Impacts of Adopting Additive Manufacturing Process on Supply Chain: Systematic Literature Review

Abstract

1. Introduction

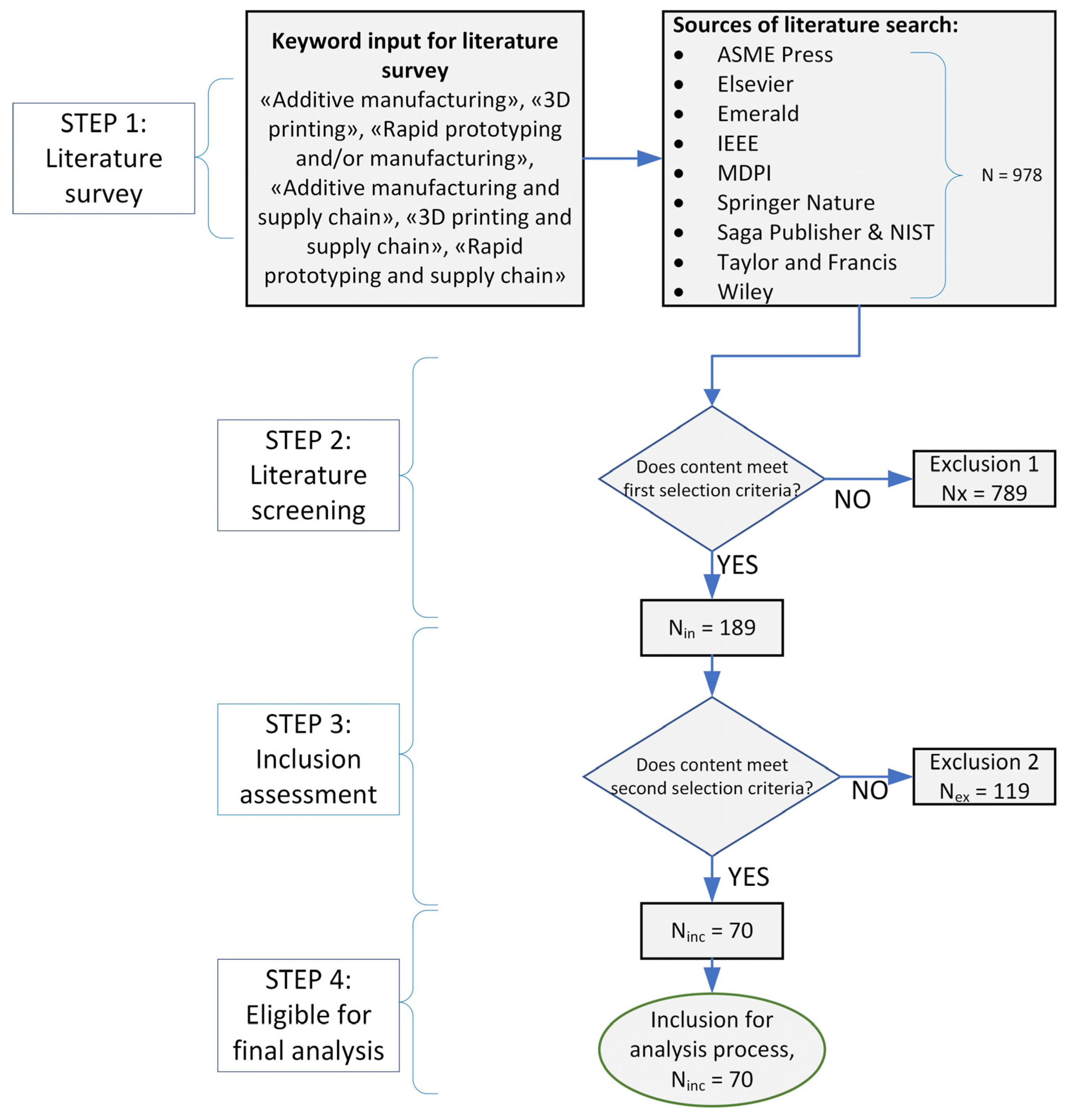

2. Materials and Methods

2.1. Literature Survey

2.2. Literature Screening

2.3. Data Analysis

3. Supply Chain in Additive Manufacturing Production Process

3.1. Time, Cost, Inventory, and Operations Efficiency-Related Factors

3.2. Resource, Energy, Pollution, and Waste-Related Factors

3.3. Triple Bottom Line

4. Findings of Bibliometric Data

4.1. Continent and Country of Origin

4.2. Publishers Contributions and Publication Trends

4.3. Study by Types of Industry

4.4. Additive Manufacturing Technology Best Practices in SC Context

- SC efficiency and firm performance;

- Cost-related factors;

- Time-related factors;

- Inventory-related factors;

- Flexibility and manufacturing-related factors;

- Energy, environmental, and waste-related factors;

- The details of these factors are presented in the following subsections.

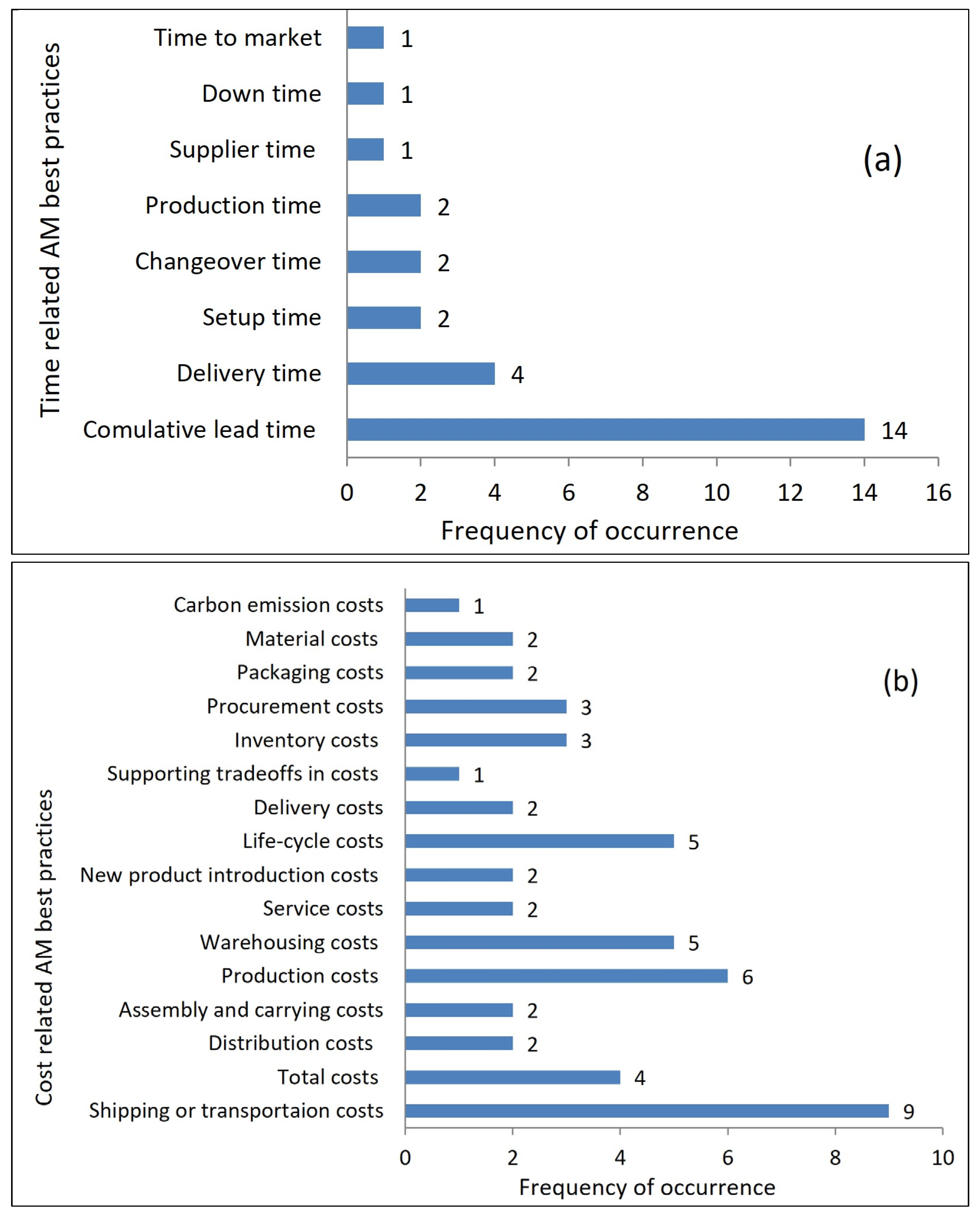

4.4.1. Time- and Cost-Related Factors

4.4.2. Inventory, Marketing (Flexibility), and Manufacturing-Related Factors

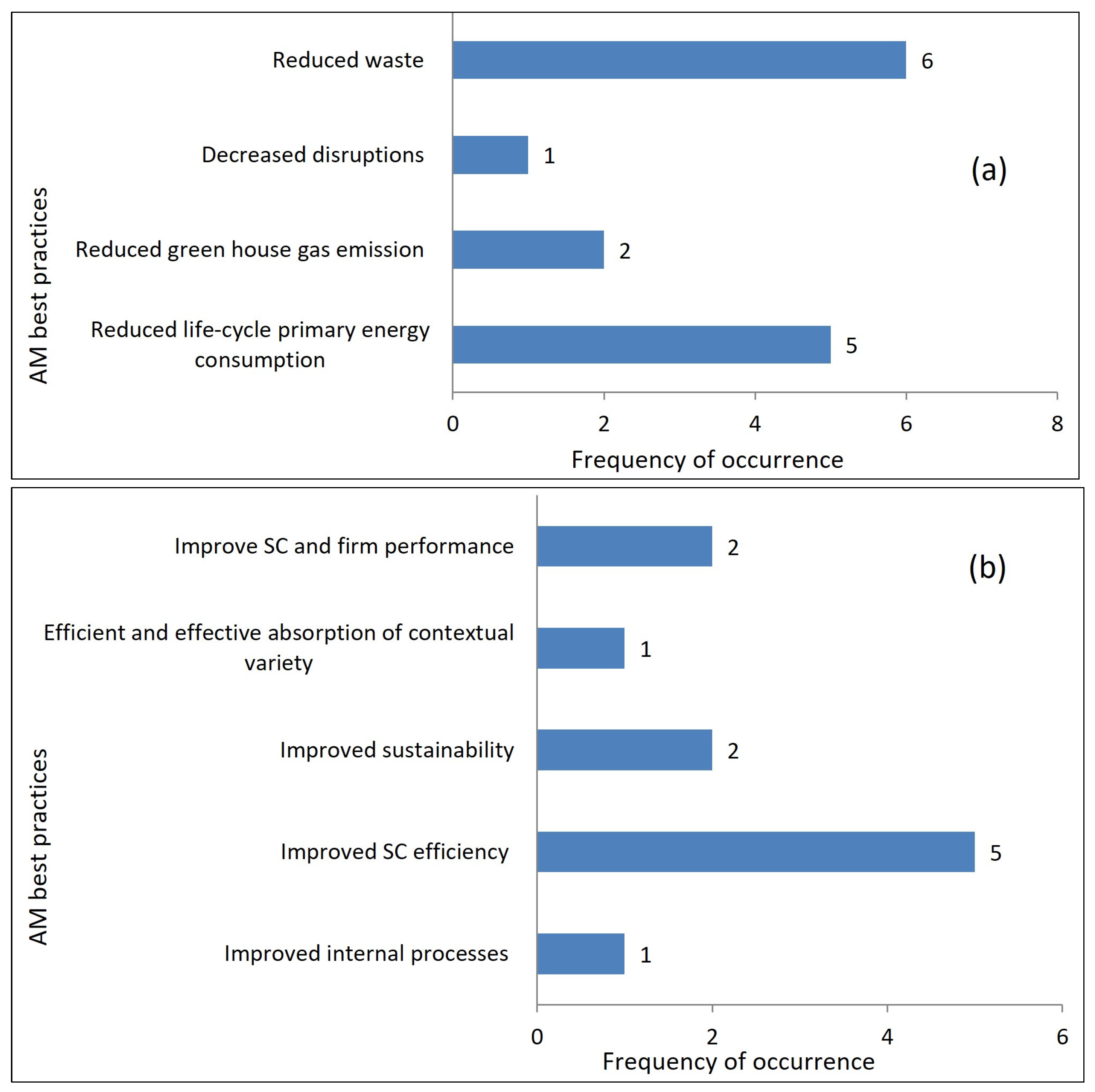

4.4.3. Energy, Environment Waste, SC Efficiency, and Firm Performance-Related Factors

5. Discussions and Future Research Directions

- [1]

- Quantitative studies can illustrate the strength and relationship between additive manufacturing best practices and supply chain elements.

- [2]

- Establishing in-depth knowledge of the key additive manufacturing best practices that affect supply chain elements.

- [3]

- Investigating the implication of implementing AM with a SC perspective in developing countries.

- [4]

- Identifying the variables that affect SCs in the AM industry and their benefits.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Almi, H.; Boumar, S. The Green Economy as a Requirement for Achieving Sustainable Development. Alger. J. Adv. Mater. 2023, 7, 142–161. [Google Scholar]

- Clark, W. Sustainability science: A room of its own. Proc. Natl. Acad. Sci. USA 2007, 104, 1737–1738. [Google Scholar] [CrossRef] [PubMed]

- Elkington, J. Cannibals with Forks: The Triple Bottom Line of 21st Century Business; Capstone: Oxford, UK, 1997; Available online: https://www.sdg.services/uploads/9/9/2/1/9921626/cannibalswithforks.pdf (accessed on 24 December 2023).

- Aguado, S.; Alvarez, R.; Domingo, R. Model of efficient and sustainable improvements in a lean production system through processes of environmental innovation. J. Clean. Prod. 2013, 47, 141–148. [Google Scholar] [CrossRef]

- Sala, S.; Ciuffo, B.; Nijkamp, P. A systemic framework for sustainability assessment. Ecol. Econ. 2015, 119, 314–325. [Google Scholar] [CrossRef]

- Azzone, G.; Noci, G.; Manzini, R.; Welford, R.; Young, C.W. Defining Environmental Performance Indicators: An Integrated Framework. Bus. Strat. Environ. 1996, 5, 69–80. [Google Scholar] [CrossRef]

- Teece, D.; Pisano, G.; Shuen, A. Dynamic Capabilities and Strategic Management. Strateg. Manag. J. 1997, 18, 509–533. [Google Scholar] [CrossRef]

- Dahmus, J.B. Can Efficiency Improvements Reduce Resource Consumption? J. Ind. Ecol. 2014, 18, 883–897. [Google Scholar] [CrossRef]

- Rajak, S.; Vinodh, S. Application of fuzzy logic for social sustainability performance evaluation: A case study of an Indian automotive component manufacturing organization. J. Clean. Prod. 2015, 108, 1184–1192. [Google Scholar] [CrossRef]

- Mitchell, I.K.; Walinga, J. The creative imperative: The role of creativity, creative problem solving, and insight as key drivers for sustainability. J. Clean. Prod. 2017, 140, 1872–1884. [Google Scholar] [CrossRef]

- Vargas, J.R.C.; Mantilla, C.E.M.; Jabbour, A.B.L. Enablers of sustainable supply chain management and its effect on competitive advantage in the Colombian context. Resour. Conserv. Recycl. 2018, 139, 237–250. [Google Scholar] [CrossRef]

- Bai, C.; Kusi-Sarpong, S.; Badri Ahmadi, H.; Sarkis, J. Social sustainable supplier evaluation and selection: A group decision-support approach. Int. J. Prod. Res. 2019, 57, 7046–7067. [Google Scholar] [CrossRef]

- Islam, T.R.; Islam, A.H.; Pitafi, L.; Xiaobei, M.; Rehmani, M.; Irfan, M.S. The Impact of Corporate Social Responsibility on Customer Loyalty: The Mediating Role of Corporate Reputation, Customer Satisfaction, and Trust. Sustain. Prod. Consum. 2021, 25, 123–135. [Google Scholar] [CrossRef]

- Men, F.; Yaqub, R.M.; Yan, R.; Irfan, M.; Haider, A. The Impact of top Management Support, Perceived Justice, Supplier Management, and Sustainable Supply Chain Management on Moderating the Role of Supply Chain Agility. Front. Environ. Sci. 2023, 10, 2599. [Google Scholar] [CrossRef]

- Sachin, N.; Rajesh, R. An Empirical Study of Supply Chain Sustainability with Financial Performances of Indian Firms. Environ. Dev. Sustain. 2022, 24, 6577–6601. [Google Scholar] [CrossRef]

- Krishnamoorthi, M.; Pratheep, B.; Aniket, M.; Mohamed, A. Additive Manufacturing—A Future Revolution in Supply Chain Sustainability and Disaster Management. In Proceedings of the 3rd North American International Conference on Industrial Engineering and Operations Management, Washington DC, USA, 27–29 September 2018; IEOM Society International: Southfield, Michigan. [Google Scholar]

- Shen, M.; Huang, W.; Chen, M.; Song, B.; Zeng, G.; Zhang, Y. (Micro) Plastic Crisis: Un Ignorable Contribution to Global Greenhouse Gas Emissions and Climate Change. J. Clean. Prod. 2020, 254, 120–138. [Google Scholar] [CrossRef]

- Sala, S.; Anton, A.; McLaren, S.J.; Notarnicola, B.; Saouter, E.; Sonesson, U. In Quest of Reducing the Environmental Impacts of Food Production and Consumption. J. Clean. Prod. 2017, 140, 387–398. [Google Scholar] [CrossRef]

- Rydzik, A.; Kissoon, C.S. Decent Work and Tourism Workers in the Age of Intelligent Automation and Digital Surveillance. J. Sustain. Tour. 2022, 30, 2860–2877. [Google Scholar] [CrossRef]

- Reeves, P. How the socioeconomic benefits of rapid manufacturing can offset technological limitations. In Proceedings of the RAPID Conference and Exposition, Lake Buena Vista, FL, USA, 4–7 February 2008; pp. 1–12. [Google Scholar]

- Filiz, I. Complexity in Supply Chains: A New Approach to Quantitative Measurement of the Supply-Chain-Complexity. Supply Chain Manag. 2011. [Google Scholar] [CrossRef][Green Version]

- Hahn, T.; Pinkse, J.; Preuss, L.; Figge, F. Tensions in corporate sustainability: Towards an integrative framework. J. Bus. Ethics 2015, 127, 297–316. [Google Scholar] [CrossRef]

- Mojtaba, K.; Fabio, N. Additive manufacturing management: A review and future research agenda. Int. J. Prod. Res. 2016, 55, 1419–1439. [Google Scholar]

- Khoo, Z.X.; Teoh, J.E.M.; Liu, Y.; Chua, C.K.; Yang, S.; An, J.; Leong, K.F.; Yeong, W.Y. 3D Printing of Smart Materials: A Review on Recent Progresses in 4D Printing. Virtual Phys. Prototyp. 2015, 10, 103–122. [Google Scholar] [CrossRef]

- Massimiliano, R.; Chris, T.; Richard, H. Make or buy analysis for rapid manufacturing. Rapid Prototyp. J. 2007, 13, 23–29. [Google Scholar]

- Bogers, M.; Hada, R.; Bilberg, A. Additive manufacturing for consumer-centric business models: Implications for supply chains in consumer goods manufacturing. Technol. Forecast Soc. Chang. 2016, 102, 225–239. [Google Scholar] [CrossRef]

- Peter, T.; Jennifer, L.; Umberto, P. Three-dimensional printing—A key tool for the humanitarian logistician? J. Humanit. Logist. Supply Chain Manag. 2015, 5, 188–208. [Google Scholar]

- Frederic, T.; Marco, W.; Hans, G.; Michelle, M.; Dominik, M.; Heiner, L.; Frank, P.; Peter, B.; Letizia, M.; Simon, F.; et al. Economic implications of additive manufacturing and the contribution of MIS. Bus. Inf. Syst. Eng. 2015, 57, 139–148. [Google Scholar]

- Joao, B.; Jose, S.; Symone, G.; Enzo, F.; Samuel, M. Optimal Design of Additive Manufacturing Supply Chains. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Pilsen, Czech Republic, 23–26 July 2019. [Google Scholar]

- Zeplin, J.H.; Hotlan, S.; Ferry, J. Impact of Internal Integration, Supply Chain Partnership, Supply Chain Agility, and Supply Chain Resilience on Sustainable Advantage. Sustainability 2021, 13, 2–18. [Google Scholar]

- Asma, M.; Shaligram, P.; Faris, T. Additive Manufacturing Technology for Spare Parts Application: A Systematic Review on Supply Chain Management. Appl. Sci. 2020, 12, 4160. [Google Scholar]

- Vojislav, P.; Juan, V.; Haro, G.; Olga, J.; Javier, D.; Jose, R. Additive Layer Manufacturing: State of the art in industrial applications through case studies. Int. J. Prod. Res. 2010, 1, 1–25. [Google Scholar]

- Huang, S.H.; Liu, P.; Mokasdar, A.; Hou, L. Additive manufacturing and its societal impact: A literature review. Int. J. Adv. Manuf. Technol. 2013, 67, 1191–1203. [Google Scholar] [CrossRef]

- Maximilian, K.; Gerald, R. How will the diffusion of additive manufacturing impact the raw material supply chain process? Int. J. Prod. Res. 2019, 58, 1540–1554. [Google Scholar]

- Halassi, S.; Janjaap, S.; Nadine, K. From Consumer to Prosumer: A Supply Chain Revolution in 3D Printing. Int. J. Phys. Distrib. Logist. Manag. 2019, 49, 200–216. [Google Scholar] [CrossRef]

- Binoy, D.; Md, S.S.; Fahmida, T.M.; Azizur, R.; Ziaul, H.A. Impact of Additive Manufacturing on the Supply Chain of Aerospace Spare Parts Industry: A Review. Logistics 2020, 6, 28. [Google Scholar]

- Jan, S.; Mika, S.; Roy, B.; Jouni, P.; Jan, H. Switchover to industrial additive manufacturing: Dynamic decision-making for problematic spare parts. Int. J. Oper. Prod. Manag. 2022, 42, 358–384. [Google Scholar]

- Levin, A.; Didar, J.; Siavash, H.; Patrik, J.; Jan, H. Additive Manufacturing of Slow-Moving Automotive Spare Parts: A Supply Chain Cost Assessment. J. Manuf. Mater. Process. 2023, 7, 2–26. [Google Scholar]

- Guido, T.; Alessandro, C.; Laoucine, K.; Michael, M.; David, B.; Matteo, C.; Hans, N. Value chain and production cost optimization by integrating additive manufacturing in injection molding process chain. Int. J. Adv. Manuf. Technol. 2018, 100, 738–795. [Google Scholar] [CrossRef]

- Eren, O.; Cihan, C.; Neslihan, D.; Ozan, S. Impacts of Additive Manufacturing on Supply Chain Flow: A Simulation Approach in Healthcare Industry. Logistics 2018, 2, 1–20. [Google Scholar]

- Sirichakwal, I.; Conner, B. Implications of Additive Manufacturing for Spare Parts Inventory. 3D Print. Addit. Manuf. 2016, 3, 56–63. [Google Scholar] [CrossRef]

- Mohsen, A. The rise of 3-D printing: The advantages of additive manufacturing over traditional manufacturing. Sci. Direct 2017, 60, 677–688. [Google Scholar] [CrossRef]

- Berman, B. 3-D Printing: The New Industrial Revolution. Bus. Horizons. 2012, 55, 155–162. [Google Scholar] [CrossRef]

- Barz, A.T.; Buer, T.; Haasis, H. A Study on the Effects of Additive Manufacturing on the Structure of Supply Networks. IFAC 2016, 49, 72–77. [Google Scholar] [CrossRef]

- Kothman, I.; Faber, N. How 3D printing technology changes the rules of the game. J. Manuf. Technol. Manag. 2016, 27, 932–943. [Google Scholar] [CrossRef]

- Milad, A.; Simone, Z.; Andrea, B.; Massimo, Z.; Marco, P. Additive manufacturing impacts on a two-level supply chain. Int. J. Syst. Sci. Oper. Logist. 2019, 16, 1–14. [Google Scholar]

- Jan, H.; Jouni, P.; Jukka, T.; Manfred, W. Rapid manufacturing in the spare parts supply chain Alternative approaches to capacity deployment. J. Manuf. Technol. Manag. 2010, 21, 687–697. [Google Scholar]

- Jairo, N.; Hugo, H.; Sylvia, M.; Angel, O. System Dynamics Modeling in Additive Manufacturing Supply Chain Management. Processes 2021, 9, 982. [Google Scholar]

- Victor, V.; Siavash, H.; Harold, K.; Mika, S.; Jan, H. Additive Manufacturing for Localized Medical Parts Production: A Case Study. IEEE Access 2021, 9, 25818–25834. [Google Scholar]

- Alyson, V.; Seung, E.; Michael, M. The application of 3D printing technology in the fashion industry. Int. J. Fash. 2016, 10, 170–179. [Google Scholar]

- Bram, W.; Rob, J.; Geert, J. Traditional or Additive Manufacturing? Assessing component design options through lifecycle cost analysis. Eur. J. Oper. Res. 2018, 270, 570–585. [Google Scholar] [CrossRef]

- Christian, F.; Stefan, K.; Stephan, M. the impact of additive manufacturing on supply chains. Int. J. Phys. Distrib. Logist. Manag. 2017, 47, 954–971. [Google Scholar]

- Desiree, U.; Rita, F. Leveraging 3D Printing Technologies: The Case of Mexico’s Footwear Industry. Res. Technol. Manag. 2021, 64, 20–30. [Google Scholar]

- Ming, C.; Yi, H. Simulation based method considering design for additive manufacturing and supply chain. Ind. Manag. Data Syst. 2016, 116, 322–348. [Google Scholar]

- Manfred, W.; Jan, H.; Hannu, Y. Rapid manufacturing and its impact on supply chain management. In Proceedings of the Logistics Research Network Annual Conference, Dublin, Ireland, 9–10 September 2004. [Google Scholar]

- Marta, R.; Mario, C.; Pasquale, M.; Marcello, F.; Roberto, M. The impact of Additive Manufacturing on Supply Chain design: A simulation study. Procedia Comput. Sci. 2021, 180, 446–455. [Google Scholar]

- Siavash, H.; Inigo, F.; Alireza, J.; Jia, A.; Chee, K.; Jan, H. Impact of Additive Manufacturing on Supply Chain Complexity. In Proceedings of the 53rd Hawaii International Conference on System Sciences, Maui, HI, USA, 7–10 January 2020; pp. 4505–4514. [Google Scholar]

- Li, Y.; Jia, G.; Cheng, Y.; Hu, Y. Additive manufacturing technology in spare parts supply chain: A comparative study. Int. J. Prod. Res. 2016, 55, 1498–1515. [Google Scholar]

- Sabarish, S.; Udhayakumar, P.; Pandiyarajan, R. Additive manufacturing for customized hearing aid parts production: An empirical study. J. Chin. Inst. Eng. 2021, 17, 704–717. [Google Scholar]

- Daniel, R.; Alexandre, T.; Andre, L.; Lorena, H. Implications of additive manufacturing on supply chain and logistics. IJM&P 2020, 11, 1279–1302. [Google Scholar]

- Konstantinos, T.; Naoum, T.; Dimitrios, V.; Loukas, T. Supply chain reconfiguration opportunities arising from additive manufacturing technologies in the digital era. Prod. Plan. Control. 2019, 30, 510–521. [Google Scholar]

- Philip, D.; Glenn, P.; Kyle, A.; Irene, N. How additive manufacturing allows products to absorb variety in use: Empirical evidence from the defense industry. Prod. Plan. Control. 2020, 33, 175–192. [Google Scholar]

- Banu, Y.E.; Nikolaos, S.; Jeremy, Z.; Ecem, E.T.; Vikas, K. Additive manufacturing integration in E-commerce supply chain network to improve resilience and competitiveness. Simul. Model. Pract. Theory 2023, 122, 1–21. [Google Scholar]

- Sudipta, C.; Jack, F.; Mohammad, M.; Linkan, B. Supply chain cost analysis for additively manufactured biomedical implants. Int. J. Syst. Sci. Oper. Logist. 2019, 7, 275–704. [Google Scholar]

- Li, C.; Yao, C.; Hau, L. Retailing with 3D Printing. Prod. Oper. Manag. 2020, 30, 1986–2007. [Google Scholar]

- Weller, C.; Kleer, R.; Piller, T. Economic implications of 3D printing: Market structure models in light of additive manufacturing revisited. Int. J. Prod. Econ. 2015, 164, 43–56. [Google Scholar] [CrossRef]

- Avner, B.; Enno, S. Decentralization and Localizationof Production: The Organizational and economic Consequences of additive manufacturing (3d Printing). Calif. Manag. Rev. 2017, 59, 5–23. [Google Scholar]

- Evgenii, A.; Olga, A.; Dmitriy, G. Impact of 3D-Printing Technologies on the Transformation of Industrial Production in the Arctic Zone. Resources 2019, 8, 2–15. [Google Scholar]

- Inigo, F.; Siavash, H.; Jouni, P. Challenges to implementing additive manufacturing in globalised production environments. Int. J. Collab. Enterp. 2016, 5, 232–247. [Google Scholar]

- Melanie, M.; Abubaker, H. Additive manufacturing in the mechanical engineering and medical industries spare parts supply chain. J. Manuf. Technol. Manag. 2017, 47, 954–971. [Google Scholar]

- Thembani, T.; Timothy, J.; Bereket, T. An additive manufacturing spare parts inventory model for an aviation use case. Eng. Manag. J. 2019, 31, 69–80. [Google Scholar] [CrossRef]

- Martin, B.; Luca, B.; Angelo, G.; Richard, H. Informing additive manufacturing technology adoption: Total cost and the impact of capacity utilization. Int. J. Prod. Res. 2017, 55, 6957–6970. [Google Scholar] [CrossRef]

- Suzanne, D.; Roy, D.; Ari, P. ; Roy, D.; Ari, P. From Supply Chain to Demand Chain: The Role of Lead Time Reduction in Improving Demand Chain Performance. J. Oper. Manag. 2004, 21, 613–627. [Google Scholar]

- Abhijeet, G.; Georgia, K.; Atanu, C.; Aravindan, S. Impact of additive manufacturing on aircraft supply chain performance: A system dynamics approach. J. Manuf. Technol. Manag. 2018, 29, 846–865. [Google Scholar]

- Tuck, C.; Hague, R.; Burns, N. Rapid manufacturing: Impact on supply chain methodologies and practice. Int. J. Serv. Oper. Manag. 2007, 3, 1–22. [Google Scholar] [CrossRef]

- Attaran, M. Additive Manufacturing: The Most Promising Technology to Alter the Supply Chain and Logistics. J. Serv. Manag. 2017, 10, 189–205. [Google Scholar] [CrossRef]

- Ageel, A.; Martin, B.; Christopher, T.; Waiel, E. The Impact of Additive Manufacturing on the Flexibility of a Manufacturing Supply Chain. Appl. sci. 2021, 11, 2–15. [Google Scholar]

- Runze, H.; Matthew, E.; Diane, G.; Sujit, D.; Sachin, N.; Joe, C.; Eric, M. Environmental and Economic Implications of Distributed Additive Manufacturing: The Case of Injection Mold Tooling. J. Ind. Ecol. 2017, 21, S130–S143. [Google Scholar]

- Daniel, B.; Anne, M. Environmental assessment of additive manufacturing in the automotive industry. J. Clean. Prod. 2019, 226, 977–987. [Google Scholar]

- Karel, K.; Evren, Y.; Wim, D.; Joost, R. Environmental Assessment of Selective Laser Melting and Selective Laser Sintering. In Proceedings of the 8th Conference of Going Green–CARE INNOVATION 2010: From Legal Compliance to Energy-Efficient Products and Services, Vienna, Austria, 8–11 November 2010. [Google Scholar]

- Zhen, C. Research on the Impact of 3D Printing on the International Supply Chain. Adv. Mater. Sci. Eng. 2016, 2016, 4173873. [Google Scholar] [CrossRef]

- Janssen, G.; Blankers, I.; Moolenburgh, E.; Posthumus, A. The Impact of 3-DPrinting on Supply Chain Management. TNO: Innovation for Life, April 2014. Available online: https://repository.tudelft.nl/islandora/object/uuid:cc288b1a-837c-4f24-8504-a45bb9636b70/datastream/URL/download (accessed on 24 December 2023).

- Filipe, M.; Gelson, D.; Enzo, M.; Joao, P.; Symone, G. Design Approach for Additive Manufacturing in Spare Part Supply Chains. IEEE Trans. Ind. Inform. 2020, 17, 757–765. [Google Scholar]

- Peng, L.; Samuel, H.; Abhiram, M.; Heng, Z.; Liang, H. The impact of additive manufacturing in the aircraft spare parts supply chain: Supply chain operation reference (scor) model-based analysis. Prod. Plan. Control. 2013, 25, 1169–1181. [Google Scholar]

- Malte, G.; Anton, J.; Schoot, U.; Cindy, V. A global sustainability perspective on 3D printing technologies. Energy Policy 2013, 74, 158–167. [Google Scholar]

- Vojislav, P.; Juan, V.; Olga, J.; Javier, D.; Jose, B.; Luis, P. Additive layered manufacturing: Sectors of industrial application shown through case studies. Int. J. Prod. Res. 2011, 49, 1071–1079. [Google Scholar]

- Thomas, B. Fabricating futures and the movement of objects. Mobilities 2013, 8, 388–405. [Google Scholar]

- Klaus, J. Additive manufacturing—Driving massive disruptive change in supply chain management. J. Wor. Appl. Manag. 2020, 12, 221–223. [Google Scholar]

- Peter, R.; Jennifer, B. Industry 4.0 and Resilience in the Supply Chain: A Driver of Capability Enhancement or Capability Loss? Int. J. Prod. Res. 2020, 58, 5006–5019. [Google Scholar]

- Radu, G.; Ines, R.; Florinda, M.; Bruna, F.; Helena, C.; Paulo, P. Impact Assessment of Additive Manufacturing on Sustainable Business Models in Industry 4.0 Context. Sustainability 2020, 12, 7066. [Google Scholar]

- Katrin, O.; Erik, H. Impact of additive manufacturing technology adoption on supply chain management processes and components. J. Manuf. Technol. Manag. 2016, 27, 1–27. [Google Scholar]

- Mia, D.; Daniel, R.; Josip, M. Additive manufacturing: Empirical evidence for supply chain integration and performance from the automotive industry. Supply Chain Manag. Int. J. 2019, 24, 604–621. [Google Scholar]

- Lucia, C.; Clara, B.; James, M. The impact of 3D printing on the humanitarian supply chain. Prod. Plan. Control. 2020, 33, 692–704. [Google Scholar]

- Fares, M.; Jean, P.; Sophie, F.; Manuele, M. Evaluating Eco-Efficiency of 3D Printing in the Aeronautic Industry. J. Ind. Ecol. 2017, 21, S37–S48. [Google Scholar]

- Paolo, M.; Daniel, R. Additive Manufacturing as a Driverfor the Sustainability of Short-Lifecycle Customized Products: The Case Study of Mobile Case Covers. Smart. Innov. Syst. Technol. 2017, 68. [Google Scholar] [CrossRef]

- Cagno, E.; Neri, A.; Howard, M.; Brenna, G.; Trianni, A. Industrial sustainability performance measurement systems: A novel framework. J. Clean. Prod. 2019, 230, 1354–1375. [Google Scholar] [CrossRef]

- Hallgren, M.; Olhager, J. Lean and agile manufacturing: External and internal drivers and performance outcomes. Int. J. Oper. Prod. Manag. 2009, 29, 976–999. [Google Scholar] [CrossRef]

- Rusinko, C.A. Green Manufacturing: An Evaluation of Environmentally Sustainable Manufacturing Practices and Their Impact on Competitive Outcomes. IEEE Trans. Eng. Manag. 2007, 54, 445–454. [Google Scholar] [CrossRef]

- Garbie, I.H. An analytical technique to model and assess sustainable development index in manufacturing enterprises. Int. J. Prod. Res. 2013, 52, 4876–4915. [Google Scholar] [CrossRef]

| Findings and Results | Author (Year) |

|---|---|

| Cost-Related Factors | |

| Reduced shipping costs (i.e., transport) and after-sale logistic costs. | Sala et al. (2015) [5], Hahn et al. (2015) [23], Khoo et al. (2015) [24], Asma et al. (2020) [31], Huang et al. (2013) [33], Jan et al. (2022) [37], Bram et al. (2018) [51] |

| Reduced total costs. | Rajak and Vinodh (2015) [9], Rydzik and Kissoon (2022) [19], Zeplin et al. (2021) [30], Asma et al. (2020) [31], |

| Reduced costs of distribution, assembly, and carry. | Azzone et al. (1996) [6], Asma et al. (2020) [31] |

| Reduced costs of production or manufacturing. | Hahn et al. (2015) [23], Asma et al. (2020) [31], Huang et al. (2013) [33], Guido et al. (2018) [39], Evgenii et al. (2019) [68], Martin et al. (2017) [72] |

| Reduced costs of warehousing (decrease holding costs). | Mojtaba and Fabio (2016) [23], Asma et al. (2020) [31], Jan et al. (2022) [37], Sirichakwal and Conner (2016) [41] |

| Reduced cost of service. | Hahn et al. (2015) [23], Asma et al. (2020) [31] |

| Low costs of new product introduction into the system. | Teece et al. (1997) [7], Asma et al. (2020) [31] |

| Reduced life-cycle costs, reducing supply chain costs. | Sachin and Rajesh (2020) [15], Bogers et al. (2016) [26], Asma et al. (2020) [31], Banu et al. (2023) [63], Janssen et al. (2014) [82] |

| Reduced delivery costs. | Massimiliano et al. (2007) [25], Asma et al. (2020) [31] |

| Supported tradeoffs in costs. | Zeplin et al. (2021) [30] |

| Reduced inventory costs. | Asma et al. (2020) [31], Huang et al. (2013) [33], Jan et al. (2022) [37] |

| Reduced procurement costs. | Asma et al. (2020) [31], Barz et al. (2016) [44], |

| Reduced packaging costs. | Jan et al. (2022) [37], Asma et al., 2020) [31] |

| Reduced raw material costs. | Dahmus (2014) [8], Asma et al. (2020) [31] |

| Reduced tone-kilometer per customer (carbon emission costs). | Asma et al. (2020) [31] |

| Time-Related Factors | |

| Lead-time reduction (shortening of lead times).New designs will take less time to reach the market. | Sala et al. (2015) [5], Dahmus (2014) [8], Rajak and Vinodh (2016) [9], Mitchell and Walinga (2017) [10], Filiz (2011) [21], Zeplin et al. (2021) [30], Vojislav et al. (2011) [32], Binoy et al. (2020) [36], Bram et al. (2018) [51], Guido et al. (2018) [39], Attaran. (2017) [76], Themban et al. (2019) [71], Suzanne et al. (2004) [73] |

| Reduced delivery lead times. | Bai et al. (2019) [12], Khoo et al. (2015) [24], Victor et al. (2021) [49], Melanie and Abubaker (2017) [70] |

| Eliminated supplier lead times. | Bai et al. (2019) [12] |

| Reduced setup times (supporting tradeoffs in lead times). | Aguado et al. (2013) [4], Zeplin et al. (2021) [30] |

| Reduced changeover times. | Aguado et al. (2013) [4], Teece et al. (1997) [7] |

| Reduced downtime. | Dahmus (2014) [8] |

| Reduction in time in production for complex parts (less production time). | Jan et al. (2022) [37] |

| Increases in supply chain dynamics by reducing the “time-to-market. | Peter (2015) [27] |

| Inventory-Related Factors | |

| Reduced safety stock inventory, decreased inventory holding concerns (reductions in inventories), lowered the stock-out, and reduced finished goods inventory. | Almi and Boumar (2023) [1], Aguado et al. (2013) [4], Khoo et al. (2015) [24], Huang et al. (2013) [33], Maximilian and Gerald (2019) [34], Halassi et al. (2019) [35], Sirichakwal and Conner (2016) [41], Berman (2012) [43], Christian et al. (2017) [52] |

| Results in a reduction of material distributions. | Aguado et al. (2013) [4] |

| Implemented a build-to-order strategy (produced when order is confirmed). | Aguado et al. (2013) [4] |

| Reduced the inventory level or balancing inventory levels. | Almi and Boumar (2023) [1], Clark (2007) [2], Aguado et al. (2013) [4], Massimiliano et al. (2007) [25], Halassi et al. (201) [35], Binoy et al. (2020) [36] |

| Achieved postponement benefits in inventory management; more flexible logistics and inventory management. | Hahn et al. (2015) [22], Joao et al. (2019) [29] |

| Reduced nonvalue-added activities, such as material movement. | Aguado et al. (2013) [4] |

| Made SC less transport intensive, reduced the flow of goods between customer, wholesaler, and retailer, reduced supplier transportation of basic materials, reduced downstream transportation for locally produced finished goods (this reduces up and downstream transportation), and reduced transportation. | Vargas et al. (2018) [11], Frederic et al. (2015) [28], Daniel et al. (2020) [60] |

| Energy- and Waste-Related Factors | |

| Reduced life-cycle primary energy consumption, reducing product weight, the volume of transportation, and the need for energy-intensiveness. | Dahmus (2014) [8], Bogers et al. (2016) [26], Daniel et al. (2020) [60], Evgenii et al. (2019) [68], Zhen (2016) [81] |

| Reduced greenhouse gas and CO2 emissions. | Dahmus (2014) [8], Bogers et al. (2016) [26] |

| Decreasing disruptions. | Dahmus (2014) [8] |

| Reduced wastes, material usage, and losses, reduced the amount of raw material required in the SC, and reduced polluting manufacturing processes. | Aguado et al. (2013) [4], Filiz (2011) [21], Vojislav et al. (2011) [32], Daniel et al. (2020) [60], Evgenii et al. (2019) [68], Karel et al. (2017) [80] |

| SC Efficiency and Firm Performance Factors | |

| Improved internal processes by eliminating the creation of new production lines for new product development, improving management activities (planning, organizing, leading, and controlling), reducing the amount of sub-production required and supply and demand-side of SCM components and processes. | Men et al. (2023) [14] |

| Improved SC efficiency (obtaining products at the right time, place, and the lowest cost, using resources efficiently); improved the efficiency of manufacturing lean just-in-time SCs; increased the efficiency of the production process and changed the structure of SC; supply chains become shortened, compressing the SC. | Aguado et al. (2013) [4], Islam, et al. (2021) [13], Asma et al. (2020) [31], Avner and Enno (2017) [67], Inigo et al. (2016) [69] |

| Significant impact on SC configuration and sustainability performance: SC can respond quickly to unexpected events and causes due to disruption. | Peter et al. (2015) [27], Mohsen (2017) [42] |

| Allow products and SC to efficiently and effectively absorb contextual variety. | Rydzik and Kissoon (2022) [19] |

| Has positive influences on SC performance and, as a result, firm performance (improve SC and firm performances). | Sachin and Rajesh (2022) [15], Reeves (2008) [20] |

| Marketing and Manufacturing-Related Factors (Decentralized Manufacturing) | |

| Increase responsiveness for demand fulfillment. | Sala et al. (2015) [5], Shen et al. (2020) [17], Hahn et al. (2015) [22], Asma et al. (2020) [31], Christian et al. (2017) [52], Avner and Enno (2017) [67], Zhen (2016) [81] |

| Better spreading and popularization of mass customization; decentralization of manufacturing (manufacture products near the customers); facilitate rapid prototyping and design freedom; increase resource efficiency and sustainability; have clearly defined legal and safety aspects, move production site closer to the customer. Bring manufacturing operations closer together as the world becomes more localized and massive industries become smaller (societal sustainability). | Aguado et al. (2013) [4] |

| Results in a lean supply chain with low costs; improves agile SC. | Teece (1997) [7], Massimiliano etal. (2007) [25], Mitchell and Walingam (2017) [10] |

| Rapid response to fluctuating demands and provides customized products, quick response to customer demand, and the provision of customized solutions to meet unanticipated operational demands. | Dahmus (2014) [8] |

| Optimized designs, improved machine throughput, and reduced machine vacancy. | Khoo et al. (2015) [24], Guido et al. (2018) [39] |

| Parts are produced on demand without the need for tooling and setup (reduces the need for tooling and setup). | Teece (1997) [7], Inigo et al. (2016) [69], Suzanne, et al. (2004) [73], Klaus et al. (2020) [88] |

| Flexibility against key market disruption; volume, mix, delivery, and new product introduction flexibility; sudden disruption flexibility scenarios, such as demand uncertainty, demand variability, lead-time compression, and product variety. Fast and flexible capacity to customize products, and react quickly and flexibly to customer requests and changing customer demands; it simplifies market entry and leads to customer individualization of the products. | Avner and Enno (2017) [67], Evgenii et al. (2019) [68], Inigo et al. (2016) [69], Suzanne et al. (2004) [73], Karel et al. (2017) [80] |

| Create development and manufacturing cycles. Enable and create more efficient, flexible, and fast product designs, and reduce the number of procedures (starting from design to warehousing). Allow near-net shape manufacturing of complex workpieces (economic sustainability) and allow quick manufacturing methods. | Sala et al. (2015) [5], Shen et al. (2020) [17], Hahn et al. (2015) [22], Asma et al. (2020) [31], Christian et al. (2017) [52], Avner and Enno (2017) [67], Zhen (2016) [81] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Woldesilassiea, T.L.; Lemu, H.G.; Gutema, E.M. Impacts of Adopting Additive Manufacturing Process on Supply Chain: Systematic Literature Review. Logistics 2024, 8, 3. https://doi.org/10.3390/logistics8010003

Woldesilassiea TL, Lemu HG, Gutema EM. Impacts of Adopting Additive Manufacturing Process on Supply Chain: Systematic Literature Review. Logistics. 2024; 8(1):3. https://doi.org/10.3390/logistics8010003

Chicago/Turabian StyleWoldesilassiea, Tekalign Lemma, Hirpa G. Lemu, and Endalkachew Mosisa Gutema. 2024. "Impacts of Adopting Additive Manufacturing Process on Supply Chain: Systematic Literature Review" Logistics 8, no. 1: 3. https://doi.org/10.3390/logistics8010003

APA StyleWoldesilassiea, T. L., Lemu, H. G., & Gutema, E. M. (2024). Impacts of Adopting Additive Manufacturing Process on Supply Chain: Systematic Literature Review. Logistics, 8(1), 3. https://doi.org/10.3390/logistics8010003