The Economics of Classroom 3-D Printing of Open-Source Digital Designs of Learning Aids

Abstract

:1. Introduction

2. Materials and Methods

3. Results

4. Discussion

4.1. Limitations of the Study

4.2. Limitations of Deployment

4.3. Teacher Training

4.4. Values and Costs

4.5. Overall Economics and Advanced Applications

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

References

- Mehrotra, S.; DelaMonica, E. Household costs and public expenditure on primary education in five low income countries: A comparative analysis. Int. J. Educ. Dev. 1998, 18, 41–61. [Google Scholar] [CrossRef]

- Feldman, S. Children in Crisis: The Tragedy of Underfunded Schools and the Students They Serve. Am. Educ. Prof J. Am. Fed. Teach. 1992, 16, 8. [Google Scholar]

- Freelon, R.; Bertrand, M.; Rogers, J. Overburndened and Underfunded: California Public Schools Amidst the Great Recession. Multidiscip. J. Educ. Res. 2012, 2, 152–176. [Google Scholar] [CrossRef]

- Danvers, K. The Effects of Underfunded Legislative Mandates on Fiscal Stability of School Districts. J. High. Educ. Theory Pract. 2019, 19. [Google Scholar] [CrossRef]

- Krausen, K.; Willis, J. Silent Recession—Why California School Districts are Underwater Despite Increases in Funding. 2018, p. 28. Available online: https://www.wested.org/resources/silent-recession/ (accessed on 26 November 2020).

- SSI. School Specialty Reports Fiscal; Financial Results: Greenville, WI, USA, 2007. [Google Scholar]

- Rulianto, A.; Yasa, E.S. Teacher Durori’s Learning Aid. In Indonesia’s Weekly News Magazine; Tempo Inti Media: Jakarta, Indonesia, 2002. [Google Scholar]

- King, A. The Technology Factor: Nine Keys to Student Achievement and Cost-Effectiveness. Proj. Red 2010, 180. Available online: https://www.k12blueprint.com/sites/default/files/Project-RED-Technolgy-Factor.pdf (accessed on 26 November 2020).

- Gershenfeld, N. How to make almost anything: The digital fabrication revolution. Foreign Aff 2012, 91, 43. [Google Scholar]

- Laplume, A.O.; Petersen, B.; Pearce, J.M. Global Value Chains from a 3D Printing Perspective. J. Int. Bus. Stud. JIBS Lit. Rev. Arch. 2016, 47, 595–609. [Google Scholar] [CrossRef]

- Gwamuri, J.; Wittbrodt, B.T.; Anzalone, N.C.; Pearce, J.M. Reversing the Trend of Large Scale and Centralization in Manufacturing: The Case of Distributed Manufacturing of Customizable 3-D-Printable Self-Adjustable Glasses. Chall. Sustain. 2014, 2, 30–40. [Google Scholar] [CrossRef]

- Campbell, I.; Diegel, O.; Kowen, J.; Wohlers, T. Wohlers Report 2018: 3D Printing and Additive Manufacturing State of the Industry: Annual Worldwide Progress Report; Wohlers Associates: Fort Collins, CO, USA, 2018. [Google Scholar]

- Piller, F.T.; Weller, C.; Kleer, R. Business Models with Additive Manufacturing—Opportunities and Challenges from the Perspective of Economics and Management. In Proceedings of the Advances in Production Technology; Brecher, C., Ed.; Springer International Publishing: Cham, Switzerland, 2015; pp. 39–48. [Google Scholar]

- Matias, E.; Rao, B. 3D printing: On its historical evolution and the implications for business. In Proceedings of the 2015 Portland International Conference on Management of Engineering and Technology (PICMET), Portland, OR, USA, 2–6 August 2015; pp. 551–558. [Google Scholar]

- Laplume, A.; Anzalone, G.C.; Pearce, J.M. Open-source, self-replicating 3-D printer factory for small-business manufacturing. Int. J. Adv. Manuf. Technol. 2016, 85, 633–642. [Google Scholar] [CrossRef] [Green Version]

- Hoy, M.B. 3D Printing: Making Things at the Library. Med. Ref. Serv. Q. 2013, 32, 93–99. [Google Scholar] [CrossRef]

- Massis, B.E. 3D printing and the library. New Libr. World 2013, 114, 351–354. [Google Scholar] [CrossRef]

- Moorefield-Lang, H. Makers in the library: Case studies of 3D printers and maker spaces in library settings. Libr. Hi Tech 2014, 32, 583–593. [Google Scholar] [CrossRef]

- Walter-Herrmann, J.; Büching, C. (Eds.) FabLab: Of Machines, Makers and Inventors; Transcript Verlag: Bielefeld, Germany, 2014. [Google Scholar]

- Byard, D.J.; Woern, A.L.; Oakley, R.B.; Fiedler, M.J.; Snabes, S.L.; Pearce, J.M. Green fab lab applications of large-area waste polymer-based additive manufacturing. Addit. Manuf. 2019, 27, 515–525. [Google Scholar] [CrossRef] [Green Version]

- Van Holm, E.J. Makerspaces and Local Economic Development. Econ. Dev. Q. 2017, 31, 164–173. [Google Scholar] [CrossRef]

- Petrick, I.J.; Simpson, T.W. 3D printing disrupts manufacturing: How economies of one create new rules of competition. Res.-Technol. Manag. 2013, 56, 12–16. [Google Scholar] [CrossRef]

- Wittbrodt, B.T.; Glover, A.G.; Laureto, J.; Anzalone, G.C.; Oppliger, D.; Irwin, J.L.; Pearce, J.M. Life-cycle economic analysis of distributed manufacturing with open-source 3-D printers. Mechatronics 2013, 23, 713–726. [Google Scholar] [CrossRef] [Green Version]

- Ishengoma, F.R.; Mtaho, A.B. 3D printing: Developing countries perspectives. arXiv 2014, arXiv:1410.5349. [Google Scholar]

- Petersen, E.E.; Pearce, J. Emergence of Home Manufacturing in the Developed World: Return on Investment for Open-Source 3-D Printers. Technologies 2017, 5, 7. [Google Scholar] [CrossRef] [Green Version]

- Shewbridge, R.; Hurst, A.; Kane, S.K. Everyday making: Identifying future uses for 3D printing in the home. In Proceedings of the 2014 Conference on Designing Interactive Systems, Vancouver, BC, Canada, 21–25 June 2014; pp. 815–824. [Google Scholar]

- Parker, S. Opening Up to Open Source. Richmond J. Law Technol. 2000, 6, 24. [Google Scholar]

- Gibb, A.; Abadie, S. Building Open Source Hardware: DIY Manufacturing for Hackers and Makers; Pearson Education: Upper Saddle River, NJ, USA, 2014. [Google Scholar]

- Oberloier, S.; Pearce, J.M. General Design Procedure for Free and Open-Source Hardware for Scientific Equipment. Designs 2018, 2, 2. [Google Scholar] [CrossRef] [Green Version]

- Jones, R.; Haufe, P.; Sells, E.; Iravani, P.; Olliver, V.; Palmer, C.; Bowyer, A. RepRap—The replicating rapid prototyper. Robotica 2011, 29, 177–191. [Google Scholar] [CrossRef] [Green Version]

- Sells, E.; Smith, Z.; Bailard, S.; Bowyer, A.; Olliver, V. RepRap: The Replicating Rapid Prototyper: Maximizing Customizability by Breeding the Means of Production. Handb. Res. Mass Cust. Pers. 2010, 1. [Google Scholar] [CrossRef] [Green Version]

- Bowyer, A. 3D Printing and Humanity’s First Imperfect Replicator. 3D Print. Addit. Manuf. 2014, 1, 4–5. [Google Scholar] [CrossRef]

- Ford, S.; Minshall, T. Invited Review Article: Where and How 3D Printing is Used in Teaching and Education. Addit. Manufacturing 2019, 25, 131–150. [Google Scholar] [CrossRef]

- Lim, K.H.A.; Loo, Z.Y.; Goldie, S.J.; Adams, J.W.; McMenamin, P.G. Use of 3D printed models in medical education: A randomized control trial comparing 3D prints versus cadaveric materials for learning external cardiac anatomy. Anat. Sci. Educ. 2016, 9, 213–221. [Google Scholar] [CrossRef]

- Garcia, J.; Yang, Z.; Mongrain, R.; Leask, R.L.; Lachapelle, K. 3D printing materials and their use in medical education: A review of current technology and trends for the future. BMJ Simul. Technol. Enhanc. Learn. 2018, 4. [Google Scholar] [CrossRef]

- Vaccarezza, M.; Papa, V. 3D printing: A valuable resource in human anatomy education. Anat. Sci. Int. 2015, 90, 64–65. [Google Scholar] [CrossRef]

- Smith, M.L.; Jones, J.F.X. Dual-extrusion 3D printing of anatomical models for education. Anat. Sci. Educ. 2018, 11, 65–72. [Google Scholar] [CrossRef]

- Cook, K.L.; Bush, S.B.; Cox, R. Creating a prosthetic hand: 3D printers innovate and inspire a maker movement. Sci. Child. 2015, 53, 80. [Google Scholar]

- Buehler, E.; Comrie, N.; Hofmann, M.; McDonald, S.; Hurst, A. Investigating the implications of 3D printing in special education. ACM Trans. Access. Comput. (TACCESS) 2016, 8, 1–28. [Google Scholar] [CrossRef]

- Neumüller, M.; Reichinger, A.; Rist, F.; Kern, C. 3D Printing for Cultural Heritage: Preservation, Accessibility, Research and Education. In 3D Research Challenges in Cultural Heritage: A Roadmap in Digital Heritage Preservation; Ioannides, M., Quak, E., Eds.; Lecture Notes in Computer Science; Springer: Berlin/Heidelberg, Germany, 2014; pp. 119–134. ISBN 978-3-662-44630-0. [Google Scholar]

- Horowitz, S.S.; Schultz, P.H. Printing Space: Using 3D Printing of Digital Terrain Models in Geosciences Education and Research. J. Geosci. Educ. 2014, 62, 138–145. [Google Scholar] [CrossRef]

- Gonzalez-Gomez, J.; Valero-Gomez, A.; Prieto-Moreno, A.; Abderrahim, M. A New Open Source 3D-Printable Mobile Robotic Platform for Education. In Proceedings of the Advances in Autonomous Mini Robots; Rückert, U., Joaquin, S., Felix, W., Eds.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 49–62. [Google Scholar]

- Martin, R.L.; Bowden, N.S.; Merrill, C. 3D Printing in Technology and Engineering Education. Technol. Eng. Teach. 2014, 73, 30–35. [Google Scholar]

- Easley, W.; Buehler, E.; Hurst, A.; Salib, G. Fabricating Engagement: Benefits and Challenges of Using 3D Printing to Engage Underrepresented Students in STEM Learning. In Proceedings of the 2017 ASEE Annual Conference & Exposition, Columbus, OL, USA, 25–28 June 2017. [Google Scholar]

- Coakley, M.F.; Hurt, D.E.; Weber, N.; Mtingwa, M.; Fincher, E.C.; Alekseyev, V.; Chen, D.T.; Yun, A.; Gizaw, M.; Swan, J.; et al. The NIH 3D print exchange: A public resource for bioscientific and biomedical 3D prints. 3D Print. Addit. Manuf. 2014, 1, 137–140. [Google Scholar] [CrossRef] [PubMed]

- Mercuri, R.T.; Meredith, K. An educational venture into 3D Printing. In Proceedings of the 2014 IEEE Integrated STEM Education Conference, Princeton, NJ, USA, 8 March 2014. [Google Scholar] [CrossRef]

- Canessa, E.; Fonda, C.; Zennaro, M. Low-cost 3D printing for science, education and sustainable development. Low-Cost 3D Printing 2013. Available online: http://sdu.ictp.it/3D/book.html (accessed on 26 November 2020).

- Schelly, C.; Anzalone, G.C.; Wijnen, B.; Pearce, J.M. Open-Source 3-D Printing Technologies for Education: Bringing Additive Manufacturing to the Classroom. J. Vis. Lang. Comput. 2015, 28, 226–237. [Google Scholar] [CrossRef] [Green Version]

- Verner, I.; Merksamer, A. Digital Design and 3D Printing in Technology Teacher Education. Procedia CIRP 2015, 36, 182–186. [Google Scholar] [CrossRef] [Green Version]

- Wang, B.; Sud, R.; Leung, M.; Yang, M.; Rodriguez, J.A.; Lee, R.; Cappelli, M. OpenEM—Electromagnetic field mapping robot for microwave and RF measurements. HardwareX 2019, 5, e00062. [Google Scholar] [CrossRef]

- Lupetti, M.L. Shybo. An open-source low-anthropomorphic robot for children. HardwareX 2017, 2, 50–60. [Google Scholar] [CrossRef] [Green Version]

- Alves-Oliveira, P.; Arriaga, P.; Paiva, A.; Hoffman, G. Guide to build YOLO, a creativity-stimulating robot for children. HardwareX 2019, 6, e00074. [Google Scholar] [CrossRef]

- Chen, M.; Zhang, Y.; Zhang, Y. Effects of a 3D printing course on mental rotation ability among 10-year-old primary students. Int. J. Psychophysiol. 2014, 2, 240. [Google Scholar] [CrossRef]

- Corum, K.; Garofalo, J. Using Digital Fabrication to Support Student Learning. 3D Print. Addit. Manuf. 2015, 2, 50–55. [Google Scholar] [CrossRef]

- Maloy, R.; Trust, T.; Kommers, S.; Malinowski, A.; LaRoche, I. 3D Modeling and Printing in History/Social Studies Classrooms: Initial Lessons and Insights. Contemp. Issues Technol. Teach. Educ. 2017, 17, 229–249. [Google Scholar]

- Craddock, I.L. Makers on the move: A mobile makerspace at a comprehensive public high school. Libr. Hi Tech 2015. [Google Scholar] [CrossRef]

- Kostakis, V.; Niaros, V.; Giotitsas, C. Open source 3D printing as a means of learning: An educational experiment in two high schools in Greece. Telemat. Inform. 2015, 32, 118–128. [Google Scholar] [CrossRef]

- Eisenberg, M. 3D printing for children: What to build next? Int. J. Child-Comput. Interact. 2013, 1, 7–13. [Google Scholar] [CrossRef]

- MyMiniFactory. Available online: https://www.myminifactory.com/ (accessed on 26 November 2020).

- Kotha, S. Competing on the Internet: The case of Amazon. com. Eur. Manag. J. 1998, 16, 212–222. [Google Scholar] [CrossRef]

- Zhu, F.; Liu, Q. Competing with complementors: An empirical look at Amazon. com. Strateg. Manag. J. 2018, 39, 2618–2642. [Google Scholar] [CrossRef]

- Weise, K. Prime Power: How Amazon Squeezes the Businesses Behind Its Store; The New York Times: New York, NY, USA, 2019. [Google Scholar]

- Tokiwa, Y.; Calabia, B.P.; Ugwu, C.U.; Aiba, S. Biodegradability of Plastics. Int. J. Mol. Sci. 2009, 10, 3722–3742. [Google Scholar] [CrossRef] [PubMed]

- Wittbrodt, B.; Pearce, J. The Effects of PLA Color on Material Properties of 3-D Printed Components. Addit. Manuf. 2015, 8. [Google Scholar] [CrossRef] [Green Version]

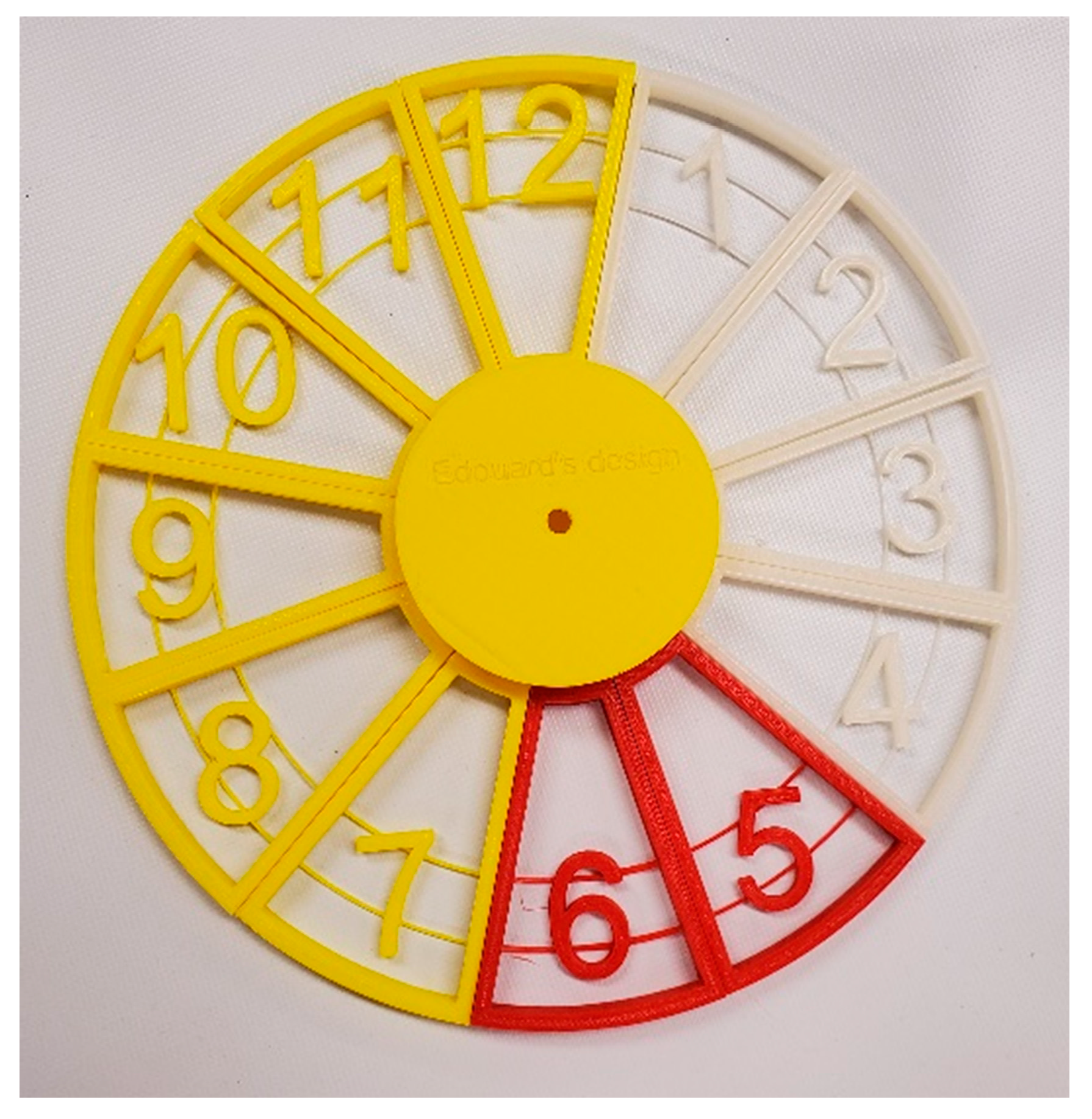

- 3D Printable Clock by Edouard Spiers. Available online: https://www.myminifactory.com/object/3d-print-3d-printable-clock-54723 (accessed on 26 November 2020).

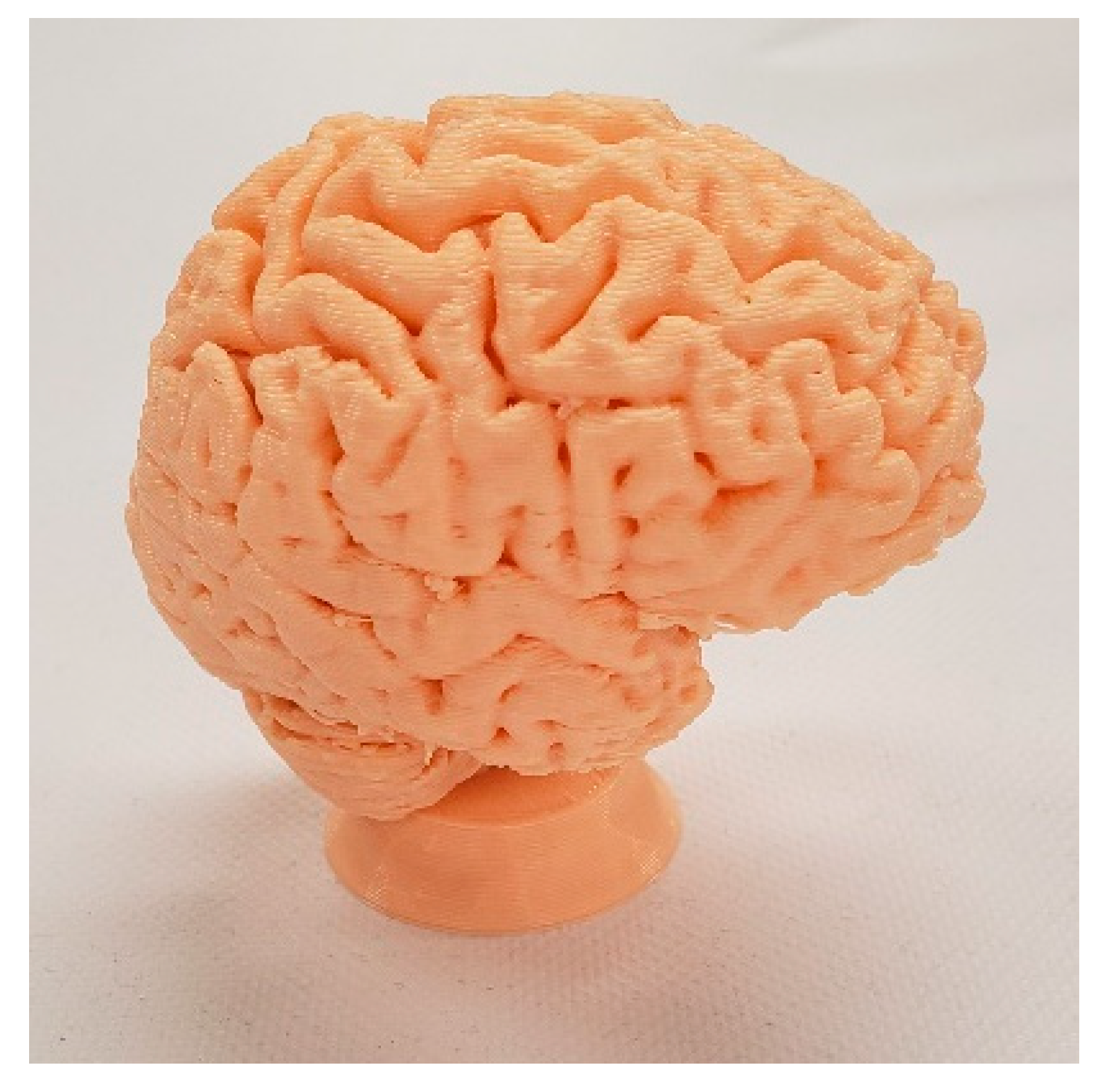

- 3D Printable Human Brain by Vaclav Krmela. Available online: https://www.myminifactory.com/object/3d-print-human-brain-11053 (accessed on 26 November 2020).

- 3D Printable Pythagorean Theorem by Cristiano Maci. Available online: https://www.myminifactory.com/object/3d-print-pythagoras-s-theorem-2807 (accessed on 26 November 2020).

- 3D Printable Spinal Stand by MyMiniFactory. Available online: https://www.myminifactory.com/object/3d-print-spinal-stand-942 (accessed on 26 November 2020).

- 3D Printable Combustion Engine by Jack Imakr. Available online: https://www.myminifactory.com/object/3d-print-engine-1406 (accessed on 26 November 2020).

- Zhao, P.; Rao, C.; Gu, F.; Sharmin, N.; Fu, J. Close-looped recycling of polylactic acid used in 3D printing: An experimental investigation and life cycle assessment. J. Clean. Prod. 2018, 2018 197, 1046–1055. [Google Scholar] [CrossRef]

- Kreiger, M.A.; Mulder, M.L.; Glover, A.G.; Pearce, J.M. Life cycle analysis of distributed recycling of post-consumer high density polyethylene for 3-D printing filament. J. Clean. Prod. 2014, 70, 90–96. [Google Scholar] [CrossRef] [Green Version]

- Zhong, S.; Pearce, J. Tightening the loop on the circular economy: Coupled distributed recycling and manufacturing with recyclebot and RepRap 3-D printing. Resour. Conserv. Recycl. 2018, 128, 48–58. [Google Scholar] [CrossRef] [Green Version]

- Junk, S.; Kuen, C. Review of Open Source and Freeware CAD Systems for Use with 3D-Printing. Procedia CIRP 2016, 50, 430–435. [Google Scholar] [CrossRef] [Green Version]

- Horvath, J. Mastering 3D Printing; Apress: New York, NY, USA, 2014. [Google Scholar]

- Wijnen, B.; Anzalone, G.; Haselhuhn, A.; Sanders, P.; Pearce, J. Free and open-source control software for 3-D motion and processing. J. Open Res. Softw. 2016, 4, e2. [Google Scholar]

- Creality. Official Creality Ender 3 3D Printer, Official Ender 3 3d Printer Store—Official Store for Creality 3D Printers and Accessories. 2020. Available online: https://www.creality3dofficial.com/products/official-creality-ender-3-3d-printer (accessed on 8 October 2020).

- Edutech. OpenScad Beginners Tutorial—EduTech Wiki. 2020. Available online: http://edutechwiki.unige.ch/en/OpenScad_beginners_tutorial (accessed on 8 October 2020).

- FreeCADweb. Basic Modeling Tutorial—FreeCAD Documentation. 2020. Available online: https://wiki.freecadweb.org/Basic_modeling_tutorial (accessed on 8 October 2020).

- Mukherjee, S. Modern Economic Theory; New Age International: Delhi, India, 2002. [Google Scholar]

- Miltenburg, J. Manufacturing Strategy: How to Formulate and Implement a Winning Plan; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Kravis, I.B.; Lipsey, R.E. The location of overseas production and production for export by US multinational firms. J. Int. Econ. 1982, 12, 201–223. [Google Scholar] [CrossRef] [Green Version]

- Ruamsook, K.; Russell, D.; Thomchick, E. US sourcing from low-cost countries: A comparative analysis of supplier performance. J. Supply Chain Manag. 2007, 43, 16–30. [Google Scholar] [CrossRef]

- Trenholm, R. Apple Spends more on Patents than R&D after Jobs Patent Vow. 2012. Available online: https://www.cnet.com/news/apple-spends-more-on-patents-than-r-d-after-jobs-patent-vow/ (accessed on 8 November 2020).

- Griffith-Greene, M. ‘Wrap Rage’ Experienced by most Canadians|CBC News. 2014. Available online: https://www.cbc.ca/news/business/excessive-packaging-dangerous-frustrating-for-consumers-poll-1.2490047 (accessed on 8 November 2020).

- Bird, J. What A Waste: Online Retail’s Big Packaging Problem. 2018. Available online: https://www.forbes.com/sites/jonbird1/2018/07/29/what-a-waste-online-retails-big-packaging-problem/ (accessed on 8 November 2020).

- Aslin, A. Retail Markups and the Power of Amazon, Market Watch. 2012. Available online: http://blogs.marketwatch.com/great-columnist/2012/10/15/retail-markups-and-the-power-of-amazon/ (accessed on 1 November 2015).

- Milne, G.R.; Boza, M.E. Trust and Concern in Consumers’ Perceptions of Marketing Information Management Practices. J. Interact. Mark. 1999, 13, 5–24. [Google Scholar] [CrossRef]

- Miller, F. 14 Best Mozilla Firefox Add-ons, Apps & Extensions of 2020 Product. Land. Available online: https://productivityland.com/best-firefox-add-ons-extensions/ (accessed on 23 February 2020).

- Spadafora, A. These Are the most Popular Google Chrome extensions. Tech. Radar. 2019. Available online: https://www.techradar.com/news/most-popular-google-chrome-extensions (accessed on 22 February 2020).

- Pearce, J.M. Energy Conservation with Open Source Ad Blockers. Technologies 2020, 8, 18. [Google Scholar] [CrossRef] [Green Version]

- Mishel, L.; Sabadish, N. CEO pay and the top 1%. Econ. Policy Inst. Issue Brief 2012, 331, 1–7. [Google Scholar]

- Burton, J.A.; Weller, C.E. Supersize this: How CEO pay took off while America’s middle class struggled; Center for American Progress: Washington, DC, USA, 2005. [Google Scholar]

- Henderson, M.T. Paying CEOs in bankruptcy: Executive compensation when agency costs are low. Nw. UL Rev. 2007, 101, 1543. [Google Scholar] [CrossRef] [Green Version]

- Pearce, J. Quantifying the Value of Open Source Hardware Development. Mod. Econ. 2015, 6, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Pearce, J.M. Return on investment for open source scientific hardware development. Sci. Public Policy 2016, 43, 192–195. [Google Scholar] [CrossRef]

- Winters, B.J.; Shepler, D. 3D printable optomechanical cage system with enclosure. HardwareX 2018, 3, 62–81. [Google Scholar] [CrossRef]

- Bravo-Martinez, J. Open source 3D-printed 1000 μL micropump. HardwareX 2018, 3, 110–116. [Google Scholar] [CrossRef]

- Vaut, L.; Scarano, E.; Tosello, G.; Boisen, A. Fully replicable and automated retention measurement setup for characterization of bio-adhesion. HardwareX 2019, 6, e00071. [Google Scholar] [CrossRef]

- Romero-Morales, A.I.; O’Grady, B.J.; Balotin, K.M.; Bellan, L.M.; Lippmann, E.S.; Gama, V. Spin∞: An updated miniaturized spinning bioreactor design for the generation of human cerebral organoids from pluripotent stem cells. HardwareX 2019, 6, e00084. [Google Scholar] [CrossRef] [PubMed]

- Kahler, A. Braille OpenSCAD Font Module. Available online: https://www.thingiverse.com/thing:4758 (accessed on 8 October 2020).

- Watkin, H. 10 Ways 3D Printing Supports the Blind. All3DP. 2016. Available online: https://all3dp.com/3d-printing-supporting-blind-people/ (accessed on 8 October 2020).

- Knochel, A.D.; Hsiao, W.H.; Pittenger, A. Touching to see: Tactile learning, assistive technologies, and 3-D printing. Art Educ. 2018, 71, 7–13. [Google Scholar] [CrossRef]

- Awad, A.; Yao, A.; Trenfield, S.J.; Goyanes, A.; Gaisford, S.; Basit, A.W. 3D Printed Tablets (Printlets) with Braille and Moon Patterns for Visually Impaired Patients. Pharmaceutics 2020, 12, 172. [Google Scholar] [CrossRef] [Green Version]

| Educational Aid | Description | Subject | Source |

|---|---|---|---|

| Colorful Clock | Clock for teacher’s aid | Math (time) | [65] |

| Brain Model | A printed model of the human brain | Biology | [66] |

| Pythagorean’s Theorem | Visual representation of the Pythagorean theorem with triangles | Math | [67] |

| Spinal Cord Model | A model of the spinal cord with each section of vertebrae color coded | Biology | [68] |

| Combustion Engine Model | A moveable combustion engine | Design and Technology | [69] |

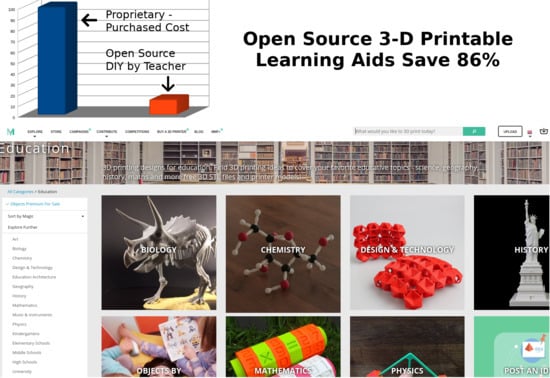

| Educational Aid | Mass (g) | Distributed Manufacturing Cost (USD) | Purchase Cost (USD) | Savings (USD) | Savings (%) |

|---|---|---|---|---|---|

| Colorful Clock | 222.98 | 11.79 | 16.99 | 5.20 | 30.6 |

| Brain Model | 52.34 | 1.12 | 58.99 | 57.87 | 98.1 |

| Pythagorean Theorem | 24.60 | 0.53 | 14.74 | 14.21 | 96.4 |

| Spinal Cord Model | 29.95 | 1.303 | 53.99 | 52.66 | 97.5 |

| Combustion Engine Model | 99.61 | 2.14 | 45.47 | 43.33 | 95.3 |

| Educational Aid | Mass of Printed Parts (kg) | Total Distributed Manufacturing Cost (USD) | Amazon Purchase Cost (USD) | Savings (USD) | Percent Savings (%) |

|---|---|---|---|---|---|

| Spirograph | 0.034 | 0.73 | 15.79 | 15.06 | 95% |

| Rubber Band-Powered Airplane | 0.005 | 0.16 | 22.95 | 22.79 | 99% |

| Multi-colored Earth Core Model | 0.219 | 4.70 | 16.27 | 11.57 | 71% |

| Color Palette | 0.038 | 0.82 | 5.99 | 5.17 | 86% |

| Multi-colored Cell Model | 0.099 | 2.13 | 15.29 | 13.16 | 86% |

| Mechanical Counter | 0.187 | 4.11 | 5.99 | 1.88 | 31% |

| Water Wheel | 0.186 | 3.99 | 11.99 | 8.00 | 67% |

| Solar System Model | 0.066 | 1.42 | 28.97 | 27.55 | 95% |

| USA States Magnetic Puzzle | 0.083 | 1.78 | 13.99 | 12.21 | 87% |

| DNA Helix Model | 0.037 | 0.79 | 15.00 | 14.21 | 95% |

| Hybridized Orbital | 0.025 | 0.54 | 29.00 | 28.46 | 98% |

| Test Tube Holder | 0.048 | 1.03 | 15.99 | 14.96 | 94% |

| Peg Board Holder Attachments/Accessories | 0.102 | 2.19 | 13.90 | 11.71 | 84% |

| Screw | 0.0006 | 0.01 | 15.98 | 15.97 | 100% |

| Colosseum | 0.139 | 2.98 | 16.95 | 13.97 | 82% |

| Great Wall of China | 0.058 | 1.25 | 94.99 | 93.74 | 99% |

| Earth Globe Model | 0.034 | 0.73 | 31.34 | 30.61 | 98% |

| Mount Vesuvius | 0.042 | 0.90 | 201.49 | 00.59 | 100% |

| Abacus | 0.119 | 2.55 | 9.99 | 7.44 | 74% |

| Center of Balance Finger Toy | 0.01 | 0.21 | 7.48 | 7.27 | 97% |

| Newton’s Cradle | 0.003 | 0.06 | 25.87 | 25.81 | 100% |

| Torso Model with Partial Dissection | 0.032 | 0.69 | 19.99 | 19.30 | 97% |

| Periodic Table Puzzle | 0.492 | 10.56 | 22.95 | 12.39 | 54% |

| DNA RNA Replication Set | 0.106 | 2.28 | 18.48 | 16.20 | 88% |

| Gear Model | 0.018 | 0.39 | 12.99 | 12.60 | 97% |

| Aztec Calendar | 0.101 | 2.17 | 35.99 | 33.82 | 94% |

| Viking Sword | 0.157 | 3.37 | 48.99 | 45.62 | 93% |

| Toronto Skyline | 0.026 | 0.56 | 2.99 | 2.43 | 81% |

| The World Continents | 0.014 | 0.30 | 10.95 | 10.65 | 97% |

| Star Tetrahedron | 0.037 | 0.79 | 39.90 | 39.11 | 98% |

| 3D Stars | 0.007 | 0.15 | 9.39 | 9.24 | 98% |

| Perpetual Motion Model | 0.062 | 10.28 | 35.99 | 25.71 | 71% |

| Pendulum Wave Machine | 0.127 | 36.22 | 51.95 | 15.73 | 30% |

| Education Aids | Savings (USD) | MyMiniFactory Downloads | Years Posted | Savings per Year (USD/Year) | Total Savings (USD) |

|---|---|---|---|---|---|

| Colorful Clock | $5.20 | 958 | 1 | 4984.32 | 4984.32 |

| Brain model | $57.87 | 2921 | 4 | 42,256.87 | 169,027.50 |

| Pythagorean Theorem | $14.21 | 408 | 5 | 1159.69 | 5798.44 |

| Spinal Cord Model | $52.66 | 9107 | 6 | 79,925.19 | 479,551.12 |

| Combustion Engine Model | $43.33 | 6280 | 5 | 54,424.46 | 272,122.32 |

| Spirograph | $15.06 | 9897 | 5 | 29,809.87 | 149,049.35 |

| Rubber Band-Powered Airplane | $22.79 | 1608 | 2 | 18,325.29 | 36,650.59 |

| Multi-colored Earth Core Model | $11.57 | 386 | 2 | 2232.68 | 4465.36 |

| Color Palette | $5.17 | 187 | 3 | 322.52 | 967.57 |

| Multi-colored Cell Model | $13.16 | 1176 | 2 | 7740.77 | 15,481.53 |

| Mechanical Counter | $1.88 | 768 | 3 | 480.08 | 1440.23 |

| Water Wheel | $8.00 | 772 | 3 | 2057.83 | 6173.50 |

| Solar System Model | $27.55 | 400 | 3 | 3673.74 | 11,021.22 |

| USA States Magnetic Puzzle | $12.21 | 219 | 4 | 668.39 | 2673.57 |

| DNA Helix Model | $14.21 | 550 | 3 | 2604.37 | 7813.11 |

| Hybridized Orbital | $28.46 | 153 | 3 | 1451.63 | 4354.88 |

| Test Tube Holder | $14.96 | 92 | 3 | 458.76 | 1376.27 |

| Peg Board Holder Attachments/Accessories | $11.71 | 2526 | 4 | 7394.97 | 29,579.87 |

| Screw | $15.97 | 3470 | 5 | 11,081.18 | 55,405.90 |

| Colosseum | $13.97 | 5002 | 5 | 13,971.40 | 69,856.98 |

| Great Wall of China | $93.74 | 197 | 1 | 18,467.73 | 18,467.73 |

| Earth Globe Model | $30.61 | 1385 | 3 | 14,131.64 | 42,394.92 |

| Mount Vesuvius | $200.59 | 345 | 3 | 23,067.65 | 69,202.96 |

| Abacus | $7.44 | 577 | 6 | 715.02 | 4290.10 |

| Center of Balance Finger Toy | $7.27 | 710 | 3 | 1719.46 | 5158.37 |

| Newton’s Cradle | $25.81 | 1275 | 2 | 16,451.07 | 32,902.13 |

| Torso Model with Partial Dissection | $19.30 | 1533 | 2 | 14,795.74 | 29,591.49 |

| Periodic Table Puzzle | $12.39 | 370 | 3 | 1527.76 | 4583.28 |

| DNA RNA Replication Set | $16.20 | 201 | 3 | 1085.69 | 3257.06 |

| Gear Model | $12.60 | 711 | 6 | 1493.52 | 8961.13 |

| Aztec Calendar | $33.82 | 2725 | 2 | 46,081.97 | 92,163.94 |

| Viking Sword | $45.62 | 389 | 5 | 3549.19 | 17,745.93 |

| Toronto Skyline | $2.43 | 87 | 3 | 70.52 | 211.57 |

| The World Continents | $10.65 | 163 | 5 | 347.17 | 1735.86 |

| Star Tetrahedron | $39.11 | 89 | 3 | 1160.13 | 3480.40 |

| 3D Stars | $9.24 | 121 | 4 | 279.50 | 1118.01 |

| Perpetual Motion Model | $25.71 | 2152 | 3 | 18,441.87 | 55,325.60 |

| Pendulum Wave Machine | $15.73 | 107 | 2 | 841.74 | 1683.48 |

| Item | Mass Manufactured Cost | Mass Manufactured Value | Self-Fabricated Cost | Self-Fabricated Value |

|---|---|---|---|---|

| Design (e.g., R&D) |  |  |  |  |

| Intellectual Property |  | NA |  | NA |

| Materials |  |  |  |  |

| Fabrication/Manufacturing (labor + energy + percentage equipment time) |  |  |  |  |

| Packaging |  | NA |  | NA |

| Shipping |  | NA |  | NA |

| Retail |  | NA |  | NA |

| Advertising |  | NA |  | NA |

| Management |  | NA |  | NA |

| Financing |  | NA |  | NA |

| Profit |  | NA |  | NA |

| Warranty |  |  |  |  |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gallup, N.; Pearce, J.M. The Economics of Classroom 3-D Printing of Open-Source Digital Designs of Learning Aids. Designs 2020, 4, 50. https://doi.org/10.3390/designs4040050

Gallup N, Pearce JM. The Economics of Classroom 3-D Printing of Open-Source Digital Designs of Learning Aids. Designs. 2020; 4(4):50. https://doi.org/10.3390/designs4040050

Chicago/Turabian StyleGallup, Nicole, and Joshua M. Pearce. 2020. "The Economics of Classroom 3-D Printing of Open-Source Digital Designs of Learning Aids" Designs 4, no. 4: 50. https://doi.org/10.3390/designs4040050

APA StyleGallup, N., & Pearce, J. M. (2020). The Economics of Classroom 3-D Printing of Open-Source Digital Designs of Learning Aids. Designs, 4(4), 50. https://doi.org/10.3390/designs4040050