Exploring Industry 4.0’s Role in Sustainable Supply Chains: Perspectives from a Bibliometric Review

Abstract

1. Introduction

2. Methods

2.1. Identification and Selection Significant Keywords for Scopus Search

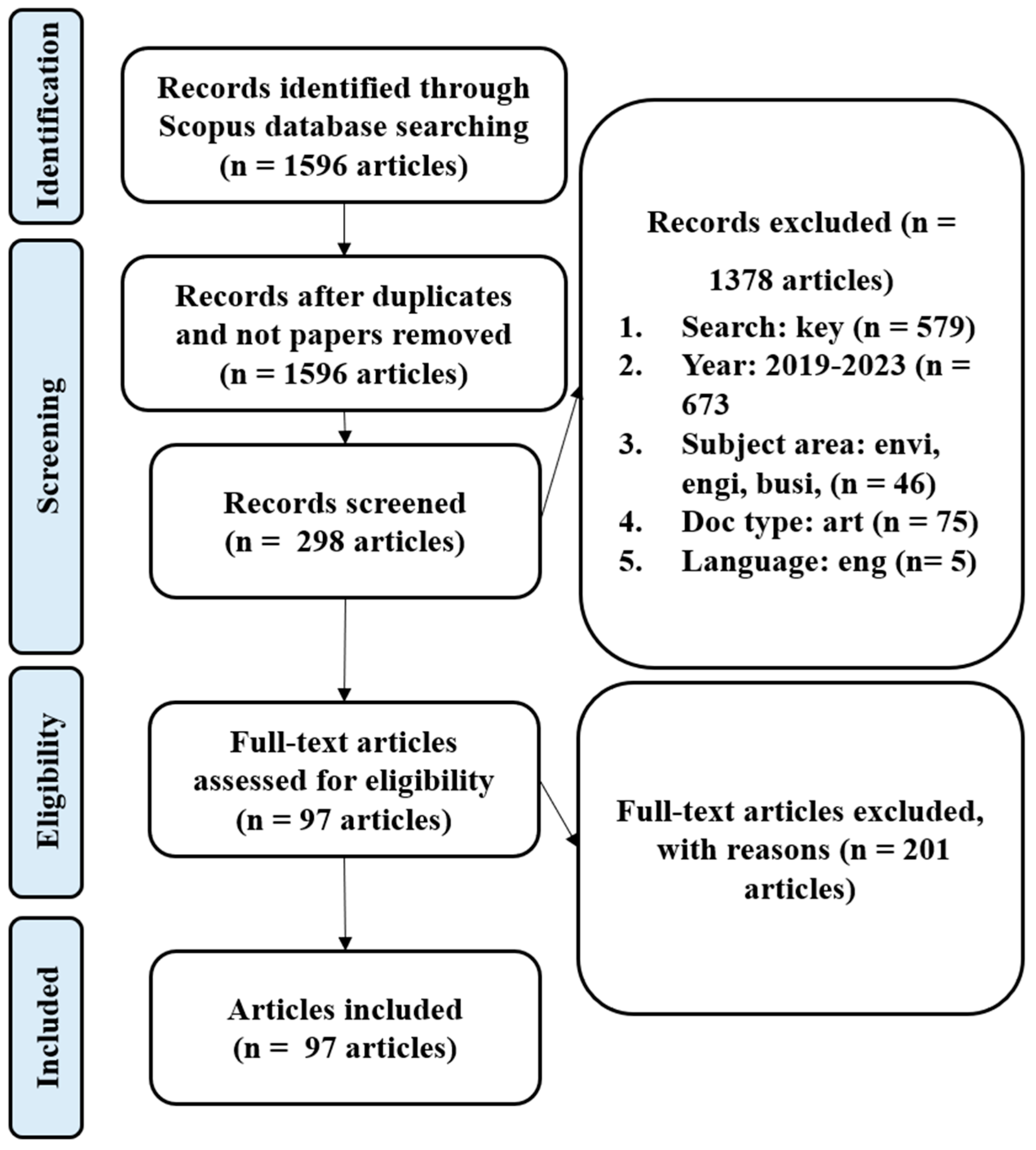

2.2. Documents Search

- Keyword Priority: Assuming that the documents’ keywords reflect the central theme developed, the search was restricted to keywords only, excluding titles and abstracts. This reduced the number of articles to 1017.

- Publication Year: The systematic science mapping analysis on I4.0 and SC from Nùnez-Merino et al. [2] shows that the trend of publications number becomes exponential from 2020. After all, it can be assumed that outdated and irrelevant articles do not provide significant contributions, as well as that relevant but older studies should have already been referenced in recent studies (in terms of citations and thematic depth). Therefore, our analysis included publications from 2021 to the current date of access to the database (2023). Such filtering reduced the number of articles to 344.

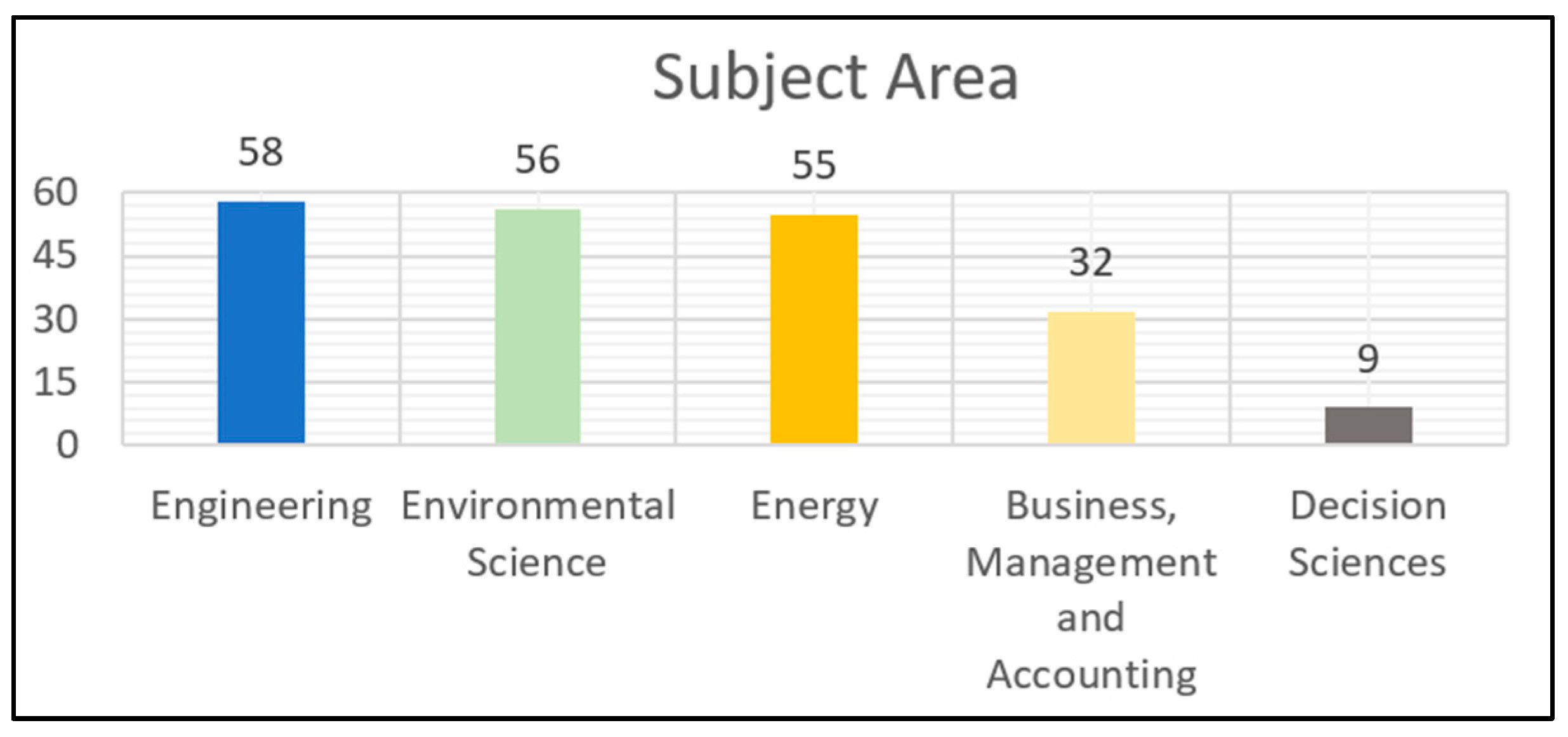

- Subject Area: The third filtering criterion focused on selecting only relevant subject areas, namely:

- Environmental Science and Energy, focusing on environmental impact analysis, CO2 emissions, and carbon footprint;

- Engineering, to include industrial engineering aspects related to CLSC production processes;

- Business, Management, and Accounting, considering economic evaluations of Industry 4.0 applications in the supply chain, particularly in terms of costs and profits linked to CO2 emissions;

- Decision Science, to involve studies on modeling complex decision-making processes in supply chain management.

- 4.

- Document Type: Assuming that journal papers represent the highest quality of work in terms of form and content compared to other document types, only journal papers were included. This step further reduced the number of articles to 223.

- 5.

- Language: By selecting only articles written in English, the dataset was reduced to 218.

- 6.

- Abstract content analysis. The reading and content analysis of the abstract allowed for the selection of works consistent with the objectives of this study. After applying this last filter, the number of articles was reduced to 97.

2.3. Scopus Filter Analysis

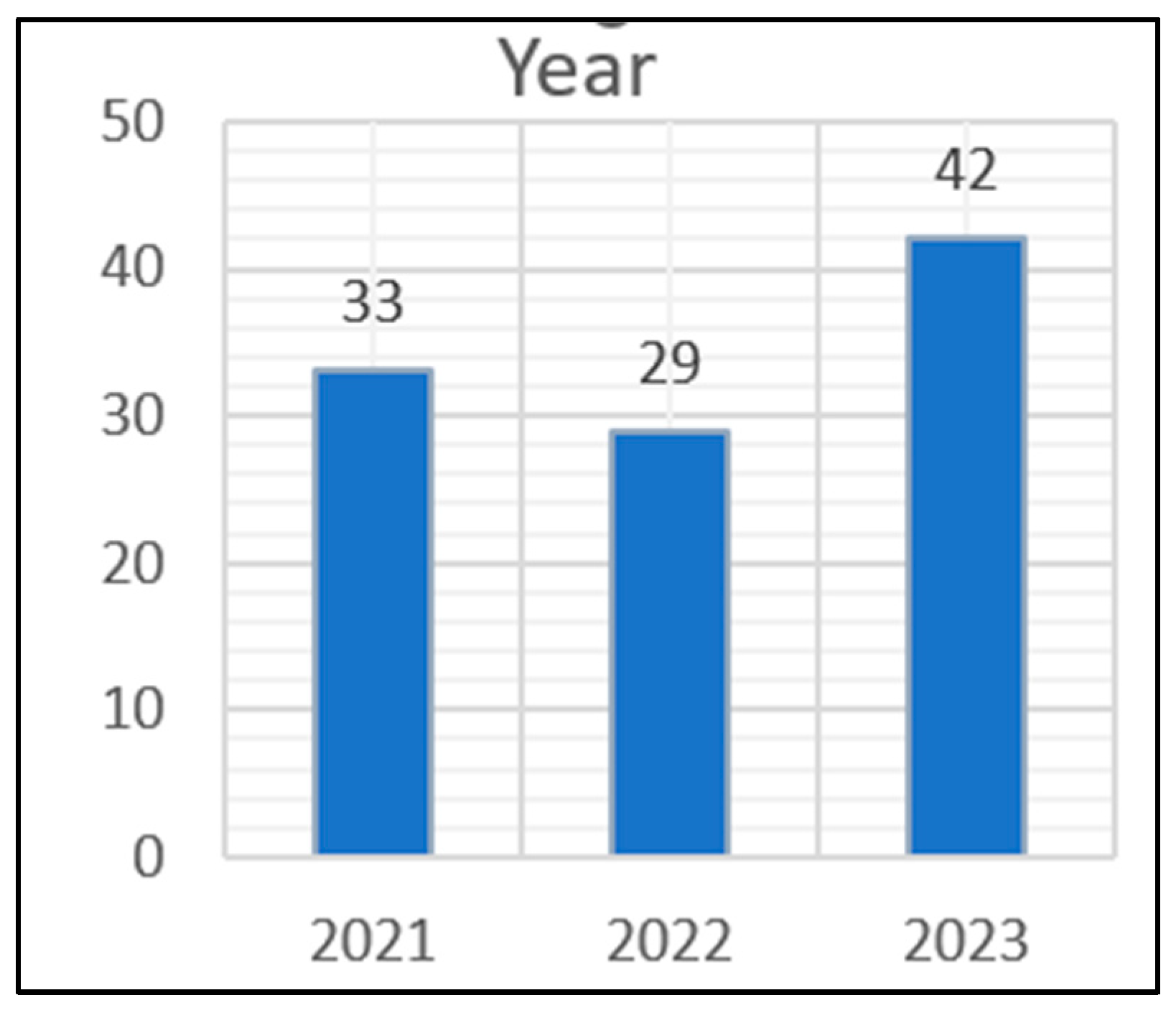

2.3.1. Years

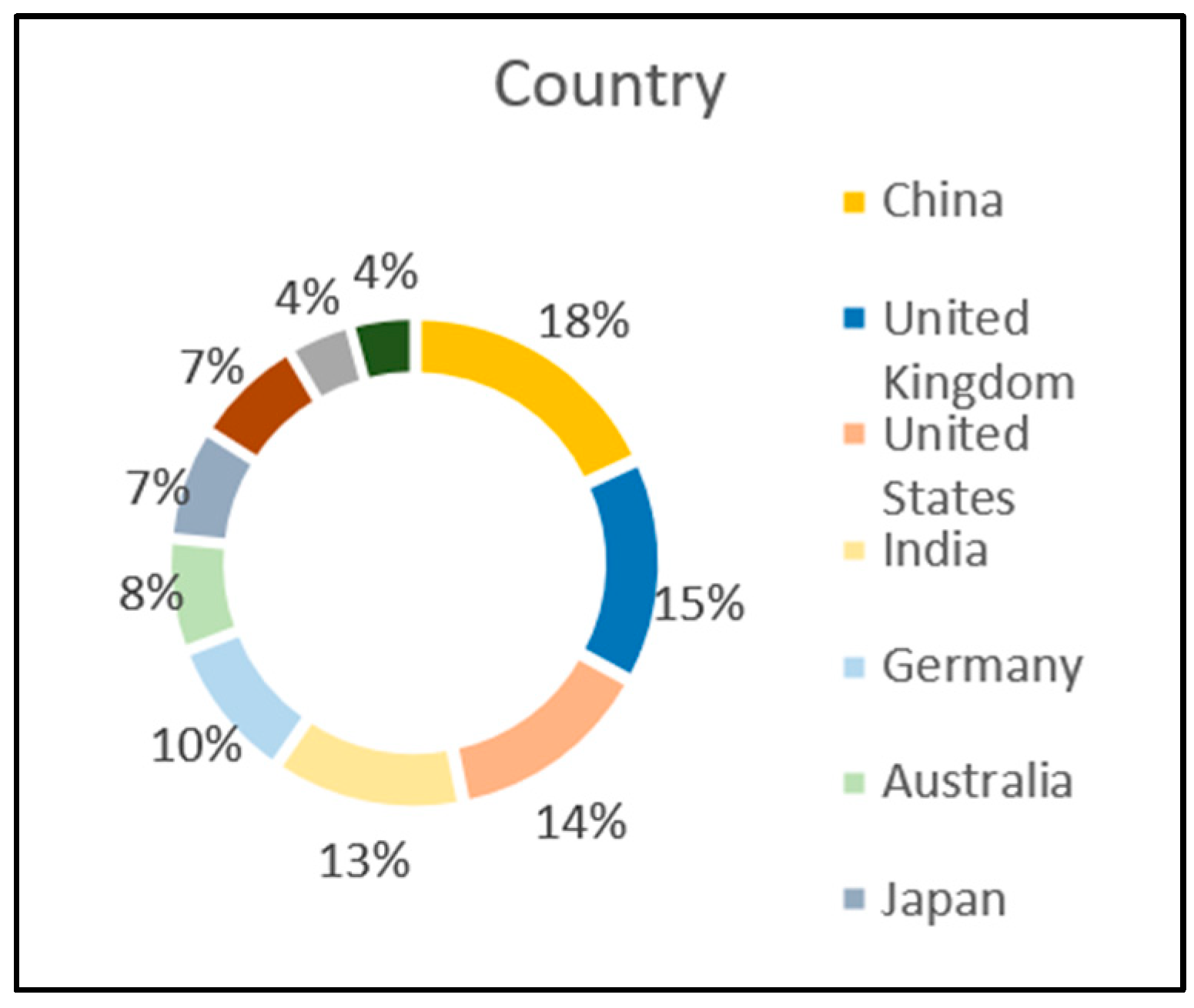

2.3.2. Country

2.3.3. Subject Areas

2.3.4. Source

2.3.5. Affiliation

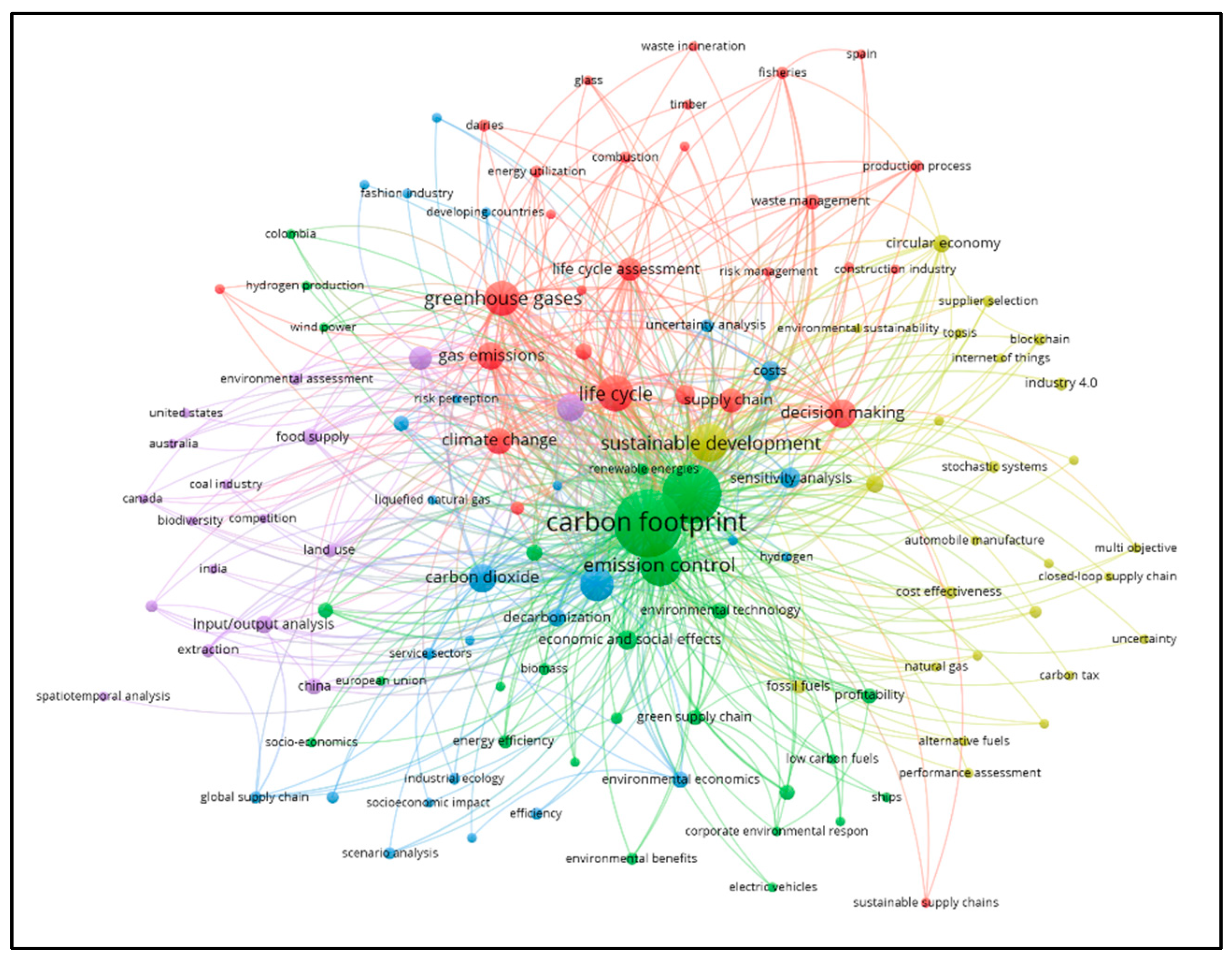

2.4. VOSviewer Analysis

- Co-occurrence Analysis: The frequency of two or more keywords appearing together in different articles was analyzed, yielding 1240 keywords. The minimum number of times a keyword must appear to be included in the software output was set to 2, resulting in 195 keywords. While this inclusive approach might appear too broad, it is aligned with the exploratory nature of this study.

- Relevant Keywords: Specific keywords were excluded due to limited relevance to the topic or redundancy. These include the following:

- Duplicates of keywords already present with higher occurrence counts, e.g., “block-chain”, “carbon”, “carbon emissions”, “carbon footprint”, “closed-loop supply chain”, “environmental sustainability”, “life cycle analysis”, “renewable energy source”, “sustainable supply chain management”, and “zero carbon”.

- Generic terms lacking precise meaning without context, such as “business”, “canning”, “case studies”, “fish”, “green”, “investments”, and “sales”.

- Niche or specific terms irrelevant to the broader analysis, such as “decomposition analysis”, “lithium-ion batteries”, “structural decomposition analysis”, and “water stress”.

- Lines Parameter (Minimum Strength): This parameter represents the minimum number of links for a line connecting two keywords to be displayed. A value of 3 was chosen as optimal.

- Cluster Analysis: The parameter “Min. Cluster Size” was set to 14, meaning that each cluster needed at least 14 keywords to be considered valid. This choice was based on the following experiments:

- Setting the parameter to 1 resulted in clusters with as few as three keywords, producing meaningless outcomes.

- Setting it to 4 identified 8 clusters, but two clusters contained very generic terms.

- Increasing the value to 11 resulted in 6 clusters, with the smallest containing 13 keywords.

- Finally, setting the value to 14 identified 5 clusters. The smallest cluster from the previous attempt was merged with others, leading to the hypothesis that 5 clusters is the optimal number for analysis.

- -

- Red cluster “LCA towards zero carbon”;

- -

- Green cluster “Supply Chain carbon footprint”;

- -

- Blue cluster “Risk and decarbonization analysis”;

- -

- Yellow cluster “Industry 4.0 and stochastic models for sustainability”;

- -

- Purple cluster “Biodiversity and environmental impact”.

3. Results and Discussion

3.1. Cluster 1 (Red)—LCA Towards Zero Carbon

- Strength 5 for the connection between “gas emissions” and “life cycle”.

- Strength 7 for the connection between “climate change” and “life cycle”.

- Strength 13 for “greenhouse gases” and “gas emissions”.

- Strength 3 for “decision making” and “life cycle”.

Cluster 1 Correlation Analysis (Table 3)

| Cluster 1 | Cluster 2 | Cluster 3 | Cluster 4 | Cluster 5 | |

|---|---|---|---|---|---|

| greenhouse gases | gas emissions (13), life cycle (11) | supply chains (24), carbon footprint (25), emission control (10) | - | - | environmental impact (6) |

| life cycle | life cycle assessment (11), greenhouse gases (11), climate change (7) | supply chains (26), carbon footprint (28), emission control (12) | carbon dioxide (6), supply chain management (6) | sustainable development (11) | environmental impact (8) |

| life cycle assessment/life cycle assessment (LCA) | life cycle (11/0) | carbon footprint (11/6), supply chains (10/0) | - | - | - |

| decision making | - | carbon footprint (17), supply chains (14) | - | sustainable development (11) | - |

| climate change | life cycle (7) | carbon footprint (14), supply chains (12), emission control (8) | - | - | - |

| supply chain | - | carbon footprint (12), supply chains (8) | - | - | - |

3.2. Cluster 2 (Green)—Supply Chain Carbon Footprint

- Strength 73 for the link between “carbon footprint” and “supply chains”;

- Strength 5 for the link between “carbon footprint” and “green supply chain”;

- Strength 4 for the link between “supply chains” and “green supply chain”.

Cluster 2 Correlation Analysis (Table 4)

| Cluster 1 | Cluster 2 | Cluster 3 | Cluster 4 | Cluster 5 | |

|---|---|---|---|---|---|

| supply chains | greenhouse gases (24), life cycle (26), gas emissions (15), decision making (14), climate change (12), life cycle assessment (10), supply chain (8), global warming (7) | carbon footprint (73), emission control (32), economic and social effects (6), environmental technology (6) | carbon dioxide (13), supply chain management (9), costs (8), sensitivity analysis (8), decarbonization (6) | sustainable development (26), circular economy (6) | environmental impact (15), sustainability (7), food supply (6) |

| carbon footprint | greenhouse gases (25), life cycle (28), decision making (17), gas emissions (16), climate change (14), supply chain (12), life cycle assessment (11), global warming (8), life cycle assessment (lca) (6) | emission control (38), supply chains (73), economic and social effects (8), environmental technology (6), environmental footprint (6) | supply chain management (24), carbon dioxide (17), sensitivity analysis (9), costs (8), decarbonization (7), environmental economics (6) | sustainable development (30), circular economy (7), recycling (7) | environmental impact (16), sustainability (11), input/output analysis (7), food supply (6), China (6) |

| emission control | life cycle (12), greenhouse gases (10), gas emissions (9), climate change (8) | carbon footprint (38), supply chains (32) | supply chain management (8), carbon dioxide (6) | sustainable development (6) | - |

3.3. Cluster 3 (Blue)—Risk and Decarbonization Analysis

Cluster 3 Correlation Analysis (Table 5)

| Cluster 1 | Cluster 2 | Cluster 4 | |

|---|---|---|---|

| supply chain management | life cycle (6) | carbon footprint (24), supply chains (9), emission control (8) | sustainable development (7) |

| carbon dioxide | life cycle (6) | carbon footprint (17), supply chains (13), emission control (6) | - |

| Sensitivity analysis | - | carbon footprint (9), supply chains (8) | - |

| costs | - | carbon footprint (8), supply chains (8) | - |

| decarbonization | - | carbon footprint (7), supply chains (6) | - |

3.4. Cluster 4 (Yellow)—Industry 4.0 and Stochastic Models for Sustainability

- Strength of 2 between “sustainable development” and “recycling”;

- Strength of 2 between “sustainable development” and “fossil fuels”.

Cluster 4 Correlation Analysis (Table 6)

| Cluster 1 | Cluster 2 | Cluster 3 | Cluster 5 | |

|---|---|---|---|---|

| sustainable development | life cycle (11), decision making (11) | carbon footprint (30), supply chains (26), emission control (6) | supply chain management (7) | environmental impact (10), sustainability (8) |

3.5. Cluster 5 (Purple)—Biodiversity and Environmental Impact

Cluster 5 Correlation Analysis (Table 7)

| Cluster 1 | Cluster 2 | Cluster 4 | |

|---|---|---|---|

| environmental impact | life cycle (8), greenhouse gases (6) | carbon footprint (16), supply chains (15) | sustainable development (10) |

| sustainability | - | carbon footprint (11), supply chains (7) | sustainable development (8) |

4. Conclusions

4.1. Practical Implications

4.2. Theoretical Contributions

4.3. Final Remarks

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kagermann, H.; Wahlster, W.; Helbig, J. Recommendations for Implementing the Strategic Initiative Industrie 4.0; Final Report of the Industrie 4.0 Working Group; Forschungsunion: Berlin, Germany, 2013. [Google Scholar]

- Nunez-Merino, M.; Maqueira-Marin, J.M.; Moyano-Fuentes, J.; Castano-Moraga, C.A. Industry 4.0 and supply chain. A Systematic Science Mapping analysis. Technol. Forecast. Soc. Change 2022, 181, 121788. [Google Scholar] [CrossRef]

- Mancusi, F.; Fruggiero, F.; Panagou, S. Mapping Uncertainty Sources Affecting Circularity: A Holonic Approach. In Proceedings of the 9th International Conference on Control, Decision and Information Technologies (CoDIT), Rome, Italy, 3–6 July 2023; pp. 2713–2720. [Google Scholar]

- Gan, S.S. Closed-Loop Supply Chain as an Agent of Sustainable Development. J. Tek. Ind. 2015, 17, 7–16. [Google Scholar]

- Souza, G.C. Closed-Loop Supply Chains: A Critical Review, and Future Research. Decis. Sci. 2013, 44, 7–38. [Google Scholar] [CrossRef]

- Ferraro, S.; Cantini, A.; Leoni, L.; De Carlo, F. Sustainable Logistics 4.0: A Study on Selecting the Best Technology for Internal Material Handling. Sustainability 2023, 15, 7067. [Google Scholar] [CrossRef]

- Butzer, S.; Kemp, D.; Steinhilper, R.; Schotz, S. Identification of Approaches for Remanufacturing 4.0. In Proceedings of the 2016 IEEE European Technology and Engineering Management Summit (E-TEMS), Frankfurt, Germany, 3–4 November 2016. [Google Scholar]

- Yang, S.; Raghavendra, M.R.; Kaminski, J.; Pepin, H. Opportunities for Industry 4.0 to Support Remanufacturing. Appl. Sci. 2018, 8, 1177. [Google Scholar] [CrossRef]

- Kerin, M.; Pham, D.T. Smart remanufacturing: A review and research framework. J. Manuf. Technol. Manag. 2020, 31, 1205–1235. [Google Scholar] [CrossRef]

- Karmaker, C.L.; Al Aziz, R.; Ahmed, T.; Misbauddin, S.M.; Abdul Moktadir, M. Impact of industry 4.0 technologies on sustainable supply chain performance: The mediating role of green supply chain management practices and circular economy. J. Clean. Prod. 2023, 419, 138249. [Google Scholar] [CrossRef]

- Machado, E.A.; Scavarda, L.F.; Gusmao Caiado, R.G.; Silva Santos, R. Industry 4.0 and Sustainability Integration in the Supply Chains of Micro, Small, and Medium Enterprises through People, Process, and Technology within the Triple Bottom Line Perspective. Sustainability 2024, 16, 1141. [Google Scholar] [CrossRef]

- Li, Q.; Tang, W.; Li, Z. Leveraging Industry 4.0 for Sustainable Manufacturing: A Quantitative Analysis Using FI-RST. Appl. Sci. 2024, 14, 9545. [Google Scholar] [CrossRef]

- Berg, H.; Bendix, P.; Jansen, M.; Le Blévennec, K.; Bottermann, P.; Magnus-Melgar, M.; Pohjalainen, E.; Wahlström, M. Unlocking the Potential of Industry 4.0 to Reduce the Environmental Impact of Production; European Environment Agency, European Topic Centre on Waste and Materials in a Green Economy: Mol, Belgium, 2021. [Google Scholar]

- Nahavandi, S. Industry 5.0—A human-centric solution. Sustainability 2019, 11, 4371. [Google Scholar] [CrossRef]

- Briatore, F.; Braggio, M. Resilience and Sustainability plants improvement through Maintenance 4.0: IoT, Digital Twin and CPS framework and implementation roadmap. IFAC-Pap. 2024, 58, 365–370. [Google Scholar] [CrossRef]

- Baas, J.; Schotten, M.; Plume, A.; Coté, G.; Karimi, R. Scopus as a curated, high-quality bibliometric data source for academic research in quantitative science studies. Quant. Sci. Stud. 2020, 1, 377–386. [Google Scholar] [CrossRef]

- Xiao, Y.; Watson, M. Guidance on Conducting a Systematic Literature Review. J. Plan. Educ. Res. 2019, 39, 93–112. [Google Scholar] [CrossRef]

- Mack, C.A. How to Write a Good Scientific Paper: Acronyms. J. Micro/Nanolithography MEMS MOEMS 2012, 11, 040102. [Google Scholar]

- Mentzer, J.T.; DeWitt, W.; Keebler, J.S.; Min, S.; Nix, N.W.; Smith, C.D.; Zacharia, Z.G. Defining Supply Chain Management. J. Bus. Logist. 2001, 22, 1–25. [Google Scholar] [CrossRef]

- Culot, G.; Nassimbeni, G.; Orzes, G.; Sartor, M. Behind the definition of Industry 4.0: Analysis and open questions. Int. J. Prod. Econ. 2020, 226, 107617. [Google Scholar] [CrossRef]

- Abeydeera, U.; Mesthrige, J.W.; Samarasinghe, T. Global Research on Carbon Emissions: A Scientometric Review. Sustainability 2019, 11, 3972. [Google Scholar] [CrossRef]

- Cui, L.; Jin, Z.; Li, Y.; Wang, Y. Effects of control mechanisms on supply chain resilience and sustainability performance. Aust. J. Manag. 2023, 48, 323–340. [Google Scholar] [CrossRef]

- Zavala-Alcívar, A.; Verdecho, M.J.; Alfaro-Saiz, J.J. Supply chain resilience: A conceptual evolution analysis. Dir. Organ. 2023, 79, 5–17. [Google Scholar] [CrossRef]

- Kirby, A. Exploratory Bibliometrics: Using VOSviewer as a Preliminary Research Tool. Publications 2023, 11, 10. [Google Scholar] [CrossRef]

- Aragão, G.M.; Saralegui-Díez, P.; Villasante, S.; López-López, L.; Aguilera, E.; Moranta, J. The carbon footprint of the hake supply chain in Spain: Accounting for fisheries, international transportation and domestic distribution. J. Clean. Prod. 2022, 360, 131979. [Google Scholar] [CrossRef]

- Melis, E.; Orrù, P.F.; Pilo, C.; Uras, G. Life cycle assessment of wood-energy supply chains in mediterranean forests. In Proceedings of the European Biomass Conference and Exhibition Proceedings, Copenhagen, Denmark, 14–17 May 2018; pp. 1324–1335. [Google Scholar]

- Stridsland, T.; Biørnstad, W.; Vigen, K.; Østergaard, K.L.; Sanderson, H. No-one left behind: An open access approach to estimating the carbon footprint of a Danish clothing company. J. Clean. Prod. 2023, 426, 139126. [Google Scholar] [CrossRef]

- Arena, S.; Cinus, A.; Deias, A.; Lera, M.; Pilloni, M.; Orrù, P. Industry 4.0 assessment in agri-food and dairy sector: A literature review of Maturity Models. In Proceedings of the 28th Summer School. Francesco Turco, Genova, Italy, 6–8 September 2023. [Google Scholar]

- Jain, R.M.M.; Mangla, S.K.; Baraiya, R. Optimizing supply chain strategies for deteriorating items and imperfect manufacturing under carbon emission regulations. Comput. Ind. Eng. 2023, 182, 109350. [Google Scholar] [CrossRef]

- Ravigné, E.; Da Costa, P. Economic and environmental performances of natural gas for heavy trucks: A case study on the French automotive industry supply chain. Energy Policy 2021, 149, 112019. [Google Scholar] [CrossRef]

- Morfeldt, J.; Davidsson Kurland, S.; Johansson, D.J.A. Carbon footprint impacts of banning cars with internal combustion engines. Transp. Res. D Transp. Environ. 2021, 95, 102807. [Google Scholar] [CrossRef]

- Dubisz, D.; Golińska-Dawson, P.; Koliński, A. Measuring CO2 emissions level for more sustainable distribution in a supply chain. Eng. Appl. Sci. Res. 2022, 49, 804–810. [Google Scholar]

- Brinken, J.; Behrendt, F.; Trojahn, S. Comparing decarbonization potential of digital and green technologies. Sustain. Futures 2023, 6, 100125. [Google Scholar] [CrossRef]

- Lee, J.; Shigetomi, Y.; Kanemoto, K. Drivers of household carbon footprints across EU regions, from 2010 to 2015. Environ. Res. Lett. 2023, 18, 044043. [Google Scholar] [CrossRef]

- Leoni, L.; Cantini, A.; De Carlo, F.; Salvio, M.; Martini, C.; Toro, C.; Martini, F. Energy-Saving Technology Opportunities and Investments of the Italian Foundry Industry. Energies 2021, 14, 8470. [Google Scholar] [CrossRef]

- Fantozzi, I.C.; Di Luozzo, S.; Schiraldi, M.M. On tasks and soft skills in operations and supply chain management: Analysis and evidence from the O*NET database. TQM J. 2024, 36, 53–74. [Google Scholar] [CrossRef]

- Manco, P.; Caterino, M.; Rinaldi, M.; Macchiaroli, R. A sustainability-oriented methodology to compare production strategies: The case of AM-based remanufacturing. J. Clean. Prod. 2023, 423, 138594. [Google Scholar] [CrossRef]

| Source Title | N° Art. | % on Tot | C. Art | C. Journal |

|---|---|---|---|---|

| Journal Of Cleaner Production | 17 | 16% | 16% | 6% |

| Computers And Industrial Engineering | 5 | 5% | 21% | 11% |

| Energies | 5 | 5% | 26% | 17% |

| Journal Of Industrial Ecology | 5 | 5% | 31% | 22% |

| Environmental Research Letters | 4 | 4% | 35% | 28% |

| Sustainability Switzerland | 4 | 4% | 38% | 33% |

| Energy | 3 | 3% | 41% | 39% |

| Energy Conversion And Management X | 3 | 3% | 44% | 44% |

| International Journal Of Production Research | 3 | 3% | 47% | 50% |

| Renewable And Sustainable Energy Reviews | 3 | 3% | 50% | 56% |

| Sustainable Production And Consumption | 3 | 3% | 53% | 61% |

| Bioresources | 2 | 2% | 55% | 67% |

| Energy Economics | 2 | 2% | 57% | 72% |

| Energy Policy | 2 | 2% | 59% | 78% |

| Environmental Science And Pollution Research | 2 | 2% | 61% | 83% |

| Fuel | 2 | 2% | 63% | 89% |

| International Journal Of Production Economics | 2 | 2% | 64% | 94% |

| Journal with only 1 article | 37 | 36% | 100% | 100% |

| Affiliation | N. Art. | % Tot | C Art. | C. Institution |

|---|---|---|---|---|

| Kyushu University | 4 | 2% | 2% | 13% |

| Ministry of Education of the PRC | 3 | 1% | 3% | 25% |

| The University of Sheffield | 3 | 1% | 5% | 38% |

| Beijing Normal University | 3 | 1% | 6% | 50% |

| Tsinghua University | 3 | 1% | 8% | 63% |

| ETH Zürich | 3 | 1% | 9% | 75% |

| Institutions with only 2 articles | 56 | 28% | 37% | 88% |

| Institutions with only 1 article | 126 | 63% | 100% | 100% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Briatore, F.; Vanni, F.; Mosca, M.T.; Mosca, R.N.; Fruggiero, F.; Mancusi, F. Exploring Industry 4.0’s Role in Sustainable Supply Chains: Perspectives from a Bibliometric Review. Logistics 2025, 9, 26. https://doi.org/10.3390/logistics9010026

Briatore F, Vanni F, Mosca MT, Mosca RN, Fruggiero F, Mancusi F. Exploring Industry 4.0’s Role in Sustainable Supply Chains: Perspectives from a Bibliometric Review. Logistics. 2025; 9(1):26. https://doi.org/10.3390/logistics9010026

Chicago/Turabian StyleBriatore, Federico, Francesca Vanni, Marco Tullio Mosca, Roberto Nicola Mosca, Fabio Fruggiero, and Francesco Mancusi. 2025. "Exploring Industry 4.0’s Role in Sustainable Supply Chains: Perspectives from a Bibliometric Review" Logistics 9, no. 1: 26. https://doi.org/10.3390/logistics9010026

APA StyleBriatore, F., Vanni, F., Mosca, M. T., Mosca, R. N., Fruggiero, F., & Mancusi, F. (2025). Exploring Industry 4.0’s Role in Sustainable Supply Chains: Perspectives from a Bibliometric Review. Logistics, 9(1), 26. https://doi.org/10.3390/logistics9010026