1. Introduction

Pushing capacity is a key parameter in racing wheelchair performance. One way to improve racing wheelchair speed is to increase energy transfer to the wheelchair. Several variables may affect energy transfer, from equipment design, athlete anthropometry, pathology and neuromuscular capabilities, to the specific motor control strategy chosen to accomplish the task [

1,

2,

3]. The pushing technique is a crucial factor in athlete performance [

4] as it ensures effective transmission of forces applied from the hand rim to the surface, thereby minimizing energy dispersions. Indeed, the forces exerted on the hand rim of the wheelchair must be optimized to enable efficient torque transmission to the surface [

5]. In addition to pushing parameters, rolling resistance [

6,

7,

8] and the coefficient of friction [

9,

10,

11] are complementary parameters considered. The latter indicates the grip of one surface relative to another [

12], here between a tire and a ground surface.

In the context of this study, the goal is to determine the parameters, among four selected, that influence the risk of skidding, by measuring the torque applied to the wheel that leads to its skidding. Ivanov et al. [

13] conducted a study to determine the skidding grip torque of a tire. Following this method, this study introduces a new approach capable of measuring tire grip through the calculation of torques (referred to as grip loss and recovery torques). The protocol focuses solely on measuring circular rotation torques with a non-fixed wheel [

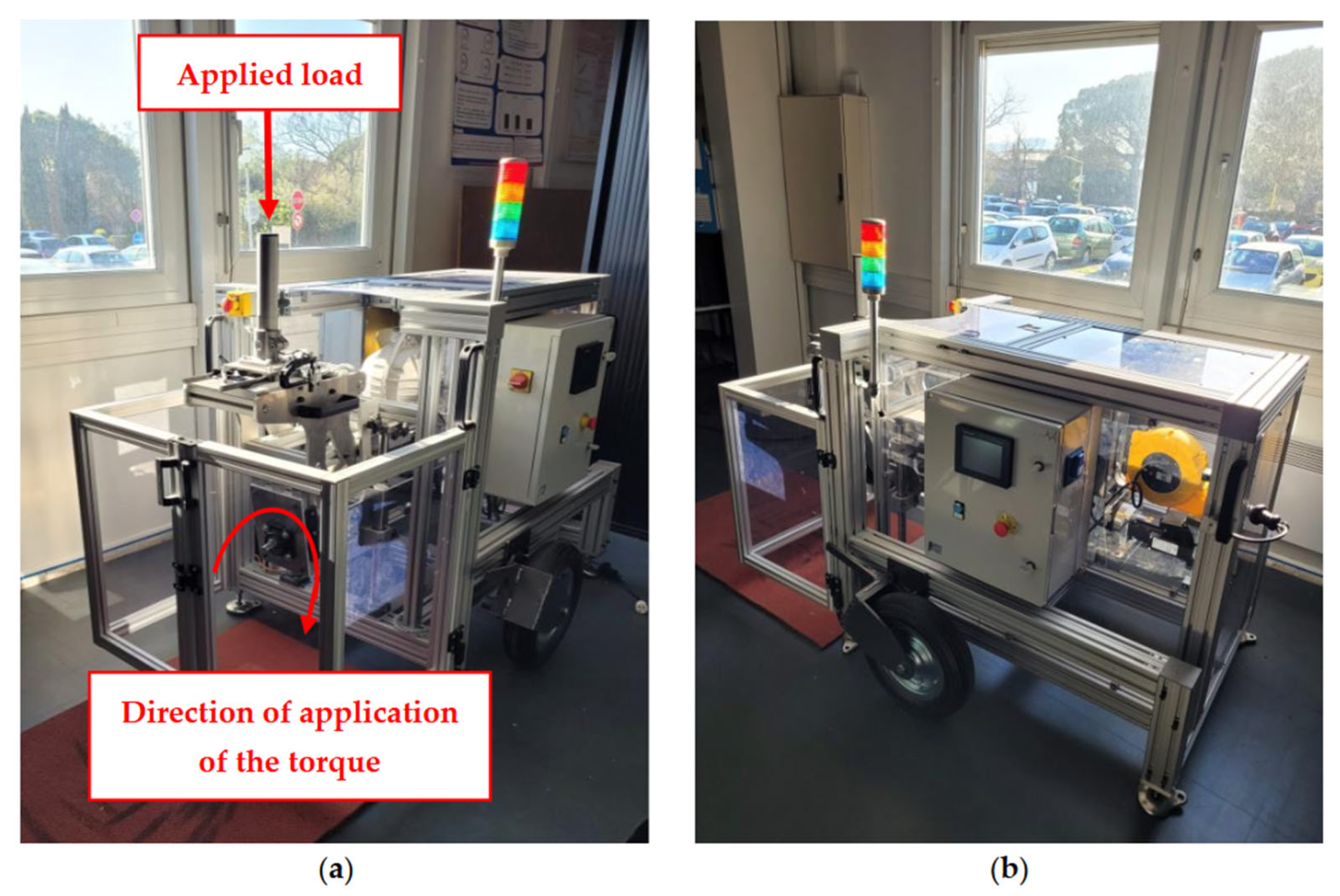

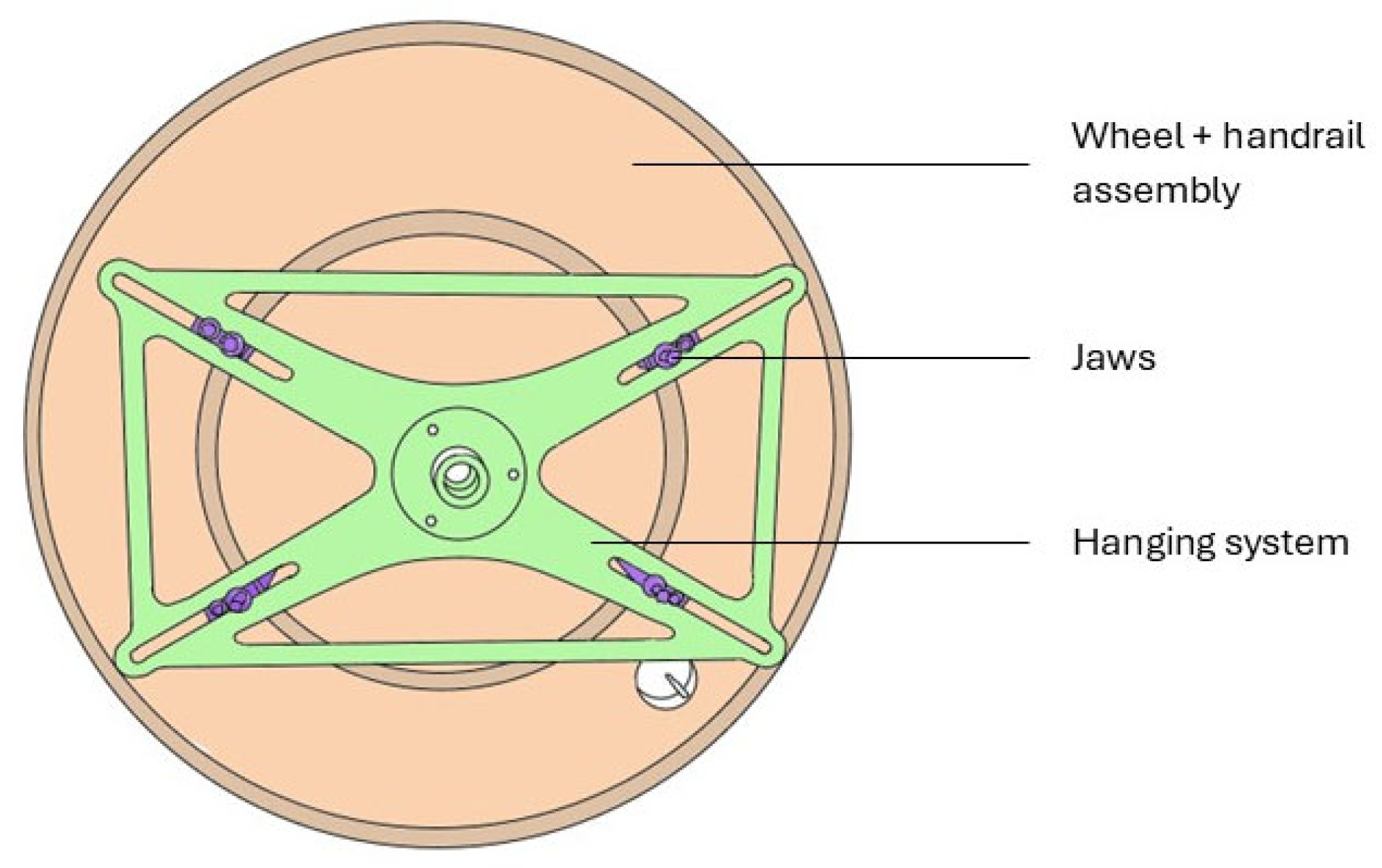

13], isolating the wheel from the rest of the wheelchair. This new protocol is tested on a tool called a skidometer. Specific parameters are studied to understand their influence on the determined torques, namely, tire pressure, wheel camber angle, and the load applied to the wheel. The selection of these parameters was based on recommendations from the scientific literature [

10,

11,

13]. The values of the variables and the types of tubulars tested were selected by the athletics federation prior to the experimentation. Based on the existing literature, each parameter studied is expected to influence skidding differently. Tire pressure plays a key role in ground adhesion: higher pressure reduces the contact patch, potentially decreasing grip and increasing the risk of skidding [

10,

13]. Conversely, lower pressure can improve grip by increasing tubular deformation but may also lead to higher rolling resistance. Wheel camber angle affects force distribution on the ground; a positive camber generally enhances lateral stability by increasing the contact area, while a neutral or negative camber may reduce stability and facilitate skidding [

11]. Finally, the load applied to the wheel directly impacts the normal force on the ground: a higher load increases this force, which tends to enhance grip and require a higher torque to initiate skidding [

13]. This study aims to experimentally assess these influences using the proposed protocol. Indeed, the hypothesis, based on the results of previous work and the objectives of our research, is as follows:

Hyp: The application of the proposed method will enable the identification of parameters among the camber angle, pressure, the load applied to the wheel, and tubular type that influence the risk of wheel skidding in wheelchair racing, by the measure of grip recovery and loss torque.

This knowledge could serve as a foundation for a more precise optimization of the individual settings of sports wheelchairs.

4. Discussion

The aim of this study was to identify the parameters between four key factors, i.e., pressure, tubular type, camber angle, and applied load on the wheel, that influence the risk of wheel skidding in racing wheelchairs. To accomplish this, the grip recovery and grip loss torques were measured using a skidometer, a tool designed to characterize a tire’s grip on a surface.

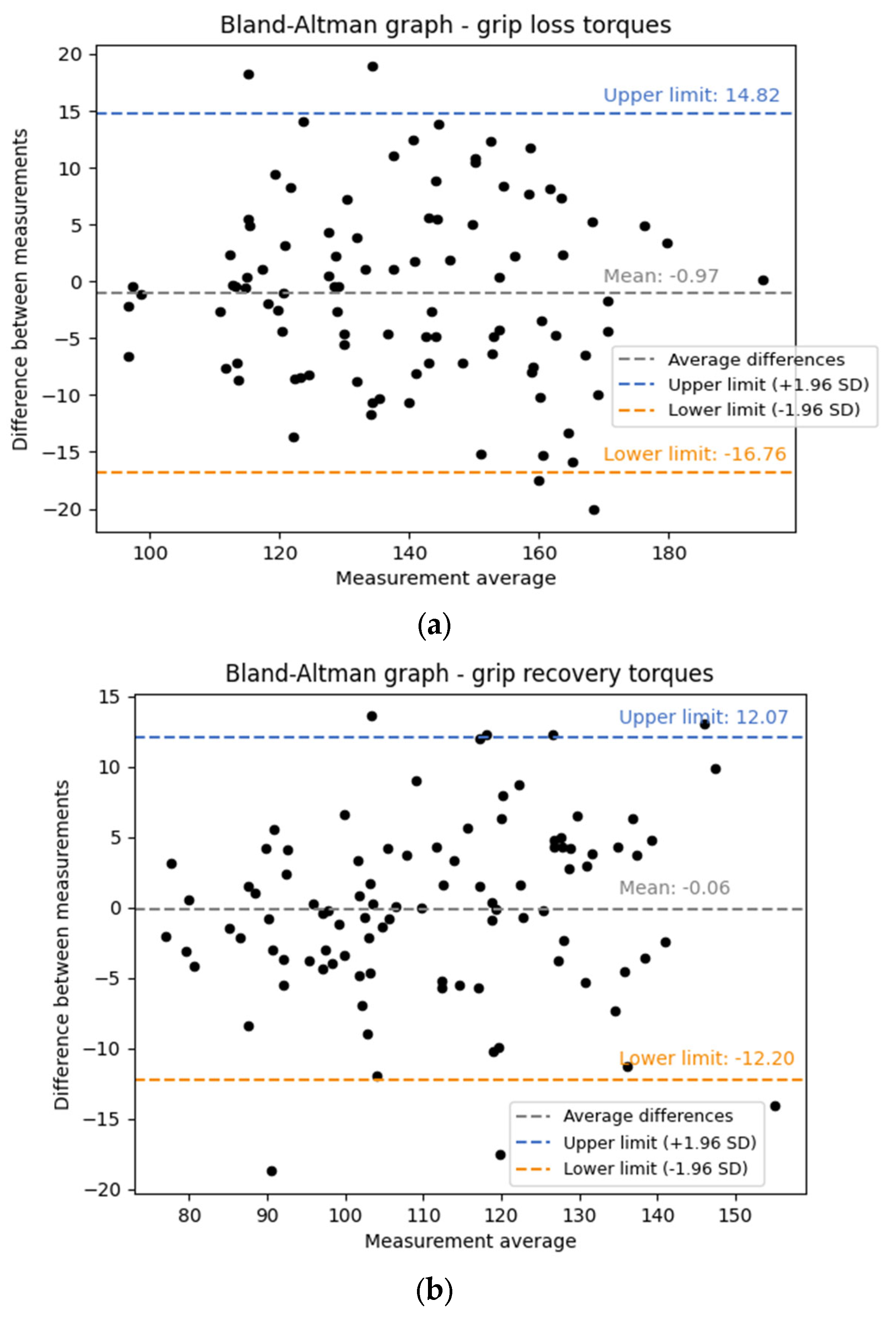

Initially, the analysis of the Bland–Altman plot indicated that the utilization of the skidometer to investigate the skidding of a wheelchair wheel on a track is a reproducible method (

Figure 3). Specifically, nearly all values lie within the agreement limits and are distributed around the mean line. The variability of the measurements is moderate for both grip loss and grip recovery torques. However, the results should be interpreted with caution, as the trials were repeated only twice due to time constraints. To enhance the reliability of these findings, it would be advisable to replicate this test with a minimum of three trials for each measurement.

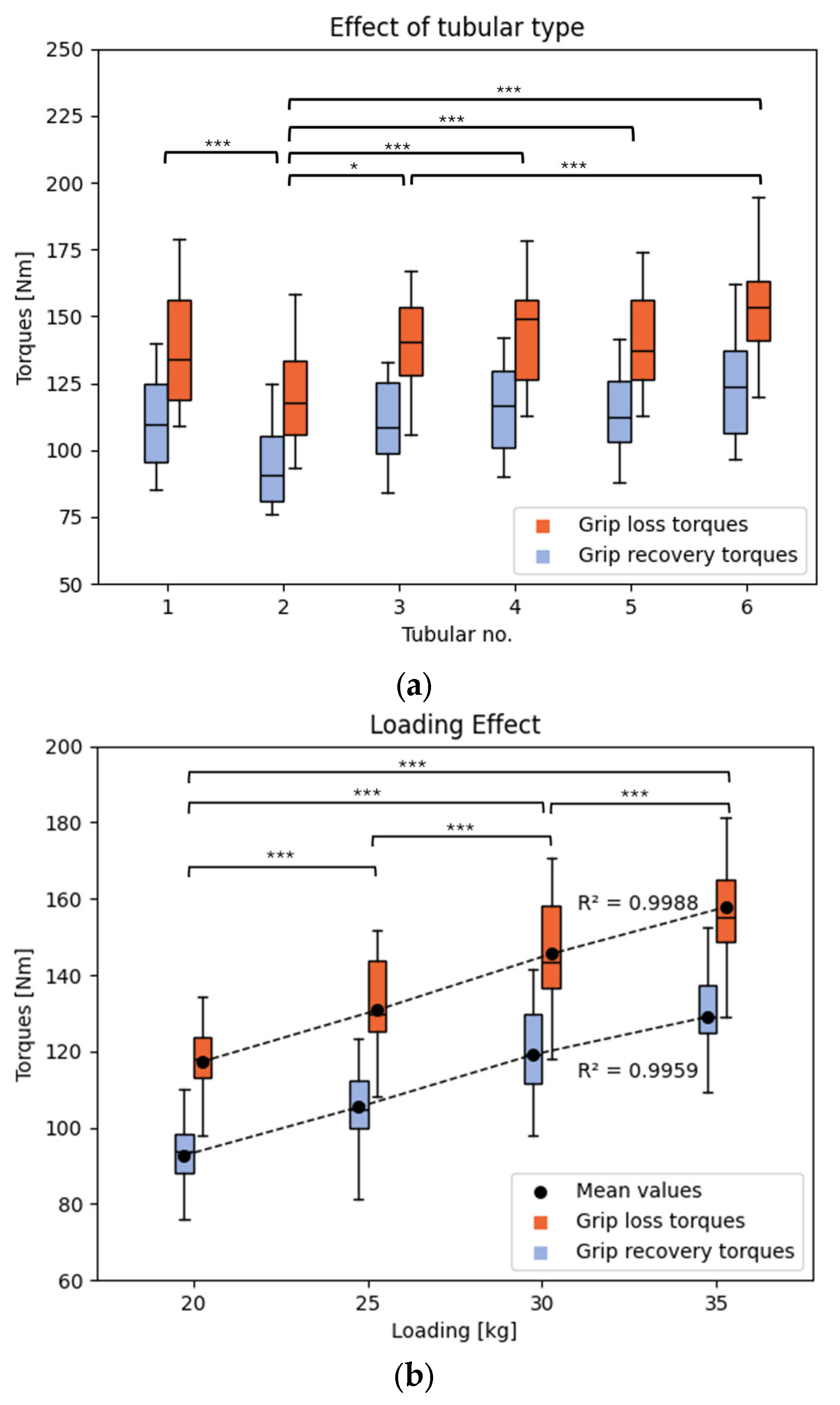

The hypothesis, which assumed that the proposed method would enable the identification of parameters among the camber angle, pressure, the load applied to the wheel, and tubular type that influence the risk of wheel skidding in wheelchair racing, has been partially validated. Based on the statistical studies conducted, only the load and tubular type demonstrated significant effects (

Table 4) on the torques obtained. This suggests that, for the tested values, the skidding of the racing wheelchair wheel is primarily influenced by the athlete’s weight and the type of tubular used, rather than tire pressure or the camber angle of the wheel. However, a

p-value indicates the probability of observing the data, assuming the null hypothesis is true. In this context, a significant

p-value suggests that the load and tubular type have a genuine effect on wheel skidding, but non-significant

p-values for tire pressure and camber angle do not necessarily mean these factors have no influence; rather, their effects may be more subtle or context-dependent.

Figure 4b illustrates the influence of the applied load on the resulting torques. The effect of loading is linear, with high coefficients of determination (R

2 = 0.9988 for grip loss torques and R

2 = 0.9959 for grip recovery torques). This linearity indicates that the risk of skidding is inversely proportional to the athlete’s weight; lighter athletes experience a higher risk of skidding compared to heavier athletes. This finding aligns with biomechanical principles, as a heavier athlete requires a greater force applied to the hand rim to induce tire skidding due to increased normal force and consequent frictional resistance. However, the application of Coulomb’s law is not straightforward in this context. The deformable nature of the tubular material (rubber tread with various coatings) and the heating of the tire in contact with the ground introduce non-linearities in the coefficient of friction (μ). These factors invalidate the direct application of Coulomb’s law, which assumes a constant coefficient of friction [

18]. The dynamic interaction between the tire and the ground, influenced by factors such as material properties, temperature, and loading conditions, necessitates a more complex biomechanical analysis. In conclusion, it is crucial to consider the athlete’s weight when assessing the risk of wheelchair skidding. The biomechanical interplay between applied forces, normal forces, and frictional dynamics underscores the need for a comprehensive understanding of these factors to mitigate skidding risks effectively.

Figure 4a illustrates the influence of tubular type on the resulting torques. In the context of wheelchair racing, the primary goal is to minimize the risk of wheel skidding, thereby achieving high grip loss and recovery torques. Additionally, the difference between grip loss and recovery torques should be minimized, as it reflects the wheel’s recovery speed after skidding on the ground. Regarding the chosen tubular types, one tubular stands out: tubular no. 6 (Vittoria Pista Speed 23–28″). This tubular is known for its durable construction and grip and exhibits the highest grip loss torque (

), while showing a grip recovery torque similar to the other tires. This combination ensures a high level of traction and quick recovery from skidding, which is crucial for maintaining control and performance during races. The specific characteristics of the Vittoria Pista Speed, such as its robust construction and optimized tread pattern, contribute to its superior performance in grip loss and recovery.

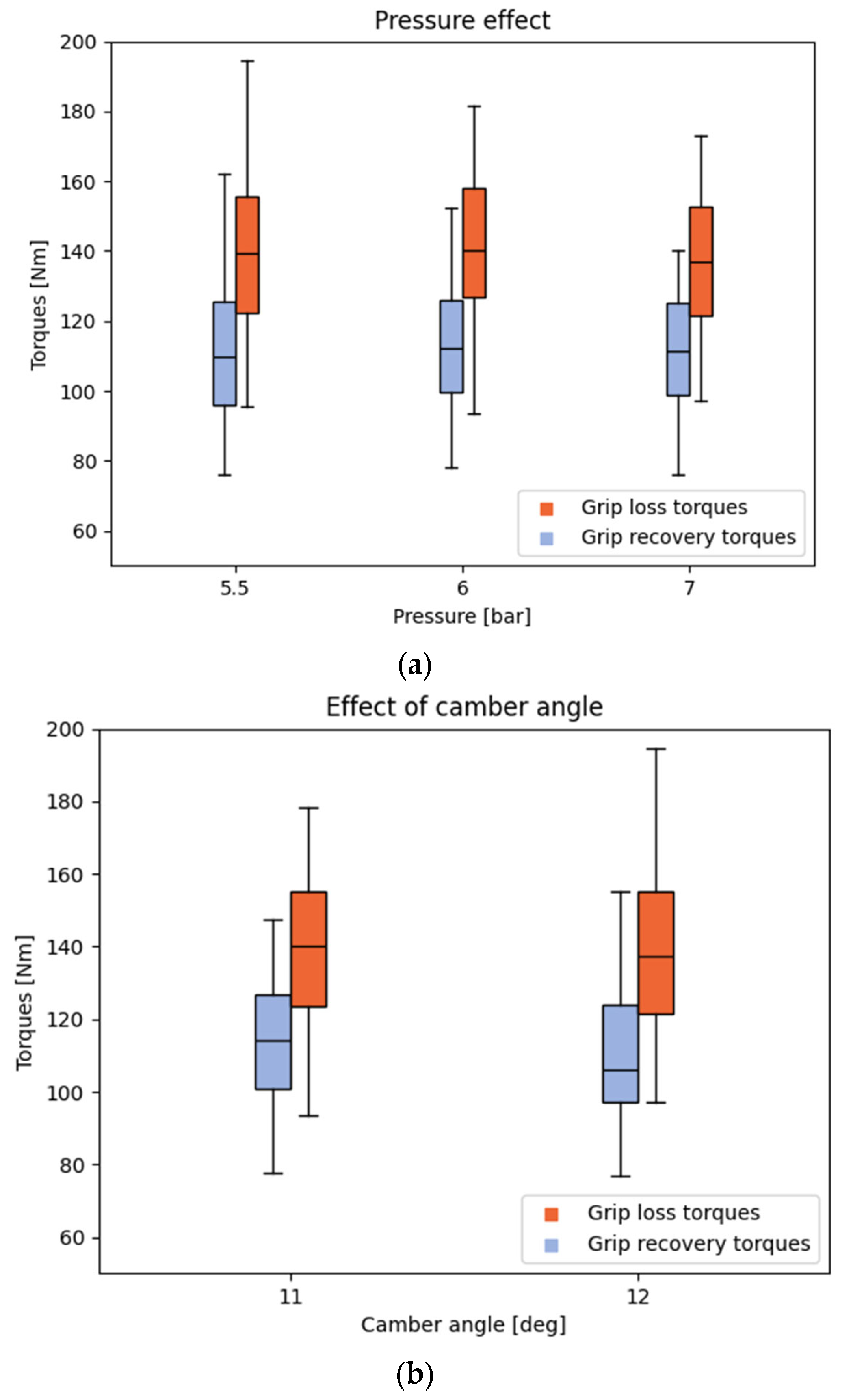

Moreover, this research found that pressure values did not have a significant effect on wheel skidding. Indeed, tire pressure influences the contact patch with the ground and, consequently, tire grip. However, this contact area also depends on other parameters such as tire type, athlete mass, speed, and environmental conditions. Therefore, analyzing pressure independently of these factors may not fully capture its role in skidding behavior. Furthermore, statistical analysis of the data revealed that, within the tested pressure range, its effect on skidding was not significant. This does not imply that tire pressure has no influence under all conditions, but rather that, under the specific experimental conditions of this study, its impact on wheel skidding did not reach statistical significance. This lack of a significant effect could be explained by the fact that, within the tested pressure range, variations in grip remain relatively small, and other parameters, such as applied load or camber angle, play a more dominant role in triggering skidding.

Additionally, the absence of a notable effect from camber angle (

Figure 5b;

Table 4) contradicts the scientific literature and can be explained by the range of values tested. Previous studies have evaluated the influence of the camber angle on various parameters. Ott et al. [

19] demonstrated that the camber angle has a weak influence on rolling resistance. However, their study only focused on evaluating angles ranging from 0° to 5°. On the other hand, Faupin et al. [

20] showed that an increase in the camber angle raises the residual torque, which leads to deceleration. Moreover, a change of 1° may not be sufficient to alter the contact area between the wheel and the ground, thus resulting in no noticeable change in force distribution. Therefore, it would be interesting to expand the range of tested angles while respecting the settings used by wheelchair athletes. This would provide a more nuanced understanding of how the camber angle affects grip loss and recovery torques, potentially leading to optimized configurations for enhanced performance in wheelchair racing.

Additional tests were conducted with the Vittoria Pista Speed 23–28″ tubular to verify the influence of pressure on grip loss and recovery torques over a wider range of values. This was performed to confirm or refute the initial results indicating that pressure has no effect on the obtained torques. The experiment was carried out by testing pressures of 6, 8, 10, and 11 bars. These values were chosen based on the product’s technical specifications to ensure a comprehensive evaluation. The results indicated that a pressure of 11 bars minimizes the risk of skidding. The effect of pressure on the obtained torques evolves in an increasing manner with the applied mass. This suggests that there is an optimal pressure range where the grip loss and recovery torques are maximized, and this range is influenced by the athlete’s weight. It appears more beneficial to increase the tire pressure when the athlete’s weight is higher. However, to confirm this initial impression, a statistical study would be necessary. Such a study would help to quantify the interaction between tire pressure, athlete weight, and the resulting torques, leading to more precise recommendations for optimizing performance in wheelchair racing.

However, the torques obtained in this experiment are below the values achieved by para-athletes. The study by Miyazaki et al. [

21] determined that the tangential forces exerted by elite para-athletes on the hand rim reach a maximum of 150 N (in a propulsion test of 10 cycles at a speed of 5.56 m/s). To determine the corresponding torque, the following mathematical relationship is applied:

where

: tangential torque

,

: tangential force

,

: radius of the wheel

.

It is found that the maximum tangential torque developed by the athletes is . The study was conducted with athletes from the T54 class, meaning those with the lowest level of disability, i.e., participants who retain upper body muscular strength and may have muscular activity throughout the torso. In our study, the risk of adhesion loss occurs at torque values of at least . Thus, the risk of skidding seems unattainable.

One reason that could explain this result lies in the application of the torque to the wheel. Indeed, the skidometer was designed so that torque is applied gradually. However, in wheelchair sports, the torque applied to the hand rim is exerted abruptly. Therefore, it would be relevant to replicate the experiment to more closely reflect the real conditions on the field.

Moreover, we acknowledge that the formula is based on the assumption of slip-free rolling, which may not hold true under skidding conditions. The hypothesis behind using this formula is to establish a baseline for comparison between the torques obtained in the experiment and those exerted by elite para-athletes under controlled conditions. While this model does not account for the complex dynamics of skidding, it provides a useful approximation for understanding the relative magnitudes of the forces involved. To address this limitation more comprehensively, future studies should consider more advanced biomechanical models that account for additional factors such as friction, deformation of the tire, and the abrupt application of torque. These factors introduce non-linearities and complex interactions that are not captured by the simple formula used.

Finally, during the experimentation, the treads of two tubulars (Dugast Pista Latex 20″ and 22″ pink) tore. As a result, they were not included in the

Section 3. One possible explanation for this phenomenon lies in the tubulars’ tread material. It consists of a thin layer of latex directly bonded to the tubular tire to reduce rolling resistance. While this material is ideal for use on a cycling track, it appears unsuitable for use on an athletics track. The thin latex layer, while providing excellent performance on smooth surfaces, may not withstand the higher frictional forces and abrupt torque applications typical of athletics tracks.

Furthermore, it should be noted that the recommended pressure in the technical specifications ranges from 8 to 13 bars. In this protocol, the tested pressures ranged between 5.5 and 7 bars. This discrepancy in pressure settings could have contributed to the tread failure, as lower pressures may not provide sufficient support and stability for the tire under the demanding conditions of the experiment. By replicating the experiment under conditions that more closely reflect real-world scenarios, we can provide a more accurate representation of the forces and torques experienced by para-athletes during wheelchair racing, thereby enhancing the validity and applicability of our findings. This includes not only adjusting the pressure settings to align with the manufacturer’s recommendations but also considering the specific material properties and their suitability for different track surfaces. Future experiments should also explore a broader range of tubular materials and designs to identify those that offer the best balance of performance, durability, and safety for wheelchair athletes.