Abstract

Background: Sustainability in food supply chains is desired for production, logistics, and waste management. However, food supply chains (SCs) have complex systems that differ from other SCs. Managing such complexities is challenging for small and medium-sized enterprises (SMEs) due to their heightened constraints, such as limited resources and inadequate awareness. Despite the challenges, there is fragmented research, understanding, and approaches to assist SMEs. SC designs need to be adapted so that SMEs can navigate the challenges and avert high wastage. The main objective of this research was to identify the practices influencing sustainable SC designs in a developing country and create a simulation model to illustrate the potential benefits and challenges of promoting sustainability in the banana SC in Malawi. Methods: Mixed-methods research was utilised, employing a literature review, participant interviews, observations, and survey data collected from 353 participants from three districts in Malawi to gain insight into the banana SC problem, establish objectives, and develop a simulation model complemented by design science research. Results: The research identified awareness, collaboration, efficiency, governance, knowledge sharing, and resilience as sustainability practices in the case study banana SC, thus forming a sustainability model. Simulation results showed improvements in key performance indicators like shelf-life, lead-time, quality, throughput, and waste through SC operation reorganisation. Conclusions: Sustainable models must be tailored to the specific challenges inherent in developing food supply chains in developing nations. The development of the models has significant managerial implications, notably enhancing strategic planning, operational efficiency, risk management, alignment of sustainability goals, performance monitoring, stakeholder engagement, and resource optimisation.

1. Introduction

Globalisation has significantly impacted the food supply chain (FSC) landscape by presenting both challenges and opportunities for sustainable management [1,2]. The FSC faces increasing pressure to reduce waste, enhance security, and ensure health and safety for practitioners and consumers [3,4]. The 2024 edition of The State of Food Security and Nutrition in the World report presents crucial insights into global food security and nutrition. For instance, in 2023, 9% of the world’s population experienced hunger, with 20% in Africa [5]. Globally, 19% of the food available to consumers is lost throughout various stages of the FSC [6]. Thus, the focus of FSC operations has shifted towards sustainable supply chain management (SSCM), with a particular emphasis on balancing the social and environmental elements. Efficiency is required to avert food waste and improve the availability of safe and nutritious food [7]. Therefore, FSCs must identify areas for improvement by efficiently performing all the logistics activities [8]. Attaining FSC efficiency and sustainability faces challenges due to the unique characteristics of food, such as seasonality, heterogeneity, edibility, and perishability [9]. It is difficult to implement the FSC activities considering the various requirements, which are further complicated by varying and unique customer demands. The unique attributes and special customer requirements set the FSC apart as more complex than other types of SCs [10].

High FSC efficiency in developed countries and a few developing countries has been achieved by utilising innovations such as product tracking tools, cold chain (CC) temperature management, skilled handling, managing shelf-life, reducing lead-time, maintaining quality, and optimising product throughput [11,12]. Enhancing sustainable SC practices in developing countries faces distinct challenges compared to developed countries. Developing countries encounter issues like infrastructure shortages, high costs of CC technology, limited investment capacity, and the need for more awareness of key sustainable practices in SCs [13]. Fruit and vegetable smallholder farmers in developing countries are especially susceptible to the challenges because of the perishable products’ requirements for unique expertise, infrastructure, resources, and stable market access [14,15]. Despite the constraints, the products from developing countries contribute significantly to the global FSC [15]. This importance reinforces the need for developing countries to align with global SC standards [16]. The international market, foreign investments, and trade agreements are opened, allowing developing countries to benefit from reduced tariffs and other trade facilitation measures [17]. Meeting global standards, thus, enables diversification, reducing dependency on a few trading partners and enhancing economic resilience [18]. Further, developing countries can achieve economic development through quality improvement, technology transfer, employment and skill development, sustainability and social responsibility, and risk management through collaboration with global partners [19]. Therefore, the lack of adequate, sustainable SC practices in developing countries can result in significant global food imbalances [20] and hinder the livelihoods of small and medium-sized enterprise (SME) farmers [21,22].

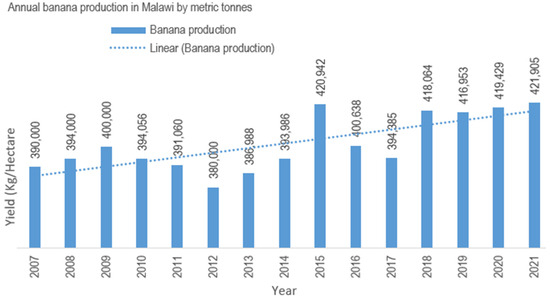

The SME farmers in Malawi, a developing country, are fragmented and operate on small pieces of land [23]. Despite various government policy supports, the SMEs in the country continue to underperform, and the farm system outputs are suboptimal [24]. For instance, Malawi has ideal climatic conditions for banana production. However, the crop is primarily produced for the local market and requires adequate research, extension services, and policy support [25]. As such, the sector has registered a rather flat level of production with a slight increase in total yield (kg/hectare) between the years 2007 and 2021 (Figure 1).

Figure 1.

Malawi banana production trend 2007–2021. Source: [26].

Bananas have a short shelf-life; therefore, they require careful handling before reaching consumers at the optimal stage [25]. Maintaining ideal conditions prevents premature ripening and chilling injuries [27]. In addition, careful handling is necessary to avoid post-harvest losses. Inadequate infrastructure, including poor roads and a lack of cold storage facilities, hampers the efficient movement of bananas from farms to markets [16]. Furthermore, compliance with food safety standards is crucial for accessing global markets, particularly for small-scale farmers. Lastly, the banana SC must address environmental concerns, such as reducing carbon footprints and waste management, to ensure long-term viability.

The banana SC in Malawi is affected by the full range of challenges such as climate change, pests and diseases, inadequate infrastructure and logistics, limited market access and pricing, financial constraints, and policy and regulatory issues. Pests and diseases, such as the Banana Bunchy Top Virus (BBTV), pose a major threat to bananas, and effective management and control measures are often lacking [28]. Inadequate infrastructure hampers the efficient SCM of bananas from farms to markets, resulting in high post-harvest losses. The SC further suffers from limited access to credit and financial services, restricting farmers’ ability to invest in improved farming practices. Finally, inconsistent policies and regulatory frameworks create barriers for farmers and stakeholders in the banana SC.

Nevertheless, bananas are essential for food security in Malawi [28,29]. According to the World Population Review [30], as of 2020, banana consumption per capita in Malawi reached 19.5 kg. While this figure is relatively modest compared to other countries, such as Uganda, Burundi, and Rwanda, bananas remain popular and a source of nutrition in Malawi. The local supply of bananas frequently falls short of meeting the demand, necessitating a dependence on imported bananas to bridge the gap. Despite the situation, both local and imported bananas often suffer high waste.

The banana SC in Malawi primarily comprises SME farmers, transporters, intermediaries, and retailers. The first-mile transport usually involves hand lifting to a convenient location, followed by farmers or intermediaries moving the product to a market. Afterward, ripening occurs at storage or other designated ripening centres, depending on the market location or SC design. The banana SC lacks a definitive framework for sustainable operation within the limits of the operating environment. Therefore, the research seeks to answer the question what are the sustainable practices for reducing waste and optimising throughput in the banana SC?

Problem Definition

Global sustainable SC practices contribute to food waste reduction, stabilisation of throughput, and sustainability improvement [22]. However, SMEs in the food sector in developing countries like Malawi face challenges in implementing sustainable SC practices to align with global standards [15]. This research aims to identify the practices influencing sustainable SC design in a developing country and develop a simulation model to highlight opportunities and barriers for improved performance.

The remainder of the article is organised as follows: the critical practices in FSCs in developing countries are reviewed in Section 2. The methodology used for the research is presented in Section 3. The research findings are presented in Section 4. Section 5 is the discussion, while the conclusions and recommendations for further research follow in Section 6.

2. Literature Review

The FSC comprises crucial functions, like product planting, harvesting, processing, packaging, distribution, and inventory management, to ensure the product remains viable for consumption [10,31]. FSCs in developing countries face challenges to comply with the various sustainability requirements [32]. However, the global importance of food and the significant post-harvest food loss being experienced necessitate implementing sustainable measures in FSCs [33,34,35]. A strategic impact assessment is crucial before implementing sustainability measures due to the divergent structures of FSCs for different products and locations [36]. Thus, integrating sustainability in FSCs presents new SC challenges [15,31], but developing models, frameworks, key performance indicators (KPIs), and objectives can help decision-makers to navigate these challenges effectively [37]. Numerous research streams have identified the challenges and developed frameworks, KPIs, and mathematical and simulation models. However, the resources developed only apply to the targeted systems since context, settings, and objectives may differ [36].

Furthermore, mathematical and simulation modelling methods have limitations [38], potentially leading to oversimplification of real-life systems when only subsets of system parameters and decision variables are modelled [39]. Frameworks developed qualitatively through literature analysis often need more practical evidence due to the need for robust real-life system testing [40]. The deficiencies have been addressed using various methods [3,14,41,42,43] or conducting in situ research using existing research as a benchmark. This section delves into the key sustainable SC practices in the FSCs and the methods used to study them, aiming to identify applicable KPIs for a developing country and formulate a model for the potential improvement of the SCs.

2.1. Food Sustainable Supply Chain Practices in Developing Countries

This subsection discusses the sustainable SC and its key practices in the food sector. A search of the relevant literature discussing various practices in developing countries was conducted using the Scopus and ScienceDirect databases. The initial search covered the period from 2001 to February 2021, later refreshed to February 2024. The generic keyword strings used were “supply chain”, “value chain”, “logistics”, “demand chain”, “sustainability”, “green”, “environment”, “food”, “edible”, “agri”, “cold chain”, “perishable”, “short life”, “fruit”, “vegetable”, “flower”, and “developing” or “non-industrial”.

The practices identified were categorised into awareness, collaboration, efficiency, governance strategy, knowledge and information-sharing, and resilience following detailed content analysis [44]. Some of the articles reviewed are discussed next under the mentioned categories of practices. In summary, the articles in this subsection discuss the sustainable SC practices in FSCs in developing countries. They highlight the diverse factors influencing practices. The factors and practices highlighted address specific FSC objectives and are grouped to benchmark model elements for a sustainable SC in an end-to-end FSC in a developing country.

2.1.1. Awareness

Awareness in SCs is heightened through the stakeholder’s intimate knowledge of the system. SC awareness refers to the understanding of processes, risks, and opportunities, recognising the interconnectedness of the SC participants and customers and the impact of SC decisions on the environmental, social, and economic aspects [45]. Much research has been conducted on the intricacies of FSCs, including potential risks, vulnerabilities, and opportunities to improve awareness and facilitate informed decision-making in sustainable SCs [1]. Raut et al. [41] analysed post-harvest losses in India and identified key interventions, awareness of environmental management practices, and regulatory and competition pressures affecting sustainability measures in SCs. Sonar et al. [15] proposed that authorities in SCs should actively create awareness among SMEs by offering incentives, training, and resources to encourage sustainability implementation. The integration of sustainable requirements into SCs is justified by increased consumer awareness of environmental and social issues, the development of environmental laws, and the businesses’ pursuit of market competitiveness [46]. However, efforts to raise awareness among all the SC participants often need to be improved [47]. Awareness practices are facilitated through concerted collaboration efforts, as discussed next.

2.1.2. Collaboration

Collaboration in sustainable SC has been extensively studied, focusing on supplier classification, private sustainability governance initiatives, waste reduction, safety, and quality improvement. Hudnurkar et al. [48] presented a decision framework for classifying suppliers in collaborative SCs from a buyer’s perspective. Nesadurai [49] explored collaboration in private sustainability governance initiatives in Indonesia’s and Malaysia’s palm oil sector to improve efficiency in SME practices. The initiatives address the need for sustainability and the enhancement of production. Kumar et al. [43] discussed the role of collaboration, governance, and efficiency in sustainable SC to reduce waste, address safety concerns, and improve quality. Tsapi et al. [47] found that integration, coordination, and synchronisation of SC flows are crucial for all SC participants to improve overall performance, collaborate effectively, and satisfy their end customers. Thus, Sharma et al. [50] created a comprehensive model that integrates multiple criteria for evaluating and selecting sustainable suppliers in the agro-food sector. The model uses Multi-Criteria Decision-Making techniques to handle complexity and uncertainty in supplier evaluation. The model prioritises KPIs reflecting sustainability aspects, including environmental, social, and economic dimensions. Inadequate collaborations can lead to SC complexities and short-circuit the efficiency performance [11]. The next section discusses efficiency.

2.1.3. Efficiency

The global SC landscape keeps evolving due to the growing importance of sustainability measures, emphasising the need for efficient SCs [40]. Efficient SCs are essential for environmental prudence, economic viability, and meeting consumer and stakeholder expectations. Thus, some research focuses on streamlining processes and adopting technology to enhance efficiency [51]. In that regard, Gardas et al. [14] proposed an integrated model using Delphi, decision-making trial and evaluation laboratory (DEMATEL), and interpretive structural modelling (ISM) techniques to improve agricultural SC efficiency in India. Key factors in the study include direct marketing, storage facilities, legislation, infrastructure, intermediaries, market transparency, stakeholder coordination, and information dissemination. Gardas et al. [3] utilised ISM to analyse performance indicators in the agri-sector. They found environmental management, regulatory pressure, and competitive pressure as the factors with the highest driving power for efficient performance. Biza et al. [52] developed a mixed-integer linear programming model to improve the efficiency and sustainability of perishable product SCs. The model addresses complexities like shelf-life, inventory management, and transportation. Strategic decisions involve selecting facility locations and allocating resources to different nodes. tactical decisions involve inventory control, transportation scheduling, and routing to minimise costs and reduce spoilage. One of the crucial facilitators for SC efficiency is information [1]. As such, information alongside knowledge sharing is discussed next.

2.1.4. Knowledge and Information-Sharing

Knowledge and information-sharing are crucial organisational building blocks, enabling enterprises to develop core competencies, identify challenges, handle complexities, and maintain competitiveness [11]. Knowledge and information-sharing in FSCs enhance operations and business performance by explaining and sharing the understanding of the underlying factors for long-term sustainability [15]. The sharing of practices is fundamental to all functional areas of SCs. For instance, farmers can have unified guidelines for land preparation [21] and follow integrated crop management practices [28]. Gardas et al. [14] concluded that knowledge and information-sharing are vital for market transparency and stakeholder coordination.

Obonyo et al. [52] revealed market access as the primary driver for information-sharing to achieve FSC efficiency, sustainability, and resilience in developing countries. The authors also found that information-sharing is limited by minimal technology adoption. Mangla et al. [53] identified key enablers for successfully implementing sustainable initiatives in the FSC, such as collaboration, SC transparency, traceability, technology adoption, consumer awareness, and stakeholder engagement. The authors expound that collaboration fosters knowledge sharing, resource pooling, and joint efforts towards sustainability goals. SC transparency ensures seamless information-sharing, while technology adoption enables real-time monitoring and efficient resource utilisation. Consumer awareness promotes responsible consumption, while transparent communication builds trust and promotes collective action towards sustainability [54].

2.1.5. Resilience

The FSC may face food availability, distribution, and affordability disruptions due to unforeseeable factors, such as climate change, pandemics, and heavy rainfall affecting production [54,55,56]. Measuring the factors concerning sustainable performance requires relevant KPIs [37]. Asian et al. [57] employed cooperative game theory to investigate the impact of a sharing economy on smallholders, focusing on community resilience, resource efficiency, sharing frequency, and utilisation rates. Namany et al. [58] studied sustainable food security decision-making using KPIs like energy, water, food usage, SC stability, resource efficiency, social equity, and environmental impact. Han et al. [59] discussed challenges in maintaining the quality and safety of fresh agriculture products during transport and storage, highlighting implicit KPIs related to resilience practice. Keeping unforeseen disruptions in check calls for new research directions in resilience, a critical attribute that necessitates finding the right equilibrium between redundancy and efficiency [40,55]. Tchonkouang et al. [60] propose adaptive strategies to improve FSC resilience, including diversifying sources, investing in climate-resilient infrastructure, and adopting sustainable agricultural practices. Knowledge of various aspects of the SC and leveraging technology can streamline the entire SC, from raw material procurement to logistical support for product delivery [2].

2.1.6. Governance

Effective governance is critical in ensuring transparency, ethical conduct, and regulatory compliance within sustainable SCs. Governance is required for establishing the necessary infrastructure to support sustainable performance initiatives [37,53]. Nesadurai [49] demonstrated that governance strategies initiated by corporations and non-governmental organisations (NGOs) can lead to sustainable SC performance. The author underscores the key mechanisms such as SC mapping, knowledge service partnerships, and meta-partnerships.

Asian et al. [57] explored measures for implementing governance strategies, including community resilience, resource efficiency, and SC participation, aiming to optimise resources, reduce waste, and build communities. Moussavi et al. [39] evaluated the governance of an agriculture SC using various distribution decision-making methods to reduce logistics costs and processing delays.

Effective governance is essential for facilitating the implementation of strategies by various stakeholders within an SC [1].

2.2. Modelling in Sustainable Supply Chains

With the various FSC practices identified, the next step is to review the SC optimisation approaches. Modelling and simulation are increasingly used to understand and optimise sustainable SC practices. By representing sustainable SC components as interconnected entities, modelling provides insights into SC behaviour, dependencies, and constraints [61]. The two primary approaches are mathematical and simulation models. Mathematical models exhibit determinism and reliance on assumptions, making them well-suited for straightforward scenarios found in small-scale SCs [62]. On the other hand, simulation models are utilised to enhance the performance of dynamic systems through logical processes and rule-specific behaviours [63]. Simulations can be deterministic or stochastic. They provide approximations and best-fit solutions through sensitivity analysis. The models are easy to learn and demonstrate and can be implemented in both small-scale and complex large-scale SCs [64,65]. Simulation aids in evaluating the benefits of SC decisions, testing feasibility, and various scenarios. The approach is also used to assess potential changes in SC performance, enabling risk assessment and decision-making under uncertainty [66]. Further, simulation empowers SC participants and decision-makers to optimise processes, enhance efficiency, and adapt to changing conditions. Hence, simulation is a more suitable approach for modelling in the present research context. The common simulation modelling techniques are summarised next.

2.2.1. Simulation Techniques

System dynamics (SD), agent-based simulation (ABS), and DES are the common simulation techniques in SC management [67]. SD uses mathematical modelling to understand nonlinear system behaviour. The method effectively considers the entire SC at tactical, strategic, and operational levels and is suitable for SCs with rapidly changing data. ABS provides a bottom-up view of the whole SC by simulating individual agents (e.g., suppliers, distributors, consumers) and their interactions in the SC. DES accurately represents discrete events (e.g., cost, inventory, order processing, price, quality, shelf-life, transport) and their impact on the SC [31]. DES presents notable advantages compared to alternative techniques. These advantages include the rapid identification of SC bottlenecks and the ability to observe stochastic elements [61]. However, DES lacks explicit mechanisms for gathering stakeholder feedback, as it does not model control and decision processes within entities [61]. Therefore, complementary methods are often required for modelling FSCs in inter-organisational settings, especially for developing country SMEs with uncertainties. Various simulation techniques can be combined, or simulation can be enriched with alternative methodologies, such as the design science research approach, as presented in the ensuing sections. DSR effectively addresses real-world problems through iterative design, implementation, and evaluation cycles, enabling continuous improvement and adaptation based on feedback [68]. DSR’s artifacts are designed to be practically relevant and immediately applicable, ensuring that solutions are not only theoretically sound but also feasible and effective in real-world settings [69].

2.2.2. Design Science Research

DSR is a modelling methodology that extends system capabilities through artefacts (e.g., conceptual models or applications) [68]. Venable and Baskerville [69] (p. 142) define DSR as “research that invents a new purposeful artefact to address a generalised type of problem and evaluates its utility for solving problems of that type”. DSR typically addresses uncertain constraints, complex interactions between system subcomponents, inherent flexibility to alter design processes, and reliance on human cognitive (e.g., innovation) and social (e.g., collaboration) abilities for effective solutions [70]. The DSR process comprises six phases: problem identification, definition of objectives, artefact design and development, demonstration, evaluation, and communication [70]. Peffers et al. [70] suggest adjusting the phases according to the research objectives.

2.2.3. DES and DSR in Combination

DSR and DES can work together effectively in several ways. For instance, DSR can use descriptive and prescriptive knowledge to identify problems, formulate research questions and objectives, and develop a conceptual model [71]. DSR can also validate DES models by comparing model results with real-world data and assessing their usefulness for decision-making [72]. Thus, DSR would inform conceptual model development, while DES provides a dynamic simulation environment for analysing the model applicability of the SC events in a real-life system.

2.2.4. Gap in the Literature

The body of literature reviewed extensively covers various practices, both explicit and implicit. However, there is a scarcity of literature that delves into multiple practices. Table 1 summarises the literature in terms of practices and modelling approaches explored. The summary reveals that only a handful of studies simultaneously address multiple practices. Furthermore, there is a notable absence of articles utilising simulation as a modelling approach. This paper seeks to bridge this gap.

Table 1.

Summary of literature review and the contribution of this paper.

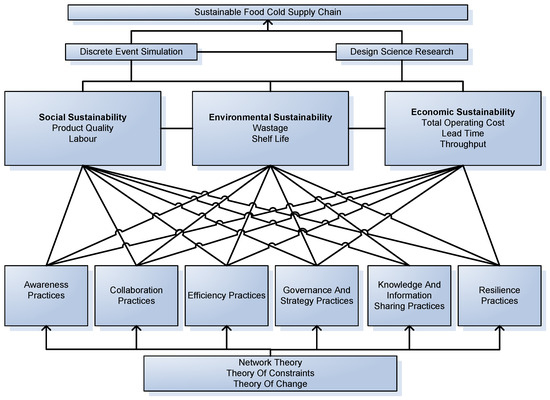

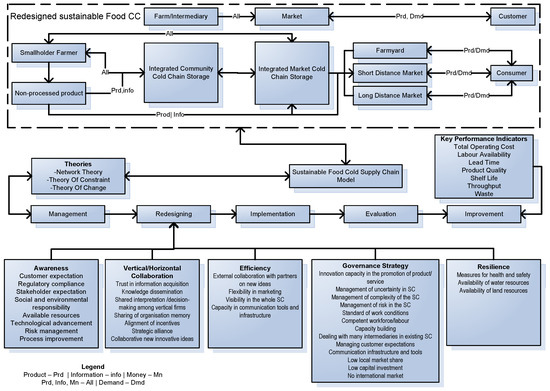

The theoretical model formulated for the sustainable FSC (Figure 2) shows that the various practices affect sustainability’s social, environmental, and economic aspects. The sustainability aspects can be measured using DES and DSR KPIs to achieve a sustainable FSC. The underlying theories in the model are discussed under materials and methods.

Figure 2.

Theoretical model for a sustainable FSC for a developing country.

3. Materials and Methods

3.1. DSR Methodological Approach

The initial step in the DSR approach involved introducing the problem, followed by a thorough literature review using available articles to emphasise the strategies explored in sustainable FSCs. The problem, as discussed in the introduction, pertains to the extent to which sustainability practices are effectively implemented to mitigate high food waste and uncertain throughput due to SMEs’ operational challenges.

In the second stage of the DSR process, a multi-faceted approach was employed to explore the intricacies of the banana SC in Lilongwe. The approach involved conducting a thorough survey, engaging in face-to-face interviews, and gathering valuable input from key informants. The primary objective was to gain a nuanced understanding of the distinct characteristics of the local SC. To accomplish the objective, a blend of network theory, theory of constraint, and theory of change was leveraged to meticulously construct a comprehensive profile of the banana SC through the lens of critical theory [44]. The detailed process employed can be viewed in the original data used in the study (Supplementary Materials).

Critical theorism, the approach utilised, is a philosophical approach that challenges conventional research methods by examining assumptions not typically relevant to design or practice [73]. It aids in the creation of critical strategies to uncover hidden ideological structures and socio-cultural contexts [74].

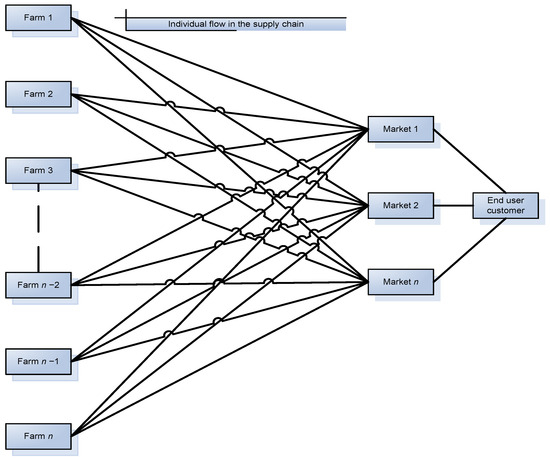

As confirmed through data analysis, the primary operations in the SC include harvesting, grading, storage/ripening, transport, and retail, with the products flowing from farm to market. Through exploratory factor analysis (EFA), the banana SC was found to be complex, with little collaboration among the SC participants (Figure 3) and low governance strategy, efficiency, and resilience in the SC. SMEs in the SC operate as individual entities rather than in collaboration, leading to uncoordinated harvesting and redundant transport capacity. For instance, a truckload carrying bananas from only one farm may not load to its full capacity, resulting in insufficient utilisation of the redundant transport capacity. Customers with unfulfilled requirements from a single source use more resources by procuring from multiple farms, leading to multiple points of waste in the SC.

Figure 3.

Illustration of current banana SC configuration. n = any number from 1 and above.

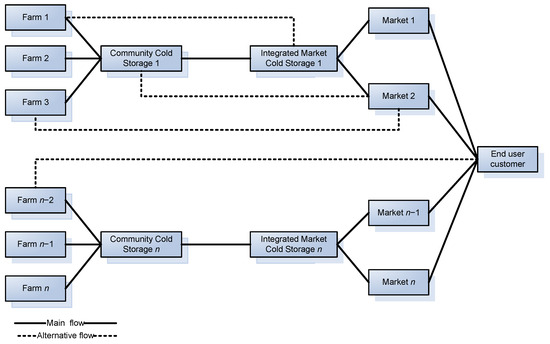

The third DSR stage involved conceptualising a model for assessing the sustainable FSC. A redesign configuration (Figure 4) was formulated through this process, which included using information gathered, the literature review, face-to-face interviews, observations, data analysis, and several iterations of discussions with the SC participants.

Figure 4.

Illustration of redesigned supply chain configuration. n = any number from 1 and above.

During the interviews, SC participants were encouraged to discuss potential changes in their operations to address existing constraints. Their inputs informed the conceptual design. The first scenario of conceptual design solutions includes making process changes that do not require long-term CC infrastructure investment, such as SC activities being conducted during cooler times of the day. For the required throughput to be achieved within the confined operating time, investments should be made to increase labour, and transport must be readily available as soon as harvesting is complete to avoid the need for temperature management infrastructures at the farm. Alternatively, increased product quantity can be sacrificed for product quality, with harvesting restricted to low-temperature periods but only a small quantity harvested due to limited labour quantity.

The second scenario suggests a consolidated approach to cost-effective CC infrastructure investment among SC participants. The strategy involves pooling resources to invest in sharing equipment, synchronising activities, and streamlining transport and storage. This approach allows SC participants to leverage resources and capacity that may not be available to them as individual entities. Figure 5 presents the proposed model.

Figure 5.

A proposed conceptual sustainable FSC model.

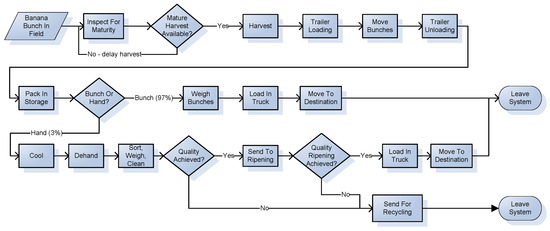

The conceptual model is demonstrated through DES. A case study enterprise, representative of the SME banana SCs in Malawi, is presented. The enterprise has several banana fields managed under single farm management. The enterprise performs harvesting, grading, storage/ripening, and transport—other SC participants also access products to handle the post-harvest processes themselves. The operations are illustrated in Figure 6.

Figure 6.

Process map for the banana SC of the case study company.

Feedback from key stakeholders was used to refine the model. From the feedback, stakeholders highlighted the market potential for banana production in Malawi despite the current high number of stock in the retail market being imported. The participants emphasised the need for government intervention, infrastructure improvement, and stakeholder involvement to develop the banana industry.

The case study enterprise provided operational details and data, which were statistically analysed and prepared for use in the DES models. The Arena® Input Analyzer tool was utilised to analyse the data and determine distribution models (Table 2). The model simulation reliability at a 95% confidence level was confirmed through goodness of fit by two-sample t-test comparison of mean with statistics obtained through observation and existing data. This was demonstrated by the mean square values close to zero and p-values higher than 0.05 [64].

Table 2.

Probability statistics for activities at the case study company.

3.2. Model Input Parameters

The data for the base model included total production costs, required labour, operation schedule, lead-time, number of transporters, capacity of transporters, daily harvest amount, harvested bunch weight, and shelf-life. The conceptual model (Figure 6) was transformed into an Arena® DES model for test runs and validation using the data in Table 2 and cost summaries from the case study enterprise. The simulation run spanned a full workday (seven hours) for the case study enterprise, covering modules from harvesting to loading and processing bunches.

3.3. Base Model Assumptions

The model was designed to be simple yet robust enough to simulate the real-life system based on the following assumptions:

- Harvest is always available; therefore, the input is not starved at any point.

- Disruptions caused by resource breakdowns are not modelled (due to a lack of the required statistical data).

- The model operates 24 h, but all operations, up to truck loading, are completed within seven hours, a typical daily shift for the case study.

- A week has five working days, but operations can occur on an additional sixth day.

- Randomness simulation in operations is not performed (due to a lack of statistical data).

- Storage capacity is unlimited at any stage in the SC for the quantities typically harvested.

- Period randomness is evened out.

- There is stable market for the products

The representatives of the case study enterprise and other SC participants familiar with the operations confirmed the initial list of KPIs with base values (Table 3).

Table 3.

Indicators for model simulation per day (base value).

3.4. Base Model Validation

A seven-hour daily operation simulation model was run for three months, with 100 replications determined based on the number of decision variables (less than ten) and the accuracy of results at a 95% confidence level [62]. Results were compared with the actual system using a two-sample t-test, which exhibited a 95% significance level match between the base model and the actual system (Table 4).

Table 4.

Comparison between simulated output and actual data (base value) per day.

3.5. Evaluation of Alternative Model Designs

Two alternative models were developed, standalone and integrated, and the results, including sensitivity analysis, presented in Table 5 and Table 6, are discussed in the next section.

Table 5.

Comparison of variables for base and standalone simulation results per day.

Table 6.

Base and integrated farm-level model comparison per day.

4. Results

4.1. Standalone Model

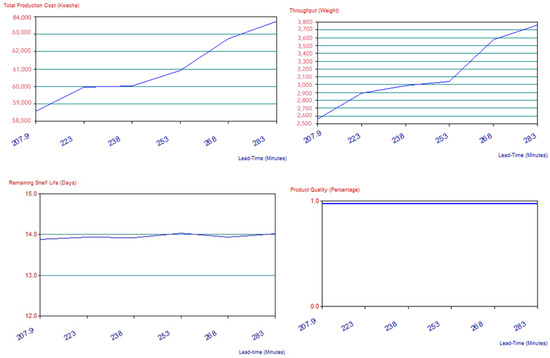

The simulation of the standalone model (Table 5) shows a 2% decrease in total production costs and a 27% improvement in lead-time (1.3 h gained per day) for a similar output of 128 banana bunches weighing approximately 2500 kg. The statistically significant difference (p-value < 0.001) suggests that throughput would increase if the model were simulated for the same total processing time as the base model. In addition, significant improvements were observed in food quality, shelf-life, and wastage. Sensitivity analysis confirmed the effect of altering lead-time on the other variables (see screenshots in Figure 7). The results in Figure 7 show that increased lead-time leads to higher total production costs. As labour resources remain constant, lead-time increases for higher throughput, while variables like shelf-life, quality, and wastage remain constant for a daily operation unless production extends beyond a day. Therefore, SME farmers without the capacity for heavy investment in CC infrastructure can adopt a cooler-period harvesting method by increasing the labour quantity to gain improvements in lead-time, food quality, shelf-life, and wastage (p-value < 0.001) with a decrease in production costs (Table 5).

Figure 7.

Sensitivity analysis for the standalone simulation model.

4.2. Integrated Model

The simulation results for the integrated model (Table 6) reveal a 6% increase in daily total production costs. The investment cost leads to a 2.2 h daily improvement in farm-level lead-time, resulting in 65 additional banana bunches and a 51% increase in throughput. Waste management also sees a 61% improvement, reducing farm-level wastage to 2.5% in the integrated model compared to 6.5% in the base model. The shelf-life increases to 14 days, representing a 93% improvement, assuming an investment in CC infrastructure across the SC. It is also assumed that the bananas are harvested at approximately 100% maturity and managed within an environment of approximately 16 °C [75] since the current target is the short-distance market. The harvesting and management practices can be altered when the target changes to a long-distance market. In this case, the bananas must be harvested at 75% maturity and managed in an environment of 13 °C (±0.5) to achieve an average 35-day shelf-life [75].

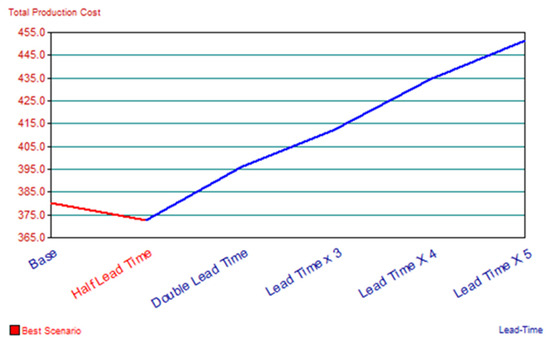

The integrated sustainable CC model was tested on various scenarios based on the KPIs, examining changes in total production costs, lead-time, quality, shelf-life, throughput, and wastage. Figure 8 shows that an increase in a one-day lead-time (base) leads to increased total production costs. A scenario where lead-time was reduced by half was also tested and found to be the best scenario, reducing total production costs.

Figure 8.

Effect of lead-time on total production costs.

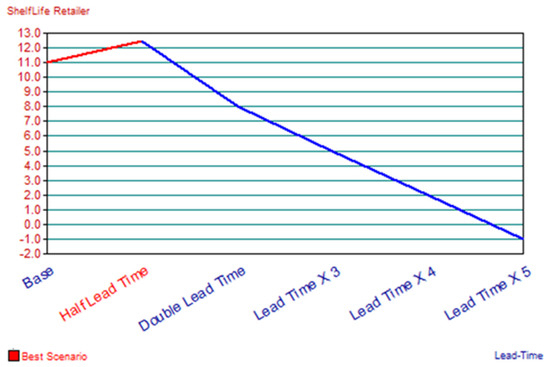

The research also analysed the impact of lead-time on shelf-life. The scenario was tested by changing the lead-time from one day (base) to half a day and subsequently increasing it, and the effect on shelf-life was observed by the time the product reached the retailer. As shown in Figure 9, the best scenario is when lead-time is 0.5 days (half lead time), which improves the remaining shelf-life at a retail level to 12.5 days. As lead-time increases, shelf-life progressively decreases.

Figure 9.

Effect of lead-time on shelf-life.

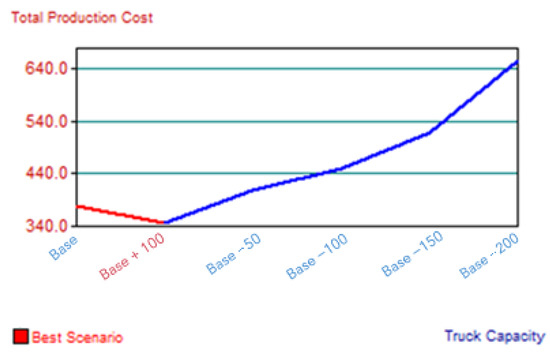

The integrated CC design model proposed using correct-sized trucks for the centrally located products. Hence, the model was tested with different truck capacity scenarios. Increasing capacity by 100 banana bunches yields the best total production costs (Figure 10). Conversely, scenarios with decreasing capacity show an increase in total production costs.

Figure 10.

Effect of truck capacity on total production costs.

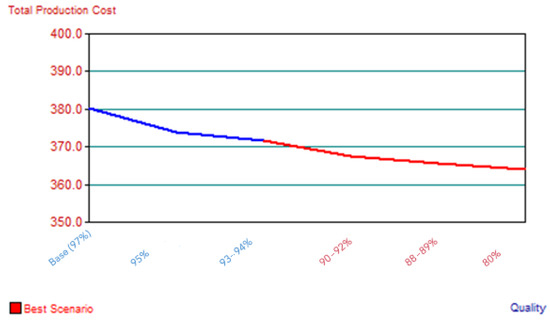

The final scenario tested was the effect of quality on total production costs. The model initially had a 97% product quality level but was tested with progressively decreasing quality levels. As quality decreases, the total production costs decrease (Figure 11).

Figure 11.

Effect of quality on total production costs.

The model was simulated for a long-term period. The results (Table 7) reveal that a 6% increase in total production costs at a farm is necessary to improve sustainability in numerous variables over three years. The increase in total production costs is primarily attributed to increased labour investment and the additional utilisation of resources, like tractors, for optimal efficiency. The lead-time improves by 47%, improvements in food quality are 4%, and shelf-life improves by 85%, while the throughput number (51%) and throughput weight (52%) are expected alongside a waste reduction of 61%.

Table 7.

Three-year forecast output of actual and simulated models.

5. Discussion

From the results, modelling is important for insights into practices and processes that affect FSC designs to achieve sustainability. Comprehensive theories enable an understanding of the various intricacies of the SC, such as the network nature, constraints, and desired objectives. Different modelling and analysis techniques are employed to achieve the desired levels of detail. A simulation technique should be chosen based on the nature of the problem to be modelled to enable scenario analysis. Simulation can be complemented by another modelling technique to compile a full profile of the factors that affect design. The DSR approach used in this research ensures that uncertainties, complexities, flexibilities, and societal and human feedback are considered in the solution modelling. Thus, simulation is based on the conceptual model constructed with factors that cannot be easily modelled in the system processes but significantly influence the SC design. The results guide the construction of informed models for efficient resource utilisation, cost planning, lead-time management, waste management, and enhancement of shelf-life, quality, and throughput.

The research findings provide valuable insights and practical applications that can benefit farmers and policymakers in Malawi. Key application areas include following key practices in adopting sustainable farming methods. This would ensure that participants share ideas in implementing climate-resilient practices and are provided with the necessary training and capacity building. The sustainable practices would also ensure that logistics and transportation are optimised to reduce lead-time and product waste. Collaboration among stakeholders can lead to better coordination and efficient distribution networks.

Practical policy initiatives guided by the model in this research would ensure targeted investment in infrastructure and establish regulatory frameworks that promote increased market penetration, including the export market for SMEs. This would require the formation of cooperatives and the creation of market linkages through information-sharing platforms.

Therefore, Malawian farmers and policymakers can work towards a more sustainable and resilient banana SC that contributes to the overall sustainability of the agricultural sector.

5.1. Theoretical Implications

The research findings have several theoretical implications for sustainable SC in a developing country. First, through theoretical analysis, it was possible to categorise the factors that affect sustainable SCs into six practice components, i.e., awareness, collaboration, efficiency, governance strategy, knowledge and information-sharing, and resilience. The categorisation provides a structured model for comprehending SMEs’ diverse challenges in FSCs in developing countries. The availability of a model leads to formulating the right KPIs to measure system performance [37].

Geographically, the research first reinforced the regional differences between developed and developing countries [13]. Second, it focused on a country with a paucity of research, especially in supporting the banana sector’s SCs [25]. Therefore, the findings are crucial since they are specific and add to the refined dimension of understanding regional and location-specific factors influencing sustainable SC dynamics.

This research used a combination of DSR and DES to evaluate the SC performance and identify key practices. This approach ensures simulation results are accurate and applicable in real-life systems, provided the practices are in place. The approach provides valuable insights into the implementation methods, as posited by Li et al. [36].

Finally, the integrated model results show a significant improvement in the system’s performance. The key factors in the model centre around collaboration and sharing, entailing that networks are an important theoretical perspective in sustainable FSC performance. SMEs should strive to enhance SC collaboration by forming cooperatives [21,23,38,43,56,57,65].

5.2. Managerial Implications

The research community has established the existence of FSC challenges in developing countries, and the need for improvement is well documented. This research offers insights into the important focus areas for a FSC in a developing country. The literature review provided various models and strategies for SC researchers and practitioners to address FSC challenges. The managerial insights emerging from this research include a better understanding of the current modus operandi and the status of specific FSCs in a developing country context. Insight is provided on each sustainable SC practice’s awareness, focus, and perceived success level. The simulated outputs, which are incumbent on the existence of practices, provide the industry and government with the tools to invest in improvement efforts in the research SC. These include a call for sustained training, capacity building, and information dissemination to improve awareness, as well as encouraging formulation of cooperatives to improve collaboration, knowledge and information-sharing, and sharing of other scarce resources, like transport and storage. Governance strategies that include guidelines and policies that facilitate sustainable SC, such as encouraging high-cost investment in transport and CC infrastructure, are also among the managerial insights. Thus, the simulation model can support practitioners in enhancing strategic planning, operational efficiency, risk management, and aligning sustainability objectives. Managers can leverage this tool to make well-informed decisions, curtail costs, evaluate risk scenarios, lessen environmental impact, champion social responsibility, and cultivate collaboration and transparency to accomplish sustainability aims.

5.3. Practical and Policy Recommendations

The government should establish sustainability policies and initiatives for SMEs in the banana sector to enhance overall awareness of sustainable practices. This could be achieved by motivating relevant institutions to implement training programs focusing on sustainable practices. A facilitation agency should be created to encourage collaborative efforts among SC participants. It should primarily focus on leveraging opportunities and partnerships across various sectors that support the banana SC. Furthermore, an investment-friendly environment should be created. This can help facilitate infrastructure installation, such as climate-controlled storage in off-grid areas through tax incentives, electrification in banana-growing regions and improvements in transportation infrastructure.

6. Conclusions

6.1. Findings

The simulation model for a banana SC shows short-term and long-term improvement potential in a research setting with constraints. The current performance of the SC is affected by a lack of awareness of sustainable SC practices. Collaboration among SC participants is crucial for sustainability as it improves visibility and facilitates informed decision-making. Efficiency ensures that resources are properly utilised. Governance provides a bird’s-eye view of the direction that ensures the relevant resources and networks are available to improve the performance, including SC resilience. Knowledge and information-sharing practices ensure that all SCs operate with the same improvement objectives. The fact that these practices were found to be inadequately implemented has a large impact on the current state of the banana SC in Malawi. Investment in the end-to-end SCs is required for significant improvement. The simulation showed short-term measures that only require awareness and a change in operations without high-cost investments in infrastructure. However, these changes result in minimal improvement. Long-term improvements necessitate significant investment in the CC infrastructure, operational changes, and capacity-building measures.

6.2. Research Limitations

As with all research, the study has limitations. First, data scarcity in some SC stages limited a widely informed end-to-end SC simulation. The challenge was that record-keeping is rare among most SMEs, which should be addressed with improved awareness. Second, disruptions that may occur due to resource breakdowns were not modelled, as there were no data to create breakdown probabilities. Similarly, operational randomness was not modelled due to a lack of statistical data.

6.3. Recommendations for Future Work

In terms of further research, the findings can be a baseline for research in other perishable FSCs that have challenges similar to those of the banana SCs of Malawi. Prospective investors in the FSCs might be interested in understanding whether the investment requirements detailed in this research are relevant to multi-product SCs—this presents another avenue for research. Subsequent research could also expand the simulation to encompass more SC stages by employing diverse data collection techniques for SMEs with inadequate record-keeping practices. Further, the supply was assumed to be unlimited in the simulation. It would be illuminating to simulate situations where the normal system is starved and there are breakdowns for various uncertain reasons.

Supplementary Materials

The following supporting information can be downloaded at: https://data.4tu.nl/datasets/6d3b376b-0e47-45b9-a4a7-a04e4d2ed489/1 (accessed on 20 May 2024), Figure S1: Theoretical model for the sustainable FSC for a developing country; Figure S2: Illustration of current banana SC configuration. n = any number from 1 and above; Figure S3: Illustration of redesigned supply chain configuration. n = any number from 1 and above; Figure S4: A proposed conceptual sustainable FSC model; Figure S5: Process map for the banana SC of the case study company; Figure S6: Sensitivity analysis for the standalone simulation model; Figure S7: Effect of lead-time on total production costs; Figure S8: Effect of lead-time on shelf-life; Figure S9: Effect of truck capacity on total production costs; Figure S10: Effect of quality on total production costs; Table S1: Probability statistics for activities at the case study company; Table S2: Indicators for model simulation per day (base value); Table S3: Comparison between simulated output and actual data (base value) per day; Table S4: Comparison of variables for base and standalone simulation results per day; Table S5: Base and integrated farm-level model comparison per day; Table S6: Three-year forecast output of actual and simulated models.

Author Contributions

Conceptualization, E.H.M.; methodology, E.H.M.; software, E.H.M.; validation, E.H.M., S.C. and J.W.; formal analysis, E.H.M.; investigation, E.H.M.; resources, E.H.M.; data curation, E.H.M.; writing—original draft preparation, E.H.M.; writing—review and editing, E.H.M., S.C. and J.W.; visualization, E.H.M.; supervision, S.C. and J.W.; project administration, E.H.M.; funding acquisition, E.H.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original data presented in the study are openly available in 4TU. ResearchData at https://doi.org/10.4121/6d3b376b-0e47-45b9-a4a7-a04e4d2ed489.v1.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Kiers, J.; Seinhorst, J.; Zwanenburg, M.; Stek, K. Which strategies and corresponding competences are needed to improve supply chain resilience: A COVID-19 based review. Logistics 2022, 6, 12. [Google Scholar] [CrossRef]

- Shakur, M.S.; Lubaba, M.; Debnath, B.; Bari, A.B.M.M.; Rahman, M.A. Exploring the challenges of industry 4.0 adoption in the FMCG sector: Implications for resilient supply chain in emerging economy. Logistics 2024, 8, 27. [Google Scholar] [CrossRef]

- Gardas, B.; Raut, R.; Jagtap, A.H.; Narkhede, B. Exploring the key performance indicators of green supply chain management in agro-industry. J. Model. Manag. 2019, 14, 260–283. [Google Scholar] [CrossRef]

- Gurrala, K.R.; Hariga, M. Key food supply chain challenges: A review of the literature and research gap. Oper. Supply Chain. Manag. 2022, 15, 441–460. [Google Scholar] [CrossRef]

- FAO; IFAD; UNICEF; WFP; WHO. The State of Food Security and Nutrition in the World 2024—Financing to End Hunger, Food Insecurity and Malnutrition in All Its Forms; FAO: Rome, Italy, 2024. [Google Scholar] [CrossRef]

- United Nations Environment Programme. Food Waste Index Report 2024; United Nations Environment Programme: Nairobi, Kenya, 2024. [Google Scholar]

- Guo, J.; Chen, L.; Tang, B. A multi-period multi-objective closed-loop blood supply chain configuration and optimisation under disruption. Int. J. Syst. Sci. Oper. Logist. 2024, 11, 2304287. [Google Scholar] [CrossRef]

- Sharma, S.; Gahlawat, V.K.; Rahul, K.; Mor, R.S.; Malik, M. Sustainable innovations in the food industry through artificial intelligence and big data analytics. Logistics 2021, 5, 66. [Google Scholar] [CrossRef]

- Fan, Y.; de Kleuver, C.; de Leeuw, S.; Behdani, B. Trading off cost, emission, and quality in cold chain design: A simulation approach. Comput. Ind. Eng. 2021, 158, 107442. [Google Scholar] [CrossRef]

- Haji, M.; Kerbache, L.; Muhammad, M.; Al-Ansari, T. Roles of technology in improving perishable food supply chains. Logistics 2020, 4, 33. [Google Scholar] [CrossRef]

- Ahmed, H.F.; Hosseinian-Far, A.; Khandan, R.; Sarwar, D.; E-Fatima, K. Knowledge sharing in the supply chain networks: A perspective of supply chain complexity drivers. Logistics 2022, 6, 66. [Google Scholar] [CrossRef]

- Malik, M.; Gahlawat, V.K.; Mor, R.S.; Dahiya, V.; Yadav, M. Application of optimisation techniques in the dairy supply chain: A systematic review. Logistics 2022, 6, 74. [Google Scholar] [CrossRef]

- Chandrasiri, C.; Dharmapriya, S.; Jayawardana, J.; Kulatunga, A.K.; Weerasinghe, A.N.; Aluwihare, C.P.; Hettiarachchi, D. Mitigating environmental impact of perishable food supply chain by a novel configuration: Simulating banana supply chain in Sri Lanka. Sustainability 2022, 14, 12060. [Google Scholar] [CrossRef]

- Gardas, B.B.; Raut, R.D.; Cheikhrouhou, N.; Narkhede, B.E. A hybrid decision support system for analysing challenges of the agricultural supply chain. Sustain. Prod. Consum. 2019, 18, 19–32. [Google Scholar] [CrossRef]

- Sonar, H.; Sharma, I.; Ghag, N.; Singh, R.K. Barriers for achieving sustainable agri supply chain: Study in context to Indian MSMEs. Int. J. Logist. Res. Appl. 2024, 27, 1–20. [Google Scholar] [CrossRef]

- Marano, V.; Wilhelm, M.; Kostova, T.; Doh, J.; Beugelsdijk, S. Multinational firms and sustainability in global supply chains: Scope and boundaries of responsibility. J. Int. Bus. Stud. 2024, 55, 413–428. [Google Scholar] [CrossRef]

- Lee, C.H. The food crisis in the new cold war era and Korea’s response. In Food in the Making of Modern Korea; Springer: Singapore, 2024; pp. 265–312. [Google Scholar]

- Heydari, M. Cultivating sustainable global food supply chains: A multifaceted approach to mitigating food loss and waste for climate resilience. J. Clean. Prod. 2024, 442, 141037. [Google Scholar] [CrossRef]

- Sukanya, R. Global trade and food security. In Food Security in a Developing World; Singh, P., Ao, B., Deka, N., Mohan, C., Chhoidub, C., Eds.; Springer: Cham, Switzerland, 2024; pp. 229–258. [Google Scholar]

- Yan, B.; Chen, X.; Yuan, Q.; Zhou, X. Sustainability in fresh agricultural product supply chain based on radio frequency identification under an emergency. Cent. Eur. J. Oper. Res. 2020, 28, 1343–1361. [Google Scholar] [CrossRef]

- Gebre, G.G.; Rik, E.; Kijne, A. Analysis of banana value chain in Ethiopia: Approaches to sustainable value chain development. Cogent Food Agric. 2020, 6, 1742516. [Google Scholar] [CrossRef]

- Ikpe, V.; Shamsuddoha, M. Functional model of supply chain waste reduction and control strategies for retailers-the USA retail industry. Logistics 2024, 8, 22. [Google Scholar] [CrossRef]

- Nyalugwe, E.P.; Malidadi, C.; Kabuli, H. An assessment of tomato production practices among rural farmers in major tomato growing districts in Malawi. Afr. J. Agric. Res. 2022, 18, 194–206. [Google Scholar]

- Nyirenda, Z.; Nankhuni, F.; Brett, M. Has Banana Bunchy Top Disease Turned Malawi into a Banana Importing Country, Forever?—An Analysis of the Malawi Banana Value Chain; Department of Agricultural, Food, and Resource Economics, Michigan State University: East Lansing, MI, USA, 2019. [Google Scholar]

- Mikwamba, K.; Dessein, J.; Kambewa, D. Fighting banana bunchy top disease in Southern Malawi. The interface of knowledge systems and dynamics in a development arena. J. Agric. Educ. Ext. 2019, 26, 163–182. [Google Scholar] [CrossRef]

- FAOSTAT 2023. Available online: https://www.fao.org/faostat/en/#data/QCL (accessed on 17 January 2024).

- Hailu, M.; Workneh, T.S.; Belew, D. Review on postharvest technology of banana fruit. Afr. J. Biotechnol. 2013, 12, 635–647. [Google Scholar]

- Busogoro, J.-P.; Suleman, J.T.; Ameny, T.; Ndamugoba, D.; Najjemba, A.; Kirichu, S.; Adusabire, M.A.; Munyenyembe, Z.B.; Maulana, T.H.; Okoth, J.R. Reviving the banana industry in Malawi through integrated crop management of local banana germplasm. Trop. Agric. Dev. 2023, 67, 1–14. [Google Scholar]

- Mbewe, W.; Mtonga, A.; Pankomera, P.; Mwamlima, L.; Katondo, H.; Nyirenda, A.; Phukaphuka, F.; Mataka, L.; Mbalame, H.; Thole, R.; et al. Banana bunchy top virus (Babuvirus; Nanoviridae) detected in all banana growing districts of Malawi. Adv. Sci. Arts 2023, 1, 1–13. [Google Scholar]

- World Population Review. Banana Consumption by Country 2024. Available online: https://worldpopulationreview.com/country-rankings/banana-consumption-by-country (accessed on 20 May 2024).

- Qasem, A.G.; Aqlan, F.; Shamsan, A.; Alhendi, M. A simulation-optimisation approach for production control strategies in perishable food supply chains. J. Simul. 2021, 17, 211–227. [Google Scholar] [CrossRef]

- Sánchez-Flores, R.B.; Cruz-Sotelo, S.E.; Ojeda-Benitez, S.; Ramírez-Barreto, M.E. Sustainable supply chain management—A literature review on emerging economies. Sustainability 2020, 12, 6972. [Google Scholar] [CrossRef]

- Crippa, M.; Guizzardi, D.; Solazzo, E.; Muntean, M.; Schaaf, E.; Monforti-Ferrario, F.; Banja, M.; Olivier, J.G.J.; Grassi, G.; Rossi, S.; et al. GHG Emissions of All World Countries; Publications Office of the European Union: Luxembourg, 2021; pp. 1–258. [Google Scholar]

- FAO. The State of Food and Agriculture 2019-Moving forward on Food Loss and Waste Reduction; FAO: Rome, Italy, 2019. [Google Scholar]

- Gavurova, B.; Rigelsky, M.; Ivankova, V. Greenhouse Gas Emissions and Health in the Countries of the European Union. Front. Public Health 2021, 9, 756652. [Google Scholar] [CrossRef]

- Li, D.; Wang, X.; Chan, H.K.; Manzini, R. Sustainable food supply chain management. Int. J. Prod. Econ. 2014, 152, 1–8. [Google Scholar] [CrossRef]

- Baba, A.A.M.; Ma’aram, A.; Ishak, F.; Sirat, R.M.; Kadir, A.Z.A. Key performance indicator of sustainability in the Malaysian food supply chain. In Proceedings of the 4th International Conference on Ergonomics & 2nd International Conference on Industrial Engineering, Kuala Terengganu, Malaysia, 27–28 August 2019; pp. 1–7. [Google Scholar]

- Mata, M.A.E.; Oguis, G.F.R.; Ligue, K.D.B.; Gamot, R.M.T.; Abaro, K.R.G.; Fordan, Y.C.; Digal, L.N. Model Simulation Approach for Exploring Profitability of Small-scale Cavendish Banana Farmers in Davao Region from Harvest Allocation to Enterprises. Philipp. J. Sci. 2020, 149, 283–298. [Google Scholar] [CrossRef]

- Moussavi, S.-E.; Sahin, E.; Riane, F. A discrete event simulation model assessing the impact of using new packaging in an agri-food supply chain. Int. J. Syst. Sci. Oper. Logist. 2024, 11, 2305816. [Google Scholar] [CrossRef]

- Negi, S. Supply chain efficiency framework to improve business performance in a competitive era. Manag. Res. Rev. 2021, 44, 477–508. [Google Scholar] [CrossRef]

- Raut, R.D.; Gardas, B.B.; Kharat, M.; Narkhede, B. Modeling the drivers of post-harvest losses–MCDM approach. Comput. Electron. Agric. 2018, 154, 426–433. [Google Scholar] [CrossRef]

- Mittal, A.; Krejci, C.C. A hybrid simulation modeling framework for regional food hubs. J. Simul. 2019, 13, 28–43. [Google Scholar] [CrossRef]

- Kumar, A.; Mangla, S.K.; Kumar, P.; Karamperidis, S. Challenges in perishable food supply chains for sustainability management: A developing economy perspective. Bus. Strategy Environ. 2020, 29, 1809–1831. [Google Scholar] [CrossRef]

- Quinlan, C.; Babin, B.; Carr, J.; Griffin, M.; Zikmund, W.G. Business Research Methods, 1st ed.; Cengage Learning EMEA: Hampshire, UK, 2015. [Google Scholar]

- Guarnieri, P.; De Aguiar, R.C.C.; Thomé, K.M.; Watanabe, E.A.d.M. The role of logistics in food waste reduction in wholesalers and small retailers of fruits and vegetables: A multiple case study. Logistics 2021, 5, 77. [Google Scholar] [CrossRef]

- Silva, W.H.; Guarnieri, P.; Carvalho, J.M.; Farias, J.S.; Dos Reis, S.A. Sustainable supply chain management: Analysing the past to determine a research agenda. Logistics 2019, 3, 14. [Google Scholar] [CrossRef]

- Tsapi, V.; Assene, M.-N.; Haasis, H.-D. The complexity of the meat supply chain in Cameroon: Multiplicity of actors, interactions and challenges. Logistics 2022, 6, 86. [Google Scholar] [CrossRef]

- Hudnurkar, M.; Jakhar, S.; Rathod, U. Factors affecting collaboration in supply chain: A literature Review. Soc. Behav. Sci. 2014, 133, 189–202. [Google Scholar] [CrossRef]

- Nesadurai, H.E.S. Transnational private governance as a developmental driver in Southeast Asia: The case of sustainable palm oil standards in Indonesia and Malaysia. J. Dev. Stud. 2019, 55, 1892–1908. [Google Scholar] [CrossRef]

- Sharma, R.; Kannan, D.; Darbari, J.D.; Jha, P.C. Group decision making model for selection of performance indicators for sustainable supplier evaluation in agro-food supply chain. Int. J. Prod. Econ. 2024. [Google Scholar] [CrossRef]

- Obonyo, E.; Formentini, M.; Ndiritu, W.S.; Naslund, D. Information sharing in African perishable agri-food supply chains: A systematic literature review and research agenda. J. Agribus. Dev. Emerg. Econ. 2023. [Google Scholar] [CrossRef]

- Biza, A.; Montastruc, L.; Negny, S.; Admassu, S. Strategic and tactical planning model for the design of perishable product supply chain network in Ethiopia. Comput. Chem. Eng. 2024, 190, 108814. [Google Scholar] [CrossRef]

- Mangla, S.K.; Luthra, S.; Rich, N.; Kumar, D.; Rana, N. Enablers to implement sustainable initiatives in agri-food supply chains. Int. J. Prod. Econ. 2018, 203, 379–393. [Google Scholar] [CrossRef]

- Zaman, S.I.; Kusi-Sarpong, S. Identifying and exploring the relationship among the critical success factors of sustainability toward consumer behavior. J. Model. Manag. 2024, 19, 492–522. [Google Scholar] [CrossRef]

- Rojas-Reyes, J.J.; Rivera-Cadavid, L.; Peña-Orozco, D.L. Disruptions in the food supply chain: A literature review. Heliyon 2024, 10. [Google Scholar] [CrossRef] [PubMed]

- Huong, P.T.T.; Everaarts, A.P.; Neeteson, J.J.; Struik, P.C. Vegetable production in the Red River Delta of Vietnam. Wagening. J. Life Sci. 2013, 67, 27–36. [Google Scholar] [CrossRef]

- Asian, S.; Hafezalkotob, A.; John, J.J. Sharing economy in organic food supply chains: A pathway to sustainable development. Int. J. Prod. Econ. 2019, 218, 322–338. [Google Scholar] [CrossRef]

- Namany, S.; Govindan, R.; Alfagih, L.; McKay, G.; Al-Ansari, T. Sustainable food security decision-making: An agent-based modelling approach. J. Clean. Prod. 2020, 255, 120296. [Google Scholar] [CrossRef]

- Han, J.-W.; Zuo, M.; Zhu, W.-Y.; Zuo, J.-H.; Yang, X.-T. A comprehensive review of cold chain logistics for fresh agricultural products: Current status, challenges, and future trends. Trends Food Sci. Technol. 2021, 109, 536–551. [Google Scholar] [CrossRef]

- Tchonkouang, R.D.; Onyeaka, H.; Nkoutchou, H. Assessing the vulnerability of food supply chains to climate change-induced disruptions. Sci. Total Environ. 2024, 920, 171047. [Google Scholar] [CrossRef]

- Tako, A.A.; Robinson, S. Model development in discrete-event simulation and system dynamics: An empirical study of expert modellers. Eur. J. Oper. Res. 2010, 207, 784–794. [Google Scholar]

- Koulouris, A.; Misailidis, N.; Petrides, D. Applications of process and digital twin models for production simulation and scheduling in the manufacturing of food ingredients and products. Food Bioprod. Process. 2021, 126, 317–333. [Google Scholar] [CrossRef]

- Turnitsa, C. Conceptual Modeling. In Modeling and Simulation in the Systems Engineering Life Cycle-Core Concepts and Accompanying Lectures; Loper, M.L., Ed.; Springer: London, UK, 2015; pp. 39–49. [Google Scholar]

- Kelton, D.; Sadowski, R.P.; Zupick, N.B. Simulation with Arena, 6th ed.; McGraw-Hill Education: New York, NY, USA, 2015. [Google Scholar]

- Gupta, E.; Kanu, N.J.; Munot, A.; Sutar, V.; Vates, U.K.; Singh, G.K. Stochastic and Deterministic Mathematical Modeling and Simulation to Evaluate the Novel COVID-19 Pandemic Control Measures. Am. J. Infect. Dis. 2020, 16, 134–170. [Google Scholar] [CrossRef]

- Rossetti, M.D. Simulation Modeling and Arena; Open Educational Resources: Fayetteville, NC, USA, 2021. [Google Scholar]

- McGarraghy, S.; Olafsdottir, G.; Kazakov, R.; Huber, É.; Loveluck, W.; Gudbrandsdottir, I.Y.; Čechura, L.; Esposito, G.; Samoggia, A.; Aubert, P.-M.; et al. Conceptual system dynamics and agent-based modelling simulation of interorganisational fairness in food value chains: Research agenda and case studies. Agriculture 2022, 12, 280. [Google Scholar] [CrossRef]

- Vaishnavi, V.K.; Kuechler, W.J. Design Science Research Methods and Patterns: Innovating Information and Communication Technology, 2nd ed.; Taylor & Francis Group: Boca Raton, FL, USA, 2015. [Google Scholar]

- Venable, J.; Baskerville, R. Eating our own cooking: Toward a more rigorous design science of research methods. Electron. J. Bus. Res. Methods 2012, 10, 141–153. [Google Scholar]

- Peffers, K.; Tuunanen, T.; Niehaves, B. Design science research genres: Introduction to the special issue on exemplars and criteria for applicable design science research. Eur. J. Inf. Syst. 2018, 27, 129–139. [Google Scholar] [CrossRef]

- Budde, L.; Liao, S.; Haenggi, R.; Friedli, T. Use of DES to develop a decision support system for lot size decision-making in manufacturing companies. Prod. Manuf. Res. 2022, 10, 494–518. [Google Scholar] [CrossRef]

- Maïzi, Y.; Bendavid, Y. Hybrid RFID-IoT simulation modeling approach for analysing scrubs’ distribution solutions in operating rooms. Bus. Process Manag. J. 2023, 29, 1734–1761. [Google Scholar] [CrossRef]

- Feng, P.; Feenberg, A. Thinking About Design: Critical Theory of Technology and the Design Process. In Philosophy and Design: From Engineering to Architecture; Vermaas, P.E., Kroes, P., Light, A., Moore, S.A., Eds.; Springer: Berlin/Heidelberg, Germany, 2008; pp. 105–118. [Google Scholar]

- Bardzell, S.; Bardzell, J.; Forlizzi, J.; Zimmerman, J.; Antanitis, J. Critical Design and Critical Theory: The Challenge of Designing for Provocation. In Proceedings of the DIS ‘12: Proceedings of the Designing Interactive Systems Conference, Newcastle, UK, 11 June 2012; pp. 288–297. [Google Scholar]

- Brat, P.; Bugaud, C.; Guillermet, C.; Salmon, F. Review of banana green life throughout the food chain: From auto-catalytic induction to the optimisation of shipping and storage conditions. Sci. Hortic. 2020, 262, 109054. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).