1. Introduction

The replacement of traditional sources of energy based on fossil fuels with renewable energies (REs) is inevitable for environmental reasons and due to the gradual depletion of fossil fuels. REs are environmentally friendly and their sources are not exhaustible. The wind blows alternatingly so the wind speed varies continuously and in some cases is less than cut-in speed, i.e., the required speed to generate electrical energy. Similarly, solar energy is not available during the night and cloudy weather. Thus, the disadvantage of REs is that their sources, such as solar power and wind, are not available all the time. Consequently, REs should be stored to continually assure the existence of electrical energy [

1,

2]. A diversity of energy storage (ES) schemes exist that involve mechanical, magnetic, chemical, electrochemical, electrical, biological, and thermal energy storage. The choice of ES scheme relies considerably on the energy source, the energy required for special implementation, funds, and the viability of system infrastructure [

3]. ES schemes involve:

Mechanical ES: This includes ES in the form of kinetic, potential, or compression energy. The most frequently utilized schemes for ES as mechanical energy are flywheels and hydroelectric pump storage [

4]. Other mechanical ES schemes exist, such as springs, compressed air, hydraulic accumulators, and gravitational potential.

Magnetic ES: In this scheme, ES is performed through supplying DC current via a coil and creating a magnetic field. In most circumstances, a superconducting magnetic coil is employed [

5]. The cooling process of the superconducting magnet can release the stored energy once again into the surroundings.

Chemical ES: In this scheme, ES is performed via chemical or physical suction, intercalation, electrochemical procedures, or chemical conversion [

6]. Presently, there is increased interest in employing methanol, methane, butanol, hydrogen, and hydrocarbons for chemical ES schemes [

7].

Electrical ES: In this scheme, ES in the form of electrical charge is performed, i.e., obtained via electricity; this process is generally accomplished via capacitors or supercapacitors [

8].

Biological ES: These schemes in general store energy which has been produced through breakdown of glucose via enzymes [

9]; nevertheless, an obstacle to biological ES schemes is that their efficiency is low at about 10%.

Thermal ES: In this scheme, ES is performed via storing heat in a latent, sensible or absorption manner. These schemes provide good opportunities for waste heat recovery and for domestic cooling/heating techniques [

10].

Electrochemical ES: The storage of electrical energy generated via RE sources in the form of electrochemical energy using rechargeable batteries is commonly implemented. Unfortunately, the life span of rechargeable batteries is short, so they need to be continuously replaced, which adds to their cost. Fuel cells (FCs) are promising means for extracting the stored energy via intermittent REs in the absence of a combustion process [

11]. Hydrogen is produced by the surplus REs via electrolyzers then, when there is shortage in REs, electrical energy is generated from hydrogen by FCs [

2]. Because of the merits of the proton exchange membrane fuel cell (PEM-FC), it is favored over other types of FC. The optimum operation of PEM-FC is investigated in this article.

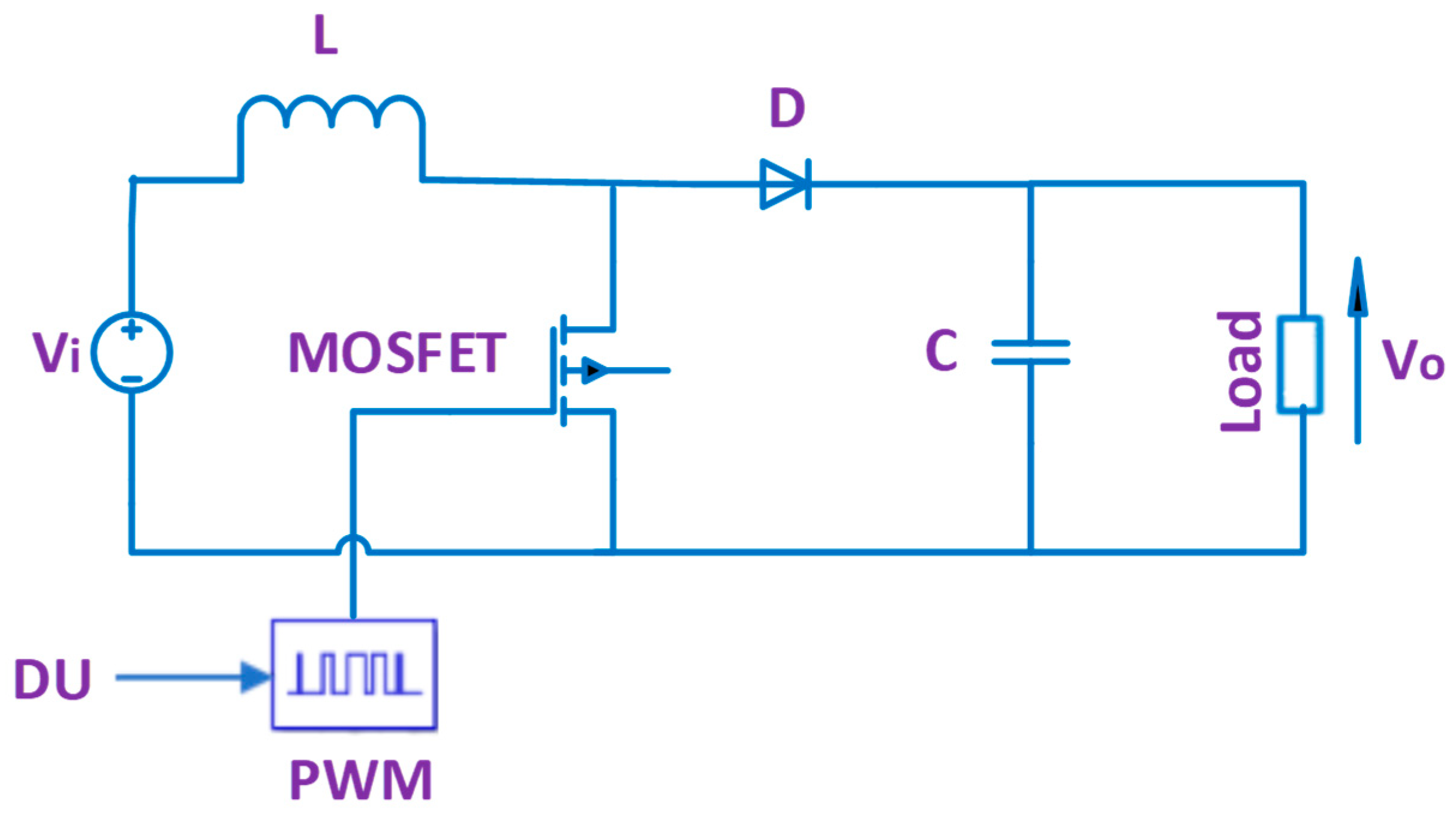

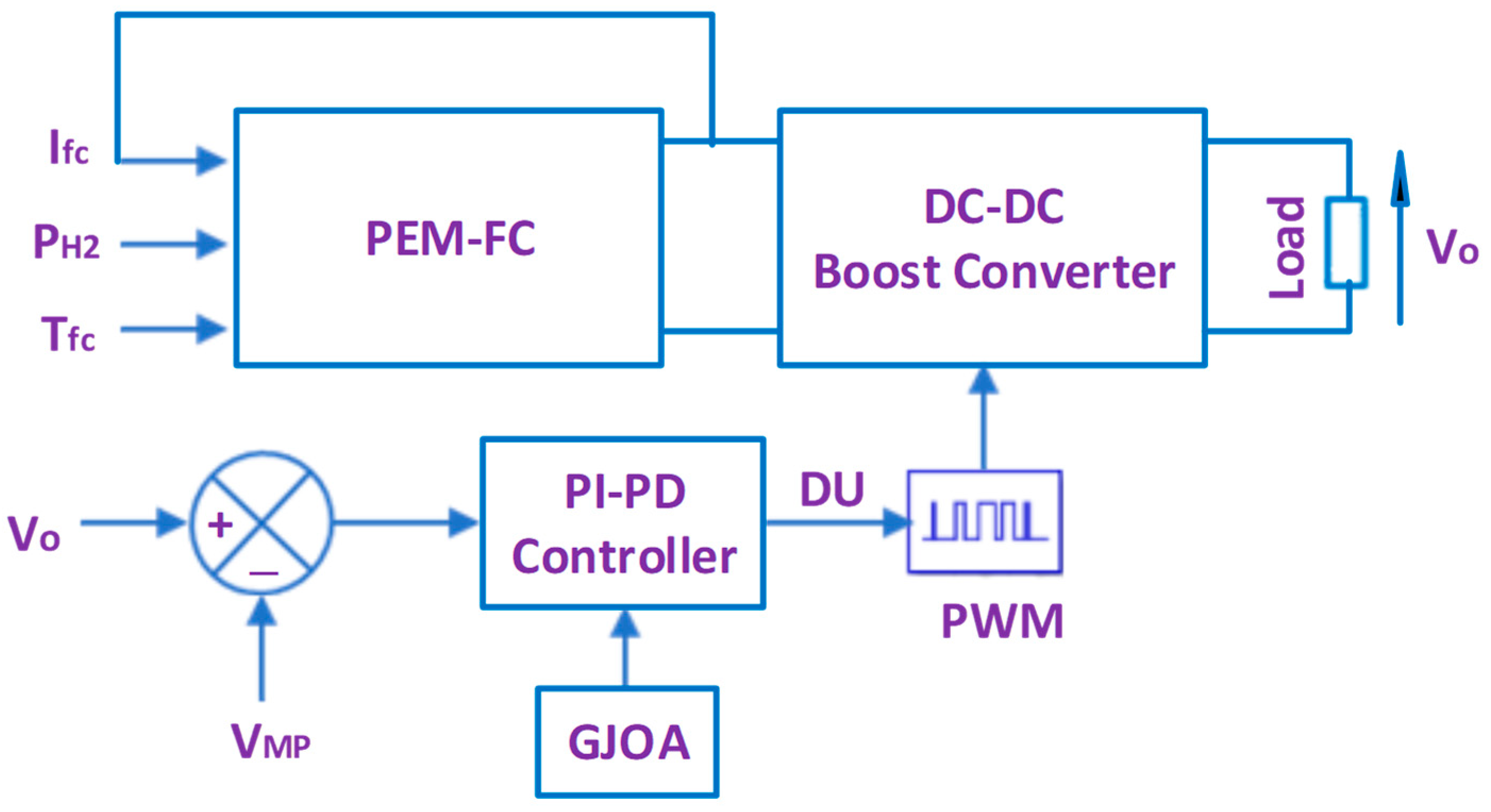

For each group of operation conditions for PEM-FC, i.e., hydrogen pressure, cell temperature, and electric load, there exists a unique point on the current–power (I/P) plot representing maximum power. Accordingly, the maximum power point tracking (MPPT) procedure is required for extraction of the maximum power from the PEM-FC at various operation conditions. The MPPT system is a DC-DC boost converter with an adjustable duty switch cycle (DU). The DC-DC boost converter is fed via the stack terminal voltage (Vsta) of PEM-FC and DU is adjusted to make the output voltage (Vo) track the voltage at MPP (VMP). The difference between the various approaches to MPPT by PEM-FC is the determination method of VMP for adjustment of DU via the DC-DC boost converter.

In this regard, perturb and observe (P&O) [

12,

13] has been utilized for MPPT of PEM-FC, where V

o is repeatedly varied via varying DU by a fixed step (ΔDU), the resultant power and voltage variations are observed and, accordingly, DU is increased or decreased in the next variation until reaching MPP. The authors of [

14] have utilized fuzzy logic (FL) to determine ΔDU size of P&O. In the incremental conductance (IC) [

15] and the incremental resistance (IR) [

16] methods, V

MP is determined wherever the derivative of power of the PEM-FC stack

with regards to the operating current of the FC (

) equals zero. The authors of [

17,

18] have employed a backstepping technique to determine DU, which makes I

FC track the current at MPP. In the prementioned methods, the power of PEM-FC is calculated via multiplying the measured values of V

o and I

FC while, in the variable step size (VSS) [

19,

20,

21], the measured value of I

FC is only utilized to decrease the cost and complexity.

In [

22,

23,

24,

25], V

sta and I

FC are entered into the trained artificial neural network (ANN) to produce the DU of the DC-DC boost converter. Adaptive ANN based on a fuzzy inference system has been applied in [

26,

27,

28].

The authors of [

29,

30,

31] have employed FL for determination of DU of the DC-DC boost converter for MPPT of PEM-FC. In the same regard, several controllers have been employed, such as model predictive control (MPC) [

32], sliding mode controller (SMC) [

33,

34,

35], fuzzy logic controller (FLC) [

36,

37,

38,

39,

40], FLC-based VSS [

41,

42,

43], and FLC optimized by various algorithms, e.g., firefly optimizer [

44] and differential evolution (DE) [

45].

In addition to the aforementioned controllers, numerous others have been employed for MPPT of PEM-FC, i.e., the proportional-integral-derivative (PID) controller optimized by numerous algorithms, such as salp swarm approach (SSA) [

46], the particle swarm optimizer(PSO) [

47], the grey wolf optimizer (GWO) [

48], the fractional-order PID controller optimized by forensic-based investigation optimizer [

49], and the fractional-order integral controller with filter [

50].

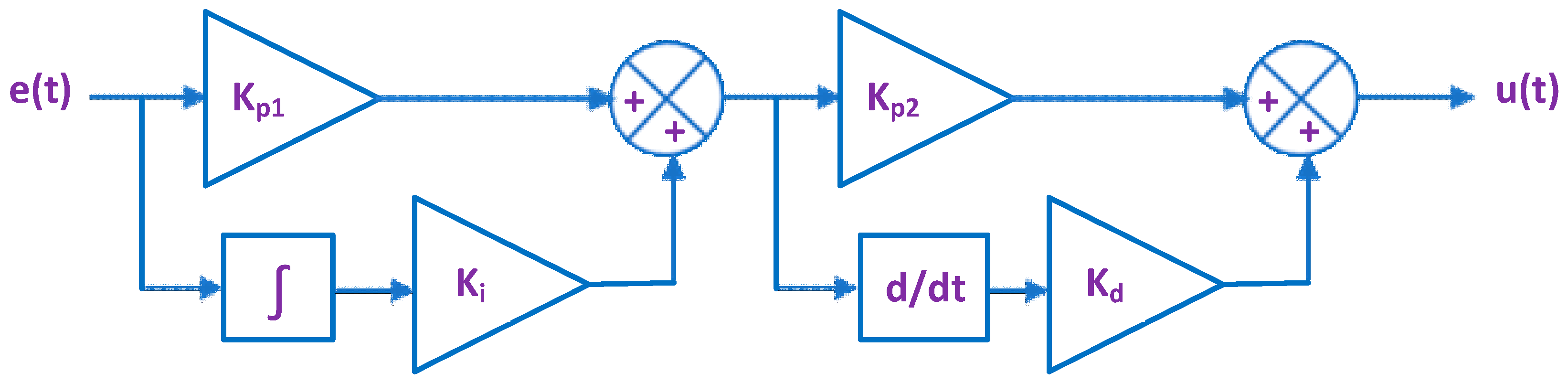

Table 1 summarizes the limitations of many published techniques. This article addresses the deficiencies of the former published works by proposing an innovative PI-PD controller for MPPT of PEM-FC. The gains of the PI-PD controller are adjusted through the golden jackal optimization algorithm (GJOA). The suggested approach (GJOA-PI-PD) and controller has the potential for improving results, since its structure (PI-PD controller) is different from those in the literature, i.e., the PID and FOPID controllers. Additionally, the results of applying the PI-PD controller for automatic generation control in [

51] revealed its advantages over PID and PI controllers.

Recently, metaheuristic optimization techniques have been applied for numerous purposes. Three kinds of these techniques are employed: evolutionary algorithms, physics-based, and swarm intelligence techniques. The first kind is driven by relying on biological evolution, e.g., DE and artificial bee colony. The second kind is driven by relying on physical laws, e.g., equilibrium algorithm and Archimedes optimizer. The last kind is driven by relying on the manners of animal groups, e.g., PSO, SSA, and GWO.

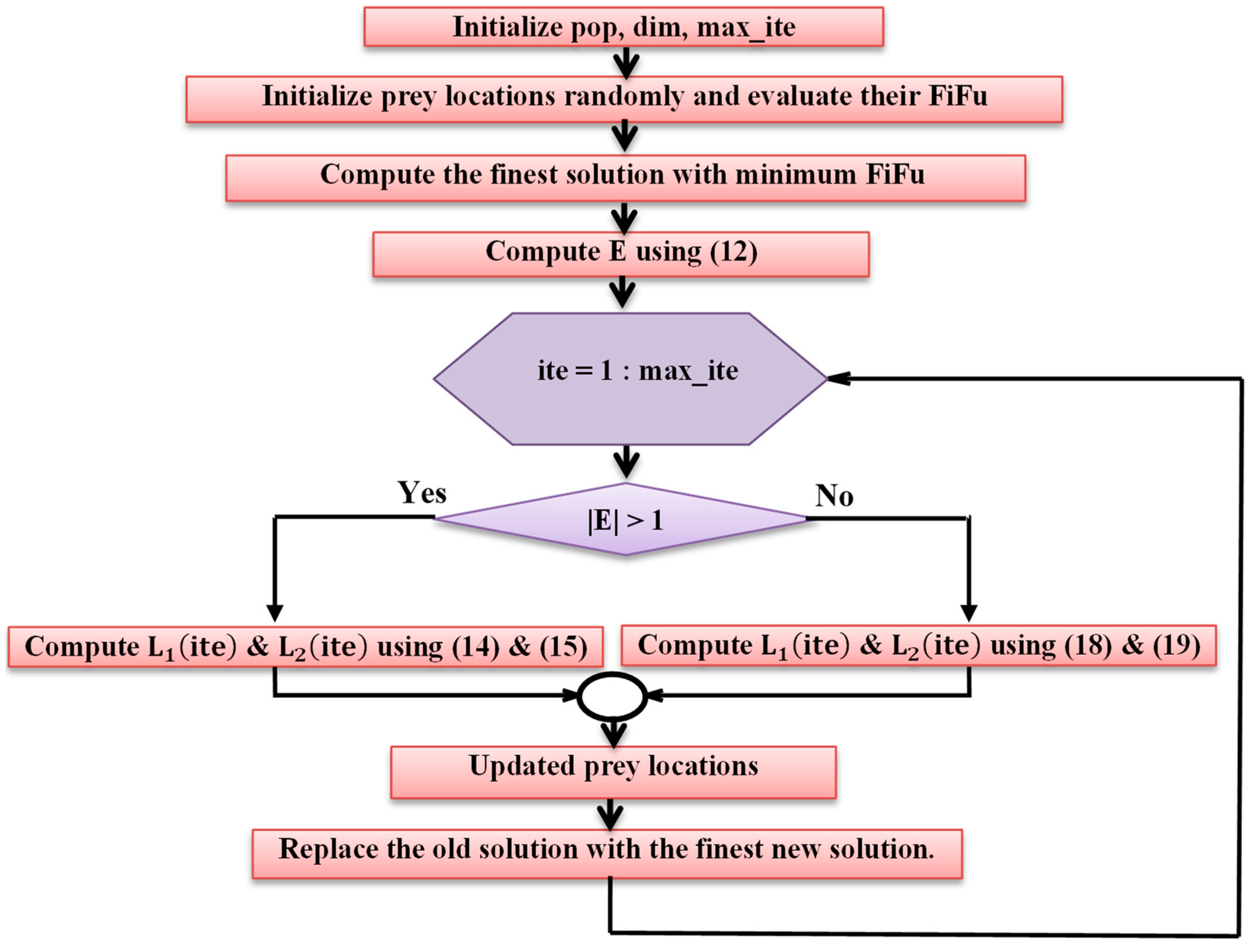

In this regard, the GJOA is suggested for adjusting the gains of the PI-PD controller. The GJOA is a metaheuristic optimizer that replicates the golden jackal’s manner during hunting [

52]. GJOA was written in 2022 and utilized successfully for economic dispatch [

52], planning of wind turbines, and for charging stations of electric vehicles [

53]. The successful utilization of GJOA for engineering optimization issues encouraged the authors to employ it to adjust the gains of the PI-PD controller for MPPT of PEM-FC.

The contributions of this article are:

The innovative employment of the PI-PD controller for MPPT of PEM-FC.

The innovative application of GJOA for adjustment of the gains of the PI-PD controller.

Comparing the acquired results using the GJOA-PI-PD controller for MPPT of PEM-FC with those based on the P&O approach, GJOA-PID, and GJOA-FOPID controllers in order to confirm its supremacy.

The GJOA-PI-PD controller performance is validated through variations in hydrogen pressure, cell temperature, and electric load.

The remainder of the article is organized as follows: FCs are overviewed in

Section 2. The PEM-FC is modeled in

Section 3. The DC-DC boost converter is revealed in

Section 4. The proposed control strategy of MPPT is clarified in

Section 5, including the PI-PD controller and GJOA plus the compared control strategies i.e., FOPID controller and P&O. The results are discussed in

Section 6. Conclusions are extracted in

Section 7.

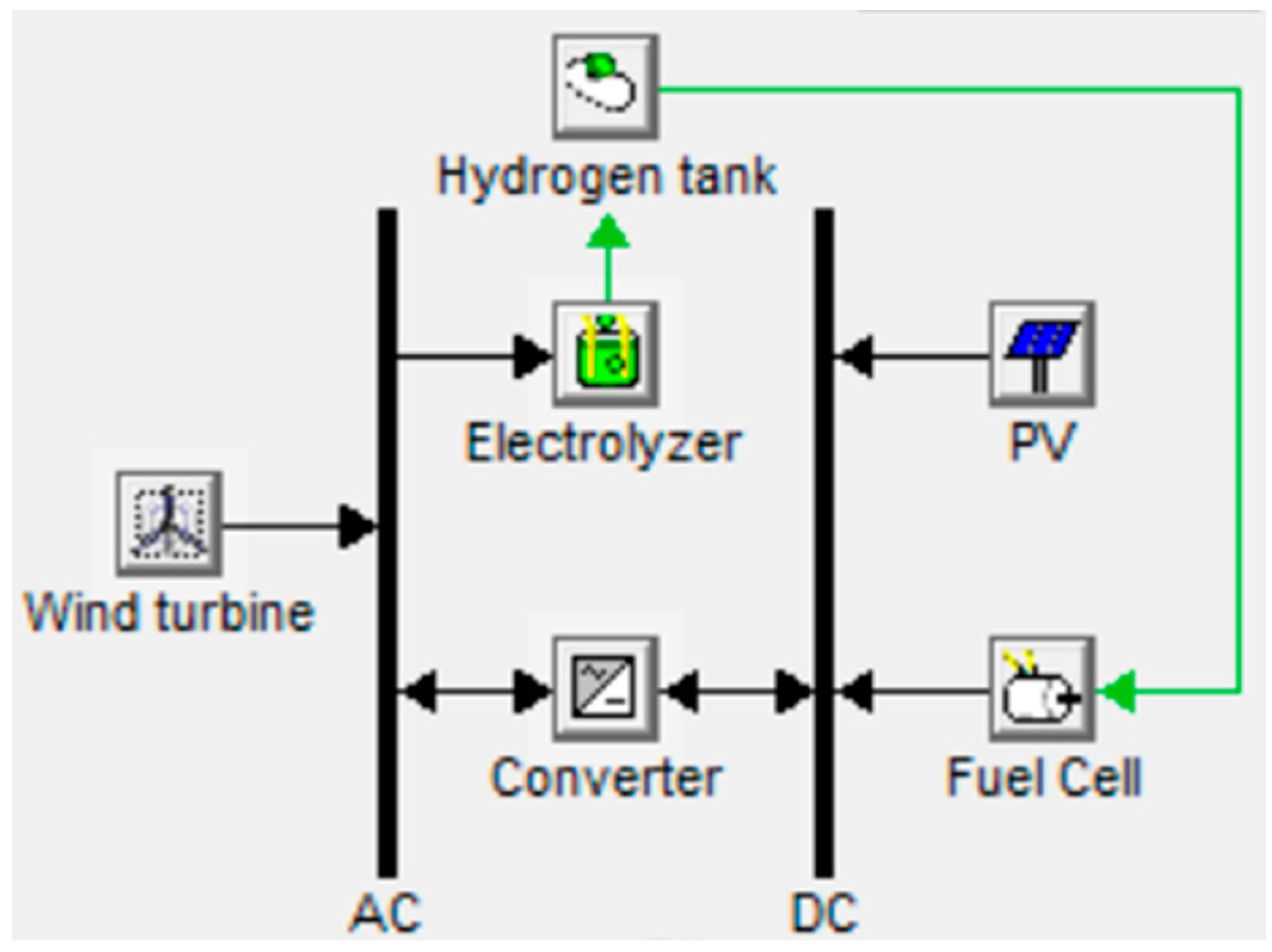

2. Overview of FCs

Figure 1 reveals the complete scheme of the FC utilized for electrochemical ES of REs. The water is distilled, then supplied to the electrolyzer by water pump. The electrolyzer produces one molecule of hydrogen (H

2) from each molecule of water (H

2O). The relationship between electrical power (

) and the volumetric hydrogen rate (

) (m

3/h) is stated in (1) [

54]:

where

and

are electrical, current, and voltaic efficiencies, respectively,

is the hydrogen density (0.08988 kg/m

3), e is the number of electrons implied in the reaction and equals 2 for water splitting, F is Faraday’s number (96,485 As/mol),

is the reversible cell voltage, and

is the relative molecular mass (2.016 g/mol). The reversible PEM fuel cells exhibited a round-trip electrical efficiency of 40–46% at current density of 500 mA/cm

2. The energy conversion process inside is clean, since FC exhaust is water vapor.

FCs are mainly categorized according to their electrolyte. This categorization establishes the type of electrochemical reactions which occur inside the FC, the type of catalysts needed, the temperature limit of the FC, the fuel needed, and other features. These FC characteristics impact their appropriate purposes. The kinds of FC include proton exchange membrane fuel cell (PEM-FC), solid oxide FC, phosphoric acid FC, alkaline FC, molten FC, and direct methanol [

55]. Comparison among kinds of FCs reveals that PEM-FC is distinguished by its low operating temperature, great power extent, rapid start-up, little corrosion, simple composition, light weight, small volume, cheap cost, and long life span [

56]. Additionally, the solid electrolyte of PEM-FCs makes electrode sealing simpler than with other kinds of FC. The operating temperature of PEM-FC ranges between 60 and 100 °C. The entire expense of a car based on the PEM-FC is 500–600

$/kW [

57]. Thus, PEM-FCs are employed in several applications for instance transportation [

56], airplanes, and distributed generators [

58].

3. PEM-FC Model

The PEM-FC stack model has been densely illustrated in the literature. For a stack composed of

as a series connected cells,

can be calculated as below [

19,

21]:

where E is open circuit potential,

and

are activation and concentration over-voltages for each cell, respectively, and

is ohmic voltage drop for each cell. These variables are computed using (3) to (6) [

19,

21].

where

is cell temperature

, and

and

are partial pressures

of

and

, respectively.

where

are empirical parameters,

is concentration of

, and

is the operating current

of the FC.

where

is parametric coefficient, and

and

are actual and maximum density of current

, respectively.

where

and

are resistances

of the membrane and connections, respectively.

is computed as below:

By reference to

to

, it is clear that

is reliant on

,

, and

which is reliant on electric load.

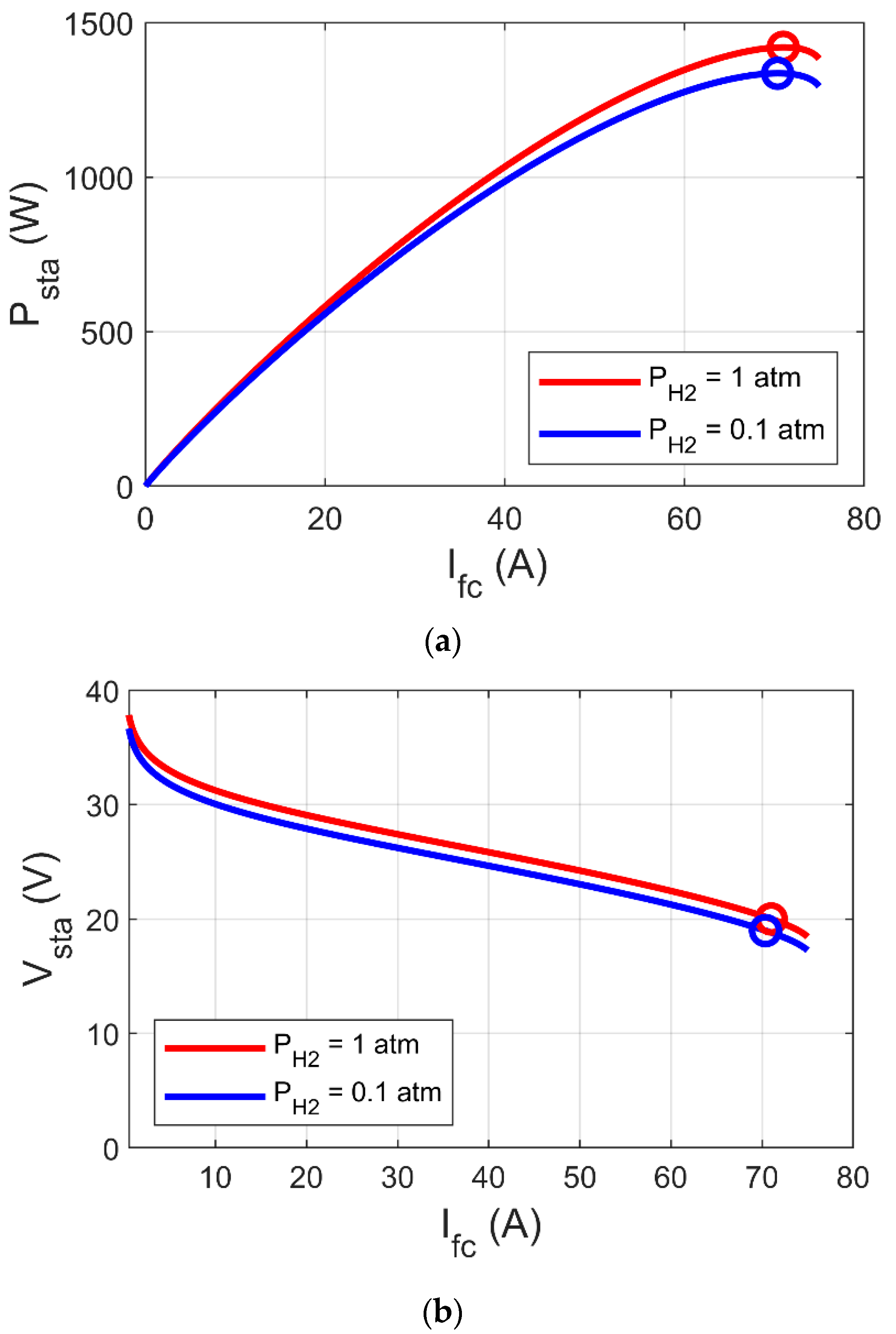

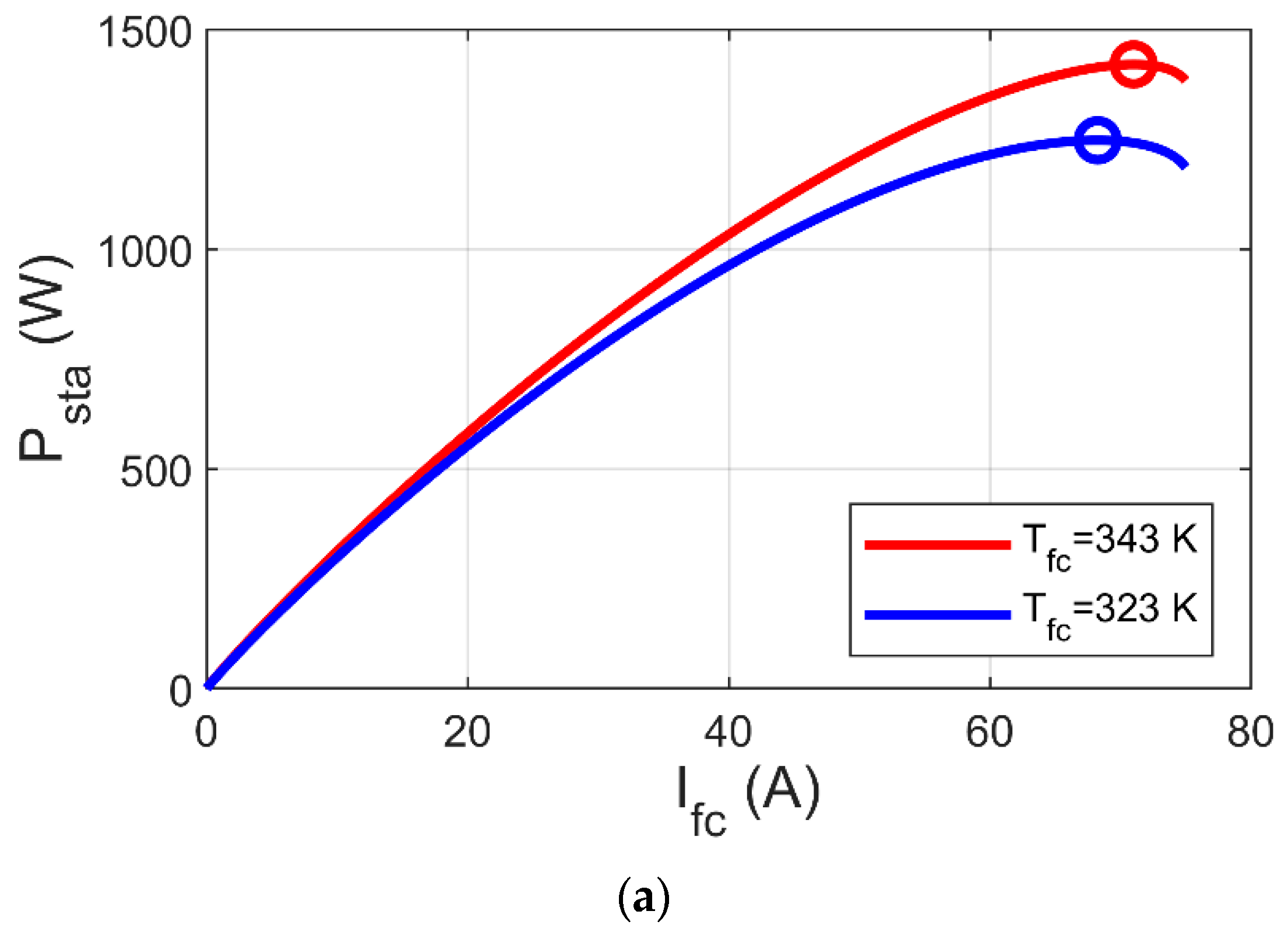

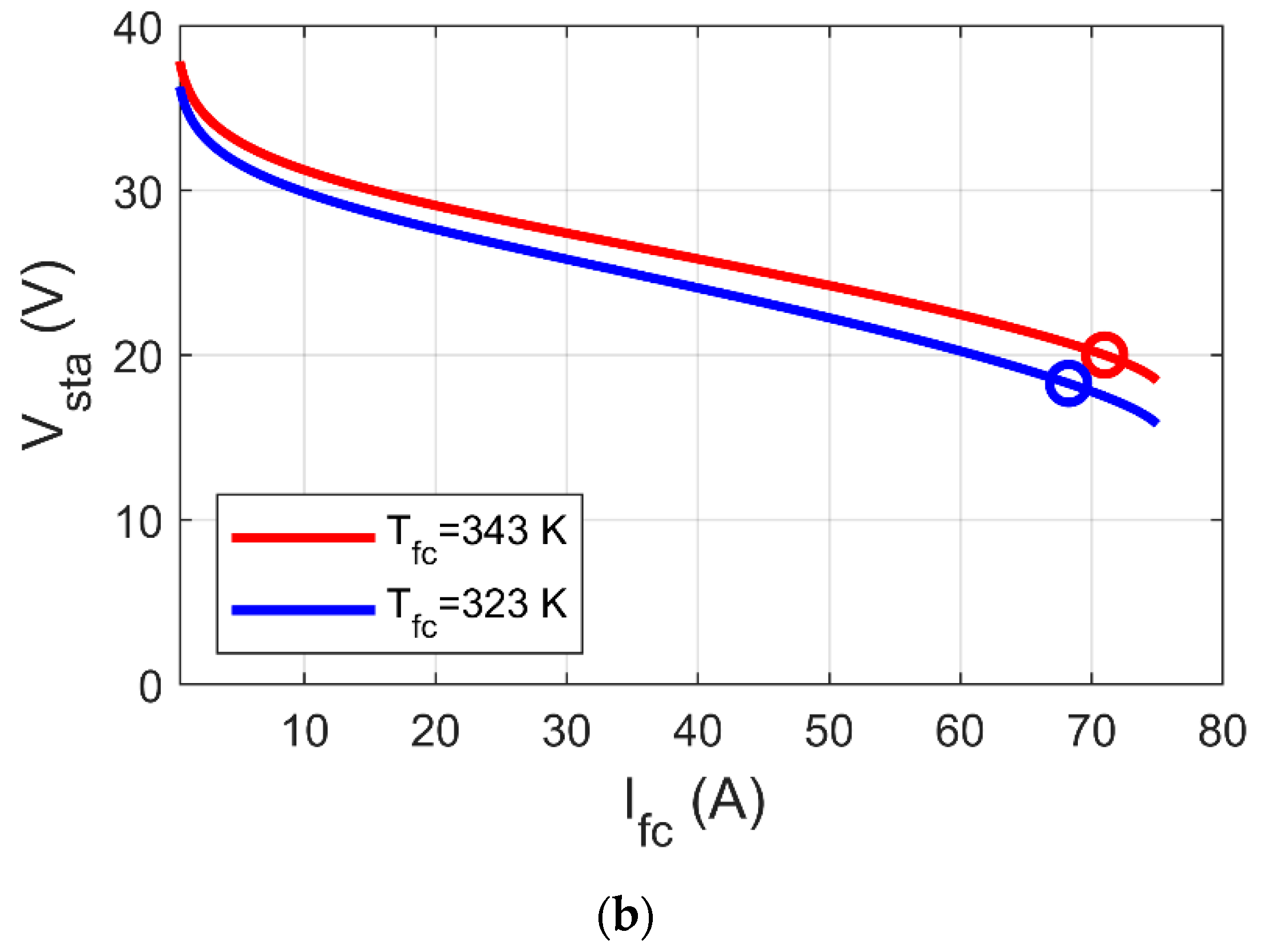

Figure 2 and

Figure 3 show the variation of MPP based on the variations of

and

, respectively, where MPP increases with increase of both

and

. In

Figure 2b and

Figure 3b, it can be observed that MPP occurs at a specific voltage (V

MP), which is reliant on

,

, and electric load. Thus, the key to reach MPP is to raise V

fc to V

MP using the DC-DC boost converter. In this article, we suggest an innovative MPPT for PEM-FC using the PI-PD controller, whose gains are tuned by GJOA. We begin with an explanation of the DC-DC boost converter in the next section.

6. Results with Discussion

The efficacy and forcefulness of MPPT of PEM-FC based on the GJOA-PI-PD controller are endorsed via comparing its results with those of other approaches. The impact of variations in , , and loading on the performance of the suggested MPPT of PEM-FC is also examined.

The simulation results have been obtained via MATLAB-R2021 in Windows 11.

The GJOA is operated with these parameters: pop = 10 and max_ite = 5. The MPPT is performed on a commercial typical PEM-FC, namely the Ballard Mark V, whose parameters are listed in

Table 2. These parameter values were extracted using the whale optimizer in [

61]. Regarding the values of parameters of the DC-DC boost converter, f

swi = 10 kHz, high f

swi is chosen to downsize the capacitors and inductors, which causes a cost decrease, L = 69 mH, and C = 1500 μF. These settings of L and C are carefully selected to assure low ripples in V

o at the indicated f

swi. The limits within which the parameters of GJOA-PID, GJOA-FOPID, and GJOA-PI-PD controllers are maintained during minimization of FiFu using GJOA are listed in

Table 3,

Table 4 and

Table 5, respectively.

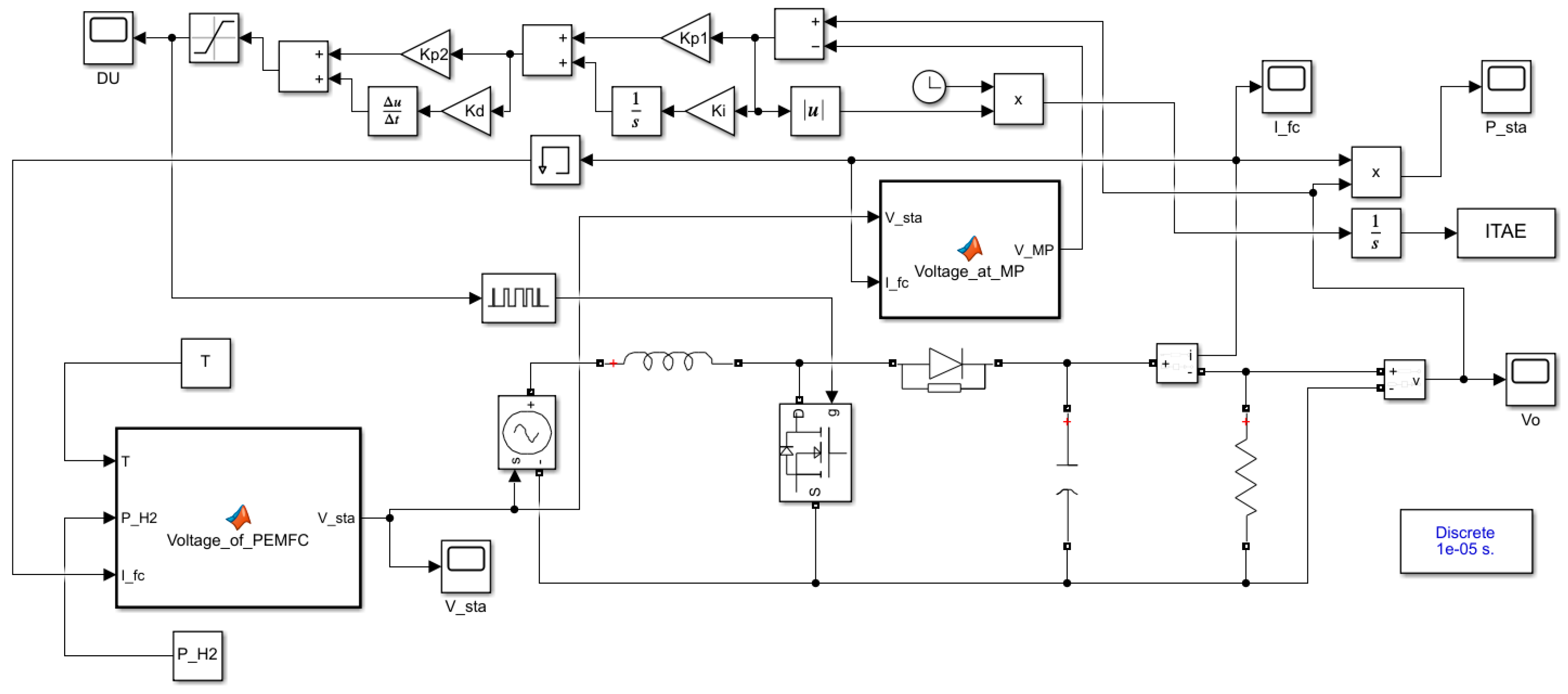

Figure 9 reveals the MATLAB Simulink model of the suggested MPPT for PEM-FC.

6.1. MPPT of PEM-FC under Normal Operating Conditions

Normal operating conditions of and for the Ballard Mark V PEM-FC are applied in this case for different schemes of MPPT of PEM-FC. In detail, and . Regarding the electric load, resistance (R) of 50 Ω is supplied by PEM-FC.

The values of optimized parameters of GJOA-PID, GJOA-FOPID, and GJOA-PI-PD controllers are listed in

Table 6,

Table 7 and

Table 8, respectively.

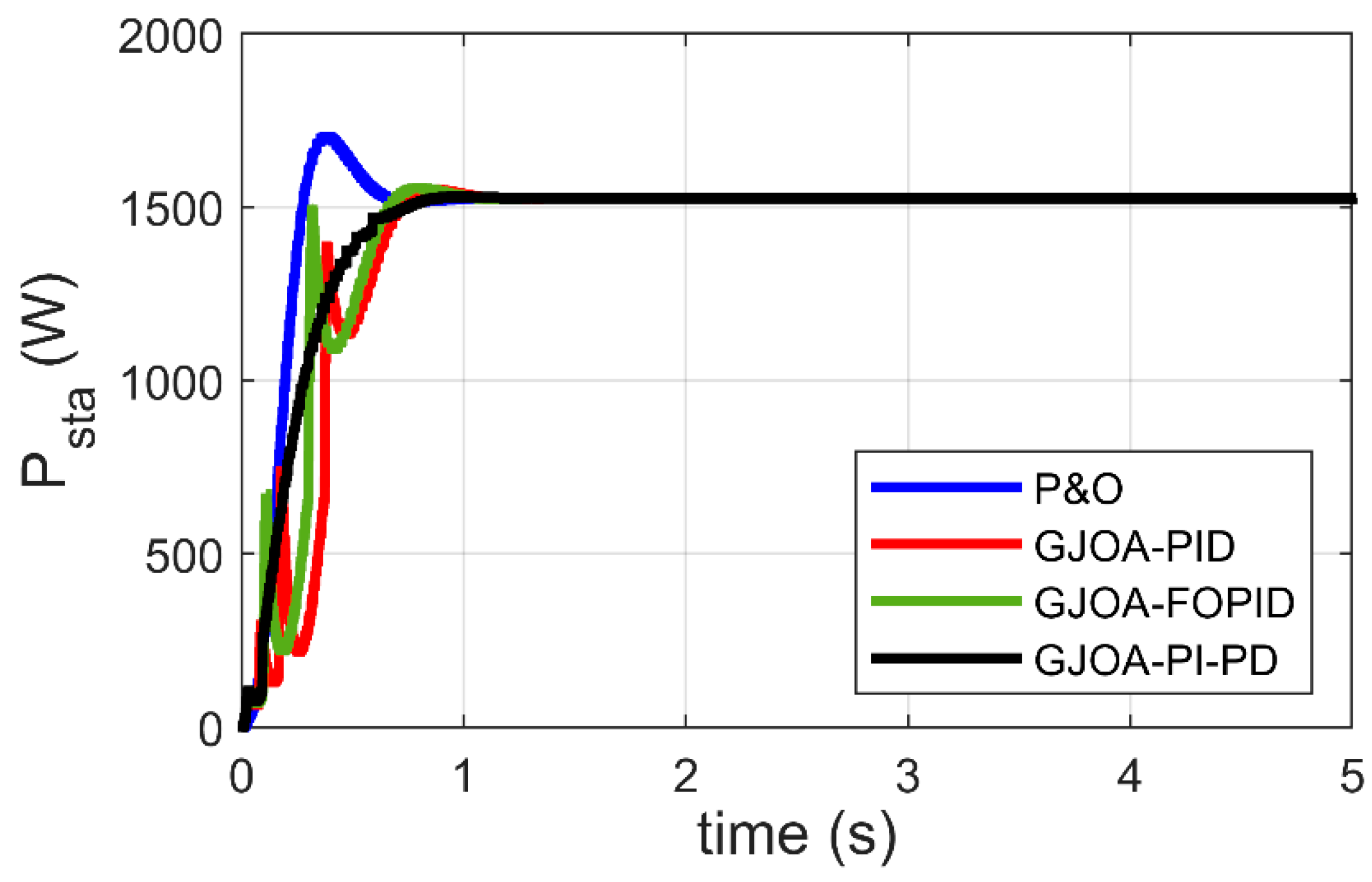

Figure 10 reveals P

sta of the Ballard Mark V PEM-FC when three MPPT schemes, plus the proposed scheme, are applied. Specifically, the P&O approach, GJOA-PID, and GJOA-FOPID controllers are compared with the proposed GJOA-PI-PD controller. High overshoot exists in the response of P

sta when the P&O scheme is employed. There are oscillations and slowness in the response of P

sta when GJOA-PID, and GJOA-FOPID controllers are employed. The resultant values of rise time (t

r) and percentage overshoot (POS) for various MPPT schemes are listed in

Table 9. The proposed GJOA-PI-PD controller results in POS of 0.2% which is the lowest overshoot compared to other MPPT schemes i.e., the P&O approach, GJOA-PID, and GJOA-FOPID controllers, by 98.26%, 86.30%, and 89.07%, respectively. The resultant value of t

r with the proposed GJOA-PI-PD controller is 0.391 s, which is less than that of the GJOA-PID, and GJOA-FOPID controllers but more than that of P&O. The criteria in comparison are that the MPPT scheme, which has the quickest response, the least oscillations, and the lowest overshoot, is preferred over other schemes. When these criteria are applied to the results revealed in

Table 8, the proposed GJOA-PI-PD controller is found to have better equilibrium among speed and overshoot than other MPPT schemes.

The previous comparison is based on visual analysis of the results. On the other hand, the comparison based on the numerical results of ITAE confirms the preference for the GJOA-PI-PD controller over other schemes, as summarized in

Table 10, where the values of ITAE are listed. The value of ITAE resulting from the GJOA-PI-PD controller is the least compared to the others, by 93.95%, 87.17%, and 87.97%. It can be said that MPPT based on the GJOA-PI-PD controller outperforms other approaches by a wide margin. The MPPT schemes can be arranged in accordance with the smallness of ITAE as follows: GJOA-PI-PD, GJOA-PID, GJOA-FOPID controllers, then the P&O scheme.

6.2. MPPT of PEM-FC under Variation of

In this subsection, the GJOA-PI-PD controller for MPPT of the Ballard Mark V PEM-FC is validated when

changes.

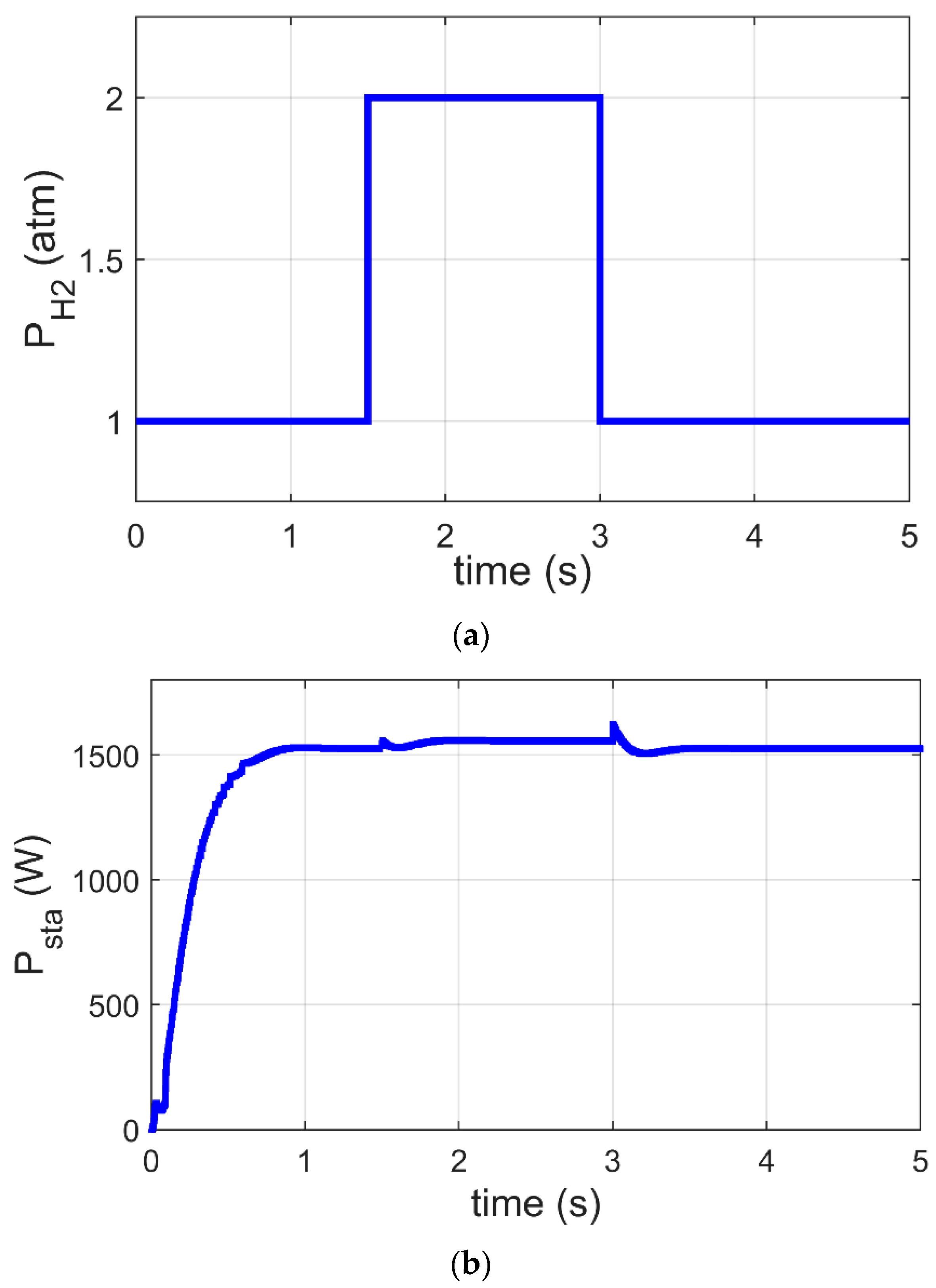

Figure 11a reveals that the value of

is initially 1 atm, then it increases to 2 atm at

and afterward it decreases to 1 atm at

.

Figure 11b reveals the corresponding response of P

sta during a change in

where we observe that MPPT based on the GJOA-PI-PD controller reacts speedily to variation in

. During the period of increase of

, P

sta increases to new value then decreases with decrease of

. This means that P

sta tracks the new MPP for new conditions. The new conditions in this case study resulted in a variation of

from 1 atm to 2 atm and then from 2 atm to 1 atm, with constant values of

and

. Additionally, the absence of oscillations is observed. Furthermore, the values of overshoot and undershoot are very small.

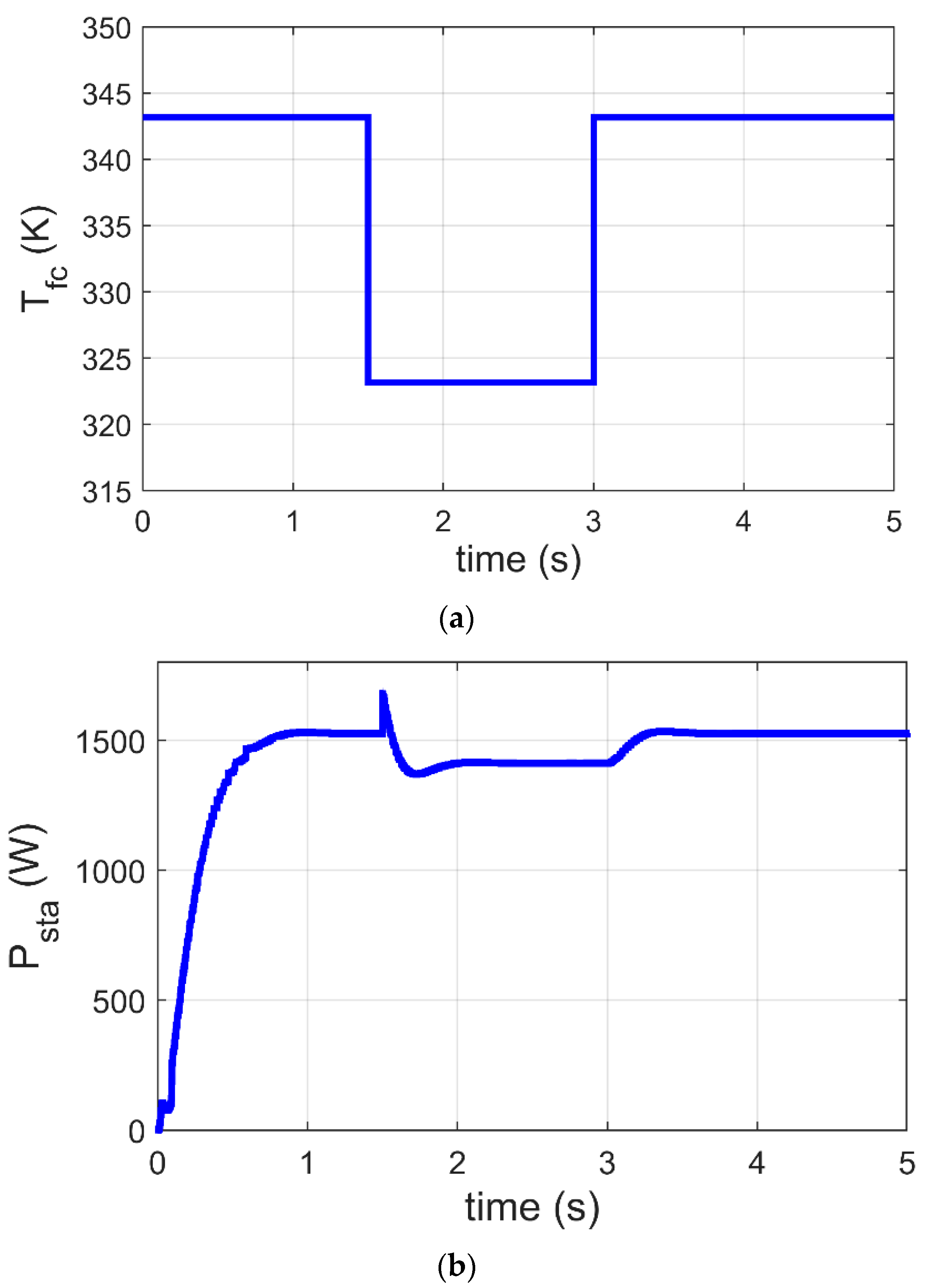

6.3. MPPT of PEM-FC under Variation of

This part presents a justification for the GJOA-PI-PD controller for MPPT of the Ballard Mark V PEM-FC when

varies. The change in

is revealed in

Figure 12a, where it is initially 343 K, then it decreases to 323 K at

and after that it increases to 343 K at

. The corresponding response of P

sta during variation of

is illustrated in

Figure 12b, where the quick performance of MPPT based on the GJOA-PI-PD controller with variation of

is observed. Throughout the period of decrease in

, P

sta decreases to its new value then increases with increase in

. This indicates that P

sta tracks new MPP for new conditions. The new conditions in this case study are caused by change in

from 343 K to 323 K and then from 323 K to 343 K, with constant values of

and

. Moreover, there are no high values for oscillations during variation in P

sta.

6.4. MPPT of PEM-FC under Variation of

In this subsection, the GJOA-PI-PD controller for MPPT of the Ballard Mark V PEM-FC is justified when

changes.

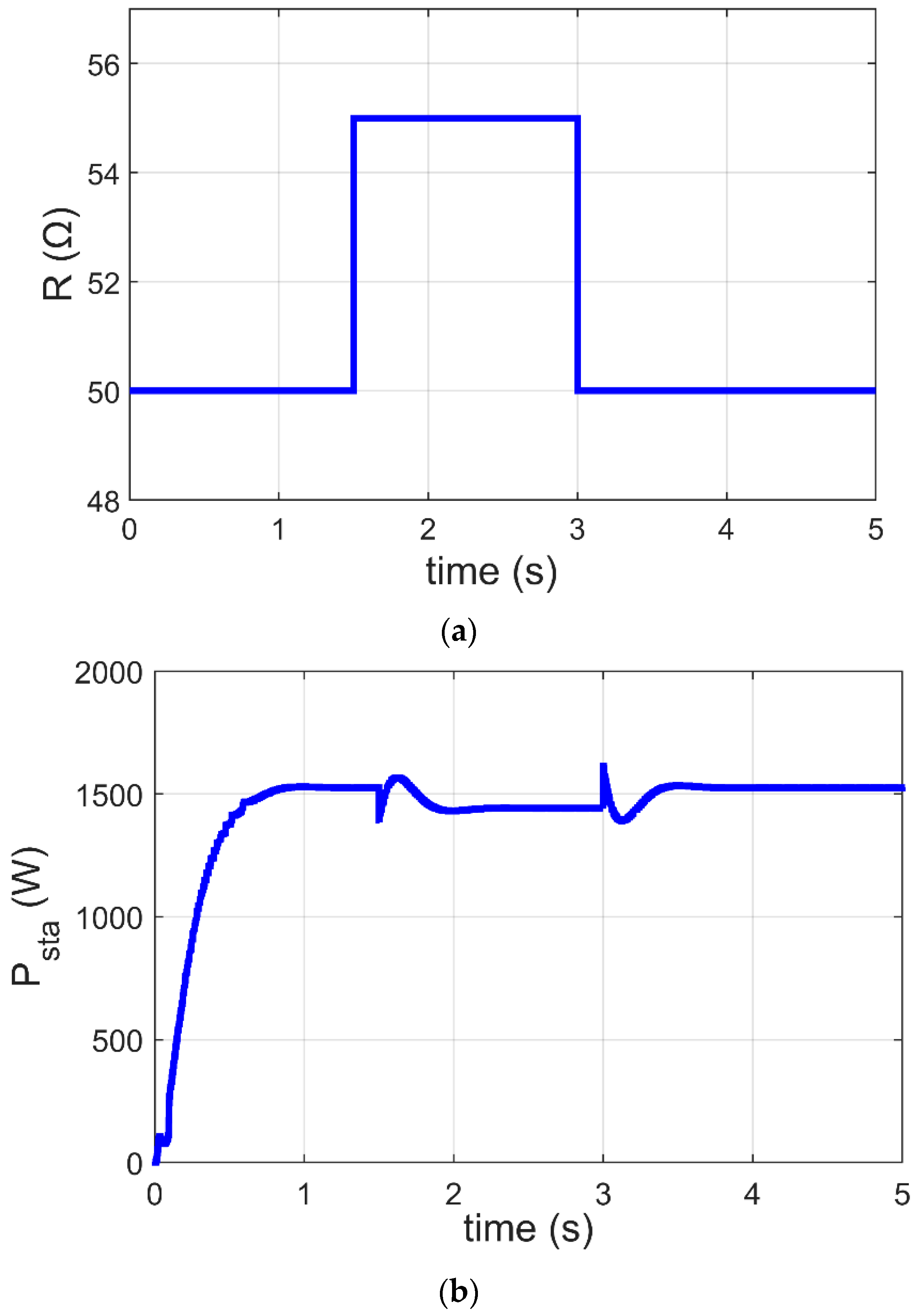

Figure 13a reveals that the value of

is initially 50 Ω, then it increases to 55 Ω at

and afterward decreases to 50 Ω at

.

Figure 13b reveals the corresponding response of P

sta during change in

where MPPT based on the GJOA-PI-PD controller responds quickly to variation in

. During the period of increase in

, P

sta decreases to its new value then increases with decrease of

. This points out that P

sta tracks new MPP for new conditions. The new conditions in this case study result in variation of

from 50 Ω to 55 Ω and then from 55 Ω to 50 Ω, with constant values of

and

. In addition, the oscillations are low.

7. Conclusions

The I/P plot of PEM-FC varies with the operating conditions, namely , , and loading. Accordingly, each group of conditions has a unique I/P plot with unique MPP. Therefore, the presence of the MPPT scheme is required to track MPP continuously. In this work, an innovative MPPT scheme for PEM-FC based on the PI-PD controller, whose gains are optimized via GJOA, has been suggested. The simulation results of the MPPT scheme based on the GJOA-PI-PD controller have been compared with those of other schemes, namely P&O, GJOA-PID, GJOA-FOPID controllers, at normal operating conditions of PEM-FC. The comparison has revealed that the ITAE which resulted using the MPPT scheme based on the GJOA-PI-PD controller is less than that of the compared schemes by 93.95%, 87.17%, and 87.97%, respectively. In addition, the simulation results have revealed that the response of the suggested scheme has the lowest oscillations and overshoot. Furthermore, the MPPT scheme based on the GJOA-PI-PD controller has been legitimized during variation in operating conditions. The simulation results of the MPPT scheme based on the GJOA-PI-PD controller during variation of , , and loading reveal the high speed of performance. Our research plan in the future is to experimentally legalize the suggested MPPT controller of PEM-FC.