Abstract

Batteries are the heart and the bottleneck of portable electronic systems. They power electronics and determine the system run time, with the size and volume determining factors in their design and implementation. Understanding the material properties of the battery components—anode, cathode, electrolyte, and separator—and their interaction is necessary to establish selection criteria based on their correlations with the battery metrics: capacity, current density, and cycle life. This review studies material used in the four battery components from the perspective and the impact of seven ions (Li, Na, K, Zn, Ca, Mg, and Al), employed in commercial and research batteries. In addition, critical factors of sustainability of the supply chains—geographical raw materials origins vs. battery manufacturing companies and material properties (Young’s modulus vs. electric conductivity)—are mapped. These are key aspects toward identifying the supply chain vulnerabilities and gaps for batteries. In addition, two battery applications, smartphones and electric vehicles, in light of challenges in the current research, commercial fronts, and technical prospects, are discussed. Bringing the next generation of batteries necessitates a transition from advances in material to addressing the technical challenges, which the review has powered.

1. Introduction

Batteries are one of the most widely commercialized energy storage systems and have been extensively used for powering portable electronic devices [1,2,3,4]. This widespread use of batteries has transformed our daily lives and is leading the future of multifunctional, interconnected, and energy-independent devices [5]. For example, the Internet of Things (IoT) integrates devices that work not just as sensors, but also as transmitters of the sensing signals, and these devices require batteries with a higher level of performance (higher energy density and long cycle life) to power their operations [5,6]. To satisfy the requirements of these applications (size, portability, and flexibility), rapid advances have been made toward exploring new materials. Different materials have been used for the battery components: cathode [7,8,9], anode [10,11,12], electrolyte [13,14,15], and separators [16,17]. Any decision about the next generation of batteries will have to move beyond trial and error toward a material-based selection. This decision has to leverage the best material performance vs. availability.

Historically, the evolution of batteries has been a slow process that combines not only intelligence but also serendipity to integrate the suitable component materials that would enable the development of practical batteries with acceptable parameters: voltage, capacity, and energy density [18]. In 1800, Alessandro Volta discovered that particular liquids allow for the flow of electrical power if they are used as a conductor. Joining silver (Ag) and zinc (Zn) electrodes in an electrolyte, Volta realized that the voltage generated in the terminals could be controlled with stacked voltaic cells [19,20]. Then, in 1802, William Cruickshank started the mass production of electric batteries (non-rechargeable), changing the Ag electrode to a copper (Cu) one. It was not until 1859 that the rechargeable battery was invented by Gaston Plante, employing an alternative technology that integrates lead (Pb) electrodes and acid as the electrolyte. Afterward, the nickel–cadmium (NiCd) battery was introduced in 1899. The use of Ni and Cd electrodes allowed for a higher energy density than Pb-acid batteries in a smaller and lighter size. The development of NiCd batteries made the use of portable devices possible. Due to safety issues, Cd was replaced with metal–hydride and, quickly, NiMH batteries became the most widely used kind of batteries in 1947 [21]. The 1960s saw the beginnings of lithium (Li) based batteries which had a higher energy density. However, it was only 30 years later that the main difficulties with Li batteries, such as volume expansion, dendrite growth, and side reactions, were acceptably resolved, resulting in the introduction of lithium-ion batteries (LIBs). At that time, these batteries reported the highest energy density by joining a graphite anode and a LiCoO cathode [22]. Since then, LIB components have been optimized to increase the energy density.

To manufacture batteries with high energy density, several materials have been used. Metals are the most promising materials for anodes because they can deliver high capacity density. Li is the most studied metal due to its high capacity density and low potential. The concern about using Li is its scarcity. It is estimated that the current Li production cannot meet the demand in the coming decade unless the sustainability of extraction methods could be improved and a recycling process could be effectively developed [23,24]. To alleviate concerns about Li availability, alternative metal anodes have been studied. These alternatives include sodium (Na), potassium (K), zinc (Zn), calcium (Ca), magnesium (Mg), and aluminum (Al), with their respective working ions [15]. Today, the use of metal anodes in practical batteries is still limited by the dendrite growth [22], the large ionic size [25], low-voltage window, and irreversibility [26]. For cathodes, sulfur (S) [7] and oxygen (O) [27] have been studied as an alternative to traditional transition metal oxide electrodes. For electrolytes, switching from carbonates and ionic liquids to polymers and ceramic solid-state is a trend that can address safety concerns and offer additional mechanical properties while fulfilling the functions of separators.

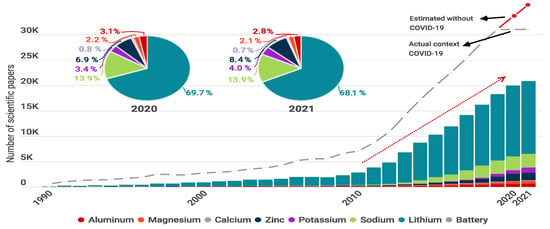

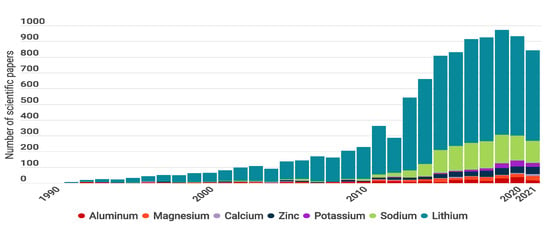

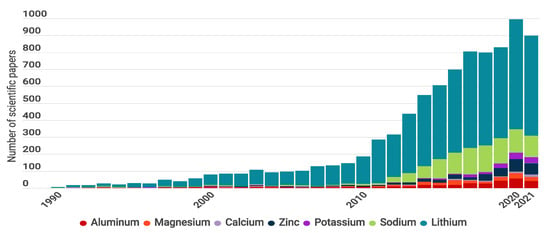

To demonstrate the evolution of batteries, Figure 1 presents a bibliometric review of published articles from 1990 to 2021 and compares seven battery types according to the working ions Li, Na, K, Zn, Ca, Mg, and Al. In Figure 1, the difference between estimations and the actual number of publications demonstrates the drop off in research in 2020 and 2021, which could be the result of the pandemic [28].

Figure 1.

Number of publications per year including words “Aluminum Battery”, “Magnesium Battery”, “Calcium Battery”, “Zinc Battery”, “Potassium Battery”, “Sodium Battery”, and “Lithium Battery”. The gray line represents the number of publications per year including “Battery” or “Batteries”. The pie charts show the percentage of publications in the years 2020 and 2021. Graph constructed by the authors. Data from Web of science.

The pie graphs show that Li-based batteries are the most studied (% of the publications), followed by Na-based batteries (% ) and Zn-based batteries (% ). This is because LIBs have shown successful practical application in portable electronic devices and electric vehicles, and most research moved to lithium systems for developing efficient battery component materials to achieve higher performance [29]. Current battery technologies based on Li include LIB ( kg−1) [4], Li-Sulfur ( Li–S 2600 kg−1) [30,31], Li-Oxygen (Li–O 3500 kg−1) [32,33], and Li-air [34] technologies.

Na-based batteries have also been widely explored since Li and Na electrode materials have similar structures, and most of the electrode materials discovered for Li batteries have been tested on Na cells [35]. Na-based batteries include Na-ion (SIB) [36], Na-sulfur ( kg−1) [37], Na-selenium (Na-Se), and Na-oxygen (Na–O) [27]. In the case of Zn-based batteries, Zn-air has been successfully commercialized as non-rechargeable cells, and used in applications such as hearing aids. Today, interest is focused on the possibility of switching to rechargeable cells [38]. Zinc-based batteries include Zn-air ( 1086 kg−1) and Zn-ion (ZIB) technology.

In contrast, the published articles for K, Ca, Mg, and Al represent only % of the total publications. This could be the result of drawbacks that have not yet been resolved and that limit the development of practical batteries. However, there seems to be a growing interest in these new technologies considering that the percentage of publications has increased from 2020 to 2021. Some examples of these technologies are K-ion (KIB) [25], K-S ( 1023 kg−1) [39], Ca-ion (CIB), Mg-ion (MIB), Mg-S, Mg-air [40], Al-ion (AIB) and Al-air batteries.

Previous reviews have addressed battery progress from three perspectives: (1) studying the state of the art of a specific battery part, such as anodes [41], cathodes [42], electrolytes [15], and separators [17], (2) focusing on only one battery technology [39], and (3) comparing two or three battery technologies [43]. The main contribution of this review is that we analyze the materials for anodes, cathodes, electrolytes, and separators from seven battery types according to the working ion: Li, Na, K, Zn, Ca, Mg, and Al. For these materials, we studied the parameters (voltage, capacity, current rate, Coulombic efficiency, retention, and cycle number) that determine the battery performance (capacity, energy, and lifetime). This review is organized as follows. Battery specifications are described in Section 2, which includes electrical parameters, battery types according to their mechanical and chemical characteristics, and sustainability factors. Anodes and cathode types are described widely in Section 3 and Section 4, respectively. Electrolytes and separators are explained in Section 5. Finally, we added a section on battery applications, and we concluded with the perspectives of materials for manufacturing electrodes, electrolytes, and separators.

2. Battery Specifications

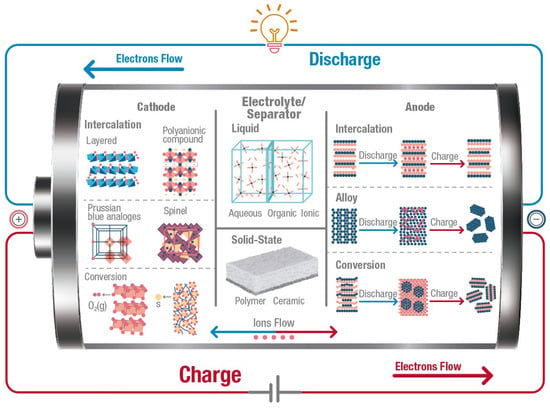

A battery is an electrochemical energy storage system that converts chemical energy into electrical energy. A battery consists of several electrochemical cells which integrate four main components as shown in Figure 2: (1) the anode or negative electrode; (2) the cathode or positive electrode; (3) the electrolyte that is the medium between the anode and cathode; and (4) the separator, a membrane to physically separate the anode and the cathode electrically. During discharge, ions move from the anode to the cathode through the electrolyte, and electrons flow from the anode to cathode through an external circuit. During charge, ions come back to the anode through the electrolyte while an external source forces the electrons to move from the cathode to the anode side. Although Li is the most used, other working ions include Na, K, Zn, Ca, Mg, and Al. It is crucial to keep in mind that the chemistry inside a battery changes according to the working ion used. Therefore, the anodes and cathodes used for Li-based batteries cannot be frequently used in the other battery types.

Figure 2.

Illustration of the crucial internal components of a battery, showing different types of materials researched for cathodes, anodes, electrolytes, and separators. Arrows indicate the flow of electrons (through the external circuit) and ions (through the electrolyte) during the charging (red) and discharging (blue) process. Graph constructed by the authors.

Figure 2 also presents a general classification of materials used for anodes, cathodes, and electrolytes, and their internal structures according to the operating mechanism. These mechanisms are explained in Section 3, Section 4 and Section 5, respectively. This section provides the terminology, including electrical parameters, types, and sustainability factors, of batteries and their component materials.

2.1. Electrical Parameters

Electrical characteristics are technical operating parameters to assess battery performance. These parameters are used to describe the present condition of a battery, such as state of charge, depth of charge, internal resistance, terminal voltage, and open-circuit voltage, or to compare manufacture specifications, such as capacity, C-rate, nominal voltage, cut-off voltage, energy, power, and cycle life. Electrical parameters are usually presented in graphics to compare different technologies. For example, the Ragone plot is a typical graph that contrasts the energy and power density of different battery chemistries.

The battery parameters used in this review are defined in this section. The first parameter is the capacity. Capacity is the charge that a battery can store and is established by the mass of the active material. Capacity refers to the total amount of Amp-hours (Ah) available when the battery is discharged. To determine the capacity, it is necessary to multiply the discharge current by the discharge time. The second relevant parameter is C-rate, which is defined as the battery discharge current according to battery capacity. C-rate gives a measure of the rate at which a battery is discharged relative to its maximum capacity. For example, 1C rate means that the battery with a capacity of 1000 could be discharged in 1 at a current of 1000 . For this battery, 5 C rate means that the battery is discharged in 12 min at 5000 , and a C/2 rate means that the battery is discharged in 2 at 500 . In addition, there is an inversely proportional relationship between the capacity and the C-rate, which means that battery capacity decreases when the C-rate increases.

Another battery parameter is voltage, which indicates the difference between cathode and anode potential. To achieve a high voltage, an ideal cathode should have a high potential, while an ideal anode should have a low potential. Usually, the reported voltage of the battery is called nominal voltage, and the minimum acceptable operational voltage, which defines the “empty” state of the battery, is the cut-off voltage. Power is how many watts are stored, which is calculated by multiplying the voltage by the current density. Commonly, power is given per unit mass, specific power ( kg−1), or per unit volume, power density (W L−1). Power density determines the battery size needed to achieve a given performance purpose. Energy is the watt hour that a battery supply at a certain C-rate. Energy is also expressed per unit mass as specific energy ( kg−1) or per unit volume as energy density (W h L−1) [44]. Cycle life is the number of discharge–charge cycles the battery performs while maintaining specific performance criteria.

State of charge (SOC%) describes the instant battery capacity as a percentage of maximum capacity. Depth of discharge (DOD%) expresses the battery capacity that has been discharged of maximum capacity as a percentage. Internal resistance is the resistance inside the battery that varies for charging and discharging. If the internal resistance increases, the battery efficiency and thermal stability are reduced since the charging energy is converted into heat.

Table 1 summarizes the standard electrical parameters that are used to evaluate the performance of batteries and their components. The symbol, the unit, and a brief definition of each parameter are included.

Table 1.

Selected electrical parameters of batteries [44,45].

2.2. Battery Types

Batteries can be classified in three different ways according to the chemical interaction of their components during the redox reaction. First, batteries are rechargeable if the redox reaction is reversible, and non-rechargeable if the reaction occurs just once. Second, batteries can be categorized as monovalent or multivalent according to the charge carrier ions. Finally, batteries can be organic or inorganic, depending on the material type used for manufacturing.

- Rechargeable or Non-Rechargeable

Inside a battery, chemical energy is converted into electrical energy through a redox reaction. The anode is oxidized and delivers electrons to the cathode that is reduced. The electrochemical reaction is irreversible in non-rechargeable systems, also known as primary batteries. In consequence, the battery must be replaced after the discharge. In a rechargeable battery, also called a secondary battery, the chemical reaction is reversible. As a result, the battery can be charged from an external source and restored to the original chemical conditions within the cell [21,46].

- Monovalent and Multivalent

A monovalent battery is a mature technology in which each ion generates one electron in the external circuit. On the other hand, in a multivalent battery, one ion generates two or three electrons in the external circuit, depending on the charge carrier ions. Consequently, in multivalent batteries, a higher current density is generated, and also the capacity could be doubled or tripled [47,48]. Common monovalent ions are Li, Na, and K, and the most researched multivalent ions are Zn, Ca, Mg, and Al.

Multivalent batteries are in the research stage, and technical challenges, such as instability and short cycle life, must be addressed to manufacture commercial applications successfully. Instability and short cycle life could be ascribed to volume expansion, interface degradation and active losing. For example, the electrode volume expansion, generated by the extra electrons, causes electrode breaks. In addition, Al and Ca electrodes reversibility was recently demonstrated [49,50], and it is still necessary to improve stability and the cycle life of these systems [47]. Finally, the cell assembly of multivalent batteries requires strong atmosphere control procedures to avoid contaminants such as water or oxygen, which could generate the formation of the passive film in an anode electrode [47].

- Organic and Inorganic

Commercial batteries are built with inorganic materials since they have a higher specific capacity than organic materials. These inorganic materials include heavy metals, such as Co, Pb, and Ni, and alkaline metals, such as Li. The concern about using these materials is because of the negative environmental impact from their toxicity and danger to human safety. Conversely, organic batteries are built using organic battery materials composed of C, H, O, N, or S. Some of the most common organic materials are based on metal-organic frameworks (MOFs) and covalent organic frameworks (COFs), that are crystalline porous materials with large surface areas, well-defined crystalline structures and highly ordered pores [51]. Interest in these organic materials surged due to their low cost and high availability. They are studied as active material in electrodes as well as electrolytes and separators [52]. Organic batteries exhibit a high rate of performance and a longer cycle life than inorganic batteries. This is to due to the fact that the redox process in organic batteries is fast, and it does not imply changes in the layer structure of intercalation materials used in inorganic batteries [52,53,54,55]. However, the low conductivity limits their practical application, and, therefore, it is necessary to continue researching solutions for this challenge [51].

- Flow Batteries

Flow batteries are an energy storage system based on electrochemical technology in which at least one electrode should be a solution. The difference between a traditional and flow battery is that the charge-discharge process occurs directly in a conventional battery since there is no spatial parting between the energy conversion unit and active material. On the other hand, in a flow battery, the energy conversion unit and active material are physically separated from each other [2]. The flow battery promises to be an alternative for large battery systems by pumping fluids from external tanks through a membrane that resembles a battery. This operation mechanism limits their application in wearable and portable devices, generating issues due to corrosion, high cost, and adverse environmental and safety impact [56].

Batteries can also be rigid or flexible according to the fabrication processes, material mechanical properties, and internal configuration. Rigid batteries have hard packing, and they are manufactured based on the slurry-casting method and also by dry electrode technology [57]. In contrast, flexible batteries (FB) are based on multilayers of a separator sandwiched by two electrodes, with a versatile packing [58]. The advantages and disadvantages of rigid and flexible batteries are described in the following paragraphs.

- Rigid Batteries or Flexible Batteries

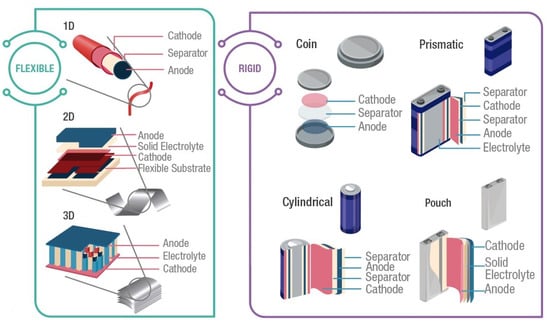

Rigid batteries are the largest commercial battery market, which provides a wide range of capacities. The rigid packages offer mechanical stability and protection to the internal components. Although today there are a large number of battery sizes and shapes, rigid batteries can be classified into four types of shape: coin, cylindrical, prismatic, and pouch [1] (Figure 3).

Figure 3.

Typical battery configurations. Flexible: 1D, 2D, and 3D. Rigid: coin, cylindrical, prismatic, and pouch. Graph constructed by the authors.

Coin cells, also known as button cells, are small disk batteries that consist of a single cell encased in stainless steel, as presented in Figure 3. Typically, these cells have a diameter of 5 mm to 25 mm and a height of 1 mm to 6 mm. Voltage in coin cells is between and 3 , and the capacity is between 1 and 2000 . Applications of coin cells include powering small portable electronic devices, such as wristwatches and hearing aids. Therefore, these cells should exhibit a long service life, at least one year, since they are frequently non-rechargeable cells. Commercial coin cells include chemistries such as Lithium-manganese dioxide, and Zinc-air [59].

Cylindrical cells consist of layered electrodes and separators rolled and encased in a metal casing as shown in Figure 3. These cells have different sizes, varying in the range of 8 to 20 in diameter and 25 to 70 in height. Standard size references are A, AA, or AAA for alkaline and Ni-metal–hydride, which have a voltage of and a capacity between 700 to 3000 . For LIB, the most common size is 18,650, which has a voltage of and a capacity of 3900 . Usually, cylindrical cells are used in portable devices, power tools, medical instruments, laptops, e-bikes, and electric vehicles due to their high specific energy, good mechanical stability, and their ability to be rechargeable or non-rechargeable. It is also easy to implement automatic manufacturing for this battery [59].

In prismatic cells, the electrodes are usually manufactured in a flattened spiral to have a very thin profile. As presented in Figure 3, the cell is contained in a rectangular package. Currently, no standard size exists; each manufacturer can design prismatic cell batteries to satisfy specific requirements of different applications. Voltage in prismatic cells is between 3 and , and the capacity is between 800 to 400 . These cells offer better space usage with a thin profile design, increasing their manufacturing cost. Additionally, they exhibit less efficiency in thermal management, producing swelling and shorter cycle life than the cylindrical design. Applications of these cells include mobile phones, tablets, and low-profile laptops [60].

Pouch cells are a soft and lightweight battery design. These cells were created using conductive foil welded to the electrodes and eliminating the metal enclosure to support expansion during battery operation. Similar to prismatic cells, pouch cells do not have a standard form, giving freedom to manufacturers to design customized cells. Commonly, pouch packs are used by Li-polymer batteries for portable applications that demand high load currents, such as drones and hobby gadgets. However, cell expansion is a hazard since pouch packs can grow from 10% over 500 cycles, and the pressure created can crack the battery cover, generating ignition [60].

FB are highly interesting since they can satisfy the superior flexibility and durability required for wearable and portable electronic devices. The market for flexible, printed, and thin-film batteries is expected to be $109.4 million by 2025 [61]. To supply the emergent demand for bendable and stretchable devices, battery components and packaging materials should be flexible in tolerating stress [62]. Therefore, alternative fabrication techniques, such as 3D printing, should be developed [63].

Currently, there are two approaches to manufacturing FB: (1) developing new flexible materials, and (2) designing innovative structures [62,64]. Flexible materials include carbon-based (carbon nanotubes CNT and graphene), metal-based, hybrid nanocomposite, and conducting polymers. Metal-based materials require particular structure manufacturing to exhibit flexible behavior, such as serpentine layouts and buckled structures, or using a flexible substrate [65,66,67]. Hybrid nanocomposites integrate the electrical properties of nanostructured rigid filler in a flexible way.

On the other hand, suggested structural designs to achieve mechanical deformations can be organized inside one of three groups: (1) one-dimensional (1D) cells; (2) two-dimensional (2D) cells; and (3) three-dimensional (3D) cells (Figure 3). One-dimensional cells include wire and ribbon shapes, which allow a deformation with different degrees of freedom. Wire structures can be a coaxial or non-coaxial design, and the device performance is influenced by the geometry of the materials used. Two-dimensional cells integrate thin-film and planar shapes. These cells are based on thin (1–10 mm thickness) film or a single-layer material. Furthermore, some 3D architectures, such as kirigami and origami, have been designed to achieve several bending modes. Three-dimensional cells are commonly used in batteries with solid electrolytes. Their design consists of interpenetrating electrodes or multi-layered devices, which are highly stretchable in the direction perpendicular or parallel to that of the electrodes [58,68].

2.3. Sustainability Factors

Battery cost is determined by different elements, including the availability of materials, cell chemistry, and the manufacturing process [23]. For example, in the last 20 years, different chemistries and materials have been tested to improve LIB performance [24]. This has increased energy stored in LIBs from around 200 W h L−1 to more than 700 W h L−1, and reduced the costs by 30 times, to around $100/kWh [23].

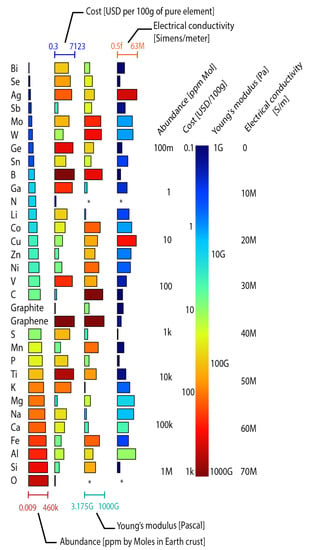

The availability of materials to supply increasing energy demand has generated debate since commercial LIBs are manufactured with lithium and cobalt, which are scarce raw materials (Figure 4). It has been forecast that this demand for electric energy could reach up to 1000 by 2025, and it will at least double by 2030. As a result, it has been estimated that the demand for these materials cannot be met, thus, increasing the cost [24]. To address raw material availability concerns, novel battery technologies based on abundant materials have been researched.

Figure 4.

Elements used in battery manufacturing organized from low to high availability. The first column represents the abundance in the earth’s crust. The second shows the cost per 100 g of the pure element. The third represents the Young modulus. The fourth shows the electrical conductivity. The length of the bars is normalized between the lowest and highest value for each parameter. The * symbol indicates that there is no value. Graph constructed by the authors. Data from Chemicool.com.

Figure 4 illustrates the abundance of the Earth’s crust, costs, Young’s modulus, and the electrical conductivity of raw materials used in commercial and prototype batteries. Na, K, Zn, Ca, Mg, and Al are promising materials for batteries since they are more abundant than Li. In addition, the costs of these abundant materials are lower than the costs of Li. Although in most batteries, the materials are used in the form of compounds instead of elements as presented in the Figure, identifying all compounds is challenging. Therefore, the elements that are used to create the compounds were selected. These results suggest that battery costs can be reduced using abundant and cheaper materials for manufacturing. Young’s modulus is a mechanical property that refers to the ratio of stress to a strain of a material. Figure of merit (fFoM) of materials flexibility exposes that a small Young’s modulus provides a high flexibility, being a critical parameter in guiding an appropriate selection of materials for the design of flexible batteries [69,70]. Finally, high electrical and ionic conductivity are crucial to promote electron transference, determining the rate performance in batteries [62].

The manufacturing process is another critical point that affects battery cost. Commercial batteries integrate raw materials that are distributed around the world, as shown in Figure 5, while the countries that fabricate batteries are not the ones that produce raw materials. For instance, the raw materials for LIBs, such as lithium and cobalt, are distributed in South America and Africa, while the significant battery manufacturing companies are in China, Germany, Japan, the Republic of Korea, and the USA. As a result, battery companies must import raw materials to manufacture batteries. Another challenge in manufacturing is to achieve sustainable production through a reliable provision of raw materials and appropriate management of materials at the end of battery life. Some proposed solutions include reusing waste battery materials, resource conservation, useful creation, and reliable mining policies [71].

Figure 5.

Geographical distribution of mineral resources vs. battery manufacturing companies. (A) Countries with mineral resources, (B) countries with mineral resources and manufacturing companies, and (C) manufacturing countries. Note: the length of the bar indicates the relative fraction of the total production. Graph constructed by the authors. Data from US Geological Survey, Mineral Commodity Summaries 2020.

Batteries manufactured annually will grow as the population and demand for portable electronic devices increase. Although batteries can help reduce the negative impacts of fossil fuels, it is necessary to address environmental pollutants that batteries generate during manufacturing, use, transportation, collection, storage, treatment, disposal, and recycling [72].

3. Anodes

The anode is the negative electrode of a battery that oxidizes (loss of electrons) during the discharge process [22], and it plays different roles according to the work ion, critical for the operation of rechargeable and non-rechargeable batteries. An ideal anode for rechargeable batteries should have a high capacity, low potential against cathode material, low volume expansion, long cycle life, low cost, and environmental compatibility [73]. Metals, such as Li, Na, K, Mg, Ca, Zn, and Al, have been explored as potential anodes due to their high energy density and low potential.

One of the main limitations of using metals as anodes is that they are susceptible to dendrite growth. Dendrite growth is a phenomenon that consists of the growth of branches on the anode surface, reducing the energy density and cycle life. Additionally, dendrites cause safety concerns since they can break the separator, generating a short circuit and battery explosion. The mechanism and behavior of dendrite growth are still being researched, and some models to describe them are (1) the thermodynamic model, (2) the space–charge model, (3) the stress and inelastic deformation model, (4) the film growth model, and (5) the phase field kinetics model [74]. To address these metal anode issues, alternative materials have been researched. These materials have been classified into three types according to the electrochemical mechanisms of operation: (1) intercalation, (2) alloys, and (3) conversion. The advantages and disadvantages of each mechanism are explained in the next paragraphs.

The intercalation mechanism consists of the intercalation and deintercalation of ions into the crystal lattice of the host material [75]. Common intercalation anodes materials are based on carbon, e.g., graphite, graphene sheets, hard carbon, and soft carbon, and titanium oxides, such as LiTiO (LTO) and TiO. Carbon-based materials have good working potential, low cost, and safety. The issues with using carbon anodes are high voltage hysteresis and high irreversibility capacity. Titanium oxide-based materials also have low cost, long cycle life, and high power capacity, but they are limited by a low energy density [73].

In the alloy mechanism, two or three elements are combined in a well-controlled process to produce desirable properties. The operation is governed by the chemical reaction of . Usually, A and M represent metals or metalloids such as Li, Na, K, Zn, Ca, Mg, Al, Si, Sn, Ge, and P. Alloys can be in a liquid or solid state at room temperature, and both metals can act as electrochemically active materials. Alloy anodes are promising materials since they have a high specific capacity, low potential, and these anodes have been shown to avoid dendrite growth [11]. Some challenges that alloys face are the volume expansion and the secondary reactions during the charge and discharge cycle. This volume expansion causes mechanical fractures, instability of the SEI, and swelling at the electrode level [73].

Conversion anodes are compounds that include oxides, fluorides, phosphides, and sulfides. The conversion redox reactions result in the formation of the metallic phase, which involves the breakdown of a single-crystalline parent material to polycrystalline metallic particles dispersed in an amorphous alkali oxide matrix [12]. Conversion reaction is determinate by the chemical reaction of where M is a transition metal, R: O, S, Se, P, H, and A represent Li, Na, K, Zn, Mg, Ca, or Al. The main advantage is the high specific and volumetric capacity. The practical application of conversion anodes is limited by the following points: (1) the large volume change, (2) the large voltage hysteresis between charge/discharge profiles, (3) the cycle instability, (4) the sloping region in the charge-discharge profile; (5) the low Coulombic efficiency, near 75%, and (6) the low diffusion coefficient of alkali ions in the material and the diffusion path length. Strategies studied for improving the performance of conversion materials are (1) size control of particles, (2) morphological control, (3) composition control of the material (sulfides, selenides, phosphides, hydrides, polymers, and carbon materials), and (4) architectural control (heterostructures based on patterned electrodes and thin-film deposition techniques) [12,73].

Figure 6 presents the increasing research on “negative electrodes”. Although anodes for Li-based batteries are the most studied, since 2010, there has been an increasing interest in abundant elements.

Figure 6.

Publications per year about negative electrodes, comparing seven battery types: Li, Na, K, Zn, Ca, Mg, and Al. Graph constructed by the authors. Data from Web of Science.

In this section, we present the anode materials commercialized and researched for each battery type, describing their main properties and showing the strategies explored to address the challenges.

3.1. Anodes for Lithium-Based Batteries

The anodes discussed for Li batteries include pure Li metal, intercalation (carbon and titanium-based), alloys (Si, Ge, B, Al ), and conversion (transition metal oxides (TMO), transition metal sulfides (TMS), phosphides, and nitrides) materials.

Li is the alkali metal with the highest theoretical specific capacity (3860 mA h g−1) and the most negative potential vs. the standard, hydrogen electrode (SHE) [22]. Li anodes have been studied since the 1970s when Stanley Whittingham introduced Li anodes in room-temperature batteries [4]. These anodes were not commercialized due to safety issues, such as explosions caused by the reactive nature of Li and dendrite growth [76]. There have been three directions to tackle the Li anode issues: (1) designing structured anodes, (2) assessing organic or solid-state electrolytes (Section 5), and (3) replacing Li anodes. As an example of structured anodes, a stable Li-metal anode composed of 2D arrays of NbN nanocrystals was explored as a Li host [77], achieving high metallic conductivity, high ion transport channels, and high capacity (2340 mA h g−1). The synthesized material showed some properties that could suppress Li dendrite growth, such as thermodynamic stability against Li, high Li affinity, fast Li-ion migration, and Li-ion transport through the porous 2D nanosheets. Consequently, the anode achieves a higher 99% Coulombic efficiency after 500 cycles. Structured Li anodes continue in a research field with some proof-of-concept for potential practical applications [22,34].

Carbon-based materials have been used by the battery industry to overcome Li anode obstacles [22,73]. LIBs are currently the most commercialized battery, and they use a graphite anode. Graphite has a theoretical specific capacity of 372 mA h g−1, and a low working potential compared to Li, allowing a good cycle life [78]. A limitation that this material faces is a low power density due to the diffusion rate of Li into graphite, which is between cm2S−1 and cm2S−1. Alternative carbon materials explored to develop high-capacity anodes are hard carbon, especially porous hard carbon. Yang et al. synthesized two typical porous carbons, achieving a reversible experimental capacity of 433 mA h g−1 and 503 mA h g−1 [79]. Ultrafine layered graphite has also been explored as anode. Chen et al. showed that reducing the size of the layered graphite particles (∼10 times) improves the Li-ions intercalation in the graphite crystals. As a result, the anode can deliver >500 mA h g−1 in the first cycle at 40 mA h g−1, and 393 mA h g−1 in the second [80].

Silicon has been studied as an alternative to Li and carbon anodes. Silicon is an alloy with a theoretical specific capacity of 4200 mA h g−1 and working potential of . The Si properties that limit its application in practical batteries include a low electrical conductivity ( S m−1) and Li-ion diffusivity ( cm2 S−1) [81]. Moreover, Si exhibit a large volume change during charge/discharge (%) and unstable solid–electrolyte interface (SEI), resulting in a rapid capacity drop, large irreversible capacity, and poor rate performance [82]. Strategies to overcome these issues include nanostructured Si, porous Si, and polymer binders (poly(vinyli-dene fluoride) (PVDF), carboxymethylcellulose sodium(CMC), poly(acrylic acid)).

To develop flexible Si anodes, MXenes have been researched due to their metallic conductivity, good hydrophilicity, and excellent mechanical properties. Reducing dimensions to change properties has been studied by Zhang et al. The authors developed an MXene nanosheet structure to confine Si-C nanoparticles [82]. The MXene framework provides high conductivity and reduces the volume change during the lithiation/delithiation process. As a result, the MXene-bonded Si-C film electrode shows flexibility, stability, high capacity, and superior rate performance. Si-C film exhibits a capacity of mA h g−1 in the first cycle and is capable of delivering mA h g−1 after 150 cycles at a current density of 420 mA g−1, and it remains a capacity of 553 mA g−1 at a current density of A g−1.

Germanium (Ge) has a high theoretical specific capacity (1600 mA h g−1), high electrical conductivity (2.20 S m−1), high Li-ion diffusivity ( cm2 S−1), and an isotropic lithiation which minimizes fracturing in the anodes [83]. The main drawback of Ge alloy materials is their huge volume expansion (%) that causes anode pulverization and cracking, reducing their cycle life. Another issue is their high cost and scarcity. Some strategies that have been researched to overcome these issues include low-dimensional nanomaterials (nanowires, nanobelts, nanoparticles, and nanotubes) [84], coating design, and porous structures. As an example, a peroxide route to produce peroxogermanate GeO thin films was demonstrated for the first time, which could be an alternative process to germanium and germanium oxide coatings [85]. The GeO thin film deposited on graphene oxide shows an initial discharge capacity of 2067 mA h g−1 at a current of 100 mA g−1, and it is capable to deliver a capacity of 740 mA h g−1 at a current rate of 2000 mA g−1. The concern using this material is its low Coulombic efficiency (69%). In another study, micro-sized porous Ge powders were synthesized and tested as anode material [83]. The researchers suggest that reducing diffusion lengths for the lithium-ion allows for a rapid charge and discharge compared to the bulk material. Additionally, it is possible to improve the electrode’s mechanical integrity through porous materials capable of hosting the volume change within their pores. As a result, the anode delivers a capacity of 1300 mA h g−1 at 1000 mA g−1 after 340 cycles, and a 469 mA h g−1 at 8000 mA g−1 after 1800 cycles. However, a low Coulombic efficiency is exhibited in the first cycle.

Alloy anodes with two metal components are studied as an effective way to protect alkali metal anodes, such as Li-B, Li-Al, Li-Mg, Li-In, Li-Zn, and Li-Sn Li-Na [11]. For example, Zhong et al. showed that the Li-B alloy is capable of maintaining its structural stability during repeated cycles [86]. Li-B anodes exhibit a capacity of 213 mA h g−1 with a retention capacity of % after 200 cycles. They also found that a Li-Al layer coating on the Li-B anode is capable of improving the retention capacity to % after 200 cycles. It is suggested that this improved performance can be associated with the effective suppression of Li-dendrite growth and the reduction of side reactions induced by the mixed ion/electronic conductor of the Li-Al layer on the Li-B electrode. Li-Mg alloy was explored since it can reach a capacity of mA h g−1, and it shows a discharge capacity of mA h g−1 after 200 cycles working in a Li-S battery [87].

Anode materials for Li-based batteries are summarized in Table 2. We include the highest reported voltage range, capacity, current density, number of cycles, and Coulombic efficiency.

Table 2.

Anode materials for Li-based batteries.

3.2. Anodes for Sodium-Based Batteries

The anodes discussed for Na batteries include pure Na metal, intercalation (hard carbon- and titanium-based), alloys (Si, Ge), and conversion (TMO and TMS) [100].

Na has been used as an anode since it has a specific capacity of 1166 mA h g−1, a voltage of vs. SHE, and it is also abundant in the Earth’s crust [100]. The development of Na-metal anodes started in the 1960s, using liquid Na in batteries that worked at high temperatures ( ). These batteries had an efficiency of 87%, and they required an external energy source to control the high operating temperature, causing high manufacturing costs and safety issues [41]. Current research focuses on developing room-temperature Na batteries, while maintaining a low-cost.

Similar to Li, graphite was explored as anode material for Na, but the intercalation was not favorable. On the other hand, hard carbon based materials are a promising anode which posses a low Na storage voltage and also they are low cost and non-toxic. However, to use hard carbon anodes it is necessary to solve the low initial Columbic efficiency, the insufficient long cycle stability and the poor rate performance [101]. An optimization strategy of hard carbon anodes is structure control. For instance, Arie et al. prepared sheet-like structures with sufficient mesopores and micropores (larger than that of graphite) to facilitate the insertion and extraction of Na during the charge-discharge process [102]. Authors developed a hard carbon derived from the ground leaves of used tea bags and showed a stable cycle profile, maintaining a specific capacity of 193 mA h g−1 after 100 cycles at a current density of 100 mA g−1 and capacity of 127 mA h g−1 after 200 cycles at 1000 mA g−1. Alternatively, Ding et al. fabricated an interconnected spiral nanofibrous hard carbon that was able to recover after mechanical deformation [103]. The material possessed a highly disordered carbonaceous structure with an interlayer spacing of , which was able to store Na and had a gravimetric capacity of 200 mA h g−1 at a current of 1000 mA g−1 after 1200 cycles.

Ti-based materials have also been an alternative anode for Na batteries. Titanium dioxide TiO has a high theoretical capacity of 335 mA h g−1, high rate performance, and good cyclability [104]. However, experimental results showed low electronic conductivity and capacities in the range from 100 to 150 . To increase the conductivity and kinetics for Na storage, Bayhan et al. prepared 2D TiO/TiS hybrid nanosheets as the anode [105]. The hybrid nanosheet showed a capacity of in the first cycle and then it was stabilized at at a current density of 1000 during 140 cycles. In addition, TiO/TiS hybrid nanosheets showed a good cycling performance with capacities of and at current densities of 10 and 20 .

Silicon also has been studied as an alloy anode for Na batteries. In 2009, the phase diagram between Na and Si by Morito et al [106] was demonstrated, suggesting that bulk Si is not a promising anode because it exhibits poor Na diffusion kinetics. In 2015, Xu et al. experimentally proved reversible electrochemical Na ion uptake in Si [107]. The anode shows a reversible capacity of 279 at a current rate of 10 and a capacity retention of 248 after 100 cycles at 20 .

Germanium as an alloy anode presents some challenges in storing Na in its crystalline structure due to the large ionic size of Na ( Å) compared to Li ( Å) and presents a high volume expansion (500%) [108]. The reduction of dimensions has been studied as an alternative to alloying Ge electrochemically with Na to form NaGe phases [109]. For example, mesoporous germanium phosphide (MGeP) microspheres were tested [108], showing a specific capacity of 1268 in the first cycle, and a Coulombic efficiency of %. The loss of capacity in the first cycle is associated with the electrolyte decomposition on the electrode surface for SEI formation, generating that the anode delivers a capacity of 704 after 100 cycles at a current density of 240 . Another alternative studied to improve the anode electrochemical performance was the synthesis of GeTe nanocomposite modified by amorphous carbon (GeTe/C) [109], which exhibits good Na storage characteristics of 335 at 300 and 300 at 900 .

Phosphorus (P) has a high theoretical capacity of 2596 , and it exists in three allotropic forms: white P, red P, and black P [110]. Due to the low stability and toxicity, white P is not used as an anode. Red P is more stable than white P, but it has lower electronic conductivity (∼10−14 S cm−1), working as an electronic insulator. On the other hand, black P is the most thermodynamically stable allotropic, and it is a semiconductor useful for energy storage. Black P is an anisotropic layered material and the bulk electrical conductivity is ∼102 S cm−1 [110]. The challenges in P-based materials are low conductivity, volume swelling, and unstable SEI. To address these issues, some strategies include designing nanostructures, using conductive agents (carbon materials), and manufacturing 3D nanostructures of P. For example, to achieve red P anodes, red P nanoparticles were homogeneously embedded in porous nitrogen-doped carbon nanofibers (P/C) [111]. This material exhibits a good rate capability of 1308 at a current rate of 200 , and 343 at 10 . Additionally, it is capable of maintaining 81% after 1000 cycles. A hybrid phosphorene graphene (P/G) composite has been tested as anode through computational calculations [112]. The calculated specific capacity is 372 , and the average open circuit voltage is 0.53 V. To achieve flexibility, red P was encapsulated in porous multichannel Carbon nanofibers (Phosphorus/PMCNFs) as flexible anodes for Na batteries [113]. The material shows a rate capability capacity of 500 at 10 and 700 at 2 after 920 cycles. The authors suggest that the improved Na storage performance is due to the special core/shell structure of P/PMCNFs.

Zhu et al. studied copper phosphide nanocrystals as anode material for Na-ion batteries due to their high specific capacity [114]. To improve the performance, the authors reported a 3D nanoarchitecture consisting of a heterostructured assembly of CuP-C nanosheets. The thin Carbon shell serves as an electron conductor and accommodates the volume change of the CuP single-crystalline nanosheet. The 3D CuP–C shows a capacity retention of 286 after 300 cycles at 100 and 156 after 1000 cycles at 1000 . Furthermore, a vanadium phosphide–phosphorus composite VPP was investigated as an anode [115]. This composite delivers a high reversible discharge capacity of 738 , with an initial Coulombic efficiency of % at 363 . Moreover, a carbon nanotube-backboned mesoporous carbon (TBMC) material was designed and synthesized for the impregnation of red P [116]. Multi-walled carbon nanotubes facilitate the electron transfer, while the mesoporous carbon layers offer voids to load appropriate amounts of P but leave enough space to alleviate the huge volume change of the P upon sodiation. The P/TBMC composite shows a capacity of 1000 at 50 and 430 retained at 8 . In addition, this material is capable of maintaining a capacity over 800 cycles at .

TMS are promising materials for anodes due to their high theoretical capacity, good cycling stability, easily controlled structure, and modifiable chemical composition [117]. Common TMS explored as anodes are copper sulfide (CuS), vanadium sulfide (VS and VS), molybdenum sulfide (MoS), iron sulfide (FeS), and cobalt sulfide (CoS). However, the practical application of TMS is limited by low electronic conductivity and large volume expansion. A strategy to reduce the negative impact of volume expansion is to manufacture porous structures. Zhang et al. fabricated single-layered mesoporous MoS/carbon composites with fast kinetics and long durability which obtained good Na absorption on the surface of the MoS [118]. As a result, the anode was able to show a capacity of 570 after 150 cycles at 50 , and it also reached 385 after 1000 cycles at 1 .

Anode materials for Na-based batteries are summarized in Table 3. We include the highest reported voltage range, capacity, current density, number of cycles, and Coulombic efficiency.

Table 3.

Anode materials for Na-based batteries.

3.3. Anodes for Potassium-Based Batteries

The anodes discussed for K-based batteries include K metal, carbon materials, organic materials, alloys, and metal-based compounds.

K metal has a theoretical capacity of (685 ), a low potential (−2.92 V vs. SHE), and it is also abundant in the Earth’s crust [143]. Challenges to developing K as an anode are (1) dendrite growth that generates safety issues, and (2) severe side reactions that limit the capacity and cause poor kinetics.

Common carbon materials studied for K-based batteries are graphite, expanded graphite, graphene, hard carbon, soft carbon, heteroatom-doped carbon, and biomass-derived carbon [25]. The main challenge for carbon anodes is the large size of K ( Å). The interaction between K and carbon (KC) was observed and studied in 1932, demonstrating a theoretical capacity of 279 . The electrochemical K insertion in graphite was reported for the first time in 2015, in a nonaqueous electrolyte [144]. The anode showed a reversible capacity of 273 at , but a low electrochemical performance. It only maintains 80 at 279 and capacity drops from 197 to 100 after 50 cycles at . To improve the performance of carbon anodes, a nongraphitic soft carbon was synthesized, exhibiting a capacity of 273 at 6 , and a high capacity of 210 and 185 at 279 and 139 , respectively. This soft carbon shows improved cyclability with a capacity retention of % after 50 cycles at 558 . To enhance the K diffusion, low-cost and commercial expanded graphite has been studied due to its good conductivity and enlarged interlayer spaces [145]. This material exhibits a capacity of 263 at 10 and maintains a capacity of 174 after 500 cycles at 200 . Hard carbon microspheres (HCSs) are an alternative to improve the anode performance by dimension reduction. HCSs show a reversible capacity of 262 , and they are capable of delivering 190 at a rate of 558 and 136 at a rate of 1395 [146].

Tetratitanate KTiO, a titanium-based material, has been studied as an intercalation anode material [147]. The material was tested for the first time in 2016, delivering a discharge capacity of 80 at a current density of 100 and 97 at 30 . Another alternative studied is KTiO, which showed a first capacity of 275 at a current of 20 and at current density of 500 , but the capacity dropped to after 50 cycles [148].

Alloy materials, such as Sn, Sb, and Bi, are alternative anodes for K batteries since they have a high theoretical capacity. The main concern of alloys is the large volume expansion during the reaction due to the larger ionic radius of K [149]. Some strategies to overcome this issue are morphology optimization and surface engineering, which allow anodes to obtain better electrochemical performance.

Organic anode materials have some advantages: (1) the precursor is renewable, which exactly fits in the requirements of being low cost, (2) the synthesis of organic electrodes is usually conducted by a low-temperature process, enabling low-energy consumption, (3) the organic materials are composed of elements with low atomic weight (C, H, O, N, S, etc.), giving rise to high theoretical gravimetric capacities, (4) the flexible molecular structure of organic materials is expected to favorably accommodate large-size K ions without much spatial hindrance, and (5) the satisfactory electrochemical performance by modifying the structure and functional groups [25].

On the other hand, transition metal oxides and transition metal sulfides have been reported as conversion anodes, with high theoretical capacities and redox reversibility. For example, CoO-FeO nanoparticles in a super P carbon matrix (CoO-FeO/C) were fabricated to improve the conductivity and to reduce the impact of volume change [150]. The anodes deliver a reversible capacity of 220 at 50 .

Anode materials for K-based batteries are summarized in Table 4. We include the highest reported voltage range, capacity, current density, number of cycles, and Coulombic efficiency.

Table 4.

Anode materials for K-based batteries.

3.4. Anodes for Zinc-Based Batteries

The anode discussed for Zn batteries is Zn metal. Zn metal has been thought of as an ideal anode material used in both non-rechargeable and rechargeable Zn-based cells. This material has many attractive properties, such as high capacity (820 ), nontoxicity, relatively low redox potential (−0.76 V vs. SHE), high safety, and low cost [172]. The Zn anodes explored in recent years focus on modifying the basic concepts, and these anodes can be organized into foil-, paste-, slurry-, and structure types [173].

The main concerns of Zn anodes are passivation, irreversibility, corrosion, and the growth of dendrites during the plating/stripping process [172]. Passivation reduces the surface contact between the electrolyte and Zn anode, generating low conductivity. The dendrite growth increases the surface area of the Zn anode, corrosion, and other surface-dependent reactions, causing low Coulombic efficiency, poor capacity, and limited cycle life. Proposed solutions to overcome these concerns include designing a nanostructure Zn metal anode, adding additives in the electrolyte, or changing Zn salt concentrations in the electrolyte. Electrolytes for Zn-based batteries are studied in Section 5.4. In this section, we focus on novel anodes for Zn batteries.

The nanostructured Zn anode is proposed as an alternative to overcome passivation and dissolution issues [174]. This anode was fabricated with ZnO nanoparticles wrapped with graphene oxide nanosheets, and the test after 150 cycles showed a retention capacity of 86%. An ion-sieving Carbon nanoshell coated ZnO nanoparticle anode was also studied as an anode material to address the same problems [175]. Results showed that cyclability improves in comparison with Zn foil. Zn sponge anodes for higher stability were explored by Stock et al. [176]. These sponge anodes were approached from two factors: (1) using an energy-saving and low-temperature preparation method; and (2) stabilizing the pore system with a lightweight anion-exchange ionomer.

Anode materials for Zn-based batteries are summarized in Table 5. We include the highest reported voltage range, capacity, current density, number of cycles, and Coulombic efficiency.

Table 5.

Anode materials for Zn-based batteries.

3.5. Anodes for Calcium-Based Batteries

The anodes discussed for Ca-based batteries include metal Ca, carbon-based, alloys, and organic materials.

Calcium possesses multivalent charge carrier ions (Ca), a low potential (−2.87 V vs. SHE), and a high capacity (1337 ). To achieve successful Ca anodes, it is necessary to produce a reversible plating and stripping of Ca [186]. The development of Ca anodes started in the 1960s, using Ca anodes in batteries that work at high temperature levels ( ). The main challenge reported for Ca anodes was the failure of Ca electrodeposition due to the passivation layer formed in the anode by the electrolyte decomposition. Some attempts to study Ca anodes focused on non-rechargeable cells until 2016, when the feasibility of Ca electrodeposition was demonstrated, enabling operation at a lower temperature between and [50]. According to Ponrouch et al., the Ca electrodeposition is possible if the following four requisites are satisfied: (1) migration of solvated Ca ion inside the electrolyte; (2) low desolvation energy barrier at the electrolyte/passivation layer interface; (3) migration of the desolvated Ca ions through the passivation layer; and (4) low energy barrier for nucleation and low growth of Ca at the electrode substrate interface. Achieving reversible Ca anodes requires more efficient electrolytes (Section 5).

Carbon-based anodes have been explored to overcome the difficulties caused by Ca plating and stripping. The use of carbon anodes requires Ca intercalation, which is a challenge due to the large ionic radius ( 1 Å) that hinders smooth intercalation into the host lattice. To achieve successful intercalation at room temperature, Wu et al. employed an isotropic graphitic layered structure called mesocarbon microbead (MCMB) as an anode [187], showing a reversible discharge capacity of 66 at a current rate of 2C and 62 at 1 C after 300 cycles with 94% retention.

Alloy anodes focus on using Si and Sn. The electrochemical decalciation of CaSi was tested with experimental and computational analysis, showing a capacity of 240 at moderate temperatures ( ) [188], an average voltage of , and a volume expansion of 306%. On the other hand, the alloying/de-alloying process of Sn anode (CaSn) exhibited a high capacity of 526 with a volume expansion of % [189]. The Sn was proved in a full cell, exhibiting a discharge capacity of 50 in the first cycle that increases to 85 at the 200th cycle and then is reduced to 80 after 350 cycles. The main challenges of alloy materials are large voltage hysteresis, high volume expansion, and low Coulombic efficiency.

Organic anodes explored include polyaniline (PANI) and polyimide poly (PNDIE). PANI has been explored as an anode because it has a lower specific weight than inorganic materials. For example, PANI was deposited over carbon cloth by in situ polymerization, showing a discharge capacity of 123 at a current of 150 with a Coulombic efficiency of % and a retention of 84% after 200 cycles [190]. On the other hand, PNDIE has reported a specific capacity of at [191] with a capacity retention of 80%, 105 after 4000 cycles at 925 and a Coulombic efficiency %. Alternative organic anode materials investigated include PTCDA.

Anode materials for Ca-based batteries are summarized in Table 6. We include the highest reported voltage range, capacity, current density, number of cycles, and Coulombic efficiency.

Table 6.

Anode materials for Ca-based batteries.

3.6. Anodes for Magnesium-Based Batteries

The anodes discussed for Mg batteries include pure Mg metal, intercalation (carbon-based), alloys (In, Sn, Sb, Pb and Bi), and conversion (transition metal oxides (TMO), transition metal sulfides (TMS), phosphides, and nitrides) materials.

Mg metal has been studied as an anode since it possesses multivalent charge carrier ions (Mg), a low potential ( V vs. SHE), a high capacity (2205 ), and it does not form dendrite. The application of Mg metal as the anode in commercial batteries is restricted due to the electrochemically inactive layer that is generated on the anode surface. This layer is an electronic and ionic insulating surface film that obstructs any electrochemical reaction, affecting the battery efficiency. It is recommended to prevent the formation of the passive surface film to achieve practical Mg anodes [195].

Lithium titanate LiTiO (LTO) has been explored as an intercalation anode for Mg batteries since it exhibits low volume changes during Mg ion intercalation–deintercalation. LTO showed a specific capacity of 175 at current density of 15 and 55 at 300 , and a high cycling stability with 100% Coulombic efficiency and capacity retention of % after 500 cycles [196].

Alloy materials which are reversibly electrochemical with Mg include some p-block elements, such as In, Sn, Sb, Pb and Bi, which form MgIn, MgSn, MgSb, MgPb and MgBi at low voltage [197]. Early studies on alloys have focused on Bi because it has a theoretical gravimetric capacity of 385 with Mg and a rhombohedral crystalline structure. In 2012, the electrodeposition of Bi as anode showed a maximum specific capacity of 257 and of 222 after 100 cycles [198]. In addition, superionic conductivity was described but only in phases . Larger capacities are achieved by replacing the Bi layers with nanotubes. A specific capacity of 350 and a Coulombic efficiency initial of 95% was reported for Bi nanotubes [199]. Although the electrochemical behavior exhibited with this nanostructure is remarkable, it is difficult to achieve commercial systems due to its exotic nature and manufacturing costs. Other composites tested as anodes include BiSb and Sb [198]. A maximum specific capacity of 298 was exhibited in the first cycle and 215 after 100 cycles by BiSb, while Sn showed a poor cycling performance after 16 cycles, . Tin (Sn) as an alloy anode has been tested because it is more abundant than Bi and tin has a high theoretical capacity over 890 [200]. The use of Sn faces a big challenge since experimental tests show non reversible reactions in the Sn anode. SnSb alloys have been explored as an alternative to overcoming the challenges that Sn and Sb have individually. The theoretical capacity of SnSb is 768 and experimental results show a high reversible capacity of 420 and cyclic stability, delivering 350 after 100 cycles [200].

Anode materials for Mg-based batteries are summarized in Table 7. We include the highest reported voltage range, capacity, current density, number of cycles, and Coulombic efficiency.

Table 7.

Anode materials for Mg-based batteries.

3.7. Anodes for Aluminum-Based Batteries

Metal Al is a promising anode since it has multivalent charge carrier ions (Al), high capacity (2980 ), a relatively low potential (−1.66 V vs. SHE), low cost, and it is the most abundant metal on the Earth’s crust [202]. The main challenge of using Al as an anode is the highly stable passivation layer, causing an electrochemical inertness [7,47,203]. Al anodes are usually foils, which work as both active material and current collector. However, this limits the active area. Three-dimensional thin film has been studied to increase the active surface area [54]. The 3D thin-film fabricated exhibited a capacity of 165 and a retention of 86% after 500 cycles. To address passivation layer problems, researchers have focused on testing different electrolytes chemistries (Section 5).

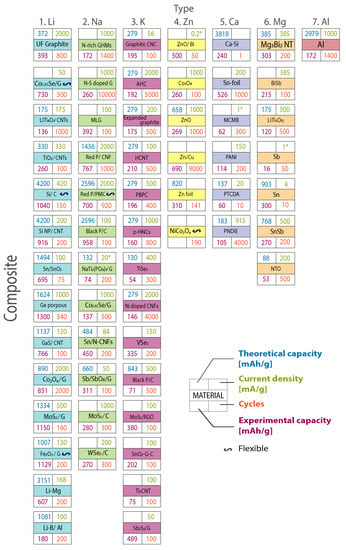

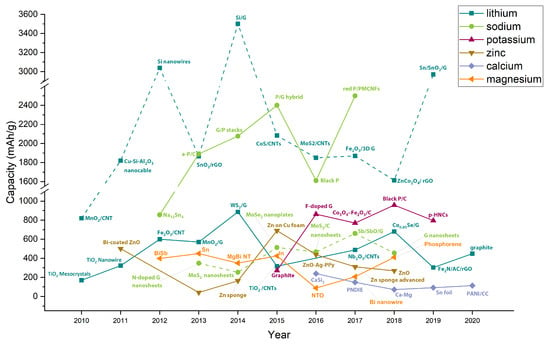

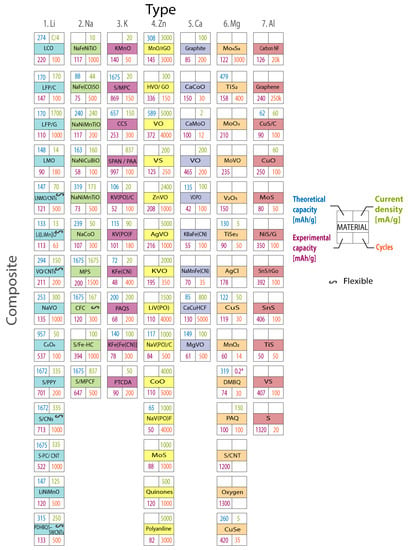

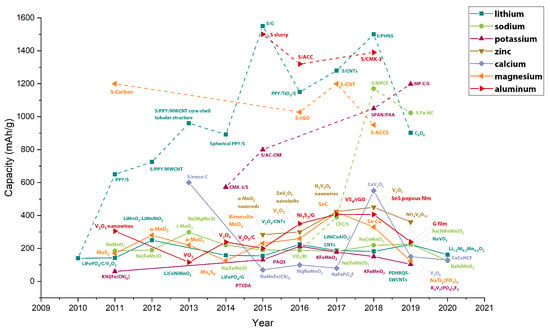

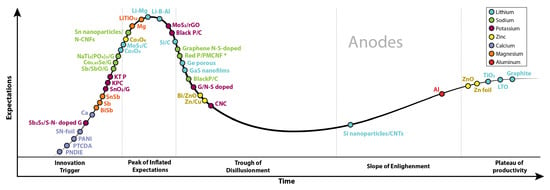

Figure 7 compares the current research in anode materials for each battery type, presenting the theoretical capacity, experimental capacity, current density, and the number of cycles for each material. Figure 8 shows the progress per year of the specific capacity in anode materials in the research field, highlighting the most relevant studied materials per year. The line color represents the battery type. For Li- and Na-based batteries, two curves are presented. The continuous lines represent traditional anode materials, which operate through an intercalation mechanism. Dot lines represent conversion materials studied in the next generation of batteries.

Figure 7.

Current research in anode materials. Columns organize the seven battery types. Rows represent the composite material group. Theoretical capacity, experimental capacity, current density, and the number of cycles are also included. A special symbol highlights flexible anode materials. Graph constructed by the authors from references in Table 2, Table 3, Table 4, Table 5, Table 6 and Table 7.

Figure 8.

The advance of the anodes’ experimental specific capacity, comparing the seven battery types: Li, Na, K, Zn, Ca, Mg, and Al. Continuous line: traditional intercalation materials. Dot lines conversion materials. Graph constructed by the authors from references in Table 2, Table 3, Table 4, Table 5, Table 6 and Table 7. NW, nanowires; NR, nanorods; NB, nanobelts.

4. Cathodes

The cathode is the positive electrode of a battery that is reduced (gain of electrons) during the discharge process [46]. Similar to the anode, the cathode plays different roles according to the work ion, establishing the operation of rechargeable and non-rechargeable batteries. Generally, cathodes have a lower capacity than anodes, limiting the battery performance [9]. Therefore, there is an interest in improving the capacity of cathodes by optimizing the chemical, electrochemical, and physical properties of materials [204]. An ideal cathode should have high performance, high potential, low cost, and low environmental impact [204]. A high cathode performance implies that the cathode offers a large reversible storage capacity at the desired electrochemical potential. A cathode with high potential allows the development of high energy density batteries [9]. Although the materials’ intrinsic nature determines the electrochemical properties of electrodes, it is possible to vary their microstructures with different synthesis methods and conditions. For example, dopants can be introduced to modify the crystal parameters to improve cyclic stability and specific capacity. The storage of ions in cathodes occurs via two mechanisms: intercalation and conversion.

In the intercalation, the electrode material must contain space to store and release working ions reversibly [204]. Intercalation cathode materials can be classified into three kinds according to their chemical composition: (1) transition metal compounds, (2) polyanionic compounds, and (3) Prussian Blue [9].

- Transition metal compounds, oxides, or complex oxides have olivine (1D), layered (2D), or spinel (3D) crystal structures [8,204]. Olivine crystal structures have 1D tunnels to allow ions to flow, causing lower rate capability. Reducing the size of the active material is a strategy to address this issue. Layered oxides have a general formula ABO, where A represents the ion carrier such as Li, Na, K, Zn, Ca, Al, and Mg, and B represents one or more metal ions such as Ni, Co, Fe, Mn, and Cu. Spinel oxides have a general formula ABO, where A represents the ion carrier such as Li, Na, K, Zn, Ca, Al, and Mg, and B can be Ti, V, and Mn [9,205]. The layered and spinel oxides offer good electronic conductivity and high densities.

- Polyanionic compounds have a general formula ABB’(XO), where A represents one ion carrier, Li, Na, K, Zn, Ca, Al, or Mg; B could be V, Ti, Fe, Tr, Al, or Nb; and X is P or S. Polyanionic compounds offer higher thermal stability and safety than the layered and spinel oxide cathodes due to the covalent bond between the oxygen and the P, S, or Si. Moreover, polyanionic cathodes include abundant transition metals, such as Fe, which contributed to their applications in storage devices for renewable energy sources. The use of polyanionic compounds requires synthesized small particles with coated conductive carbon due to the poor electronic conductivity, increasing the cost, reducing the volumetric energy density, and leading to low performance [9].

- Prussian blue analogues (PBA) have a general formula ABB(CN). A is usually Li, Na, K, Zn, Ca, Mg, or Al, while B and B can be Fe, Mn, Ni, Co, or Cu. The use of PBA as an electrode is due to two structural characteristics: (1) large 3D diffusion channels that facilitate its inward and outward transport by the weak interaction with the diffusing ion, and (2) control of the [B(CN)] vacancies that improve the crystallinity by changing the stoichiometry and the preparation conditions. Moreover, PBA has a high theoretical specific capacity, a simple synthesis, and a low cost [206].

Opposite to intercalation, in conversion, the material does not have active intercalation sites, but the material reacts electrochemically during discharge, breaking chemical bonds and creating new ones [8]. For this reason, the bulk material may react electrochemically during discharge. Conversion mechanism occurs in metal–air and metal–S technologies. During metal–S battery operation, S is reduced electrochemically to produce metal sulfide. The reaction is expressed as , where M is Li, Na, K, Zn, Mg, Ca, or Al, and [39]. In theory, sulfur can be combined with any metal anode to form metal sulfide. Although S has a low electrochemical potential (0.4 V), it exhibits extremely high theoretical specific capacity (1675 ). The main limitation of using S is the volumetric changes due to the density changes during cycling. In addition, the use of conversion materials is limited by their irreversibility. Some strategies to improve the reversibility are the development of small particle sizes ( in diameter), and the combination with alloying materials [7,204].

Metal–air batteries follow the reaction with aqueous electrolytes and (x = 1 or 2) with aprotic electrolytes [207]. These technologies offer high theoretical energy densities. However, rechargeable metal–air batteries suffer slow kinetics and overpotential, which limit their practical application.

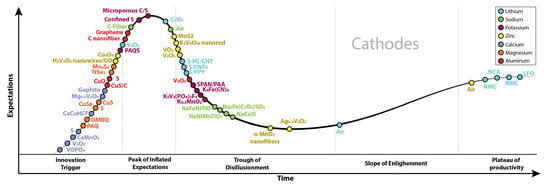

The selection criteria to choose cathode materials include the abundance in the Earth’s crust, eco-friendly nature for processing, usage and recycling, and cost. Figure 9 presents the increasing interest in the research about “positive electrodes”. In this section, we present the cathode materials commercialized and researched for each battery type, describing their main properties and showing the strategies explored to address the challenges.

Figure 9.

Publications per year about positive electrodes, comparing seven battery types: Li, Na, K, Zn, Ca, Mg, and Al. Graph constructed by the authors. Data from Web of Science.

4.1. Cathodes for Lithium-Based Batteries

The cathodes discussed for Li batteries include layer (lithium cobalt oxide LCO (LiCoO), lithium nickel cobalt aluminum oxide NCA (LiNiCoAlO), and lithium nickel cobalt manganese oxide NMC (LiNiMnCoO2), spinel ( lithium manganese oxide LMO (LiMn2O4), and lithium nickel manganese spinel LNMO (LiNiMnO4), olivine (LFP—lithium iron phosphate (LiFePO4), and S, and O2. The introduction of cathodes for batteries is not straightforward. For example, LCO began to be successfully used in commercial batteries in 1991, 11 years after its discovery [9].

LCO is a layered material that has a theoretical capacity of 273 . LCO has a rhombohedral structure and can achieve open-circuit voltages of 4 to 5 and stable operating voltages at . The main issues of LCO are a short life span, low thermal stability, and limited load capabilities [9]. Therefore, in practical application, LCO only achieves . To develop a high voltage and high energy density cathode, multi-functional material coatings have been studied [208]. Xing has demonstrated that cover LCO electrode with metal fluoride, metal phosphate, Li metal oxide and Li metal phosphate, increase the specific capacity to 220 , and the voltage cycle stability (3 – ). The use of LCO as a cathode requires that it be charged and discharged at a current equal to its C-rating. Forcing a fast charge or applying a load higher than 1 C causes overheating and undue stress. Finally, LCO cathodes raise some concerns about their toxicity, high price, and limited production. For example, Co represents up to 60% of the materials cost for battery manufacturers and, to be profitable, these industries require a continual supply of economic Co. To enhance longevity, loading capabilities, and cost, new materials such as nickel, manganese, and aluminum, have been integrated into LCO cathodes. In addition, to improve the rate capability, researchers focus on the control of particle morphology, while to achieve high capacity, they focus on increased charge voltage.

NMC has a specific capacity and operating voltage similar to LCO, as well as a lower cost since the Co content is lowered [9]. Different Li:M ratios have been studied to determine the optimal value to produce this material to favor physical and electrochemical properties. NMC-111, NMC-442, and NMC-532 are currently the state of the art of these cathode materials. To achieve higher specific energy and lower costs, Ni-rich NMC cathode materials, such as NMC-811 and NMC-622, will be developed in the coming years.

LiFePO4 (LFP) was identified as a polyanionic compound in 1987, but it was suggested as a potential cathode for rechargeable lithium batteries by JB Goodenough et al. in 1997 [9]. LFP has good electrochemical performance with low resistance, high current rating, long cycle life, good thermal stability, enhanced safety, and tolerance if abused. Therefore, it seems to be an alternative to replace the LCO cathode. Although LFP is more tolerant to full charge conditions when kept at high voltage for a long time, it shows a low electronic conductivity (∼10−9 S cm−1) and low theoretical capacity (170 ). These values are related to its olivine structure, which has a one-dimensional diffusion channel and limits the diffusion of ions. Strategies to increase the capacity include morphology and particle size control, doping, surface coating, and the addition of prelithiation additives [209]. Wang et al. proposed a new morphology joining porous LFP microspheres with carbon and CNTs [210]. As a result, the cathode material showed a discharge capacity of 115 at 1700 , maintaining 113 after 1000 cycles. The reduction in dimensions, using nanoscale materials, is another option explored to improve the electronic and ionic transport lengths [3].

LiMn2O4 (LMO) was first reported by M. Thackeray et al. in 1983, and it was commercialized as a cathode material by Moli Energy. LMO has a spinel structure consisting of a three-dimensional structure (usually composed of diamond shapes connected into a lattice) that improves ion flow on the electrode generating lower internal resistance and a more stable structure than LCO. In addition, LMO possesses a competitive cost advantage with the lowest price ($10 ), non-toxicity, three-dimensional Li+ diffusion pathways, high thermal stability, and enhanced safety. Some disadvantages of using LMO are a limited cycle life, low capacity (theoretical capacity: 148 ), and poor high-temperature performance due to its instability in the electrolyte and capacity loss [3].

NCA has been proposed since 1999 for specific applications, showing high specific energy, good specific power, and a long life span. NCA is a compound that integrates Co and Al in a LiNiO2. The integration of Al helps to minimize negative phase transitions, improve the thermal stability of LiNiO2, and keeps the crystal structure stable. On the other hand, Co helps to reduce cation mixing and also stabilize the layered structure. In addition, Co is electrochemically active, improving the performance of NCA with higher specific capacity (200 ), high energy density (200 ), and long cycle life [3]. To increase NCA cathode performance, some researchers have explored the use of CNTs to modify NCA surfaces. For example, LiNi0.8Co0.15Al0.05O2/CNT (NCA/CNT) composite has been studied, exhibiting a reversible capacity of 181 with a discharge retention of 96% after 60 cycles at a current of 50 . The result suggests that NCA/CNT material enhances the capacity of pristine NCA by 18%, and at a high current rate of 1000 , it can deliver a reversible capacity of 160 [211].

To address the Co concern as a critical material, novel research focuses on a new class of cobalt-free materials. Muralidharan et al. have developed a material called lithium iron aluminum nickelate with the formula LiNixFeyAlzO2 (). The results showed a good performance with a specific capacity of 200 , and 80% capacity retention after 100 cycles at a rate capability of C/3 [212]. The cobalt-free material was synthesized through the sol-gel method that allows varying aluminum and iron composition amounts. Li-rich manganese-based cathode materials have also been explored, such as the cobalt-free material Li1.2Ni0.2Mn0.6O2. However, their practical application is limited by a low Coulombic efficiency during the first cycle, a low rate capability, and a pronounced capacity and voltage fading during cycling. The influence of synthesis conditions have been studied as a critical factor in the characteristics and electrochemical performance of electrode materials [213]. Zhao et al. showed that the increase in calcination temperature ( ) could improve the layered structure of Li[Li1/5Fe1/10Ni3/20Mn11/20]O2, delivering a discharge capacity of .

The next generation of batteries focuses on a conversion mechanism with higher specific capacities than intercalation materials. For example, sulfur has a theoretical capacity of 1675 [214]. The use of sulfur requires addressing some challenges: (1) the polysulfides formed during the discharge and the low electrical conductivity, causing high internal resistance of the batteries and limiting the active material utilization efficiency and rate capability; (2) the migration of polysulfides onto the Li anode by a shuttle effect, generating an electrochemically inactive layer that reduces the battery efficiency; (3) the volume change of sulfur during the cycling process, resulting in a volumetric increase in % after discharge. This significant volume change makes Li2S lose its electrical contact with the conductive substrate or the current collector, causing a fast capacity fading and fast degradation of the cell due to mechanical stress. [7,31,215,216,217]. The strategies to overcome these challenges include using coatings (polymeric species, ceramic membranes, and carbon materials), and encapsulating S into porous carbon matrices [218].