Abstract

The use of biochar in soilless media is becoming more common in greenhouse production. This study was conducted to evaluate Eastern red cedar biochar as a soilless-media supplement for the growth of geranium (Pelargonium graveolens L.) and petunia (Petunia sp. J.) as potted plants in greenhousese. Eastern red cedar biomass was produced at three different temperature ranges 300–350 °C, 400–450 °C, and 500–550 °C and applied at 15%, 30%, 45%, and 60% v/v to a soilless media plus a control. Additionally, Eastern red cedar (ERC) bark was also applied at 15%, 30%, 45%, and 60% v/v to a soilless media. The growth characteristics of the plants along with the physical and nutrient properties of the growth media were recorded. For physical properties, 100% soilless media had the greatest bulk density, 60% biochar at 400–450 °C showed the greatest total porosity, and 60% ERC bark showed the greatest air porosity. For geranium, 15% biochar at 500–550 °C showed the greatest height, water use efficiency, and shoot dry weight, while 15% biochar at 300–350 °C showed the greatest width. The greatest number of flowers was at 45% biochar at 500–550 °C. For petunia, 15% biochar at 300–350 °C showed the greatest height, and 15% biochar at 500–550 °C showed the greatest width. The greatest number of flowers and flower diameter was achieved with 100% soilless media. The 15% biochar at 500–550 °C had the greatest shoot dry weight and water use efficiency, and 60% biochar at 400–450 °C had the greatest root dry weight. Biochar treatment outperforms the ERC bark treatment for both species. Within biochar treatment, 15% biochar outperforms dry biomass, while for flowering, 100% soilless media performs best for petunia, and biochar performs best at less than 45% for geranium.

1. Introduction

Approximately 11 million megagrams (Mg) of peat moss per year is used in soilless media for greenhouse production [1]. Peat moss is primarily a decomposed sphagnum moss and other plant materials and has been considered a good choice as a component of growth media due to its high-water holding capacity (WHC), low density, and high air capacity [2]. While undisturbed peatland acts as a carbon (C) sink, when disturbed, it decomposes quickly, producing greenhouse gases (GHGs) [3]. The overharvesting of peatlands introduces environmental concerns like ecosystem disturbance and GHGs; therefore, peatland protection has become more significant in recent years [4]. Due to the negative impact of peatland harvests, the search for peat moss alternatives has intensified in recent years [5]. Biochar has gained popularity as a potential supplement for peat moss and other substrates like perlite, vermiculite, barks, and fiber replacement [6].

Biochar is a C-rich compound produced by heating biomass at high temperatures in the absence of oxygen [7]. Notable properties like high porosity, high surface area, low density, high WHC, and cation exchange capacity (CEC) make the biochar a suitable peatmoss supplement [1,6]. Moreover, as the stable form of C produced from biomass, biochar aids in C sequestration, reducing the atmospheric carbon dioxide concentration [8]. Additionally, Crutchfield et al. [9] emphasized that increasing the biochar rate reduces the rate of leaching of nitrate (NO3−), ammonium (NH4+), and ortho-phosphate (PO43−) ions from both planted and unplanted pots. Some studies have reported an increase in phosphorus (P) content in soil with biochar application [10,11]. Conversely, others reported a decrease in water-soluble P, which might be due to the formation of stable P [12]. Aside from its impact on nutrient content, biochar’s alkalinity helps to improve the pH of the growing media [13]. Various feedstocks and temperatures have been used to produce biochar and applied to different soilless media mixes, and the results have been mixed [14]. Compared to high temperatures, biochar produced at low temperatures holds onto more chemicals and volatile matter (VM) and less condensed C [15]. Nutrient-rich feedstock high in potassium produces saline biochar, whereas nutrient-deficient feedstock produces alkaline and non-saline biochar [16].

Biochar application showed negative, positive, and no effects on plant performance based on biochar type and plant selected for growth [17]. Petunia (Petunia sp. J.) and geranium (Pelargonium graveolens L.) were used as our plant materials because of their popularity as garden flowers and common bedding plants suitable for spring cultivation. Petunia belongs to the Solanaceae family, whose generic name is derived from the word ‘petum’ or ‘betum’ (the native name of tobacco) due to their similarity [18]. Geranium belongs to the family Geraniaceae and is used for the extraction of essential oils and to produce perfume [19]. Petunia and geranium plants showed greater shoot dry weight and number of flowers in the treatment of commercial pine (Pinus monticola) biochar (Biochar Solutions Inc., Carbondale, CO, USA) less than 12% as a peat moss substitute [20]. Petunia showed increased shoot dry weight (up to 37%) and flowering (43%), while geranium produced up to 108% more flowers using a ratio of 86:10:04 (peat-based substrate/vermiculite/pine biochar) [21]. A 10% rice (Oryza sativa L.)-hull biochar showed a greater shoot dry weight of geranium compared to 30% [22]. From 25% to 75% biochar, the lavender (Lavandula angustifolia L.) plant’s height, number of leaves, and shoot dry weight decreased, possibly as a result of high pH and low water and nutrient retention [23]. Despite a reduction in the dry weight and growth index, the application of biochar up to 80% did not affect the visual rating or growth index of poinsettia plants (Euphorbia pulcherrima Willd.) [24]. Plants grown with a lower rate of biochar grew better, which could be due to lower bulk density, electrical conductivity (EC), and sodium (Na), and higher P concentrations [25].

In recent years, Eastern red cedar (ERC) (Juniperus virginiana L.) has been considered invasive in the Great Plains as the trees grow at a high rate dislodging native grasses [26]. The proliferation growth of ERC has led to many adverse impacts, including heightened soil water usage, potentially leading to future water shortage, habitat loss of native plants and birds, and diminished forage production [27,28]. According to previous research, biochar produced from Eastern red cedar wood flakes has high porosity, allowing it to mitigate undesirable odors [29] and making it suitable for soilless-media supplementation. However, plant responses can vary depending on the biochar source and application rate, emphasizing the importance of analyzing the suitability of biochar as a peat moss supplement [5]. Therefore, the objective was to evaluate the use of biochar produced by the pyrolysis process of ERC under different temperatures in soilless media for the production of petunia and geranium plants in the greenhouses.

2. Methods and Materials

2.1. Preparation of Biochar

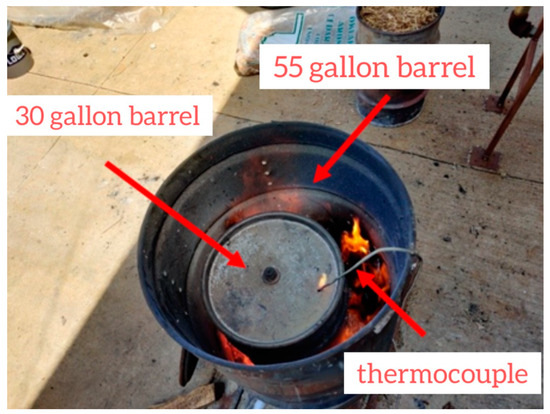

Biochar was prepared from ERC bark (Custom Wood Fibers & Cedar ERC bark, LLC., Stillwater, OK, USA) through the pyrolysis process [30]. To prepare the biochar, a double barrel system was used with a 30-gal (0.114 m3) barrel as the inner (carbonization) barrel with a lid and a 55-gal (0.208 m3) barrel as the outer (burning) barrel [31] (Figure 1). Thirty-two small holes (1.27 cm) were drilled around the large barrel (spaced 10 cm vertically and 50 cm horizontally) to facilitate the airflow, with one larger 7 cm diameter hole so an aluminum pipe could be inserted to provide air from a fan (motor horsepower 3 hp, high pressure blower, the radial base of 0.3 m in wheel diameter, 230/460 voltage) (Chicago Blower Corporation, Glendale Heights, Chicago, IL, USA). Two barrels were connected to the fan through a three-way pipe system. Likewise, eight equally spaced smaller holes (0.95 cm) were drilled in the base of the small barrel so that syngas produced inside the barrel could pass. Another hole (2.12 cm) was drilled in the middle of the lid for a thermocouple (SZZJ INC, Shenzhen, Guangdong). The thermocouple was connected to a PID controller (Ink bird, Shenzhen, Guangdong). Seasoned (weathered for 2–3 years) wood (35 cm × 15 cm) from Payne Country Tree Service (Stillwater, OK, USA) was placed in between the small and large barrels to create a fire. Biochar was produced by pyrolysis of the ERC biomass at three temperature ranges of 300–350 °C, 400–450 °C, and 500–550 °C for 3 h after the temperature hit the set point. With the temperature range of 200–250 °C, the complete conversion of the biomass to biochar was not observed and maintaining temperatures above 500–550 °C challenged the thermocouple functionality due to the risk of burnout and subsequent malfunctioning. So, we selected these three ranges of temperature for pyrolysis. After the production of the biochar, it was stored in the shade and used after approximately after a month of storage.

Figure 1.

Double barrel system [30].

2.2. Plant Materials and Growth Conditions

The experiment was conducted at the Department of Horticulture and Landscape Architecture Research Greenhouses of Oklahoma State University located in Stillwater, OK. The greenhouse temperature was set at 21.9 ± 4.1 °C. No additional light was used, and the daily light integral averaged 19.3 ± 0.7 mol m−2 d−1. A 15.24 cm azalea pot (850 cm3) was used for the study.

Petunia ‘Prostate Wave Pink’ from a 160-cell tray and geranium ‘Diploid Maverick Red’ from a 288-cell tray from Raker-Roberta’s Young Plants (Litchfield, MI) were planted on 8 January 2023 in 15.24 cm pots. Both petunia and geranium were transplanted with one plug per pot. Plants were irrigated once a day through pressure-compensated drip emitters and fertilized with 200 mg L−1 nitrogen (N) with 20N-4.3P-16.6K fertilizer with micronutrients (J.R Peter’s Inc., 6656 Grant Way, Allentown, PA, USA).

2.3. Treatment and Experimental Design

The experiment included a total of 17 treatments for different potting mixes, 12 treatments of potting-mix biochar (prepared at three different temperatures and mixed at four different ratios), four treatments of potting mixes with ERC bark (mixed with potting media at four different rates) and a control (100% soilless media) (Table 1). Biochar produced at each temperature was mixed with soilless media (Environmental Soil Solutions, Stroud, OK, USA) at ratios based on volume (60%:40%, 45%:55%, 30%:70%, and 15%:85% biochar:soilless media ratios), and control was only soilless media. In addition, ERC bark at the same volume ratio as biochar was included to observe if the ERC bark would have a similar impact on plant growth when applied at the same rate of biochar. The biochar size used in this research ranges from 2 mm to 20 mm.

Table 1.

Experimental treatments using Eastern red cedar (ERC) bark and biochar with biochar made at different temperatures then mixed and soilless media.

A pot experiment was conducted in a split-plot design with 17 treatments. The main plot was the media ratio, and the subplot included biochar temperature and ERC bark. Tables were randomly assigned based on the volume of the potting mixture, and ERC bark and temperature factors were randomized within each table. The replication consisted of 10 pots per treatment. The experiment was replicated twice, with one replication in the east side and the other on the west side. There were 170 pots per replication per species and 340 pots per species.

2.4. Physical Properties of Growth Media

Various treatment blends were prepared for a 15.24 cm pot. These blends were thereafter weighed to determine the weight of the media, using a graduated cylinder. The graduated cylinder was then dropped five times from a height of 10 cm, and the volume of the media was recorded. Following this, the media were transferred to a zipper bag placed inside the pot. Water was poured into the media until a thin film developed on the top. The amount of water applied was then recorded. Finally, the zipper bag was perforated with five equally spaced 0.3 mm holes at the bottom (five holes per bag). Subsequently, the media were allowed to drain for 30 min. Then, the amount of water drained was recorded.

The physical properties of media, including bulk density (weight of substrate/ volume of substrate), percent porosity (ml of water to saturate substrate/total ml of substrate), percent air space (volume of drained water (ml)/ total ml of substrate), and WHC (percent porosity percent sir space) were determined according to [32]. This evaluation was performed using an in situ technique with plastic zipper bags punctured with five equally spaced 0.3 mm holes in the bottom.

2.5. Plant Growth Parameters

The total amount of water applied to each plant was recorded to determine water use efficiency (WUE) (shoot and root dry weight/total amount of water applied). At the time of harvest (12 weeks after transplanting for petunia and 14 weeks after transplanting for geranium), measurements were taken of plant height (from the top of the pot to the top of the plant), plant width (two perpendicular measurements), days to flowering (from plantation to the day bud showed the color), numbers of flowers, flower diameter (two perpendicular measurements), shoots, and root dry weight. For geranium, the number of umbels and height of umbels (from the node where the umbel arises to the tip of the umbel) were also recorded. Two leaves from the middle part of the plant were selected to measure chlorophyll levels in leaves using a chlorophyll meter (atLEAF; FT Green LLC, Wilmington, MA, USA). Roots were washed and then oven-dried at 60 °C for 3 days for the dry weight. Two samples of both leaves and media per treatment per replication were chosen for total nutrient analysis and submitted to the Soil, Water, and Forage Analytical Laboratory at Oklahoma State University (Stillwater, OK, USA), using a LECO TruSpec Carbon and Nitrogen Analyzer (LECO Corporation, St. Joseph, MI, USA). The media samples were dried at 65 °C for 6 to 12 h and ground to pass through a 2 mm sieve. The ammonium (NH4+) and nitrate (NO3−) were analyzed using a flow injection autoanalyzer, and inductively coupled plasma (ICP) spectroscopy was utilized for micro and macronutrient analysis. Leaf samples were ground and passed through a 1 mm sieve after drying at 85 °C for 12 h. The mineral content of leaf samples was analyzed by a Spectro ARCOS-2 ICP (Spectro Analytical Instruments GmbH, Kleve, Germany) following acid digestion [33].

2.6. Statistical Analysis

Statistical analysis was performed using PROC GLIMMIX in SAS/STAT software (Version 9.4; SAS Institute, Cary, NC, USA). Tests of significance were reported at the 0.05, 0.01, and 0.001 levels. When F-values were significant, Tukey’s highly significant difference multiple comparison methods were used to separate the means. Significant differences between means were estimated at a 95% confidence level.

3. Results

3.1. Physical Properties of 17 Different Potting Mix Ratios Determined from a 15.24 cm Pot

There was a significant effect of different potting mixes for bulk density, total porosity, aeration porosity, and water holding capacity (Table 2). The greatest bulk density was recorded at T1, and the lowest was observed at T5, which was reduced by 50% compared to T1. For total porosity, the greatest value was observed at T13, which was increased by 41.57% compared to T1, and it was similar to T5, T9, T11, T12, T15, and T17. The greatest aeration porosity was observed at T5, which was 222.4% greater compared to T1. The greatest water holding capacity was observed at T11 and was increased by 26.39% compared to T1.

Table 2.

Physical properties of 17 different potting mix ratios using Eastern red cedar (ERC), bark or biochar, and soilless media determined from a 15.24 cm pot for bulk density (BD), total porosity (TP), aeration porosity (AP), and water holding capacity (WHC).

3.2. Geranium Growth and Development

In geranium, there was a significant effect of different potting mixes for height, width, number of umbels, number of flowers, umbel height, shoot dry weight, and WUE (Table 3). There were no significant effects on chlorophyll content, days to flowering, and the root dry weight of the plant. The greatest height was with T14, which was different from T4, T5, T8, T9, T13, and T17. T6 showed the greatest width, which was 39.90% greater than T5, which showed the lowest width of the plant. The greatest number of umbels was with T16, which was 23.33% greater compared to T1. In comparison to T1, T16 increased the number of flowers by 54.86%. T5 showed the lowest number of flowers, which was 195.65% less than T16. T11 increased the umbel height by 4.27% compared to T1. The greatest root-to-shoot ratio was at T5. Shoot dry weight and WUE show a similar trend in response to different treatments. The greatest shoot dry weight and WUE were recorded at T14, which were 16.40% and 14.29% greater compared to T1, respectively. A greater rate (60%) of biochar lowered plant growth and performance compared to lower rates.

Table 3.

Effect of 17 different potting mix ratios using Eastern red cedar (ERC), bark or biochar, and soilless media on growth and plant quality of geranium.

3.3. Geranium Leaf Nutrient

Different potting mix treatments showed significant effects on total nitrogen (TN), potassium (K), sulfur (S), boron (B), zinc (Zn), copper (Cu), and manganese (Mn) (Table 4). Total nitrogen was greatest at T10 and was only different from T5. Moreover, both T9 and T16 reduced the K content by 23.07% compared to T1. Zinc was greatest at T4 and was only different from T3, T7, T9, T10, T13, T16, and T17. The greatest Cu was recorded at T6 and was only different from T1 and T17. Cu content was increased by 115.38% with T6 compared with T1. Manganese was the greatest with T8, which was 91.48% greater compared to T17.

Table 4.

Effect of 17 different potting mix ratios using Eastern red cedar (ERC), bark or biochar, and soilless media on geranium leaf nutrient.

3.4. Geranium Growing Media Nutrients

Except for NO3− content, different treatments significantly affected all other parameters (Table 5). The pH was greatest with T6 and was only different from T5. T10 showed the greatest EC and was only different from T9, and T13. The greatest NH4+ was recorded at T1, and the addition of biochar reduced NH4+ content up to 78.79% with T17. Phosphorus was greatest at T2 and reduced the content up to 39.2% with T9. The addition of ERC bark reduced the Na content up to 35.8%, and the addition of biochar reduced it up to 30.58% compared to T1. Potassium was greatest with T12, which was 53.22% greater compared to T9. Calcium was greatest at T2 and was only different from T9, T11, T12, T13, T16 and T17. Similarly, the greatest Mg content was at T2 and was not different from T1, T3, T5, T6, T8, T10, T14 and T15. Chlorine was greatest at T2 and was greater by 5.856% compared to T1. The T10 had the greatest S and was only different from T3, T4, T5, and T9. Boron was greatest at T1 and was 33.33% greater compared to T3, T4, T9, T11, T12, T13, and T17. Compared with T12, T13, and T17, boron was increased by 33.33% at T1.

Table 5.

Effect of 17 different potting mix ratios using Eastern red cedar (ERC), bark or biochar, and soilless media on geranium growing media nutrient.

3.5. Petunia Growth and Development

For petunia, there was a significant potting mix treatment effect for all growth parameters except for chlorophyll content and days to flowering (Table 6). Greatest height was with T6, which was similar with T1, T3, T7, T11, and T16. The width at T14 was increased by 27.48% compared to T1. The greatest number of flowers and flower diameter were with T1. Biochar application reduced the flower numbers from 23.11% to 76.58% compared to T1. Additionally, ERC bark addition reduced the flower numbers from 23.11% to 77.04% compared to T1. The greatest shoot dry weight was with T14 but was not different from T10 and T16. T14 increased the shoot dry weight by 13.26%. The greatest WUE was with T14 but was not different from T1, T10, and T16. The greatest root dry weight was with T13, which was 168.18% greater compared to T1. Similarly, the greatest root-to-shoot ratio was with T13, which was increased by 100% compared to T1.

Table 6.

Effect of 17 different potting mix ratios using Eastern red cedar (ERC), bark or biochar, and soilless media on growth and plant quality of petunia.

3.6. Petunia Leaf Nutrients

Different potting mix treatments showed significant effects on P, Mg, S, B, Fe, and Zn, whereas TN, Ca, K, Mn, and Cu were found to be non-significant (Table 7). The greatest P was with T11 and T12 and was 75% greater compared to T5. Mg was greatest with T17 and increased by 66.7% compared to T4 and T5. T11, T12, T13, and T17 showed the greatest S but were only different from T4. Iron was greatest at T3 by 82.7% compared to T17. T7 showed the greatest Zn content and was greater by 54.9% compared to T9. Boron was greatest with T13 and was increased by 75.57% compared to T1.

Table 7.

Effect of 17 different potting mix ratios using Eastern red cedar (ERC), bark or biochar, and soilless media on petunia leaf nutrients.

3.7. Petunia Growing Media Nutrients

For petunia soil nutrients, all the parameters were significantly affected by 17 different treatments (Table 8). The addition of biochar increased the pH up to 5.13% compared to T1. Electrical conductivity was greatest with T13 and was increased by 59.43% compared to T6. Ammonium was greatest with T14 and was 416.67% greater compared to T2. T1 showed the greatest NO3 content. Similarly, P was greatest at T1 and T8, and T13 decreased the P content by 50.3% and 48.5%, respectively. Calcium and Mg were recorded to be greatest at T2 and were similar to T1, T3, T4, T5, T8, and T14. T13 showed an increase in K content by 96.48% compared to T1. However, chlorine was greatest at T2, which was greater by 163.36% compared to T6. Sulfur at T14 was greater by 92.82% and 94.56% compared to T4 and T6. Boron was greatest at T1 and only different from T3, T4, T9, T11, T12, T13, and T17. Biochar addition reduced the B content up to 33.33% compared to T1. The greatest Na was with T14 but was only different from T3, T4, T5, and T6.

Table 8.

Effect of 17 different potting mix ratios using Eastern red cedar (ERC), bark or biochar, and soilless media on petunia growing media nutrients.

4. Discussion

4.1. Effect of Biochar on Physical Properties of Growing Media

The biochar addition resulted in decreased bulk density and an increase in the WHC of growing media. The decreased bulk density with a high biochar rate can be attributed to the expansion of pore space and reduction of biochar density [34]. On the contrary, Vaughn et al. [35] reported an increase in bulk density of growing media by 12–34% with hardwood pellets and a straw biochar addition of 5–15%. Furthermore, Mendez et al. [36] also reported an increase in the bulk density and total porosity of growing media (peat and coir) with the addition of 50% de-inking sludge biochar produced at 300 °C. The increase in bulk density with a biochar addition can be explained by the lower density of media compared to biochar, resulting in an increase in bulk density upon biochar addition. In addition to temperature and rate, the size of biochar also affects the properties of the growing media. The biochar used in this study was of coarse texture (up to 20 mm). Furthermore, Werdin et al. [37] explained that the fine biochar improved WHC compared to coarse biochar, which explains our result. The increased WHC of the media with the biochar addition could be influenced by pores and the surface area of crushed biochar [38,39]. For ERC bark treatment, the increased air porosity with the high rate of ERC bark could be due to increased macrospores, attributed to larger ERC bark pieces [40]. Additionally, we observed an increase in air porosity with higher temperatures and a greater rate of biochar, which was similar to the findings of [38]; this might be due to the greater particle size of biochar compared to media [41]. The differences in bulk density, WHC, air porosity, and total porosity compared to other studies might be due to the different properties of the media used [42]. Thus, it is crucial to consider the texture and particle size of soilless media to determine the air porosity, WHC, and bulk density [43].

4.2. Effect on Plant Growth and Quality

The height, width, and shoot dry weight of geranium decreased with an increased biochar rate. This is consistent with Altland and Locke [22], who showed a decreased shoot dry weight of geranium with 30% rice-hull biochar compared to 10% and 20% biochar. Similarly, Fascella et al. [25] found that sphagnum peat can be replaced by wood biochar at a rate lower than 25% for rose (Rosa rugosa T.). This result corresponds with Conversa et al. [44], who suggest that it might be due to the lower microbial activity or immobilization of N with a greater rate of biochar. Chlorophyll concentration, which is influenced by N, K, and Mg concentrations [45], was found to be uniform in all treatments. Also, stress due to greater biochar rate and low moisture leads to smaller and thicker leaves, accounting for similar chlorophyll content [46]. In addition, Quilliam et al. [47] also found that different rates of biochar showed no significant effect on chlorophyll content in beans (Phaseolus vulgaris L.), which was similar to our findings. Fornes and Belda [48] reported a reduction in the number of flowers in petunia when forest-waste biochar was applied above 25% due to high pH. Similarly, Conversa et al. [44] found that 100% peat moss and 70% peat moss/30% fir (Abies alba M.) biochar had a similar effect on geranium growth and quality, but 70% biochar reduced plant height, flower numbers, flower cluster dry weight, and the number of branches. Our study showed reduced flowering at 60% biochar application. Similar to our result, a biochar rate greater than 50% reduced the flower numbers and shoot dry weight of viola (Viola cornuta L.) [17]. High K content with a high rate of biochar reducing the availability of Ca and Mg due to their antagonistic behavior might be the reason for reduced plant performance in the study. The reduction in flowering percentage and growth might be attributed to phytotoxicity caused by hydrocarbons and phenols accumulation at a higher biochar rate. [49].

This study also noted that the plant growth and quality were reduced with an ERC bark rate greater than 45%. The poor performance of plants with ERC bark might be due to the presence of water-soluble and plant-suppressive chemicals in red cedar wood chips [50], which obstruct plant growth. Moreover, Fox [51] reported reduced ‘Sooner Red’ geranium height and dry weight with 75% ERC bark compared to 25% and 50% ERC bark rates. Likewise, the decreased plant performance with a greater ERC bark rate might be attributed to an increase in air space and reduced container capacity due to the bigger ERC bark particle size [52]. Furthermore, as reported by Conversa et al. [44], greater total porosity was associated with the WHC of the media, potentially leading to the poor growth of geranium.

4.3. Effects on Leaf Nutrient Content

Biochar addition showed no significant effect on the leaf N concentration of petunia plants, consistent with findings from a study by [53], who reported that 10%, 20%, 30%, and 40% wood-chip and rice-husk biochar showed no difference in N concentration in the leaves of rhododendron (Rhododendron delavayi Franch.). Even though the substrate had a high C/N ratio, there were no significant differences in foliar N concentrations, indicating negligible N immobilization [49]. The P concentration in geranium leaves was reduced, and Mg in petunia leaves increased with the increase in biochar rate. A similar result was reported by Fascella et al. [25], who carried out a study on the conifer-wood biochar effect on rose. The greater P concentration in geranium leaves at a lower biochar rate might be attributed to mycorrhizal colonization when mixed with arbuscular mycorrhizal fungi inoculum in a growth chamber study [44]. However, there was no effect on foliar Ca concentration. Furthermore, it is noted that each plant species responds to the types and rates biochar differently, as reported by [25,54]. Leaf chlorophyll of the lavender plant was observed to be decreased with an increasing (>25%) rate of wood biochar, while the leaf carotenoids increased along with a greater rate of biochar (75%) [23]. Additionally, Ca and Mg content in the leaves of rose was increased with a greater rate (75%) of wood biochar [25]. However, Calathea insignis Ca and Mg content and carotenoids decreased with an increase in the coir biochar rate greater than 20% [39].

4.4. Effects on Growing Media Properties

Greater rates of biochar decreased the N, EC, P, Ca, and Mg concentration of the media. For geranium, NH4+ concentration was greatest with 100% soilless media and ERC bark mixed with soilless media compared to the biochar mixture. The greatest N content in soilless media with mulch compared to soilless media with biochar could be due to the volatilization loss of N during pyrolysis [55]. In line with our findings, the reduction of EC when the wood-chip biochar application increased from 10% to 50%, which had not been reported before [13]. The reduction in EC with a greater rate of biochar might be due to a lower ash content in biochar produced from woody sources [56] or because of the greater EC of soilless media that was used compared to the biochar [57]. The results of container grown ‘Sooner Red’ geranium and Chinese pistache (Pistacia chinensis B.) showed decreased pH and EC with a higher cedar ERC bark rate, which corresponds with our study [56,57].

According to Buss et al. [58], Ca and Mg content decreased with a greater rate of biochar due to volatilization loss during pyrolysis. Prasad et al. [13] also reported a decrease in P content with a higher biochar rate, which might be due to the high pH associated with biochar [23]. The pH of biochar used in our study was >8.0. Contrarily, woodchip biochar showed a decrease in K content when the biochar rate increased from 25% to 50%, while forest wood and paper-fiber biochar showed increased K content with a higher rate of biochar [13]. This suggests that types of feedstocks will impact the nutrient content of biochar. The lowest S and Na content with the greater rate of ERC bark might be due to greater air space of media, with larger pieces of bark having smaller pore volumes and causing a leachate of nutrients in the growing media [59].

4.5. Other Factors Influencing the Biochar Effect

In addition to rate and temperature, other factors have been observed to influence plant growth and quality. Plants performed better in higher-temperature biochar than in lower-temperature biochar, similar to the findings of [15], who reported increased rye (Lolium perenne L.) grass biomass with birch biochar at 375 °C and 475 °C compared to 300 °C. The good performance of the plant might be due to the high CEC of the media with high temperatures of biochar, which helps to hold the nutrients in the media, making them available for plants. However, Gunes et al. [60] reported reduced dry weight for lettuce (Lactuca sativa L.) and corn (Zea mays L.), with the biochar at 10 g kg−1 soil above 300 °C and 350 °C, respectively. In contrast to our findings, Naeem et al. [61] reported a decrease in the shoot and root dry mass of corn grown in calcareous soil with wheat (Triticum aestivum L.)-straw and rice-straw biochar produced at 500 °C compared to 300 °C and 400 °C, which might be due to the increased pH of high-temperature biochar reducing the P availability due to P binding with Ca, forming a less-soluble compound like calcium phosphide.

The different particle sizes of the same source of biochar showed varying effects on plant growth. The particle size of biochar used in our study ranges from 2 mm–20 mm. According to Thomas [62], biochar with particle sizes of 0.50 mm–0.99 mm had the greatest influence on plant growth compared to both smaller and larger biochar particles. The larger biochar particle size increased the media air porosity but reduced the water content and availability to the plants [44]. Conversely, smaller particle size biochar is known to improve CEC, pH, and micro-porosity of media which positively impacts plant growth; however, some studies find a negative impact of too small size on plant growth [62,63]. Another study reported an increase in total N uptake and N content in lentil (Lens culinaris Medik.) straw with biochar particle size < 5 mm (18.5 g kg−1 and 88.8 kg ha−1) compared to 5–10 mm sized biochar which was 17.05 g kg−1 and 84.6 kg ha−1, respectively [64]. This increase in N content and uptake might be due to the greater surface area of fine biochar, which binds with NH4+ and NO3−, thereby improving the availability of these nutrients to plants for a longer period [65,66].

5. Conclusions

In the present study, there was a decrease in bulk density and an increase in the WHC of media with biochar addition. For geranium, 15% of 500–550 °C biochar had the greatest height, shoot dry weight, WUE, and number of umbels. The 30–45% biochar as a supplement for soilless media performed the best in terms of number of flowers. Total nitrogen (TN) in the geranium leaf was greatest at 15% biochar of 400–450 °C, and the greatest K content in the leaf was with 100% soilless media. For petunia, 100% soilless media had the greatest number of flowers and flower diameter, and 15% biochar had the greatest height, width, shoot weight, and WUE. The greatest P content in leaves was with 30% and 45% biochar at 400–450 °C. The effect of biochar rate and temperature on leaf and soil nutrients was different for both plant species. For both plants, 60% ERC bark reduced the growth and quality of a plant. This study suggests that 15% ERC biochar can be used as a supplement for soilless media for the greenhouse production of geranium. However, further research is necessary to understand the interaction of biochar and soilless media for the growth of other plant species, and determining rates, particle sizes, and pyrolysis temperature will be important for plant growth and flowering.

Author Contributions

Conceptualization, H.S. and B.L.D.; methodology, B.L.D. and B.L; formal analysis, H.S.; investigation, B.L.; data curation, B.L.; writing—Original draft preparation, B.L.; writing—Review and editing, B.L.D., H.S., A.K. and F.B.N.; funding acquisition, H.S. and B.L.D. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Oklahoma Center for Advancement of Science & Technology (OCAST) grant number G2B004184.

Data Availability Statement

Data are contained within this article.

Acknowledgments

We thank Stephan Stanphill for helping with greenhouse management and Angelika Ouedraogo for helping with biochar production.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Steiner, C.; Harttung, T. Biochar as a growing media additive and peat substitute. Solid Earth 2014, 5, 995–999. [Google Scholar] [CrossRef]

- Bachmann, R.T.; Adawiyah, S.; Krishnan, T.; Khoo, B.; Sian, T.S.; Richards, T. Partial substitution of peat moss with biochar for sustainable cultivation of Durio zibethinus L. in nurseries. Arab J. Geosci. 2018, 11, 426. [Google Scholar] [CrossRef]

- Cleary, J.; Roulet, N.T.; Moore, T.R. Greenhouse gas emissions from Canadiac peat extraction, 1990–2000: A life-cycle analysis. AMBIO J. Hum. Environ. 2005, 34, 456–461. [Google Scholar] [CrossRef]

- Schmilewski, G. The role of peat in assuring the quality of growing media. Mires Peat 2008, 3, 1–8. [Google Scholar]

- Margenot, A.J.; Griffin, D.E.; Alves, B.S.Q.; Rippner, D.A.; Li, C.; Parikh, S.J. Substitution of peat moss with softwood biochar for soil-free marigold growth. Ind. Crops Prod. 2018, 112, 160–169. [Google Scholar] [CrossRef]

- Kern, J.; Tammeorg, P.; Shanskiy, M.; Sakrabani, R.; Knicker, H.; Kammann, C.; Tuhkanen, E.-M.; Smidt, G.; Prasad, M.; Tiilikkala, K.; et al. Synergistic use of peat and charred material in growing media—An option to reduce the pressure on peatlands? J. Environ. Eng. Landsc. Manag. 2017, 25, 160–174. [Google Scholar] [CrossRef]

- Kazemi Shariat Panahi, H.; Dehhaghi, M.; Ok, Y.S.; Nizami, A.-S.; Khoshnevisan, B.; Mussatto, S.I.; Aghbashlo, M.; Tabatabaei, M.; Lam, S.S. A comprehensive review of engineered biochar: Production, characteristics, and environmental applications. J. Clean. Prod. 2020, 270, 122462. [Google Scholar] [CrossRef]

- Woolf, D.; Amonette, J.E.; Street-Perrott, F.A.; Lehmann, J.; Joseph, S. Sustainable biochar to mitigate global climate change. Nat. Commun. 2010, 1, 56. [Google Scholar] [CrossRef] [PubMed]

- Crutchfield, E.F.; McGiffen, M.E., Jr.; Merhaut, D.J. Effects of biochar on nutrient leaching and begonia plant growth. J. Environ. Hort. 2018, 36, 126–132. [Google Scholar] [CrossRef]

- Masto, R.E.; Ansari, M.A.; George, J.; Selvi, V.A.; Ram, L.C. Co-application of biochar and lignite fly ash on soil nutrients and biological parameters at different crop growth stages of Zea mays. Ecol. Eng. 2013, 58, 314–322. [Google Scholar] [CrossRef]

- Xu, C.-Y.; Hosseini-Bai, S.; Hao, Y.; Rachaputi, R.C.N.; Wang, H.; Xu, Z.; Wallace, H. Effect of biochar amendment on yield and photosynthesis of peanut on two types of soils. Environ. Sci. Pollut. Res. 2015, 22, 6112–6125. [Google Scholar] [CrossRef]

- Liang, Y.; Cao, X.; Zhao, L.; Xu, X.; Harris, W. Phosphorus release from dairy manure, the manure-derived biochar, and their amended soil: Effects of phosphorus nature and soil property. J. Environ. Qual. 2014, 43, 1504–1509. [Google Scholar] [CrossRef]

- Prasad, M.; Tzortzakis, N.; McDaniel, N. Chemical characterization of biochar and assessment of the nutrient dynamics by means of preliminary plant growth tests. J. Environ. Manag. 2018, 216, 89–95. [Google Scholar] [CrossRef] [PubMed]

- Alvarez, J.M.; Pasian, C.; Lal, R.; Lopez Nunez, R.; Fernandez Martínez, M. Vermicompost and biochar as substitutes of growing media in ornamental-plant production. J. Appl. Hortic. 2017, 19, 205–214. [Google Scholar] [CrossRef]

- Hagner, M.; Kemppainen, R.; Jauhiainen, L.; Tiilikkala, K.; Setälä, H. The effects of birch (Betula spp.) biochar and pyrolysis temperature on soil properties and plant growth. Soil Tillage Res. 2016, 163, 224–234. [Google Scholar] [CrossRef]

- Fornes, F.; Belda, R.M.; Lidon, A. Analysis of two biochars and one hydrochar from different feedstock: Focus set on environmental, nutritional and horticultural considerations. J. Clean. Prod. 2015, 86, 40–48. [Google Scholar] [CrossRef]

- Regmi, A.; Singh, S.; Moustaid-Moussa, N.; Coldren, C.; Simpson, C. The negative effects of high rates of biochar on violas can be counteracted with fertilizer. Plants 2022, 11, 491. [Google Scholar] [CrossRef] [PubMed]

- Stehmann, J.R.; Lorenz-Lemke, A.P.; Freitas, L.B.; Semir, J. The Genus Petunia. In Petunia; Gerats, T., Strommer, J., Eds.; Springer: New York, NY, USA, 2009; pp. 1–28. ISBN 9780387847955. [Google Scholar]

- Gomes, P.B.; Mata, V.G.; Rodrigues, A.E. Production of rose geranium oil using supercritical fluid extraction. J. Supercrit. Fluids 2007, 41, 50–60. [Google Scholar] [CrossRef]

- Alvarez, J.M.; Pasian, C.; Lal, R.; Lopez, R.; Díaz, M.J.; Fernandez, M. Morpho-physiological plant quality when biochar and vermicompost are used as growing media replacement in urban horticulture. Urban For. Urban Green. 2018, 34, 175–180. [Google Scholar] [CrossRef]

- Alvarez, J.M.; Pasian, C.; Lal, R.; Lopez, R.; Fernandez, M. Vermicompost and biochar substrates can reduce nutrients leachates on containerized ornamental plant production. Hortic. Bras. 2019, 37, 47–53. [Google Scholar] [CrossRef]

- Altland, J.E.; Locke, J.C. High rates of gasified rice hull biochar affect geranium and tomato growth in a soilless substrate. J. Plant Nutr. 2017, 40, 1816–1828. [Google Scholar] [CrossRef]

- Fascella, G.; Mammano, M.M.; D’Angiolillo, F.; Pannico, A.; Rouphael, Y. Coniferous wood biochar as substrate component of two containerized lavender species: Effects on morpho-physiological traits and nutrients partitioning. Sci. Hortic. 2020, 267, 109356. [Google Scholar] [CrossRef]

- Guo, Y.; Niu, G.; Starman, T.; Volder, A.; Gu, M. Poinsettia growth and development response to container root substrate with biochar. Horticulturae 2018, 4, 1. [Google Scholar] [CrossRef]

- Fascella, G.; Mammano, M.M.; D’Angiolillo, F.; Rouphael, Y. Effects of conifer wood biochar as a substrate component on ornamental performance, photosynthetic activity, and mineral composition of potted Rosa rugosa. J. Hortic. Sci. Biotechnol. 2018, 93, 519–528. [Google Scholar] [CrossRef]

- Pierce, A.M.; Reich, P.B. The effects of eastern red cedar (Juniperus virginiana) invasion and removal on a dry bluff prairie ecosystem. Biol. Invasions 2010, 12, 241–252. [Google Scholar] [CrossRef]

- Caterina, G.L.; Will, R.E.; Turton, D.J.; Wilson, D.S.; Zou, C.B. Water use of Juniperus virginiana trees encroached into mesic prairies in Oklahoma, USA. Ecohydrology 2014, 7, 1124–1134. [Google Scholar] [CrossRef]

- Yang, Z.; Kumar, A.; Huhnke, R.L.; Buser, M.; Capareda, S. Pyrolysis of eastern redcedar: Distribution and characteristics of fast and slow pyrolysis products. Fuel 2016, 166, 157–165. [Google Scholar] [CrossRef]

- Vaughn, S.F.; Byars, J.A.; Jackson, M.A.; Peterson, S.C.; Eller, F.J. Tomato seed germination and transplant growth in a commercial potting substrate amended with nutrient-preconditioned Eastern red cedar (Juniperus virginiana L.) wood biochar. Sci. Hortic. 2021, 280, 109947. [Google Scholar] [CrossRef]

- Lamichhane, B.; Dunn, B.; Singh, H. Preparation of Biochar for Use as a Soil Amendment. Oklahoma Cooperative Extension Service. HLA-6502. 2023. Available online: https://extension.okstate.edu/fact-sheets/preparation-of-biochar-for-use-as-a-soil-amendment.html (accessed on 23 January 2024).

- Abdelhafez, A.A.; Li, J.; Abbas, M.H.H. Feasibility of biochar manufactured from organic wastes on the stabilization of heavy metals in a metal smelter contaminated soil. Chemosphere 2014, 117, 66–71. [Google Scholar] [CrossRef]

- Davidson, H.; Mecklenburg, R.; Peterson, C. Nursery Management: Administration and Culture, 4th ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2000. [Google Scholar]

- Zhang, H.; Henderson, K. Procedures Used by OSU Soil, Water and Forage Analytical Laboratory. Oklahoma Cooperative Extension Service. PSS-2901. 2016. Available online: https://extension.okstate.edu/fact-sheets/procedures-used-by-osu-soil-water-and-forage-analytical-laboratory.html (accessed on 23 January 2024).

- Githinji, L. Effect of biochar application rate on soil physical and hydraulic properties of a sandy loam. Arch. Agron. Soil Sci. 2014, 60, 457–470. [Google Scholar] [CrossRef]

- Vaughn, S.F.; Kenar, J.A.; Thompson, A.R.; Peterson, S.C. Comparison of biochars derived from wood pellets and pelletized wheat straw as replacements for peat in potting substrates. Ind. Crops Prod. 2013, 51, 437–443. [Google Scholar] [CrossRef]

- Mendez, A.; Paz-Ferreiro, J.; Gil, E.; Gasco, G. The effect of paper sludge and biochar addition on brown peat and coir based growing media properties. Sci. Hortic. 2015, 193, 225–230. [Google Scholar] [CrossRef]

- Werdin, J.; Conn, R.; Fletcher, T.D.; Rayner, J.P.; Williams, N.S.G.; Farrell, C. Biochar particle size and amendment rate are more important for water retention and weight of green roof substrates than differences in feedstock type. Ecol. Eng. 2021, 171, 106391. [Google Scholar] [CrossRef]

- Kaudal, B.B.; Chen, D.; Madhavan, D.B.; Downie, A.; Weatherley, A. An examination of physical and chemical properties of urban biochar for use as growing media substrate. Biomass Bioenergy 2016, 84, 49–58. [Google Scholar] [CrossRef]

- Zhang, L.; Sun, X.; Tian, Y.; Gong, X. Biochar and humic acid amendments improve the quality of composted green waste as a growth medium for the ornamental plant Calathea insignis. Sci. Hortic. 2014, 176, 70–78. [Google Scholar] [CrossRef]

- Huang, L.; Niu, G.; Feagley, S.E.; Gu, M. Evaluation of a hardwood biochar and two composts mixes as replacements for a peat-based commercial substrate. Ind. Crops Prod. 2019, 129, 549–560. [Google Scholar] [CrossRef]

- Huang, L.; Gu, M. Effects of biochar on container substrate properties and growth of plants—A Review. Horticulturae 2019, 5, 14. [Google Scholar] [CrossRef]

- Bilderback, T.E.; Warren, S.L.; Owen, J.S.; Albano, J.P. Healthy substrates need physicals too! HortTechnology 2005, 15, 747–751. [Google Scholar] [CrossRef]

- Abad, M.; Noguera, P.; Bures, S. National inventory of organic wastes for use as growing media for ornamental potted plant production: Case study in Spain. Bioresour. Technol. 2001, 77, 197–200. [Google Scholar] [CrossRef]

- Conversa, G.; Bonasia, A.; Lazzizera, C.; Elia, A. Influence of biochar, mycorrhizal inoculation, and fertilizer rate on growth and flowering of pelargonium (Pelargonium zonale L.) plants. Front. Plant Sci. 2015, 6, 127299. [Google Scholar] [CrossRef]

- Shi, J.; Wang, Y.; Li, Z.; Huang, X.; Shen, T.; Zou, X. Simultaneous and nondestructive diagnostics of nitrogen/magnesium/potassium-deficient cucumber leaf based on chlorophyll density distribution features. Biosyst. Eng. 2021, 212, 458–467. [Google Scholar] [CrossRef]

- Zhang, H.; Ge, Y.; Xie, X.; Atefi, A.; Wijewardane, N.K.; Thapa, S. High throughput analysis of leaf chlorophyll content in sorghum using RGB, hyperspectral, and fluorescence imaging and sensor fusion. Plant Methods. 2022, 18, 60. [Google Scholar] [CrossRef] [PubMed]

- Quilliam, R.S.; Marsden, K.A.; Gertler, C.; Rousk, J.; DeLuca, T.H.; Jones, D.L. Nutrient dynamics, microbial growth and weed emergence in biochar amended soil are influenced by time since application and reapplication rate. Agric. Ecosyst. Environ. 2012, 158, 192–199. [Google Scholar] [CrossRef]

- Fornes, F.; Belda, R.M. Biochar versus hydrochar as growth media constituents for ornamental plant cultivation. Sci. Agric. 2018, 75, 304–312. [Google Scholar] [CrossRef]

- Graber, E.R.; Meller Harel, Y.; Kolton, M.; Cytryn, E.; Silber, A.; Rav David, D.; Tsechansky, L.; Borenshtein, M.; Elad, Y. Biochar impact on development and productivity of pepper and tomato grown in fertigated soilless media. Plant Soil 2010, 337, 481–496. [Google Scholar] [CrossRef]

- Rathinasabapathi, B.; Ferguson, J.; Gal, M. Evaluation of allelopathic potential of wood chips for weed suppression in horticultural production systems. HortScience 2005, 40, 711–713. [Google Scholar] [CrossRef]

- Fox, T.E. Physical and Cultural Properties of Cedar Mulch Amended Growth Media Affecting Container Grown Ornamental Plants. (Ph.D. in Horticulture) Graduate Thesis and Dissertations, Texas A&M University, College Station, TX, USA, 1979. [Google Scholar]

- Starr, Z.; Boyer, C.; Griffin, J. Growth of Pistacia chinensis in a red cedar–amended substrate. In Combined Proceedings International Plant Propagators’ Society; IPPS: Monroe, CT, USA, 2010; Volume 60, pp. 602–606. [Google Scholar]

- Bu, X.; Ji, H.; Ma, W.; Mu, C.; Xian, T.; Zhou, Z.; Wang, F.; Xue, J. Effects of biochar as a peat-based substrate component on morphological, photosynthetic and biochemical characteristics of Rhododendron delavayi Franch. Sci. Hortic. 2022, 302, 111148. [Google Scholar] [CrossRef]

- Headlee, W.L.; Brewer, C.E.; Hall, R.B. Biochar as a substitute for vermiculite in potting mix for hybrid poplar. Bioenergy Res. 2014, 7, 120–131. [Google Scholar] [CrossRef]

- Sasmita, K.D.; Anas, I.; Anwar, S.; Yahya, S.; Djajakirana, G. Application of biochar and organic fertilizer on acid soil as growing medium for cacao (Theobroma cacao L.) seedlings. Int. J. Sci. Basic Appl. Res. 2017, 36, 261–273. [Google Scholar]

- Rajkovich, S.; Enders, A.; Hanley, K.; Hyland, C.; Zimmerman, A.R.; Lehmann, J. Corn Growth and nitrogen nutrition after additions of biochars with varying properties to a temperate soil. Biol. Fertil. Soils 2012, 48, 271–284. [Google Scholar] [CrossRef]

- Chrysargyris, A.; Prasad, M.; Kavanagh, A.; Tzortzakis, N. Biochar type and ratio as a peat additive/partial peat replacement in growing media for cabbage seedling production. Agronomy 2019, 9, 693. [Google Scholar] [CrossRef]

- Buss, W.; Graham, M.C.; Shepherd, J.G.; Masek, O. Suitability of marginal biomass-derived biochars for soil amendment. Sci. Total Environ. 2016, 547, 314–322. [Google Scholar] [CrossRef]

- Basiri Jahromi, N.; Fulcher, A.; Walker, F.; Altland, J. Optimizing substrate available water and coir amendment rate in pine bark substrates. Water 2020, 12, 362. [Google Scholar] [CrossRef]

- Gunes, A.; Inal, A.; Sahin, O.; Taskin, M.B.; Atakol, O.; Yilmaz, N. Variations in mineral element concentrations of poultry manure biochar obtained at different pyrolysis temperatures, and their effects on crop growth and mineral nutrition. Soil Use Manag. 2015, 31, 429–437. [Google Scholar] [CrossRef]

- Naeem, M.A.; Khalid, M.; Aon, M.; Abbas, G.; Tahir, M.; Amjad, M.; Murtaza, B.; Yang, A.; Akhtar, S.S. Effect of wheat and rice straw biochar produced at different temperatures on maize growth and nutrient dynamics of a calcareous soil. Arch. Agron. Soil Sci. 2017, 63, 2048–2061. [Google Scholar] [CrossRef]

- Thomas, S.C. Post-processing of biochars to enhance plant growth responses: A review and meta-analysis. Biochar 2021, 3, 437–455. [Google Scholar] [CrossRef]

- Chen, J.; Li, S.; Liang, C.; Xu, Q.; Li, Y.; Qin, H.; Fuhrmann, J.J. Response of microbial community structure and function to short-term biochar amendment in an intensively managed bamboo (Phyllostachys praecox) plantation soil: Effect of particle size and addition rate. Sci. Total Environ. 2017, 574, 24–33. [Google Scholar] [CrossRef]

- Billah, M.M.; Ahmad, W.; Ali, M. Biochar particle size and rhizobia strains effect on the uptake and efficiency of nitrogen in lentils. J. Plant Nutr. 2019, 42, 1709–1725. [Google Scholar] [CrossRef]

- Major, J.; Rondon, M.; Molina, D.; Riha, S.J.; Lehmann, J. Nutrient leaching in a colombian savanna oxisol amended with biochar. J. Environ. Qual. 2012, 41, 1076–1086. [Google Scholar] [CrossRef]

- Yao, Z.; Zheng, X.; Dong, H.; Wang, R.; Mei, B.; Zhu, J. A 3-Year Record of N2O and CH4 Emissions from a sandy loam paddy during rice seasons as affected by different nitrogen application rates. Agric. Ecosyst. Environ. 2012, 152, 1–9. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).