Evaluating Logistics Performances of Agricultural Prunings for Energy Production: A Logistics Audit Analysis Approach

Abstract

1. Introduction

1.1. Biomass as Renewable Energy Source

1.2. Some Relevant Biomass Properties in Investigating PtE Value Chains

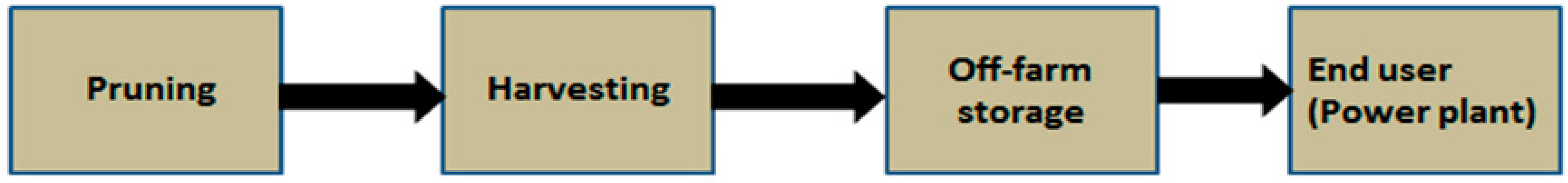

1.3. Main Characteristics of Logistics Chain in PtE Value Chains

1.4. Main Logistics Operations in PtE Value Chains

1.4.1. Pruning

1.4.2. Biomass Harvesting

1.4.3. Storage

- On-field biomass storage is less costly but has some disadvantages, such as material loss, difficulty in controlling biomass moisture, potential risk to health (formation of spore and fungus) and safety issue (self-ignition may happen), and difficulty in land management if the farmer uses the storage place for the following cultivation. Because of these risks, the on-field storage is limited to short-term storage.

- Intermediate storage is storage located between the fields and power plants.

- A storage facility at biomass power plant is a type of storage that can facilitate the biomass drying process (controlling moisture content) by using the dumped heat (without extra energy consumption).

1.4.4. Biomass Pre-Treatment Activities

1.4.5. Biomass Transport Activities

1.5. Main Actors and Their Roles in the PtE Value Chain

- Biomass producer: at a farm level, a producer carries out activities such as raw material (biomass) production; pruning and collection, and processing (chipping and baling); on-field storage; and loading for transport; as well as, in some cases, delivering the biomass to the end user.

- Processor: can be a trader and performs treatment/processing (drying, baling, and chipping), storage, buying/selling, and unloading/loading.

- Distributor: performs activities such as procurement and trading; treatment (storage, drying, baling, chipping, blending, and grading); quality control; inventory; and unloading/loading for transport and transportation.

- End user: performs activities such as procurement, biomass quality control, storage, and mainly energy/heat production.

1.6. Identification of Knowledge Gap and Required Interventions

2. Material and Methodology

2.1. Data Survey and Study Area

2.2. Logistics Audit Analysis

2.2.1. Logistics Audit Concept and Methodology

2.2.2. Logistics Audit Check List That Can Be Applied for Biomass Flow

- Biomass sources and productivity: identifying all biomass potential sources (e.g., single source or multi-biomass sources), seasonal variation, and productivity per hectare.

- Collection/harvesting of biomass: identifying types of harvesting and collection techniques and/or machines.

- Purchasing and procurement of biomass product: considering the (available) supply and demand contracts during biomass procurement, identifying the regulatory interventions and stimulation measures (government programs, tax cuts and exemptions, subsidies, and mandatory blending for biofuels) included in contracts, selection of biomass suppliers, and biomass transport during procurement process

- Storage and activities at storage level: types of storages (on-field storage, intermediate storage, or near-plant storage), location of storage facilities, types of pre-treatment methods used, location and capacity of storage for semi-finished and finished products, technical conditions, and facilities of storage infrastructures.

- Transportation: type of primary transportation; biomass transport to storage and/or to energy plants; transport of semi-finished and finished products; and management of packaging, loading, and unloading activities.

- Power plant/biomass consumer characteristics: capacity, flexibility, and limitation of the plant; types of conversion technologies; condition of machines and transport facilities at the power plant; operation time window; and load factor (percentage of time the equipment used within the operation time window).

- Information technology (IT) at different levels of biomass supply chain: identifying types of IT tools, means of communication, and information and data gathering and handling methods at different levels of the PtE value chain.

- System cost: This may include investment costs, biomass buying and selling prices, pruning costs, harvesting and processing costs, storage costs, and transportation costs.

- Sustainability of PtE system: investigating the economic, environmental, and social impacts; constraints; and opportunities that impact the sustainability of the system; as well as using techno-economic analyses.

- Performance improvement: providing recommendations for the improvement of the PtE value chain design and management system.

3. Results and Discussion

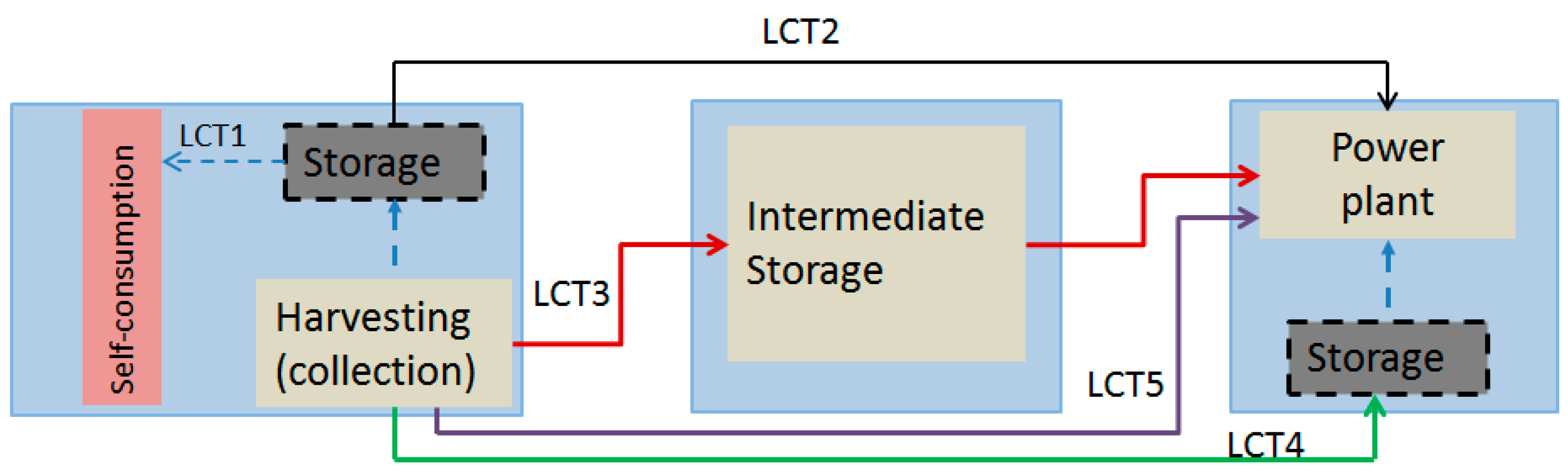

3.1. Logistics Configurations and Major Actors

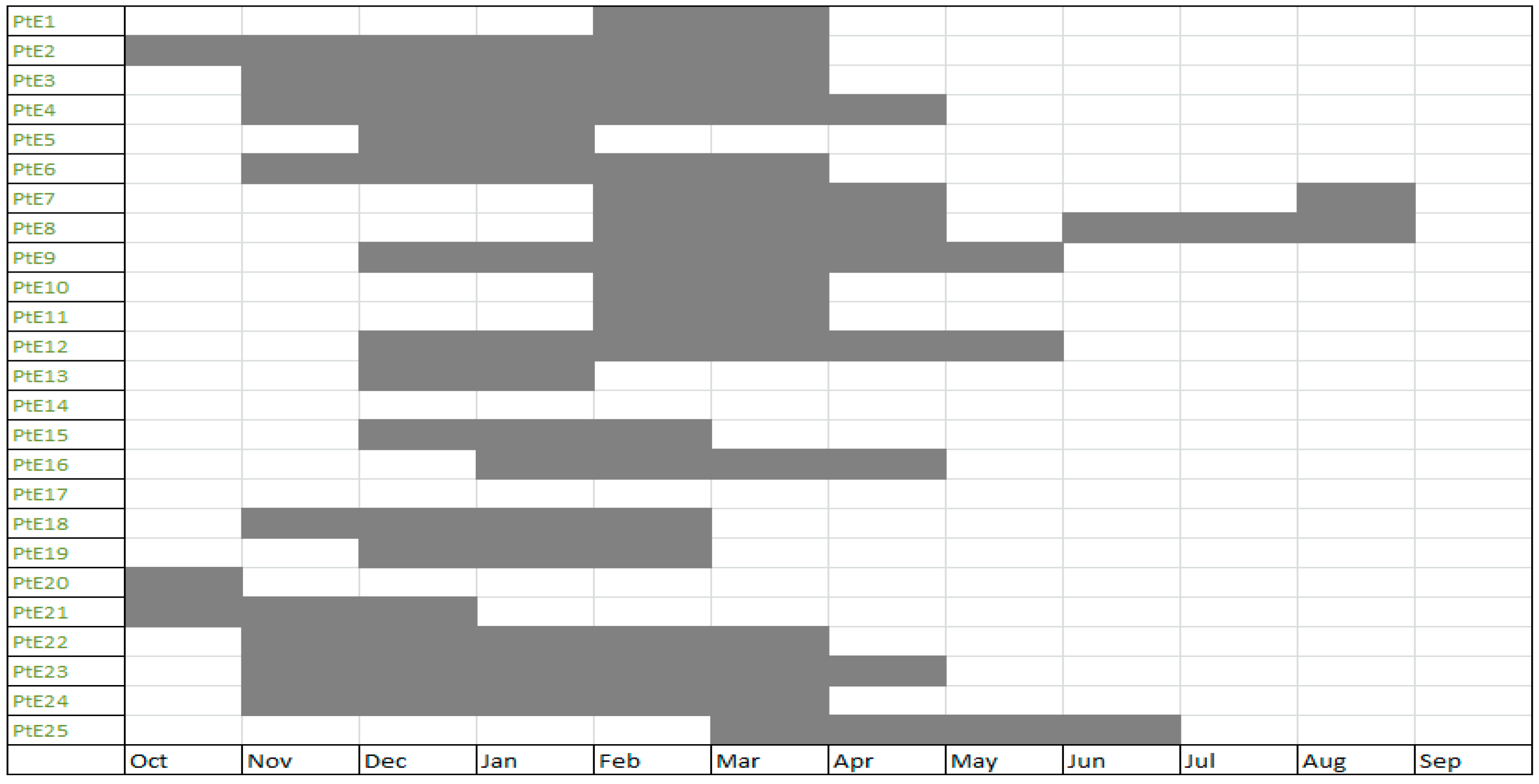

3.2. Pruning Activity and Characteristics

3.3. Pruning Collection/Harvesting

3.4. Storage Characterstics and Activities at Storage Level

3.5. Transport

3.6. Power Plant Characteristics

3.7. Information Flow along PtE Value Chain

3.8. Purchasing and Procurement of Biomass

3.9. System Cost

3.10. Sustainability of PtE System

3.10.1. Biomass Losses along the PtE Chain

3.10.2. Major Constraints and Knowledge Gap Identified along the PtE Value Chain

3.10.3. Benefits of PtE and Opportunities to Promote Sustainability of PtE Initiatives

3.10.4. Interventions Recommended to Increase the Sustainability of PtE Initiatives

- Encouraging the producers by designing competitive and cost effective PtE system that reduces biomass losses, mainly at the collection and storage levels.

- Establishing a PtE initiative in the area where pruning biomass is available, to guarantee the pruning supply.

- Introducing a best system design for the PtE chain (i.e., integrated harvesting/chipping process and supply of chips instead of bales).

- A cooperative approach should be used, including many farmers, local administrators such as municipalities, and relevant companies, which are very important to establish sustainable pruning biomass to energy value chain.

- Creating network of similar PtE value chains and integrating the society as means of cooperation can promote the sustainability of PtE initiatives, where it is economically feasible.

- Involving the consumers at the initial stage of the PtE initiative so that it facilitates the implementation of the PtE initiative.

4. Conclusions

- Biomass losses (at harvesting, storage, and transport) vary from 0.5% to 37% for chips, and 1.20% to 32% for bales.

- Estimated total operational cost (at harvesting, storage, and transport stages) ranges between 27 €/t and 149 €/t (wet base) when supplied in form of bales, and 32 €/t to 123 €/t for the case of chips.

- Pruning biomass selling price varies from 45 €/t to 70 €/t for chips and from 37 €/t to 73 €/t for bales.

- Expected minimum revenue from PtE business ranges between 30 €/t and 80 €/t.

- In order to purchase harvesting machines (baler or chipper) and initiate an attractive PtE value chain, at least about 100 ha of plantation size is recommendable.

Author Contributions

Funding

Conflicts of Interest

References

- Velázquez-Martí, B.; Fernández-González, E.; López-Cortés, I.; Salazar-Hernández, D.M. Quantification of the residual biomass obtained from pruning of vineyards in Mediterranean area. Biomass Bioenergy 2011, 35, 3453–3464. [Google Scholar] [CrossRef]

- Marques, A.; Rasinmäki, J.; Soares, R.; Amorim, P. Planning woody biomass supply in hot systems under variable chips energy content. Biomass Bioenergy 2018, 108, 265–277. [Google Scholar] [CrossRef]

- EUROSTAT. Renewable Energy Statistics. 2016. Available online: http://ec.europa.eu/eurostat/statistics-explained/index.php/Renewable_energy_statistics (accessed on 2 August 2018).

- Iakovou, E.; Karagiannidis, A.; Vlachos, D.; Toka, A.; Malamakis, A. Waste biomass-to-energy supply chain management: A critical synthesis. Waste Manag. 2010, 30, 1860–1870. [Google Scholar] [CrossRef] [PubMed]

- Andersen, R.S.; Towers, W.; Smith, P. Assessing the potential for biomass energy to contribute to Scotland’s renewable energy needs. Biomass Bioenergy 2005, 29, 73–82. [Google Scholar] [CrossRef]

- Efthymios, R.; Remigio, B.; Dionysis, B.; Patrizia, B.; Alessandro, S. A Computational Tool for Comparative Energy Cost Analysis of Multiple-Crop Production Systems. Energies 2017, 10, 831. [Google Scholar] [CrossRef]

- Ciubota-Rosie, C.; Gavrilescu, M.; Macoveanu, M. Biomass—An important renewable source of energy in romania. Environ. Eng. Manag. J. 2008, 7, 559–568. [Google Scholar] [CrossRef]

- Velázquez-Martí, B.; Ferníndez-Gonzílez, E.; López-Cortés, I.; Salazar-Hernández, D.M. Quantification of the residual biomass obtained from pruning of trees in Mediterranean olive groves. Biomass Bioenergy 2011, 35, 3208–3217. [Google Scholar] [CrossRef]

- Esteban, L.S.; Carrasco, J.E. Biomass resources and costs: Assessment in different EU countries. Biomass Bioenergy 2011, 35, S21–S30. [Google Scholar] [CrossRef]

- Frombo, F.; Minciardia, R.; Robbaa, M.; Rossob, F.; Sacilea, R. Planning woody biomass logistics for energy production: A strategic decision model. Biomass Bioenergy 2009, 33, 372–383. [Google Scholar] [CrossRef]

- COFORD. Quality Wood Chips Fuel. 2006. Available online: http://www.coford.ie/media/coford /content/publications/projectreports/cofordconnects/finalfuelquality.pdf (accessed on 2 August 2018).

- SLU. Report on Logistics Chain and Knowledge Gaps of Biomass. EuroPruning Project D5.1. 2016. Available online: http://www.europruning.eu/web/lists/pubfiles.aspx?type =pubdeliverables (accessed on 2 August 2018).

- Dyjakon, A. Harvesting and Baling of Pruned Biomass in Apple Orchards for Energy Production. Energies 2018, 11, 1680. [Google Scholar] [CrossRef]

- Rentizelas, A.A.; Tolis, A.J.; Tatsiopoulos, I.P. Logistics issues of biomass: The storage problem and the multi-biomass supply chain. Renew. Sustain. Energy Rev. 2009, 13, 887–894. [Google Scholar] [CrossRef]

- Pari, L.; Suardi, A.; Santangelo, E.; García-Galindo, D.; Scarfone, A.; Alfano, V. Current and innovative technologies for pruning harvesting: A review. Biomass Bioenergy 2017, 107, 398–410. [Google Scholar] [CrossRef]

- Dyjakona, A.; Boera, J.; García-Galindob, D.; Adamczyk, F.; Lopez, E.; Sebastian, F.; Suardid, A.; Gebresenbete, G.; Jirjise, R.; Bosonae, T.; et al. Orchards pruning to energy—The results of the environmental impact assessment of the new logistic chain developed within the europruning project—Part 2. Agric. Eng. 2018, 22, 37–48. [Google Scholar] [CrossRef]

- Uslu, A.; Faaij, A.P.C.; Bergman, P.C.A. Pre-treatment technologies, and their effect on international bioenergy supply chain logistics. Technoeconomic evaluation of torrefaction, fast pyrolysis and pelletisation. Energy 2008, 33, 1206–1223. [Google Scholar] [CrossRef]

- S2Biom. Review of the Main Logistical Components. Deliverable Report D3.1. 2014. Available online: www.S2Biom.eu (accessed on 1 August 2018).

- SLU. Report on Economic Evaluation of Biomass Supply Chain. EuroPruning Project D8.2. 2016. Available online: http://www.europruning.eu/web/lists/pubfiles.aspx?type=pubdeliverables (accessed on 2 August 2018).

- Alfonso, D.; Perpiñá, C.; Pérez-Navarro, A.; Peñalvo, C.; Vargas, C.; Cárdenas, R. Methodology for optimization of distributed biomass resource evaluation, management and final energy use. Biomass Bioenergy 2009, 33, 1070–1079. [Google Scholar] [CrossRef]

- Wawrzynowicz, J.; Wajszczuk, K. The model of logistics audit for agricultural enterprises. In Proceedings of the Carpathian Logistics Congress, Jesenik, Czech Republic, 7–9 November 2012. [Google Scholar]

- Sekulová, J.; Blinova, E.; Nedeliaková, E.; Majerčák, J. Logistic Audit of a Company; Univerzita Pardubice: Pardubice, Czech Republic, 2014; Volume 2, pp. 67–73. [Google Scholar]

- Bozicnik, S.; Letnik, T.; Stiglic, M. Audit tool for efficient logistics policy. Transport Research Arena-Europe 2012. Procedia-Soc. Res. Behav. Sci. 2012, 48, 2967–2977. [Google Scholar] [CrossRef]

- Distrilogistcs. Logistics Audit. 2013. Available online: http://www.distrilogistics.com/files/2011/09/logistics-audit-2011-website-1.pdf (accessed on 1 October 2013).

- CIRCE. Mapping and Analysis of the Pruning Biomass Potential in Europe. EuroPruning Project D3.1. 2014. Available online: http://www.europruning.eu/web/lists/pubfiles.aspx?type=pubdeliverables (accessed on 2 August 2018).

- Picchi, G.; Spinelli, R. Industrial harvester biomass procurement of olive trees residues. In Proceedings of the 19th Europian Biomass Conference and Exhibition, Berlin, Germany, 6–10 June 2011. [Google Scholar]

- López, F.J.; Pinzi, S.; Ruiz, J.J.; López, A.; Dorado, M.P. Economic viability of the use of olive tree pruning as fuel for heating systems in public institutions in south Spain. Fuel 2010, 89, 1386–1391. [Google Scholar] [CrossRef]

- Spinelli, R.; Picchi, G. Industrial harvesting of olive tree pruning residue for energy biomass. Bioresour. Technol. 2010, 101, 730–735. [Google Scholar] [CrossRef] [PubMed]

- Spinelli, R.; Magagnotti, N.; Nati, C. Harvesting vineyard pruning residues for energy use. Biosyst. Eng. 2010, 105, 316–322. [Google Scholar] [CrossRef]

- Magagnotti, N.; Pari, L.; Picchi, G.; Spinelli, R. Technology alternatives for tapping the pruning residue resource. Bioresour. Technol. 2013, 128, 697–702. [Google Scholar] [CrossRef] [PubMed]

- Ruiz, J.A.; Juarez, M.C.; Morales, M.P.; Munoz, P.; Mendivil, M.A. Biomass logistics: Financial and environmental costs. Case study: 2MW electrical power plants. Biomass Bioenergy 2013, 56, 260–267. [Google Scholar] [CrossRef]

- Bosona, T.; Gebresenbet, G.; Olsson, S. Traceability System for Improved Utilization of Solid Biofuel from Agricultural Prunings. Sustainability 2018, 10, 258. [Google Scholar] [CrossRef]

- Perpiñá, C.; Alfonso, D.; Pérez-Navarro, A.; Peñalvo, E.; Vargas, C.; Cárdenas, R. Methodology based on Geographic Information Systems for biomass logistics and transport optimisation. Renew. Energy 2009, 34, 555–565. [Google Scholar] [CrossRef]

- Stanley, E.; Fawcett, S.E.; Cooper, M.B. Logistics Performance Measurement and Customer Success. Ind. Mark. Manag. 1998, 27, 341–357. [Google Scholar] [CrossRef]

| Distinctive Characteristics That Affect the Biomass Supply Chain Management Performance | Major Impacts on the Biomass-to-Energy System |

|---|---|

| Multiple biomass suppliers | It increases the complexity of the system and the difficulty in biomass procurement |

| Seasonality problem | It increases the storage volume, storing time, and inventory costs |

| Perishability of some (or all) biomass to be supplied | It constrains the transportation lead time and length of storage time |

| Low energy density per unit mass (for most forms of biomass) compared to fossil fuels | It increases the logistics (handling, storage, and transportation) cost per unit of energy to be generated |

| Dependency of demand of produced energy on type of biomass-to-energy conversion plants and/or price of fuel substitutes | A robust and flexible supply chain is required for the system |

| Supply and demand uncertainty | It makes the decision making process more complex; it could interrupt the supply of biomass |

| Dispersed geographical distribution of biomass | It requires biomass identification and selection processes |

| Logistics Configuration Type (LCT) | PtE Value Chain | ||

|---|---|---|---|

| Number | % | ||

| LCT1 | Self-consumption (with or without storage), no significant transport | 4 | 16 |

| LCT2 | On-farm storage, then direct delivery to final user | 6 | 24 |

| LCT3 | Intermediate Storage | 9 | 36 |

| LCT4 | Direct delivery and storage at final user | 3 | 12 |

| LCT5 | No-storage but direct delivery | 3 | 12 |

| Total | 25 | 100 | |

| PtE | LCT | Majors Actors | Logistics Activities |

|---|---|---|---|

| PtE1 | LCT3 | Farmers, trader (transporter), and end user | Pruning is collected manually, chipped on farm, and transported to end user. |

| PtE2 | LCT2 | Farmer, service provider, subcontractor, consumer | Pruning is collected, stored, and chipped at the side of the field (by subcontractor), and transported to the end user. |

| PtE3 | LCT4 | Farmer | Pruning is processed into bales and transported to storage for own consumption. |

| PtE4 | LCT3 | Farmer and a company owning pelletizing truck. | Pruning is processed into bales and transported to off-farm storage where it will be processed into pellets. |

| PtE5 | LCT3 | farmer | Pruning is processed into bales and transported to storage for own consumption. |

| PtE6 | LCT1 | Farmer | Pruning is harvested (chipped) and stored for own consumption by the actor. |

| PtE7 | LCT1 | Farmers | Pruning is collected, stored on-farm, and chipped for own consumption for heating. |

| PtE8 | LCT2 | Farmer (main actor) and consumer | Pruning is processed into bales, stored at farm, and transported to final consumer. |

| PtE9 | LCT3 | Farmers, trader with transport, and end users | Pruning is manually windrowed and harvested (chipped) with machine, stored at off-farm storage, and transported to end user for power generation. |

| PtE10 | LCT4 | Farmers, pellet manufacturing plant, and final consumers (multiple) | Pruning is collected, stored, shredded at on-farm storage, and transported to where it will be processed into pellets. |

| PtE11 | LCT3 | Farmers, trader with transport, storage, and final consumer | Pruning is windrowed, raked and stacked manually, transported to off-farm storage where it is screened and chipped to be used for pellet production. |

| PtE12 | LCT2 | Farmers, trader with transport, and final consumer | Pruning is windrowed (by farmers), harvested (integrated harvesting/pre-shredding (by trader)); and completely shredded on-site and transported to power plant for electricity generation. |

| PtE13 | LCT2 | Trader, farmer, reseller, and final consumer | Raking of pruning is done using tractor with fork; pruning is piled, stored, and chipped (at on-farm storage site) with forestry chipper, and transported to the final consumer. |

| PtE14 | LCT2 | Farmers, service company (with transport), processing plant, intermediary, and final consumers | Pruning is collected, stored at side of farm and transported (bulk branches) to the pellets producing plant which produces pellets and distribute to the final consumers. |

| PtE15 | LCT3 | Farmers, service company/trader, and final consumers | Pruning is collected (picking and chipping), stored at off-farm storage, and transported to the final consumer to be used for heating purposes. |

| PtE16 | LCT1 | Farmer | Pruning is collected and shredded using own machine and the chips are used for heating purposes (own consumption). |

| PtE17 | LCT5 | Farmers, trader with transport, and end consumer | Pruning is collected in an integrated windrowing/chipping system, and the chips are transported to the end users with heating plants. |

| PtE18 | LCT5 | Farmers, cooperative, transport company, and final consumer | Pruning is collected in an integrated windrowing/chipping system, and the chips are transported to the end users for production of thermal energy. |

| PtE19 | LCT5 | Farmers, cooperative, trader with transport, and final consumers | Pruning is collected in an integrated windrowing/baling system, and the bales are transported to the end users with boilers that can consume (burn) pruning bales. |

| PtE20 | LCT4 | Farmers | Pruning is collected manually and chipped with a machine, partly used for own consumption, and the rest is transported to the end user (plant nursery) to be stored and used. |

| PtE21 | LCT3 | Farmers, service company (trader), and final consumer | Pruning is windrowed and harvested in the form of bales (integrated system), stored and shredded at off-farm site, and transported to end users to produce heat and power. |

| PtE22 | LCT1 | Farmer | Pruning is harvested (chipped) and stored on-site for own consumption by the actor. |

| PtE23 | LCT3 | Farmer, fruit cooperative, trader (with transport), and final consumer | Pruning collected, shredded, stored at off-farm storage, and transported to the end user in the form of chips. |

| PtE24 | LCT3 | Farmer, cooperative, trader, and final consumer | Pruning collected, shredded, stored at off-farm storage, and transported to the end user. |

| PtE25 | LCT2 | Fruit cooperative, traders, and final consumers | Pruning is collected, stored on site by fruit cooperative, chipped on site, and transported to the end user for heat and power generation. |

| Description | Farm-to-Storage (km) | Storage-to-Consumer (km) | Farm-to-Consumer (km) |

|---|---|---|---|

| Data survey for 16 existing chains | 15 | 28 | 43 |

| Data survey for all 25 chains | 14 | 116 | 130 |

| Project demonstration activity in Spain | 317 | 362 | 679 |

| Project demonstration activity in Germany | 48 | 123 | 171 |

| PtE Value Chain | Logistics Configuration | Country | Species | Operational Cost (Harvesting, Storage, Transport) | Minimum Expected Revenue from PtE | Selling Price (Related Product Type in Next Column) | Product Type (Related to Indicated Selling Price) | Affordable Energy Price (% More Than Fossil Energy) |

|---|---|---|---|---|---|---|---|---|

| €/t | €/t | €/t | ||||||

| PtE1 | LCT3 | Germany | Apple, cherry, pear, and plum with age of 50 years. | 53 | na | 60 | chips | na |

| PtE2 | LCT2 | Germany | Apple and pear trees of 50–60 years age | 95 | 62 | 63 | chips | na |

| PtE3 | LCT4 | France | Grape (merlot 95%, cabernets francs 3%, and cabernets sauvignons 2%) | 27 | na | na | na | |

| PtE4 | LCT3 | France | Grapes for wine from tree; age 4–35 years. | 51 | na | na | na | |

| PtE5 | LCT3 | Italy | Grapes from vineyards | 114 | 50 | 70 | chips | na |

| PtE6 | LCT1 | Italy | Vines, apricot, and olive trees, age 4–20 years | 40 | na | na | na | |

| PtE7 | LCT1 | Poland | Apple, pear, peach, cherries, and nuts; age 1–25 years | 101 | na | na | na | |

| PtE8 | LCT2 | Poland | Apples of 1–20 years old | 44 | 75 | 73 | bale | 15 |

| PtE9 | LCT3 | Spain | Olive trees of 100 years | 55 | 80 | 55 | chips | 10 |

| PtE10 | LCT4 | Spain | Olive of 70 years | 54 | 50 | na | chips | 10 |

| PtE11 | LCT3 | Spain | Cherry, almond, carob, olive, vineyard, orange, and lemon tree | 76 | na | na | 25 | |

| PtE12 | LCT2 | Spain | Olive trees | 32 | na | 37 | branch | 5 |

| PtE13 | LCT2 | Spain | Olive tree | 46 | na | 45 * | chips | 20 |

| PtE14 | LCT2 | Spain | Vineyards | 26 | na | 65 | chips | na |

| PtE15 | LCT3 | Spain | Vineyards with age 2 to 30 year | 102 | 50 | 70 | chips | 10 |

| PtE16 | LCT1 | Denmark | Apple, pears, and plums of 12–14 years old | 44 | na | na | 15 | |

| PtE17 | LCT5 | Germany | Apple, 15–20; cherry, 30–40; plum, 20–25; and peach, 15–20 years old | 73 | na | 70 | na | |

| PtE18 | LCT5 | Spain | Almond of 30 years old | 123 | na | 70 | almond shells | 5 |

| PtE19 | LCT5 | Spain | Vineyard of 5–15 years age | 149 | na | 60 | straw bale | |

| PtE20 | LCT4 | Spain | 10 years old peach and 1 year old almond | 56 | 30 | 58 | chips | na |

| PtE21 | LCT3 | Spain | Peach of 8–12 years | 80 | na | 58 | chips | na |

| PtE22 | LCT1 | France | Grapes for wine | 44 | na | na | na | |

| PtE23 | LCT3 | France | Vineyard of 20 (years). | 152 | na | na | 10 | |

| PtE24 | LCT3 | France | Vineyard of 20 years old (40 years of typical renovation age). | 68 | na | na | 15 | |

| PtE25 | LCT2 | Poland | Apple of 35–40 years old | 31 | 70 | 70 ** | chips | 15 |

| Average Losses | Chips (%), Range | Bale (%), Range |

|---|---|---|

| Harvesting | 9.22 (0.2–27.0) | 9.42 (1.0–22.00) |

| Storage | 6.7 (0.3–15.0) | 2.84 (0.2–10.00) |

| Total chain | 12.39 (0.50–37) | 15.45 (1.20–32.00) |

| Stage Along Chain | Major Constraints | Proposed Action Measures |

|---|---|---|

| Entire PtE chain |

|

|

| Harvesting |

|

|

| Storage |

|

|

| Transport |

|

|

| End user |

|

|

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bosona, T.; Gebresenbet, G. Evaluating Logistics Performances of Agricultural Prunings for Energy Production: A Logistics Audit Analysis Approach. Logistics 2018, 2, 19. https://doi.org/10.3390/logistics2030019

Bosona T, Gebresenbet G. Evaluating Logistics Performances of Agricultural Prunings for Energy Production: A Logistics Audit Analysis Approach. Logistics. 2018; 2(3):19. https://doi.org/10.3390/logistics2030019

Chicago/Turabian StyleBosona, Techane, and Girma Gebresenbet. 2018. "Evaluating Logistics Performances of Agricultural Prunings for Energy Production: A Logistics Audit Analysis Approach" Logistics 2, no. 3: 19. https://doi.org/10.3390/logistics2030019

APA StyleBosona, T., & Gebresenbet, G. (2018). Evaluating Logistics Performances of Agricultural Prunings for Energy Production: A Logistics Audit Analysis Approach. Logistics, 2(3), 19. https://doi.org/10.3390/logistics2030019