When Tomatoes Hit the Winter: A Counterattack to Overwinter Production in Soft-Shell Solar Greenhouses in North China

Abstract

1. Introduction

2. Materials and Methods

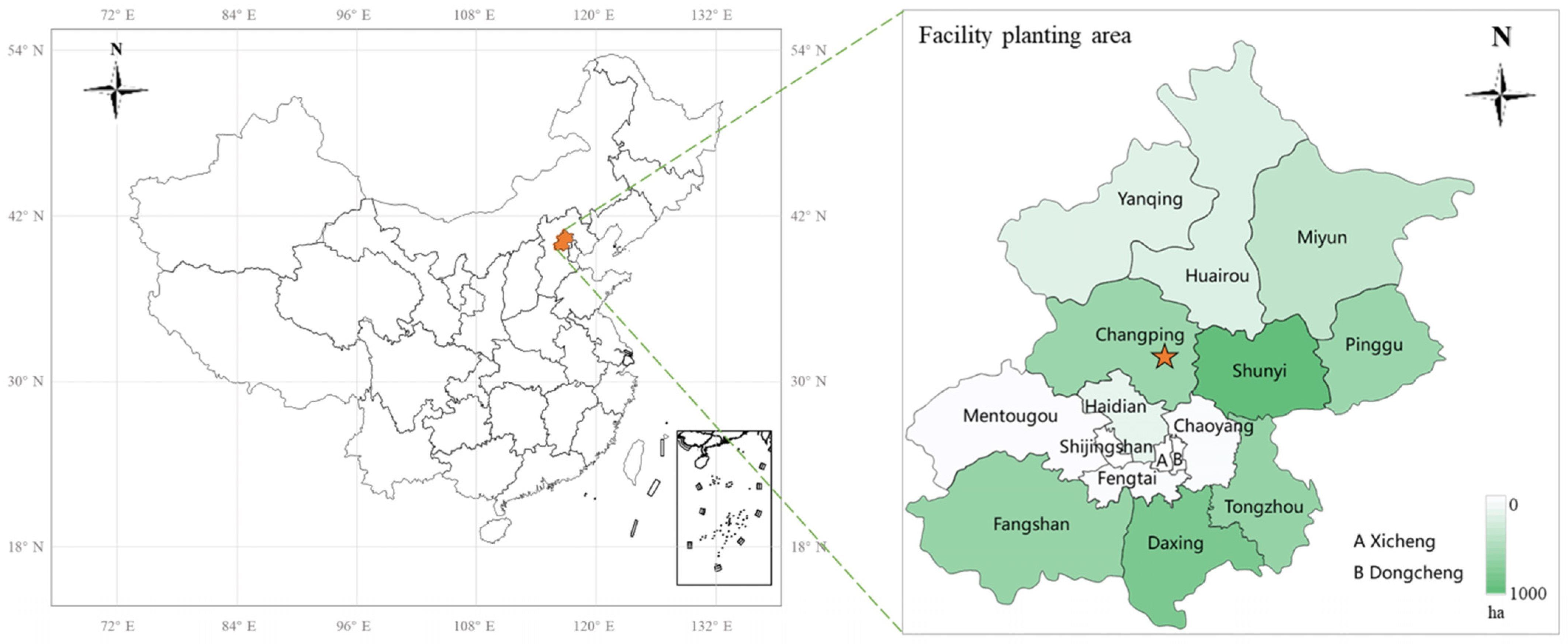

2.1. Study Area

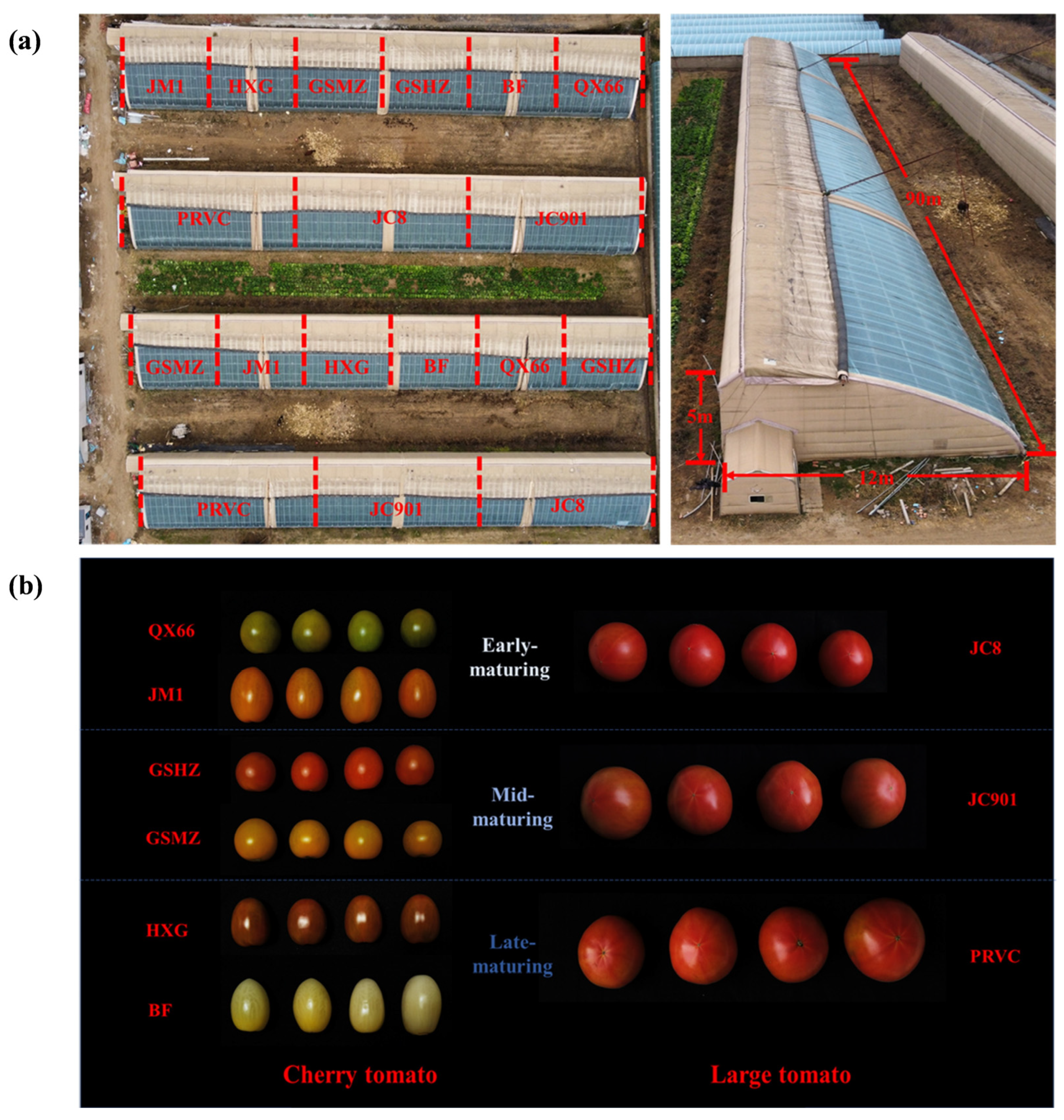

2.2. Study Design and Materials

2.3. Tomato Fruit Yield Parameters

2.4. Tomato Fruit Quality

2.5. Data Sources

2.6. Data Analysis

3. Results

3.1. Soft-Shell Solar Greenhouse Environmental Factors

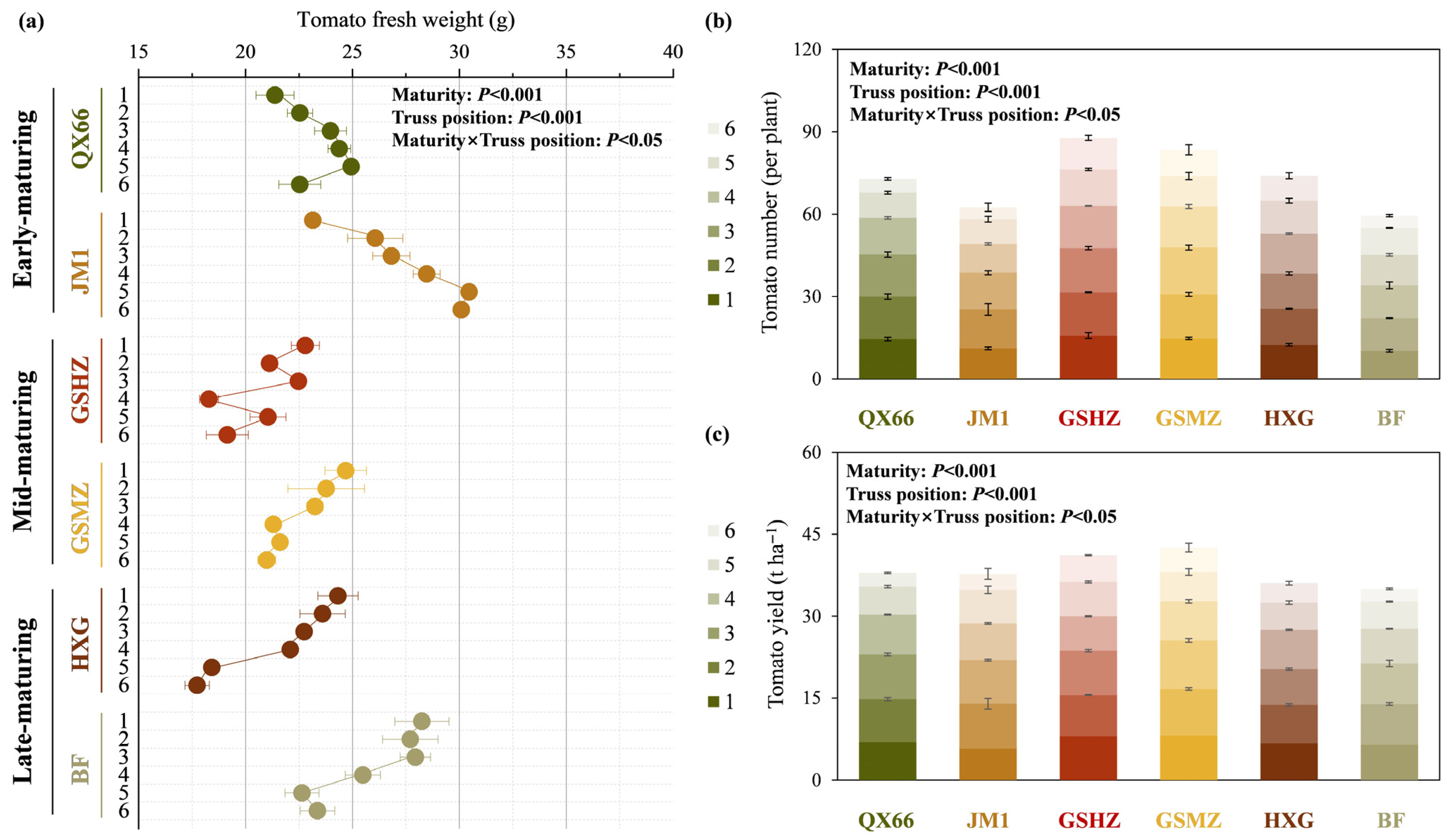

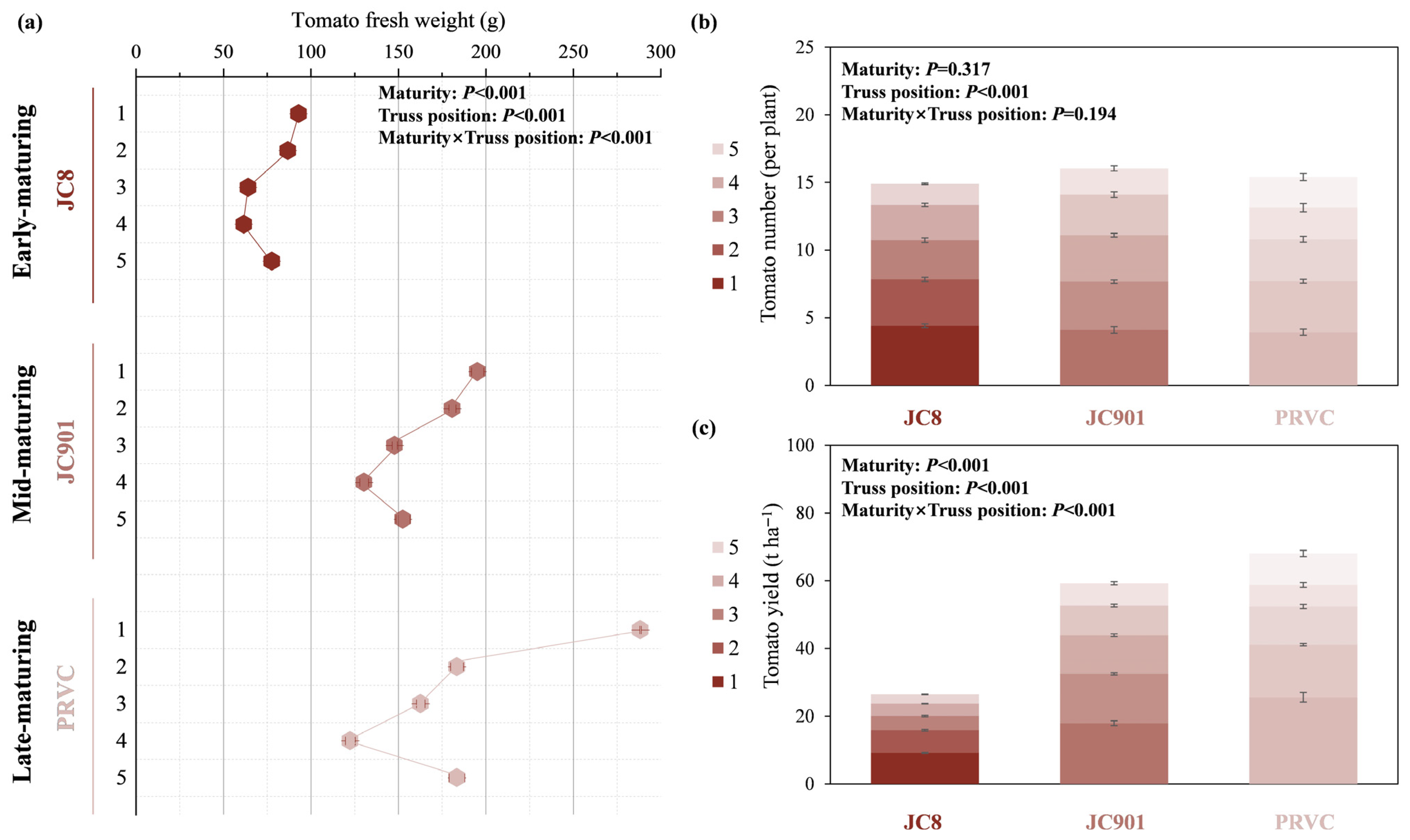

3.2. Cherry and Large Tomato Yield Parameters

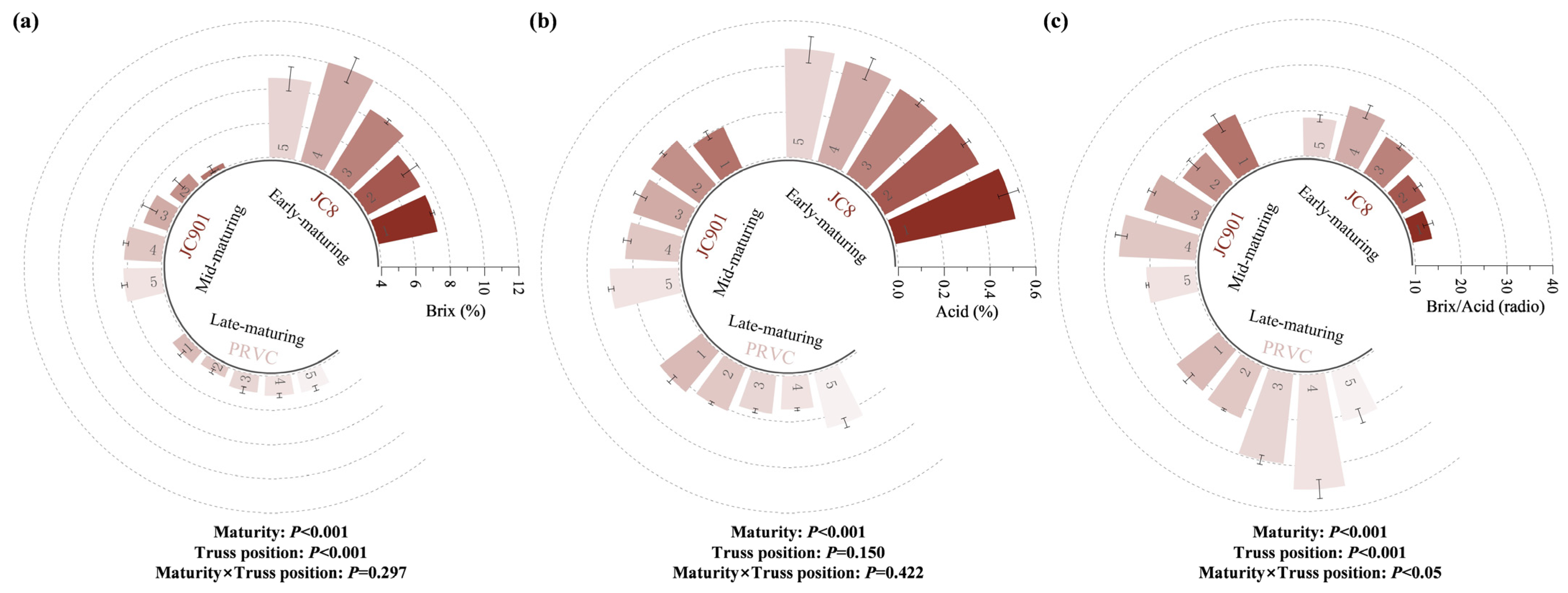

3.3. Cherry and Large Tomato Fruit Quality

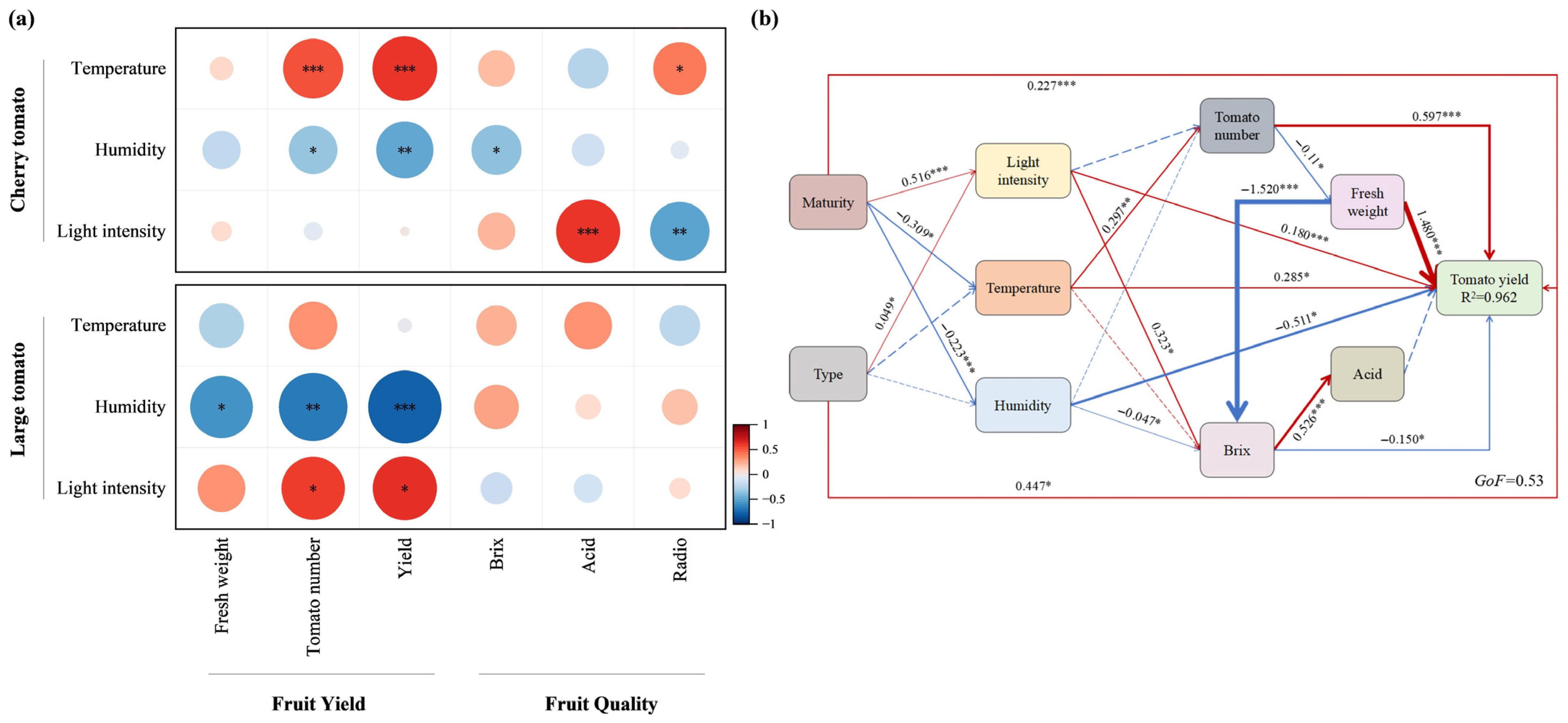

3.4. Impact of Soft-Shell Solar Greenhouse Environment on Tomato Production

3.5. Economic Benefit

4. Discussion

4.1. Analysis of Environmental Regulation Efficiency and Ecological Benefits of Soft-Shell Solar Greenhouses

4.2. Yield and Quality Performance of Tomato Varieties Under Environmental Regulation

4.3. Innovation and Practical Challenges of Production–Market Synergy Models

4.4. Limitations and Exploration of Sustainable Development Pathways

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- FAO. FAOSTAT Database 2023. Available online: http://www.fao.org/statistics/en (accessed on 1 March 2025).

- World Processing Tomato Council. Tomato News 2021. Available online: http://www.tomatonews.com/en/wptc_3_411002.html (accessed on 1 March 2025).

- Cammarano, D.; Jamshidi, S.; Hoogenboom, G.; Alex, C.R.; Niyogi, D.; Ronga, D. Processing tomato production is expected to decrease by 2050 due to the projected increase in temperature. Nat. Food 2022, 3, 437–444. [Google Scholar] [CrossRef] [PubMed]

- Yu, J.Q.; Zhou, J. Progress in protected vegetable production and research during China’s 12th. China Veg. 2016, 9, 18–30. [Google Scholar] [CrossRef]

- Li, J.G.; Liu, H.B.; Wang, H.Y.; Luo, J.F.; Zhang, X.J.; Liu, Z.H. Managing irrigation and fertilization for the sustainable cultivation of greenhouse vegetables. Agric. Water Manag. 2018, 210, 354–363. [Google Scholar] [CrossRef]

- Li, Y.; Xue, X.; Xu, F.; Guo, W.; Duan, M.; Lin, S. Negative-pressure irrigation improves water and fertilizer use efficiencies and fruit yield of greenhouse tomato on the North China Plain. Irrig. Drain. 2021, 70, 1027–1038. [Google Scholar] [CrossRef]

- Liu, H.; Shao, M.; Yang, L. Photosynthesis Characteristics of Tomato Plants and Its’ Responses to Microclimate in New Solar Greenhouse in North China. Horticulturae 2023, 9, 197. [Google Scholar] [CrossRef]

- Niu, Y.; Wang, X.J.; Chen, X.; Yan, Y.; Wang, J.S. Current situation, problems and countermeasures of tomato industry development in China and achievements of tomato industry development in Ningxia. Heilongjiang Agric. Sci. 2022, 12, 70–74. [Google Scholar]

- Wang, L.; Yu, X.; Guo, B.; Li, Q.; Lai, K.; Wang, X. Fruit rot on tomatoes caused by Talaromyces stipitatus newly reported in China. Crop Prot. 2024, 181, 106698. [Google Scholar] [CrossRef]

- Li, M.; Chen, S.; Liu, F. A risk management system for meteorological disasters of solar greenhouse vegetables. Precis. Agric. 2017, 18, 997–1010. [Google Scholar] [CrossRef]

- IPCC. Climate Change 2023 Synthesis Report. 2023. Available online: https://www.ipcc.ch/report/sixth-assessment-report-cycle/ (accessed on 5 March 2025).

- Ballesta, M.; Egea, I.; Estrada, Y.; Morales, M.B.; Egea-Fernández, J.M.; Bolarín, M.C. Interest of traditional tomato cultivars adapted to the Mediterranean environmental constraints for their improvement of fruit quality under high temperatures and water scarcity conditions. Acta Hortic. 2023, 1372, 43–50. [Google Scholar] [CrossRef]

- U.S. Department of Agriculture (USDA). U.S. Agricultural Trade Data. 2023. Available online: https://www.ers.usda.gov/topics/international-markets-u-s-trade/u-s-agricultural-trade/data/ (accessed on 6 March 2025).

- Fu, D.; Ding, Y. The study of changing characteristics of the winter temperature and extreme cold events in China over the past six decades. Int. J. Climatol. 2021, 41, 2480–2494. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, Z.; Xiao, M.; Chao, J.; Dai, Y.; Liu, G. Effects of organic mulching on moisture and temperature of soil in greenhouse production of tomato under unheated greenhouse cultivation in the cold zone of China. Food Sci. Nutr. 2023, 11, 4829–4842. [Google Scholar] [CrossRef] [PubMed]

- Chu, X.L.; Zheng, L.X.; Ye, G.S. Comparison of greenhouse gas emissions between open field and facility tomato production in China. J. Agro-Environ. Sci. 2023, 42, 1870–1881. [Google Scholar]

- Doddrell, N.H.; Lawson, T.; Raines, C.A.; Wagstaff, C.; Simkin, A.J. Feeding the world: Impacts of elevated [CO₂] on nutrient content of greenhouse grown fruit crops and options for future yield gains. Hortic. Res. 2023, 10, uhad026. [Google Scholar] [CrossRef]

- NBS. China Statistical Yearbook; China Statistical Press: Beijing, China, 2023. Available online: https://www.stats.gov.cn/sj/ndsj/2023/indexch.htm (accessed on 10 March 2025).

- Jiang, Z.; Jing, G.; He, M. Development Status, Problems and Countermeasures of Facility Agriculture in Beijing. In Proceedings of the 2016 International Conference on Material, Energy and Environment Engineering (ICM3E 2016), Beijing, China, 1–5 October 2016; pp. 551–556. [Google Scholar]

- Wang, Y.; Wang, H.R. Sustainable use of water resources in agriculture in Beijing: Problems and countermeasures. Water Policy 2005, 7, 345–357. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, Y.; Wang, K.; Tian, J.; Chen, Y.; Zou, G. Pollution Characteristics and Potential Sources of Microplastics in Facility Agricultural Soil in Beijing. Asian J. Ecotoxicol. 2022, 17, 333–344. [Google Scholar] [CrossRef]

- Xie, Y.L.; Qi, C.J. Supply and Demand Adaptation of “Vegetable Basket” Products: Mechanism, Effect and Governance Path. Econ. Probl. Agric. 2021, 42, 55–68. [Google Scholar]

- Beijing Municipal People’s Government. Beijing 14th Five-Year Rural Revitalization Plan. 2021. Available online: https://www.gov.cn/xinwen/2021-08/12/content_5630961.htm (accessed on 10 March 2025).

- Li, Y.D.; Miao, T.; Zhu, C.; Ji, J.W. The design and implementation of intelligent monitoring system of the northern greenhouse. J. Agric. Sci. Technol. 2016, 18, 94–101. [Google Scholar] [CrossRef]

- Tian, D.; Li, Y.; Zhao, S.; Wu, Q.; Ma, C.; Song, W. An Analysis of the Influence of Construct Parameters on the Solar Radiation Input in an Insulated Plastic Greenhouse. Agronomy 2024, 14, 510. [Google Scholar] [CrossRef]

- Hou, Y.; Li, A.; Li, Y.; Jin, D.C.; Tian, Y.; Zhang, D.; Wu, D.M.; Zhang, L.H.; Lei, W.J. Analysis of microclimate characteristics in solar greenhouses under natural ventilation. Build. Simul. 2021, 14, 1811–1821. [Google Scholar] [CrossRef]

- Luo, G.L.; Cheng, R.F.; Zhang, Y.; Fang, H.; Li, D.; Zhang, J.F.; Song, G.X. Sunlight greenhouse active heat storage system optimization. Trans. Chin. Soc. Agric. Eng. 2020, 36, 8. [Google Scholar] [CrossRef]

- Li, H.; Lu, J.R.; He, X.Y.; Zong, C.J.; Song, W.T.; Zhao, S.M. Effect of installation factors on the environment uniformity of multifunctional fan-coil unit system in Chinese solar greenhouse. Case Stud. Therm. Eng. 2024, 60, 104818. [Google Scholar] [CrossRef]

- He, M.; Wan, X.C.; Liu, H.L.; Xia, T.Y.; Gong, Z.R.; Li, Y.M.; Liu, X.G.; Li, T.L. Theory and application of sustainable energy-efficient solar greenhouse in China. Energy Convers. Manag. 2025, 352, 119394. [Google Scholar] [CrossRef]

- Wang, Y.F.; Lei, X.H.; LI, W.; Niu, M.L.; Wang, B.H.; Wang, F.D. Application Status and Development Suggestions for Greenhouse with Flexible Thermal Insulation Wall in Beijing. China Veg. 2023, 1, 11–16. [Google Scholar] [CrossRef]

- Li, L.B.; Wang, Z.R.; Zhang, D.; Zhou, Z.C.; Li, X.G.; Qu, W.M. Research on winter temperature field distribution of a new flexible wall solar greenhouse. Agric. Sci. Eng. China 2023, 35, 36–41. [Google Scholar] [CrossRef]

- Abdelghany, A.E.; Dou, Z.Y.; Alashram, M.G.; Eltohamy, K.M.; Elrys, A.S.; Liu, X.Q.; Wu, Y.; Cheng, M.H.; Fan, J.L.; Zhang, F.C. The joint application of biochar and nitrogen enhances fruit yield, quality and water-nitrogen productivity of water-stressed greenhouse tomato under drip fertigation. Agric. Water Manag. 2023, 290, 108605. [Google Scholar] [CrossRef]

- Ruizendaal, J.; Polder, G.; Kootstra, G. Automated and non-destructive estimation of soluble solid content of tomatoes on the plant under variable light conditions. Biosyst. Eng. 2024, 242, 80–90. [Google Scholar] [CrossRef]

- Rivelli, A.R.; Castronuovo, D.; Gatta, B.L.; Liberatore, M.T.; Libutti, A. Qualitative Characteristics and Functional Properties of Cherry Tomato under Soilless Culture Depending on Rootstock Variety, Harvesting Time and Bunch Portion. Foods 2024, 13, 1450. [Google Scholar] [CrossRef]

- Liu, H.; Tian, Y.; Zhao, H.; Liu, S.; Zhu, N.; Wang, Y.; Li, W.; Sun, D.; Wang, T.; Li, L. Decoding the Secrets of Agricultural Light, Heat, and Water Resources in Beijing Under Climate Change: Spatio-Temporal Variations on a Small Scale and Future Prospects. Agriculture 2025, 15, 371. [Google Scholar] [CrossRef]

- Dai, Y.T.; Hu, B.; Feng, B.J.; Li, M.B.; Jia, D.Z.; Yang, M.Y.; Wang, T.C. High yield cultivation technology of high-quality tomato in the long winter season in solar greenhouse. China Veg. 2025, 2, 172–175. [Google Scholar] [CrossRef]

- Lee, S.K.; Chiang, M.S.; Hseu, Z.Y.; Kuo, C.H.; Liu, C.T. A photosynthetic bacterial inoculant exerts beneficial effects on the yield and quality of tomato and affects bacterial community structure in an organic field. Front. Microbiol. 2022, 13, 959080. [Google Scholar] [CrossRef]

- Dong, S.C.; Zhang, J.W.; Ling, J.Y.; Xie, Z.X.; Song, L.X.; Wang, Y.L.; Zhao, L.P.; Zhao, T.M. Comparative analysis of physical traits, mineral compositions, antioxidant contents, and metabolite profiles in five cherry tomato cultivars. Food Res. Int. 2024, 194, 114897. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.Y.; Zhu, Y.B.; Guo, Y.B.; Li, P.; Cheng, J.Y.; Zhao, S.M.; Sun, G.Z.; Wei, M. Distribution characteristics and improvement measures of light environment of flexible thermal insulation solar greenhouse. J. China Agric. Univ. 2025, 30, 197–205. [Google Scholar]

- Matsuda, R.; Ozawa, N.; Fujiwara, K. Leaf photosynthesis, plant growth, and carbohydrate accumulation of tomato under different photoperiods and diurnal temperature differences. Sci. Hortic. 2014, 170, 150–158. [Google Scholar] [CrossRef]

- Ruiz-Nieves, J.M.; Ayala-Garay, O.J.; Serra, V.; Dumont, D.; Vercambre, G.; Génard, M.; Gautier, H. The effects of diurnal temperature rise on tomato fruit quality. Can the management of the greenhouse climate mitigate such effects? Sci. Hortic. 2021, 278, 109836. [Google Scholar] [CrossRef]

- Cao, K.; Xu, H.J.; Zhang, R.; Xu, D.W.; Yan, L.L.; Sun, Y.C.; Xia, L.R.; Zhao, J.T.; Zou, Z.R.; Bao, E.C. Renewable and sustainable strategies for improving the thermal environment of Chinese solar greenhouses. Energy Build. 2019, 202, 109414. [Google Scholar] [CrossRef]

- Argento, S.; Garcia, G.; Treccarichi, S. Sustainable and Low-Input Techniques in Mediterranean Greenhouse Vegetable Production. Horticulturae 2024, 10, 997. [Google Scholar] [CrossRef]

- Liu, R.; Shi, Y.; Bournet, P.-E.; Liu, K. Development of a Machine Learning Natural Ventilation Rate Model by Studying the Wind Field Inside and Around Multiple-Row Chinese Solar Greenhouses. Horticulturae 2024, 10, 1226. [Google Scholar] [CrossRef]

- Chen, F.C.; Zhang, Z.S.; Omer, A.A.A.; Zhang, F.X.; Fan, L.L.; Ma, H.Y.; Lu, H.; Li, M.; Zhang, X.Y.; Liu, W. Photon management heightens the energy use efficiency of greenhouses through the integration of photovoltaic systems and supplemental lighting. Renew. Energy 2025, 247, 123009. [Google Scholar] [CrossRef]

- Guo, J.J.; Zhang, B.B.; Lin, L.J.; Xu, Y.D.; Zhou, P.; Luo, S.W.; Zhuo, Y.H.; Ji, J.Y.; Luo, Z.J.; Hassan, S.G. Multi-model fusion method for predicting CO2 concentration in greenhouse tomatoes. Comput. Electron. Agric. 2024, 227, 2. [Google Scholar] [CrossRef]

- Zhu, Z.; Miller, S.A. Greenhouse gas emissions of tomato production and supply: A systematic review. Resources. Conserv. Recycl. 2025, 218, 108236. [Google Scholar] [CrossRef]

- Shamshiri, R.R.; Jones, J.W.; Thorp, K.R.; Ahmad, D.; Man, H.C.; Taheri, S. Review of optimum temperature, humidity, and vapour pressure deficit for microclimate evaluation and control in greenhouse cultivation of tomato: A review. Int. Agrophys. 2018, 32, 287–302. [Google Scholar] [CrossRef]

- Mao, Q.J.; Peng, Y.; Ji, C.C.; Li, H.W.; Li, T. Effect of external shading on the temperature distribution performance of glass greenhouse in Wuhan region. Case Stud. Therm. Eng. 2024, 61, 104879. [Google Scholar] [CrossRef]

- Lin, Y.; Jen, L. The impact of consumer heterogeneity in the product life cycle on the diffusion patterns of user reviews and sales. J. Retail. Consum. Serv. 2024, 76, 103558. [Google Scholar] [CrossRef]

- Li, J.; Liu, F.H.; Wu, Y.; Tang, Z.Q.; Zhang, D.; Lyu, J.; Khan, K.S.; Xiao, X.M.; Yu, J.H. Evaluation of nutritional composition, biochemical, and quality attributes of different varieties of tomato (Solanum lycopersicum L.). J. Food Compos. Anal. 2024, 132, 106384. [Google Scholar] [CrossRef]

- Saavedra, F.M.; Villanueva, G.; Gramazio, P.; Vilanova, S.; Mauceri, A.; Abenavoli, M.R.; Sunseri, F.; Prohens, J.; Plazas, M. Nitrogen use efficiency, growth and physiological parameters in different tomato genotypes under high and low N fertilisation conditions. Plant Physiol. Biochem. 2024, 208, 108447. [Google Scholar] [CrossRef]

- Xia, J.; Huang, W.T.; Wang, X.; Zhu, Z.Q.; Zhang, M.J.; Zhang, X.S. Flexible sensing technology for fruit quality control in the cold chain: Characterization, application, and improvement. Food Control 2023, 154, 109976. [Google Scholar] [CrossRef]

- Slapø, H.; Bugge, A.B.; Sandaker, I.; Lekhal, S. Can in-store interventions reduce the socioeconomic gap in fruit and vegetable purchases in grocery stores? A descriptive study of volume sales from 2012 to 2020 in Norway’s largest grocery store chain. Appetite 2022, 176, 106100. [Google Scholar] [CrossRef]

- Peña, A.; Rovira-Val, M.R.; Mendoza, J.M.F. Life cycle cost analysis of tomato production in innovative urban agriculture systems. J. Clean. Prod. 2022, 367, 133037. [Google Scholar] [CrossRef]

| Type | Maturing | Variety | Transplanting Date | Tomato Ripening Period (DAT) | Growth Period (DAT) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | |||||

| Cherry tomato | Early- | QX66 | 31 August 2024 | 67 | 81 | 96 | 113 | 131 | 152 | 152 |

| JM1 | 69 | 82 | 98 | 116 | 135 | 155 | 155 | |||

| Mid- | GSHZ | 71 | 85 | 100 | 118 | 138 | 161 | 161 | ||

| GSMZ | 72 | 86 | 102 | 121 | 141 | 164 | 164 | |||

| Late- | HXG | 74 | 88 | 104 | 124 | 145 | 169 | 169 | ||

| BF | 74 | 89 | 106 | 127 | 149 | 174 | 174 | |||

| Large tomato | Early- | JC8 | 83 | 101 | 124 | 150 | 162 | 162 | ||

| Mid- | JC901 | 88 | 108 | 133 | 161 | 174 | 174 | |||

| Late- | PRVC | 91 | 114 | 140 | 171 | 184 | 184 | |||

| Cherry Tomato | Large Tomato | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| QX66 | JM1 | GSHZ | GSMZ | HXG | BF | JC8 | JC901 | PRVC | ||

| Seedling Stage | Seed | 0.379 | 0.379 | 0.253 | 0.253 | 0.379 | 0.379 | 0.205 | 0.190 | 0.158 |

| Substrate | 0.051 | 0.051 | 0.051 | 0.051 | 0.051 | 0.051 | 0.051 | 0.051 | 0.051 | |

| Plug Tray | 0.023 | 0.023 | 0.023 | 0.023 | 0.023 | 0.023 | 0.023 | 0.023 | 0.023 | |

| Pesticide Soaking for Seeds | 0.003 | 0.003 | 0.003 | 0.003 | 0.003 | 0.003 | 0.003 | 0.003 | 0.003 | |

| Before Planting | Sulfur Fumigation for Shed | 0.011 | 0.011 | 0.011 | 0.011 | 0.011 | 0.011 | 0.011 | 0.011 | 0.011 |

| Organic Fertilizer | 0.211 | 0.211 | 0.211 | 0.211 | 0.211 | 0.211 | 0.211 | 0.211 | 0.211 | |

| Soybean Meal | 0.042 | 0.042 | 0.042 | 0.042 | 0.042 | 0.042 | 0.042 | 0.042 | 0.042 | |

| Microbial Bactericide | 0.042 | 0.042 | 0.042 | 0.042 | 0.042 | 0.042 | 0.042 | 0.042 | 0.042 | |

| Mechanical Land Preparation | 0.032 | 0.032 | 0.032 | 0.032 | 0.032 | 0.032 | 0.032 | 0.032 | 0.032 | |

| After Planting | Potassium Fertilizer | 0.253 | 0.253 | 0.253 | 0.253 | 0.253 | 0.253 | 0.211 | 0.211 | 0.211 |

| Root-promoting Fertilizer | 0.063 | 0.063 | 0.063 | 0.063 | 0.063 | 0.063 | 0.053 | 0.053 | 0.053 | |

| Foliar Fertilizer | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.021 | 0.021 | 0.021 | |

| Insulation Quilt Maintenance | 0.032 | 0.032 | 0.032 | 0.032 | 0.032 | 0.032 | 0.032 | 0.032 | 0.032 | |

| Male Bee | 0.063 | 0.063 | 0.063 | 0.063 | 0.063 | 0.063 | 0.063 | 0.063 | 0.063 | |

| Insecticide | 0.101 | 0.101 | 0.101 | 0.101 | 0.101 | 0.101 | 0.084 | 0.084 | 0.084 | |

| Fungicide | 0.126 | 0.126 | 0.126 | 0.126 | 0.126 | 0.126 | 0.105 | 0.105 | 0.105 | |

| Yellow Sticky Board | 0.032 | 0.032 | 0.032 | 0.032 | 0.032 | 0.032 | 0.032 | 0.032 | 0.032 | |

| Harvesting | Packaging Materials | 0.666 | 0.662 | 0.722 | 0.747 | 0.633 | 0.614 | 0.518 | 1.081 | 1.242 |

| Others | Greenhouse Expense | 0.822 | 0.831 | 0.866 | 0.883 | 0.909 | 0.952 | 0.770 | 0.831 | 0.892 |

| Land Rent | 0.219 | 0.222 | 0.231 | 0.235 | 0.242 | 0.254 | 0.205 | 0.222 | 0.238 | |

| Water Fee | 0.092 | 0.093 | 0.098 | 0.100 | 0.103 | 0.109 | 0.086 | 0.093 | 0.102 | |

| Electricity Fee | 0.092 | 0.093 | 0.097 | 0.099 | 0.103 | 0.108 | 0.086 | 0.093 | 0.101 | |

| Labor Cost | 0.750 | 0.758 | 0.790 | 0.806 | 0.829 | 0.869 | 0.703 | 0.758 | 0.814 | |

| Total Cost of Production | 41.295 | 41.470 | 41.645 | 42.312 | 43.070 | 43.939 | 35.874 | 42.814 | 45.596 | |

| Gross Tomato Value | 207.742 | 206.668 | 225.333 | 233.059 | 197.375 | 191.704 | 169.116 | 282.807 | 349.625 | |

| Net Income | 166.447 | 165.198 | 183.688 | 190.747 | 154.305 | 147.765 | 133.242 | 239.993 | 304.028 | |

| Daily Net Income | 1.074 | 1.046 | 1.120 | 1.142 | 0.897 | 0.835 | 0.808 | 1.356 | 1.626 | |

| Fruit Type | Sales Form | Selling Price (USD kg−1) | Sales Percentage (%) |

|---|---|---|---|

| Cherry Tomato | Gift Box | 8.425 | 10 |

| Farm Park Picking | 8.425 | 20 | |

| Vegetable Box | 5.617 | 20 | |

| Group Purchase | 4.212 | 30 | |

| Retail | 2.808 | 20 | |

| Large Tomato | Gift Box | 8.425 | 10 |

| Farm Park Picking | 7.021 | 20 | |

| Vegetable Box | 5.617 | 20 | |

| Group Purchase | 2.106 | 20 | |

| Retail | 1.685 | 30 | |

| JC8 | Gift Box | 8.425 | 50 |

| Farm Park Picking | 7.021 | 10 | |

| Vegetable Box | 5.617 | 20 | |

| Group Purchase | 2.808 | 10 | |

| Retail | 1.685 | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Zhao, H.; Liu, S.; Tian, Y.; Li, W.; Wang, B.; Hu, X.; Sun, D.; Wang, T.; Wu, S.; et al. When Tomatoes Hit the Winter: A Counterattack to Overwinter Production in Soft-Shell Solar Greenhouses in North China. Horticulturae 2025, 11, 436. https://doi.org/10.3390/horticulturae11040436

Liu H, Zhao H, Liu S, Tian Y, Li W, Wang B, Hu X, Sun D, Wang T, Wu S, et al. When Tomatoes Hit the Winter: A Counterattack to Overwinter Production in Soft-Shell Solar Greenhouses in North China. Horticulturae. 2025; 11(4):436. https://doi.org/10.3390/horticulturae11040436

Chicago/Turabian StyleLiu, Hongrun, He Zhao, Song Liu, Yanan Tian, Wei Li, Binghua Wang, Xiaoyi Hu, Dan Sun, Tianqun Wang, Shangjun Wu, and et al. 2025. "When Tomatoes Hit the Winter: A Counterattack to Overwinter Production in Soft-Shell Solar Greenhouses in North China" Horticulturae 11, no. 4: 436. https://doi.org/10.3390/horticulturae11040436

APA StyleLiu, H., Zhao, H., Liu, S., Tian, Y., Li, W., Wang, B., Hu, X., Sun, D., Wang, T., Wu, S., Wang, F., Zhu, N., Tao, Y., & Lei, X. (2025). When Tomatoes Hit the Winter: A Counterattack to Overwinter Production in Soft-Shell Solar Greenhouses in North China. Horticulturae, 11(4), 436. https://doi.org/10.3390/horticulturae11040436