Whist Game Cards Calibration Strategies-Based Technique for Conceptual Design Morphological Chart Refinement

Abstract

1. Introduction

2. Literature Review

3. Research Methodology

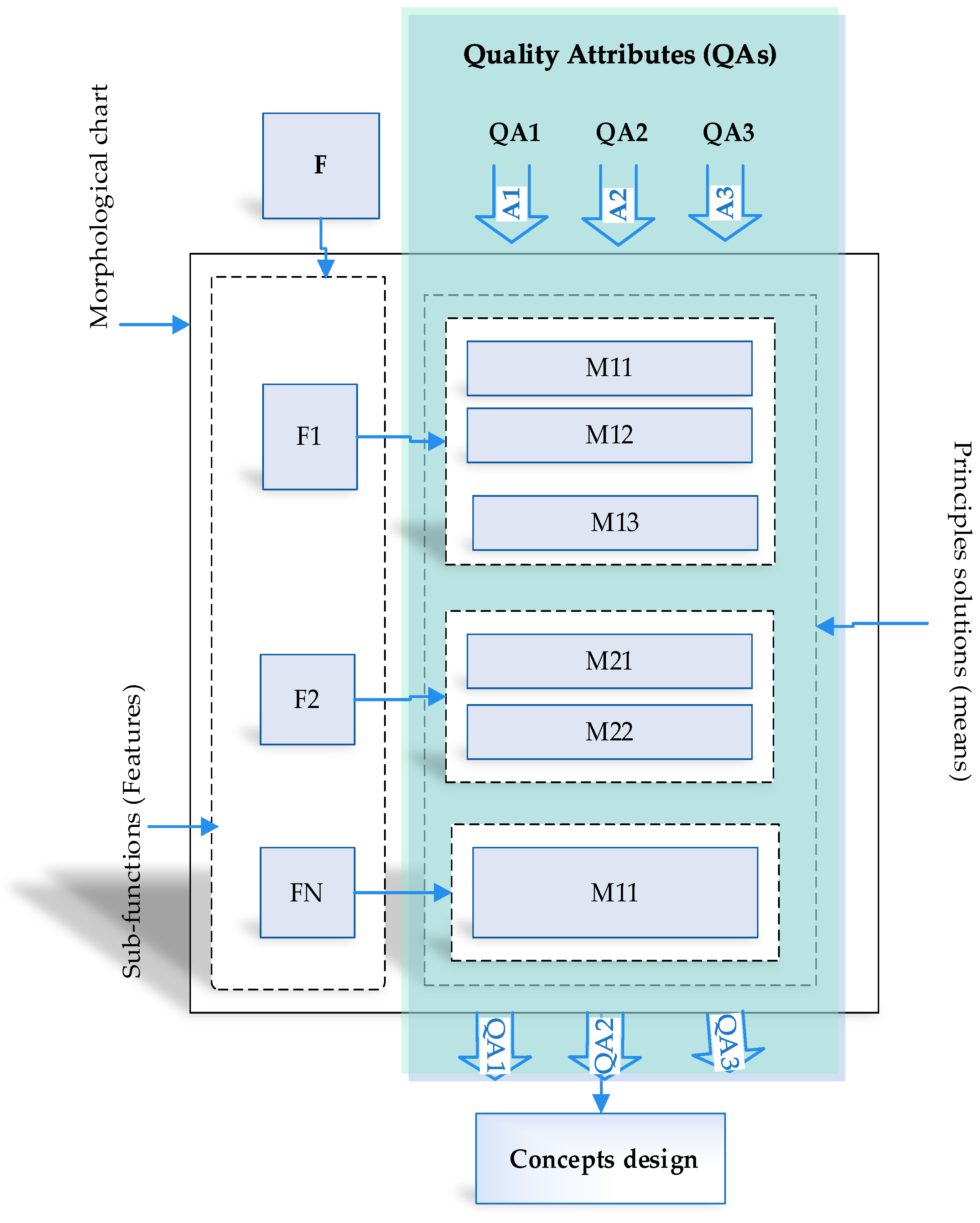

- Set the conceptual design morphological cart; within this step the product overall function decomposes into sub-functions or features (F).

- Obtain the sub-function means (M); searching of possible principle solutions of each sub-function.

- Set the quality attributes (QAs); a package of QAs develops to represent the designers and customers required quality attributes for on product.

- Apply QAs to the sub-function means; to estimate QAs numerical scale on the specific sub-function means.

- Estimate QAs numerical scale “cards” on the sub-function means; the numerical scales are whist game cards suit; 2, 3, 4, 5, 6, 7, 8, 9 distribute to two opponents (means) which relate to specific sub-function.

- Calibrate M regarding QAs numerical scales obtained in the previous step, the calibration process will make to determine every M numerical value.

- Refine M with respect to numerical values; the sub-functions’ means reduce and morphological chart narrow down by the refinement proceeding to M.

- Set the refined morphological chart; the morphological chart reformed with less sub-functions means (i.e., the most promising sub-functions means), and then less concepts design generated as a result of the refinement processes.

3.1. Quality Attributes (QAs) Application Reasons

- Performance attribute; performance defined as the final function or service which product design to provide it exactly as the end users want, thus performance applied to sub-function-means to predict its structural performance and performance values;

- Weight attribute; applied to sub-function means to estimate durability and material characteristics;

- Cost attribute; cost means contribution analysis which use to estimate profitability at the markets segment and consumers level, so it enhances the decision making;

- Shape attribute; applied to sub-function-means to define the instructions for combining means into concepts design, and the shape complexity level;

- Abundancy attribute; applied for sub-function means to evaluate its abundance percentage, sources availability and quality accessibility;

- Novelty attribute; defined as being original or new therefore interesting, and this original usage is derived as the concepts design;

3.2. Whist Strategies Based Numerical Scales Calibration

3.2.1. Two QAs Numerical Scales Calibration

3.2.2. Three QAs Numerical Scales Calibration

3.2.3. Four QAs Numerical Scales Calibration

4. Case Study

4.1. Product Quality Attributes (QAs) Specification

4.2. Numerical Scales Calibration and Numerical Values (Nv) Modelling

4.3. The Calibration Results and Numerical Values Analyses

5. Discussion and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Richardson, J., III; Summers, J.; Mocko, G. Function Representations in Morphological Charts: An Experimental Study on Variety. In Proceedings of the Interdisciplinary Design: 21st CIRP Design Conference, Online Conference, 19–21 May 2011. [Google Scholar]

- Ahmed, S.; Wallace, K.M.; Blessing, L.T. Understanding the Differences between How Novice and Experienced Designers Approach Design Tasks. Res. Eng. Des. 2003, 14, 1–11. [Google Scholar] [CrossRef]

- Smith, G.; Richardson, J.; Summers, J.D.; Mocko, G.M. Concept Exploration through Morphological Charts: An Experimental Study. J. Mech. Des. 2012, 134, 051004. [Google Scholar] [CrossRef]

- Cross, N. Engineering Design Methods: Strategies for Product Design; John Wiley & Sons: Hoboken, NJ, USA, 2021; ISBN 1119724406. [Google Scholar]

- Pasko, A.; Adzhiev, V.; Sourin, A.; Savchenko, V. Function Representation in Geometric Modeling: Concepts, Implementation and Applications. Vis. Comput. 1995, 11, 429–446. [Google Scholar] [CrossRef]

- Ulrich, K.T.; Eppinger, S.D. Product Architecture. Prod. Des. Dev. 2004, 3, 163–186. [Google Scholar]

- Dym, C.L.; Little, P. Engineering Design: A Project-Based Introduction; John Wiley & Sons: Hoboken, NJ, USA, 1999; ISBN 0471282960. [Google Scholar]

- Lo, C.-H.; Tseng, K.C.; Chu, C.-H. One-Step QFD Based 3D Morphological Charts for Concept Generation of Product Variant Design. Expert Syst. Appl. 2010, 37, 7351–7363. [Google Scholar] [CrossRef]

- Dankwort, C.W.; Weidlich, R.; Guenther, B.; Blaurock, J.E. Engineers’ CAx Education—It’s Not Only CAD. Comput. Des. 2004, 36, 1439–1450. [Google Scholar] [CrossRef]

- Bardenhagen, A.; Rakov, D. Advanced Morphological Approach in Aerospace Design during Conceptual Stage. Facta Univ. Ser. Mech. Eng. 2019, 17, 321–332. [Google Scholar] [CrossRef]

- Shetty, Y.K. Product Quality and Competitive Strategy. Bus. Horiz. 1987, 30, 46–52. [Google Scholar] [CrossRef]

- Brito, I.; Moreira, A.; Araújo, J. A Requirements Model for Quality Attributes. Asp. Requir. Eng. Archit. Des. Ger. 2002, 6, 1–3. [Google Scholar]

- Wang, L.; Shen, W.; Xie, H.; Neelamkavil, J.; Pardasani, A. Collaborative Conceptual Design—State of the Art and Future Trends. Comput. Des. 2002, 34, 981–996. [Google Scholar] [CrossRef]

- Yang, M.C. Observations on Concept Generation and Sketching in Engineering Design. Res. Eng. Des. 2009, 20, 1–11. [Google Scholar] [CrossRef]

- Ulrich, K.; Eppinger, S. EBOOK: Product Design and Development; McGraw Hill: New York, NY, USA, 2011; ISBN 0077143965. [Google Scholar]

- Dym, C.L.; Agogino, A.M.; Eris, O.; Frey, D.D.; Leifer, L.J. Engineering Design Thinking, Teaching, and Learning. J. Eng. Educ. 2005, 94, 103–120. [Google Scholar] [CrossRef]

- Beitz, W.; Pahl, G.; Grote, K. Engineering Design: A Systematic Approach. In Mrs Bulletin; Cambridge University Press: Cambridge, UK, 1996; Volume 71. [Google Scholar]

- Hubka, V. Principles of Engineering Design; Elsevier: Amsterdam, The Netherlands, 2015; ISBN 1483102033. [Google Scholar]

- Zwicky, F. The Morphological Approach to Discovery, Invention, Research and Construction. In New Methods of Thought and Procedure; Springer: Berlin, Germany, 1967; pp. 273–297. [Google Scholar]

- Richey, R.C.; Klein, J.D. Design and Development Research. In Handbook of Research on Educational Communications and Technology; Springer: Berlin, Germany, 2014; pp. 141–150. [Google Scholar]

- Ritchey, T. Problem Structuring Using Computer-Aided Morphological Analysis. J. Oper. Res. Soc. 2006, 57, 792–801. [Google Scholar] [CrossRef]

- Álvarez, A.; Ritchey, T. Applications of General Morphological Analysis. Acta Morphol. Gen. 2015, 4, 1–40. [Google Scholar]

- Mansor, M.R.; Sapuan, S.M.; Zainudin, E.S.; Nuraini, A.A.; Hambali, A. Conceptual Design of Kenaf Fiber Polymer Composite Automotive Parking Brake Lever Using Integrated TRIZ–Morphological Chart–Analytic Hierarchy Process Method. Mater. Des. 2014, 54, 473–482. [Google Scholar] [CrossRef]

- Shah, J.J.; Kulkarni, S.V.; Vargas-Hernandez, N. Evaluation of Idea Generation Methods for Conceptual Design: Effectiveness Metrics and Design of Experiments. J. Mech. Des. 2000, 122, 377–384. [Google Scholar] [CrossRef]

- Hurst, K. Engineering Design Principles; Butterworth-Heinemann: Oxford, UK, 1999; ISBN 0080531016. [Google Scholar]

- Dragomir, M.; Banyai, D.; Dragomir, D.; Popescu, F.; Criste, A. Efficiency and Resilience in Product Design by Using Morphological Charts. Energy Procedia 2016, 85, 206–210. [Google Scholar] [CrossRef][Green Version]

- Wästlund, J. Two-Person Symmetric Whist; Linköping University Electronic Press: Linköping, Sweden, 2005. [Google Scholar]

- Burgess, S.C. A Backwards Design Method for Mechanical Conceptual Design. J. Mech. Des. 2012, 134, 031002. [Google Scholar] [CrossRef]

- Shah, J.J. Experimental Investigation of Progressive Idea Generation Techniques in Engineering Design. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Atlanta, GA, USA, 13–16 September 1998; American Society of Mechanical Engineers: New York, NY, USA, 1998; Volume 80333, p. V003T03A004. [Google Scholar]

- Seepersad, C.C.; Allen, J.K.; McDowell, D.L.; Mistree, F. Robust Design of Cellular Materials with Topological and Dimensional Imperfections. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Long Beach, CA, USA, 24–28 September 2005; Volume 4739, pp. 807–821. [Google Scholar]

- Adelson, B. Cognitive Research: Uncovering How Designers Design; Cognitive Modeling: Explaining and Predicting How Designers Design. Res. Eng. Des. 1989, 1, 35–42. [Google Scholar] [CrossRef]

- Barbacci, M.; Klein, M.H.; Longstaff, T.A.; Weinstock, C.B. Quality Attributes; Carnegie-Mellon University Pittsburgh Pa Software Engineering Institute: Pittsburgh, PA, USA, 1995. [Google Scholar]

- Huang, G.Q.; Mak, K.-L. Web-Based Morphological Charts for Concept Design in Collaborative Product Development. J. Intell. Manuf. 1999, 10, 267–278. [Google Scholar] [CrossRef]

- Kahn, J.; Lagarias, J.C.; Witsenhausen, H.S. Single-Suit Two-Person Card Play III. The Misère Game. SIAM J. Discret. Math. 1989, 2, 329–343. [Google Scholar] [CrossRef]

- Kahn, J.; Lagarias, J.C.; Witsenhausen, H.S. Single-Suit Two-Person Card Play. Int. J. Game Theory 1987, 16, 291–320. [Google Scholar] [CrossRef]

- Whist Game Rules—How to Play Whist the Card Game. Available online: https://gamerules.com/rules/whist-card-game/ (accessed on 24 September 2022).

- Strawbridge, Z.; McAdams, D.A.; Stone, R.B. A Computational Approach to Conceptual Design. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Montréal, QC, Canada, 29 September–2 October 2002; Volume 3624, pp. 15–25. [Google Scholar]

- Jiang, S.; Jing, L.; Peng, X.; Chai, H.; Li, J. Conceptual Design Conceptual Scheme Optimization Based on Integrated Design Objectives. Concurr. Eng. 2018, 26, 231–250. [Google Scholar] [CrossRef]

| Means (M) | |||||

|---|---|---|---|---|---|

| Sub-Functions (F) | M1 | M2 | M3 | M4 | |

| F1 | Driving device | Hydraulic drive | Electromagnetic drive | Motor drive | |

| F2 | Transfer torque | Gear transmission | V-belt transmission | Bar transmission | Chain wheel transmission |

| F3 | Connecting transmission surface | Square surface | Circular surface | ||

| F4 | Transmission frame layout | Concatenated | Integrated | ||

| F5 | Install device | Horizontal installation | Gradient installation | ||

| F6 | Protect device | Independent motor | Wireless switch | Overload protection | |

| F7 | Place cargo | Positioning slot | Positioning cylinder | Positioning board | |

| F | M | |||

|---|---|---|---|---|

| F1 | M11 | M12 | M13 | |

| F2 | M21 | M22 | M23 | M24 |

| F3 | M31 | M32 | ||

| F4 | M41 | M42 | ||

| F5 | M51 | M52 | ||

| F6 | M61 | M62 | M63 | |

| F7 | M71 | M72 | M73 | |

| F | M | Numerical Scales of QAs | Nv | ||||

|---|---|---|---|---|---|---|---|

| Productconceptual design | F1 | M11 M12 | 9 8 | 6 7 | 5 4 | 3 2 | 1.500 2.500 |

| M11 M13 | 9 7 | 8 6 | 5 3 | 4 2 | 2.000 2.000 | ||

| F2 | M21 M22 | 7 9 | 4 8 | 3 6 | 2 5 | 1.000 3.000 | |

| M21 M23 | 8 9 | 5 7 | 4 6 | 2 3 | 1.500 2.500 | ||

| M21 M24 | 8 9 | 7 6 | 4 5 | 2 3 | 1.500 2.500 | ||

| F3 | M31 M32 | 9 8 | 7 5 | 6 4 | 3 2 | 2.500 1.500 | |

| F4 | M41 M42 | 8 9 | 7 6 | 5 4 | 2 3 | 3.000 1.000 | |

| F5 | M51 M52 | 9 8 | 7 6 | 4 5 | 2 3 | 2.250 1.750 | |

| F6 | M61 | 7 | 5 | 4 | 3 | 1.000 | |

| M62 | 9 | 8 | 6 | 2 | 3.000 | ||

| F7 | M71 | 9 | 8 | 7 | 2 | 3.000 | |

| M72 | 6 | 5 | 4 | 3 | 1.000 | ||

| Item | X-Numerical Scales of QAs | Y-Numerical Scales of QAs | X-Numerical Values | Y-Numerical Values |

|---|---|---|---|---|

| 01 | 9 8 7 6 | 5 4 3 2 | 4.000 | 0.000 |

| 02 | 9 8 7 5 | 6 4 3 2 | 3.500 | 1.500 |

| 03 | 9 8 7 4 | 6 5 3 2 | 3.000 | 1.000 |

| 04 | 9 8 7 3 | 6 5 4 2 | 3.000 | 1.000 |

| 05 | 9 8 7 2 | 6 5 4 3 | 3.000 | 1.000 |

| 06 | 9 8 6 5 | 7 4 3 2 | 3.000 | 1.000 |

| 07 | 9 8 6 4 | 7 5 3 2 | 2.000 | 2.000 |

| 08 | 9 8 6 3 | 7 5 4 2 | 2.000 | 2.000 |

| 09 | 9 8 5 4 | 7 6 3 2 | 2.000 | 2.000 |

| 10 | 9 8 5 3 | 7 6 4 2 | 2.500 | 1.500 |

| 11 | 9 8 4 3 | 7 6 5 2 | 2.000 | 2.000 |

| 12 | 9 7 6 4 | 8 5 3 2 | 2.500 | 1.500 |

| 13 | 9 7 6 3 | 8 5 4 2 | 2.500 | 1.500 |

| 14 | 9 7 5 4 | 8 6 3 2 | 2.500 | 1.500 |

| 15 | 9 7 5 3 | 8 6 4 2 | 2.500 | 1.500 |

| 16 | 9 7 4 3 | 8 6 5 2 | 1.500 | 3.500 |

| 17 | 9 6 5 4 | 8 7 3 2 | 3.000 | 1.000 |

| 18 | 9 6 5 3 | 8 7 4 2 | 2.500 | 1.500 |

| 19 | 9 6 4 3 | 8 7 5 2 | 1.000 | 3.000 |

| 20 | 8 7 6 5 | 9 4 3 2 | 3.000 | 1.000 |

| 21 | 8 7 6 4 | 9 5 3 2 | 2.500 | 1.500 |

| 22 | 8 7 6 3 | 9 5 4 2 | 2.500 | 1.500 |

| 23 | 8 7 6 2 | 9 5 4 3 | 2.125 | 1.875 |

| 24 | 8 7 5 4 | 9 6 3 2 | 2.000 | 2.000 |

| 25 | 8 7 5 3 | 9 6 4 2 | 2.000 | 2.000 |

| 26 | 8 7 5 2 | 9 6 4 3 | 2.000 | 2.000 |

| 27 | 8 7 4 3 | 9 6 5 2 | 1.875 | 2.125 |

| 28 | 8 7 4 2 | 9 6 5 3 | 1.750 | 2.250 |

| 29 | 8 7 3 2 | 9 6 5 4 | 1.500 | 2.500 |

| 30 | 8 6 5 3 | 9 7 4 2 | 1.750 | 2.250 |

| 31 | 8 6 5 2 | 9 7 4 3 | 1.500 | 2.500 |

| 32 | 8 6 4 2 | 9 7 5 3 | 1.500 | 2.500 |

| 33 | 8 6 3 2 | 9 7 5 4 | 1.500 | 2.500 |

| 34 | 8 5 4 3 | 9 7 6 2 | 1.500 | 2.500 |

| 35 | 8 5 4 2 | 9 7 6 3 | 1.500 | 2.500 |

| 36 | 8 5 3 2 | 9 7 6 4 | 1.500 | 2.500 |

| 37 | 7 6 5 4 | 9 8 3 2 | 2.000 | 2.000 |

| 38 | 7 6 5 3 | 9 8 4 2 | 1.750 | 2.250 |

| 39 | 7 6 5 2 | 9 8 4 3 | 1.500 | 2.500 |

| 40 | 7 6 4 3 | 9 8 5 2 | 1.500 | 2.500 |

| 41 | 7 6 4 2 | 9 8 5 3 | 1.500 | 2.500 |

| 42 | 7 6 3 2 | 9 8 5 4 | 1.250 | 2.750 |

| 43 | 7 5 4 3 | 9 8 6 2 | 1.000 | 3.000 |

| 44 | 7 5 4 2 | 9 8 6 3 | 1.000 | 3.000 |

| 45 | 7 5 3 2 | 9 8 6 4 | 1.000 | 3.000 |

| 46 | 7 4 3 2 | 9 8 6 5 | 1.000 | 3.000 |

| 47 | 6 5 4 3 | 9 8 7 2 | 1.000 | 3.000 |

| 48 | 6 5 4 2 | 9 8 7 3 | 0.875 | 3.125 |

| 49 | 6 5 3 2 | 9 8 7 4 | 0.750 | 3.250 |

| 50 | 6 4 3 2 | 9 8 7 5 | 0.500 | 3.500 |

| F | M | |

|---|---|---|

| 1 | M12 | |

| 2 | M22 | M24 |

| 3 | M31 | |

| 4 | M41 | |

| 5 | M51 | |

| 6 | M62 | |

| 7 | M71 | |

| Sub-Functions (F) | Means (M) | ||

|---|---|---|---|

| 1 | Driving device | Electromagnetic drive | |

| 2 | Transfer torque | V-belt transmission | Chain wheel transmission |

| 3 | Connecting transmission surface | Square surface | |

| 4 | Transmission frame layout | Concatenated | |

| 5 | Install device | Horizontal installation | |

| 6 | Protect device | Independent motor | |

| 7 | Place cargo | Positioning slot | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jamea, A.; Jing, L.; Peng, X.; Li, J.; Jiang, S. Whist Game Cards Calibration Strategies-Based Technique for Conceptual Design Morphological Chart Refinement. Designs 2023, 7, 4. https://doi.org/10.3390/designs7010004

Jamea A, Jing L, Peng X, Li J, Jiang S. Whist Game Cards Calibration Strategies-Based Technique for Conceptual Design Morphological Chart Refinement. Designs. 2023; 7(1):4. https://doi.org/10.3390/designs7010004

Chicago/Turabian StyleJamea, Ali, Liting Jing, Xiang Peng, Jiquan Li, and Shaofei Jiang. 2023. "Whist Game Cards Calibration Strategies-Based Technique for Conceptual Design Morphological Chart Refinement" Designs 7, no. 1: 4. https://doi.org/10.3390/designs7010004

APA StyleJamea, A., Jing, L., Peng, X., Li, J., & Jiang, S. (2023). Whist Game Cards Calibration Strategies-Based Technique for Conceptual Design Morphological Chart Refinement. Designs, 7(1), 4. https://doi.org/10.3390/designs7010004