1. Introduction

Movement of goods is a significant factor in modern supply chains. Rising fuel and labor costs contribute to the overall operational costs of an organization when moving goods from one location to another. Within this movement of goods, last-mile delivery is considered the most expensive portion of the entire supply chain [

1]. The growth in ecommerce, specifically with regards to last-mile delivery [

2,

3] and the end-consumer preference for cheap and fast shipping, has led to businesses and academia focusing on various improvement strategies to lower last-mile delivery costs [

4,

5] and provide more value to end users, i.e., customers within a supply chain.

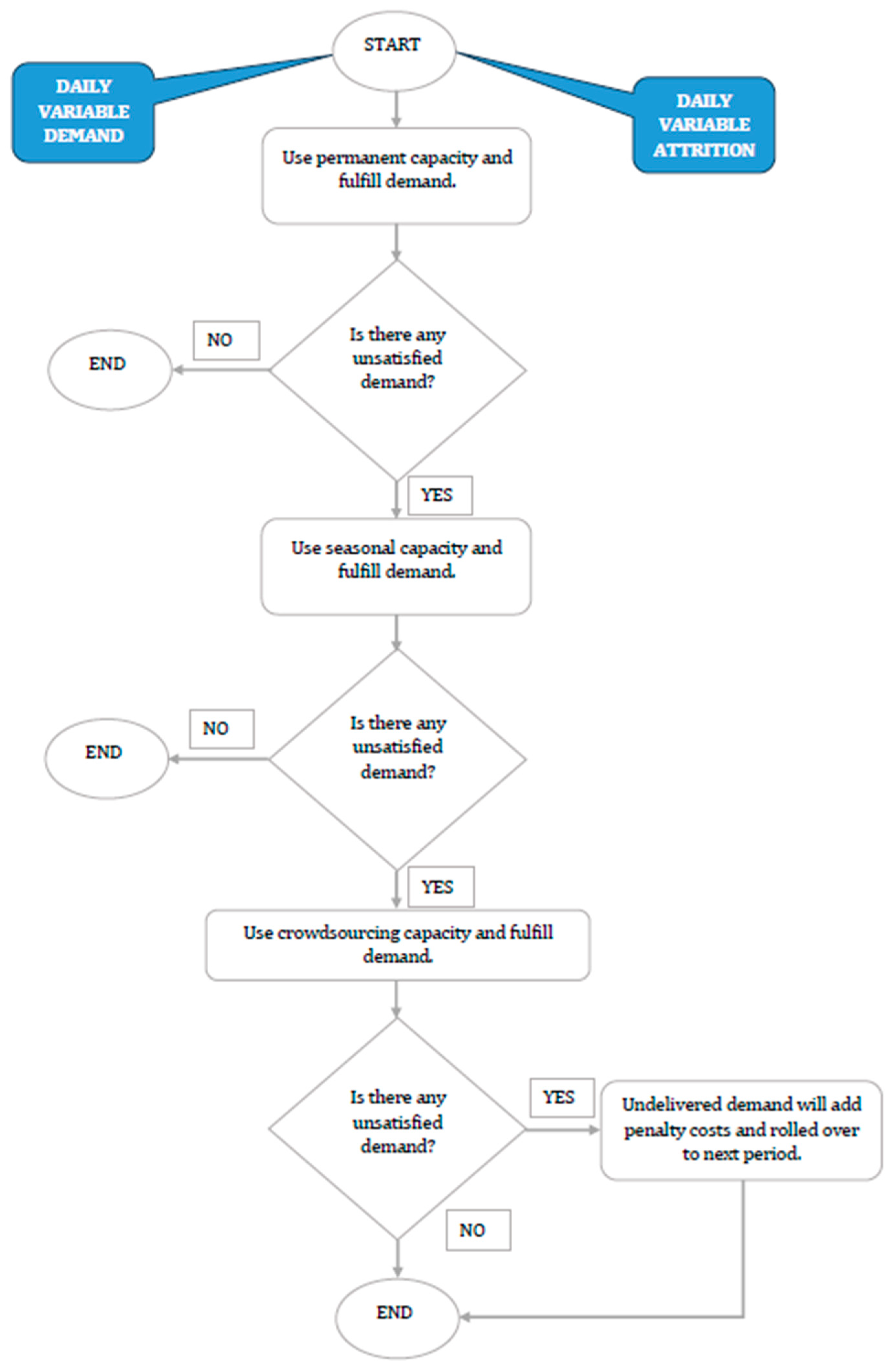

Most of the studies observed in the literature focus on operational efficiency improvements by considering optimal transportation routes, equipment, or providing optimal schedules. Very few studies focus on an aggregate delivery capacity plan considering a hybrid structure of permanent and/or seasonal and/or crowdsourcing capacity and/or robots. In this research, we expand this adoption of a hybrid capacity structure while accounting for the daily nuances related to employee attrition, which impact capacity, leading to deliveries being missed. Monte Carlo simulation is used to determine the optimal capacity plan to meet the demand.

Lowering last-mile delivery costs has been extensively studied based on route analysis [

6], type of vehicle used [

7,

8], public vs. private transport [

9], scheduling enhancements [

10], and automation such as drones or robots [

11]. In this pursuit, most of the studies are either focused on optimization, simulation at an operational level, or environmental sustainability. Among these improvement strategies, one avenue that was explored was the utilization of crowd capacity for last-mile delivery services [

12]. In this concept, the existing traffic is used to deliver goods, thereby lowering the burden on transportation companies to increase delivery capacity meeting ever-increasing consumer demand. This gives a delivery services company an opportunity to pool its capacity to handle varying demands.

This study considers a combination of capacities, such as permanent, seasonal, and crowdsourcing, along with the opportunity to use advanced automation such as robots for last-mile delivery. Simulation is used to address the attrition of permanent and seasonal capacities. Thus, an aggregate capacity plan is explored considering the variations that a business might face with regards to crowdsourcing capacity, crowdsourcing cost, employee attrition (permanent and seasonal), and end-consumer demand. Along with these variations, the benefits of automation are also studied.

The rest of the paper is organized as follows. The related literature is reviewed in

Section 2.

Section 3 provides the materials and method used, and

Section 4 provides the results, followed by the related discussion in

Section 5. Lastly,

Section 6 concludes this research with future research directions.

2. Literature Review

This work is related to two streams of research: studies which use simulation to optimize the utilization of crowdsourcing capacity and studies that consider aggregate capacity planning for last-mile delivery.

The use of crowdsourcing for last-mile delivery has been studied to lower operational costs. In a review paper [

13], it has been highlighted that there is an increase in last-mile delivery due to the changing needs of the retail and ecommerce sectors. This growth and efforts to maintain operational efficiencies emphasize the need for innovative solutions [

10] to optimize the last-mile delivery process. In their study, they highlighted crowdsourcing as a viable option for reducing last-mile delivery costs. Also, e-retailers have adopted crowdsourcing logistics [

14] to fulfill deliveries in a cost-effective manner, and one other study shows that crowdsourcing for last-mile delivery can be used to be cost effective and sustainable [

15]. On the same note, a study has reviewed challenges associated with the use of crowdsourcing [

16], specifically with the aspect of capacity building. This is one of our motivations, where crowdsourcing is an uncertain aspect, guaranteeing that it does not impact service levels.

A simulation exploring how same-day delivery services can be improved using crowdsourcing considering time windows and daily demand was performed [

17], where on-time deliveries and total number of deliveries were taken into consideration for the simulation model. In other research [

12], the authors explored how crowdsourcing capacity (considering ecommerce, trust, and technology) would help last-mile delivery lower operational costs. To achieve this, the authors performed a simulation considering the inputs of population size, online vs. supermarkets, deliverers, order arrival, delivery time, and associated costs. They concluded that although crowdsourcing shows significant savings, a hybrid delivery network balances the challenges of each approach. A multi-stage stochastic model was proposed and solved using a simulation–optimization strategy [

18] investigating dynamic and stochastic vehicle routing. Their findings showed economic as well as environmental benefits. Simulating benefits of crowdsourcing with different types of fleets used for delivery purposes, bike, car, or both was also observed [

19]. A bike or bicycle-based mode of transport was found to be economical. A study also focused on the fresh produce sector to assign crowd-based capacity [

20]. Their approach used an optimization package accounting for time and space considerations with verification from experiments using simulation. Use of simulation is also widely observed, where it could be used to explore the adoption of hybrid fleets for last-mile delivery services [

21] or to put more focus on the routes and transportation along with crowdsourcing [

22].

Most of the studies that use simulation focus on the operational level, leading to a gap in using simulation to set permanent, seasonal, and crowdsourcing capacities for last-mile delivery services. One particular study [

23] simulated the online food ordering methods, considering the behaviors of customers, merchants, dispatchers, and couriers towards a multiagent model. Their experiments led to an understanding that a larger load capacity of couriers is more of an advantage towards order completion rate.

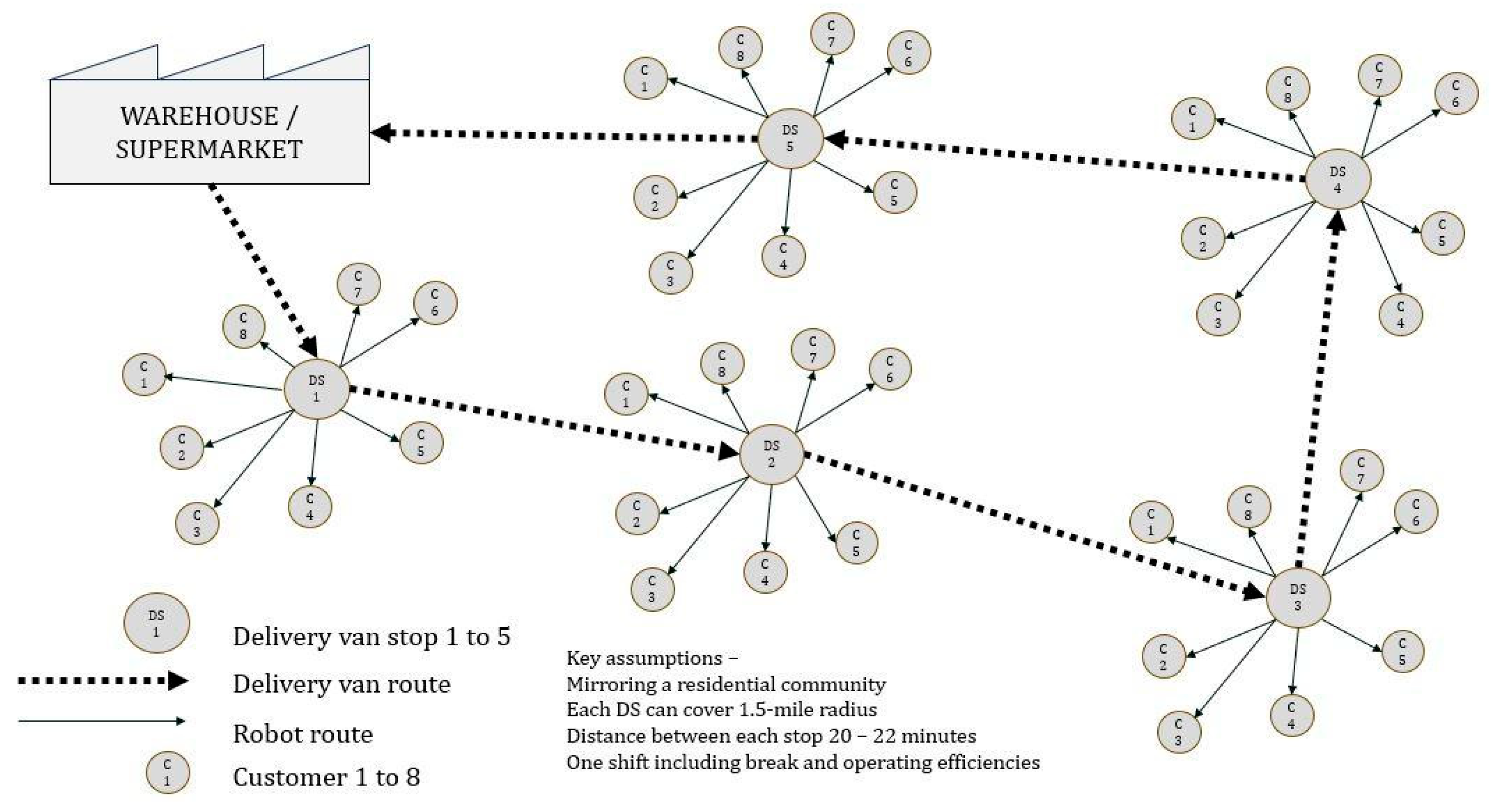

Along with simulation exercises, it is intriguing to observe the use of automation and how it can assist in determining optimal capacities for low operational costs while maintaining service levels. The use of trucks and autonomous robots for last-mile delivery [

11] has also been explored. The authors work on a scheduling problem to assess the merits of this concept. In this study, decentralized robot depots were found to be efficient. A similar type of combination of truck and autonomous robots [

7] but with consideration of multiple trucks delivering robots to drop-off points from which the robots make the final delivery step was studied. It was observed that transportation costs could be reduced. Aerial automation has also been explored for last-mile deliveries [

24]. Here, they have both drones and ground delivery robots under consideration. Drones were found to be economical in less dense and larger service regions, while ground delivery robots were found to be profitable in denser neighborhoods. Benefits of using autonomous robots for last-mile delivery have been well explored [

25]. Combinations of trucks and robots are used for last-mile delivery. It was observed that the use of a combination of trucks and robots led to cost savings when compared to truck-only delivery.

Another study [

26] has acknowledged the growth of ecommerce deliveries and the use of automated robots for delivery. Their research focuses on this increased adoption of robots and the increased regulations by local agencies. A study [

27] that explored the use of autonomous vehicles for last-mile delivery compared their results with traditional services. Here, it is observed that the introduction of autonomous vehicles saves operational time. With parking time being considered, higher savings could be realized. Similarly, authors [

28] have presented a two-echelon van-based robot last-mile pickup-and-delivery system. They compared their results with two classical models and found their results to be competitive. Based on these studies, it could be well perceived that economic benefits are observed when using automation for last-mile delivery services. Another study on the application of robots to last-mile delivery services leading to a truck–robot [

29] system found that robot-assisted last-mile delivery is efficient. This depends on how dense the area is and how much storage can be accommodated by the robots.

For any new technology, stakeholder acceptance is key for successful adoption. There are studies that focus on such acceptance, such as exploring the impact of autonomous vehicle acceptance by end consumers. Their findings suggest that price sensitivity is the strongest point when it comes to user acceptance [

30]. Another study [

31] focused on the public acceptance of use of autonomous delivery robots for last-mile delivery. Their objective was to facilitate the mass adoption of delivery robots while ensuring the public acceptance of such delivery methods.

There is an emphasis on the need for innovative solutions, and [

32] proposed a mixed truck and robot delivery concept. Their research leads to a conclusion that such innovative solutions lead to a better return when compared to a traditional delivery method of using trucks for last-mile delivery. In this pursuit, various combinations of vehicles have been explored. One such approach [

33], where a vehicle would carry parcels from a central depot to facilities, from which robots would be used to make last-mile deliveries, is used as a reference in our study in terms of using a combination of vans and robots to determine the optimal capacity plan. The use of robots for e-grocery delivery was also explored [

34], where the primary objective was to minimize unfulfilled customer demand. It was concluded that considering the uncertainties, a broad time delivery window, and a moderate speed ratio of robots/vans, robots do assist in reducing unmet demand. A review study [

35] also emphasizes the merits of using such automation technologies for last-mile delivery.

Previous works that studied the combination of capacities were either analytical, with capacity and cost of crowdsourcing being fixed [

36], or used a stochastic program to account for the uncertainties of crowdsourcing capacity and costs [

37]. The optimal business solutions were obtained in each of the situations. However, these studies did not account for random employee attrition, a factor that simulation can capture to provide refined insights for an optimal strategy for last-mile delivery services. Another recent technological advancement is the ability to use robots for daily operations and how they would add value to operations for developing an aggregate capacity plan.

Though robots and crowdsourcing have been extensively studied in the literature, a model which combines both these options remains a research gap. Further, no studies considering these new innovations have yet accounted for employee attrition in more traditional approaches to last-mile delivery and its impact on unfilled deliveries. This identifies a second gap in the literature. To address these gaps, we propose a simulation model which allows for traditional or robot delivery combined with a crowdsourcing option while accounting for attrition in traditional delivery.

To summarize, our work is the first to use simulation for an aggregate delivery capacity plan with robots, permanent, seasonal, and crowdsourcing capacities. Further, we study the impact of the attrition rate and undelivered units rolling over to the next period for delivery while optimizing the operational costs for the last-mile delivery services. A key question is how the adoption of robots may alleviate this situation.

These innovative aspects of our work allow us to answer the following research questions:

Can the flexibility of crowdsourcing assist with the challenges caused by attrition? And does the on-demand nature of crowdsourcing capacity mitigate the impact of attrition?

When attrition is in place, do these automated technologies alleviate the problems of missed deliveries and higher operational costs due to attrition?

What are the managerial implications of adopting such automated technologies like robots alongside traditional permanent and seasonal capacities that face such attrition rates and the on-demand nature of crowdsourcing capacity?

5. Discussion

This simulation study focused on assessing the impact of attrition of permanent and seasonal capacities and how advanced automation such as the use of robots might help in lowering operational costs.

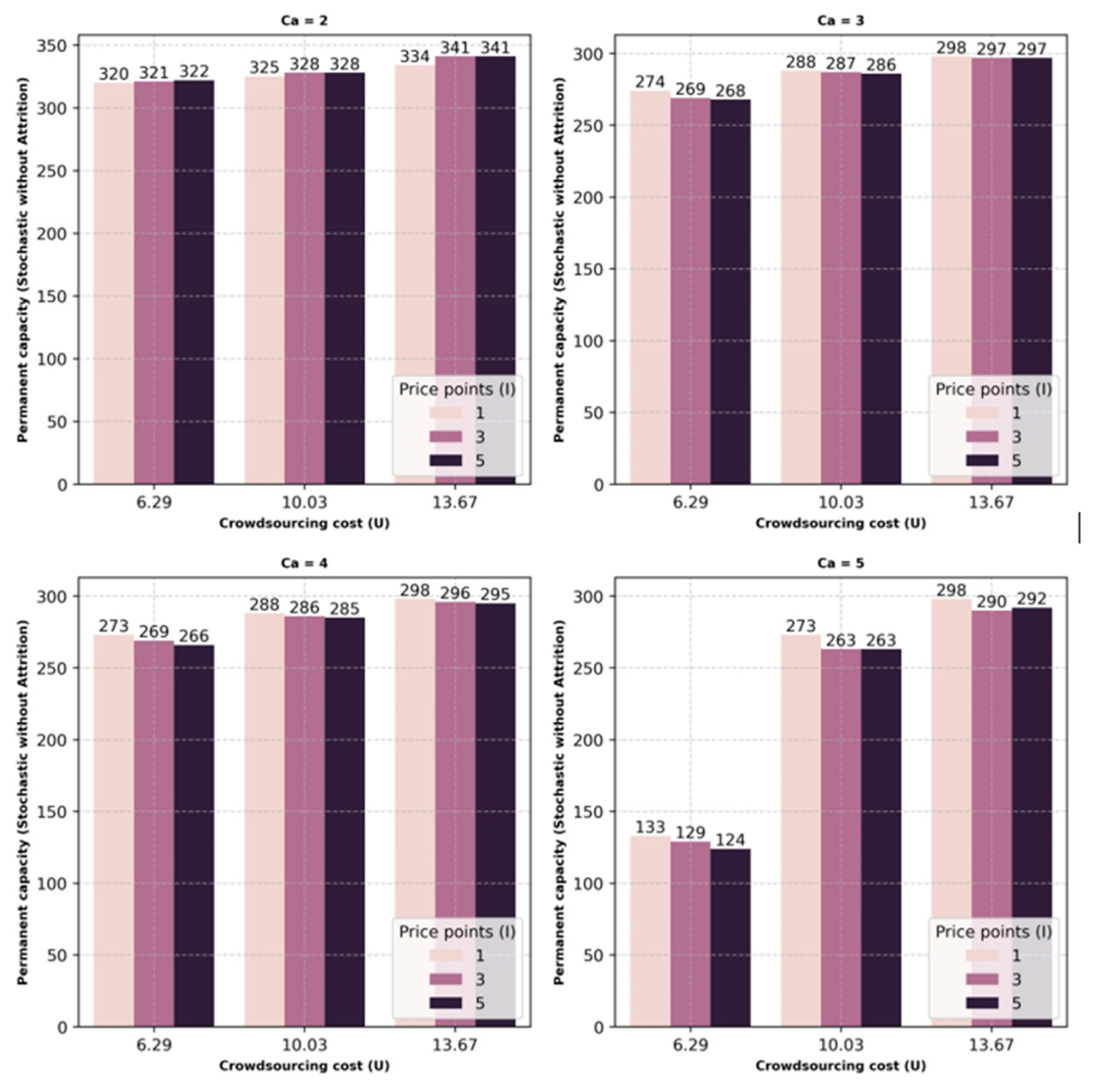

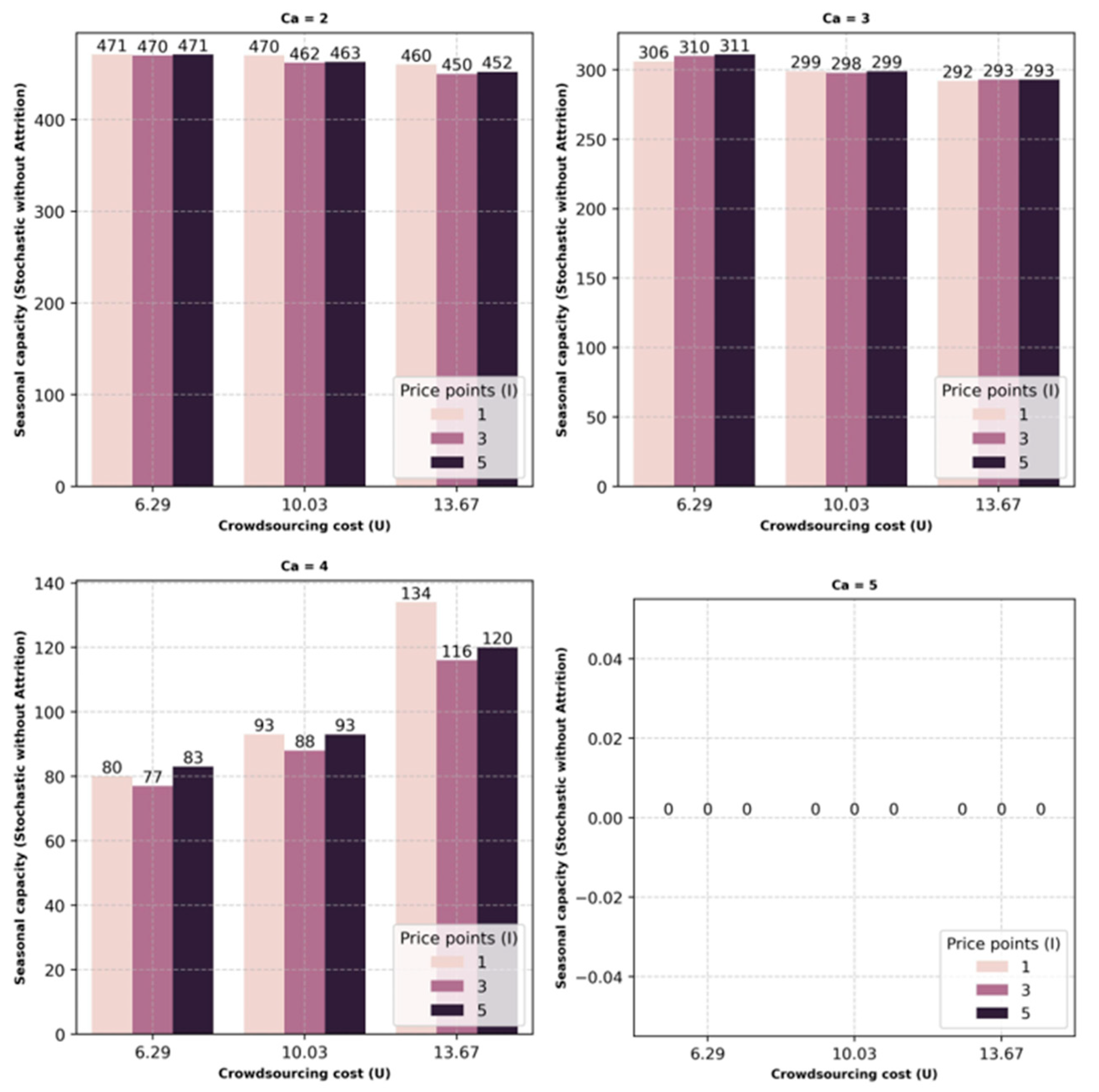

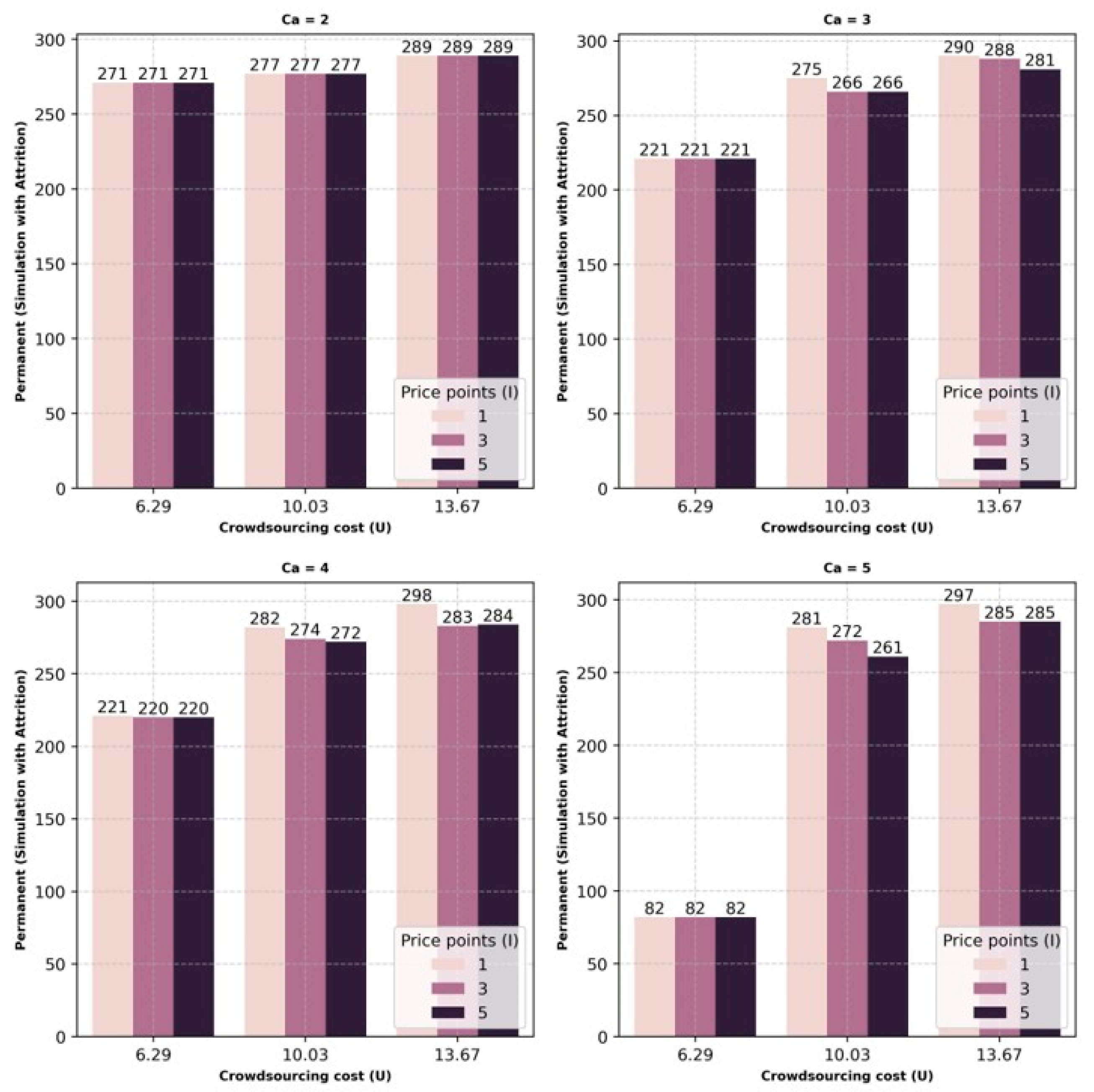

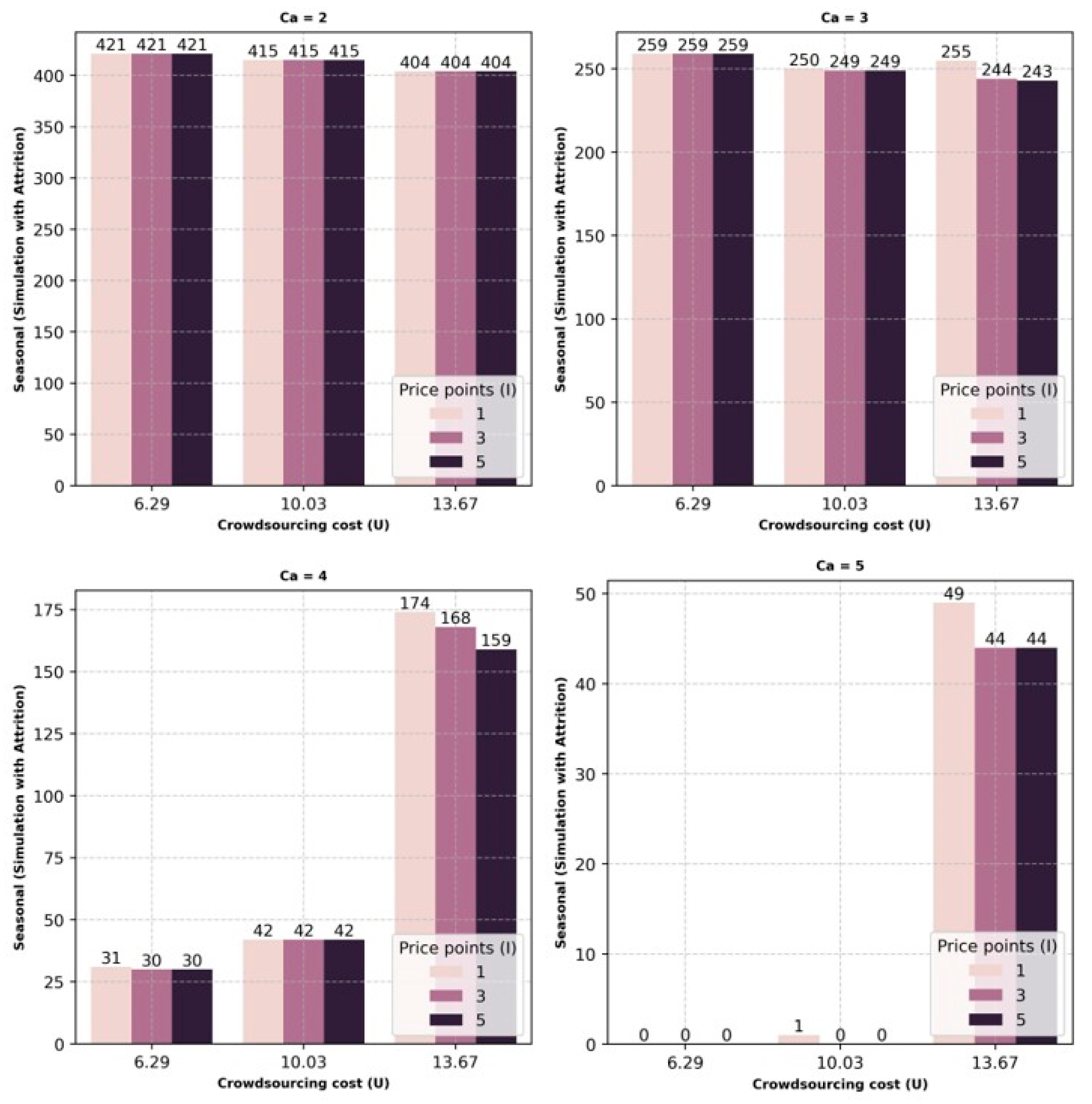

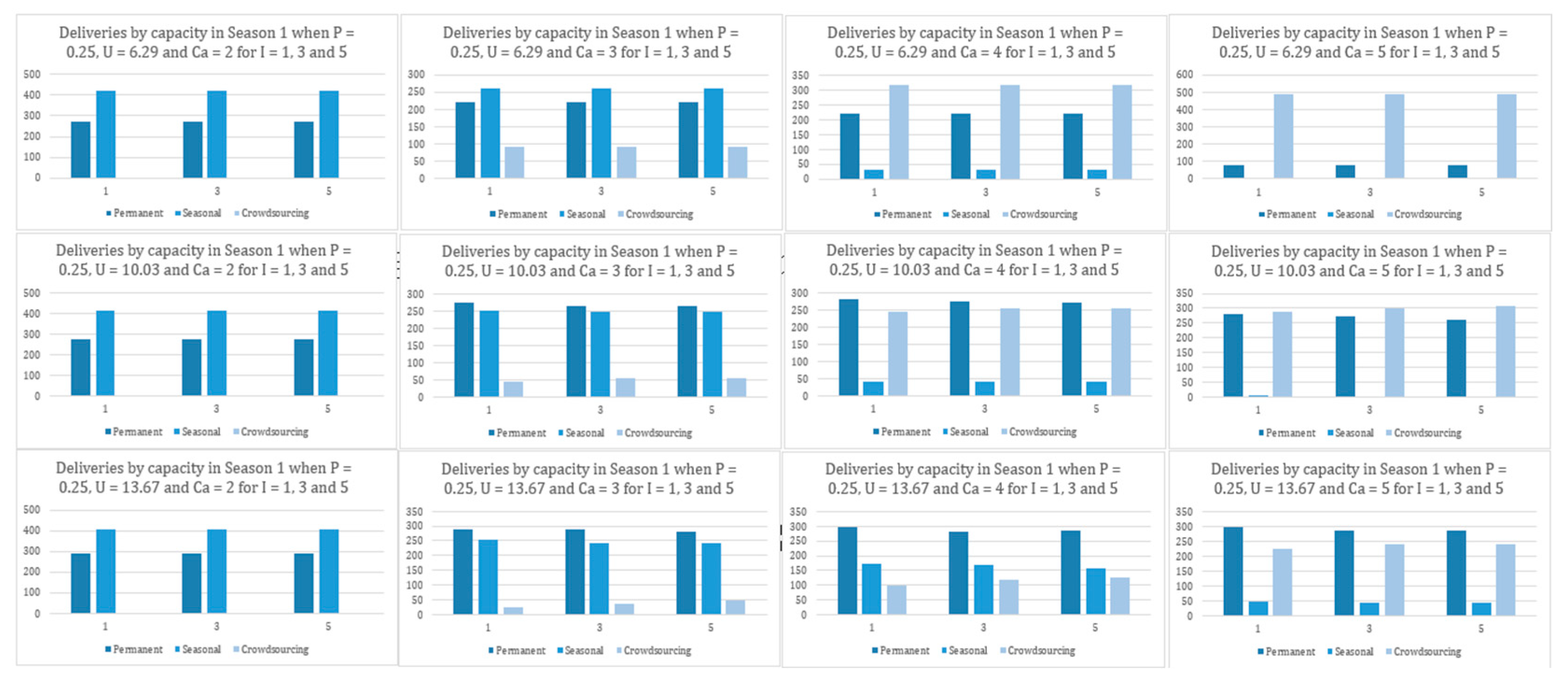

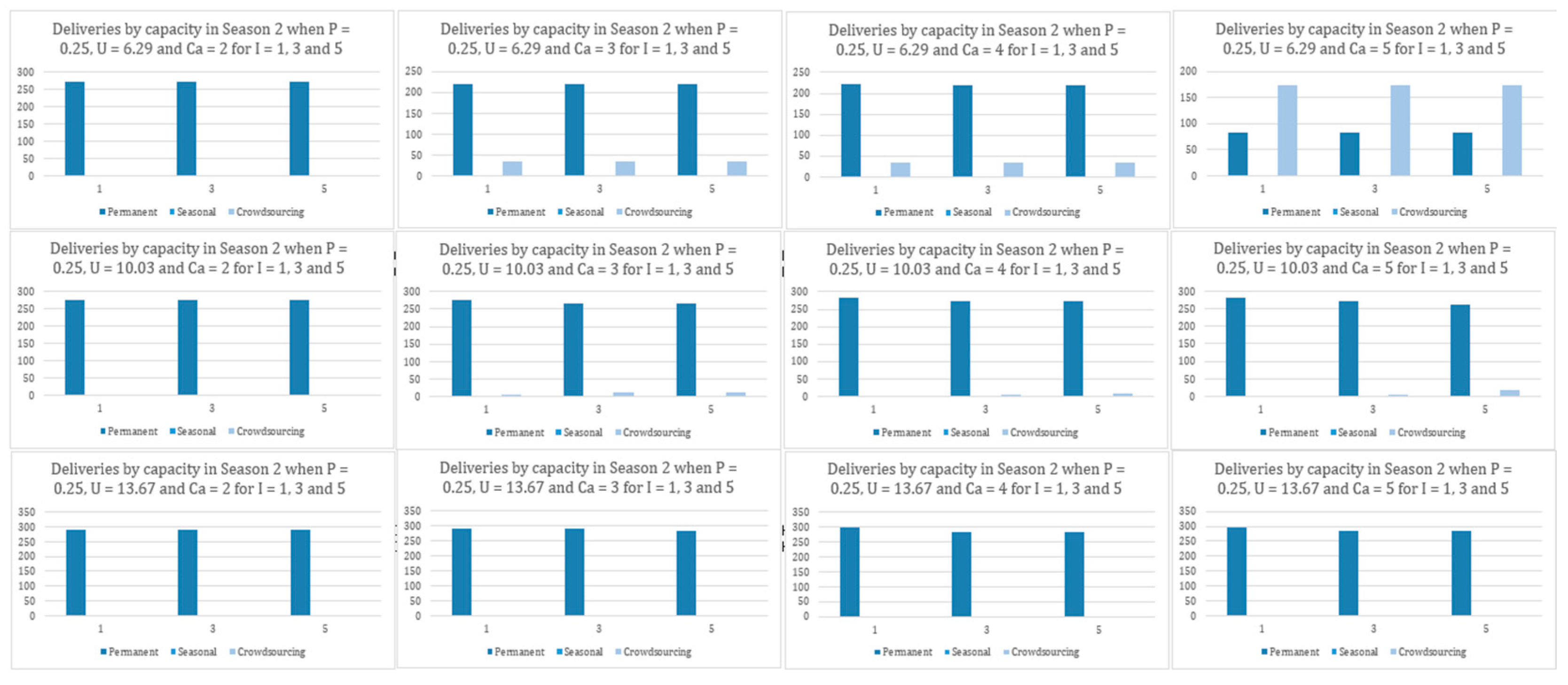

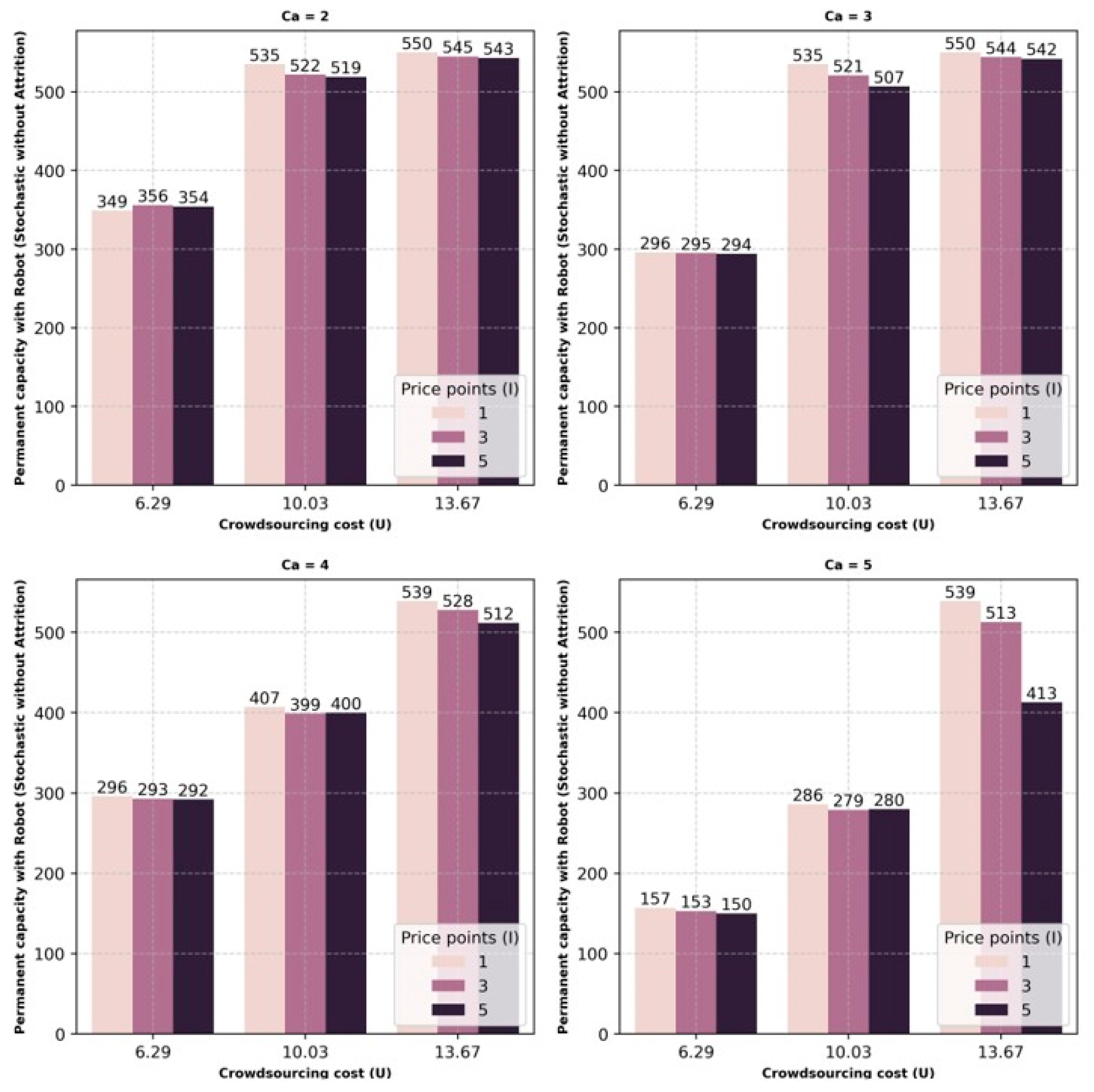

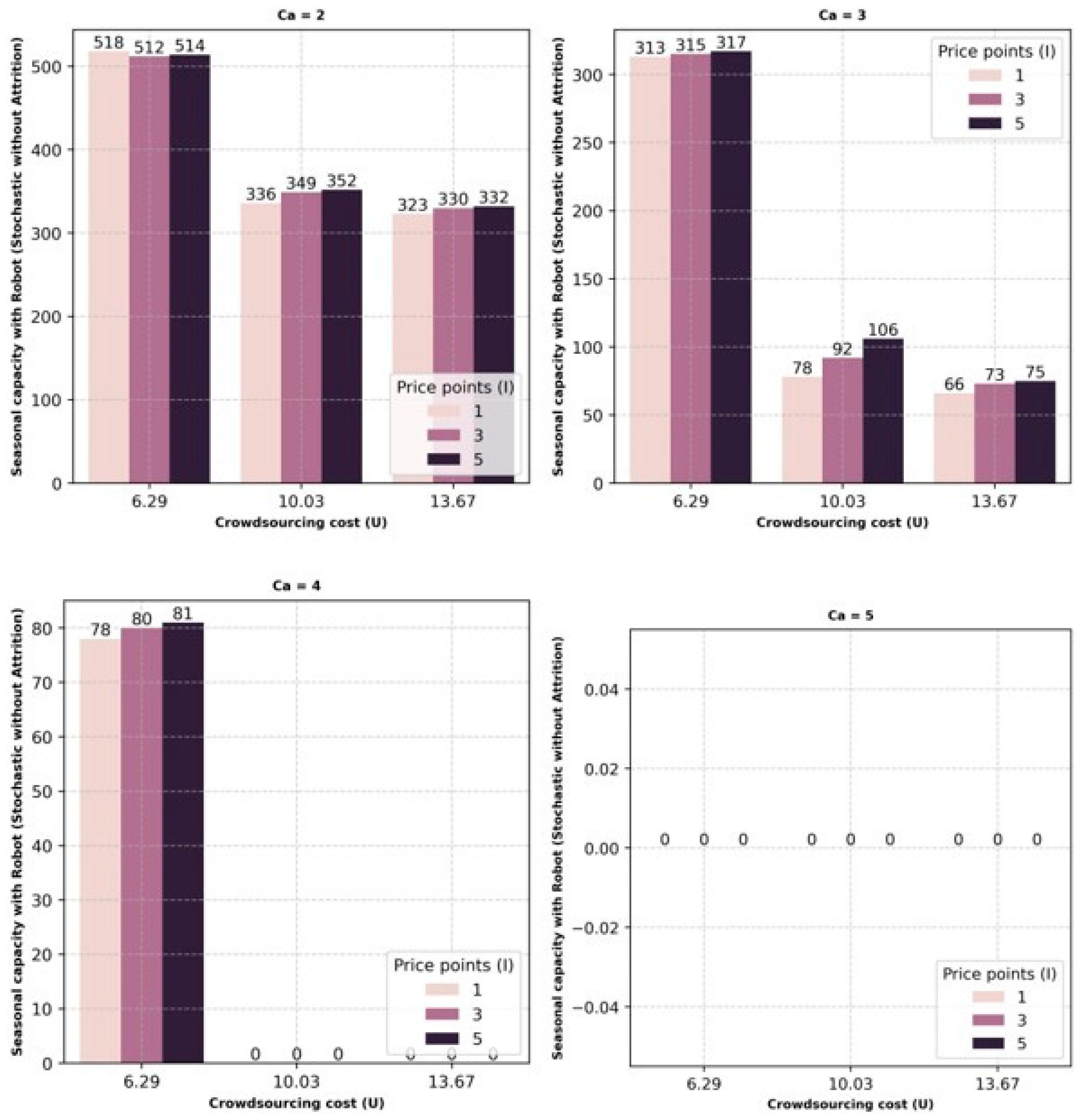

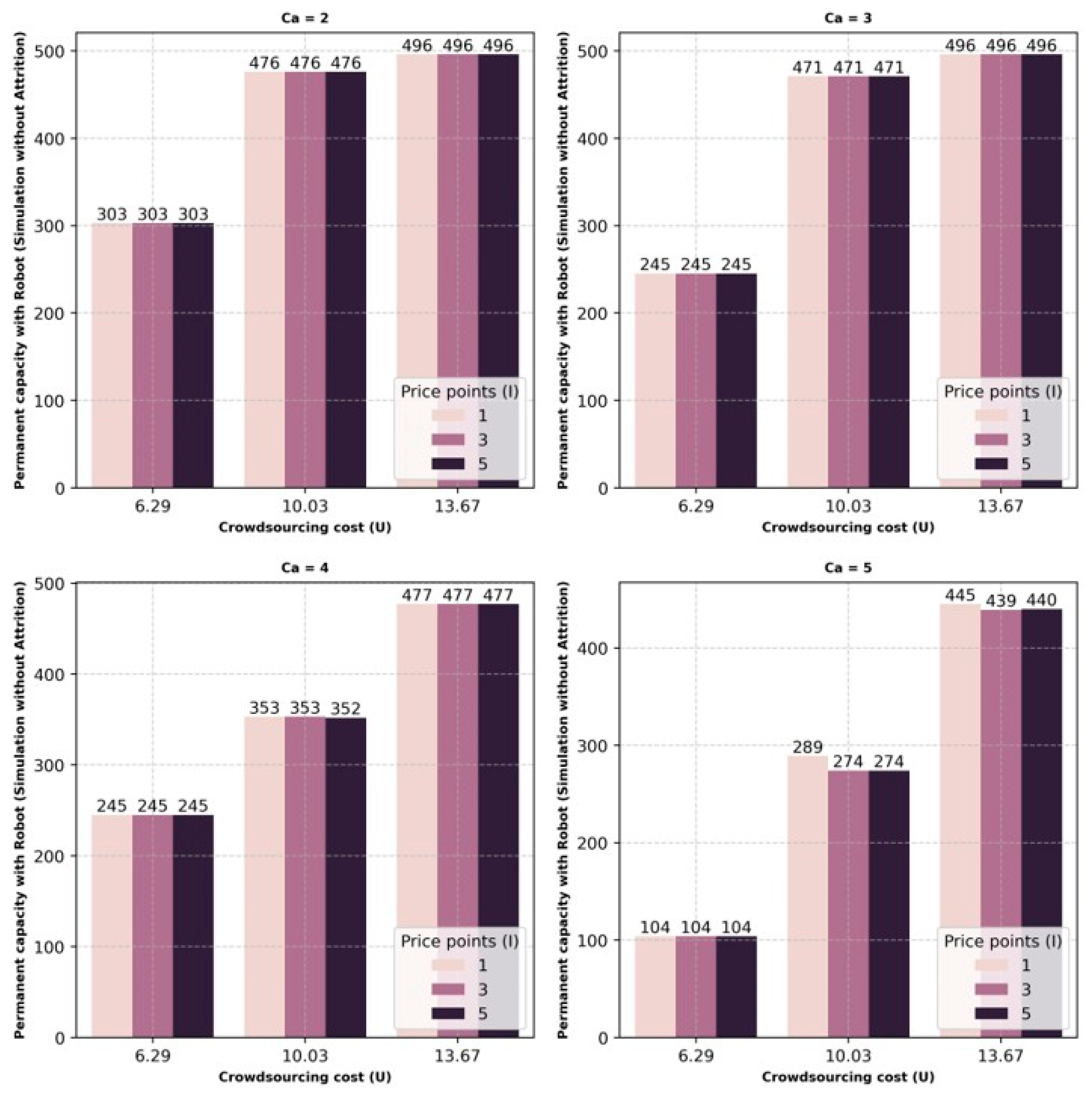

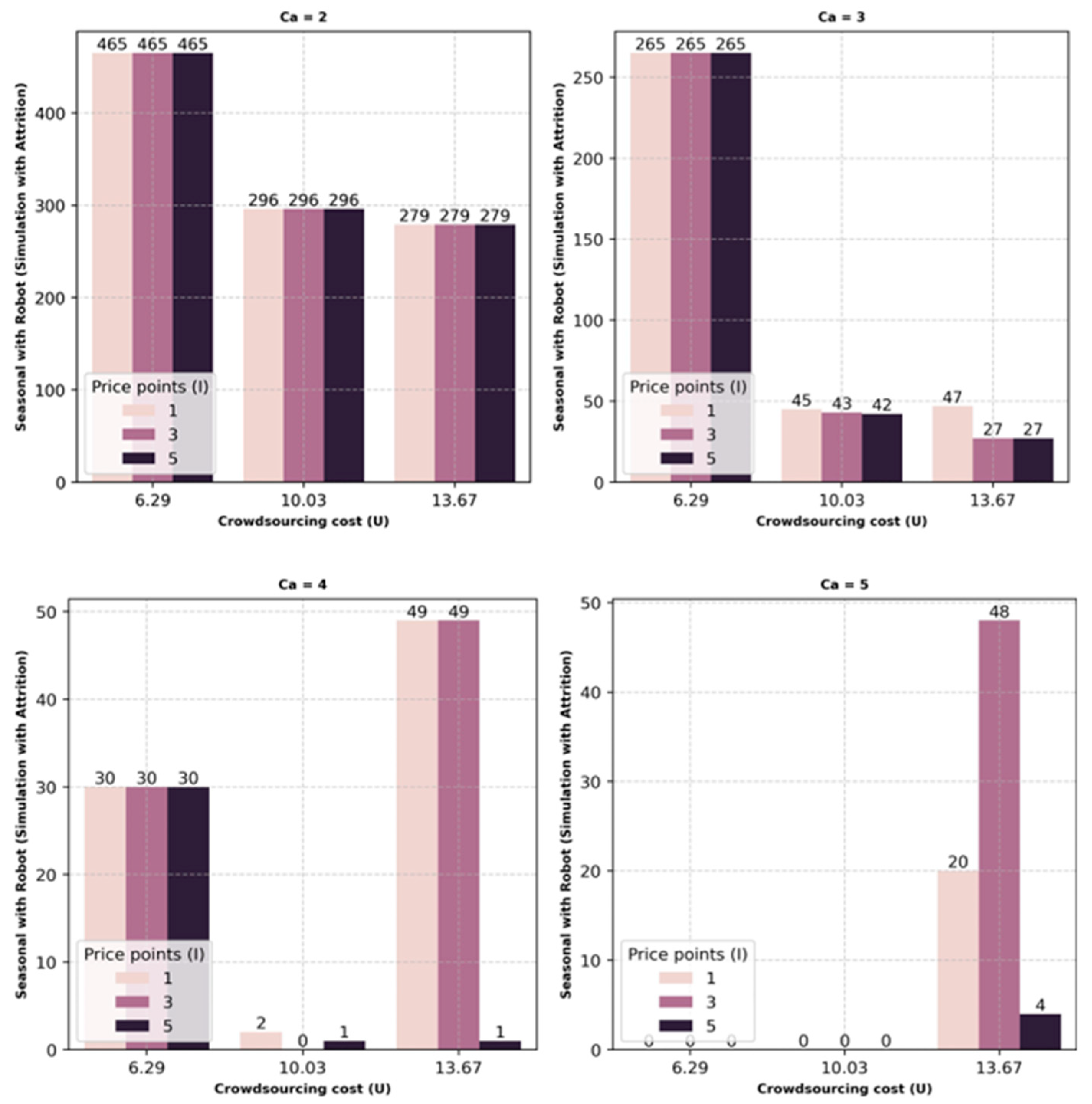

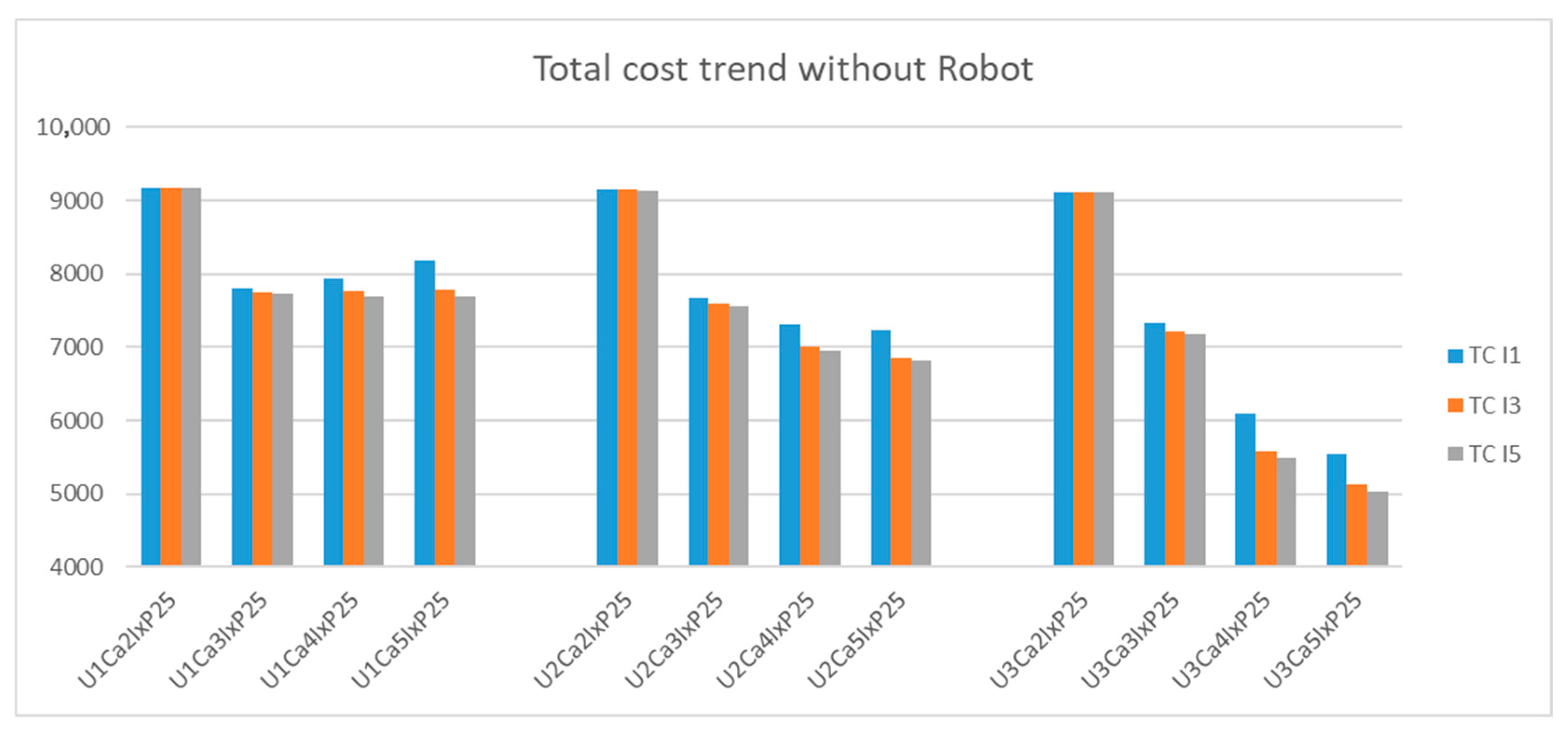

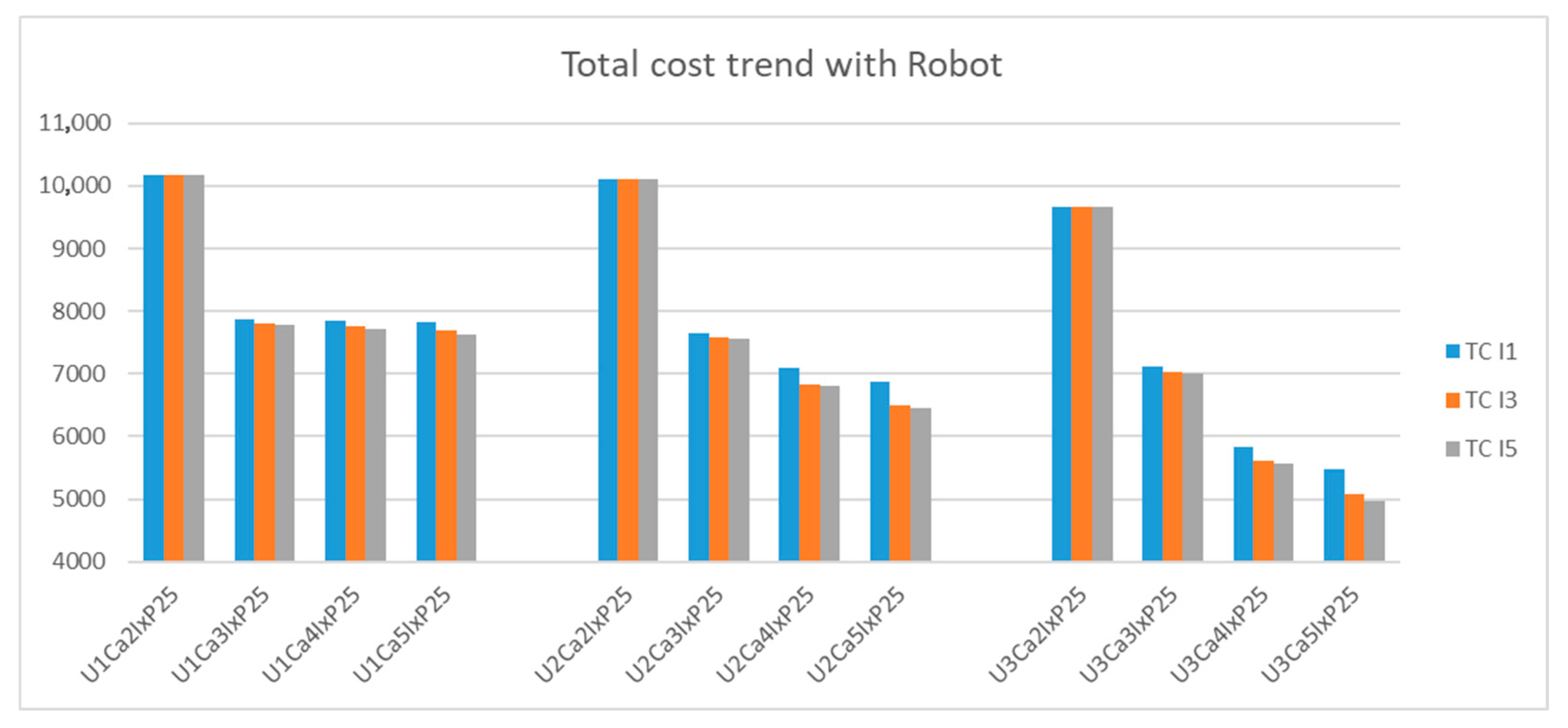

The results from the simulation generated an optimal combination of permanent, seasonal, and crowdsourcing capacity that would lower operational costs or provide an optimal combination for last-mile delivery services. This combination was determined for each scenario, percentage variations, number of price points for crowdsourcing capacity costs, various capacities of crowdsourcing, and considering attrition for permanent and seasonal capacities. Within each scenario, as the capacity of crowdsourcing increases, the utilization of permanent and seasonal capacity reduces. Between permanent and seasonal capacity, a drastic decrease in seasonal capacity is observed, whereas the utilization of permanent capacity shows only a minor rate of decrease. With this drastic decrease in seasonal capacity, the utilization of crowdsourcing capacity is observed to increase, implying that a drop in the utilization of seasonal capacity is compensated for by crowdsourcing.

Based on the results, we refer to our three research questions and provide some managerial insights for aggregate capacity planning.

The biggest threat for delivery companies is that any loss of capacity will lead to dissatisfaction among customers from the impact on service levels. Flexible crowdsourcing capacity can support this organizational need by filling in whenever there is loss of capacity due to attrition. The on-demand nature of crowdsourcing capacity does indeed help overcome employee absence on short notice. This is a positive sign for businesses that can avoid lost revenue. The one caveat might be the capacity of crowdsourcing during a given period. As observed in the results, the reduction in seasonal or permanent capacities was lower when the crowdsourcing capacity was at its lowest and increased as the crowdsourcing capacity increased. Alternatively, this would imply that the optimum cost profile changes with the increase or decrease in the flexible crowdsourcing capacity. This information could be used to emphasize permanent or seasonal resources for regions or periods where it is expected that the crowdsourcing capacity will be low or high, for example, an urban versus rural environment or a holiday versus regular season.

The output of the numerical experiments considering the use of van–robot delivery provides us with some valuable insights for managerial decisions. Specifically, with regards to robots, they assist in lowering the service level impact as attrition is reduced. Addition of robots in last-mile delivery operations show cost savings opportunities in certain scenarios. With this van–robot combination, the preference for permanent capacity is higher due to the operation costs of automation. Crowdsourcing capacity is used to fill the gap only when permanent capacity becomes exhausted.

As observed in this simulation, the demand being random and the flexibility of the crowdsourcing considered assists in determining an optimal combination of capacities. This is carried out considering the crowdsourcing cost points and capacities. For businesses, this type of analysis will be beneficial in case of providing an aggregate capacity plan for the upcoming operational year. Having an understanding of the forecasted demand, costs of permanent and seasonal capacities, and expected capital investments for automation will be imperative. In addition, the costs and capacities of crowdsourcing available in a region will further motivate decision-makers to plan for optimal capacities where one can ensure that there is no expenditure for surplus capacity when demand is low and use crowdsourcing when the demand spikes. This analysis serves as an input point for decision-making. Managerial insights obtained from such studies will definitely be an added advantage for businesses providing last-mile delivery services.

6. Conclusions

In this study, we considered the impact of attrition to determine the optimal aggregate delivery capacity plan. In addition, we explored the use of automation to assist in further optimizing the operational costs and service levels. Through numerical experiments we observe cost savings for certain scenarios and opportunities for businesses to improve service levels.

Overall, this study provides businesses with insights needed for aggregate capacity planning when dealing with attrition, an option for automation, and an option for crowdsourcing. This analysis answered the fundamental questions necessary for capacity planning by determining an optimal capacity plan. Specifically, a business should have a solid understanding of the crowdsourcing capacity landscape, as crowdsourcing can provide added flexibility and the volume of demand, which is essential for justifying the ROI for automation projects. This is demonstrated in the results by available crowdsourcing capacity reducing the amount of seasonal capacity as opposed to permanent capacity. For automation projects, it was seen that project ROI was highly dependent on crowdsourcing costs and capacities, demonstrating the need to analyze a wide range of scenarios to identify the potential benefit of automation.

As for further research, it would be worthwhile to explore the stochastic nature of automation or examine the positive impact on the environment by easing traffic in a dense city scenario or reducing emissions. This has tremendous potential to lower operational costs and reduce environmental impact. Thus, more research can be carried out to understand the challenges and benefits new technologies will provide in the long run. Empirical case data or applying a business case to derive managerial insights is another direction for future research that can further test the validity of our results. The insights from this type of analysis are anticipated to assist with policy formulations regarding the use of automation in public spaces and business decisions.