Modern Applications of 3D Printing: The Case of an Artificial Ear Splint Model

Abstract

:1. Introduction

2. Experimental Design

2.1. Materials

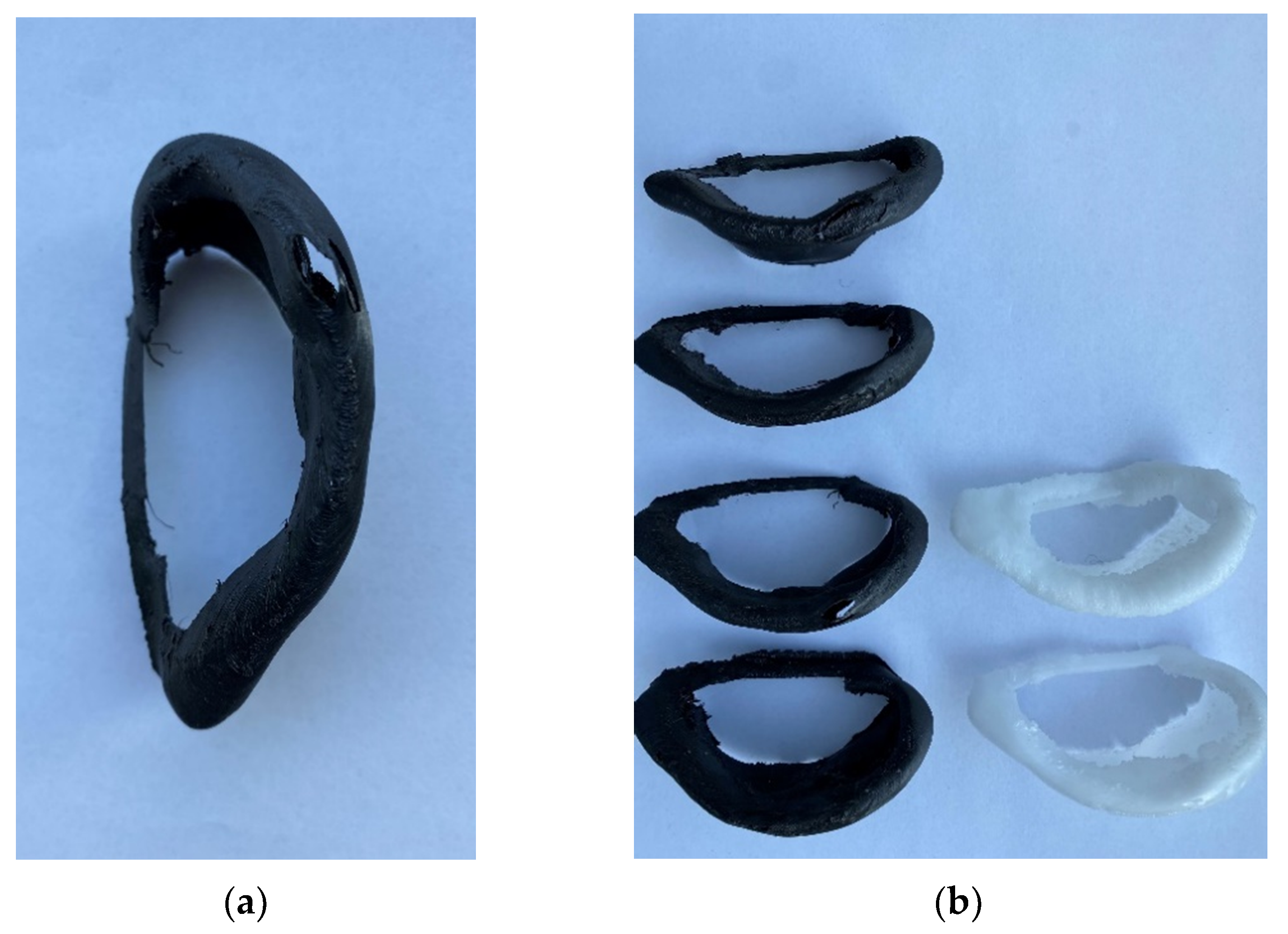

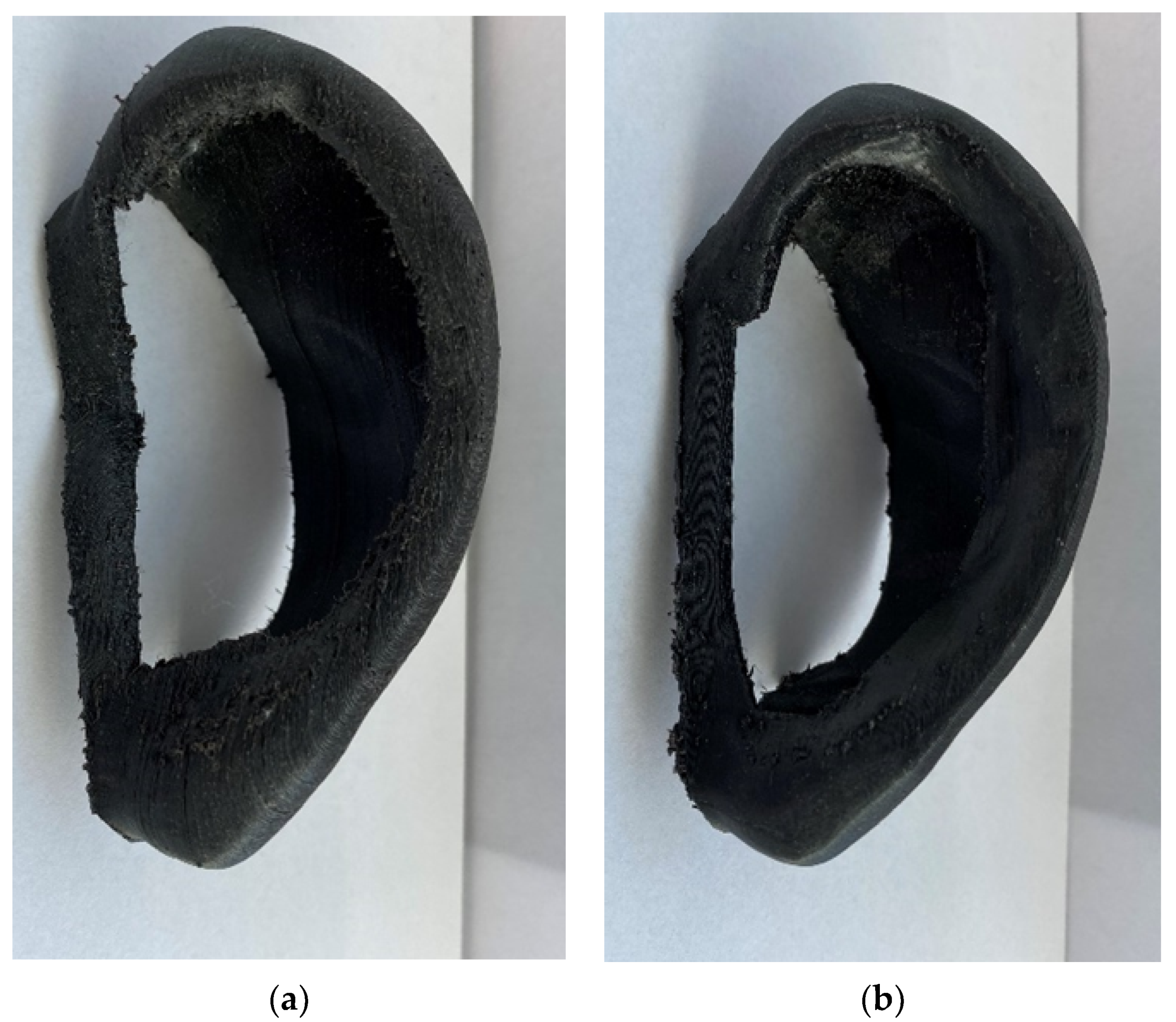

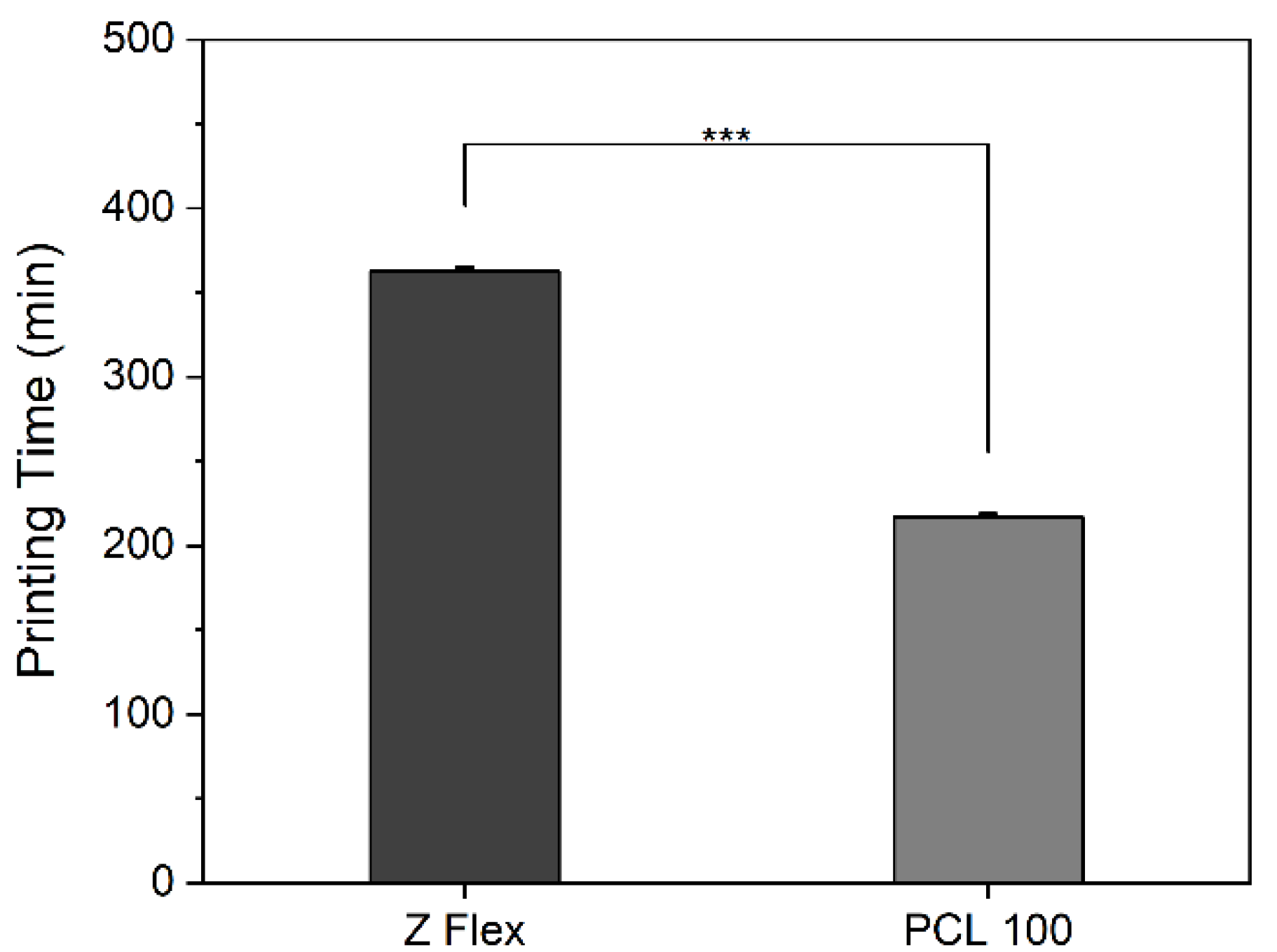

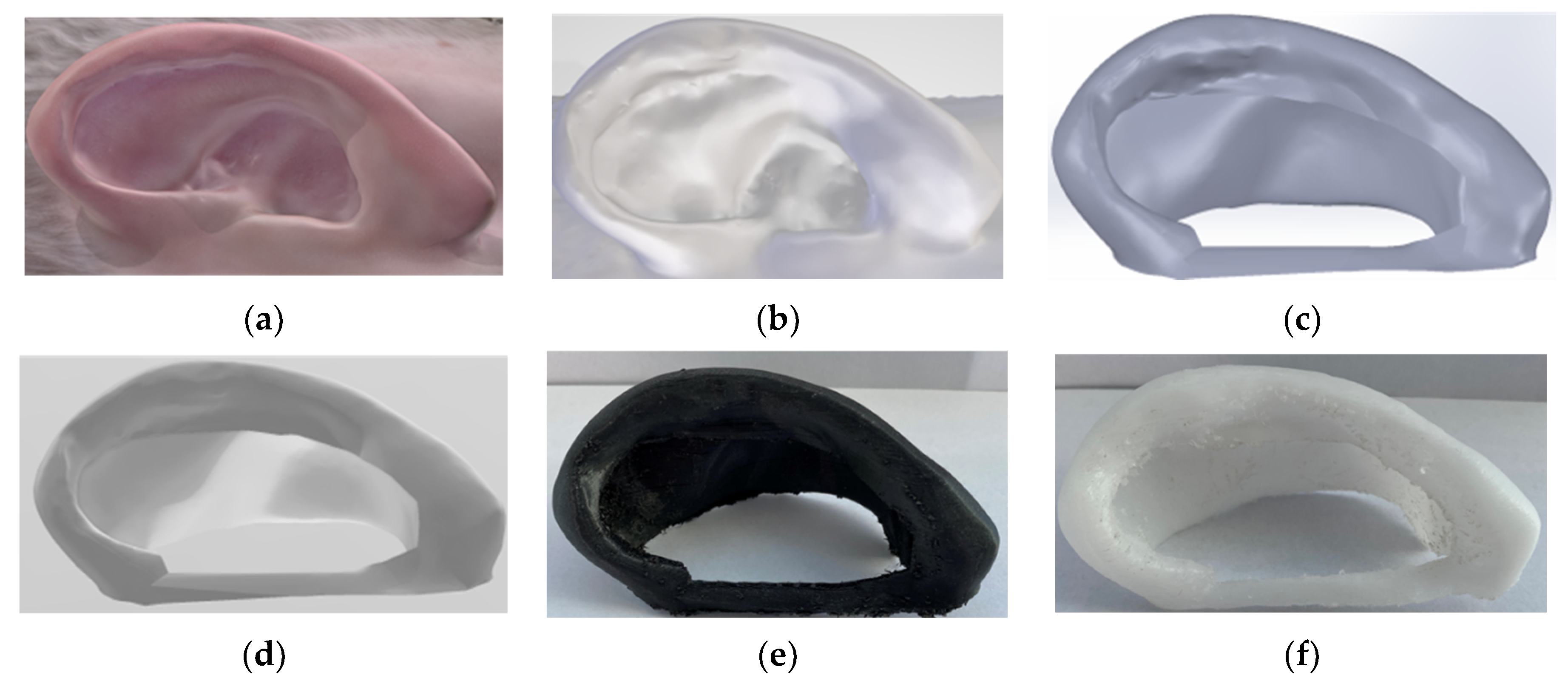

- Z-Flex is an elastomeric and thermoplastic material that is manufactured by Zortrax in Poland. It was the first choice for our experimental plan because of its elasticity, mechanical properties, and the fact that it is a nontoxic filament [10]. After 6 h and 5 min, the ear splint made from Z-Flex was printed properly, weighting only 15 g, with dimensions according to the patient’s ear, 79.36 mm in length, 34.01 mm in width, and 44.05 mm in height.

- Polycaprolactone 100, known as PCL 100, is one of the most widely used materials in universities for medical research. Its flexibility and biocompatibility are the key factors for its selection as the 2nd material in this research study [11]. The printing time for the PCL 100 ear splint was 3 h and 39 min, and its weight was 14 g, while the dimensions were the same as those of the Z-Flex model.

2.2. Equipment

3. Procedure

3.1. 3D-Scanning. 00:10 Hours

- The whole scan procedure of the auricle can be done by using a photographic instrument, such as a smartphone. The scan should involve a 180-degree view of the human ear, start at the front side of ear and the tragus, then continue to the helix and antihelix sides and end at the back of the auricle beyond the connection to the head.

- Selecting of the appropriate place for scanning the patients’ ear.

- Exporting the digital ear model file.

3.2. Reverse Engineering. 01:30 Hours

- Importing all these data from the scan photos to Geomagic and exporting a .obj file.

- Using tools in the Meshlab program to set up the scale of the digital ear model and measure the actual distances of three points between the ear and the head. Specifically, the distance between the top point of the helix and the head was 10 mm, the middle point was 16 mm, and the point from the lobule to the head was 19 mm [12].

3.3. Computer Aided Design. 00:30 Hours

- Appling the delete face function on all the surfaces that are around the ear.

- Closing the holes by surface filling.

- Converting to mesh body.

- Increasing the mesh refinement to fine, so as to increase the corresponding triangles in the STL file.

3.4. Conversion to STL & STL File Manipulation. 00:10 Hours

- 1.

- Exporting the file from SLDPRT to STL.

- 2.

- Using different custom profiles to set up the appropriate settings for both materials, Z-Flex and PCL 100.

- 3.

- Z-Flex profile:

- Nozzle diameter and layer thicknesses are 0.4 mm and 0.09 mm, respectively.

- Extrusion and platform temperatures are 230 °C and 60 °C, respectively.

- Extruder speed is 20 mm/s and the distance is 2.5 mm.

- Offset is 0.5.

- 4.

- PCL 100 profile:

- Nozzle diameter and layer thicknesses are 0.4 mm and 0.09 mm, respectively.

- Extrusion and platform temperatures are 130 °C and 30 °C, respectively.

- Extruder speed is 20 mm/s and the distance is 1.0 mm.

- Offset is 0.5.

- 5.

- Placing the supports manually on both profiles.

- 6.

- Exporting the gcode file and inserting it into the specific SD card.

3.5. 3D Printer Setup. 00:10 Hours

- Heat the platform.

- Heat the extruder.

- Load material.

- Select the gcode file to print.

- Start the process.

3.6. Application. 01:30 Hours

- Remove the printed model from the platform.

- Carefully remove all the supports using specific tools.

4. Expected Results

5. Recommendations

6. Patents

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Otto, I.; Capendale, P.; Garcia, J.; de Ruijter, M.; van Doremalen, R.; Castilho, M.; Lawson, T.; Grinstaff, M.; Breugem, C.; Kon, M.; et al. Biofabrication of A Shape-Stable Auricular Structure for The Reconstruction of Ear Deformities. Mater. Today Bio. 2021, 9, 100094. [Google Scholar] [CrossRef] [PubMed]

- Salgarello, M.; Gasperoni, C.; Montagnese, A.; Farallo, E. Otoplasty for Prominent Ears: A Versatile Combined Technique to Master the Shape of The Ear. Otolaryngol.–Head Neck Surg. 2007, 137, 224–227. [Google Scholar] [CrossRef] [PubMed]

- Handler, E.; Song, T.; Shih, C. Complications of Otoplasty. Facial Plast. Surg. Clin. N. Am. 2013, 21, 653–662. [Google Scholar] [CrossRef] [PubMed]

- Baby’s Ears starting to Stick Out or Fold Over? | EarBuddies™. Available online: https://www.earbuddies.com/ (accessed on 30 May 2021).

- Argyropoulos, A.; Botsaris, P. Research, Study, Design and Development of An Artificial Ear Splint Model by Using A 3D Printer. MATEC Web Conf. 2020, 318, 01018. [Google Scholar] [CrossRef]

- Liaw, C.; Guvendiren, M. Current and Emerging Applications Of 3D Printing in Medicine. Biofabrication 2017, 9, 024102. [Google Scholar] [CrossRef] [PubMed]

- Bannink, T.; Bouman, S.; Wolterink, R.; van Veen, R.; van Alphen, M. Implementation Of 3D Technologies in the Workflow of Auricular Prosthetics: A Method Using Optical Scanning and Stereolithography 3D Printing. J. Prosthet. Dent. 2021, 125, 708–713. [Google Scholar] [CrossRef] [PubMed]

- Gibson, I.; Rosen, D.W.; Stucker, B. Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping and Direct Digital Manufacturing, 2nd ed.; Springer: New York, NY, USA; London, UK, 2015. [Google Scholar]

- Argyropoulos, A. Research, Study, Design and Development by Using a 3D Printer Model of an Artificial Ear Splint. Master Thesis, University of Thrace, Xanthi, Greece, 11 November 2019. [Google Scholar]

- Z-FLEX. Available online: https://zortrax.com/filaments/z-flex/ (accessed on 30 May 2021).

- Facilan™ PCL 100 Filament. Available online: https://www.3d4makers.com/products/facilan-pcl-100-filament (accessed on 30 May 2021).

- Schneider, A.L.; Sidle, D.M. Cosmetic Otoplasty. Facial Plast. Surg. Clin. N. Am. 2018, 26, 19–29. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Argyropoulos, A.; Botsaris, P.N. Modern Applications of 3D Printing: The Case of an Artificial Ear Splint Model. Methods Protoc. 2021, 4, 54. https://doi.org/10.3390/mps4030054

Argyropoulos A, Botsaris PN. Modern Applications of 3D Printing: The Case of an Artificial Ear Splint Model. Methods and Protocols. 2021; 4(3):54. https://doi.org/10.3390/mps4030054

Chicago/Turabian StyleArgyropoulos, Athanasios, and Pantelis N. Botsaris. 2021. "Modern Applications of 3D Printing: The Case of an Artificial Ear Splint Model" Methods and Protocols 4, no. 3: 54. https://doi.org/10.3390/mps4030054

APA StyleArgyropoulos, A., & Botsaris, P. N. (2021). Modern Applications of 3D Printing: The Case of an Artificial Ear Splint Model. Methods and Protocols, 4(3), 54. https://doi.org/10.3390/mps4030054