Study on the Vibration Isolation Mechanism of Loofah Sponge

Abstract

1. Introduction

2. Materials and Methods

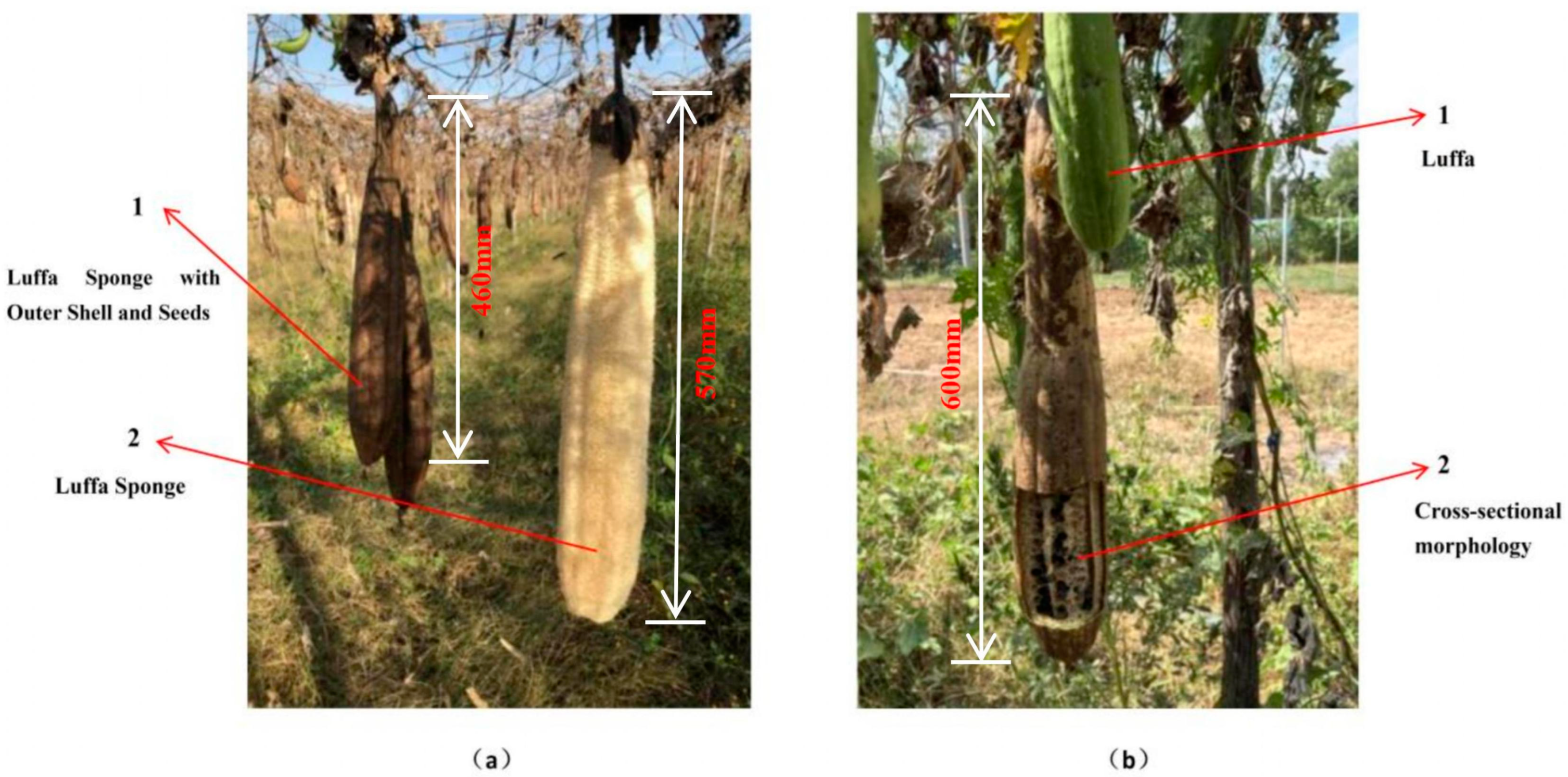

2.1. Loofah Sponge Structure

2.2. Specimen of Loofah Sponge

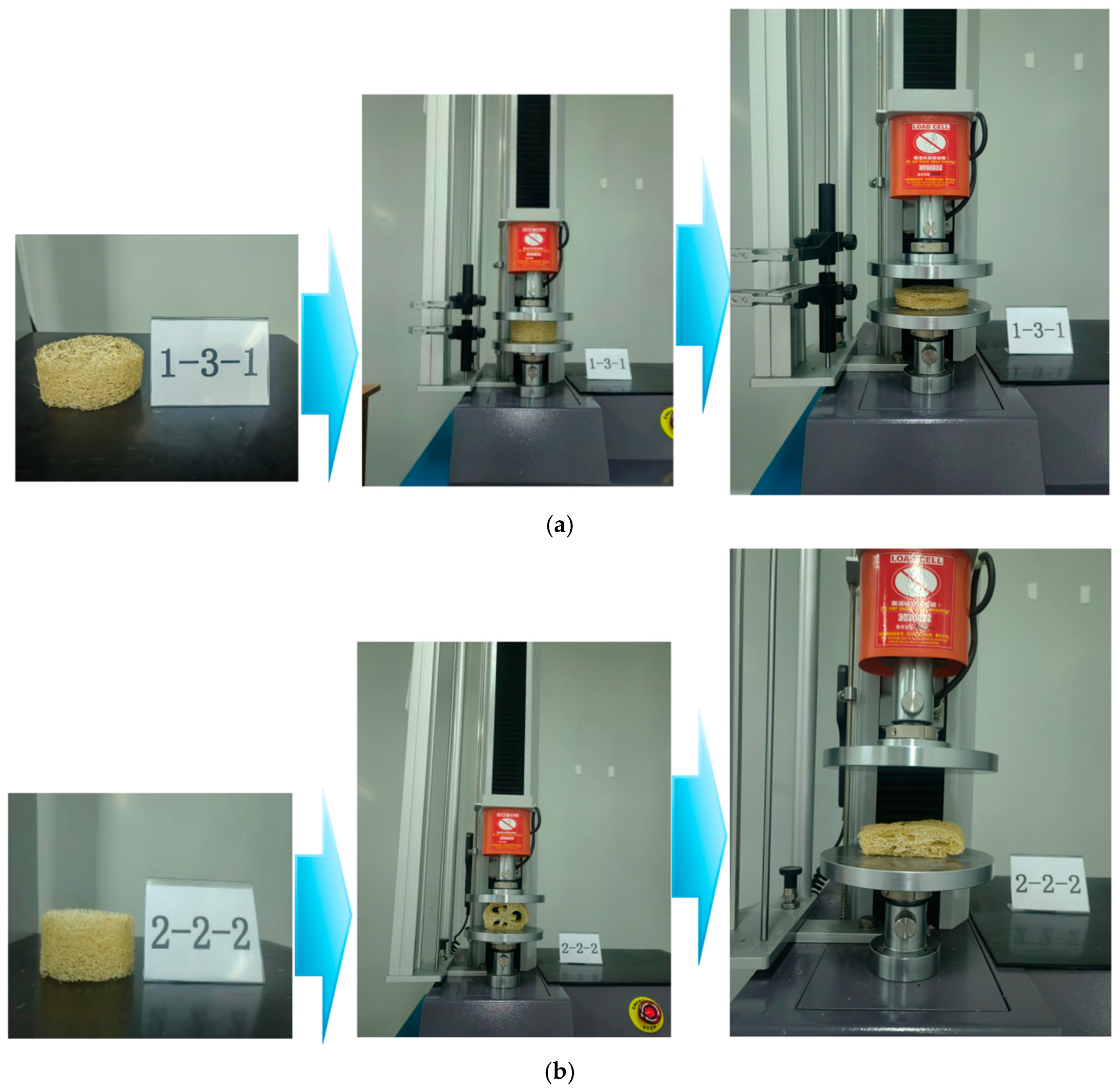

2.3. Static Compression Test of Loofah Sponge

2.4. Loofah Sponge Vibration Isolation Test

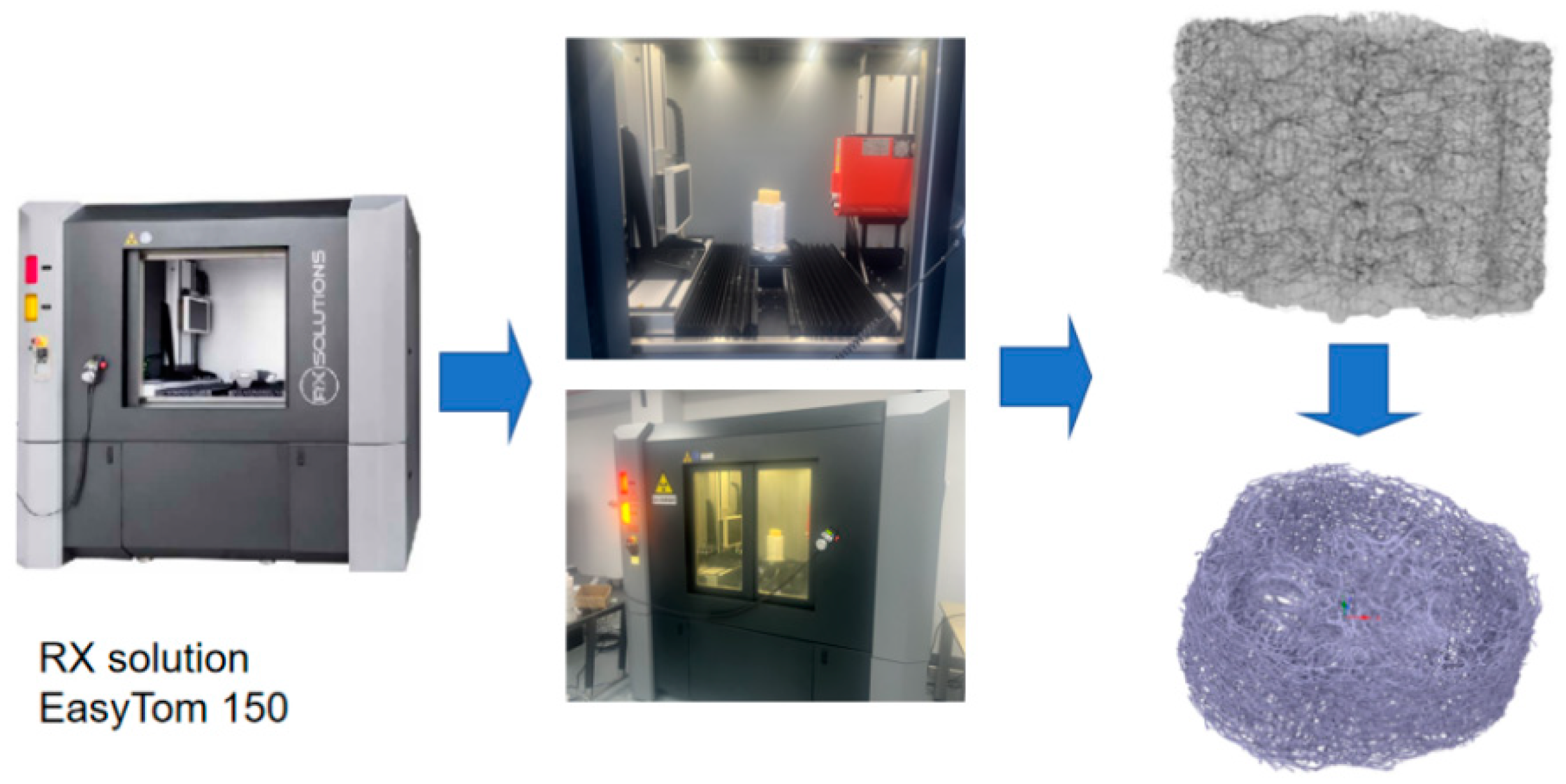

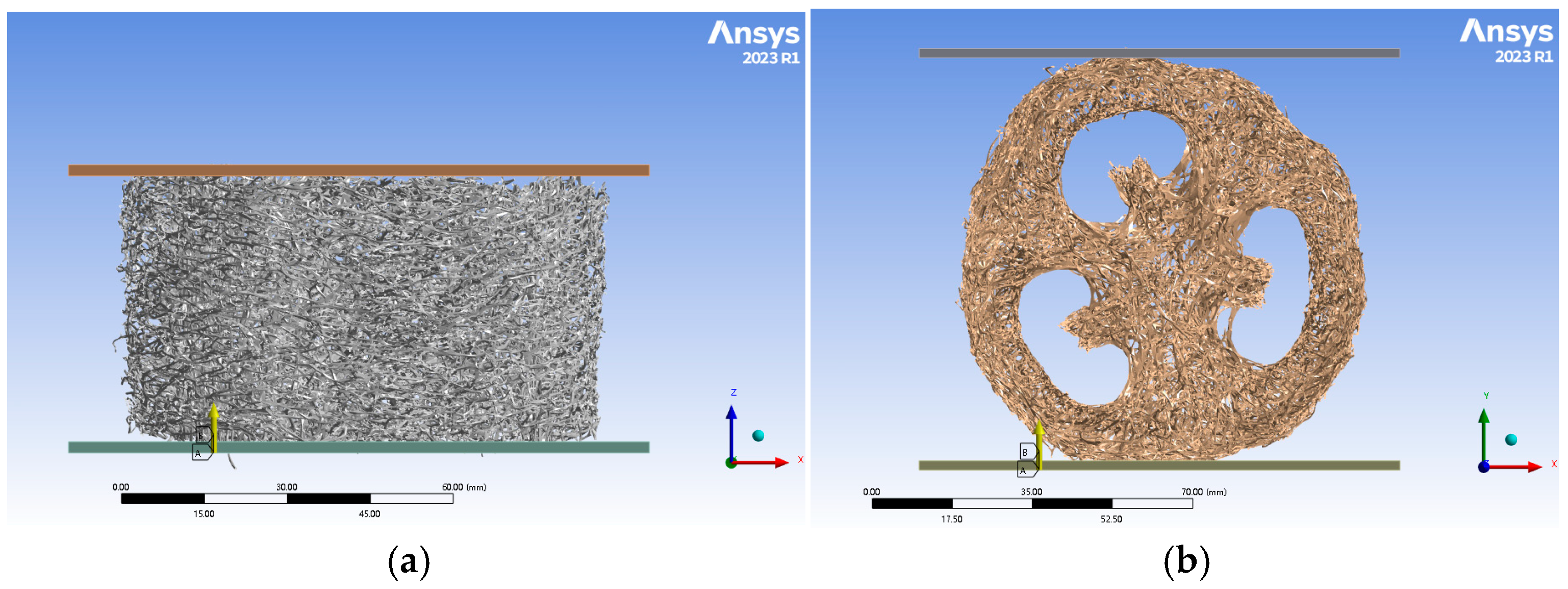

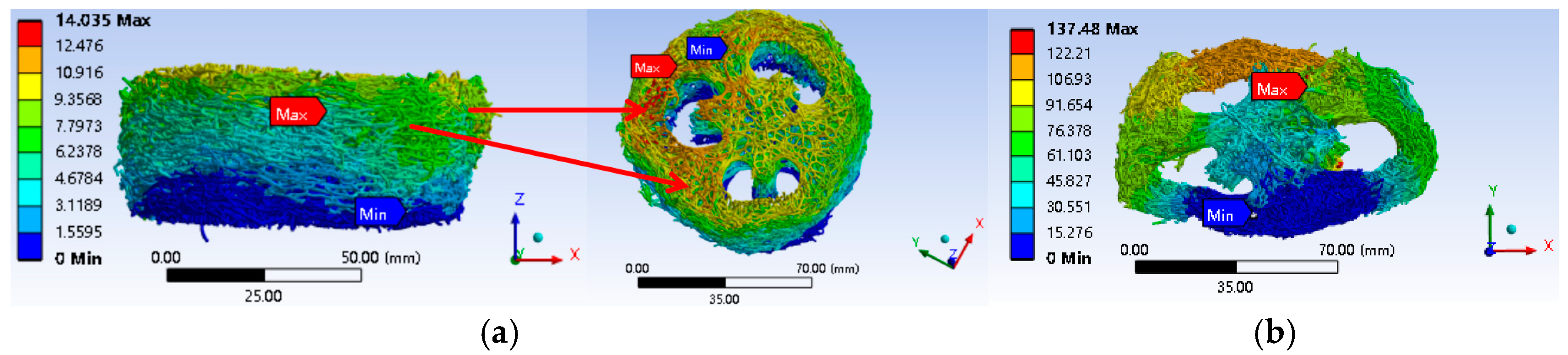

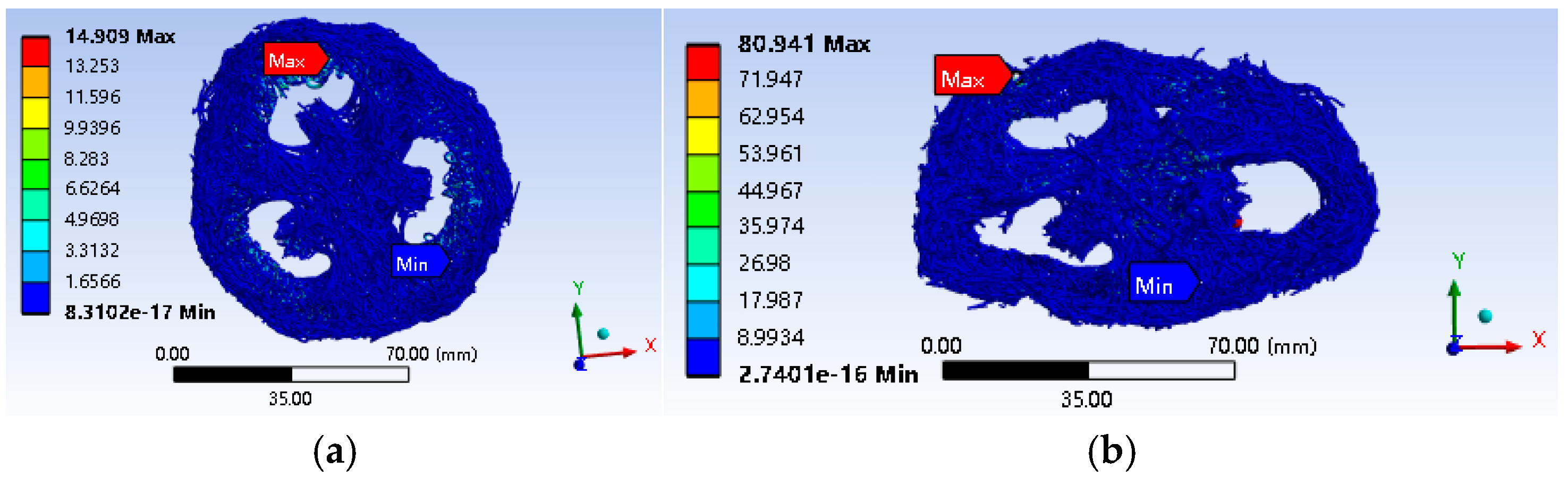

2.5. Loofah Sponge Model Construction and Simulation

3. Results and Discussion

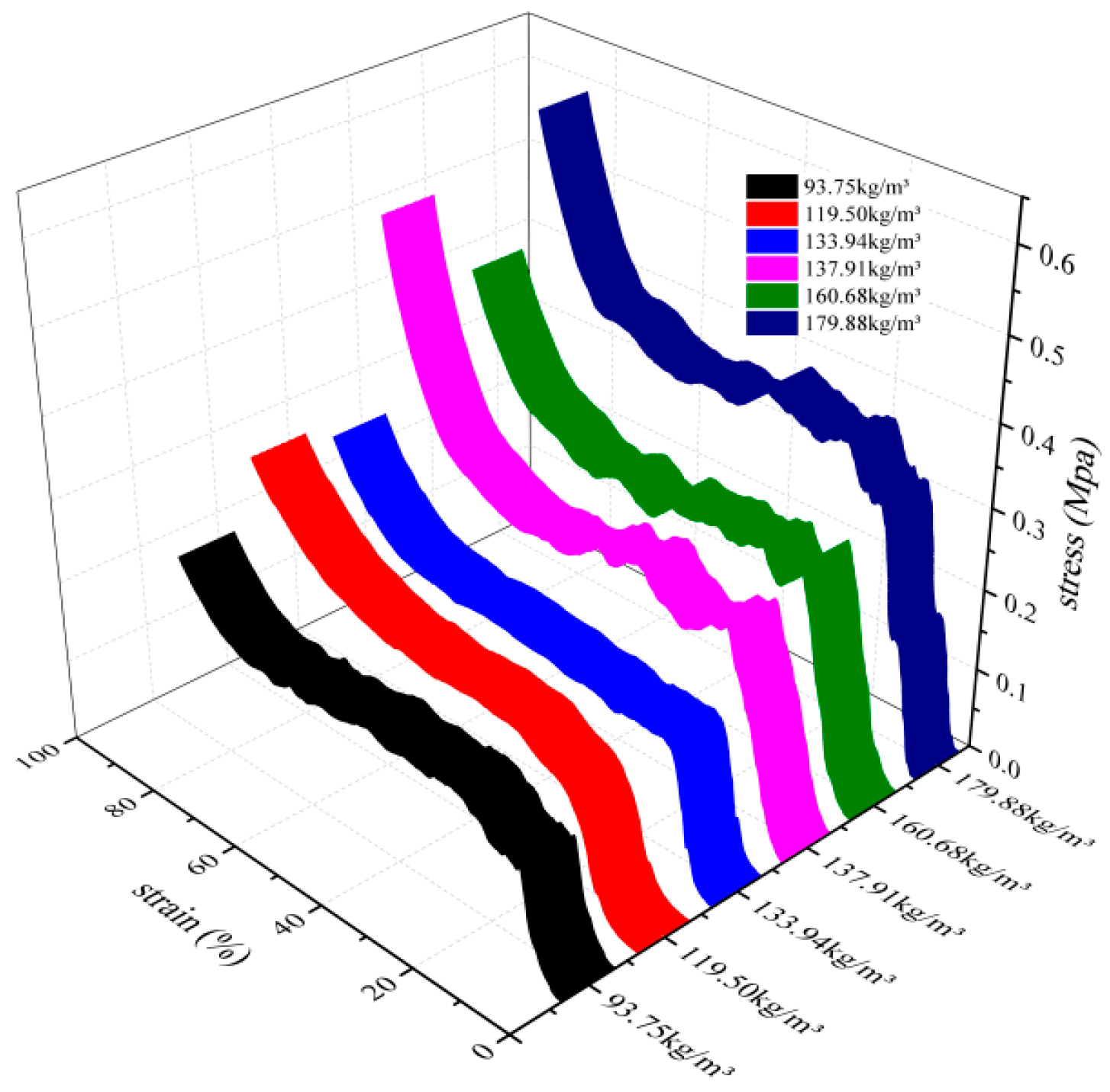

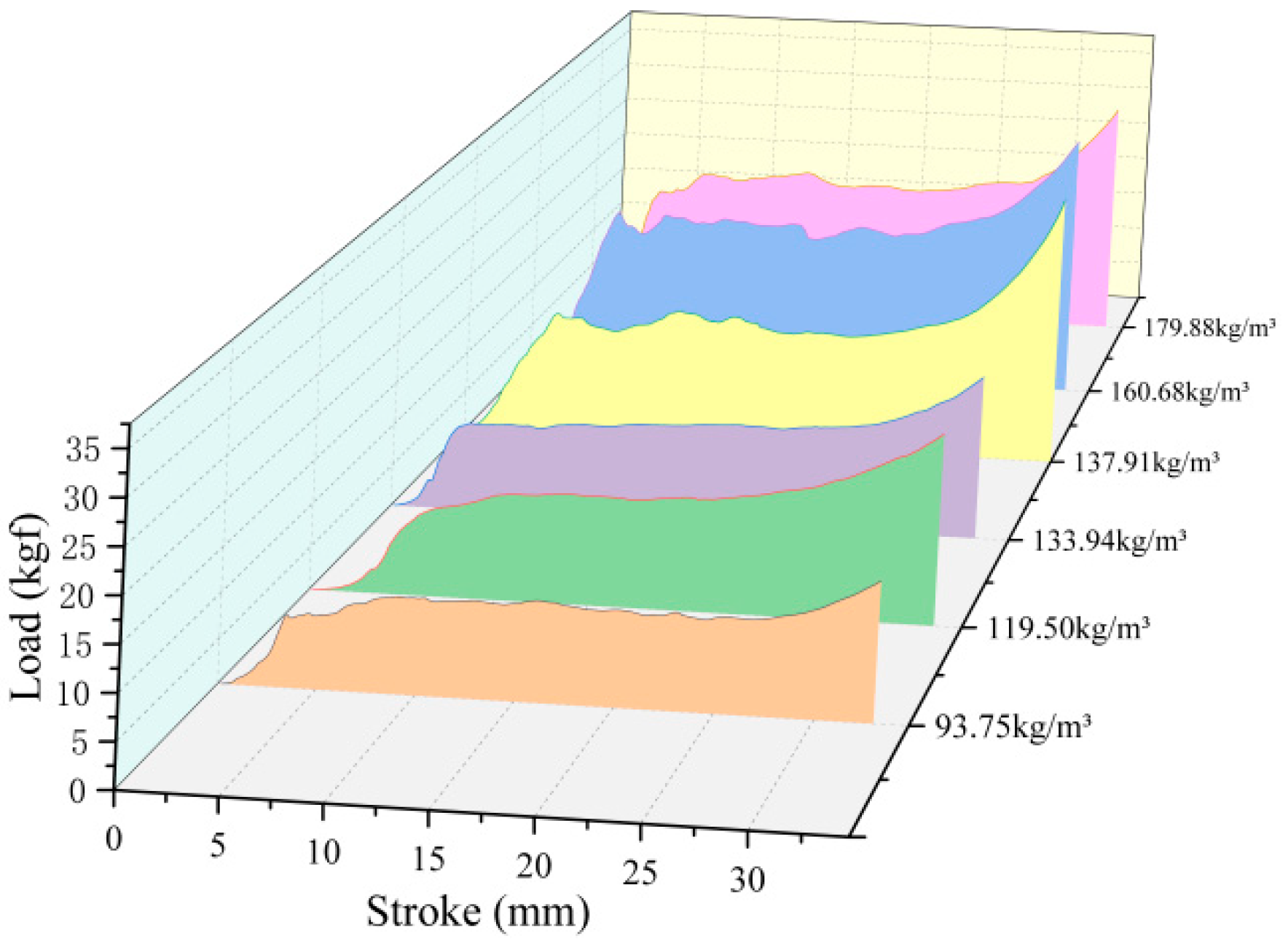

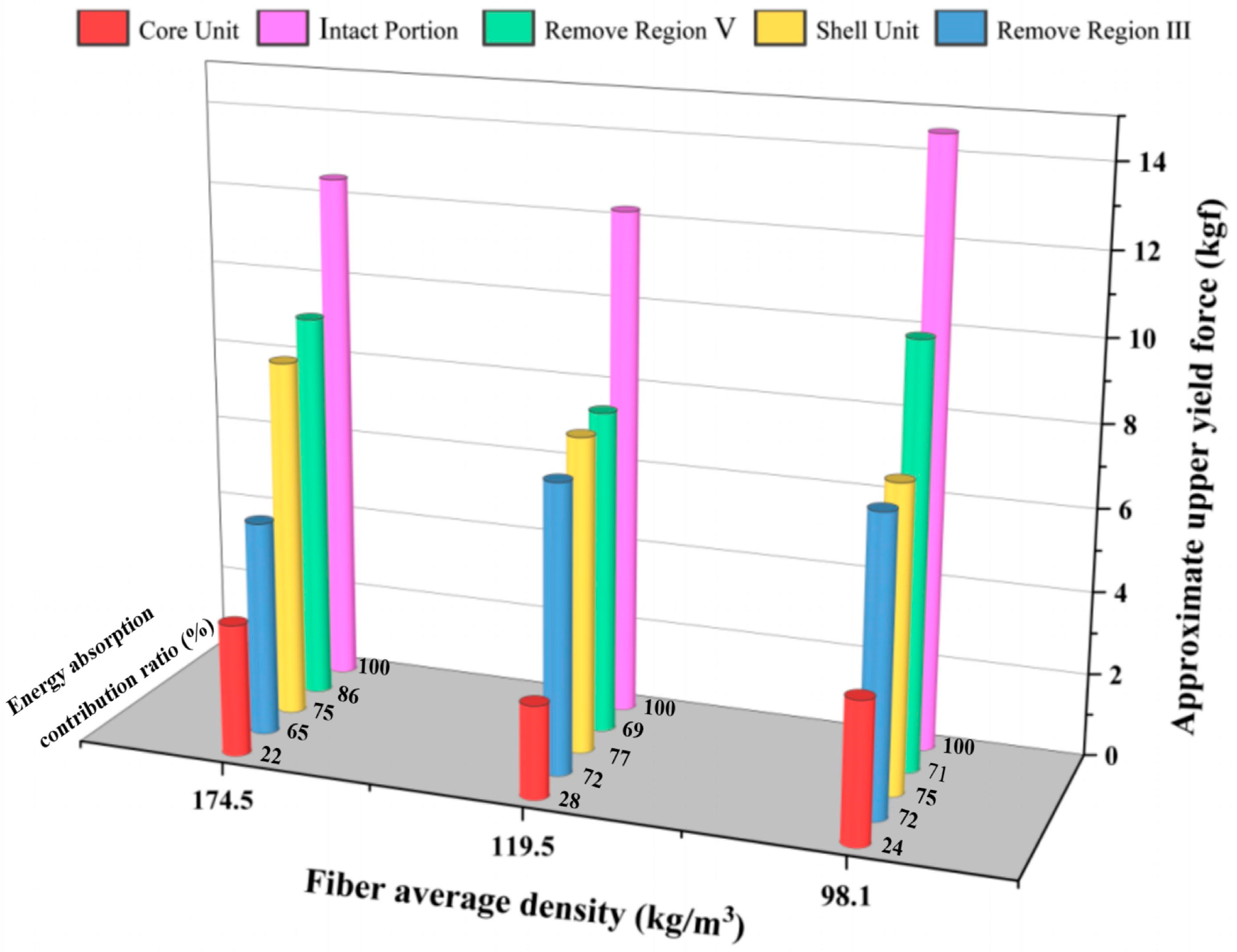

3.1. Absorbent Energy Properties of Loofah Sponge

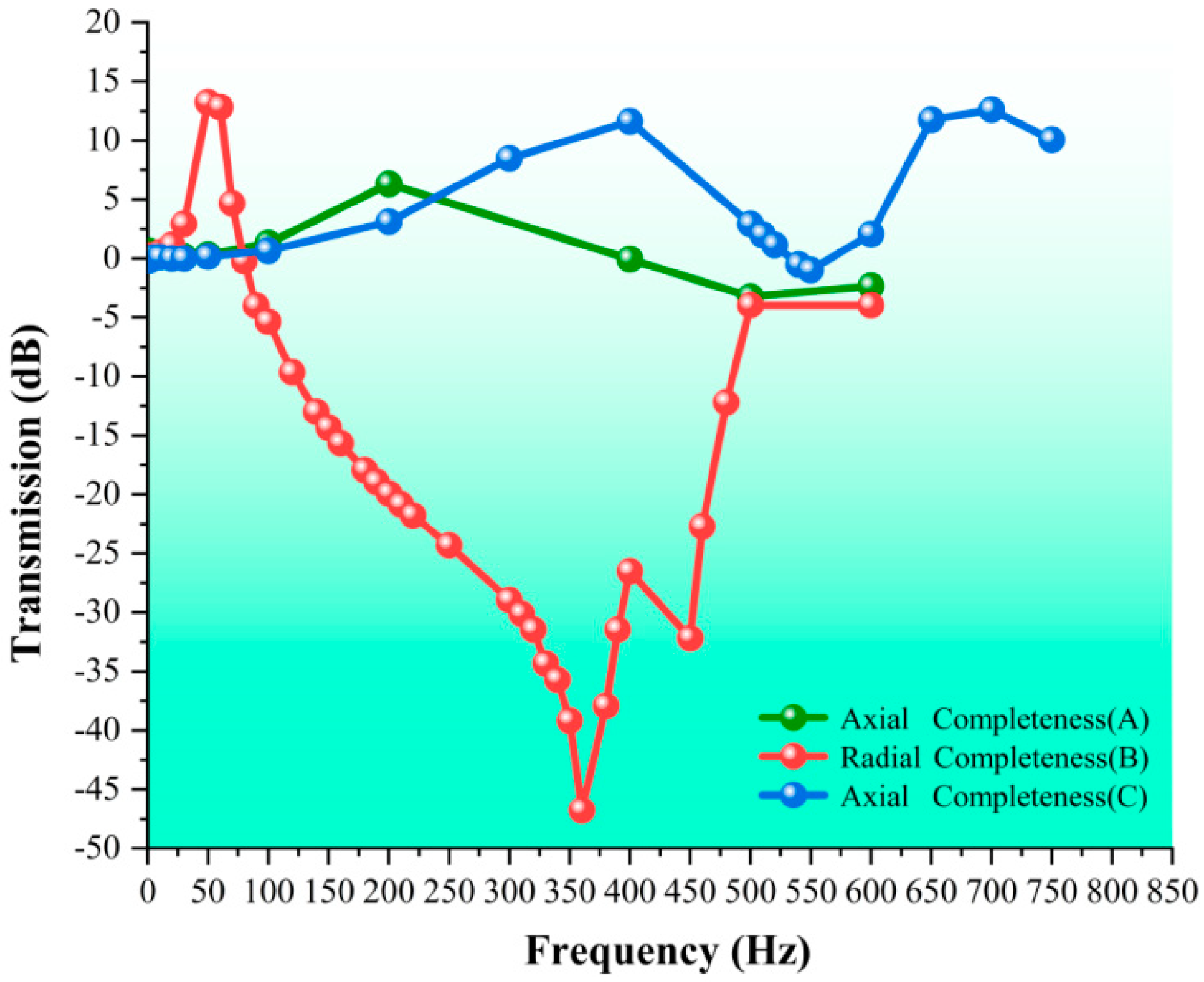

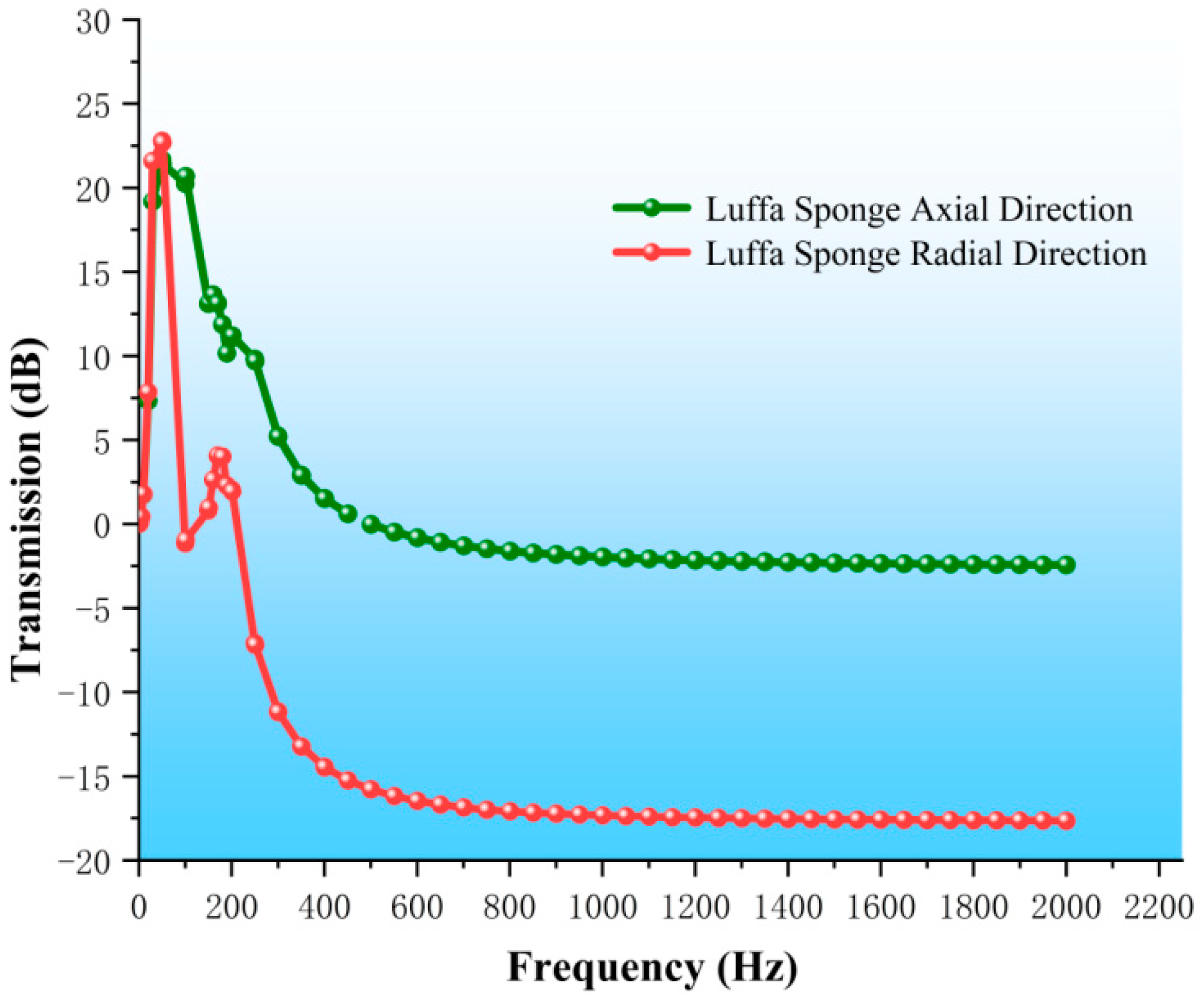

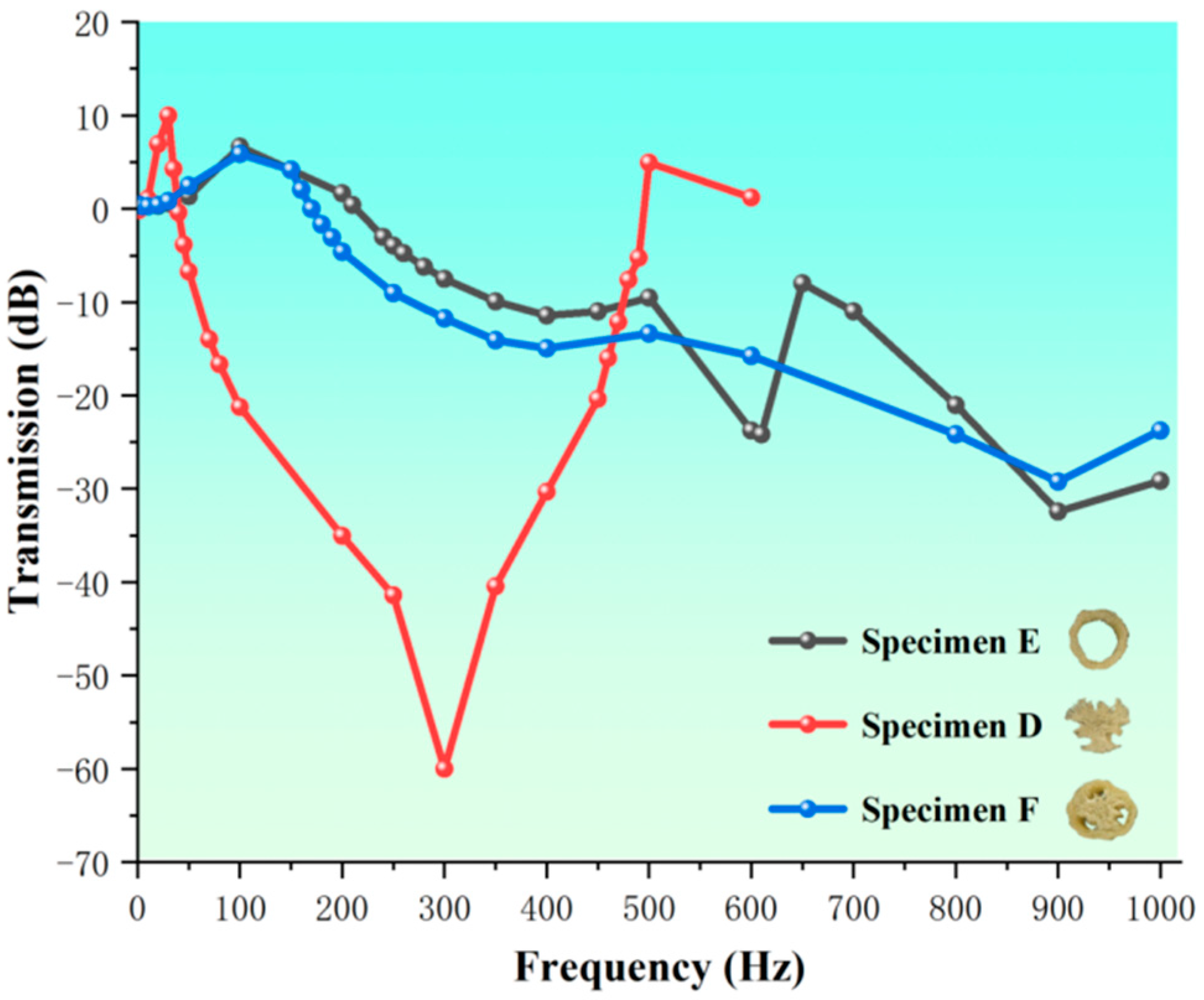

3.2. Vibration Isolation Properties of Loofah Sponge

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Jesionowski, T.; Norman, M.; Żółtowska-Aksamitowska, S.; Petrenko, I.; Joseph, Y.; Ehrlich, H. Marine spongin: Naturally prefabricated 3D scaffold-based biomaterial. Mar. Drugs 2018, 16, 88. [Google Scholar] [CrossRef] [PubMed]

- Alhijazi, M.; Safaei, B.; Zeeshan, Q.; Asmael, M.; Eyvazian, A.; Qin, Z. Recent Developments in Luffa Natural Fiber Composites: Review. Sustainability 2020, 12, 7683. [Google Scholar] [CrossRef]

- Paglicawan, M.A.; Cabillon, M.S.; Cerbito, R.P.; Santos, E.O. Loofah Fiber as Reinforcement Material for Composite. Philipp. J. Sci. 2005, 134, 113–120. [Google Scholar]

- Ghali, L.; Msahli, S.; Zidi, M.; Sakli, F. Effect of pre-treatment of Luffa fibres on the structural properties. Mater. Lett. 2009, 63, 61–63. [Google Scholar] [CrossRef]

- Saeed, A.; Iqbal, L.M. Loofa (Luffa cylindrica) Sponge: Review of Development of the Biomatrix as a Tool for Biotechnological Applications. Biotechnol. Prog. 2013, 29, 573–600. [Google Scholar] [CrossRef] [PubMed]

- Ekici, B.; Kentli, A.; Küçük, H. Improving Sound Absorption Property of Polyurethane Foams by Adding Tea-Leaf Fibers. Arch. Acoust. 2012, 37, 515–520. [Google Scholar] [CrossRef]

- Shen, J.; Xie, Y.M.; Huang, X.; Zhou, S.; Ruan, D. Behavior of Luffa Sponge Material Under Dynamic Loading. Int. J. Impact Eng. 2013, 57, 17–26. [Google Scholar] [CrossRef]

- Chen, Q.; Shi, Q.; Gorb, S.N.; Li, Z. A multiscale study on the structural and mechanical properties of the luffa sponge from Luffa cylindrica plant. J. Biomech. 2014, 47, 1332–1339. [Google Scholar] [CrossRef]

- Papanicolaou, G.C.; Psarra, E.; Anastasiou, D. Manufacturing and mechanical response optimization of epoxy resin/Luffa cylindrica composite. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef]

- Chen, Y.; Su, N.; Zhang, K.; Zhu, S.; Zhao, L.; Fang, F.; Ren, L.; Guo, Y. In-Depth Analysis of the Structure and Properties of Two Varieties of Natural Luffa Sponge Fibers. Materials 2017, 10, 479. [Google Scholar] [CrossRef]

- Yin, S.; Wang, H.; Li, J.; Ritchie, R.O.; Xu, J. Light but tough bio-inherited materials: Luffa sponge based nickel-plated composites. J. Mech. Behav. Biomed. Mater. 2019, 94, 10–18. [Google Scholar] [CrossRef] [PubMed]

- Mohanta, N.; Acharya, S.K. Investigation of mechanical properties of Luffa cylindrica fibre reinforced epoxy hybrid composite. Int. J. Eng. Sci. Technol. 2015, 7, 1–10. [Google Scholar] [CrossRef]

- Parida, C.; Dash, S.K.; Das, S.C. Effect of Fiber Treatment and Fiber Loading on Mechanical Properties of Luffa-Resorcinol Composites. Indian J. Mater. Sci. 2015, 2015, 658064. [Google Scholar] [CrossRef]

- Demir, H.; Atikler, U.; Balköse, D.; Tıhmınlıoğlu, F. The Effect of Fiber Surface Treatments on the Tensile and Water Sorption Properties of Polypropylene-Luffa Fiber Composites. Compos. Part A Appl. Sci. Manuf. 2006, 37, 447–456. [Google Scholar] [CrossRef]

- Oboh, I.O.; Aluyor, E.O.; Audu, T.O.K. Application of Luffa cylindrica in Natural Form as Biosorbent to Removal of Divalent Metals from Aqueous Solutions—Kinetic and Equilibrium Study. In Waste Water Treatment and Reutilization; Einschlag, F.S.G., Ed.; InTech: London, UK, 2011; pp. 195–212. [Google Scholar]

- Petrenko, I.; Summers, A.P.; Simon, P.; Żółtowska-Aksamitowska, S.; Motylenko, M.; Schimpf, C.; Rafaja, D.; Roth, F.; Kummer, K.; Brendler, E.; et al. Extreme biomimetics: Preservation of molecular detail in centimeter-scale samples of biological meshes laid down by sponges. Sci. Adv. 2019, 5, eaax2805. [Google Scholar] [CrossRef] [PubMed]

- Louden, D.; Inderbitzin, S.; Peng, Z.; de Nys, R. Development of a new protocol for testing bath sponge quality. Aquaculture 2007, 271, 275–285. [Google Scholar] [CrossRef]

- Su, H.; Guo, X.; Chen, G.; Zhang, Q.; Huang, D.; Zhang, J. A novel honeycomb-like porous carbon from loofah sponge for form-stable phase change materials with high encapsulation capacity and reliability. Mater. Lett. 2022, 308, 131118. [Google Scholar] [CrossRef]

- Al-Mobarak, T.; Mina, M.F.; Gafur, M.A. Improvement in mechanical properties of sponge-gourd fibers through different chemical treatment as demonstrated by utilization of the Weibull distribution model. J. Nat. Fibers 2020, 17, 573–588. [Google Scholar] [CrossRef]

- Liu, L.; Yang, S.; Hu, H.; Zhang, T.; Yuan, Y.; Li, Y.; He, X. Lightweight and Efficient Microwave-Absorbing Materials Based on Loofah-Sponge-Derived Hierarchically Porous Carbons. ACS Sustain. Chem. Eng. 2018, 7, 1228–1238. [Google Scholar] [CrossRef]

- Yusuf, S.; Islam, N.; Ali, H.; Akram, M.W.; Siddique, M.A. Towards the optimization of process parameters for impact strength of natural fiber reinforced composites: Taguchi method. Adv. Mater. Sci. 2020, 20, 54–70. [Google Scholar] [CrossRef]

- Yuan, Y.; Zhao, K.; Zhao, Y.; Sahmani, S.; Safaei, B. Couple stress-based nonlinear buckling analysis of hydrostatic pressurized functionally graded composite conical microshells. Mech. Mater. 2020, 148, 103507. [Google Scholar] [CrossRef]

- Yuan, Y.; Zhao, K.; Han, Y.; Sahmani, S.; Safaei, B. Nonlinear oscillations of composite conical microshells with in-plane heterogeneity based upon a couple stress-based shell model. Thin-Walled Struct. 2020, 154, 106857. [Google Scholar] [CrossRef]

- Genc, G.; Koruk, H. Identification of the Dynamic Characteristics of Luffa Fiber Reinforced Bio-Composite Plates. BioResources 2017, 12, 5358–5368. [Google Scholar] [CrossRef][Green Version]

- Chen, B.Q.; Guan, H.Y. Mechanical Relaxation Characteristics of Sofa Cushion Luffa Sponge Filling. Packag. Eng. 2022, 43, 51–57. [Google Scholar]

- An, X.; Fan, H. Hybrid design and energy absorption of luffa-sponge-like hierarchical cellular structures. Mater. Des. 2016, 106, 247–257. [Google Scholar] [CrossRef]

- Yang, K.; Li, Z.; Huang, P.; Lin, Y.; Huang, L. Mechanical and failure characteristics of novel tailorable architected metamaterials against crash impact. Eng. Fail. Anal. 2024, 159, 108141. [Google Scholar] [CrossRef]

- Yang, K.; Hu, X.; Pan, F.; Qiao, C.; Ding, B.; Hu, L.; Hu, X.; He, Z.; Chen, Y. An on-demand tunable energy absorption system to resolve multi-directional impacts. Int. J. Solids Struct. 2023, 271–272, 112257. [Google Scholar] [CrossRef]

- Shen, J.H.; Xie, Y.M.; Huang, X.D.; Zhou, S.; Ruan, D. Mechanical Properties of Luffa Sponge. J. Mech. Behav. Biomed. Mater. 2012, 15, 141–152. [Google Scholar] [CrossRef]

- Alghamdi, A.A.A. Collapsible impact energy absorbers: An overview. Thin-Walled Struct. 2001, 39, 189–213. [Google Scholar] [CrossRef]

- Liu, X.J. Static Cushion Property Tests and Analysis of Luffa Sponge Materials. Packag. Eng. 2018, 39, 57–63. [Google Scholar]

| Actual Density ρs (kg/m3) | Structural Density ρz (kg/m3) | Height H (mm) | Diameter of the Dross-Section D (mm) | Cross-Sectional Area S (cm2) | Type of Specimen | Compression Direction |

|---|---|---|---|---|---|---|

| 93.75 | 13.22 | 40 | 73.00 | 5.90 | Specimen A | Axial |

| 119.50 | 12.45 | 40 | 89.10 | 9.72 | Specimen A | Axial |

| 133.94 | 12.08 | 40 | 92.04 | 6.00 | Specimen A | Axial |

| 137.91 | 14.71 | 40 | 85.50 | 6.13 | Specimen A | Axial |

| 160.68 | 17.26 | 40 | 93.50 | 7.38 | Specimen A | Axial |

| 179.88 | 21.12 | 40 | 73.64 | 4.32 | Specimen A | Axial |

| 174.48 | 15.39 | 40 | 89.70 | 5.58 | Specimen A | Axial |

| 98.13 | 12.02 | 40 | 77.32 | 5.75 | Specimen A | Axial |

| 161.91 | 14.73 | 40 | 97.20 | 9.72 | Specimen A | Radial |

| 89.76 | 10.79 | 40 | 74.56 | 5.25 | Specimen B | Axial |

| 146.22 | 12.70 | 40 | 81.90 | 8.19 | Specimen B | Radial |

| 277.21 | 16.95 | 40 | 69.20 | 2.30 | Specimen B | Axial |

| 91.10 | 9.86 | 40 | 82.24 | 5.75 | Specimen B | Axial |

| 136.65 | 10.65 | 40 | 93.72 | 9.38 | Specimen C | Radial |

| 94.74 | 9.86 | 40 | 80.16 | 5.25 | Specimen C | Axial |

| 106.26 | 10.55 | 40 | 89.52 | 6.25 | Specimen C | Axial |

| 191.65 | 13.35 | 40 | 88.90 | 4.32 | Specimen C | Axial |

| 55.50 | 7.32 | 40 | 65.00 | 4.38 | Specimen D | Axial |

| 132.42 | 14.06 | 40 | 53.36 | 2.38 | Specimen D | Axial |

| 52.90 | 7.19 | 40 | 63.08 | 4.25 | Specimen D | Axial |

| 82.30 | 8.06 | 40 | 65.00 | 6.50 | Specimen D | Radial |

| 167.56 | 9.26 | 40 | 97.50 | 9.75 | Specimen E | Radial |

| 219.15 | 11.59 | 40 | 88.80 | 3.28 | Specimen E | Axial |

| 111.46 | 8.49 | 40 | 92.54 | 5.13 | Specimen E | Axial |

| 86.80 | 8.41 | 40 | 85.00 | 5.50 | Specimen E | Axial |

| Actual Density ρs (kg/m3) | 179.88 | 160.68 | 137.91 | 133.94 | 119.50 | 93.75 |

| Energy absorption per unit volume(kJ/m3) | 188.40 | 137.5 | 127.70 | 99.40 | 91.30 | 90.30 |

| Actual Density ρs (kg/m3) | 179.88 | 160.68 | 137.91 | 133.94 | 119.50 | 93.75 |

| Energy absorption (J) | 3.77 | 4.06 | 3.13 | 2.39 | 2.38 | 2.13 |

| Specific Energy Absorption (MJ/kg) | 1.048 | 0.857 | 0.926 | 0.744 | 0.766 | 0.963 |

| Loofah Sponge Specimen Type | Intact Portion | Remove Region V | Remove Region III | Shell Unit | Core Unit |

|---|---|---|---|---|---|

| Energy absorbed (kJ) | 91.3 | 63.7 | 66.9 | 72.3 | 38.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, W.; Li, X.; Wu, X.; Kong, L.; Wang, N.; Cao, S. Study on the Vibration Isolation Mechanism of Loofah Sponge. Biomimetics 2025, 10, 5. https://doi.org/10.3390/biomimetics10010005

Tian W, Li X, Wu X, Kong L, Wang N, Cao S. Study on the Vibration Isolation Mechanism of Loofah Sponge. Biomimetics. 2025; 10(1):5. https://doi.org/10.3390/biomimetics10010005

Chicago/Turabian StyleTian, Weijun, Xu Li, Xiaoli Wu, Linghua Kong, Naijing Wang, and Shasha Cao. 2025. "Study on the Vibration Isolation Mechanism of Loofah Sponge" Biomimetics 10, no. 1: 5. https://doi.org/10.3390/biomimetics10010005

APA StyleTian, W., Li, X., Wu, X., Kong, L., Wang, N., & Cao, S. (2025). Study on the Vibration Isolation Mechanism of Loofah Sponge. Biomimetics, 10(1), 5. https://doi.org/10.3390/biomimetics10010005