1. Introduction

In early 2020, a previously unidentified zoonotic coronavirus, which was later named COVID-19, affected humans, leading to widespread infections [

1]. Initially, it was believed that the virus was limited to China, but it eventually spread worldwide [

2]. As a result of the quick escalation in coronavirus cases and its transmission through droplets, there was a worldwide surge in the need for Personal Protective Equipment to safeguard both citizens and healthcare workers, causing a substantial shortage of these essential supplies since the initial stages of the outbreak [

3,

4].

European Union regulation 425/2016 specifies that the primary function of Personal Protective Equipment is to shield the user from health or safety hazards caused by other individuals. Personal Protective Equipment serves as a barrier between infectious substances and the skin, mouth, nose, and eyes. The present study concentrates on the types of Personal Protective Equipment most applicable to COVID-19, such as masks, visors, protective glasses, gloves, and gowns.

When the pandemic began, the World Health Organization projected that the healthcare industry would require 89 million masks, 76 million gloves, and 1.6 million protective glasses each month to combat COVID-19 worldwide effectively. Correspondingly, there was a surge in demand for Personal Protective Equipment globally, particularly during the first wave of the pandemic, which caused a shock in the global supply chain for these essential goods [

5]. China, which is the primary manufacturer and exporter of Personal Protective Equipment [

6], was the first nation to implement a lockdown period, resulting in the closure of manufacturing firms and export restrictions. Concurrently, China also acquired a significant portion of the worldwide supply of Personal Protective Equipment [

7].

The considerable reduction in production and export capacity that began in China and spread to other nations, along with the Just in Time method applied in recent decades to handle Personal Protective Equipment inventories and minimize operating expenses, induced a quick depletion of the already low Personal Protective Equipment stock levels due to increased demand, without the possibility of replenishment in a short time [

8,

9] [

10].

Additionally, COVID-19 restrictions such as road closures and quarantine protocols resulted in port congestion and cargo loading/unloading delays, hampering global supply chain connectivity for all the products, including Personal Protective Equipment and their essential components [

11,

12].

The widespread shortage of Personal Protective Equipment remarkably contributed to accelerating the infection spread among healthcare workers and the general population during the early months of the pandemic [

13,

14].

Current studies on the effects of the COVID-19 pandemic on the Personal Protective Equipment supply chain concentrate mainly on the healthcare end-user perspective, addressing the causes and solutions to disruptions. Few studies examine the upstream supply chain echelons and how and why the primary logistics variables, such as orders, stocks, and lead times, changed during the epidemiological crisis.

Additionally, although Italy was the first Western nation seriously affected by COVID-19 [

13], a limited number of contributions focus on the Italian Personal Protective Equipment supply chain, still five years after the pandemic outbreak. In fact, most of the available scientific works discussing the use of Personal Protective Equipment in Italy under COVID-19 address infection diffusion among healthcare workers [

15,

16], the impacts of adopting Personal Protective Equipment on the performance of healthcare professionals [

17], and the Personal Protective Equipment management in healthcare organizations [

18].

The present study addresses the following research gap: the lack of investigation of changes affecting key variables in the upstream supply chain of Personal Protective Equipment during the early stages of COVID-19, which were the most disruptive, with a particular focus on Italy.

To help bridge such a gap, this work aims to identify critical issues within the Personal Protective Equipment supply chain through empirical research. In particular, the study seeks to answer the following research questions:

RQ1: How did the main variables in the Italian Personal Protective Equipment supply chain change during the early stages of the pandemic?

RQ2: How can we explain such changes?

The study involves the development of a questionnaire directed at Personal Protective Equipment producers and traders. Its aim is to understand how their daily operations were affected during the initial pandemic wave, specifically in March–May 2020, and in the period that followed. The study will analyze and explain changes in customer demand, supplier orders, lead times, and stock levels.

This research shifts the focus from the commonly analyzed perspective of Personal Protective Equipment end-user to the perspective of the upstream supply chain echelons, offering an exploration of the Italian case, which has been largely overlooked in the existing literature.

Therefore, researchers studying supply chain behavior during crises and resilience, as well as professionals involved in Personal Protective Equipment supply chains or other supply chains significantly impacted by the pandemic, may find the results of this study valuable in providing knowledge that could inform future actions.

The remainder of the paper is organized as follows.

Section 2 provides a detailed background on the relevant literature, while

Section 3 outlines the adopted methodology and the questionnaire. The survey results are analyzed in

Section 4, while

Section 5 interprets them and discusses the implications of the study. Finally,

Section 6 concludes the paper by presenting the key findings and limitations of the work and drawing future research directions.

2. Literature Review

The scientific literature examining the effects of COVID-19 on the Personal Protective Equipment supply chain can be categorized into three groups: disruptions in the Personal Protective Equipment supply chain, proposed improvements to solve this issue, and surveys exploring the impacts of the pandemic on Personal Protective Equipment accessibility, with a specific focus on the viewpoint of healthcare professionals.

2.1. Causes for Personal Protective Equipment Global Supply Chain Disruptions

The first category of papers is focused on the global Personal Protective Equipment supply chain and the criticalities coming from the COVID-19 pandemic due to the unique features of the products at issue [

5,

11].

A sudden surge in demand resulted in a shortage of key components for Personal Protective Equipment manufacturing, including nonwoven polypropylene and melt-blown fabric. This led to a bottleneck in the overall mask production process [

19]. Due to the substantial initial investments required for machinery, the production of melt-blown fabric is limited to a small number of companies worldwide.

The demand for large quantities of such a material necessitated an increase in production capacity; however, establishing new production facilities typically requires at least six months. Therefore, it proved challenging to increase the melt-blown fabric supply during the crisis and find companies that could quickly switch to its production without making significant investments.

Furthermore, China is an important hub for Personal Protective Equipment production, and half of the world’s mask supply originates from its factories. So, when quarantines were initially imposed on Chinese workers and export restrictions were later established in many other Asian countries that are major exporters of key materials, Personal Protective Equipment production was significantly impacted [

20,

21,

22].

To mitigate the manufacturing shortage, several new Personal Protective Equipment producers worldwide entered the market following the outbreak of COVID-19. However, many of them failed in a short time due to their inability to produce high-quality products and manage supply chains effectively. The significant upfront investment required for manufacturing facilities further hindered their ability to compete and sustain operations.

This situation was further complicated by roadblocks, stricter border controls, and quarantines for incoming products designed to control the spread of the virus. Most cargo flights were stopped and shipping products through passenger flights became infeasible due to the drastic reduction in such flights during the initial wave of the pandemic. This led to congestion and delays in both raw material and final product supplies, resulting in a substantial rise in supply chain costs [

7,

23].

Focusing on the downstream portion of the Personal Protective Equipment supply chain, a Just in Time approach was implemented in recent years to reduce production, storage, and distribution costs. This was due to limited budgets faced by some key end-users, such as healthcare institutions [

24], prompting a shift toward maintaining minimal inventory levels and relying on timely deliveries to meet immediate needs without incurring the expenses of holding large stockpiles. The sudden and unexpected increase in demand quickly resulted in shortages of Personal Protective Equipment at all the supply chain levels [

10].

Finally, the critical importance of Personal Protective Equipment necessitates compliance with specific regulations for its sale and use. The time needed for regulatory compliance was yet another bottleneck hindering the rapid production and export of Personal Protective Equipment [

11].

2.2. Solutions to Improve the Personal Protective Equipment Supply Chain

Academicians and professionals have proposed various solutions to contain shortages in the Personal Protective Equipment supply chain.

Several studies have been carried out around the world to address the impact of the COVID-19 pandemic on the Personal Protective Equipment supply chain, highlighting different regional approaches and offering valuable insights into crisis response strategies. Some countries attempted to adopt centralized methods to deal with the supply disruption, for instance by making it easier for non-medical device manufacturers to start the production of Personal Protective Equipment.

This strategy aimed to expand the manufacturing base, increase supply, and reduce dependence on traditional suppliers during the pandemic. In the European area, ref. [

25] report the European Commission’s decision to create a strategic stockpile of medical equipment to help European Union countries in the context of the COVID-19 pandemic. This reflects another centralized, collaborative approach, whose effectiveness depends on the speed and efficiency of its deployment.

In contrast, analyses from the United States underscore systemic issues, including hospital budgeting and federal oversight, pointing to a fragmented response and the need for comprehensive reforms to strengthen resilience. In fact, ref. [

26] identified four main factors that contributed to the Personal Protective Equipment shortages: hospital budgeting practices, unexpected surges in domestic demand, failures of the federal government, and disruptions in the global supply chain. To address these issues, they recommend enhancing the ability of both federal and local governments to store and distribute Personal Protective Equipment, implementing regulations to promote the proper use of these products, and reducing dependence on imports.

Meanwhile, in Asia, governments have taken proactive measures to subsidize production and scale up capacity, emphasizing the critical role of state intervention in ensuring supply continuity. For instance, the Chinese government implemented special initiatives to boost mask production, including subsidies for raw material purchases and workforce recruitment.

The Japanese government also supported companies to make capital investments in mask production increase and guarantee a monthly supply of over 600 million masks in 2020 [

5]. However, these approaches raised questions about long-term sustainability and the balance between centralized control and local adaptability in managing future crises.

Additionally, non-country-specific studies have emphasized the need for systemic resilience. Among them, ref. [

6] advocates for a more robust and adaptive design of the Personal Protective Equipment supply chain. They propose conducting stress tests focused on resilience, responsiveness, and reconfigurability capabilities rather than on cost, quality, and delivery performance measures. Also, [

27] recognizes the importance of stress testing in ensuring a rapid increase in domestic Personal Protective Equipment production.

To mitigate supply risks, companies should establish strategies to maintain an adequate stock level, as well as rely on multiple suppliers of key components located in different regions, enabling them to quickly switch to alternative sources if necessary [

28]. Careful consideration should be given to Sales and Operations Planning. Centralizing Personal Protective Equipment orders, distribution, and usage monitoring, increasing stock visibility, and facilitating information sharing across supply chain levels would improve demand forecasting. Digital technologies may contribute to improving operations management [

29].

For example, Additive Manufacturing can be beneficial in expanding local Personal Protective Equipment supply capacity [

30,

31,

32]. Such literature contributions underscore the importance of proactive risk mitigation. However, the feasibility of implementing these strategies, particularly in resource-constrained environments, and the potential trade-offs between cost efficiency and resilience warrant further critical examination.

2.3. Empirical Studies About the Effects of COVID-19 on the Personal Protective Equipment Supply Chain

In the literature, some contributions focus on surveys administered to healthcare users regarding the lack of Personal Protective Equipment. These surveys report critical perspectives and reveal systemic weaknesses across diverse contexts.

The Royal College of Surgeons of England studied the reactions of surgical personnel to the Personal Protective Equipment shortage during the early stages of the pandemic. The investigation found that a third of respondents believe that the supply and management of Personal Protective Equipment at their hospitals was insufficient to perform their jobs safely and over half reported Personal Protective Equipment shortages within their organizations [

33], underscoring widespread dissatisfaction.

Additionally, the Association for Professionals in Infection Control and Epidemiology, COVID-19 task force, conducted an online questionnaire among its US members, which shows that Personal Protective Equipment supply chains were disrupted, leading to unsafe practices such as reusing or decontaminating Personal Protective Equipment [

34]. Finally, an online survey conducted among over 800 doctors in Nepal further emphasizes the global nature of the problem revealing that 94.7% of the respondents considered the supply of Personal Protective Equipment to be inadequate [

35].

In response to the critical need to prevent the spread of the pandemic in Intensive Care Units, some authors analyze the use of Personal Protective Equipment in this context. A questionnaire investigating healthcare professionals collected information on the availability and utilization of Personal Protective Equipment when treating patients with COVID-19 in Intensive Care Units. Once again, the survey results show a widespread shortage of Personal Protective Equipment and a resulting need for the reuse of items intended for single-use [

36].

Another survey, which evaluated Personal Protective Equipment availability across Intensive Care Units in six Asia–Pacific countries, produced similar results [

37]. Despite a general understanding of the World Health Organization’s Personal Protective Equipment conformity guidelines, the supply was severely limited in the surveyed countries, often leading to the use of low-quality equipment.

Considering how healthcare organizations reacted to Personal Protective Equipment shortages, ref. [

38] investigates the perspective of supply chain managers. They conducted a survey to assess the impact of COVID-19 on the availability of masks, face shields, medical gowns, N95 respirators, and drugs in Saudi Arabia.

The survey revealed that 33% of respondents experienced a shortage of Personal Protective Equipment, highlighting weaknesses in downstream supply chain management and distribution. Hu [

39] examines the perspective of upstream supply chain tiers by interviewing sales and export managers of business-to-business companies in Italy. This study aims to investigate how digital technologies and social media were utilized to manage the Personal Protective Equipment disruption during the first wave of the pandemic, thus underscoring their growing importance as tools for crisis management.

The conducted literature review highlights that despite being a relatively new topic, numerous studies have already addressed the adverse effects of COVID-19 on the Personal Protective Equipment supply chain and the potential remedies. Nevertheless, the impacts on critical logistics variables for companies in the upstream echelons have not yet been extensively studied.

In fact, research has typically concentrated on end-users, particularly those in the healthcare sector. Moreover, although Italy was one of the countries most affected by the first wave of the COVID-19 pandemic, the published literature available on this topic is limited. To address such a gap, the current study employs a survey to examine the main Personal Protective Equipment supply chain variables, such as lead times, demand rates, and stock levels, for Italian producers, importers, and distributors in response to the pandemic. The causes of their changes are discussed to offer useful interpretations for a deeper understanding of the reasons for shortages and delays in the supply of Personal Protective Equipment, which resulted in serious public health consequences.

3. Methodology

The present survey is based on a questionnaire aimed at companies that produce, import, and distribute Personal Protective Equipment in Italy.

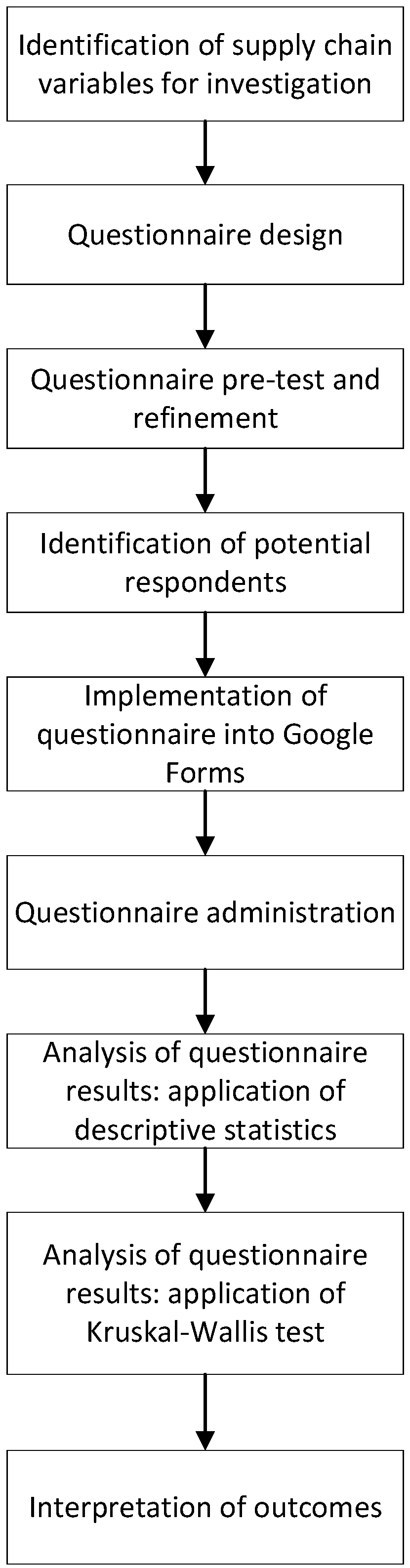

Figure 1 illustrates the research process that was followed and will be explained in this and the following sections.

To build the group of potential respondents, the authors reviewed and cross-checked several national official lists of producers and sellers.

They include the list of companies authorized to sell Personal Protective Equipment by the Italian Institute for Work Accidents, the list of companies that received economic incentives to either expand or convert their production to Personal Protective Equipment according to the Law Decree n. 18 on 17 March 2020, named “Cura Italia” Decree, the lists of companies authorized to produce Personal Protective Equipment during the pandemic by the Italian Healthcare National Institute (Istituto Superiore di Sanità), the list of Personal Protective Equipment suppliers and producers according to the Small Industry Emergency Management Program by The General Confederation of Italian Industry (Confindustria), and the list of Personal Protective Equipment suppliers provided by the Italian Federations of Medical Radiology, Rehabilitation, and Prevention Technicians and Technical Healthcare Professionals.

In addition, several regional lists of Personal Protective Equipment producers and traders have been considered. As a result, 994 companies have been selected as potential questionnaire respondents. It is important to emphasize that all the companies in the above-mentioned lists, whether they are producers, importers, or distributors of Personal Protective Equipment, were included in the pool of potential respondents.

The questionnaire was developed through Google Forms and the associated link was delivered to the involved companies by e-mail (

Section 3.1). The administration period lasted three months, during which the surveyed organizations received three reminders to complete the questionnaire. In total, 94 answers were collected, giving a response rate equal to 9.5%. This is already a relevant achievement. In fact, the literature shows how difficult it is to obtain double-digit response rates in surveys [

40], especially under particular circumstances, such as a pandemic. Responses were recorded in an Excel spreadsheet to build a dataset for the statistical analysis. Both descriptive statistics and a quantitative statistical technique were applied.

As the data collected are not normally distributed and the Likert scales adopted (

Section 3.1) are ordinal in nature, the non-parametric Kruskal–Wallis test is used [

41]. The purpose here is to study whether and how the most relevant variables of the Personal Protective Equipment supply chain changed with the COVID-19 spread in different echelons. The Kruskal–Wallis test analyzes whether two or more populations have identical medians, which means that samples come from the same distribution. The associated statistic

K is given in the following equation:

where

g is the number of groups (samples);

ni is the number of observations in group i;

rij is the rank (among all the observations) of observation j from group i; and N is the total number of observations across all the groups.

is the average calculated over all the rij values.

If the

p-value associated with the test is less than a set significant threshold, usually equal to 5% [

42], the null hypothesis that the populations have identical medians is rejected and the alternative hypothesis, namely that there is at least one different median value among the groups, can be considered true [

41]. In this study, two categorical variables are analyzed using the Kruskal–Wallis test conducted with Minitab statistical software: the supply chain role and the main geographical area served by the respondent companies. The results obtained are then interpreted (

Section 4).

3.1. Questionnaire Construction

As a first step in questionnaire structuring, the main Personal Protective Equipment supply chain variables affected by COVID-19 according to the literature are identified. Thus, the main topics investigated are as follows: supply lead times, inventory levels and the associated management policies, number of orders and related quantities, number of order lines, and customer location [

5,

10,

28,

43,

44].

In particular, the survey questions aim to capture the significant changes in the key supply chain variables, both during the COVID-19 onset and after such a first pandemic period, compared with the 2019 values. To this end, the first Italian lockdown period, going from 9 March until 3 May 2020, which was the most severe one with the closure of almost all the commercial and business activities, is considered as a reference in the present study.

The questionnaire is organized in three sections. The first section gathers general information about the respondent companies. It is important to note that the company’s name is omitted to maintain its anonymity. Questions regarding yearly revenue and the geographical area where most customers are located help to cluster the respondent organizations by size and to analyze trends in customer demand based on the country. In fact, the COVID-19 pandemic had heterogeneous evolutions in different parts of the world, especially in terms of time [

45].

Next, the role of the respondent is examined, focusing on producers, importers, and distributors, who are recognized as the main players in the Personal Protective Equipment supply chain according to the existing literature [

3,

46].

The subsequent two questionnaire sections follow the traditional company supply chain schema, starting from the side that was most affected by the pandemic, namely the customer one [

5]. Thus, the second section addresses the relationship between the respondent and its customers, the stock levels, and the relationship with suppliers. The questions here are designed to assess the relevant Personal Protective Equipment supply chain variables impacted by the pandemic, as stated before in this section.

The third section of the questionnaire focuses on stock management and disruption management. Particular attention is paid to the Just in Time approach as the main policy to manage Personal Protective Equipment inventories before the pandemic [

10]. The aim is to understand whether it was still common after the COVID-19 onset, when it played a key role in determining stockouts. Additionally, there is a question regarding the implementation of plans for supply chain disruption management. Plans to counteract supply chain disruptions were important in the pandemic period to make businesses keep pace with the changed market and operational conditions [

47].

About the assessment scales that are used, the answers to the questions related to changes in the number of orders, product quantities, and the number of order lines in

Section 2 and

Section 4 of the questionnaire are scored through a 7-item Likert scale as follows:

Seven-point Likert scales prove to be quite accurate and suitably reflect the respondents’ evaluations. Also, they provide more data to perform statistical analyses than five-point scales [

48]. Moreover, the scale definition, which gives more relevance to increases in the assessed quantities, is conceived based on the literature evidence that the main Personal Protective Equipment logistics variables, such as the number of orders, order lines, and delivered quantities, increased after the pandemic outbreak rather than decreasing [

49]. The four levels available for assessing increases in the variable under consideration allow for a detailed analysis of the extent of change and comparisons among different respondent groups.

Changes in stock levels in

Section 3 are assessed again using a 7-item Likert scale designed to appropriately keep track of both inventory increases and decreases:

Significantly decreased;

Moderately decreased;

Slightly decreased;

Unchanged;

Slightly increased;

Moderately increased;

Significantly increased.

Finally, the lead time variable in

Section 2 and

Section 4 is scored by the following 5-item Likert scale:

<5 days;

Between 5 and 7 days;

Between 8 and 10 days;

Between 11 and 15 days;

>15 days.

The questionnaire underwent a pre-test by a group of supply chain experts, who provided suggestions for improving clarity. Their recommendations were implemented before the administration of the questionnaire.

3.2. Sample Description

Most of the 94 questionnaire respondents constituting the final sample were small and medium enterprises. This is reflected by their yearly revenue: nearly 54% of these companies had revenue less than EUR 2 M, while only 14% were characterized by a revenue greater than EUR 10 M [

50].

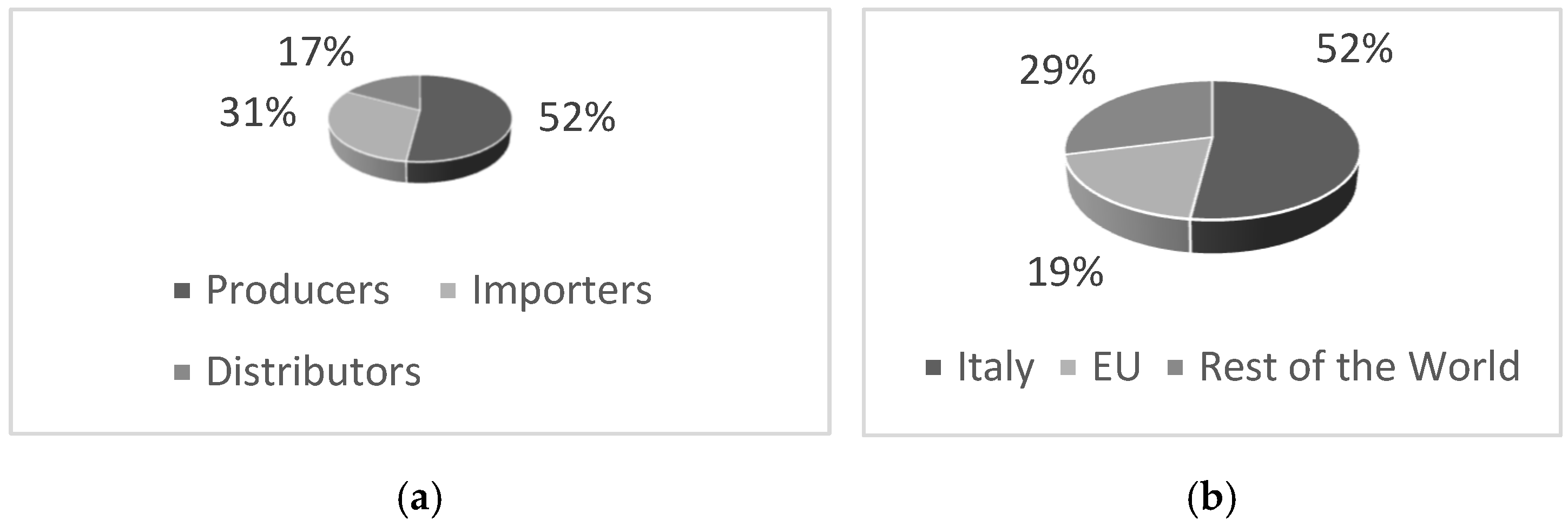

Figure 2 presents the distribution of respondents by supply chain roles and the geographical locations of the markets served. These diagrams reflect the changes that occurred in Italy in the aftermath of the pandemic.

Figure 2a shows the supply chain roles performed by the companies participating in this empirical study. There is a substantial balance between Personal Protective Equipment producers (52%) and traders (48%), the latter including importers (31%) and distributors to retail stores (17%). The high demand for Personal Protective Equipment has prompted many small companies to address the significant decline in sales of their traditional products by shifting their focus to the production of protective equipment. In fact,

Figure 2a illustrates the relevant role played by small- and medium-sized manufacturers in the supply chain, which was even greater than that of distributors and importers.

The distribution of the sample allows for an investigation of critical issues in the supply chain, related not only to production but also to other levels of the supply chain. Additionally,

Figure 2b demonstrates that this sample enables an analysis of the effects of COVID-19 on Personal Protective Equipment supply chains at an international level. In fact, 48% of the respondent companies report that they operate in European and global markets. However, more than half of the respondents mainly serve the national market.

This is primarily because the respondents are mostly small and medium enterprises. Furthermore, the data presented in

Figure 2b highlight the substantial demand for Personal Protective Equipment in the Italian market compared to the European market and the rest of the world during the pandemic.

4. Analysis of Results

In the following two sections, the questionnaire outcomes will be discussed to address the two research questions outlined in

Section 1.

4.1. Descriptive Statistics of the Outcomes

4.1.1. Supply Chain Variables

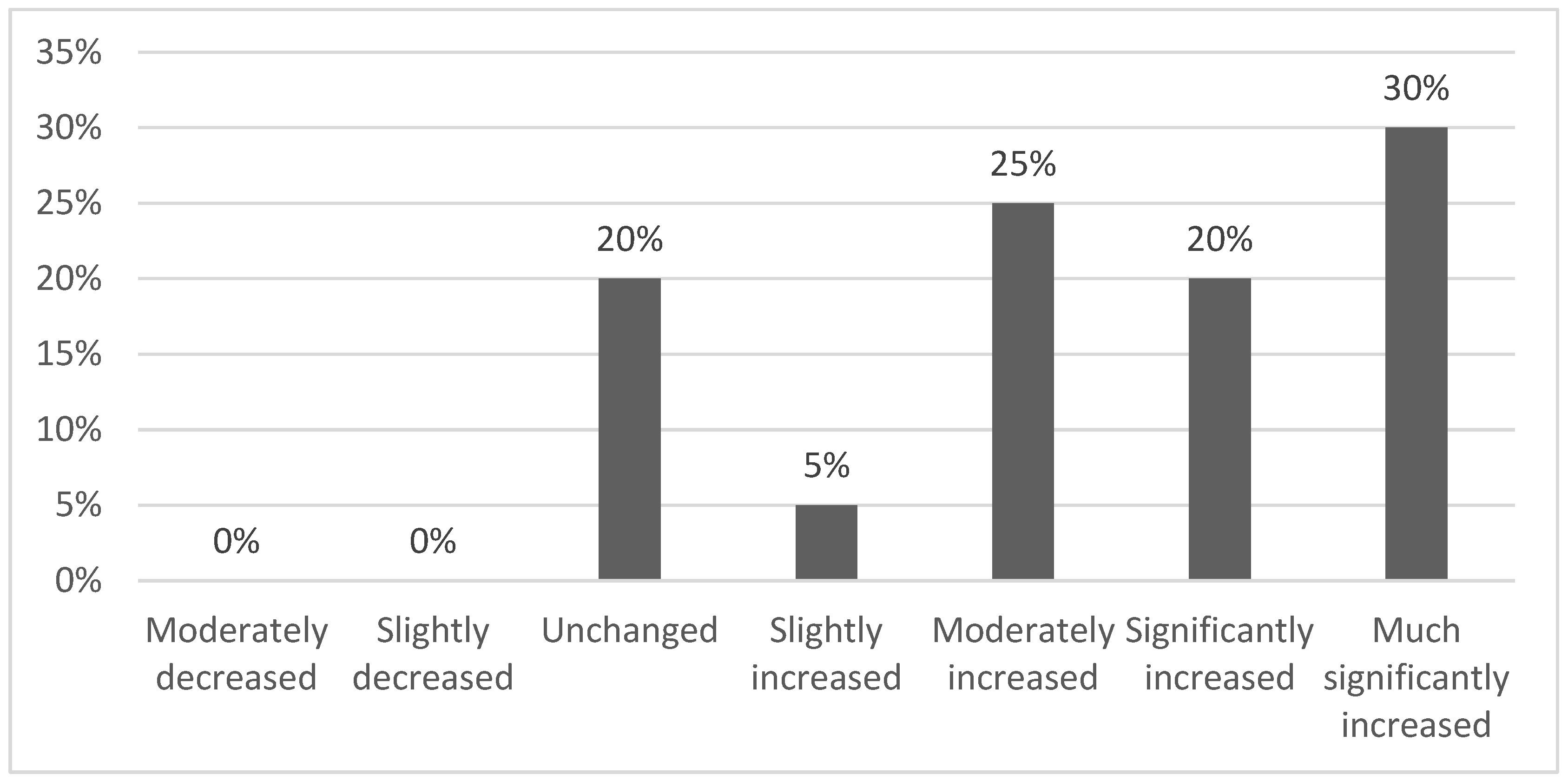

The COVID-19 pandemic caused a surge in the Personal Protective Equipment demand. Thus, the first variable that is interesting to investigate is the variation in the number of weekly customer orders during the Italian lockdown compared to the 2019 values.

Coherently with the expectations, orders increased for 80% of the respondents, with 50% reporting a significant growth (

Figure 3). Such a trend is confirmed after the lockdown period as the percentage of companies facing an order increase went up to 93% and 62% of the respondents declared a very relevant boost. This might be due to the worsening of the pandemic in Europe from the summer of 2020.

The augmented number of Personal Protective Equipment orders is accompanied by larger quantities demanded. In fact, the quantities shipped weekly during the Italian lockdown increased for 85% of the respondents, where nearly 50% of the companies had to address either a moderate or a significant growth and 30% of them a very significant one. The quantity increase appears slightly more limited after the lockdown but overall, the situation remains unchanged.

Actually, the increase in the number of weekly outgoing order lines is more relevant after the lockdown than during it, with 45% of the companies facing a moderate growth of this quantity in the period March–May 2020, while only 20% reported the same level from May 2020 onwards. On the contrary, the order lines augmented in a very relevant way for almost 30% of the respondent companies after the lockdown. The progressive end of hard social and business limitations induced people to protect themselves and others from the virus with a variety of different kinds of Personal Protective Equipment.

As witnessed by the literature, the combined effect of demand increase and limitations to good movements during the first pandemic phases impacted stock levels and lead times [

10]. Although 35% of the respondent companies declared to have been able to keep the average inventory level unchanged during the lockdown compared with the 2019 values, 10% reported slight to significant decreases in the same period. The ability to contain stock shortages is because most of the respondent companies did not adopt a strict Just in Time policy before COVID-19 (

Section 4.1.2).

The risk of stockouts, together with quite long supplier lead times, made companies build a proper amount of stock after the lockdown so that 70% of the investigated Personal Protective Equipment supply chain players reported slight to significant inventory increases in that time frame.

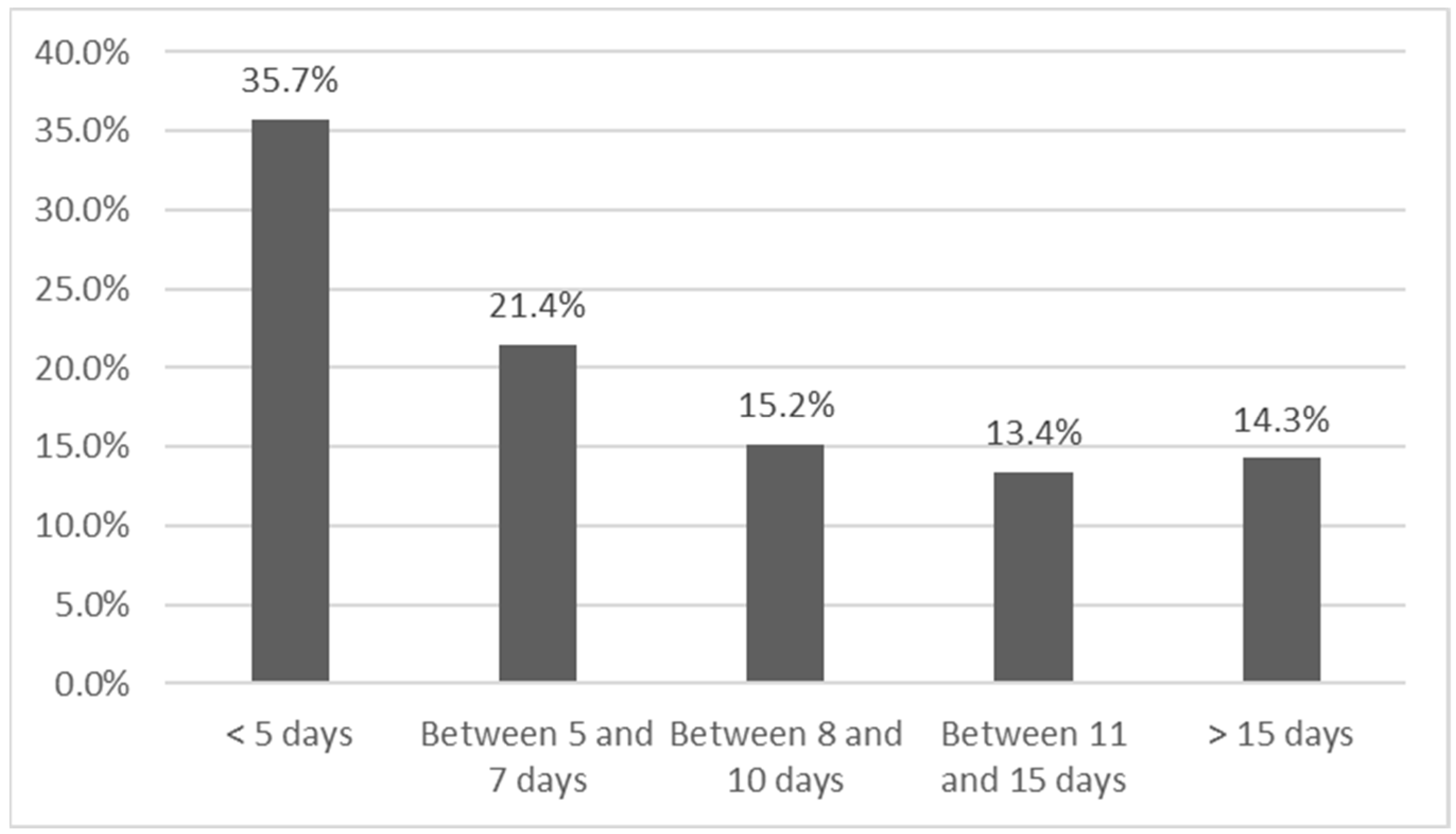

Figure 4 reveals the distribution of supplier lead time values experienced during the Italian lockdown by the respondents. Almost 43% of the companies reported an average lead time of about 10 days or even longer.

The supplier lead time during the lockdown period drives the delivery lead time of the respondent supply chain players. In fact, for 43% of them, it was equal to or longer than about 10 days. The situation significantly improved after the end of the lockdown, and so for the strict limitations to transportation, as the delivery lead times were less than 5 days for 59% of the companies and only 25% declared a value longer than 10 days.

Finally, the number of weekly orders placed with suppliers reflects, albeit with some delay, the growth in customer orders. In fact, during the lockdown, only 25% of the respondents significantly increased such orders, while 55% reported only slight or moderate increases. This was also due to the ability of the respondent companies to rely on a certain amount of stock they had previously built. In contrast, after the lockdown, most companies (54%) substantially increased the number of weekly orders to suppliers, while only 34% experienced slight or moderate increases in their order quantities.

4.1.2. Stock and Disruption Management

The respondent companies were also asked about their inventory and supply chain disruption management policies.

As far as the Personal Protective Equipment stock management approach is concerned, although 40% of the respondents adopted a Just in Time approach before the pandemic, surprisingly 60% of them were not used to implementing it. Then, due to its negative effects on inventories in light of a large and unpredictable product demand increase, the percentage of companies applying Just in Time during and after the lockdown reduced to 36% and 29%, respectively, while stock policies not based on Just in Time further increased their adoption share.

Regarding company supply chain disruption mitigation plans, 50% of the respondents declared to have developed them for the first time after the COVID-19 pandemic onset. However, 31% of the companies already issued mitigation plans before the pandemic, showing quite good attention to disruption issues. This evidence is corroborated by the fact that only 19% of the investigated supply chain players never adopted or were not aware of the existence of supply chain mitigation plans in their organizations.

4.2. Empirical Analysis

First, the Kruskal–Wallis test was conducted by examining the various roles within the supply chain represented in the sample (

Table 1). To complete it, numerical scores were associated with the questionnaire answers. The values assigned to the possible answers to the questions on the changes in the number of orders, product quantities, and number of order lines were 1: moderately decreased; 2: slightly decreased; 3: unchanged; 4: slightly increased; 5: moderately increased; 6: significantly increased; and 7: much significantly increased. The values assigned to the answers about the stock level variations were 1: significantly decreased; 2: moderately decreased; 3: slightly decreased; 4: unchanged; 5: slightly increased; 6: moderately increased; and 7: significantly increased. Finally, the values associated with the lead time intervals represented in the questionnaire were 1: <5 days; 2: between 5 and 7 days; 3: between 8 and 10 days; 4: between 11 and 15 days; and 5: >15 days.

As shown in

Table 1, producers, importers, and distributors reported a moderate to significant increase in the number of customer orders, product quantities, and the number of order lines weekly shipped during the first Italian lockdown period. It is also interesting to note that importers and distributors faced larger order increases than producers after the lockdown. Numerous manufacturing companies decided to enter the Personal Protective Equipment market after the COVID-19 pandemic onset. However, they were unable to immediately start their manufacturing operations because they had to set up the necessary production equipment first.

Additionally, many small and medium enterprises operating in Italy applied to benefit from governmental subsidies issued to help businesses react to the economic crisis induced by the pandemic. In particular, the so-called “Cura Italia” Decree allocated EUR 50 M to support Italian firms willing to expand and reconvert their business to produce Personal Protective Equipment. Such funds began to be disbursed in April 2020.

On the contrary, importers and distributors could offer a larger supply than producers already toward the end of the first lockdown period, when the Personal Protective Equipment supply chain began to be relieved from disruptions. This was possible thanks to foreign manufacturers. However, the associated supplier lead time was still long, mainly due to difficulties and delays in transportation [

5]. Consequently, to meet the raised customer demand, importers and distributors increased the weekly supplier orders after the lockdown more than during it.

A further reason making importers and distributors more quickly able than producers to satisfy the growing Personal Protective Equipment demand is that they did not have to modify their business structure to respond to market changes. There is no statistically significant difference in the delivery lead times reported by the three supply chain echelons investigated. However, they were a little bit longer during the lockdown than in the period immediately after it.

In fact, from May 2020 main transportation blocks started being relaxed. Finally, by looking at the average stock levels, it can be seen that they increased for almost all three supply chain players, except for producers who declared not to have faced inventory increases during the lockdown period. Importers and distributors reported higher increases in stock values than producers due to the Just in Time management of inventories they applied before the pandemic. In fact, after the COVID-19 onset, they significantly increased their inventory to keep up with a dramatically growing customer demand [

51].

Table 2 presents the results of the Kruskal–Wallis tests performed by considering the geographical areas served by the respondent companies and the questions about the relationship with customers.

During the first Italian lockdown period, companies with customers located outside Italy and the European Union experienced larger increases in the number of weekly orders, quantities shipped, and outgoing order lines than companies with customers limited to such areas. As a matter of fact, in the very first COVID-19 phase the country most needing Personal Protective Equipment was China. Then, the number of cases went up in Europe and Italy, so the three variables at issue reported a growth in their mean scores for Italy and the European Union after the lockdown, while they remain unchanged or slightly decreased for the rest of the world.

This is a consequence of the Chinese demand for Personal Protective Equipment imports after May 2020, which did not increase a lot since internal production had already been restored after the shock due to the pandemic onset and the related business shutdowns. The European epidemiological situation, instead, progressively got worse after a decreasing trend of the infection in the summer of 2020 and reached a worrying status in the winter [

52].

5. Discussion

The present work is based on a survey to investigate the behavior of the Italian Personal Protective Equipment supply chain in the first phases of the COVID-19 pandemic by comparing it with the situation in 2019. The study explores the criticalities suffered by the Italian Personal Protective Equipment industry and helps to understand the weak points of the strategies adopted. This, in turn, can support improvements in resilience to be better prepared to address future similar shortages of the products at issue.

The reaction of the Personal Protective Equipment supply chain to COVID-19 in Italy has already been studied but in a very limited way. Additionally, the behavior of each single supply chain echelon has not been addressed. In fact, the available international literature on the Personal Protective Equipment supply chain usually focuses on how product shortages and delays affected end-users, in particular healthcare professionals [

33,

36], without delving into the logistics causes for them. The lack of works on the impacts of the pandemic on the upstream echelons of the Personal Protective Equipment supply chain in Italy, one of the Western countries that most suffered from COVID-19, is still evident four years after the beginning of the epidemic and calls for further investigation.

The interpretation of the survey results sheds light on how the Italian Personal Protective Equipment supply chain navigated demand surges, supply constraints, and policy adaptations during the COVID-19 pandemic, and offers lessons for future crises.

The findings reveal how adaptable the Italian Personal Protective Equipment supply chain was during the early stages of the pandemic, highlighting differences in performance among supply chain actors and the broader implications of their strategies.

Importers and distributors demonstrated greater agility than producers, leveraging established foreign supply networks and avoiding the operational reconfigurations faced by producers. Conversely, producers experienced delays in acquiring production equipment and slow disbursement of government subsidies, highlighting the challenges of reactive responses to crises. Such a situation underscores the need for proactive planning and faster policy support. Extended supplier lead times during the first Italian lockdown, together with logistics bottlenecks, exacerbated the aforementioned challenges. This exemplifies the interconnectedness of global supply chains, where disruptions can cascade across regions, emphasizing the need for robust contingency plans.

Following the initial lockdown period, significant increases in inventory levels compared to the pre-pandemic period suggested a strategic shift from Just in Time practices to stockpiling, which ensures resilience against ongoing demand surges. Such a situation highlights the limitations of Just in Time systems in times of crisis and suggests that precautionary inventory strategies are preferable to buffer against future disruptions. Additionally, it reflects a key lesson from the pandemic: prioritizing resilience over efficiency during crises. In fact, the delayed increase in supplier orders after the first Italian lockdown, particularly among importers and distributors, underscores the critical need for maintaining safety stocks and adopting dynamic procurement practices.

Geographical demand trends revealed initial surges in non-European Union regions such as China, followed by rising demand in Europe and Italy, highlighting the relevance of flexible, regionally responsive supply chain strategies.

These findings illustrate the significance of resilience-focused strategies, diversified sourcing, and strategic policy interventions to better equip the supply chain for future crises.

Finally, the survey results reveal the significant impact of the COVID-19 pandemic on the perception and management of supply chain risks. This crisis prompted many companies to develop disruption mitigation plans for the first time. However, some companies remained unprepared or unaware of such plans after the pandemic onset, highlighting the need to promote wider adoption of supply chain resilience strategies.

Some implications for both researchers and practitioners can be identified. The survey conducted and its results might foster studies on the challenges faced by Personal Protective Equipment supply chain echelons during the pandemic and how companies were able to address them. Furthermore, this study may prompt research into the effects of material management methodologies, such as Just in Time, aimed at minimizing inventory levels during unexpected demand surges across various supply chains. These contributions may help to determine whether Just in Time remains an effective strategy in business environments following the COVID-19 pandemic, especially as many organizations are now moving away from it.

Additionally, the present study might inspire assessments of the suitability of the structure of the Personal Protective Equipment supplier network to cope with the risks posed by the interruption in critical material sourcing. Finally, the survey outcomes might inspire new supply chain risk management methodologies and contingency plan development approaches to deal with events characterized by a low probability of occurrence but extremely high impacts. In this way, the research might stimulate companies to be more aware of the importance of having appropriate contingency plans, although Personal Protective Equipment supply chain organizations in Italy are already quite keen to adopt them.

From a practical point of view, the questionnaire outcomes might assist companies in shedding light on the causes of the supply chain events that affected the Personal Protective Equipment industry during the early stages of the COVID-19 pandemic. Such knowledge helps to increase their flexibility and resilience to similar disruptions in future. Furthermore, companies can gain insight from the comprehensive supply chain perspective provided by this work, enabling them to consider factors beyond just their own echelon.

The findings highlight the crucial role of the interdependence of supply chain actors, indicating that strengthening partnerships among producers, importers, and distributors, as well as establishing multiple supplier relationships across geographies, can improve coordination and facilitate smoother responses to reduce vulnerabilities. Also, companies serving international markets experienced varying demand shifts. So, practitioners could build on the outcomes of the present study to tailor strategies to specific regional dynamics, considering differences in crisis timelines, regulatory environments, and various logistics challenges.

Finally, practitioners could use the evidence presented in this work to re-evaluate their reliance on Just in Time and Lean practices, particularly for critical supplies like Personal Protective Equipment. For similar products, investing in strategic inventory reserves or creating more flexible procurement policies can help reduce future risks.

6. Conclusions

The present research underscores notable weaknesses and adaptive strategies within the Italian Personal Protective Equipment supply chain during the initial phases of COVID-19, offering important insights that are widely applicable in light of the current ongoing geopolitical issues.

In particular, the study points out that the reliance on global manufacturing—especially in China—and Just in Time inventory approaches left the Personal Protective Equipment supply chain ill prepared for an unforeseen spike in demand. In response, many companies moved away from Just in Time practices, raising their inventory levels to reduce future risks. The crisis also highlighted the importance of proactive strategies to effectively manage supply chain interruptions.

Key takeaways include the urgent need for a diverse range of suppliers, robust inventory management practices, and proactive crisis preparedness to improve resilience. Such insights are particularly pertinent given the current geopolitical strife, trade tensions, and regional instability that could lead to supply chain disruptions similar to those experienced during the pandemic. Furthermore, these lessons may apply beyond the Personal Protective Equipment supply chain to other sectors, like pharmaceuticals, food and beverage, and electronics supply chains, which encountered similar difficulties during COVID-19.

By leveraging the insights from this study, organizations in various fields can improve their resilience and adaptability, thereby ensuring increased greater in the face of possible future disruptions.

However, the work suffers from some limitations. First, it includes multiple Personal Protective Equipment types without focusing on any possible supply chain specificities of each individual product category. Second, the survey is limited to what happened in Italy. Lastly, only the first national lockdown period and the immediately following pandemic phases are considered.

Therefore, future research will extend the empirical analysis to multiple European countries, to compare the associated trends in the main variables of the Personal Protective Equipment supply chain. This research will also explore different demand and inventory management policies that may be implemented. In such a way, the impacts of the geographical location of supply chain players on demand and stock disruptions and the ways to tackle them will be uncovered. Furthermore, the authors would like to include also the late COVID-19 phases in the analysis to investigate how the Personal Protective Equipment supply chain variables evolved with the different pandemic conditions.