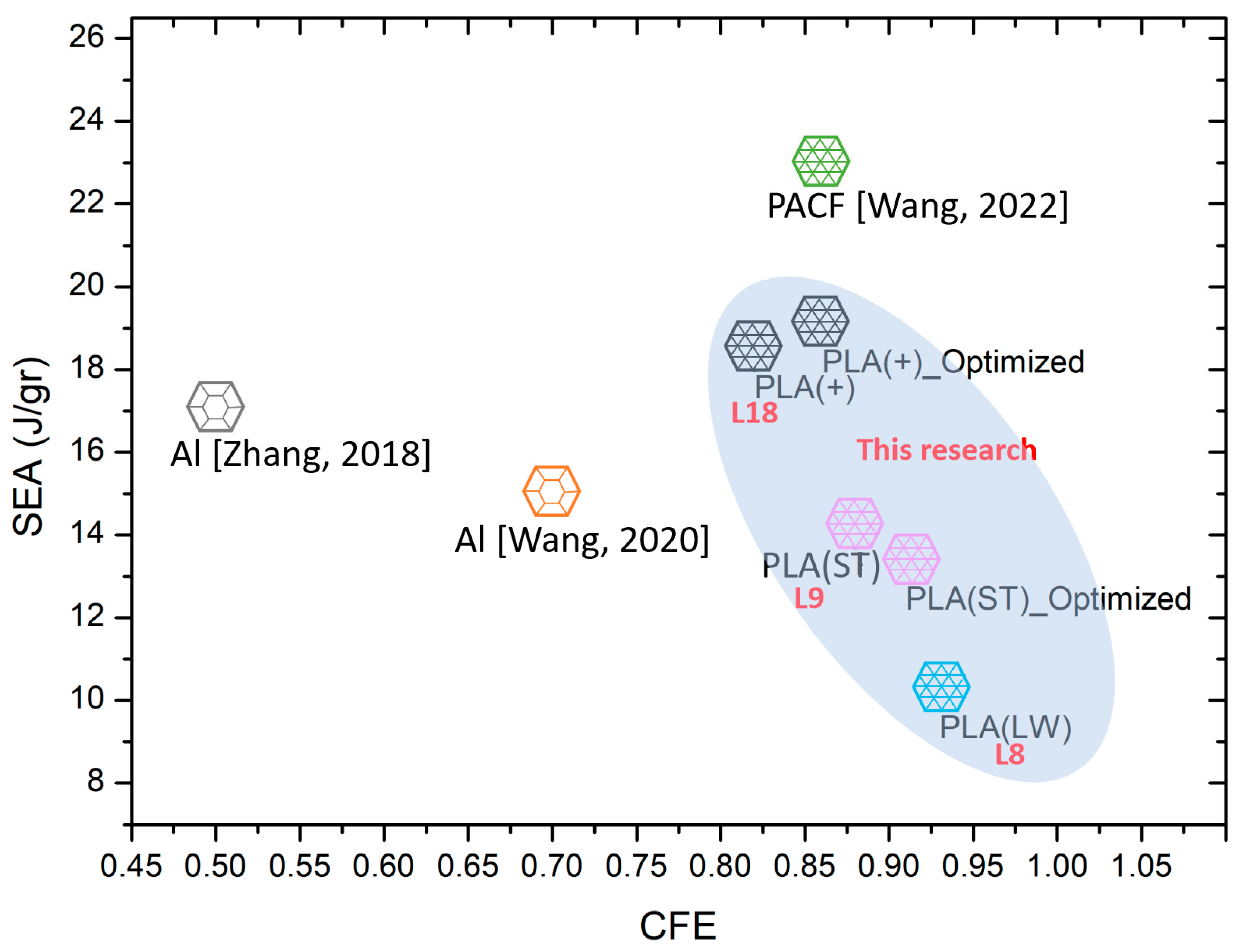

3.5. Experimental Verification of the Optimal Combinations

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Palomba, G.; Epasto, G.; Crupi, V. Lightweight sandwich structures for marine applications: A review. Mech. Adv. Mater. Struct. 2022, 29, 4839–4864. [Google Scholar]

- Mou, H.; Xie, J.; Feng, Z. Research status and future development of crashworthiness of civil aircraft fuselage structures: An overview. Prog. Aerosp. Sci. 2020, 119, 100644. [Google Scholar]

- Tang, Z.; Liu, S.; Zhang, Z. Analysis of energy absorption characteristics of cylindrical multi-cell columns. Thin-Walled Struct. 2013, 62, 75–84. [Google Scholar]

- Hou, S.; Li, Q.; Long, S.; Yang, X.; Li, W. Multiobjective optimization of multi-cell sections for the crashworthiness design. Int. J. Impact Eng. 2008, 35, 1355–1367. [Google Scholar]

- Qiu, N.; Gao, Y.; Fang, J.; Feng, Z.; Sun, G.; Li, Q. Crashworthiness analysis and design of multi-cell hexagonal columns under multiple loading cases. Finite Elem. Anal. Des. 2015, 104, 89–101. [Google Scholar]

- Zhang, X.; Cheng, G. A comparative study of energy absorption characteristics of foam-filled and multi-cell square columns. Int. J. Impact Eng. 2007, 34, 1739–1752. [Google Scholar]

- Sun, G.; Liu, T.; Huang, X.; Zheng, G.; Li, Q. Topological configuration analysis and design for foam filled multi-cell tubes. Eng. Struct. 2018, 155, 235–250. [Google Scholar]

- Sathies, T.; Senthil, P.; Anoop, M. A review on advancements in applications of fused deposition modelling process. Rapid Prototyp. J. 2020, 26, 669–687. [Google Scholar]

- Mohammadi, M.; Kouzani, A.Z.; Bodaghi, M.; Xiang, Y.; Zolfagharian, A. 3D-Printed Phase-Change Artificial Muscles with Autonomous Vibration Control. Adv. Mater. Technol. 2023, 2300199. [Google Scholar] [CrossRef]

- Meram, A.; Sözen, B. Experimental investigation on the effect of printing parameters on the impact response of thin-walled tubes produced by additive manufacturing method. Int. J. Crashworth. 2022, 28, 32–45. [Google Scholar]

- Zeenat, L.; Zolfagharian, A.; Sriya, Y.; Sasikumar, S.; Bodaghi, M.; Pati, F. 4D Printing for Vascular Tissue Engineering: Progress and Challenges. Adv. Mater. Technol. 2023, 2300200. [Google Scholar] [CrossRef]

- Gupta, B.; Revagade, N.; Hilborn, J. Poly (lactic acid) fiber: An overview. Prog. Polym. Sci. 2007, 32, 455–482. [Google Scholar]

- Wittbrodt, B.; Pearce, J.M. The effects of PLA color on material properties of 3-D printed components. Addit. Manuf. 2015, 8, 110–116. [Google Scholar]

- Lokesh, N.; Praveena, B.; Reddy, J.S.; Vasu, V.K.; Vijaykumar, S. Evaluation on effect of printing process parameter through Taguchi approach on mechanical properties of 3D printed PLA specimens using FDM at constant printing temperature. Mater. Today: Proc. 2022, 52, 1288–1293. [Google Scholar]

- Isaac, C.W.; Duddeck, F. Current trends in additively manufactured (3D printed) energy absorbing structures for crashworthiness application—A review. Virtual Phys. Prototyp. 2022, 17, 1058–1101. [Google Scholar]

- Hidayat, D.; Istiyanto, J.; Nabilah, J.D.; Ardiansyah, R.; Saptari, S.A.; Kurniawan, F.; Sumarsono, D.A. Experimental investigation on axial quasi-static crushing of Al/PLA hybrid tubes. In Proceedings of the 2022 International Conference on Mechanical, Aerospace and Automotive Engineering, Beijing, China, 2–4 December 2023; 2023. [Google Scholar]

- Fu, X.; Zhang, X.; Huang, Z. Axial crushing of Nylon and Al/Nylon hybrid tubes by FDM 3D printing. Compos. Struct. 2021, 256, 113055. [Google Scholar]

- Wang, J.; Xiang, J.; Lin, H.; Wang, K.; Yao, S.; Peng, Y.; Rao, Y. Effects of scanning strategy and printing temperature on the compressive behaviors of 3D printed polyamide-based composites. Polymers 2020, 12, 1783. [Google Scholar]

- Nian, Y.; Wan, S.; Li, M.; Su, Q. Crashworthiness design of self-similar graded honeycomb-filled composite circular structures. Constr. Build. Mater. 2020, 233, 117344. [Google Scholar]

- Liu, Y.; Wang, J.; Cai, R.; Xiang, J.; Wang, K.; Yao, S.; Peng, Y. Effects of loading rate and temperature on crushing behaviors of 3D printed multi-cell composite tubes. Thin-Walled Struct. 2023, 182, 110311. [Google Scholar]

- Wang, K.; Liu, Y.; Wang, J.; Xiang, J.; Yao, S.; Peng, Y. On crashworthiness behaviors of 3D printed multi-cell filled thin-walled structures. Eng. Struct. 2022, 254, 113907. [Google Scholar]

- Tsouknidas, A.; Pantazopoulos, M.; Katsoulis, I.; Fasnakis, D.; Maropoulos, S.; Michailidis, N. Impact absorption capacity of 3D-printed components fabricated by fused deposition modelling. Mater. Des. 2016, 102, 41–44. [Google Scholar] [CrossRef]

- Nugroho, A.; Ardiansyah, R.; Rusita, L.; Larasati, I.L. Effect of layer thickness on flexural properties of PLA (PolyLactid Acid) by 3D printing. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2018. [Google Scholar]

- Harpool, T.D. Observing the Effect of Infill Shapes on the Tensile Characteristics of 3D Printed Plastic Parts. Master’s Thesis, Wichita State University, Wichita, KS, USA, 2016. [Google Scholar]

- Qattawi, A.; Alrawi, B.; Guzman, A. Experimental optimization of fused deposition modelling processing parameters: A design-for-manufacturing approach. Procedia Manuf. 2017, 10, 791–803. [Google Scholar]

- Hikmat, M.; Rostam, S.; Ahmed, Y.M. Investigation of tensile property-based Taguchi method of PLA parts fabricated by FDM 3D printing technology. Results Eng. 2021, 11, 100264. [Google Scholar] [CrossRef]

- Shenzhen Esun Industrial Co., Ltd. 2023. Available online: https://www.esun3d.com/ (accessed on 7 February 2023).

- Wang, Z.; Zhang, J.; Li, Z.; Shi, C. On the crashworthiness of bio-inspired hexagonal prismatic tubes under axial compression. Int. J. Mech. Sci. 2020, 186, 105893. [Google Scholar] [CrossRef]

- Yang, Z.; Yu, Y.; Wei, Y.; Huang, C. Crushing behavior of a thin-walled circular tube with internal gradient grooves fabricated by SLM 3D printing. Thin-Walled Struct. 2017, 111, 1–8. [Google Scholar] [CrossRef]

- Taguchi, G.; Phadke, M.S. Quality Engineering through Design Optimization. Quality Control, Robust Design, and the Taguchi Method; Springer: Boston, MA, USA, 1989; pp. 77–96. [Google Scholar]

- De Bruijn, A.C.; Gómez-Gras, G.; Fernández-Ruano, L.; Farràs-Tasias, L.; Pérez, M.A. Optimization of a combined thermal annealing and isostatic pressing process for mechanical and surface enhancement of Ultem FDM parts using Doehlert experimental designs. J. Manuf. Process. 2023, 85, 1096–1115. [Google Scholar] [CrossRef]

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM: West Conshohocken, PA, USA, 2014.

- Sun, G.; Li, S.; Liu, Q.; Li, G.; Li, Q. Experimental study on crashworthiness of empty/aluminum foam/honeycomb-filled CFRP tubes. Compos. Struct. 2016, 152, 969–993. [Google Scholar] [CrossRef]

- Hidayat, D.; Nurrohmad, A.; Nugroho, A.; Isna, L.R. Experimental investigation on crashworthiness characteristics of e-glass–lycal composite tube and local product aluminum tube using quasi-static crushing test. In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2020. [Google Scholar]

- Zhu, G.; Liao, J.; Sun, G.; Li, Q. Comparative study on metal/CFRP hybrid structures under static and dynamic loading. Int. J. Impact Eng. 2020, 141, 103509. [Google Scholar] [CrossRef]

- Yao, R.; Pang, T.; Zhang, B.; Fang, J.; Li, Q.; Sun, G. On the crashworthiness of thin-walled multi-cell structures and materials: State of the art and prospects. Thin-Walled Struct. 2023, 189, 110734. [Google Scholar] [CrossRef]

- Agaliotis, E.M.; Ake-Concha, B.D.; May-Pat, A.; Morales-Arias, J.P.; Bernal, C.; Valadez-Gonzalez, A.; Herrera-Franco, P.J.; Proust, G.; Koh-Dzul, J.F.; Carrillo, J.G.; et al. Tensile Behavior of 3D Printed Polylactic Acid (PLA) Based Composites Reinforced with Natural Fiber. Polymers 2022, 14, 3976. [Google Scholar] [CrossRef]

- MAwd Allah, M.; Abdel-Aziem, W.; AAbd El-baky, M. Collapse Behavior and Energy Absorbing Characteristics of 3D-Printed Tubes with Different Infill Pattern Structures: An Experimental Study. Fibers Polym. 2023, 24, 2609–2622. [Google Scholar] [CrossRef]

- Liao, Y.; Liu, C.; Coppola, B.; Barra, G.; Di Maio, L.; Incarnato, L.; Lafdi, K. Effect of porosity and crystallinity on 3D printed PLA properties. Polymers 2019, 11, 1487. [Google Scholar] [CrossRef] [PubMed]

- Afshar, R.; Jeanne, S.; Abali, B.E. Nonlinear Material Modeling for Mechanical Characterization of 3-D Printed PLA Polymer With Different Infill Densities. Appl. Compos. Mater. 2023, 30, 987–1001. [Google Scholar] [CrossRef]

- Bakar, M.S.A.; Salit, M.S.; Yusoff MZ, M.; Zainudin, E.S.; Ya, H.H. The crashworthiness performance of stacking sequence on filament wound hybrid composite energy absorption tube subjected to quasi-static compression load. J. Mater. Res. Technol. 2020, 9, 654–666. [Google Scholar] [CrossRef]

- Huo, X.; Sun, G.; Zhang, H.; Lv, X.; Li, Q. Experimental study on low-velocity impact responses and residual properties of composite sandwiches with metallic foam core. Compos. Struct. 2019, 223, 110835. [Google Scholar] [CrossRef]

- Abeykoon, C.; Sri-Amphorn, P.; Fernando, A. Optimization of fused deposition modeling parameters for improved PLA and ABS 3D printed structures. Int. J. Lightweight Mater. Manuf. 2020, 3, 284–297. [Google Scholar] [CrossRef]

- Huang, Z.; Zhang, X.; Yang, C. Static and dynamic axial crushing of Al/CRFP hybrid tubes with single-cell and multi-cell sections. Compos. Struct. 2019, 226, 111023. [Google Scholar] [CrossRef]

- Zolfagharian, A.; Bodaghi, M.; Hamzehei, R.; Parr, L.; Fard, M.; Rolfe, B.F. 3D-printed programmable mechanical metamaterials for vibration isolation and buckling control. Sustainability 2022, 14, 6831. [Google Scholar] [CrossRef]

- Yousefi, A.; Jolaiy, S.; Dezaki, M.L.; Zolfagharian, A.; Serjouei, A.; Bodaghi, M. 3D-Printed Soft and Hard Meta-Structures with Supreme Energy Absorption and Dissipation Capacities in Cyclic Loading Conditions. Adv. Eng. Mater. 2023, 25, 2201189. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, J.; Wang, C.; Zeng, Y.; Chen, T. Crashworthiness of bionic fractal hierarchical structures. Mater. Des. 2018, 158, 147–159. [Google Scholar] [CrossRef]

| Properties | PLA(+) | PLA(LW) | PLA(ST) |

|---|---|---|---|

| Density (g/cm3) | 1.23 | 1.2 | 1.25 |

| Tensile Strength (MPa) | 63 | 32.2 | 34.3 |

| Elongation at Break (%) | 20 | 68.9 | 90 |

| Flexural Strength (MPa) | 74 | 41.31 | 43 |

| Flexural Modulus (MPa) | 1973 | 1701 | 1477 |

| IZOD Impact Strength (kJ/m2) | 9 | 8.58 | 63 |

| Symbol | Parameter | Level | Unit | ||

|---|---|---|---|---|---|

| 1 | 2 | 3 | |||

| A | Nozzle diameter | 0.4 | 0.6 | 0.8 | mm |

| B | Layer height | 0.1 | 0.2 | 0.3 | mm |

| C | Nozzle temperature | 210 | 220 | 230 | °C |

| D | Printing speed | 30 | 60 | 90 | mm/s |

| E | Wall thickness | 0.8 | 1.2 | 1.6 | mm |

| F | Materials | PLA(+) | PLA(LW) | PLA(ST) | - |

| Filament | Young’s Modulus (GPa) | Tensile Strength (MPa) | Breakpoint Strain (% GL) |

|---|---|---|---|

| PLA(+) | 2.72 | 31.48 | 1.46 |

| PLA(LW) | 1.43 | 6.96 | 0.35 |

| PLA(ST) | 2.14 | 20.93 | 0.91 |

| Experiment Number | Parameter | SEA | CFE | Manufacturing Time | |||||

|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | (J/gr) | (min) | ||

| L1 | 0.4 | 0.1 | 210 | 30 | 0.8 | PLA(+) | 12.98 | 0.52 | 515 |

| L2 | 0.4 | 0.1 | 210 | 30 | 1.2 | PLA(LW) | 6.44 | 0.72 | 658 |

| L3 | 0.4 | 0.1 | 210 | 30 | 1.6 | PLA(ST) | 12.37 | 0.66 | 613 |

| L4 | 0.4 | 0.2 | 220 | 60 | 0.8 | PLA(+) | 15.64 | 0.63 | 147 |

| L5 | 0.4 | 0.2 | 220 | 60 | 1.2 | PLA(LW) | 8.62 | 0.92 | 203 |

| L6 | 0.4 | 0.2 | 220 | 60 | 1.6 | PLA(ST) | 13.92 | 0.77 | 187 |

| L7 | 0.4 | 0.3 | 230 | 90 | 0.8 | PLA(+) | 15.89 | 0.75 | 81 |

| L8 | 0.4 | 0.3 | 230 | 90 | 1.2 | PLA(LW) | 10.25 | 0.93 | 124 |

| L9 | 0.4 | 0.3 | 230 | 90 | 1.6 | PLA(ST) | 14.19 | 0.88 | 114 |

| L10 | 0.6 | 0.1 | 220 | 90 | 0.8 | PLA(LW) | 7.57 | 0.96 | 252 |

| L11 | 0.6 | 0.1 | 220 | 90 | 1.2 | PLA(ST) | 11.97 | 0.78 | 367 |

| L12 | 0.6 | 0.1 | 220 | 90 | 1.6 | PLA(+) | 18.12 | 0.80 | 340 |

| L13 | 0.6 | 0.2 | 230 | 30 | 0.8 | PLA(LW) | 8.58 | 0.76 | 260 |

| L14 | 0.6 | 0.2 | 230 | 30 | 1.2 | PLA(ST) | 10.50 | 0.82 | 331 |

| L15 | 0.6 | 0.2 | 230 | 30 | 1.6 | PLA(+) | 16.30 | 0.87 | 308 |

| L16 | 0.6 | 0.3 | 210 | 60 | 0.8 | PLA(LW) | 8.72 | 0.96 | 103 |

| L17 | 0.6 | 0.3 | 210 | 60 | 1.2 | PLA(ST) | 12.79 | 0.80 | 142 |

| L18 | 0.6 | 0.3 | 210 | 60 | 1.6 | PLA(+) | 18.46 | 0.82 | 132 |

| L19 | 0.8 | 0.1 | 230 | 60 | 0.8 | PLA(ST) | 8.59 | 0.93 | 304 |

| L20 | 0.8 | 0.1 | 230 | 60 | 1.2 | PLA(+) | 13.94 | 0.82 | 423 |

| L21 | 0.8 | 0.1 | 230 | 60 | 1.6 | PLA(LW) | 9.94 | 0.90 | 364 |

| L22 | 0.8 | 0.2 | 210 | 90 | 0.8 | PLA(ST) | 11.24 | 0.80 | 126 |

| L23 | 0.8 | 0.2 | 210 | 90 | 1.2 | PLA(+) | 16.03 | 0.74 | 184 |

| L24 | 0.8 | 0.2 | 210 | 90 | 1.6 | PLA(LW) | 11.01 | 0.83 | 171 |

| L25 | 0.8 | 0.3 | 220 | 30 | 0.8 | PLA(ST) | 9.70 | 0.92 | 175 |

| L26 | 0.8 | 0.3 | 220 | 30 | 1.2 | PLA(+) | 15.11 | 0.85 | 223 |

| L27 | 0.8 | 0.3 | 220 | 30 | 1.6 | PLA(LW) | 11.22 | 0.77 | 207 |

| Level | Nozzle Diameter (mm) | Layer Height (mm) | Nozzle Temperature (°C) | Printing Speed (mm/s) | Wall Thickness (mm) | Materials |

|---|---|---|---|---|---|---|

| 1 | 21.45 | 20.68 | 21.39 | 20.88 | 20.52 | 23.94 |

| 2 | 21.55 | 21.64 | 21.57 | 21.47 | 21.09 | 21.26 |

| 3 | 21.31 | 21.99 | 21.35 | 21.95 | 22.70 | 19.11 |

| Delta | 0.24 | 1.31 | 0.22 | 1.07 | 2.18 | 4.84 |

| Rank | 5 | 3 | 6 | 4 | 2 | 1 |

| Level | Nozzle Diameter (mm) | Layer Height (mm) | Nozzle Temperature (°C) | Printing Speed (mm/s) | Wall Thickness (mm) | Materials |

|---|---|---|---|---|---|---|

| 1 | −2.60 | −2.21 | −2.49 | −2.44 | −2.07 | −2.52 |

| 2 | −1.53 | −2.05 | −1.77 | −1.58 | −1.75 | −1.81 |

| 3 | −1.54 | −1.42 | −1.41 | −1.66 | −1.85 | −1.34 |

| Delta | 1.07 | 0.79 | 1.08 | 0.86 | 0.32 | 1.18 |

| Rank | 3 | 5 | 2 | 4 | 6 | 1 |

| Level | Nozzle Diameter (mm) | Layer Height (mm) | Nozzle Temperature (°C) | Printing Speed (mm/s) | Wall Thickness (mm) | Materials |

|---|---|---|---|---|---|---|

| 1 | −46.94 | −52.19 | −47.11 | −50.33 | −45.43 | −47.04 |

| 2 | −47.13 | −46.15 | −47.00 | −46.01 | −48.21 | −47.07 |

| 3 | −47.06 | −42.78 | −47.01 | −44.79 | −47.48 | −47.02 |

| Delta | 0.19 | 9.41 | 0.11 | 5.54 | 2.78 | 0.05 |

| Rank | 4 | 1 | 5 | 2 | 3 | 6 |

| SEA (J/gr) | |||||

|---|---|---|---|---|---|

| Source | SEA | ||||

| DF | Contribution (%) | Adj SS | Adj MS | p-Value | |

| Nozzle diameter (mm) | 1 | 0.25 | 0.692 | 0.692 | 0.303 |

| Layer height (mm) | 1 | 4.16 | 11.543 | 11.543 | 0.000 |

| Nozzle temperature (°C) | 1 | 0.07 | 0.187 | 0.187 | 0.589 |

| Printing speed (mm/s) | 1 | 3.42 | 9.495 | 9.495 | 0.001 |

| Wall thickness (mm) | 1 | 14.17 | 39.340 | 39.340 | 0.000 |

| Materials | 2 | 73.70 | 204.577 | 102.289 | 0.000 |

| Error | 19 | 4.23 | 11.747 | 0.618 | |

| Total | 26 | 100.00 | |||

| CFE | |||||

| Source | CFE | ||||

| DF | Contribution (%) | Adj SS | Adj MS | p-Value | |

| Nozzle diameter (mm) | 1 | 11.88 | 0.033599 | 0.033599 | 0.035 |

| Layer height (mm) | 1 | 6.68 | 0.018892 | 0.018892 | 0.105 |

| Nozzle temperature (°C) | 1 | 13.49 | 0.038145 | 0.038145 | 0.026 |

| Printing speed (mm/s) | 1 | 6.58 | 0.018605 | 0.018605 | 0.107 |

| Wall thickness (mm) | 1 | 0.13 | 0.000369 | 0.000369 | 0.814 |

| Materials | 2 | 17.53 | 0.049573 | 0.024786 | 0.041 |

| Error | 19 | 43.70 | 0.123560 | 0.006503 | |

| Total | 26 | 100.00 | |||

| Manufacturing time (min) | |||||

| Source | Time | ||||

| DF | Contribution (%) | Adj SS | Adj MS | p-Value | |

| Nozzle diameter (mm) | 1 | 1.99 | 12,013 | 12,013 | 0.119 |

| Layer height (mm) | 1 | 59.13 | 357,013 | 357,013 | 0.000 |

| Nozzle temperature (°C) | 1 | 1.03 | 6235 | 6235 | 0.255 |

| Printing speed (mm/s) | 1 | 21.57 | 130,220 | 130,220 | 0.000 |

| Wall thickness (mm) | 1 | 2.06 | 12,429 | 12,429 | 0.114 |

| Materials | 2 | 0.00 | 17 | 8 | 0.998 |

| Error | 19 | 14.22 | 85,861 | 4519 | |

| Total | 26 | 100.00 | |||

| Response Parameter | Variable | Setting | Prediction Value | Experimental Value | Percentage Error (%) |

|---|---|---|---|---|---|

| SEA (J/gr) | Nozzle diameter (mm) | 0.6 | 19.41 | 19.08 | 1.73 |

| Layer height (mm) | 0.3 | ||||

| Nozzle temperature (°C) | 220 | ||||

| Printing speed (mm/s) | 90 | ||||

| Wall thickness (mm) | 1.6 | ||||

| Materials | PLA(+) | ||||

| CFE | Nozzle diameter (mm) | 0.8 | 0.97 | 0.91 | 6.85 |

| Layer height (mm) | 0.3 | ||||

| Nozzle temperature (°C) | 230 | ||||

| Printing speed (mm/s) | 90 | ||||

| Wall thickness (mm) | 1.6 | ||||

| Materials | PLA(ST) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hidayat, D.; Istiyanto, J.; Sumarsono, D.A.; Kurniawan, F.; Ardiansyah, R.; Wandono, F.A.; Nugroho, A. Investigation on the Crashworthiness Performance of Thin-Walled Multi-Cell PLA 3D-Printed Tubes: A Multi-Parameter Analysis. Designs 2023, 7, 108. https://doi.org/10.3390/designs7050108

Hidayat D, Istiyanto J, Sumarsono DA, Kurniawan F, Ardiansyah R, Wandono FA, Nugroho A. Investigation on the Crashworthiness Performance of Thin-Walled Multi-Cell PLA 3D-Printed Tubes: A Multi-Parameter Analysis. Designs. 2023; 7(5):108. https://doi.org/10.3390/designs7050108

Chicago/Turabian StyleHidayat, Dony, Jos Istiyanto, Danardono Agus Sumarsono, Farohaji Kurniawan, Riki Ardiansyah, Fajar Ari Wandono, and Afid Nugroho. 2023. "Investigation on the Crashworthiness Performance of Thin-Walled Multi-Cell PLA 3D-Printed Tubes: A Multi-Parameter Analysis" Designs 7, no. 5: 108. https://doi.org/10.3390/designs7050108

APA StyleHidayat, D., Istiyanto, J., Sumarsono, D. A., Kurniawan, F., Ardiansyah, R., Wandono, F. A., & Nugroho, A. (2023). Investigation on the Crashworthiness Performance of Thin-Walled Multi-Cell PLA 3D-Printed Tubes: A Multi-Parameter Analysis. Designs, 7(5), 108. https://doi.org/10.3390/designs7050108