Prediction of Battery Cycle Life Using Early-Cycle Data, Machine Learning and Data Management

Abstract

1. Introduction

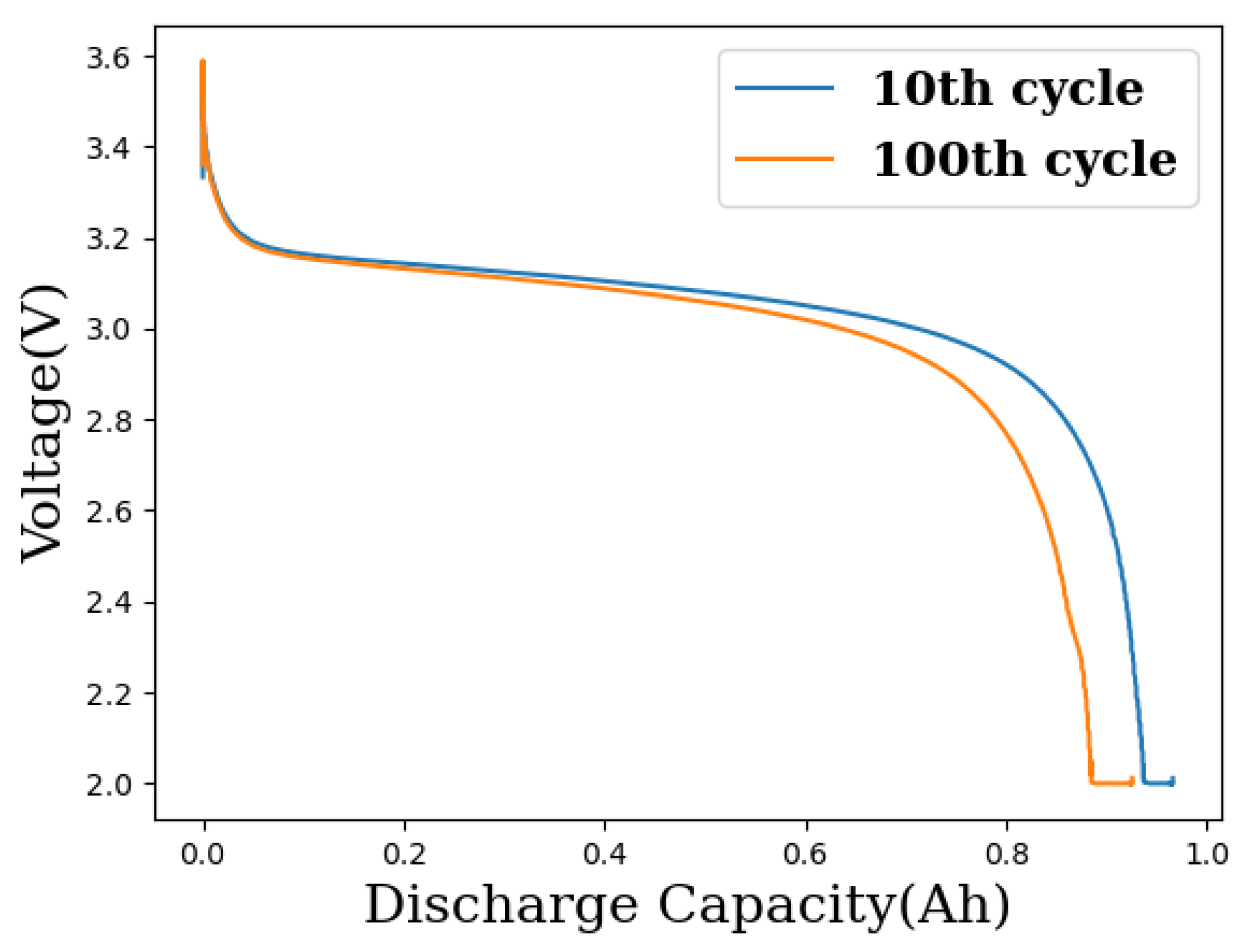

2. Materials and Methods

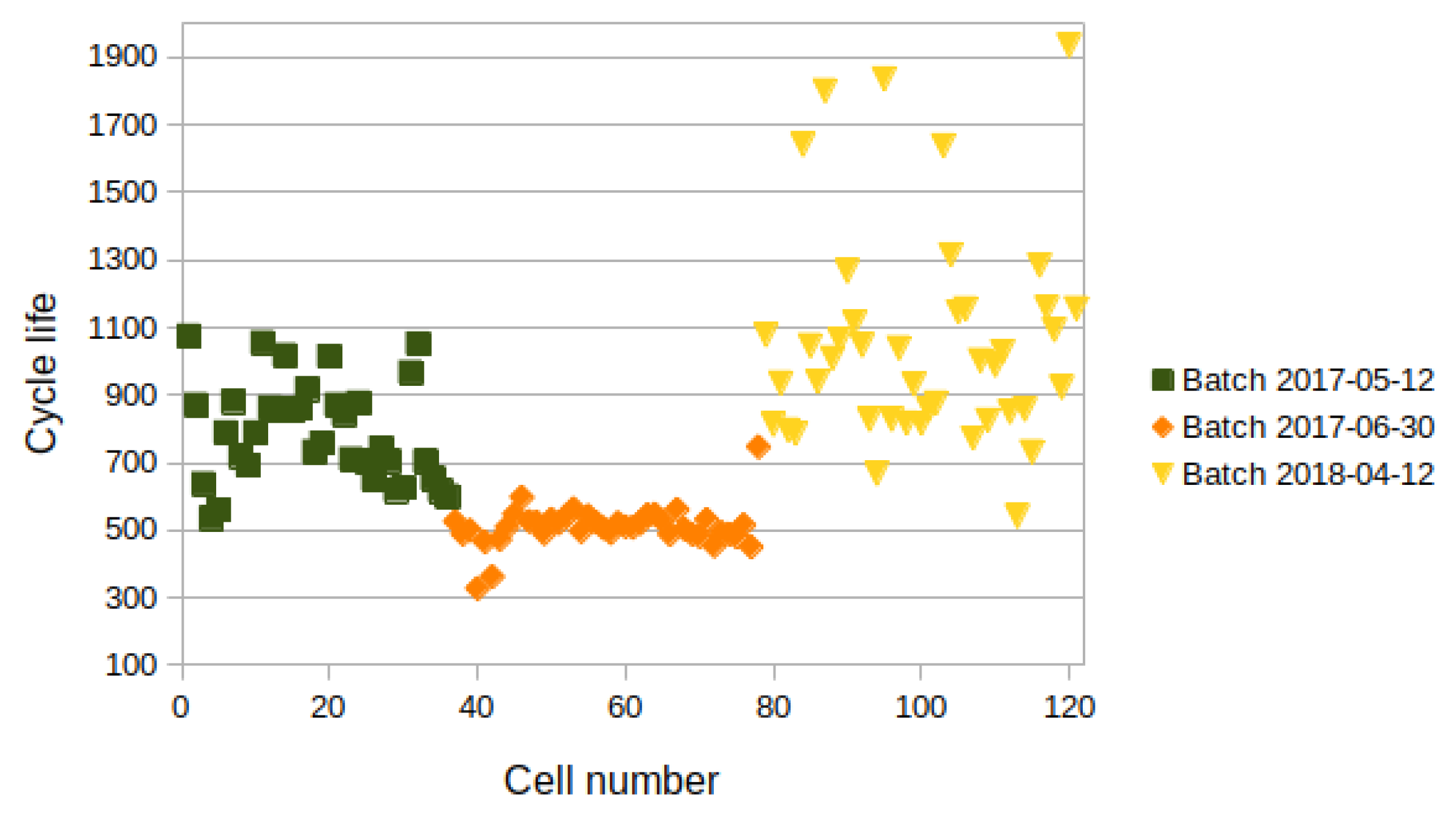

- For batch “2017-05-12”, channels 1, 2, 3, 4, 5, 6, 8, 13, 19, 21, 22 and 31 were excluded. Channels 4 and 8 did not successfully start and thus did not have data. The cells in channels 1, 2, 3, 5 and 6 were stopped at the end of the test and resumed in the “2017-06-30” batch. This pause in cycling led to a rise in capacity upon resuming the tests. The tests in channels 13, 19, 21, 22 and 31 were terminated before the cells reached 80% of nominal capacity.

- For batch “2017-06-30”, channels 1, 2, 3, 5, 6 and 10 were excluded. Channels 1, 2, 3, 5 and 6 were not new experiments but a continuation of experiments from the “2017-05-12” batch. The cell on channel 10 was possibly defective as it died quickly.

- For batch “2018-04-12”, channels 26, 31, 33, 41 and 46 were excluded. No data were provided for channels 26 and 31. The tests in channels 33 and 41 were terminated before the cells reached 80% of the nominal capacity. The cell in channel 46 had noisy voltage profiles due to an electronic connection error.

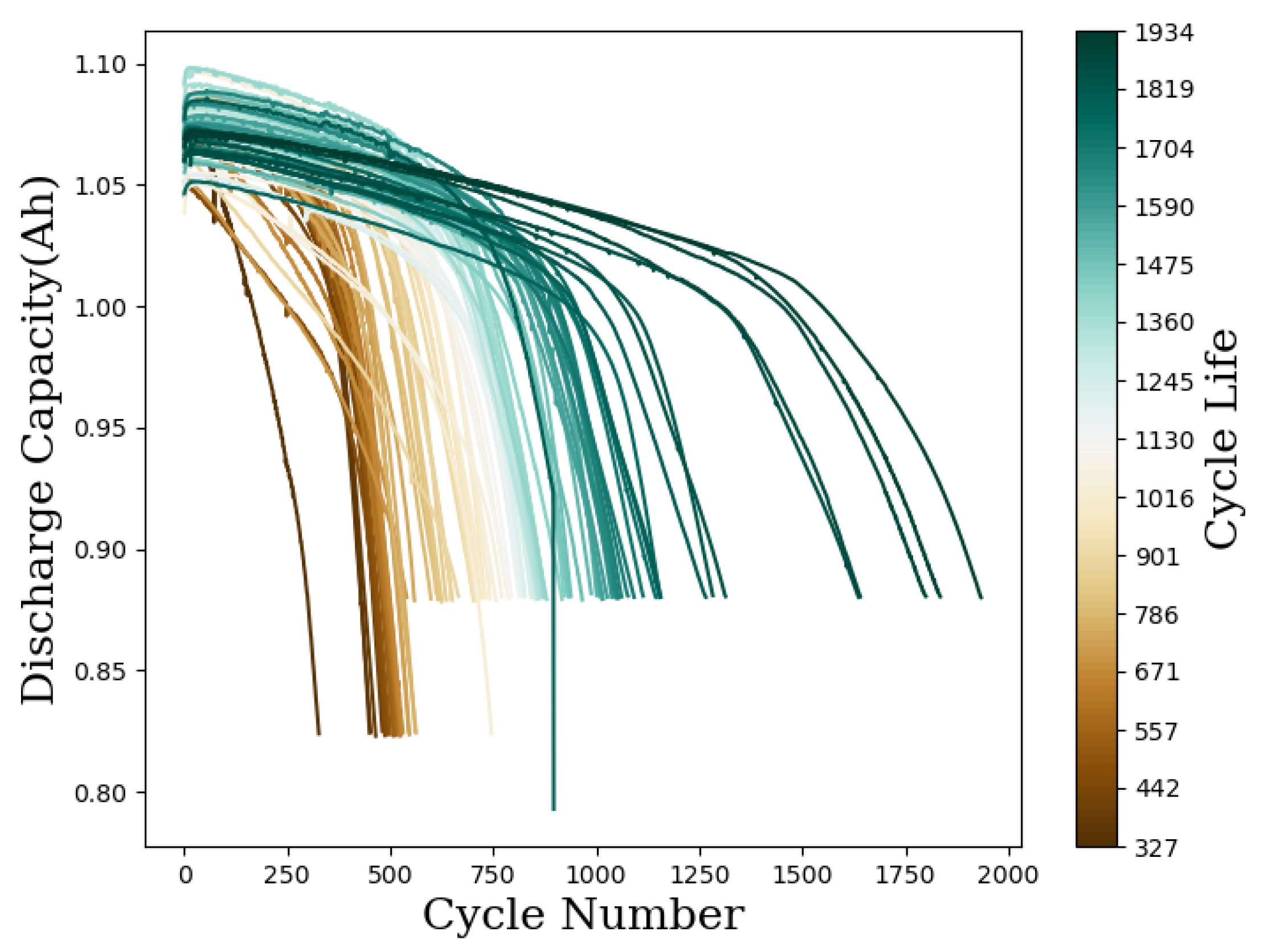

3. Results and Discussion

3.1. Prediction of Life Cycle

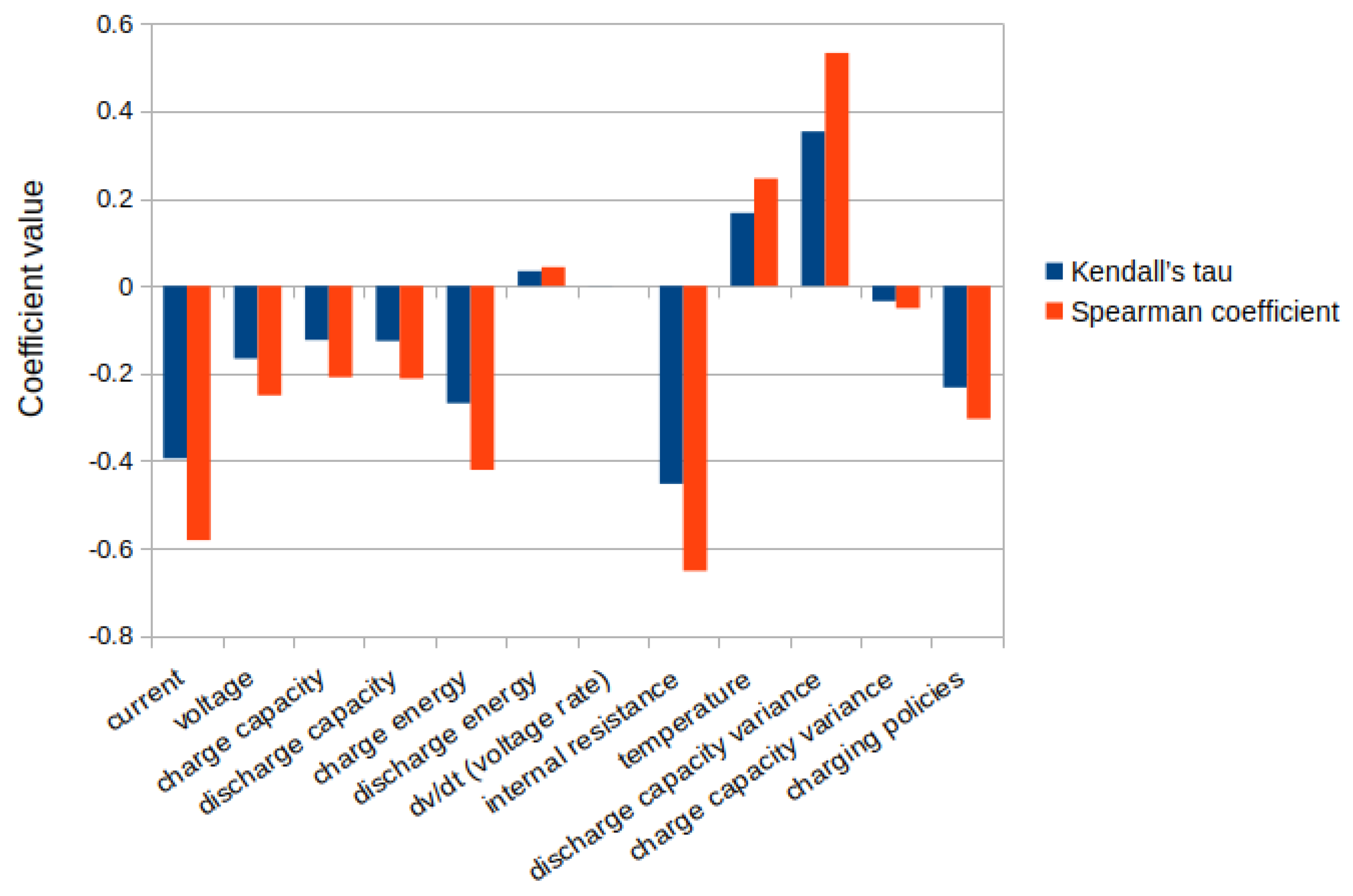

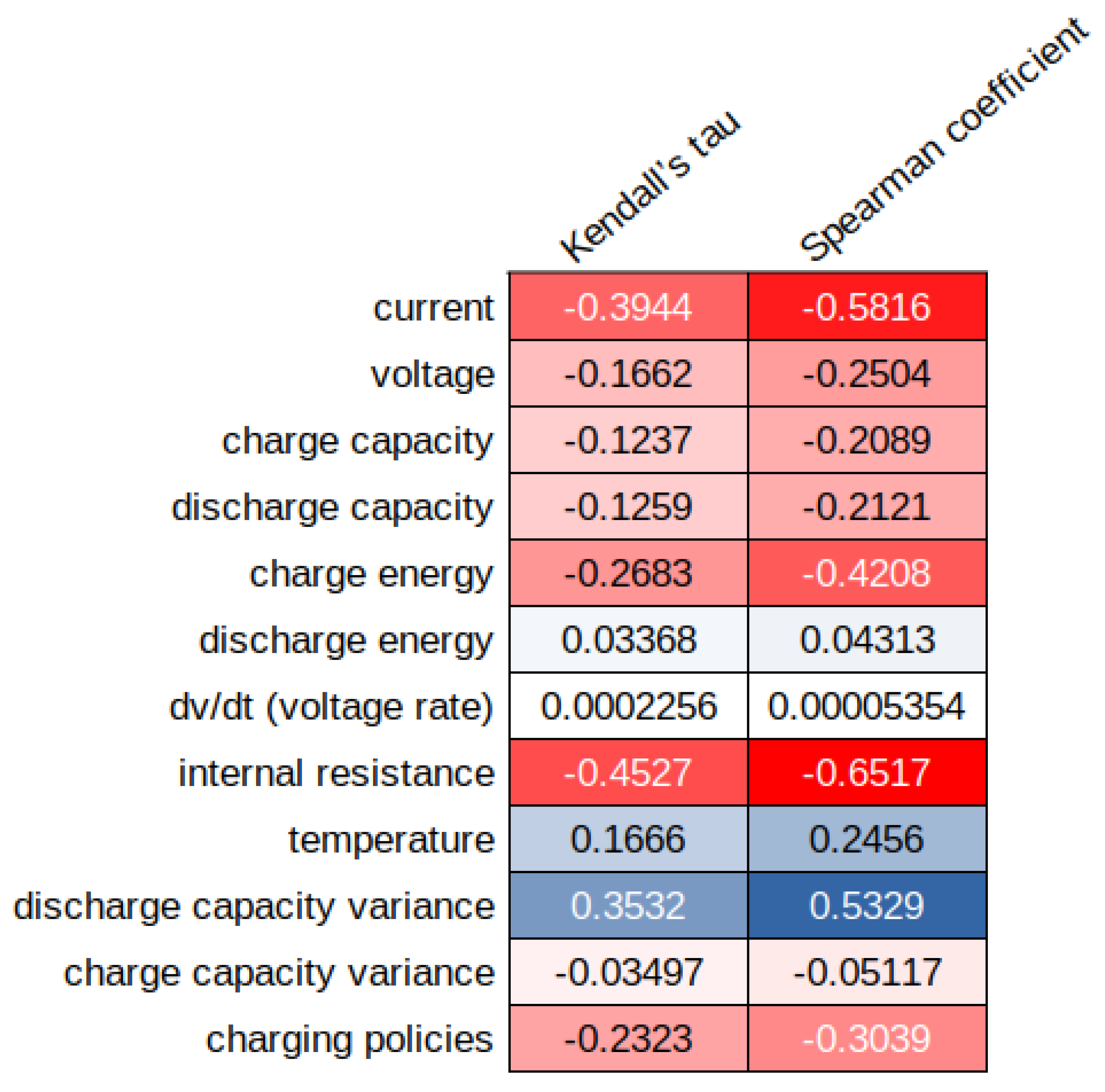

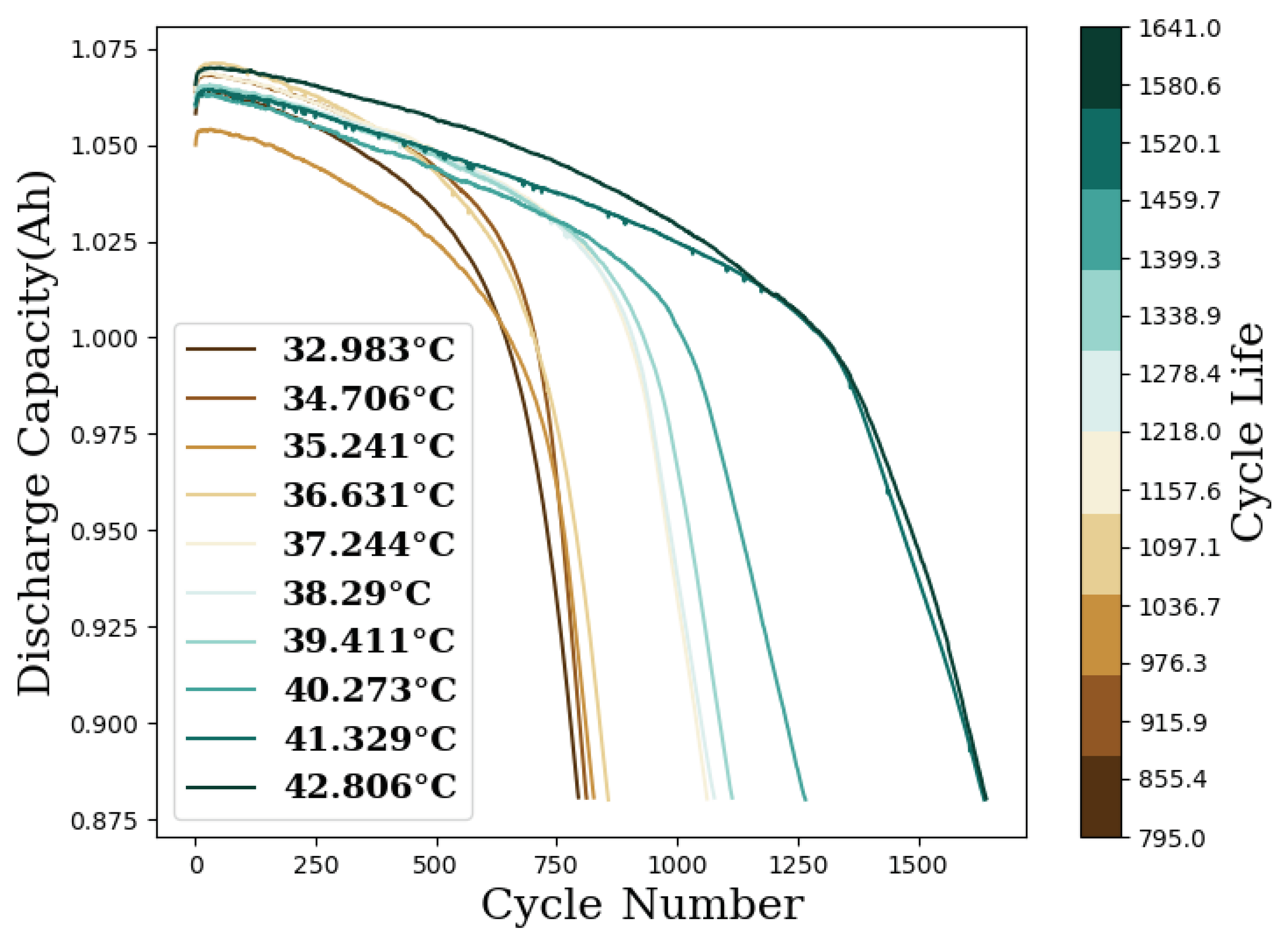

3.2. Analysis of Input Variables

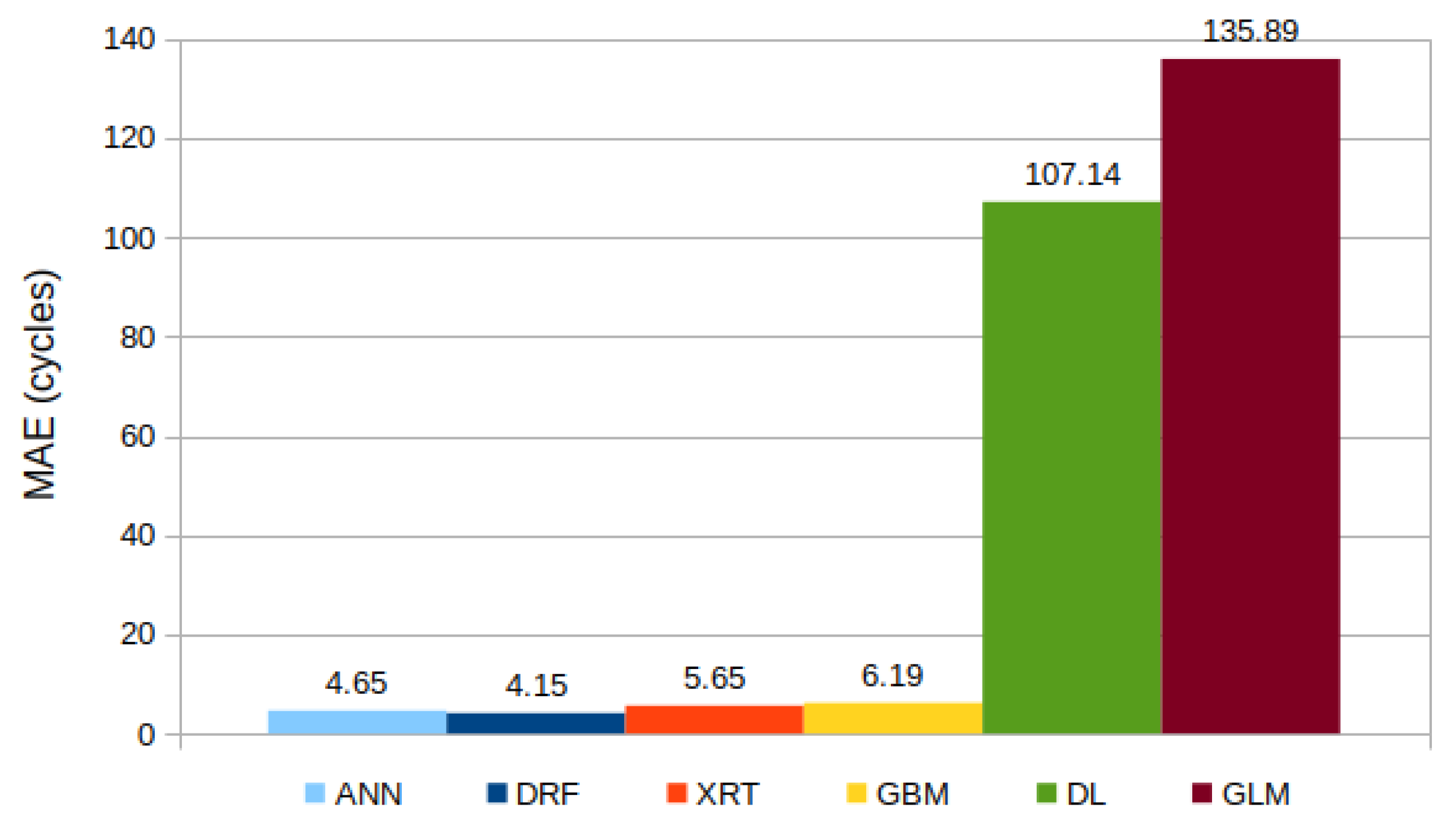

3.3. Prediction Error Comparison

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| SEI | Solid electrolyte interphase |

| ML | Machine learning |

| ANN | Artificial neural network |

| DRF | Default random forest |

| GBM | Gradient boosting models |

| XRT | Extremely randomized trees |

| DL | Deep learning |

| GLM | Generalized linear model |

| NASA | National Aeronautics and Space Administration |

| NREL | National Renewable Energy Laboratory |

| SoC | State of charge |

| MAE | Mean absolute error |

| MAPE | Mean absolute percentage error |

References

- Grey, C.; Hall, D. Prospects for lithium-ion batteries and beyond—A 2030 vision. Nat. Commun. 2020, 11, 2–5. [Google Scholar] [CrossRef] [PubMed]

- Wen, J.; Yu, Y.; Chen, C. A review on lithium-ion batteries safety issues: Existing problems and possible solutions. Mater. Express 2012, 2, 197–212. [Google Scholar] [CrossRef]

- Han, X.; Lu, L.; Zheng, Y.; Feng, X.; Li, Z.; Li, J.; Ouyang, M. A review on the key issues of the lithium ion battery degradation among the whole life cycle. eTransportation 2019, 1, 100005. [Google Scholar] [CrossRef]

- Barré, A.; Deguilhem, B.; Grolleau, S.; Gérard, M.; Suard, F.; Riu, D. A review on lithium-ion battery ageing mechanisms and estimations for automotive applications. J. Power Sources 2013, 241, 680–689. [Google Scholar] [CrossRef]

- Vetter, J.; Novák, P.; Wagner, M.; Veit, C.; Möller, K.C.; Besenhard, J.; Winter, M.; Wohlfahrt-Mehrens, M.; Vogler, C.; Hammouche, A. Ageing mechanisms in lithium-ion batteries. J. Power Sources 2005, 147, 269–281. [Google Scholar] [CrossRef]

- Severson, K.; Attia, P.; Jin, N.; Perkins, N.; Jiang, B.; Yang, Z.; Chen, M.; Aykol, M.; Herring, P.; Fraggedakis, D.; et al. Data-driven prediction of battery cycle life before capacity degradation. Nat. Energy 2019, 4, 383–391. [Google Scholar] [CrossRef]

- Wang, A.; Kadam, S.; Li, H.; Shi, S.; Qi, Y. Review on modeling of the anode solid electrolyte interphase (SEI) for lithium-ion batteries. NPJ Comput. Mater. 2018, 4, 15. [Google Scholar] [CrossRef]

- Nie, M.; Abraham, D.; Chen, Y.; Bose, A.; Lucht, B. Silicon solid electrolyte interphase (SEI) of lithium battery characterized by microscopy and spectroscopy. J. Phys. Chem. C 2013, 117, 13403–13412. [Google Scholar] [CrossRef]

- An, S.; Li, J.; Daniel, C.; Mohanty, D.; Nagpure, S.; Wood, D. The state of understanding of the lithium-ion-battery graphite solid electrolyte interphase (SEI) and its relationship to formation cycling. Carbon 2016, 105, 52–76. [Google Scholar] [CrossRef]

- Li, Y.; Liu, K.; Foley, A.; Zülke, A.; Berecibar, M.; Nanini-Maury, E.; Van Mierlo, J.; Hoster, H. Data-driven health estimation and lifetime prediction of lithium-ion batteries: A review. Renew. Sustain. Energy Rev. 2019, 113, 109254. [Google Scholar] [CrossRef]

- Keil, P.; Jossen, A. Charging protocols for lithium-ion batteries and their impact on cycle life - An experimental study with different 18650 high-power cells. J. Energy Storage 2016, 6, 125–141. [Google Scholar] [CrossRef]

- Leng, F.; Tan, C.; Pecht, M. Effect of Temperature on the Aging rate of Li Ion Battery Operating above Room Temperature. Sci. Rep. 2015, 5, 12967. [Google Scholar] [CrossRef] [PubMed]

- Pinson, M.; Bazant, M. Theory of SEI Formation in Rechargeable Batteries: Capacity Fade, Accelerated Aging and Lifetime Prediction. J. Electrochem. Soc. 2013, 160, A243–A250. [Google Scholar] [CrossRef]

- Schuster, S.; Bach, T.; Fleder, E.; Müller, J.; Brand, M.; Sextl, G.; Jossen, A. Nonlinear aging characteristics of lithium-ion cells under different operational conditions. J. Energy Storage 2015, 1, 44–53. [Google Scholar] [CrossRef]

- Krewer, U.; Röder, F.; Harinath, E.; Braatz, R.; Bedürftig, B.; Findeisen, R. Review—Dynamic Models of Li-Ion Batteries for Diagnosis and Operation: A Review and Perspective. J. Electrochem. Soc. 2018, 165, A3656–A3673. [Google Scholar] [CrossRef]

- Chen, C.; Zuo, Y.; Ye, W.; Li, X.; Deng, Z.; Ong, S. A Critical Review of Machine Learning of Energy Materials. Adv. Energy Mater. 2020, 10, 1903242. [Google Scholar] [CrossRef]

- Ng, M.F.; Zhao, J.; Yan, Q.; Conduit, G.; Seh, Z. Predicting the state of charge and health of batteries using data-driven machine learning. Nat. Mach. Intell. 2020, 2, 161–170. [Google Scholar] [CrossRef]

- Waag, W.; Fleischer, C.; Sauer, D. Critical review of the methods for monitoring of lithium-ion batteries in electric and hybrid vehicles. J. Power Sources 2014, 258, 321–339. [Google Scholar] [CrossRef]

- Si, X.; Wang, W.; Hu, C.; Zhou, D. Remaining useful life estimation—A review on the statistical data driven approaches. Eur. J. Oper. Res. 2011, 213, 1–14. [Google Scholar] [CrossRef]

- Abiodun, O.; Jantan, A.; Omolara, A.; Dada, K.; Mohamed, N.; Arshad, H. State-of-the-art in artificial neural network applications: A survey. Heliyon 2018, 4, e00938. [Google Scholar] [CrossRef]

- Yang, D.; Wang, Y.; Pan, R.; Chen, R.; Chen, Z. A Neural Network Based State-of-Health Estimation of Lithium-ion Battery in Electric Vehicles. Energy Procedia 2017, 105, 2059–2064. [Google Scholar] [CrossRef]

- You, G.w.; Park, S.; Oh, D. Real-time state-of-health estimation for electric vehicle batteries: A data-driven approach. Appl. Energy 2016, 176, 92–103. [Google Scholar] [CrossRef]

- Guo, Y.; Zhao, Z.; Huang, L. SoC Estimation of Lithium Battery Based on Improved BP Neural Network. Energy Procedia 2017, 105, 4153–4158. [Google Scholar] [CrossRef]

- Biau, G.; Scornet, E. A random forest guided tour. Test 2016, 25, 197–227. [Google Scholar] [CrossRef]

- Natekin, A.; Knoll, A. Gradient boosting machines, a tutorial. Front. Neurorobot. 2013, 7, 21. [Google Scholar] [CrossRef] [PubMed]

- Geurts, P.; Ernst, D.; Wehenkel, L. Extremely randomized trees. Mach. Learn. 2006, 63, 3–42. [Google Scholar] [CrossRef]

- Lecun, Y.; Bengio, Y.; Hinton, G. Deep learning. Nature 2015, 521, 436–444. [Google Scholar] [CrossRef]

- Dobson, A.; Barnett, A. An Introduction to Generalized Linear Models, 4th ed.; Chapman and Hall/CRC: Boca Raton, FL, USA, 2018; p. 392. [Google Scholar] [CrossRef]

- Andersson, S.; Bathula, D.; Iliadis, S.; Walter, M.; Skalkidou, A. Predicting women with depressive symptoms postpartum with machine learning methods. Sci. Rep. 2021, 11, 7877. [Google Scholar] [CrossRef]

- Finegan, D.; Zhu, J.; Feng, X.; Keyser, M.; Ulmefors, M.; Li, W.; Bazant, M.; Cooper, S. The Application of Data-Driven Methods and Physics-Based Learning for Improving Battery Safety. Joule 2021, 5, 316–329. [Google Scholar] [CrossRef]

- Finegan, D.; Cooper, S. Battery Safety: Data-Driven Prediction of Failure. Joule 2019, 3, 2599–2601. [Google Scholar] [CrossRef]

- Attia, P.; Grover, A.; Jin, N.; Severson, K.; Markov, T.; Liao, Y.; Chen, M.; Cheong, B.; Perkins, N.; Yang, Z.; et al. Closed-loop optimization of fast-charging protocols for batteries with machine learning. Nature 2020, 578, 397–402. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Zhu, J.; Xia, Y.; Gorji, M.; Wierzbicki, T. Data-Driven Safety Envelope of Lithium-Ion Batteries for Electric Vehicles. Joule 2019, 3, 2703–2715. [Google Scholar] [CrossRef]

- Johnen, M.; Pitzen, S.; Kamps, U.; Kateri, M.; Dechent, P.; Sauer, D. Modeling long-term capacity degradation of lithium-ion batteries. J. Energy Storage 2021, 34, 102011. [Google Scholar] [CrossRef]

- Walker, W.; Darst, J.; Finegan, D.; Bayles, G.; Johnson, K.; Darcy, E.; Rickman, S. Decoupling of heat generated from ejected and non-ejected contents of 18650-format lithium-ion cells using statistical methods. J. Power Sources 2019, 415, 207–218. [Google Scholar] [CrossRef]

- Finegan, D.; Darst, J.; Walker, W.; Li, Q.; Yang, C.; Jervis, R.; Heenan, T.; Hack, J.; Thomas, J.; Rack, A.; et al. Modelling and experiments to identify high-risk failure scenarios for testing the safety of lithium-ion cells. J. Power Sources 2019, 417, 29–41. [Google Scholar] [CrossRef]

- Yin, A.; Tan, Z.; Tan, J. Life prediction of battery using a neural gaussian process with early discharge characteristics. Sensors 2021, 21, 1087. [Google Scholar] [CrossRef] [PubMed]

- Fei, Z.; Zhang, Z.; Yang, F.; Tsui, K.; Li, L. Early-stage lifetime prediction for lithium-ion batteries: A deep learning framework jointly considering machine-learned and handcrafted data features. J. Energy Storage 2022, 52, 104936. [Google Scholar] [CrossRef]

- Strange, C.; dos Reis, G. Prediction of future capacity and internal resistance of Li-ion cells from one cycle of input data. Energy AI 2021, 5, 100097. [Google Scholar] [CrossRef]

- Hsu, C.; Xiong, R.; Chen, N.; Li, J.; Tsou, N. Deep neural network battery life and voltage prediction by using data of one cycle only. Appl. Energy 2022, 306, 118134. [Google Scholar] [CrossRef]

- Alipour, M.; Tavallaey, S.; Andersson, A.; Brandell, D. Improved Battery Cycle Life Prediction Using a Hybrid Data-Driven Model Incorporating Linear Support Vector Regression and Gaussian. ChemPhysChem 2022, 23, e202100829. [Google Scholar] [CrossRef]

- Gong, D.; Gao, Y.; Kou, Y.; Wang, Y. Early prediction of cycle life for lithium-ion batteries based on evolutionary computation and machine learning. J. Energy Storage 2022, 51, 104376. [Google Scholar] [CrossRef]

- Afshari, S.; Cui, S.; Xu, X.; Liang, X. Remaining Useful Life Early Prediction of Batteries Based on the Differential Voltage and Differential Capacity Curves. IEEE Trans. Instrum. Meas. 2022, 71, 3117631. [Google Scholar] [CrossRef]

- Zhang, Y.; Peng, Z.; Guan, Y.; Wu, L. Prognostics of battery cycle life in the early-cycle stage based on hybrid model. Energy 2021, 221, 119901. [Google Scholar] [CrossRef]

- Yang, F.; Wang, D.; Xu, F.; Huang, Z.; Tsui, K. Lifespan prediction of lithium-ion batteries based on various extracted features and gradient boosting regression tree model. J. Power Sources 2020, 476, 228654. [Google Scholar] [CrossRef]

- Fei, Z.; Yang, F.; Tsui, K.; Li, L.; Zhang, Z. Early prediction of battery lifetime via a machine learning based framework. Energy 2021, 225, 120205. [Google Scholar] [CrossRef]

- Brandt, N.; Griem, L.; Herrmann, C.; Schoof, E.; Tosato, G.; Zhao, Y.; Zschumme, P.; Selzer, M. Kadi4Mat: A Research Data Infrastructure for Materials Science. Data Sci. J. 2021, 20, 8. [Google Scholar] [CrossRef]

- Stonebraker, M.; Rowe, L. The design of POSTGRES. ACM SIGMOD Record 1986, 15, 340–355. [Google Scholar] [CrossRef]

- LeDell, E.; Poirier, S. H2O AutoML: Scalable Automatic Machine Learning. In Proceedings of the 7th ICML Workshop on Automated Machine Learning (AutoML), Online, 18 July 2020. [Google Scholar]

- Kendall, M.G. A new measure of rank correlation. Biometrika 1938, 30, 81–93. [Google Scholar] [CrossRef]

- Spearman, C. The Proof and Measurement of Association between Two Things. Am. J. Psychol. 1904, 15, 72–101. [Google Scholar] [CrossRef]

- Akoglu, H. User’s guide to correlation coefficients. Turk. J. Emerg. Med. 2018, 18, 91–93. [Google Scholar] [CrossRef]

- Pedregosa, F.; Varoquaux, G.; Gramfort, A.; Michel, V.; Thirion, B.; Grisel, O.; Blondel, M.; Prettenhofer, P.; Weiss, R.; Dubourg, V.; et al. Scikit-learn: Machine Learning in Python. J. Mach. Learn. Res. 2011, 12, 2825–2830. [Google Scholar]

- Buitinck, L.; Louppe, G.; Blondel, M.; Pedregosa, F.; Mueller, A.; Grisel, O.; Niculae, V.; Prettenhofer, P.; Gramfort, A.; Grobler, J.; et al. API design for machine learning software: Experiences from the scikit-learn project. In Proceedings of the ECML PKDD Workshop: Languages for Data Mining and Machine, Prague, Czech Republic, 23–27 September 2013. [Google Scholar]

- Keil, P. Aging of Lithium-Ion Batteries in Electric Vehicles. Ph.D. Thesis, Technische Universität München, München, Germany, 2017. [Google Scholar]

- Jülich Supercomputing Centre. JURECA: Data Centric and Booster Modules implementing the Modular Supercomputing Architecture at Jülich Supercomputing Centre. J. Large-Scale Res. Facil. 2018, 7, A182. [Google Scholar] [CrossRef]

| Dataset | 1st: MAE (Cycles)/MAPE (%) | 2nd: MAE (Cycles)/MAPE (%) | 3rd: MAE (Cycles)/MAPE (%) |

|---|---|---|---|

| Control | 12.16/1.54 | 13.00/1.71 | 13.81/1.68 |

| New | 7.78/0.88 | 7.06/0.87 | 4.65/0.57 |

| Model | MAE (Cycles) | MAPE (%) |

|---|---|---|

| XRT | 1.49 | 0.19 |

| DRF | 2.15 | 0.30 |

| GBM | 3.61 | 0.49 |

| Ref. | Number of Cells Analyzed from the Database | Number of Input Cycles | ML Method | Lowest MAPE (%) |

|---|---|---|---|---|

| This work | 121 | 100 | Extremely randomized trees | 0.19 |

| [6] | 124 | 100 | Elastic net | 9.1 |

| [37] | 124 | 110 | Neural Gaussian process | 8.8 |

| [38] | 123 | 100 | Gaussian process regression | 8.2 |

| [39] | 124 | 100 | Convolutional neural networks | 8.6 |

| [40] | 95 | 100 | Deep neural network | 3.97 |

| [41] | Less than 124 * | 100 | Linear support vector regression and Gaussian process regression | 8.2 |

| [42] | 123 | 100 | Elastic net | 5.21 |

| [43] | 124 | 100 | Bayesian sparse learning | 8.4 |

| [44] | 123 | 80 | Random forest, artificial bee colony and general regression neural network | 6.3 |

| [45] | 124 | 250 | Gradient boosting regression tree | 7.0 |

| [46] | 124 | 100 | Support vector machine | 8.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Celik, B.; Sandt, R.; dos Santos, L.C.P.; Spatschek, R. Prediction of Battery Cycle Life Using Early-Cycle Data, Machine Learning and Data Management. Batteries 2022, 8, 266. https://doi.org/10.3390/batteries8120266

Celik B, Sandt R, dos Santos LCP, Spatschek R. Prediction of Battery Cycle Life Using Early-Cycle Data, Machine Learning and Data Management. Batteries. 2022; 8(12):266. https://doi.org/10.3390/batteries8120266

Chicago/Turabian StyleCelik, Belen, Roland Sandt, Lara Caroline Pereira dos Santos, and Robert Spatschek. 2022. "Prediction of Battery Cycle Life Using Early-Cycle Data, Machine Learning and Data Management" Batteries 8, no. 12: 266. https://doi.org/10.3390/batteries8120266

APA StyleCelik, B., Sandt, R., dos Santos, L. C. P., & Spatschek, R. (2022). Prediction of Battery Cycle Life Using Early-Cycle Data, Machine Learning and Data Management. Batteries, 8(12), 266. https://doi.org/10.3390/batteries8120266