Perspectives of Insulating Biodegradable Composites Derived from Agricultural Lignocellulosic Biomass and Fungal Mycelium: A Comprehensive Study of Thermal Conductivity and Density Characteristics

Abstract

1. Introduction

2. Materials and Methods

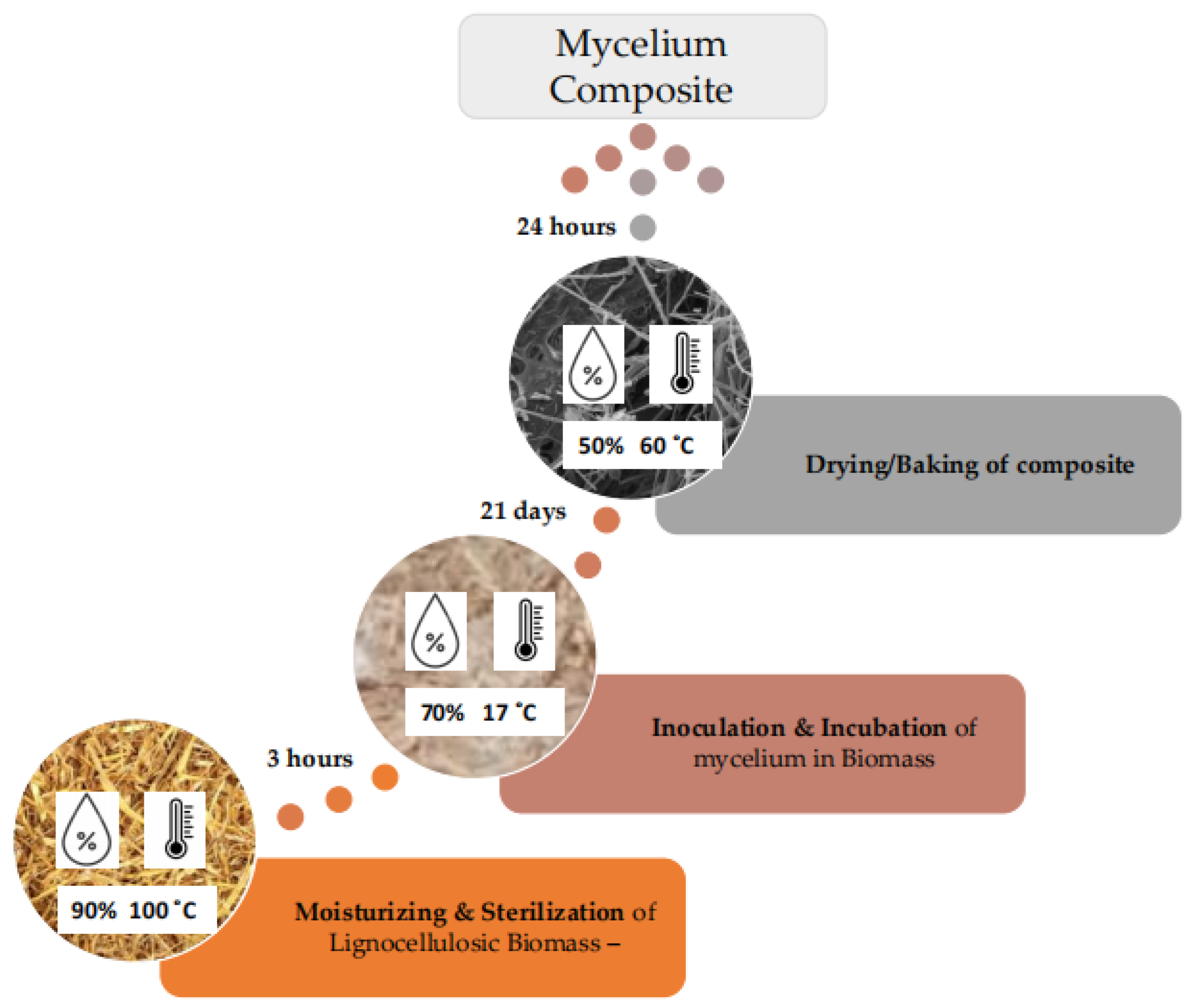

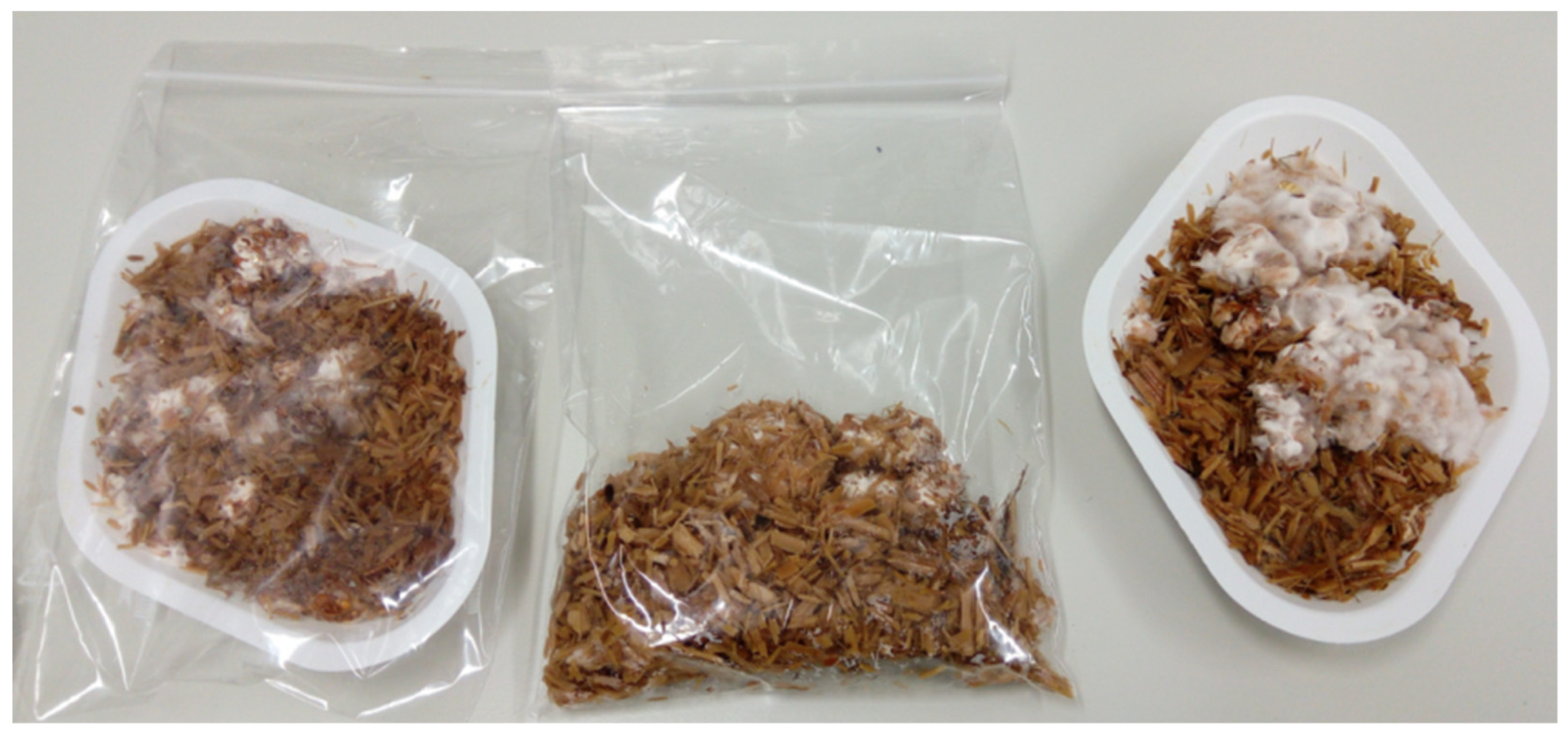

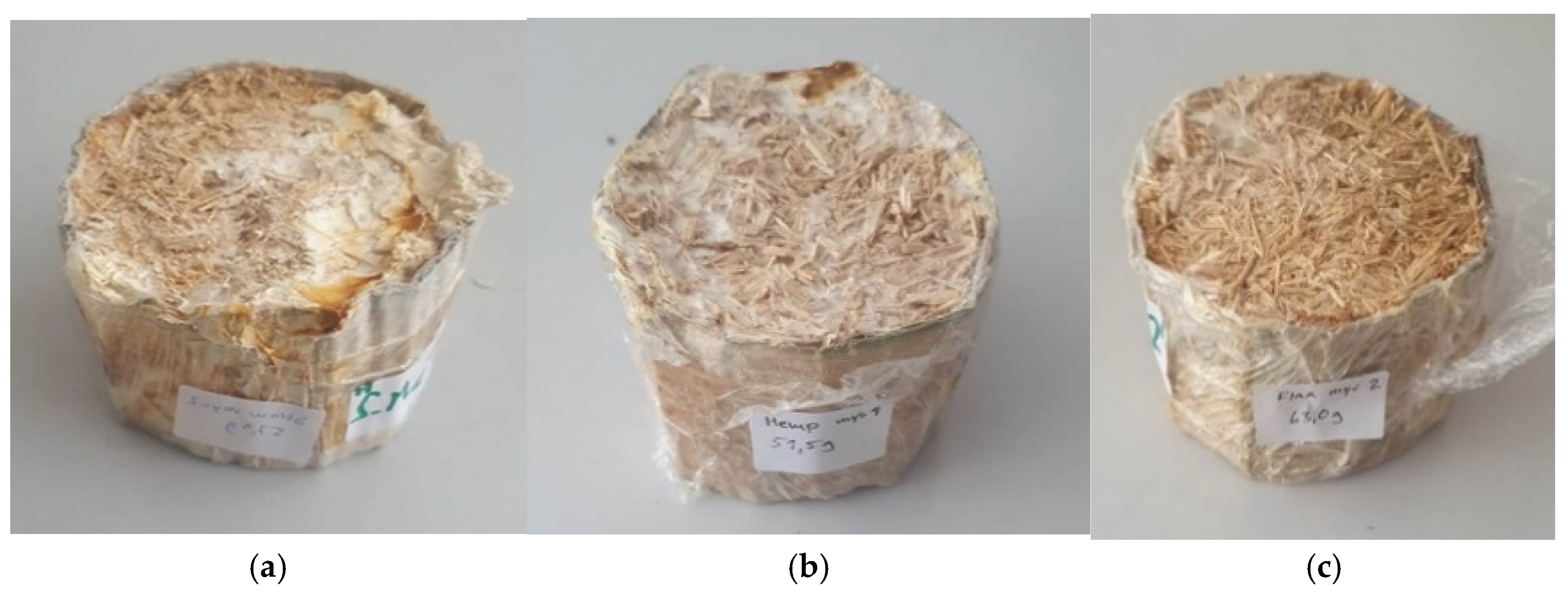

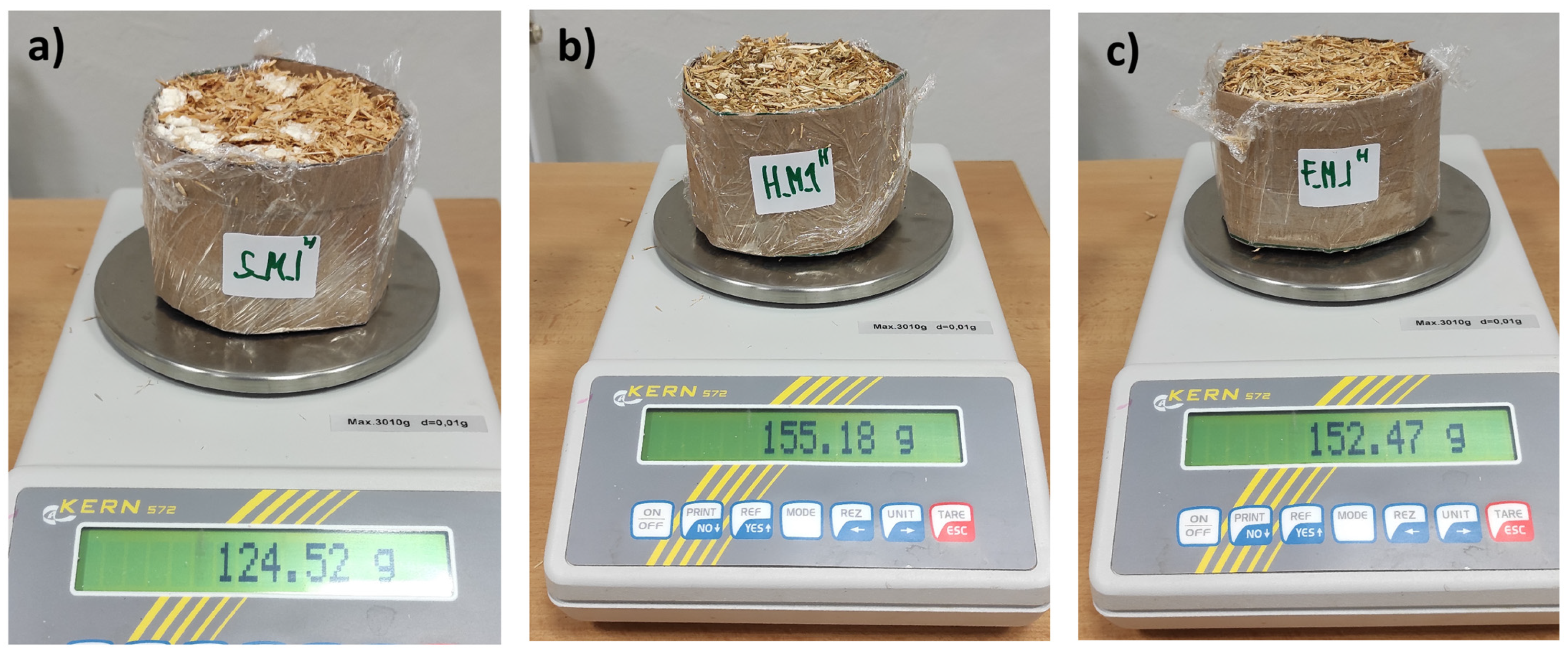

2.1. Sample Formation Technique

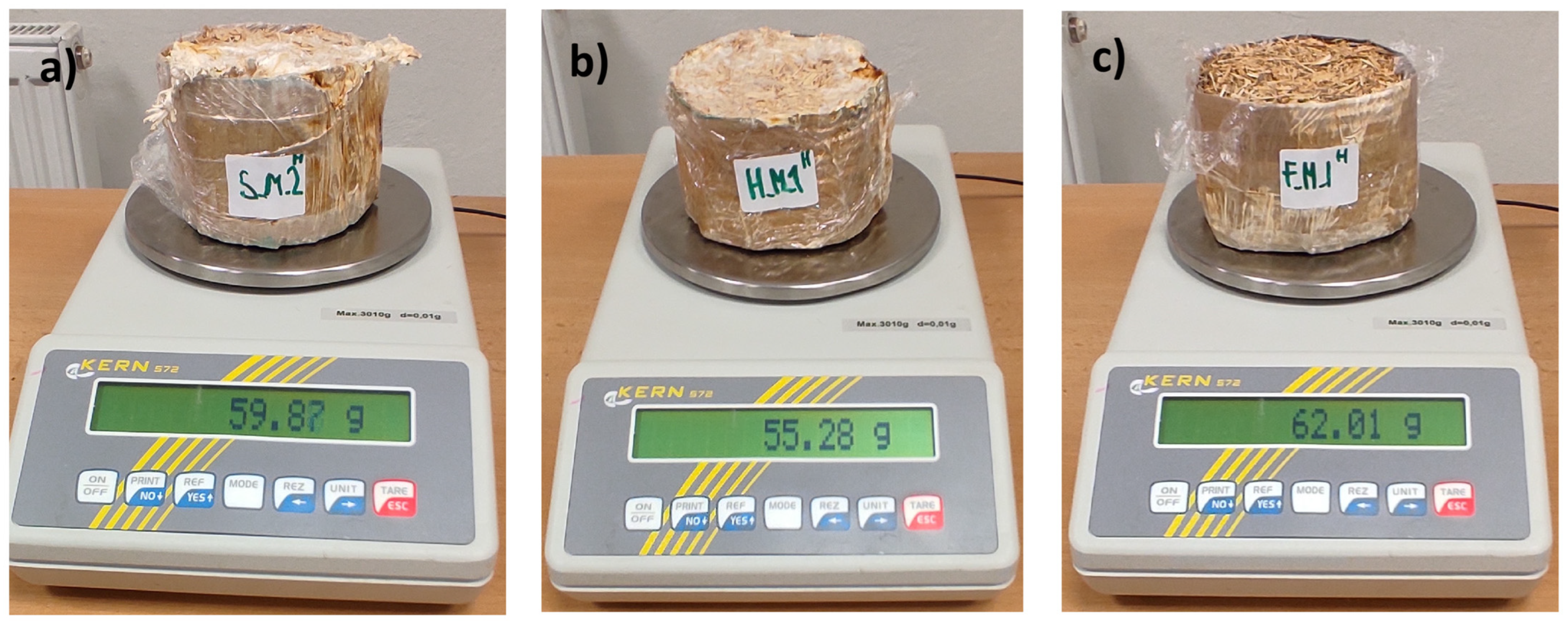

2.2. Thermal Conductivity and Density Measurements

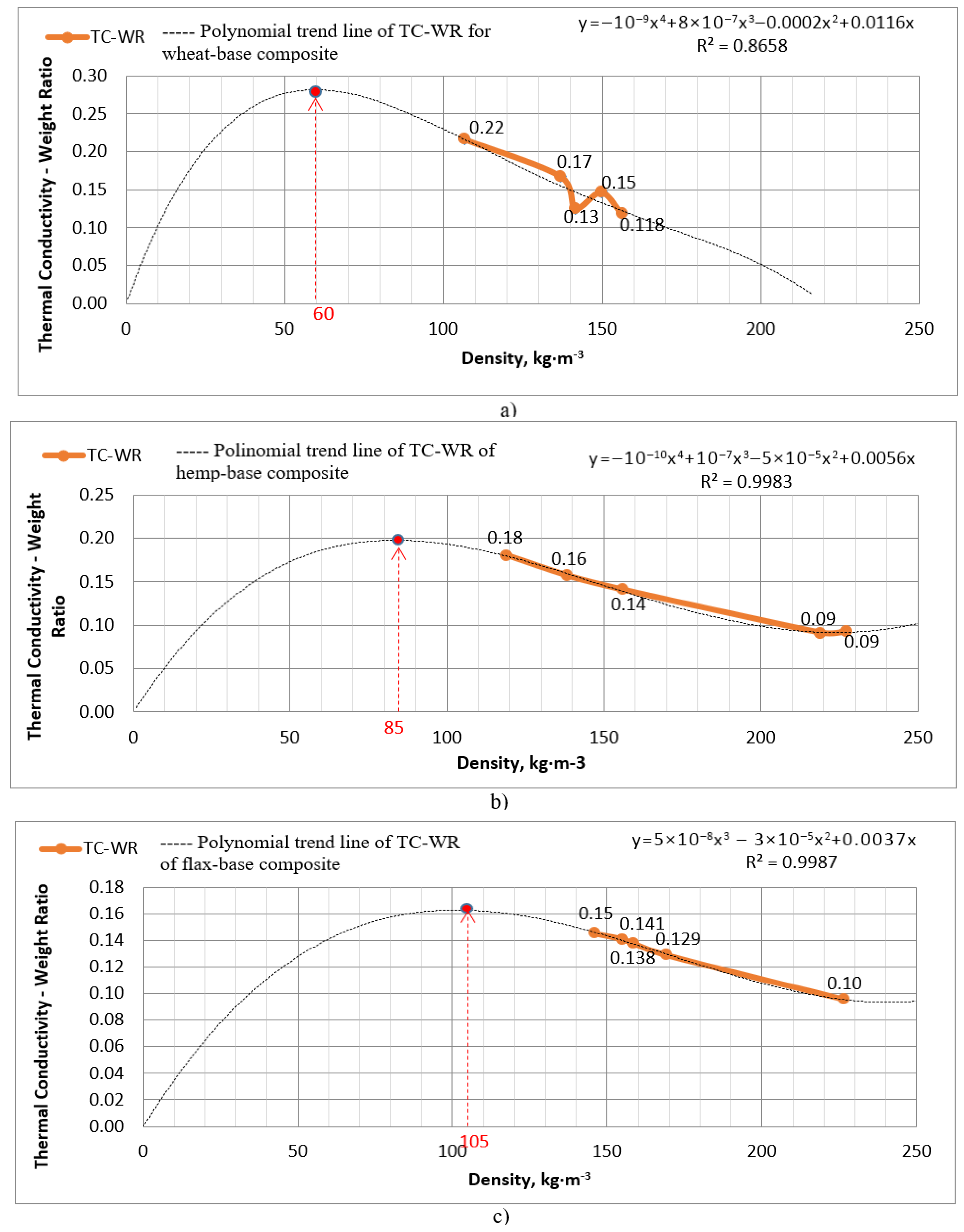

2.3. TC-WR Indicator and Polynomial Trend Analysis

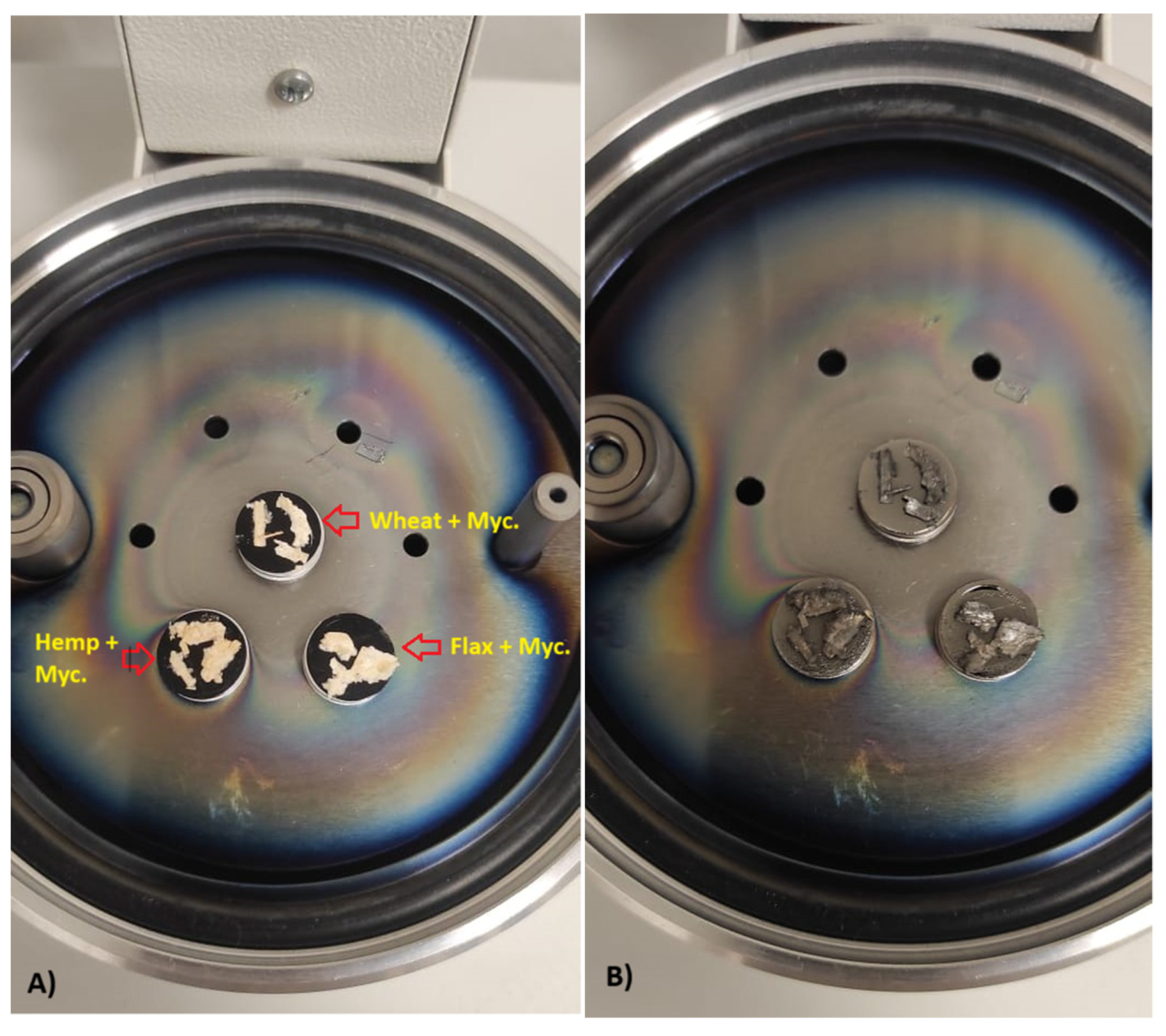

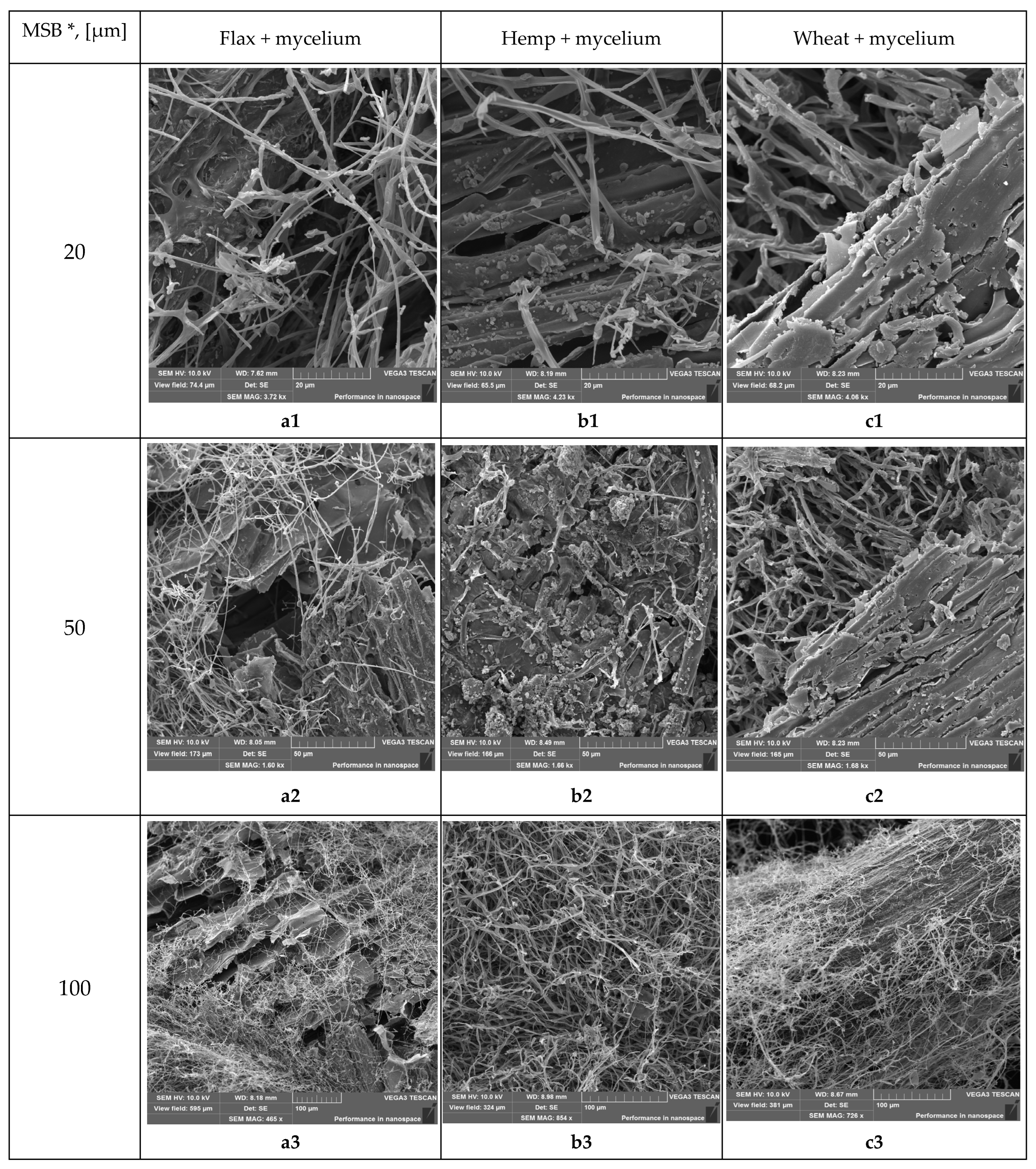

2.4. Scanning Electron Microscope (SEM) Analysis

3. Results

| Insulation Material | Thermal Conductivity at 10 °C, λmin–λmax [W·m−1·K−1] | Dry Density (Own Mean.), ρmin–ρmax [kg·m−3] | Bio 1 | Reference | Average Thermal Conductivity *, λAvg [W·m−1·K−1] | Average Density *, ρAvg [kg·m−3] | Thermal Conductivity-Weight Ratio *, 1/(λAvg·ρAvg) [W−1·kg−1·m4·K] |

|---|---|---|---|---|---|---|---|

| Vacuum Insulation panels (VIP) | 0.004 | 160–200 | N | [6,57] | 0.004 | 180 | 1.389 |

| Polyurethane rigid foam (PUR) | 0.020–0.030 | 30–45 | N | [51,52] | 0.025 | 38 | 1.053 |

| Expanded polystyrene (EPS) | 0.030–0.040 | 15–40 | N | [53,54] | 0.035 | 27.5 | 1.039 |

| Sheep wool | 0.032–0.054 | 10–40 | Y | [60,61,62] | 0.043 | 25 | 0.930 |

| Extruded polystyrene (XPS) | 0.028–0.040 | 25–45 | N | [55,56] | 0.034 | 35 | 0.840 |

| Cellulose Fibers | 0.036–0.042 | 40–70 | Y | [63,64] | 0.039 | 55 | 0.466 |

| Wheat + mycelium Trametes versicolor | 0.042 | 94 | Y | [12] | 0.042 | 94 | 0.252 |

| Hemp + mycelium Trametes versicolor | 0.040 | 99 | Y | [12] | 0.040 | 99 | 0.250 |

| Mineral Wool | 0.034–0.045 | 120–140 | Y | [58,59] | 0.039 | 130 | 0.197 |

| Wheat + mycelium Ganoderma lucidum * | 0.043–0.056 | 107–156 | Y | Current research | 0.048 | 138 | 0.148 |

| Cork | 0.040–0.050 | 80–240 | Y | [65,66] | 0.045 | 160 | 0.139 |

| Flax + mycelium Trametes versicolor | 0.058 | 135 | Y | [12] | 0.058 | 135 | 0.128 |

| Flax + mycelium Ganoderma lucidum * | 0.045–0.047 | 146–220 * | Y | Current research | 0.046 | 171 | 0.127 |

| Hemp + mycelium Ganoderma lucidum * | 0.045–0.050 | 119–227 | Y | Current research | 0.047 | 172 | 0.123 |

| Soybean straw + Mycelium Ceriporia lacerata | 0.054 | 160 | [67] | 0.054 | 160 | 0.116 | |

| Rapeseed bagasse + mycelium Ganoderma lucidu | 0.057 | 156 | Y | [36] | 0.057 | 156 | 0.112 |

| various substrate materials + mycelium Irpex lacteus | 0.060 | 180 | Y | [35] | 0.060 | 180 | 0.092 |

| Bark fiber | 0.044–0.063 | 164–276 | Y | [68] | 0.0535 | 220 | 0.084 |

| Flax + waterglass | 0.066–0.068 | 235–284 | Y | [31] | 0.0672 | 259.5 | 0.057 |

| Cotton Stalks | 0.058–0.081 | 150–450 | Y | [2,27] | 0.070 | 300 | 0.048 |

| Hempcrete | 0.057–0.066 | 389–441 | Y | [32] | 0.0619 | 365 | 0.044 |

| Light-earth | 0.060–0.120 | 190–353 | Y | [69] | 0.090 | 271.5 | 0.041 |

| Cellulose fiber + mycelium Ganoderma lucidu | 0.085 | 373 | [36] | 0.085 | 373 | 0.031 | |

| Timber (softwood) | 0.130 | 500 | Y | [70] | 0.130 | 500 | 0.015 |

4. Discussion

4.1. General Perspectives

4.2. Industrialization and Distinctive Features

5. Conclusions

- Research on thermal conductivity. In particular, the thermal conductivity coefficient measurements indicated quite close results across three lignocellulosic material variations and lie between 0.435 and 0.585 W·m−1·K−1. It is evident that the value remains consistent regardless of the type of agricultural residues.

- Analysis by thermal conductivity—weight ratio (TC-WR) coefficient. During the investigation, the suggestion was made to utilize a qualitative TC-WR coefficient in evaluating thermal insulation materials, considering the inverse correlation between the density and thermal conductivity derivatives. The flax- and hemp-based samples displayed quite a close TC-WR meanings of 0.127 W−1·kg−1·m4·K and 0.123 W−1·kg−1·m4·K, respectively. However, the wheat-based sample showed a higher value of 0.148 W−1·kg−1·m4·K, which can be attributed to its lower density. In particular, the biomass with fungal mycelium binder demonstrated excellent values for this ratio and was one of the leading among biodegradable conventional materials included in the comparison. There were three that performed better: sheep wool (0.93 W−1·kg−1·m4·K), cellulose fibers (0.466 W−1·kg−1·m4·K), and mineral wool (0.197 W−1·kg−1·m4·K). Cork showed a middle performance among cellulosic agro ‘waste’, with mycelium having the indicative ratio of 0.139 W−1·kg−1·m4·K appropriately. Among the known analog composites derived from biomass and mycelium, suggested composites ranked third, fifth, and sixth out of ten types based on the TC-WR indicator (Table 3). Two first mycelium containing compounds in ranking may be attributed to the lower density of samples.

- Predicting an optimal density. Our analysis aimed at identifying the optimal density to achieve the best proposed TC-WR coefficient. The values obtained exhibit a strong correlation with the findings from other comparable studies, although they show minor differences in absolute terms. For instance, Elsacker et al (2019) reported densities of 99 kg·m−3 for hemp biomass with mycelium, whereas our findings demonstrated the optimum density for this biomass at 85 kg·m−3. Specifically, a polynomial trend line was utilized to determine the most optimal production densities for wheat, hemp, and flax biomass, resulting in recommendations of 60–85–105 kg·m−3, respectively, to achieve the optimal TC-WR value for them. These densities strike a balance between thermal conductivity and weight of the insulating material, leading to TC-WR coefficients of 0.28–0.20–0.165 W−1·kg−1·m4·K for wheat–hemp–flax composites, respectively, which has a better potential for wheat with mycelium Ganoderma lucidum against mineral wool insulation with 0.197 W−1·kg−1·m4·K on average and wheat biomass with mycelium Trametes versicolor at 0.252 W−1·kg−1·m4·K.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Dilmac, S.; Kesen, N. A comparision of new Turkish thermal insulation standard (TS 825), ISO 9164, EN 832 and German regulation. Energy Build 2003, 35, 161–174. [Google Scholar] [CrossRef]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A review of unconventional sustainable building insulation materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Humaish, H.H. Thermal Techniques for Characterizing Building Insulation Materials. Ph.D. Thesis, Université de Picardie Jules Verne, Amiens, France, 2016. [Google Scholar]

- Lassandro, P. Durability of Building Components After the Useful Life of a Building: Reuse or Recycling of Materials/Components. 2003. Available online: https://www.researchgate.net/publication/306365258_Durability_of_building_components_after_the_useful_life_of_a_building_reuse_or_recycling_of_materialscomponents (accessed on 1 March 2023).

- Jelle, B.P. Traditional, State-of-the-Art and Future Thermal Building Insulation Materials and Solutions—Properties, Requirements and Possibilities; Norwegian University of Science and Technology (NTNU): Trondheim, Norway, 2011; Available online: https://ntnuopen.ntnu.no/ntnu-xmlui/bitstream/handle/11250/2436166/Traditional+State-of-the-Art+and+Future+Thermal+Building+Insulation+Materials+and+Solutions+-+Properties+Requirements+and+Possibilities57823.pdf?sequence=1 (accessed on 23 February 2023).

- Tenpierik, M.; Cauberg, H. Vacuum Insulation Panel: Friend or foe? In Proceedings of the PLEA2006—The 23rd Conference on Passive and Low Energy Architecture, Geneva, Switzerland, 6–8 September 2006. [Google Scholar]

- Sydor, M.; Cofta, G.; Doczekalska, B.; Bonenberg, A. Fungi in Mycelium-Based Composites: Usage and Recommendations. Materials 2022, 15, 6283. [Google Scholar] [CrossRef] [PubMed]

- Girometta, C.; Picco, A.M.; Baiguera, R.M.; Dondi, D.; Babbini, S.; Cartabia, M.; Pellegrini, M.; Savino, E. Physico-Mechanical and Thermodynamic Properties of Mycelium-Based Biocomposites: A Review. Sustainability 2019, 11, 281. [Google Scholar] [CrossRef]

- Ziegler, A.R.; Bajwa, S.G.; Holt, G.A.; McIntyre, G.; Bajwa, D.S. Evaluation of Physico-Mechanical Properties of Mycelium Reinforced Green Biocomposites Made from Cellulosic Fibers. Appl. Eng. Agric. 2016, 32, 931–938. [Google Scholar] [CrossRef]

- Appels, F.V.; Camere, S.; Montalti, M.; Karana, E.; Jansen, K.M.; Dijksterhuis, J.; Krijgsheld, P.; Wösten, H.A. Fabrication factors influencing mechanical, moisture- and water-related properties of mycelium-based composites. Mater. Des. 2019, 161, 64–71. [Google Scholar] [CrossRef]

- Haneef, M.; Ceseracciu, L.; Canale, C.; Bayer, I.S.; Heredia-Guerrero, J.A.; Athanassiou, A. Advanced Materials from Fungal Mycelium: Fabrication and Tuning of Physical Properties. Sci. Rep. 2017, 7, 41292. [Google Scholar] [CrossRef]

- Elsacker, E.; Vandelook, S.; Brancart, J.; Peeters, E.; De Laet, L. Mechanical, physical and chemical characterisation of mycelium-based composites with different types of lignocellulosic substrates. PLoS ONE 2019, 14, e0213954. [Google Scholar] [CrossRef]

- Babenko, M.; Estokova, A.; Unčik, S.; Savytskyi, M. Comparative study of lightweight concretes based on hemp and flax straw. Slovak J. Civ. Eng. 2022, 30, 11–16. [Google Scholar] [CrossRef]

- Islam, M.R.; Tudryn, G.; Bucinell, R.; Schadler, L.; Picu, R.C. Morphology and mechanics of fungal mycelium. Sci. Rep. 2017, 7, 13070. [Google Scholar] [CrossRef]

- Jones, M.; Mautner, A.; Luenco, S.; Bismarck, A.; John, S. Engineered Mycelium Composite Construction Materials from Fungal biorefineries: A Critical Review. Mater. Des. 2020, 187, 108397. [Google Scholar] [CrossRef]

- Dias, P.P.; Jayasinghe, L.B.; Waldmann, D. Investigation of Mycelium-Miscanthus composites as building insulation material. Results Mater. 2021, 10, 100189. [Google Scholar] [CrossRef]

- Mbabali, H.; Lubwama, M.; Yiga, V.A.; Were, E.; Kasedde, H. Development of Rice Husk and Sawdust Mycelium-Based Bio-composites: Optimization of Mechanical, Physical and Thermal Properties. J. Inst. Eng. India Ser. D 2024, 105, 97–117. [Google Scholar] [CrossRef]

- Abu-Jdayil, B.; Mourad, A.H.; Hittini, W.; Hassan, M.; Hameedi, S. Traditional, state-of-the-art and renewable thermal building insulation materials: An overview. Constr. Build. Mater. 2019, 214, 709–735. [Google Scholar] [CrossRef]

- Erlandsson, M.; Byfors, K.; Lundin, J.S. Byggsektorns Historiska Klimatpåverkan och en Projektion för nära noll; IVL Svenska Miljöinstitutet: Stockholm, Sweden, 2017. [Google Scholar]

- Geremew, A.; Winne, P.; Demissie, T.; Backer, H. Characterization of Wheat Straw Fiber Grown Around Jimma Zone, ETHIOPIA. J. Nat. Fibers 2022, 20, 2134268. [Google Scholar] [CrossRef]

- Zhang, L.; Larsson, A.; Moldin, A.; Edlund, U. Comparison of lignin distribution, structure, and morphology in wheat straw and wood. Ind. Crops Prod. 2022, 187, 115432. [Google Scholar] [CrossRef]

- Bakisgan, C.; Dumanli, A.; Yürüm, Y. Trace elements in Turkish biomass fuels: Ashes of wheat straw, olive bagasse and hazelnut shell. Fuel 2009, 88, 1842–1851. [Google Scholar] [CrossRef]

- Al-Akhras, N.M.; Abu-Alfoul, B.A. Effect of wheat straw ash on mechanical properties of autoclaved mortar. Cem. Concr. Res. 2002, 32, 859–863. [Google Scholar] [CrossRef]

- Liu, M.; Thygesen, A.; Summerscales, J.; Meyer, A.S. Targeted pre-treatment of hemp bast fibres for optimal performance in biocomposite materials: A review. Ind. Crops Prod. 2017, 108, 660–683. [Google Scholar] [CrossRef]

- Ding, J.; Liang, L.; Meng, X.; Yang, F.; Pu, Y.; Ragauskas, A.J.; Yoo, C.G.; Yu, C. The physiochemical alteration of flax fibers structuring components after different scouring and bleaching treatments. Ind. Crops Prod. 2021, 160, 113112. [Google Scholar] [CrossRef]

- Cetiner, I.; Shea, A.D. Wood waste as an alternative thermal insulation for buildings. Energy Build. 2018, 168, 374–384. [Google Scholar] [CrossRef]

- Zhou, X.; Zheng, F.; Li, H.; Lu, C. An environment-friendly thermal insulation material from cotton stalk fibers. Energy Build. 2010, 42, 1070–1074. [Google Scholar] [CrossRef]

- Gaujena, B.; Agapovs, V.; Borodinecs, A.; Strelets, K. Analysis of Thermal Parameters of Hemp Fiber Insulation. Energies 2020, 13, 6385. [Google Scholar] [CrossRef]

- Florea, I.; Manea, D.L. Analysis of Thermal Insulation Building Materials Based on Natural Fibers. Procedia Manuf. 2019, 32, 230–235. [Google Scholar] [CrossRef]

- Babenko, M.; Estokova, A.; Savytskyi, M.; Unčík, S. Study of Thermal Properties of Lightweight Insulation Made of Flax Straw. Slovak J. Civ. Eng. 2018, 26, 9–14. [Google Scholar] [CrossRef]

- Cerny, P.; Babenko, M.; Bartos, P.; Kononets, Y.; Kriz, P.; Rabenseifer, R.; Spalek, F. Complex Study of the Composite Building Material Based on Flax Straw Organic Waste: Hygrothermal and Physicochemical Properties. Waste Biomass Valorization 2024, 15, 2231–2247. [Google Scholar] [CrossRef]

- Bedlivá, H.; Isaacs, N. Hempcrete—An Environmentally Friendly Material? Adv. Mater. Res. 2014, 1041, 83–86. [Google Scholar] [CrossRef]

- Abdellatef, Y.; Khan, M.A.; Khan, A.; Alam, M.I.; Kavgic, M. Mechanical, thermal, and moisture buffering properties of novel insulating hemp-lime composite building materials. Materials 2020, 13, 5000. [Google Scholar] [CrossRef] [PubMed]

- Kalnæs, S.E.; Jelle, B.P. Vacuum insulation panel products: A state-of-the-art review and future research pathways. Appl. Energy 2014, 116, 355–375. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, F.; Still, B.; White, M.; Amstislavski, P. Physical and mechanical properties of fungal mycelium-based biofoam. J. Mater. Civ. Eng. 2017, 29, 04017030. [Google Scholar] [CrossRef]

- Gauvin, F.; Tsao, V.; Vette, J.; Brouwers, H.J.H. Physical properties and hygrothermal behavior of mycelium-based composites as foam-like wall insulation material. In Construction Technologies and Architecture; Trans Tech Publications Ltd.: Wollerau, Switzerland, 2022. [Google Scholar] [CrossRef]

- Aiduang, W.; Kumla, J.; Srinuanpan, S.; Thamjaree, W.; Lumyong, S.; Suwannarach, N. Mechanical, physical, and chemical properties of mycelium-based composites produced from various lignocellulosic residues and fungal species. J. Fungi 2022, 8, 1125. [Google Scholar] [CrossRef] [PubMed]

- Holt, G.A.; Mcintyre, G.; Flagg, D.; Bayer, E.; Wanjura, J.D.; Pelletier, M.G. Fungal Mycelium and Cotton Plant Materials in the Manufacture of Biodegradable Molded Packaging Material: Evaluation Study of Select Blends of Cotton Byproducts. J. Biobased Mater. Bioenergy 2012, 6, 431–439. [Google Scholar] [CrossRef]

- Pelletier, M.G.; Holt, G.A.; Wanjura, J.D.; Bayer, E.; McIntyre, G. An evaluation study of mycelium based acoustic absorbers grown on agricultural by-product substrates. Ind. Crops Prod. 2013, 51, 480–485. [Google Scholar] [CrossRef]

- Pelletier, M.G.; Holt, G.A.; Wanjura, J.D.; Greetham, L.; McIntyre, G.; Bayer, E.; Kaplan-Bie, J. Acoustic evaluation of mycological biopolymer, an all-natural closed cell foam alternative. Ind. Crops Prod. 2019, 139, 111533. [Google Scholar] [CrossRef]

- Xing, Y.; Brewer, M.; El-Gharabawy, H.; Griffith, G.; Jones, P. Growing and testing mycelium bricks as building insulation materials. IOP Conf. Ser. Earth Environ. Sci. 2018, 121, 022032. [Google Scholar] [CrossRef]

- Ridzqo, I.F.; Susanto, D.; Panjaitan, T.H.; Putra, N. Sustainable Material: Development Experiment of Bamboo Composite Through Biologically Binding Mechanism. IOP Conf. Ser. Mater. Sci. Eng. 2020, 713, 012010. [Google Scholar] [CrossRef]

- Jauk, J.; Vašatko, H.; Gosch, L.; Christian, I.; Klaus, A.; Stavric, M. Digital Fabrication of Growth-Combining Digital Manufacturing of Clay with Natural Growth of Mycelium. In Proceedings of the 26th CAADRIA Conference, Hong Kong, China, 29 March–1 April 2021; Association for Computer Aided Architectural Design Research in Asia (CAADRIA): Hong Kong, China, 2021; Volume 1, pp. 753–762. Available online: https://papers.cumincad.org/data/works/att/caadria2021_282.pdf (accessed on 12 November 2024).

- ISOMET 2114 Thermal Properties Analyzer User’s Guide Version 1.57 ISOMET 2114 User’s Guide. Available online: https://www.appliedp.com/download/manual/isomet2114_ug_en.pdf (accessed on 7 April 2024).

- Halliday, D.; Resnick, R.; Walker, J. Fundamentals of Physics, 10th ed.Wiley: Hoboken, NJ, USA, 2013. [Google Scholar]

- ISO 16979; Wood-Based Panels—Determination of Moisture Content. ANSI: Washington, DC, USA, 2003.

- Pollock, D. Estimation of Polynomial Trends. In Handbook of Time Series Analysis, Signal Processing, and Dynamics; Elsevier: Amsterdam, The Netherlands, 1999; pp. 261–291. [Google Scholar] [CrossRef]

- Stewart, J. Calculus: Early Transcendentals, 8th ed.Cengage Learning: Boston, MA, USA, 2015. [Google Scholar]

- Michaelides, M.; Spanos, A. On modeling heterogeneity in linear models using trend polynomials. Econ. Model. 2020, 85, 74–86. [Google Scholar] [CrossRef]

- Scanning Electron Microscope Tescan Vega 3 SEM/SBU: Instruction for Use; TESCAN, a.s.: Brno, Czech Republic, 2013; Available online: https://www.csuchico.edu/sem/_assets/documents/vega-manual-2014.pdf (accessed on 2 November 2024).

- Federation of European Rigid Polyurethane Foam Associations (FERPFA). Thermal Insulation Materials Made of Rigid Polyurethane Foam (PUR/PIR) Properties-Manufacture. Available online: https://highperformanceinsulation.eu/wp-content/uploads/2016/08/Thermal_insulation_materials_made_of_rigid_polyurethane_foam.pdf (accessed on 12 November 2024).

- Carriço, C.; Fraga, T.; Carvalho, V.; Pasa, V. Polyurethane Foams for Thermal Insulation Uses Produced from Castor Oil and Crude Glycerol Biopolyols. Molecules 2017, 22, 1091. [Google Scholar] [CrossRef]

- Doğan, B.; Tan, H. The Numerical and Experimental Investigation of the Change of the Thermal Conductivity of Expanded Polystyrene at Different Temperatures and Densities. Int. J. Polym. Sci. 2019, 2019, e6350326. [Google Scholar] [CrossRef]

- EN 13163; Thermal Insulation Products for Buildings—Factory Made Expanded Polystyrene (EPS) Products—Specification. European Committee for Standardization: Brussels, Belgium, 2017.

- BS EN 13164, 2012+A1 2005; Thermal Insulation Products for Buildings—Factory Made Products of Expanded Polystyrene (EPS)—Specification. British Standards Institution: London, UK, 2015. Available online: https://assets.grenfelltowerinquiry.org.uk/BSI00001739_BS%20EN%2013164-2012%2BA1-2015--2020-11-19--12-08-51%20PM.pdf (accessed on 12 November 2024).

- Yousefi, Y.; Tariku, F. Thermal Conductivity and Specific Heat Capacity of Insulation materials at Different Mean Temperatures. J. Phys. Conf. Ser. 2021, 2069, 012090. [Google Scholar] [CrossRef]

- Simmler, H.; Brunner, S.; Heinemann, U.; Schwab, H.; Kumaran, K.; Mukhopadhyaya, P.; Quénard, D.; Sallée, H.; Noller, K.; Kücükpinar-Niarchos, E.; et al. HiPTI-High Performance Thermal Insulation IEA/ECBCS Annex 39. 2005. Available online: https://www.iea-ebc.org/Data/publications/EBC_Annex_39_Report_Subtask-A.pdf (accessed on 12 November 2024).

- EN 13162; Thermal Insulation Products for Buildings—Factory-Made Products of Polyethylene Foam (PEF)—Specification. European Committee for Standardization: Brussels, Belgium, 2012.

- Bai, Q.; Bai, Y. Pipe-in-Pipe and Bundle Systems. In Subsea Pipeline Design, Analysis, and Installation; Elsevier B.V.: Amsterdam, The Netherlands, 2014; pp. 405–433. [Google Scholar] [CrossRef]

- Hetimy, S.; Megahed, N.; Eleinen, O.A.; Elgheznawy, D. Exploring the potential of sheep wool as an eco-friendly insulation material: A comprehensive review and analytical ranking. Sustain. Mater. Technol. 2024, 39, e00812. [Google Scholar] [CrossRef]

- Dénes, T.-O.; Iştoan, R.; Tǎmaş-Gavrea, D.R.; Manea, D.L.; Hegyi, A.; Popa, F.; Vasile, O. Analysis of Sheep Wool-Based Composites for Building Insulation. Polymers 2022, 14, 2109. [Google Scholar] [CrossRef]

- Zach, J.; Korjenic, A.; Petránek, V.; Hroudová, J.; Bednar, T. Performance evaluation and research of alternative thermal insulations based on sheep wool. Energy Build. 2012, 49, 246–253. [Google Scholar] [CrossRef]

- EN 13171; Thermal Insulation Products for Buildings—Factory-Made Products of Expanded Polystyrene (EPS)—Specification. European Committee for Standardization: Brussels, Belgium, 2012.

- Pavatex, S.A. Environmental Product Declaration. 2014. Available online: https://www.lifepanels.com/wp-content/uploads/2022/08/2.-PAVAFLEX-PLUS-Environmental-Product-Declaration-EPD.pdf (accessed on 7 April 2024).

- Simões, N.; Fino, R.; Tadeu, A. Uncoated medium density expanded cork boards for building façades and roofs: Mechanical, hygrothermal and durability characterization. Constr. Build. Mater. 2019, 200, 447–464. [Google Scholar] [CrossRef]

- EN 13170; Thermal Insulation Products for Buildings—Factory-Made Products of Extruded Polystyrene Foam (XPS)—Specification. European Committee for Standardization: Brussels, Belgium, 2012.

- Shao, G.B.; Yang, P.; Jiang, W.X. Research and preparation of mycelium-soybean straw composite materials. In Proceedings of the 2nd Annual International Conference on Advanced Material Engineering (AME 2016), Wuhan, China, 15–17 April 2016; Atlantis Press: Amsterdam, The Netherlands, 2016. [Google Scholar] [CrossRef][Green Version]

- Giannotas, G.; Kamperidou, V.; Barboutis, I. Tree bark utilization in insulating bio-aggregates: A review. Biofuels Bioprod. Biorefin. 2021, 15, 1989–1999. [Google Scholar] [CrossRef]

- Colinart, T.; Vinceslas, T.; Lenormand, H.; De Menibus, A.H.; Hamard, E.; Lecompte, T. Hygrothermal properties of light-earth building materials. J. Build. Eng. 2020, 29, 101134. [Google Scholar] [CrossRef]

- Building Regulations (BR) Part L2. Office of the Deputy Prime Minister (ODPM). 2001. Available online: https://www.legislation.gov.uk/uksi/2001/3335/made (accessed on 12 November 2024).

- Gou, L.; Li, S.; Yin, J.; Li, T.; Liu, X. Morphological and physico-mechanical properties of mycelium biocomposites with natural reinforcement particles. Constr. Build. Mater. 2021, 304, 124656. [Google Scholar] [CrossRef]

- Kunanopparat, T.; Menut, P.; Morel, M.-H.; Guilbert, S. Reinforcement of plasticized wheat gluten with natural fibers: From mechanical improvement to deplasticizing effect. Compos. Part A Appl. Sci. Manuf. 2008, 39, 777–785. [Google Scholar] [CrossRef]

- Bennick, A. Interaction of plant polyphenols with salivary proteins. Crit. Rev. Oral Biol. Med. Off. Publ. Am. Assoc. Oral Biol. 2002, 13, 184–196. [Google Scholar] [CrossRef]

- Alaneme, K.K.; Anaele, J.U.; Oke, T.M.; Kareem, S.A.; Adediran, M.; Ajibuwa, O.A.; Anabaranze, Y.O. Mycelium based composites: A review of their bio-fabrication procedures, material properties and potential for green building and construction applications. Alex. Eng. J. 2023, 83, 234–250. [Google Scholar] [CrossRef]

| Type of Mass | Cellulose [%] | Hemicellulose [%] | Ash [%] | Lignin [%] | Source |

|---|---|---|---|---|---|

| Wheat | 28–39 | 20–30 | 8–9 | 15 | [20,21,22,23] |

| Hemp | 70–76 | 11–17 | 3–4 | 2–5 | [24] |

| Flax | 73–76 | 12–16 | 3–4 | 2–5 | [25] |

| Biocomposite, Sample No. | Mass Before Drying, [kg] | Mass After Drying, [kg] | Initial Moisture Content MC [%] | Thermal Conductivity, λ [W·m−1·K−1] | Average Thermal Conductivity, λAvg [W·m−1·K−1], dev. ± 0.9% | Density, ρ [kg·m−3] | Average Density, ρAvg [kg·m−3], dev. ± 1 % |

|---|---|---|---|---|---|---|---|

| Flax + Mycelium, 1 | 59.60 | 0.045 | 158 | ||||

| Flax + Mycelium, 2 | 0.046 | 220 | |||||

| Flax + Mycelium, 3 | 0.160 | 0.064 | 0.047 | 0.046 | 146 | 170 | |

| Flax + Mycelium, 4 | 0.045 | 155 | |||||

| Flax + Mycelium, 5 | 0.045 | 169 | |||||

| Hemp + Mycelium, 1 | 53.08 | 0.047 | 227 | ||||

| Hemp + Mycelium, 2 | 0.045 | 156 | |||||

| Hemp + Mycelium, 3 | 0.152 | 0.071 | 0.046 | 0.047 | 119 | 172 | |

| Hemp + Mycelium, 4 | 0.046 | 138 | |||||

| Hemp + Mycelium, 5 | 0.050 | 219 | |||||

| Wheat + Mycelium, 1 | 54.82 | 0.043 | 137 | ||||

| Wheat + Mycelium, 2 | 0.043 | 107 | |||||

| Wheat + Mycelium, 3 | 0.135 | 0.061 | 0.056 | 0.048 | 142 | 138 | |

| Wheat + Mycelium, 4 | 0.054 | 156 | |||||

| Wheat + Mycelium, 5 | 0.045 | 150 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Babenko, M.; Kononets, Y.; Bartos, P.; Pont, U.; Spalek, F.; Zoubek, T.; Kriz, P. Perspectives of Insulating Biodegradable Composites Derived from Agricultural Lignocellulosic Biomass and Fungal Mycelium: A Comprehensive Study of Thermal Conductivity and Density Characteristics. Biomimetics 2024, 9, 707. https://doi.org/10.3390/biomimetics9110707

Babenko M, Kononets Y, Bartos P, Pont U, Spalek F, Zoubek T, Kriz P. Perspectives of Insulating Biodegradable Composites Derived from Agricultural Lignocellulosic Biomass and Fungal Mycelium: A Comprehensive Study of Thermal Conductivity and Density Characteristics. Biomimetics. 2024; 9(11):707. https://doi.org/10.3390/biomimetics9110707

Chicago/Turabian StyleBabenko, Maryna, Yevhen Kononets, Petr Bartos, Ulrich Pont, Frantisek Spalek, Tomas Zoubek, and Pavel Kriz. 2024. "Perspectives of Insulating Biodegradable Composites Derived from Agricultural Lignocellulosic Biomass and Fungal Mycelium: A Comprehensive Study of Thermal Conductivity and Density Characteristics" Biomimetics 9, no. 11: 707. https://doi.org/10.3390/biomimetics9110707

APA StyleBabenko, M., Kononets, Y., Bartos, P., Pont, U., Spalek, F., Zoubek, T., & Kriz, P. (2024). Perspectives of Insulating Biodegradable Composites Derived from Agricultural Lignocellulosic Biomass and Fungal Mycelium: A Comprehensive Study of Thermal Conductivity and Density Characteristics. Biomimetics, 9(11), 707. https://doi.org/10.3390/biomimetics9110707