1. Introduction

Stroke is a leading cause of disability worldwide, with over 13.7 million new patients annually. Stroke survivors often suffer from motor dysfunction and require external assistance for basic activities of daily life (ADL), which is crucial for maintaining quality of life [

1]. The absence of independence in ADL diminishes their quality of life and reduces life satisfaction. Unfortunately, approximately 65% of stroke survivors face hand impairments that significantly impede their ability to perform ADL tasks [

2]. Thus, various mechanical exoskeletons have been developed to aid in hand rehabilitation and restore survivors’ independence [

3,

4].

Traditional hand rehabilitation systems typically rely on rigid links and electric motors [

5], which have the distinctive characteristics of cumbersome support, easily causing secondary damage to wearers, and interfering with normal motion in performing ADL tasks. Thus, some wearable pneumatic hand rehabilitation exoskeletons made of soft/elastic material came into being, possessing the advantages of being light, with a high power-to-weight ratio, of low cost, and being comfortable [

6]. Polygerinos et al. developed an elastomer-based robotic glove to augment hand rehabilitation at home for individuals with function grasp pathologies, which was able to carry out gross and precise grasping [

7]. Yap et al. presented a fully fabric-based bidirectional soft glove design to assist hand-impaired patients, which can realize active finger flexion and extension for training [

8]. Correia et al. created a textile-based soft robotic glove controlled by the user with a button and then tested it in thirteen tetraplegic patients using the Jebsen–Taylor hand function test, which showed the effectiveness of this system [

9]. Li et al. proposed a variable stiffness pneumatic actuator coupled with a multi-stage articulated steel layer and verified the extension effect of the actuator over a clenched artificial hand with damper force [

10].

Various pneumatic soft gloves have been conducted in typical hand rehabilitation scenarios to validate their performance [

9,

11,

12,

13,

14], but few exoskeleton systems can directly quantitatively characterize the assistant effect after wear in ADL tasks, such as extension angle and predicted joint stiffness. The existing hand function scale of the modified Ashworth scale (MAS) is subjective and affected by the doctor’s experience, which is not conducive to evaluation [

15,

16]. Shi et al. replicated a standalone desktop device to measure the passive joint moment and angle for the MCP joint in the index finger [

17]. However, the bulky size of the test bench limits the potential to characterize the other joints and take advantage of portability. Heung et al. introduced a soft-composite rehabilitation actuator that objectively reflects the condition of post-stroke, which was validated by simulations and experiments [

18,

19]. Matsunaga et al. combined information from a joint modular soft actuator and a marker-less hand joint position acquisition device for finger joint stiffness estimation in a tele-rehabilitation environment [

20]. However, it has limited potential for wide applications because an external camera is required to supervise the bending process during operation. Matsunaga et al. proposed artificial neural network (ANN)-based models to simultaneously estimate the stiffness of the distal interphalangeal (DIP) joint, the proximal interphalangeal (PIP) joint, and the metacarpophalangeal (MCP) joint for index fingers [

21]. Still, it is challenging to prove the validity of the stiffness estimation methods and requires a lot of training data from dummy fingers using machine learning. Lai et al. focused on a soft pneumatic glove with honeycomb pneumatic actuators (HPAs) for assisting ADL tasks and developed two customized finger-force products for quantifying enhanced finger function in patients [

22]. The primary function of these systems is almost always performance evaluation, and they cannot simultaneously be employed in rehabilitation ADL tasks.

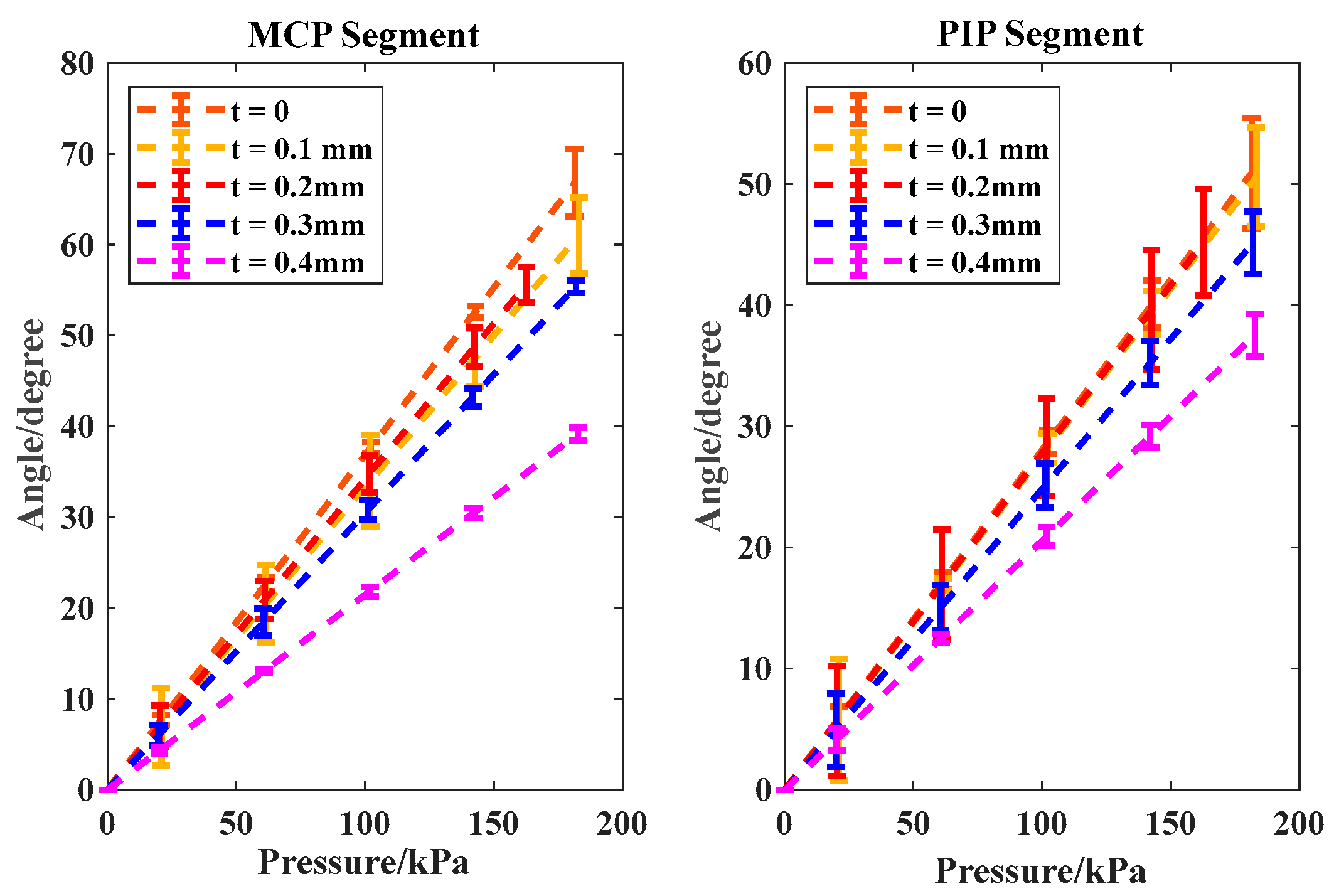

For different pneumatic soft robotic systems designed for hand rehabilitation/assistance, as listed in

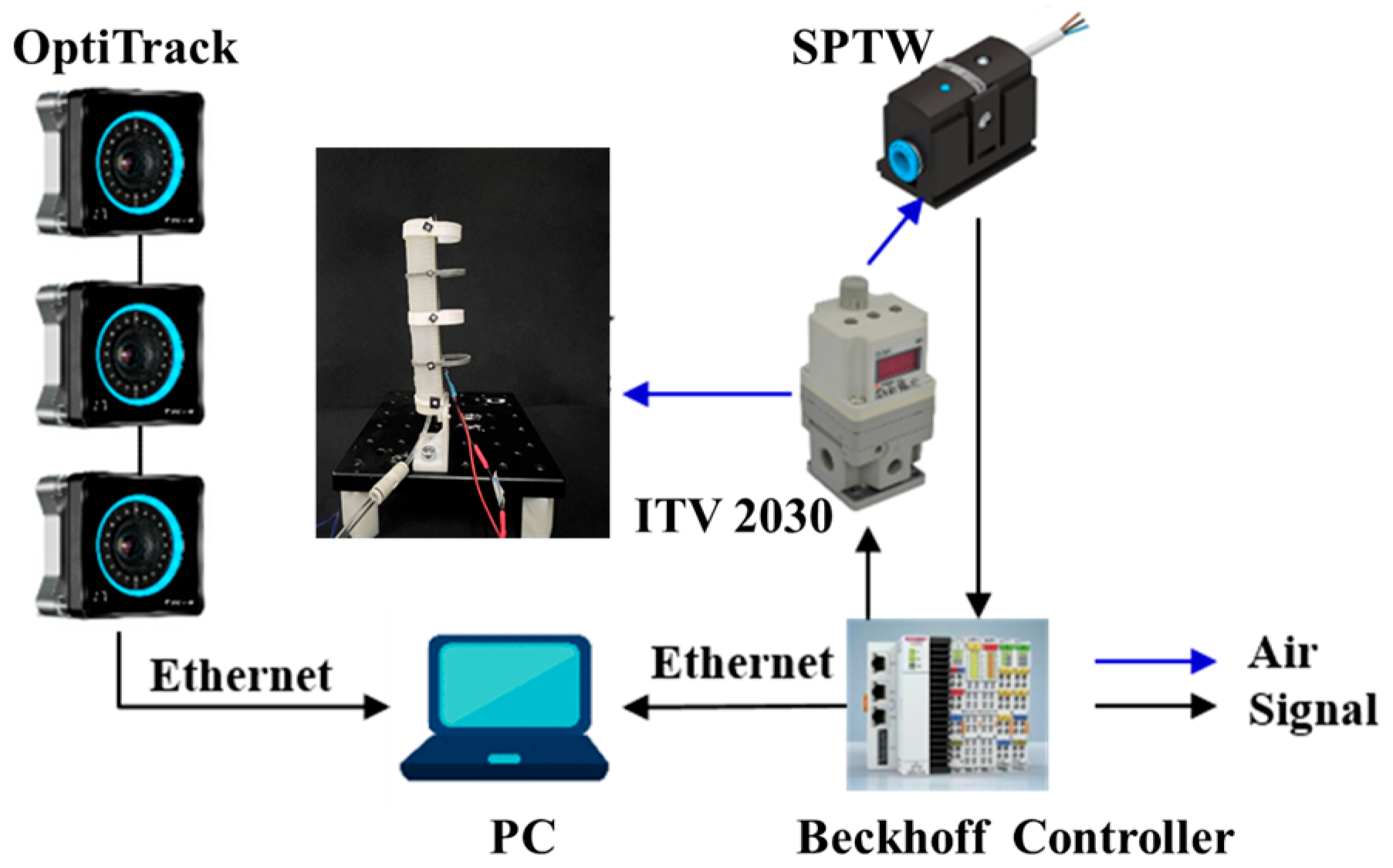

Table A3, various rehabilitation training modes have been explored for an integrated “human–soft exoskeleton” system in ADL tasks. Sui et al. engineered a soft-packaged rehabilitation glove with tight integration of sensing, actuation, human–machine interference, and a closed-loop algorithm to regain fine motor skills in hand rehabilitation [

12]. Zhou et al. adopted a state machine controller based on signals from integrated sensors to detect users’ intuition in hand–object interactions, inflating the corresponding actuators at maximum operation pressure [

23]. Chen et al. provided a tendon-driven soft hand exoskeleton with a hybrid configuration based on a graphical user interface (GUI) open-loop control strategy, in which the training paradigm parameters are directly predefined by the kinematic model [

24]. Chen et al. also accomplished dexterous hand/forearm manipulation with the assistance of a foot-controlled interface by utilizing movements of the unaffected foot as command signals, which is an open-loop limb mapping control scheme [

25]. Tang et al. proposed a model-based online learning adaptive control algorithm for a wearable soft robotic glove by predefined trajectory, taking its interaction with the human fingers into account [

26].

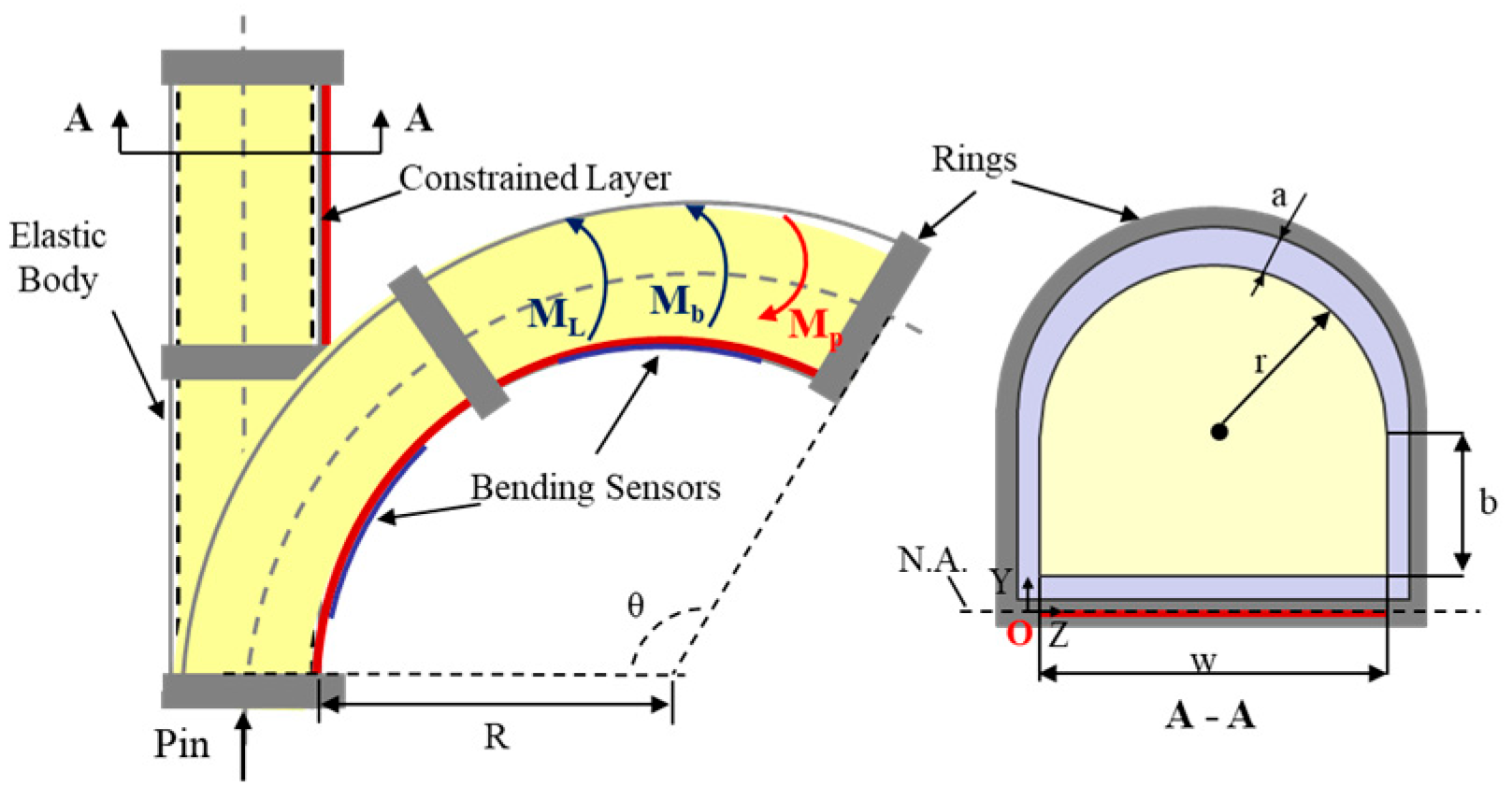

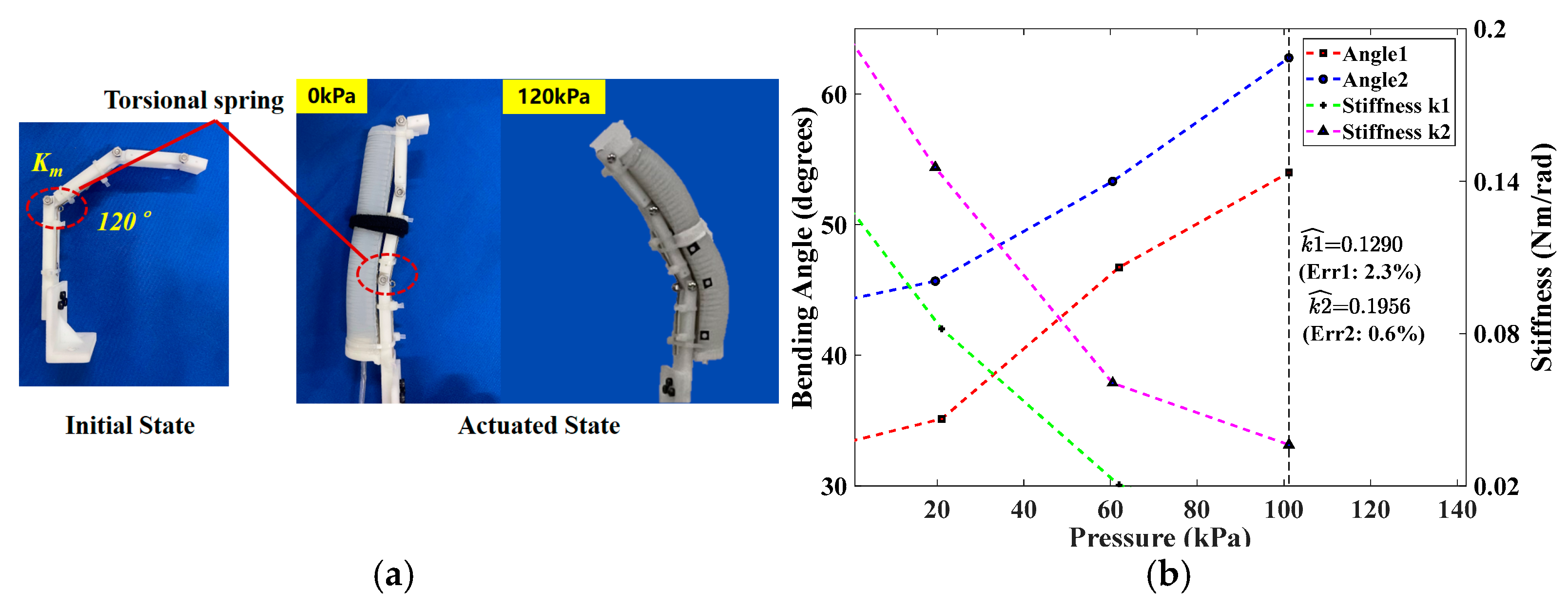

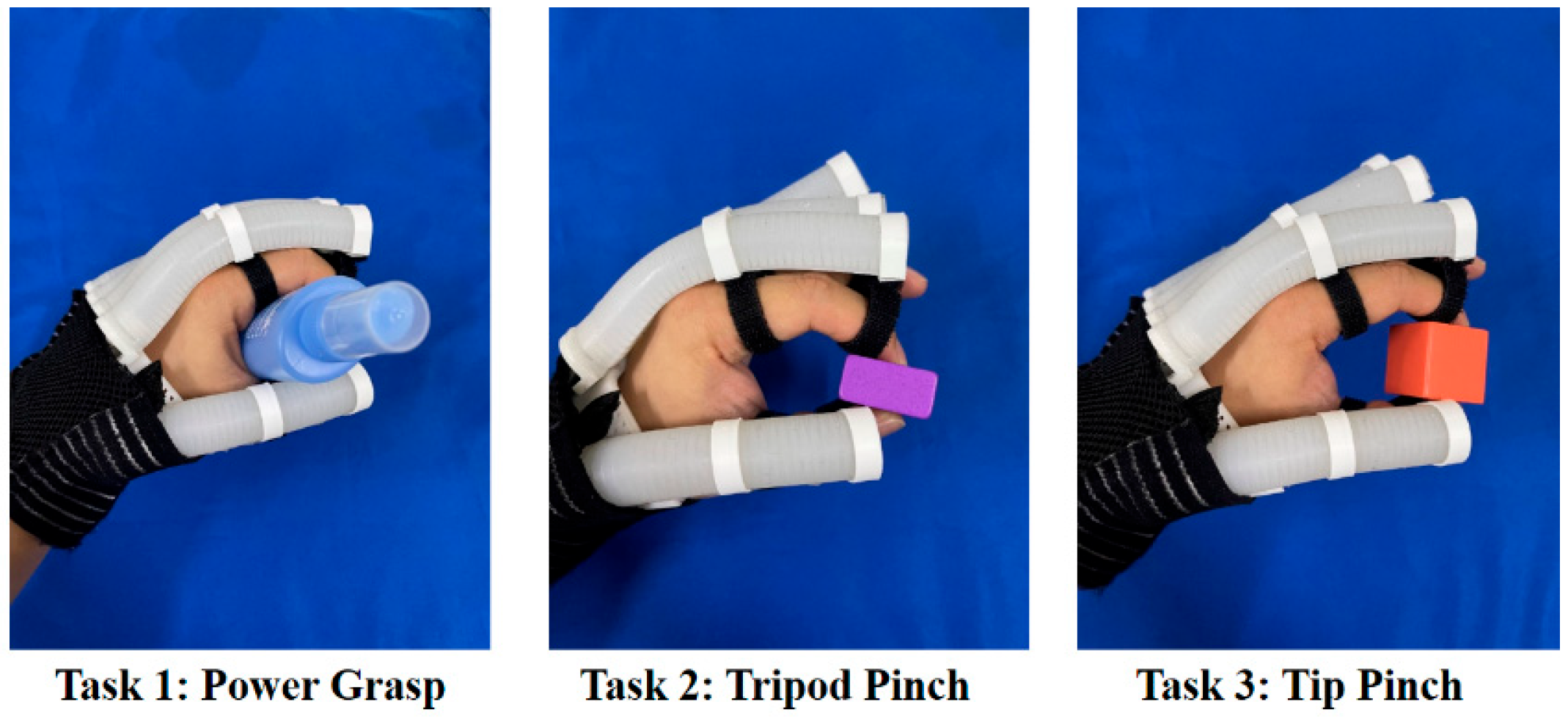

In this study, we propose a pneumatic soft hand exoskeleton system based on SCPBAs that incorporates a fiber-elastic body and stiffness-compensating layer-integrated bending sensors to realize predicted finger joint stiffness, reverse stretching motion, and rehabilitation training in ADL tasks simultaneously. First, the bioinspired principle behind and fabrication of the SCPBAs are presented. A flexible-joint–rigid-bone segmented configuration inspired by the anatomy of the human finger is put forward for the proposed SCPBAs. Next, the analytical models of the SCPBAs for both free space and constrained space are presented. The stiffness-compensating layer integrated proprioceptive sensors attached to the bottom of the SCPBAs can monitor the bending deformation and reversely extend for hand dysfunction, such as a clamp-shape hand. A reorganized analytical model that establishes the relationship between the inflated pressure, bending angle, and joint stiffness is also applied to evaluate finger joint stiffness in an integrated finger–actuator condition. Performance characterizations using the dummy/mannequin finger and task-oriented training strategies involving one healthy subject were conducted. The soft hand exoskeleton realized the bending deformation tracking as well as rehabilitation training in ADL tasks, such as tripod pinch and tip pinch.

2. Design and Fabrication of the SCPBAs

In this section, based on our previous work [

27], the proposed SCPBAs inspired by the anatomy of the human finger are formulated first. Then, the improved modular molding method is used to prototype the actuators, which is also called secondary post-processing.

2.1. The Bio-Inspiration and Implementation of the SCPBAs

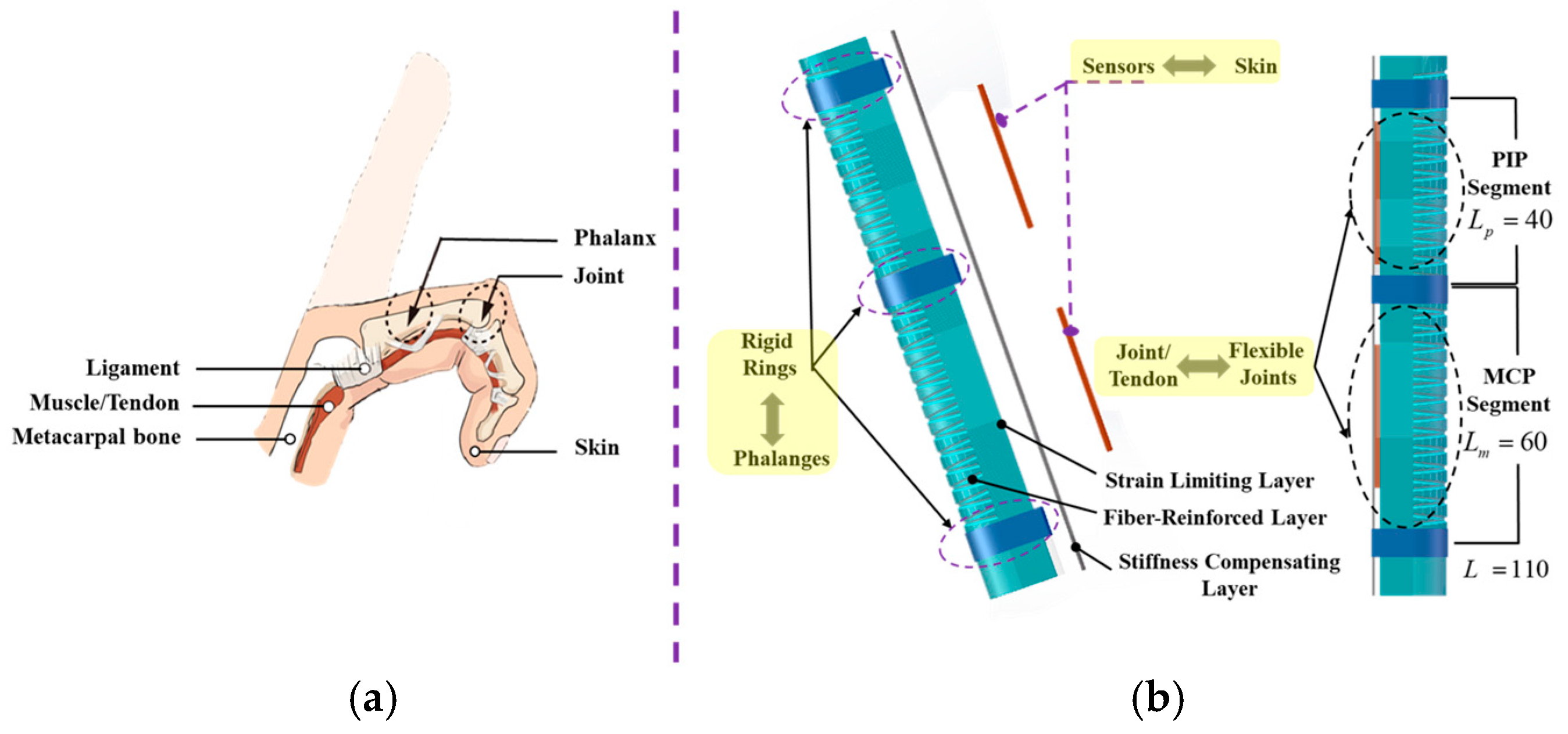

As in the anatomical diagram of the hand/finger in

Figure 1a [

27,

28], the structure of the finger consists of phalanx/bone, joint, skin, muscle/tendon, and ligament. First, from the perspective of hand motor function, the phalanges have been linked with three joints: the MCP joint, the PIP joint, and the DIP joint. The tendon transforms the actuation force from the muscle to the corresponding finger joint. Second, from the ontological sensing function, the skin acts as a soft cushion, as well as the proprioceptor, which can guarantee non-destructive interaction and also provide perception information.

Considering the two aforementioned aspects of the finger/digit, the proposed bionic SCPBAs can greatly conform to the profiles of the finger and also provide motion information in real time. The principles of its biomimetic design are as follows.

(1) First, from the perspective of structural motion biomimetics, distinct from traditional fiber-reinforced actuators (FRAs), the SCPBA assembly incorporates rigid rings not only simply mimicking the soft-joint–rigid-bone anatomy of the fingers but also provides multi-joint/segmented bending morphing, which can enhance the conformability interaction of the finger joint. In other words, the proposed SCPBAs can promote segmented bending on the flexible joint section and keep the matrix from deforming in the rigid phalangeal sections where bending is not desired during the whole actuated process. This secondary post-processing method, called mechanical programming, relies on the utilized materials’ mechanical properties.

(2) Next, to realize the sensing function of the abovementioned fingers, a stiffness-compensating layer with a sensing function element is attached to the bottom surface of the SCPBAs, which can simultaneously enhance body stiffness and monitor bending deformation.

As shown in

Figure 1b, the pneumatic SCPBAs incorporate a fiber-reinforced semi-obround elastomer embedded with rigid rings to mimic the soft-joint–rigid-bone anatomy of human fingers. The semi-obround matrix is surrounded by a network of fibers (fiber-reinforced layer), several rigid segments (the bottom strain-limiting layer, the stiffness-compensating layer, and rigid rings), and an outer elastomeric skin (outer wrappage). However, the DIP joint contributes only 15% of the function grip. Thus, the proposed SCPBAs for a wearable exoskeleton are double-segmented and lack covering of the DIP joint.

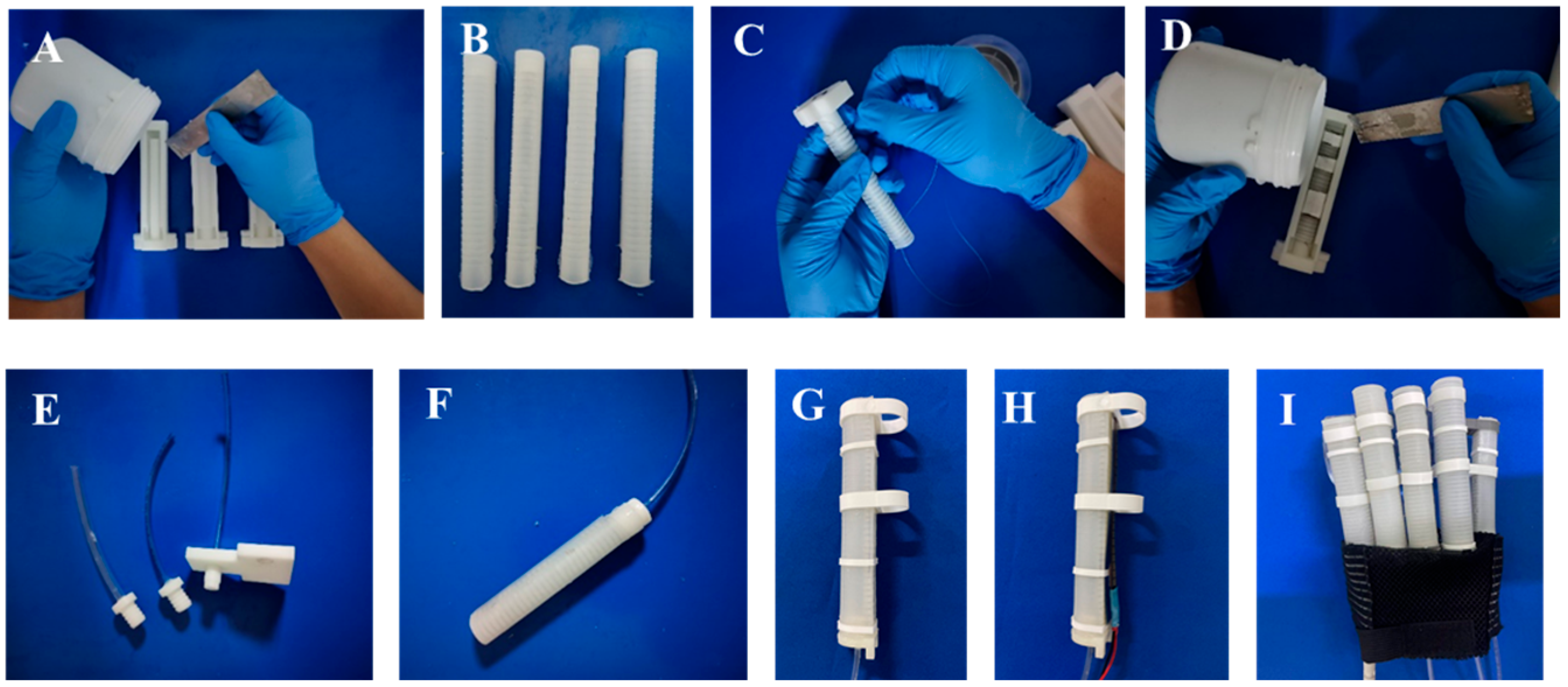

2.2. Actuator Fabrication

The proposed SCPBAs have the advantages of scalable fabrication, personalized customization, and low cost. The SCPBAs consist of a semi-obround matrix surrounded by a network of fibers (fiber-reinforced layer), several rigid segments (the bottom strain-limiting layer, the stiffness-compensating layer, and rigid rings), and an outer elastomeric skin (outer wrappage).

The main fabrication and assembly of the bioinspired SCPBAs are detailed in our previous study [

27]. The inner elastomeric tube (2 mm thickness) is made of silicone elastomer (Dragon Skin 30, Smooth on Inc., Macungie, the U.S.) (

Figure 2A,B). A single polyethylene thread (0.165 mm thickness, Yunshangpiao Co., Ltd, Jinhua, China.) is wound around the inner tube, forming the fiber-reinforced layer to provide radial constraint during the inner tube inflation, and a flexible but inextensible strain-limiting layer is attached to the bottom of the fiber-reinforced layer to construct the flexion motion. The strain-limiting layer is a piece of fabric strip 0.2 mm thick (

Figure 2C). The outer skin silicone elastomer, 0.5 mm thick (Ecoflex 00-30, Smooth on Inc., Macungie, PA, USA), with a lower Young’s modulus than the inner tube fixes all components and provides a cosmetic appearance (

Figure 2D). Three rigid rings, made of resin by 3D printing with mounting slots, are attached to the elastomeric body to keep these sections straight upon pressurization (

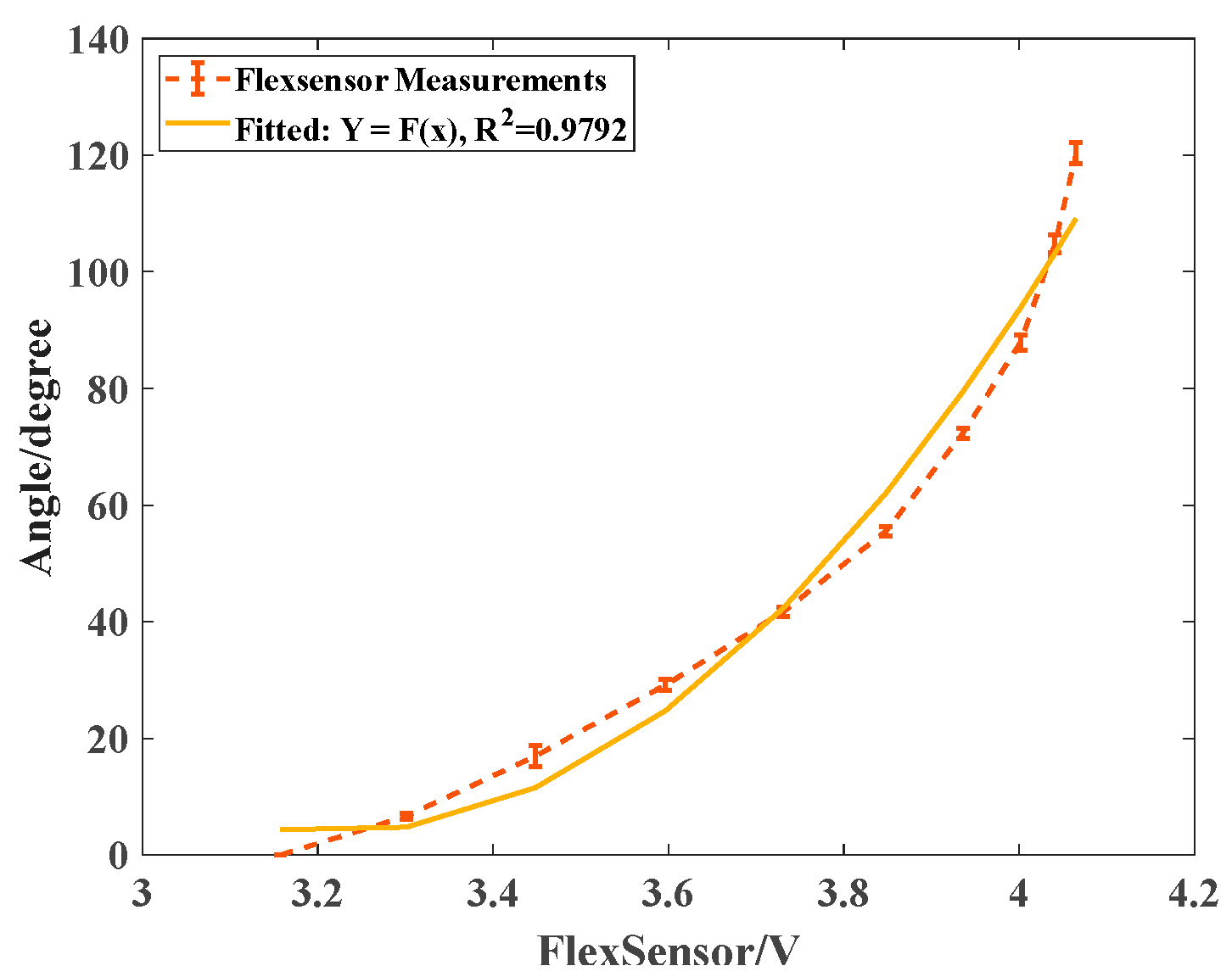

Figure 2G). The stiffness-compensating layer with flexible bending sensors (FlexSensor 2.2/4.5, Spectrasymbol) is placed in the mounting slots (

Figure 2H). Inspired by the anatomy of human fingers, we designed the index, middle, ring, and little fingers with three rigid segments and the thumb with two rigid segments, as shown in

Figure 2E,F,I.

6. Conclusions

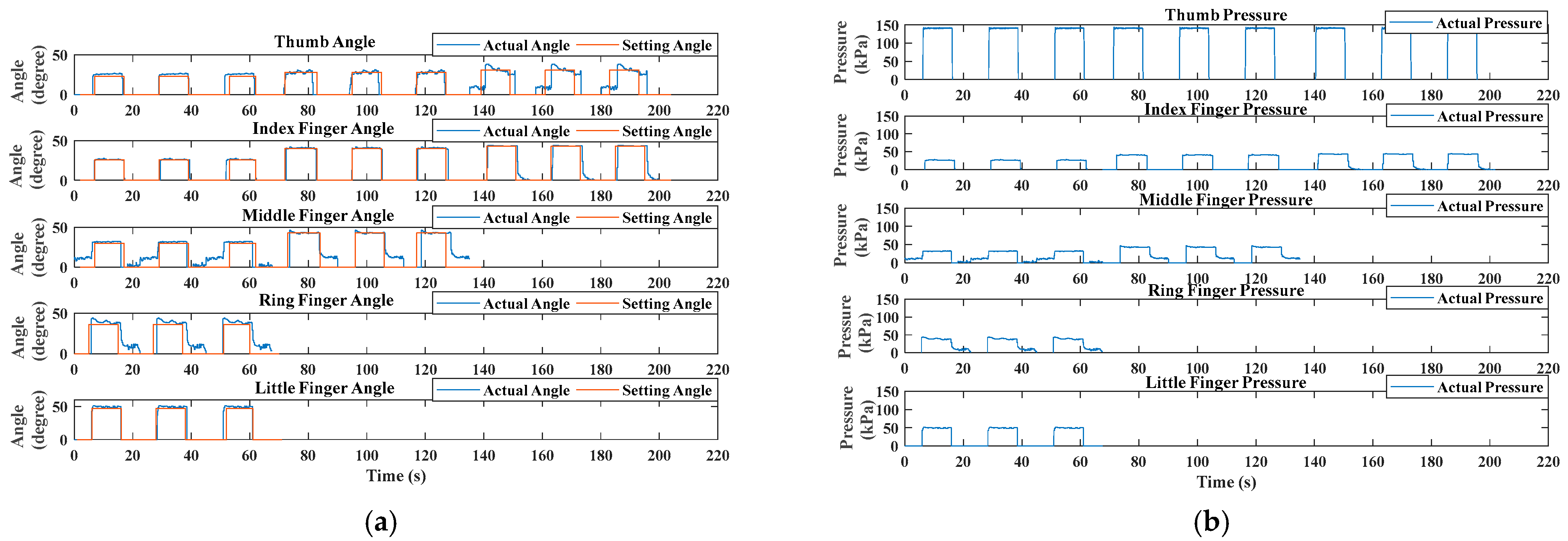

In conclusion, this paper presented the design, modeling, and evaluation of pneumatic bioinspired SCPBAs for hand rehabilitation in ADL tasks. The contributions of this research mainly include the following. (1) The SCPBAs take inspiration from the anatomy of human fingers, which makes the actuator match the finger profile and attain compatible motion coupled with a finger. (2) The proposed SCPBAs have significant advantages in the accuracy of predicted joint stiffness and extension angle. (3) The soft hand exoskeleton based on the SCPBAs integrated the proprioceptive stiffness-compensating layer, and was able to monitor the bending deformation and applied pressure in ADL tasks. Under an input pressure of 180 kPa, the proposed SCPBAs drove fingers to 113° with a maximum extension angle of 22.3°.

In future work, customized designs for multi-material three-dimensional technologies able to realize multi-gradient hardness will be utilized for stroke patients in hand rehabilitation training. Moreover, a feedback control system with flexible electronic sensing for wearable devices will be researched to enable more precise motion, accurately assess motor function, monitor a whole rehabilitation training trial, and achieve active training by users’ intention.