Abstract

Last mile handover is the most problematic phase in the delivery process, while real-time communication and dynamic scheduling are major problem areas associated with attended last mile handovers. These problem areas need to be addressed holistically to facilitate efficient last mile handovers. The aim of this paper is to report the design and functionalities of a decision-support system which holistically addresses these problem areas. The functionalities of decision-support system which addresses dynamic scheduling and real-time communication problem areas are discussed using case studies. We conclude that a holistic decision-support system with multiparty communication among the stakeholders facilitates improving customer satisfaction, business opportunities and reducing operational costs for logistics companies.

1. Introduction

Technological development has increased the competitiveness of retail markets due to the growth of shopping over the internet [1]. It is estimated that the e-tailing market will reach an estimated value of $1.4 trillion worldwide by 2020 [2]. The final leg of supply chain logistics, also known as the last mile handover, which is concerned with the delivery and pick-up of products to and from consumers, is one of the most difficult parts [3,4]. E-tailing allows purchases of products with low value as well, which is not always sustainable for a retailer. High-volume handovers of low-value products make it challenging for retailers and logistics companies to operate profitably [5]. It has been estimated that the last mile handover costs can be up to 50% of the total logistical costs [6,7]. Currently in attended handovers, by far the most common method of communication with the consumer happens during the handover, which is risky as it can lead to missed handovers. Customer satisfaction and business opportunities can be adversely affected if the logistics company misses the handover due to a lack of real-time handover information or long delivery windows. This is further exacerbated due to an increased number of consumers and competitive markets. Therefore, efficient and successful attended handovers are critical to the success and sustainability of e-tailing [8]. Apart from increased operational costs, last mile handovers also lead to congestion, noise and air pollution [9,10].

Two methods for last mile handovers are dominant: attended and unattended handovers. Attended handovers need the consumer to attend the handover while unattended handovers are made to a service point or automated parcel lockers [11,12]. According to an online survey conducted using social networking sites, the majority of consumers were interested in attended handovers, making it an attractive form of last mile handovers [8]. Attended handovers are also more problematic for making profits when compared to unattended handovers, because of the route complexity involved in reaching the handover locations and the necessity of a consumer being at home for the handover to take place. However, the use of a single delivery truck can replace several vehicle trips of consumer handovers, which is economically and environmentally efficient [13,14,15]. The majority of the population in Western countries are active in the labor market and are not available at home during the main delivery hours [5]. Since most of the handovers take place during general working hours, which are between 9 a.m. and 5 p.m., this is problematic for the consumers, leading to missed home deliveries [8]. It would be expensive to have the handovers in the evening or after the main working hours. Therefore, real-time information of handovers along with a short delivery window would enable the consumer to be at home for a short duration, reducing the scope of missed handovers. The estimated time of arrival (ETA) can be provided to the consumer to minimize the delivery window. Missed handovers can be reduced if the consumer is able to provide an alternate handover location which is not too far from the actual handover location. With the use of real-time information, the consumer can decide to use an alternate handover location.

There are two major problem areas in attended last mile handovers. The first major problem area for attended last mile handovers is related to the communication between the logistics company and the consumer [16]. Poor communication affects the consumers’ willingness to pay for handover services [17], as does low consumer satisfaction, long time windows for handovers and missed handovers [18]. According to a study [19], 5% of consumers were unable to track the status of their deliveries, 15% missed their home deliveries and 13% faced a delay in deliveries. Suppliers or retailers are burdened with additional financial costs due to unsuccessful or returned deliveries [8]. Real-time information on handovers must be communicated to the consumer. The second problem area is related to simplistic scheduling, which leads to inefficient vehicle routing [16]. Drivers traveling to handover locations based on their previous experience might not be optimal all the time. Therefore, the use of optimized routes facilitates reduced operation costs. Similarly, with the use of real-time communication, the consumer can choose an alternate handover location if they are not available at home. The handover route should be dynamically updated for the driver. Algorithms such as a genetic algorithm and integer programming can be used to generate optimized routes. An iterative search of optimized routes is needed to dynamically update vehicle routing. The consumer might want to have the handover during a particular time slot or at an alternate handover location, which increases the complexity in routing. These problems lead to increased costs, pollution and a loss of business opportunities. Therefore, there is a need for a decision-support system to enable real-time communication and dynamic scheduling.

Previous studies discuss solutions within the two problem areas, i.e., simplistic scheduling and customer communication, individually with few or no connections to each other. However, the two problem areas are dependent on each other and need to be addressed simultaneously to achieve an efficient solution. A dynamic real-time information flow should be established between the stakeholders, which are the retailer, the logistics company and the consumer [5]. Discussing functionalities related to only one problem area does not facilitate achieving an efficient last mile handover solution. According to our literature review, discussions of, or proposals for, a decision-support system which holistically addresses the problems in last mile handovers are scarce in previous research. Therefore, the aim of this paper is to report the design and development of decision-support system’s functionalities which holistically address major last mile handover problems in customer communication and scheduling areas. The holistic decision-support system is referred to as the Smart lAst mILe cOmmeRce (SAILOR) system in this paper. The decision-support system facilitates making attended handovers profitable by reducing operational costs and improving business opportunities. Encouraging attended handovers would increase the market of online shopping. This paper also contributes to existing literature by holistically addressing major last mile transportation problems, which is also beneficial to logistic companies or retailers performing last mile activities.

This paper is organized in the following way: Section 2 discusses previous research on last mile handovers; Section 3 discusses the resources and tools used in planning and designing the SAILOR system; Section 4 discusses the used cases of SAILOR in addressing last mile handover problems; the paper ends with a conclusion in Section 5.

2. Literature Review

What are the common modes of handover employed by a couple of major worldwide retail giants, such as Amazon and IKEA, who have already established well-connected logistic networks? Amazon is a major e-tailing company, while IKEA is a major furniture store with physical stores setup in various locations. Amazon has set up transportation hubs in densely populated areas to carry out last mile handovers [20]. Despite the robust consumer service presence and logistic networks available for Amazon, the majority of deliveries are unattended handovers made to pick-up points in Sweden. IKEA consists of 31 centralized distribution centers around the world. Transportation between supplier and distribution centers is well-planned and managed through a network of rail, road and air modes of transportation. However, even IKEA encourages consumers to pick-up their products from the store, which is facilitated by large parking areas. An additional shipping fee is charged if the consumer chooses the attended handover option and the delivery window on the date of delivery in Sweden is at least five hours. Therefore, attended handovers are either not supported, incur an extra charge, or involve long delivery times. This may be due to the possibility of unsuccessful deliveries and increased operational costs. There is always a risk of missed handovers due to the customer not being at home, since the exact location of the customer cannot be ascertained. If the delivery is not successful, the company charges again for the repeated handover, which is not appreciated by the consumer, thus adversely affecting customer satisfaction. Logistic companies providing handover services in rural areas lack critical mass, making it a challenge to operate profitably [21]. Unlike in higher density regions, such as cities, large distances need to be traversed for handovers in rural areas, and the increased vehicle delivery distance increases handover costs for the logistics companies. There are other ways in which attended handovers can be made, such as crowd shipping, where retailers use consumers to deliver products for other consumers [22]. The retailer offers discounts to the consumers who make such deliveries. MyWays, in Sweden, and Walmart offer such services. This kind of delivery reduces transportation costs for the delivery company and solves consumer unavailability issues. However, crowd shipping is prone to theft and security issues and is therefore unreliable. Drones have also been tested to improve last mile delivery for the future. The travelled distance is reduced by using drones but there is no standard delivery procedure to handover a parcel [23]. The limited battery life of a drone and its vulnerability to hacking provide security implications which need to be resolved.

Consumer communication is one of the major problem areas in last mile handovers. Lack of communication with the consumer regarding product details and handover arrangements impacts customer satisfaction. Therefore, involving the consumer in the delivery process and enabling real-time communication would improve the planning of distribution and increase consumer satisfaction [8]. Enabling real-time information would facilitate providing ETA information to the consumer, which can be used, for example, in reducing the handover window or delivery time. Consumer satisfaction with the logistics solution provided is necessary in making handovers sustainable [24]. Therefore, the use of alternate handover locations when the consumer is not available at home would facilitate reducing missed handovers and improve customer satisfaction to a great extent. A near real-time communication should be established to enable this functionality. The updated customer handover location should also be dynamically updated to the driver in real time. Customer satisfaction can be improved even by short-term measures, such as providing an estimated delivery date. Based on previous literature, consumer preferences with respect to last mile handovers were dependent on four aspects: delivery information with options, delivery fees, successful delivery and order tracking [25]. Delivery information should be flexible with multiple available timeslots giving options to the consumer to select a feasible handover window [26,27]. The option of time slots increases consumer repurchase intention. Delivery fees affect consumer purchase patterns which can be dependent on the consumer’s budget and time allocation [28]. Authors who discuss the use of delivery times in home delivery assume that the consumer will be at home during the delivery [10,21,29,30]. The assumption is reasonable if the consumers themselves choose the time window at their convenience. However, the choice of location and time restrictions proposed by the consumer can create complexity in vehicle routing, leading to increased handover costs.

Successful delivery has a positive effect on consumer satisfaction [31,32]. However, up to 60% of first-time handovers were unsuccessful, leading to increased costs and consumer dissatisfaction [33]. Missed handovers are a common problem during home deliveries, leading to unsuccessful transactions. One reason for this can be that home deliveries are commonly scheduled over weekdays during working hours and it is problematic for the consumer to attend the handover [8]. To avoid this problem, logistics companies can schedule home deliveries after normal working hours, arrange weekend deliveries, or facilitate delivery on a desired date [8]. However, this would lead to a higher expenditure for the retailer and logistics company, even though it would mean increased convenience for the consumer. An alternate handover location could be used to avoid missed handovers. This alternate location could be a neighbor’s address, or a nearby location near the previously defined location. If the alternate location is too far away it would delay the subsequent handovers and impose additional operational costs for the logistics company and the retailer. The change in the location, time, route and behavior of the consumer were analysed using regression models to estimate the reason for unsuccessful deliveries [34]. The study found a higher number of unsuccessful handovers in urban areas compared to rural areas. Similarly, the tracking of orders also increased consumer satisfaction, involving the real-time information flow between the logistics company and the consumer [35]. Tracking can be performed using GPS-enabled mobile communication devices. This paper does not discuss multiple time slots and delivery fees, which can improve consumer repurchase intention.

The other problem area is scheduling, which deals with optimized routes. The use of optimized routes would facilitate reducing vehicle distance and pollution. Vehicle restrictions and time-slot limitations are critical components in planning efficient vehicle routing. There are several studies which discuss vehicle routing problems and propose algorithms for scheduling handovers and reducing transportation costs. Generally, vehicle routing for handovers falls under Travelling Salesman Problems, with time windows where the driver visits multiple locations and hand over parcels. Optimized routes to multiple locations need to be generated from the distribution center to reduce operational costs for the logistics company. In urban areas, due to increased density, the delivery vehicle need not travel for long distances to make handovers. However, in rural areas, the handover vehicle needs to travel for long distances, and the use of optimized routes is important in reducing operational costs. If the customer is not at home and an alternate location is given, the optimized route to the alternate handover location is generated with the help of multiple optimization algorithms. An iterative search of optimized routes is performed whenever there is a change in traffic situations or handover locations. A near real-time communication between the consumer and driver is needed to dynamically update the route. We shall now look at some of the algorithms discussed in previous literature. Dijkstra’s shortest path algorithm and the Nested Monte-Carlo search algorithms were implemented in [36], where public transport is integrated with private transportation in simulation. The results from this study suggest that integrating public transport decreased vehicle travelling distance. However, the use of public transport might not always be feasible, and the shortest path algorithm does not always generate optimal routes for multiple stops. There can also be delays leading to missed connections, which delay the handover. This mode of transport can be useful for small and medium-sized handovers with large delivery windows. The use of large delivery windows affects customer satisfaction negatively. In [26], an integer programming approach and continuous approximation are used for scheduling last mile handovers. According to a case study in [37], a Genetic Algorithm (GA) and particle swarm optimization algorithms were used to generate optimized routes. A GA was originally used to generate the optimal value of organism’s survivability, while the particle swarm optimization is a population-based random search algorithm. Therefore, a GA is the central algorithm used by the reported decision-support system in this paper. In [38], a hybrid artificial bee colony and a simulated annealing algorithm were used to generate optimized routes which perform better than a GA and an artificial bee colony algorithm. Similarly in [39], a GA and memetic algorithm are used to generate optimal routes in a time-constrained delivery service, and the Gilmore–Gomory algorithm is used to order the optimal routes. A combination of these algorithms would be feasible in generating dynamic routing to multiple handover locations. The global retail companies with their sophisticated logistics networks do not encourage attended handovers either, due to the involved complexities. The previous literature discusses customer satisfaction, missed handovers, vehicle routing and optimized routes. However, literature that holistically discusses real-time customer communication and dynamic scheduling problem areas is scarce.

3. Planning and Design Model of the Solution System

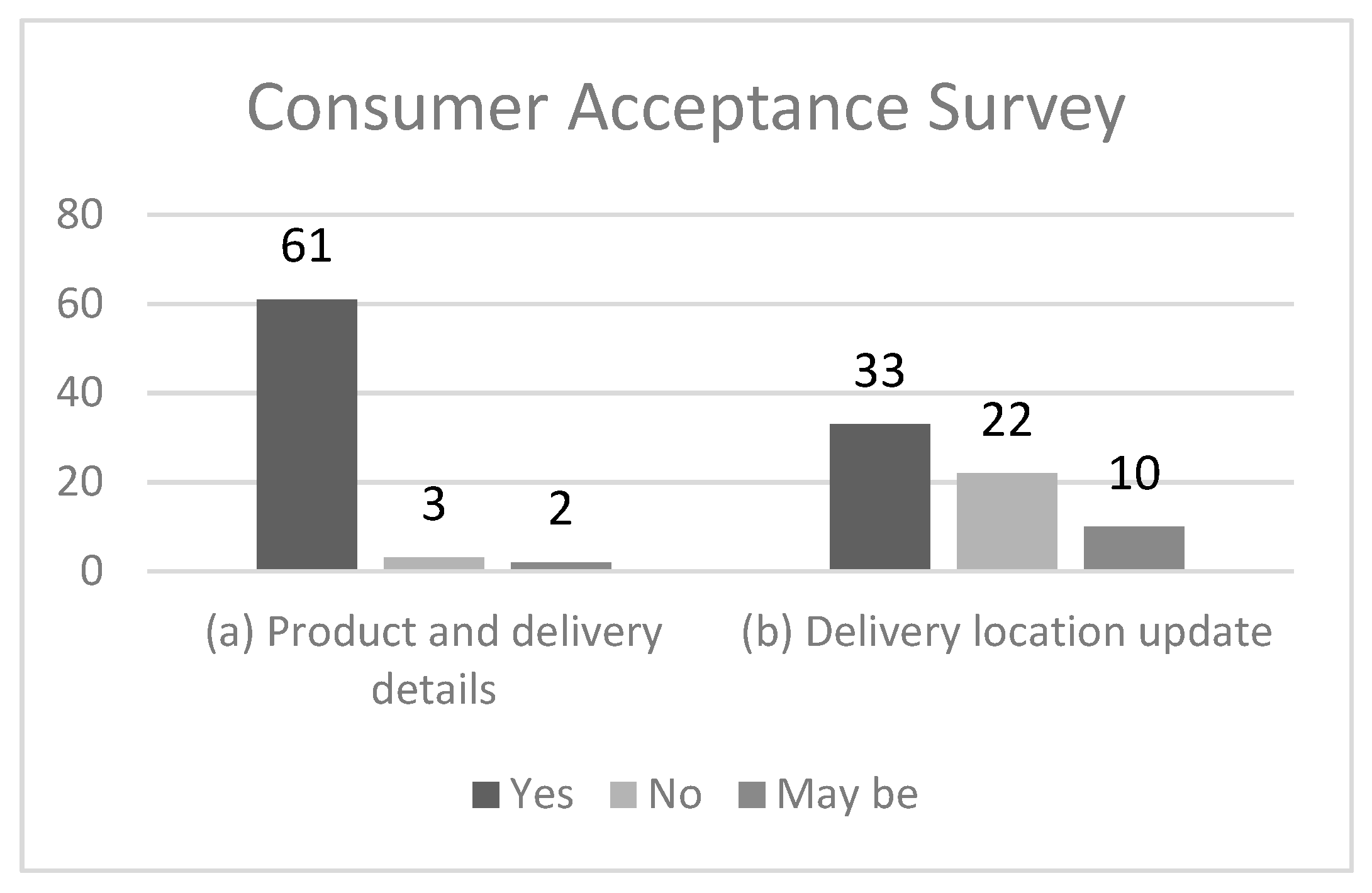

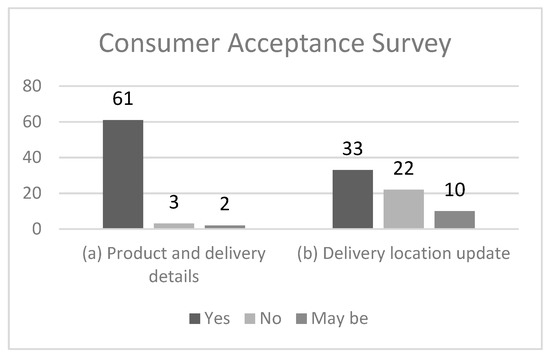

The proposed holistic solution can serve as a decision-support system for drivers, consumers and administrators of the logistics company or retailers. Integrating information flow between the consumer and logistics companies or retailers would facilitate new business opportunities and improve consumer satisfaction [5]. A survey was conducted with the users of a delivery company to measure consumers’ acceptance of using a mobile application to improve communication. The delivery company’s mean number of customers per month is approximately 215 and the survey was sent to 120 consumers. The response rate was 55% where we reported the responses to two questions. The first question asked whether the user was interested in using a mobile application to obtain product details, delivery details and ETA information. As shown in Figure 1a, the majority of the respondents were interested in accessing product and delivery details using a mobile application. The second question asked whether the user was interested in changing the delivery address using a mobile application. As shown in Figure 1b, majority of the respondents were interested in using a mobile application to update delivery location. The short survey with the consumers indicates that customer satisfaction can be improved by enabling communication between the consumer and the logistics company using mobile applications.

Figure 1.

Consumer acceptance survey.

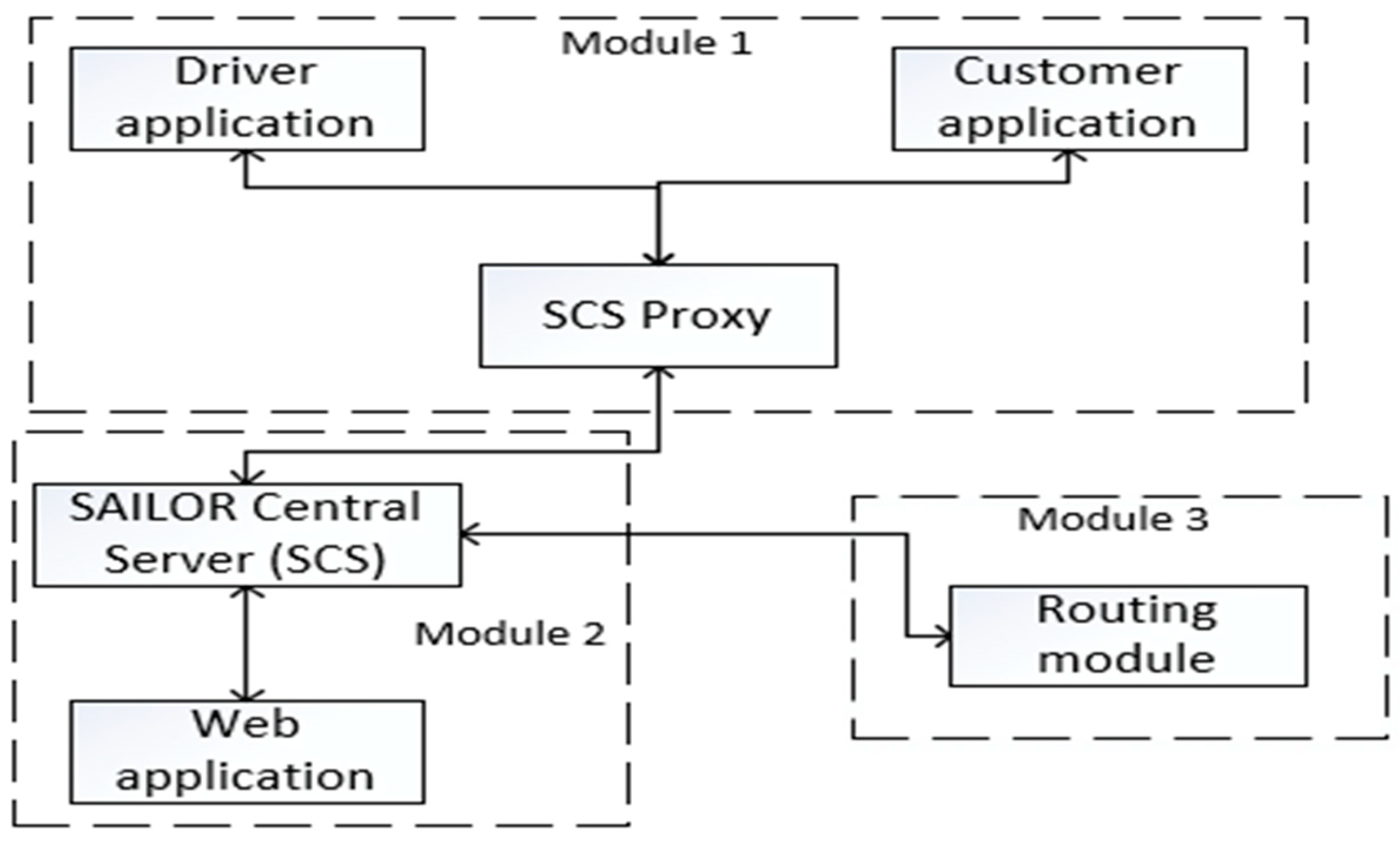

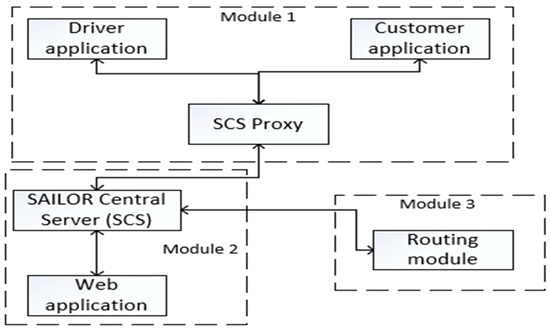

Once the design of the SAILOR system was finalized the requirements were given to the development team. The SAILOR system serves as an open, service-oriented system, which enhances dynamic multiparty interaction between the logistics company and the consumer, enabling coordinated decision-making on an operational level for all parties. Since a real-time information flow should be established between all the stakeholders, the use of mobile and web applications was incorporated into the decision-support system as they are common tools of communication [1,5,40]. The use of mobile applications was also accepted as a convenient tool for disseminating information based on the survey results illustrated in Figure 1. The three developed modules illustrated in Figure 2 are:

Figure 2.

System deployment.

- Driver and consumer mobile applications: These are android-supported mobile applications which are used by the driver and consumer. The driver application is used to provide details of scheduled orders and optimized routes to the handover locations. The driver application provides optimized routes based on real-time traffic information. The consumer application is used for details of the order in question, the estimated time of arrival (ETA) and managing the handover location.

- Web application and central server: The central server is the point of contact for mobile applications, web applications and routing modules. The web application is used by the administrator to add, manage or schedule order details. The orders can be exported into the SAILOR application using a spreadsheet or Application Programming Interface (API). The SAILOR system does not handle the purchase of products, but only facilitates the delivery process of these products.

- Routing module: This module facilitates generating the optimized handover routes and scheduling the added orders, based on the location of the handovers. Google APIs are used to obtain optimized routes based on time and real-time traffic information. Therefore, the optimized routes can be updated based on real-time traffic information.

When the driver initiates the handover process in the driver application, the consumer receives the ETA information in the customer application. Similarly, the driver receives the scheduled order of handovers with the optimized routes. Communication between the mobile devices and the web application takes place in near real time. However, this is dependent on good internet connectivity. Lack of a good internet network would affect the real-time communication between the devices.

3.1. SAILOR Handling of Operational Problems

We conducted expert group interviews and workshops with development and logistics companies to design the decision-support system, the SAILOR. Based on the group interviews and a literature review, the major operational problem areas were identified for the logistics company and customers and are given below. The SAILOR enables dynamic scheduling and real-time customer communication to address the aforementioned operational problems.

3.1.1. Operational Problems for the Logistics Company

- Missed handovers: If a customer is unavailable and this information is unavailable to the logistics company, the driver travels to the handover location and waits for the customer. This leads to time-wasting for the driver and increased fuel costs. The SAILOR addresses this problem by allowing the customer to cancel/reschedule the handover using the mobile application.

- Lack of optimized routes: Traditionally, the driver navigates to multiple handover locations based on experience. This can lead to increased fuel costs if the driver is unfamiliar with the area of operation, or if the route taken to the handover location is not optimal. This occurs predominantly in urban locations where there are dense road networks. The SAILOR handles this problem by utilizing Google APIs for generating optimized routes to multiple handover locations, based on real-time traffic information. The optimized routes are generated based on travelling time. However, there can be cases where reducing travel time can increase fuel costs due to traffic conditions. Nevertheless, we assume such cases to be minimal, as Google APIs select routes based on real-time traffic information. Alternate routes are selected if the traffic is very heavy or congested.

- Dynamic scheduling of handovers: When there are multiple handover locations, the driver chooses the order of locations based on experience, which might not be optimal, thus leading to increased fuel costs. The ordering of handover locations in the SAILOR is based on route distance and time generated by Google APIs enabling dynamic scheduling.

3.1.2. Operational Problems for Customers

- Longer handover windows: The handover durations are from 4 to 9 hours, varying with different companies. The customer must stay at home for these durations if they do not want to miss the handover. The SAILOR provides ETA information of the handover, which is calculated using the location of the driver, thus enabling real-time customer communication. In this way, the SAILOR facilitates a shorter duration time for the customer.

- Alternate handover location: If the customer is not at home it leads to missed home handovers. Using the SAILOR, the customer can reschedule the order if they are unavailable using the mobile application. The SAILOR also enables the customer to change the handover location before the driver starts, and even when the driver is on-route to make the handovers. However, there are limited conditions for changing the handover location while the driver is on-route. More details about these conditions can be found in Section 4.2.

4. Use-Case Designs of the SAILOR System

The SAILOR system is a decision-support system where near-real-time optimal scheduling, the dynamic management of orders and routing are provided for last mile handovers. Based on expert group interviews and workshops, two use-cases were designed and developed. The use-cases consisted of a sequence of interactions between the stakeholders, enabling customer communication and dynamic scheduling. The first use-case deals with the management of scheduling problems. The second use-case deals with the management of customer communication problem.

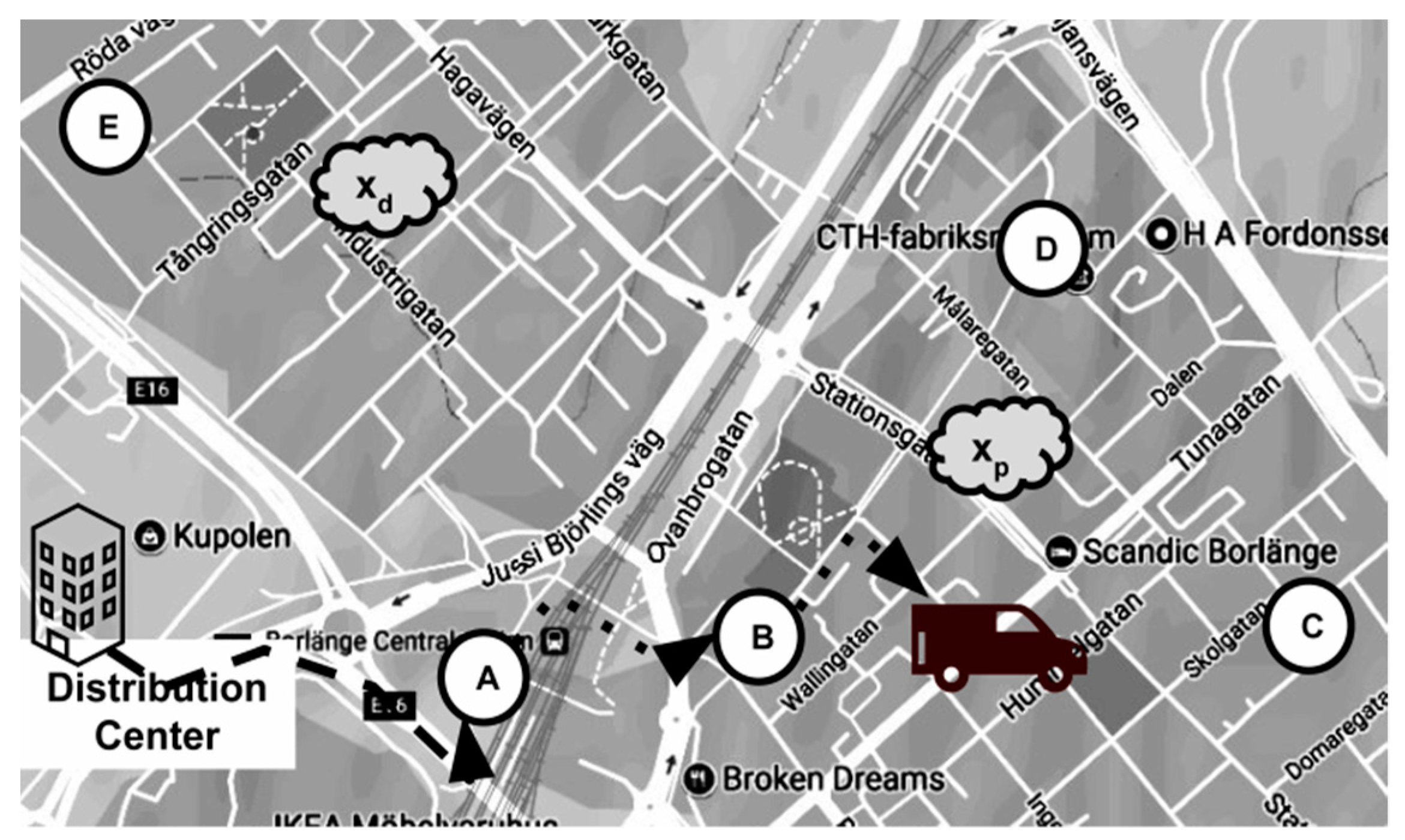

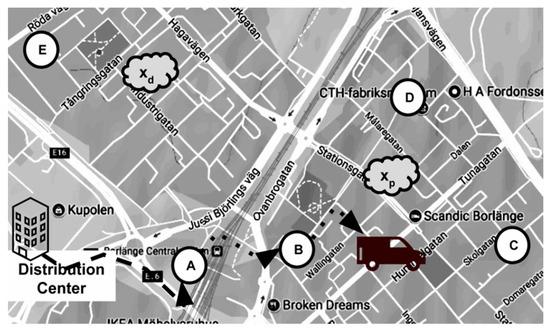

4.1. Use-Case 1: Scheduling and Management of Handovers

The SAILOR system facilitates the addition of new handovers before or during the handover process using the web and customer applications. The driver application receives these handovers along with optimized routes to the dynamically scheduled orders, thereby reducing the routing time and operational costs for the logistics company. For instance, the vehicle is loaded with five parcels (i.e., A, B, C, D and E) at the distribution center, which is located outside the city center, as shown in Figure 3. The driver, after handing over the first two parcels, i.e., A and B, receives two new handovers, Xd and Xp. Xd refers to the new delivery location, while Xp refers to the new pick-up location. The new pick-up and delivery locations are scheduled with the remaining orders, along with the optimized routes. Once a new handover is added, the routes are re-calculated and re-scheduled, by calling Google API. Whenever there is a change in orders or handover location, the route is dynamically updated.

Figure 3.

Vehicle routing of deliveries and pick-ups.

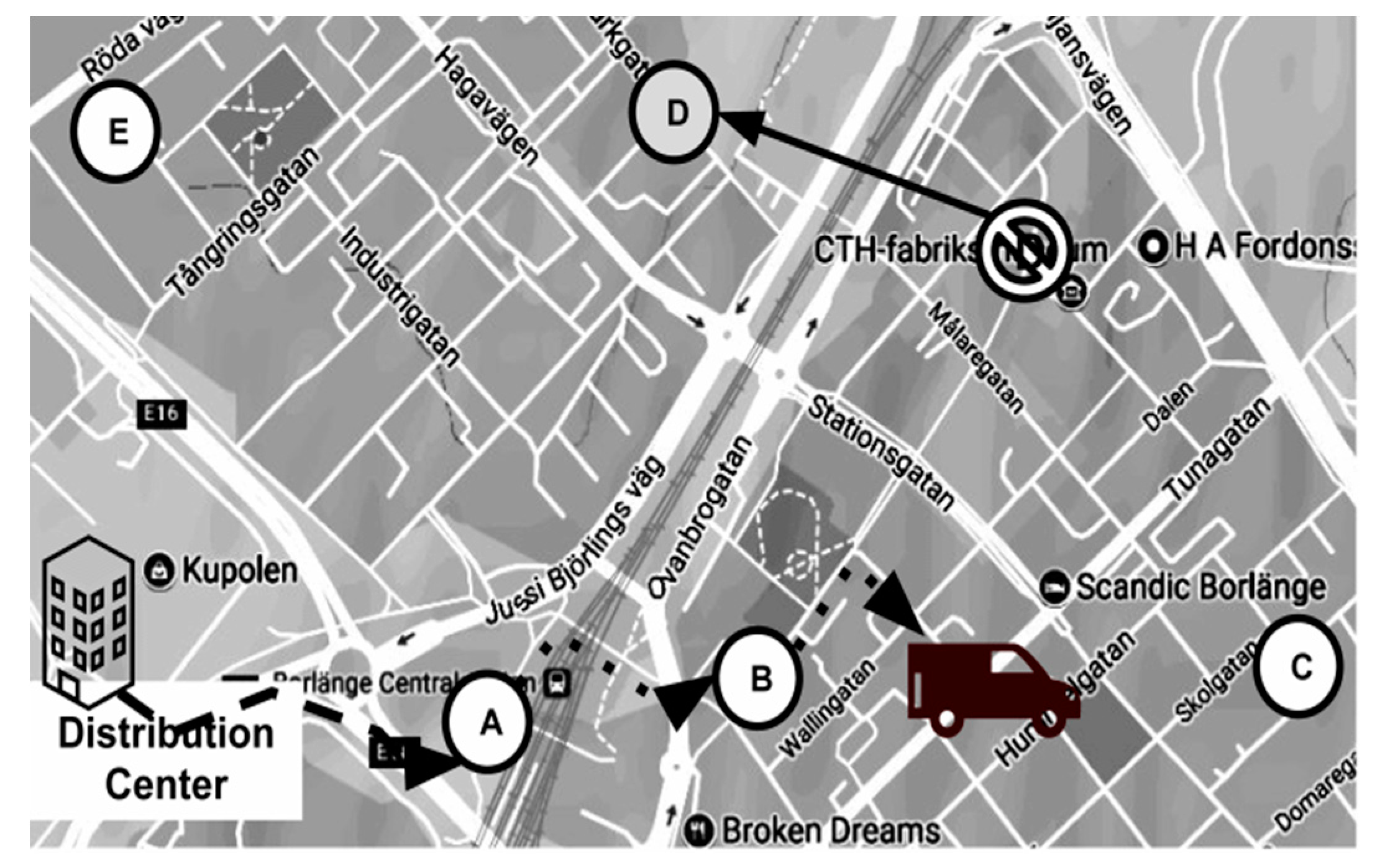

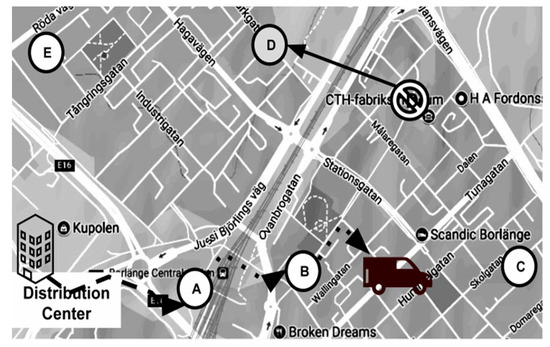

4.2. Use-Case 2: Consumer Communication and Alternate Handover Address

This use-case enables communication between the logistics company and the consumer. It facilitates the improvement of customer satisfaction by providing product details, ETA information and an alternate handover location. This feature does not eliminate missed deliveries completely but should reduce missed deliveries due to improved communication and the use of an alternate handover location. However, the consumer should be willing to use the application for utilizing the feature. Since ETA information is provided by the system, the consumer is not required to be available for a long time at their residence. The consumer gets the ETA information in the consumer application. The consumer is then able to react to this information in the following ways:

- Respond that the consumer is not at home, which will delete the handover from the route;

- State an alternative handover location;

- Do nothing and anticipate the handover.

If an alternative address is given, the system must re-calculate the route in which the new location is considered. The consumer can change to an alternate handover location without any restrictions if the handover process in not initiated. When the driver is on-route, the consumer is allowed to change the address to a new location until 15 mins before the arrival of the handover vehicle, and within a radius of 5 kms. For instance, as shown in Figure 4, there are five handover locations (i.e., A, B, C, D and E) where the driver had completed handling parcels at A and B locations. When the driver is on-route to location C, the customer at location D chooses an alternate handover location. If the alternate location falls within the conditions, then the new handover location of D is accepted, and the driver gets an update route map in the driver application. Operational costs and vehicle distances are linearly proportional. Therefore, the use of optimized delivery routes is imperative in reducing additional operational costs. The optimized delivery routes provided by the application are based on travelling time and traffic conditions. Mid-sized and larger cities consist of larger road networks and there are greater possibilities of alternative routes which reduce the travel distance. However, a possible optimized route can lead to increased fuel costs due to congested traffic conditions. The use of optimized routes might not be beneficial all the time, but they are the best possible way for reducing fuel costs.

Figure 4.

Consumer communication.

5. Conclusions

An attended handover is an environmentally friendly and popular mode of last mile handover method capable of improving business opportunities. However, consumer communication and scheduling problem areas are major issues affecting the efficiency of attended last mile handovers. The previous literature discusses these problems individually, which is not beneficial to logistics companies performing last mile transportation activities. Therefore, an integrated decision-support system, such as the SAILOR, enables a real time information flow between the consumer, the logistics company and the retailer using mobile communication devices. The SAILOR facilitates dynamic scheduling by managing missed handovers, providing optimal scheduling and routing, which are beneficial to the logistics company. Similarly, customer communication is enabled by providing shipping details, ETA and alternate handover locations. A logistics company might already have an enterprise management system in place to manage the purchased orders. The SAILOR system can be integrated into their system using an API, or orders can be exported into the SAILOR using a spreadsheet to avoid manually adding the orders. The SAILOR system manages the critical last phase of the delivery by enabling communication between the stakeholders and dynamic scheduling. Therefore, we conclude that a holistic decision-support system enabling real-time information flow between the stakeholders would facilitate the reduction of operational costs for logistics companies and improve consumer satisfaction, thereby increasing business opportunities.

Author Contributions

Conceptualization and methodology, J.H. and R.G.N.; Writing—original draft preparation, V.P. and R.G.N.; Writing—review and editing, V.P.; Supervision, J.H. and R.G.N.; Investigation, V.P., R.G.N. and J.H.; Software, V.P. and R.G.N.; Analysis, V.P., R.G.N. and J.H.; Funding acquisition, J.H. All authors have read and agreed to the published version of the manuscript.

Funding

The research and APC was funded by VINNOVA: 2016-02762.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Digiesi, S.; Fanti, M.P.; Mummolo, G.; Silvestri, B. Externalities reduction strategies in last mile logistics: A review. In 2017 IEEE International Conference on Service Operations and Logistics, and Informatics (SOLI); IEEE: Piscataway, NJ, USA, 2017; pp. 248–253. [Google Scholar]

- Forrester. eCommerce Trends and Outlook in Australia, China, India, Japan, and South Korea; Forrester: Cambridge, MA, USA, 2016. [Google Scholar]

- Visser, J.; Nemoto, T.; Browne, M. Home delivery and the impacts on urban freight transport: A review. Procedia-Soc. Behav. Sci. 2014, 125, 15–27. [Google Scholar] [CrossRef]

- Gevaers, R.; Van De Voorde, E.; Vanelslander, T. Cost modelling and simulation of last-mile characteristics in an innovative B2C supply chain environment with implications on urban areas and cities. Procedia-Soc. Behav. Sci. 2014, 125, 398–411. [Google Scholar] [CrossRef]

- Petrovic, O.; Harnisch, M.J.; Puchleitner, T. Opportunities of mobile communication systems for applications in last-mile logistics. In Proceedings of the 2013 International Conference on Advanced Logistics and Transport, Sousse, Tunisia, 29–31 May 2013; pp. 354–359. [Google Scholar]

- Kuhn, H.; Sternbeck, M.G. Integrative retail logistics: An exploratory study. Oper. Manag. Res. 2013, 6, 2–18. [Google Scholar] [CrossRef]

- Vanelslander, T.; Deketele, L.; Van Hove, D. Commonly used e-commerce supply chains for fast moving consumer goods: Comparison and suggestions for improvement. Int. J. Logist. Res. Appl. 2013, 16, 243–256. [Google Scholar] [CrossRef]

- Holdorf, S.; Haasis, H.-D. Last mile delivery concepts in E-Commerce an empirical approach. In Proceedings of the 8th International Conference on Software, Knowledge, Information Management and Applications (SKIMA 2014), Dhaka, Bangladesh, 18–20 December 2014; pp. 1–6. [Google Scholar]

- Ranieri, L.; Digiesi, S.; Silvestri, B.; Roccotelli, M. A review of last mile logistics innovations in an externalities cost reduction vision. Sustainability 2018, 10, 782. [Google Scholar] [CrossRef]

- Brown, J.R.; Guiffrida, A.L. Carbon emissions comparison of last mile delivery versus customer pickup. Int. J. Logist. Res. Appl. 2014, 17, 503–521. [Google Scholar] [CrossRef]

- Moroz, M.; Polkowski, Z. The last mile issue and urban logistics: Choosing parcel machines in the context of the ecological attitudes of the Y generation consumers purchasing online. Transp. Res. Procedia 2016, 16, 378–393. [Google Scholar] [CrossRef]

- Iwan, S.; Kijewska, K.; Lemke, J. Analysis of parcel lockers’ efficiency as the last mile delivery solution–the results of the research in Poland. Transp. Res. Procedia 2016, 12, 644–655. [Google Scholar] [CrossRef]

- Edwards, J.B.; Mckinnon, A.C.; Cullinane, S.L. Comparative analysis of the carbon footprints of conventional and online retailing: A “last mile” perspective. Int. J. Phys. Distrib. Logist. Manag. 2010, 40, 103–123. [Google Scholar] [CrossRef]

- Coley, D.; Howard, M.; Winter, M. Local food, food miles and carbon emissions: A comparison of farm shop and mass distribution approaches. Food Policy 2009, 34, 150–155. [Google Scholar] [CrossRef]

- Van Loon, P.; Mckinnon, A.; Deketele, L.; Dewaele, J. The growth of online retailing: A review of its carbon impacts. Carbon Manag. 2014, 5, 285–292. [Google Scholar] [CrossRef]

- Leung, K.; Choy, K.; Siu, P.K.; Ho, G.; Lam, H.; Lee, C.K. A B2C e-commerce intelligent system for re-engineering the e-order fulfilment process. Expert Syst. Appl. 2018, 91, 386–401. [Google Scholar] [CrossRef]

- Hübner, A.; Kuhn, H.; Wollenburg, J. Last mile fulfilment and distribution in omni-channel grocery retailing: A strategic planning framework. Int. J. Retail Distrib. Manag. 2016, 44, 228–247. [Google Scholar] [CrossRef]

- Dell’amico, M.; Hadjidimitriou, S. Innovative logistics model and containers solution for efficient last mile delivery. Procedia-Soc. Behav. Sci. 2012, 48, 1505–1514. [Google Scholar]

- European Commission. Flash Eurobarometer 299 (Consumer attitudes towards cross-border trade and consumer protection. Available online: https://dbk.gesis.org/dbksearch/SDesc2.asp?DB=E&no=5466 (accessed on 20 July 2011).

- Yu, Y.; Wang, X.; Zhong, R.Y.; Huang, G.Q. E-commerce logistics in supply chain management: Practice perspective. Procedia Cirp 2016, 52, 179–185. [Google Scholar] [CrossRef]

- Boyer, K.K.; Prud’homme, A.M.; Chung, W. The last mile challenge: Evaluating the effects of customer density and delivery window patterns. J. Bus. Logist. 2009, 30, 185–201. [Google Scholar] [CrossRef]

- Estellés-Arolas, E.; González-Ladrón-DE-Guevara, F. Towards an integrated crowdsourcing definition. J. Inf. Sci. 2012, 38, 189–200. [Google Scholar] [CrossRef]

- Yoo, H.; Chankov, S. Drone-delivery Using Autonomous Mobility: An Innovative Approach to Future Last-mile Delivery Problems. In Proceedings of the 2018 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Bangkok, Thailand, 16–19 December 2018; pp. 1216–1220. [Google Scholar]

- Småros, J.; Holmström, J.; Kämäräinen, V. New service opportunities in the e-grocery business. Int. J. Logist. Manag. 2000, 11, 61–74. [Google Scholar] [CrossRef]

- Nguyen, D.H.; De Leeuw, S.; Dullaert, W.; Foubert, B.P. What is the right delivery option for you? Consumer preferences for delivery attributes in online retailing. J. Bus. Logist. 2019, 40, 299–321. [Google Scholar] [CrossRef]

- Agatz, N.; Campbell, A.; Fleischmann, M.; Savelsbergh, M. Time slot management in attended home delivery. Transp. Sci. 2011, 45, 435–449. [Google Scholar] [CrossRef]

- Rao, S.; Goldsby, T.J.; Griffis, S.E.; Iyengar, D. Electronic logistics service quality (e-LSQ): Its impact on the customer’s purchase satisfaction and retention. J. Bus. Logist. 2011, 32, 167–179. [Google Scholar] [CrossRef]

- Becerril-Arreola, R.; Leng, M.; Parlar, M. Online retailers’ promotional pricing, free-shipping threshold, and inventory decisions: A simulation-based analysis. Eur. J. Oper. Res. 2013, 230, 272–283. [Google Scholar] [CrossRef]

- Wang, X.; Regan, A.C. Local truckload pickup and delivery with hard time window constraints. Transp. Res. Part B Methodol. 2002, 36, 97–112. [Google Scholar] [CrossRef]

- Nanry, W.P.; Barnes, J.W. Solving the pickup and delivery problem with time windows using reactive tabu search. Transp. Res. Part B Methodol. 2000, 34, 107–121. [Google Scholar] [CrossRef]

- Blut, M. E-service quality: Development of a hierarchical model. J. Retail. 2016, 92, 500–517. [Google Scholar] [CrossRef]

- Gawor, T.; Hoberg, K. Customers’ valuation of time and convenience in e-fulfillment. Int. J. Phys. Distrib. Logist. Manag. 2019, 49, 75–98. [Google Scholar] [CrossRef]

- Song, L.; Cherrett, T.; Mcleod, F.; Guan, W. Addressing the last mile problem: Transport impacts of collection and delivery points. Transp. Res. Rec. 2009, 2097, 9–18. [Google Scholar] [CrossRef]

- Van Duin, J.; De Goffau, W.; Wiegmans, B.; Tavasszy, L.; Saes, M. Improving home delivery efficiency by using principles of address intelligence for B2C deliveries. Transp. Res. Procedia 2016, 12, 14–25. [Google Scholar] [CrossRef]

- Garver, M.S.; Williams, Z.; Stephen Taylor, G.; Wynne, W.R. Modelling choice in logistics: A managerial guide and application. Int. J. Phys. Distrib. Logist. Manag. 2012, 42, 128–151. [Google Scholar] [CrossRef]

- Chatterjee, R.; Greulich, C.; Edelkamp, S. Optimizing Last Mile Delivery using Public Transport with Multi-Agent based Control. In Proceedings of the 2016 IEEE 41st Conference on Local Computer Networks Workshops (LCN Workshops), Dubai, UAE, 7–10 November 2016; pp. 205–212. [Google Scholar]

- Guo, J.; Wang, X.; Fan, S.; Gen, M. Forward and reverse logistics network and route planning under the environment of low-carbon emissions: A case study of Shanghai fresh food E-commerce enterprises. Comput. Ind. Eng. 2017, 106, 351–360. [Google Scholar] [CrossRef]

- Yilmaz, Ö.F.; Pardalos, P.M. Minimizing average lead time for the coordinated scheduling problem in a two-stage supply chain with multiple customers and multiple manufacturers. Comput. Ind. Eng. 2017, 114, 244–257. [Google Scholar] [CrossRef]

- Geismar, H.N.; Laporte, G.; Lei, L.; Sriskandarajah, C. The integrated production and transportation scheduling problem for a product with a short lifespan. Inf. J. Comput. 2008, 20, 21–33. [Google Scholar] [CrossRef]

- Tiwapat, N.; Pomsing, C.; Jomthong, P. Last Mile Delivery: Modes, Efficiencies, Sustainability, and Trends. In 2018 3rd IEEE International Conference on Intelligent Transportation Engineering (ICITE); IEEE: Piscataway, NJ, USA, 2018; pp. 313–317. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).