Use of a Polyetheretherketone Clasp Retainer for Removable Partial Denture: A Case Report

Abstract

1. Introduction

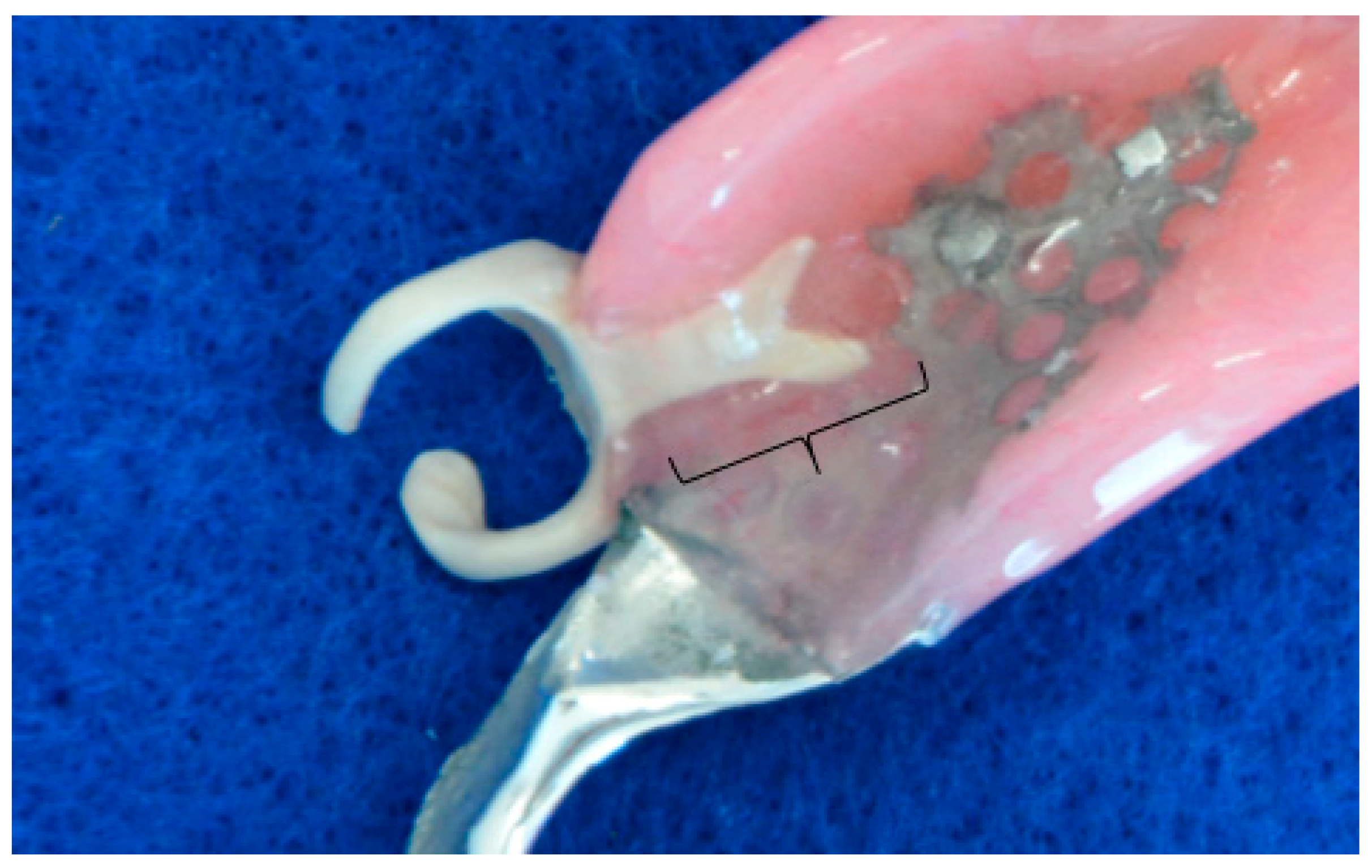

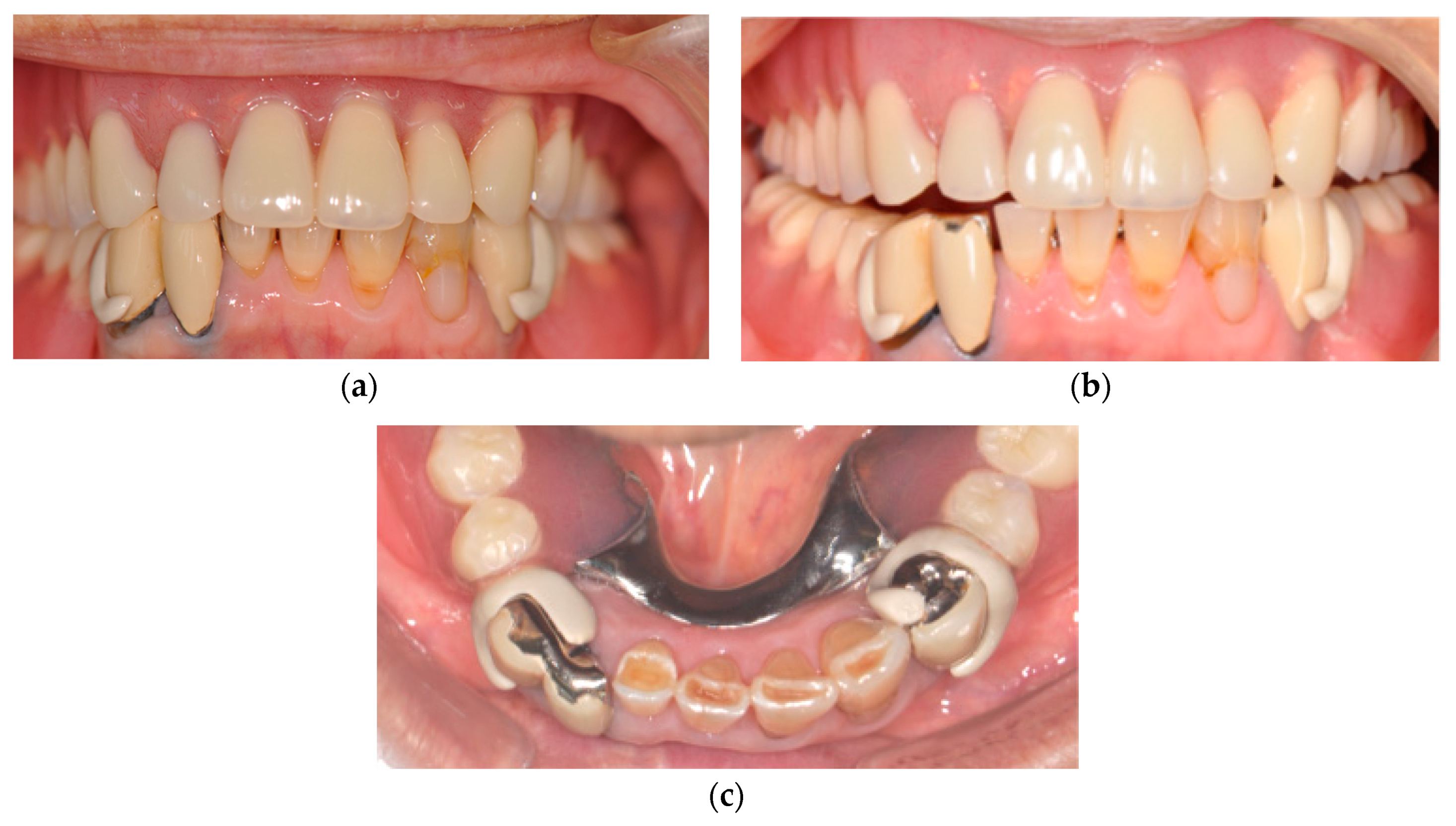

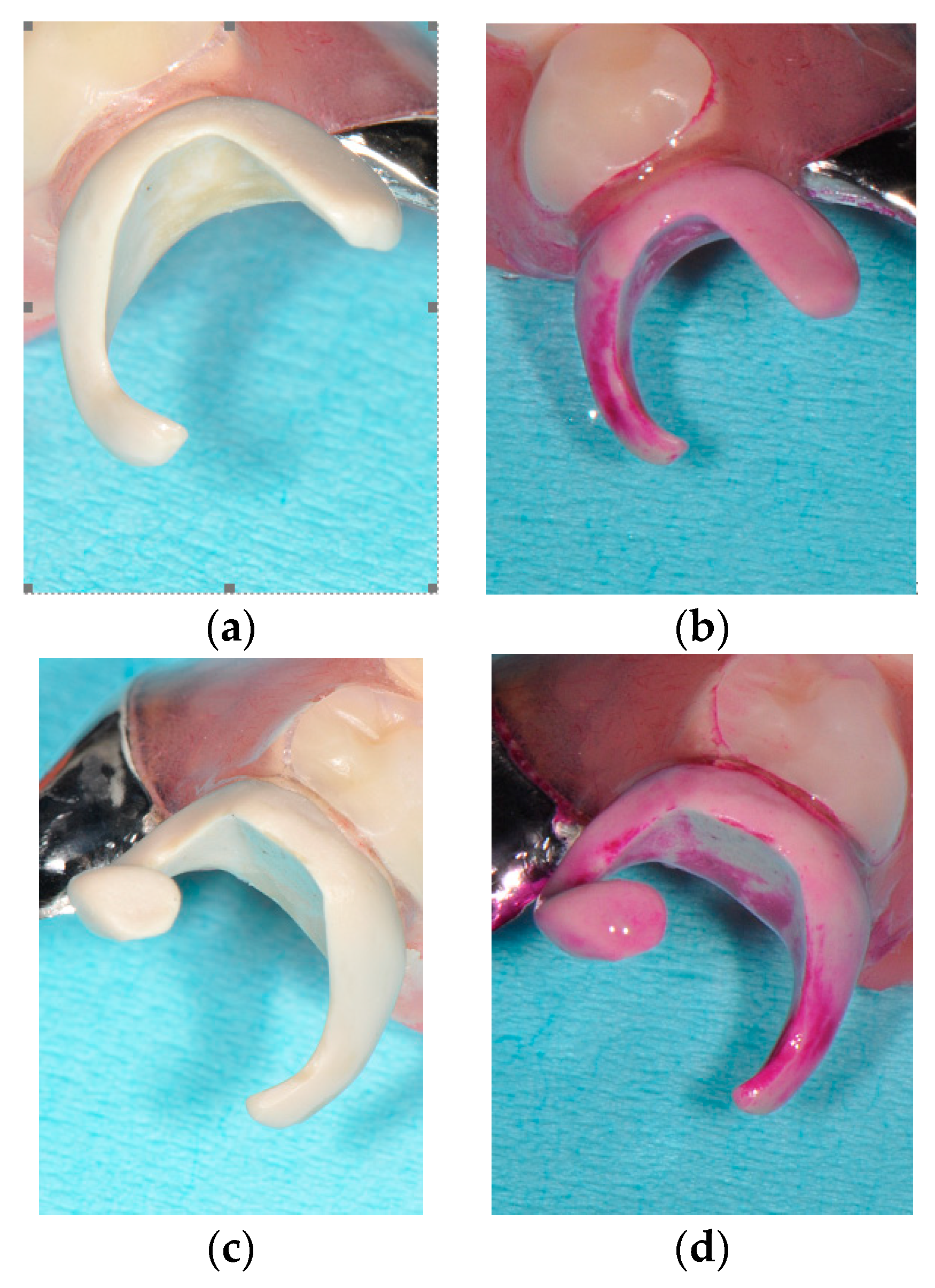

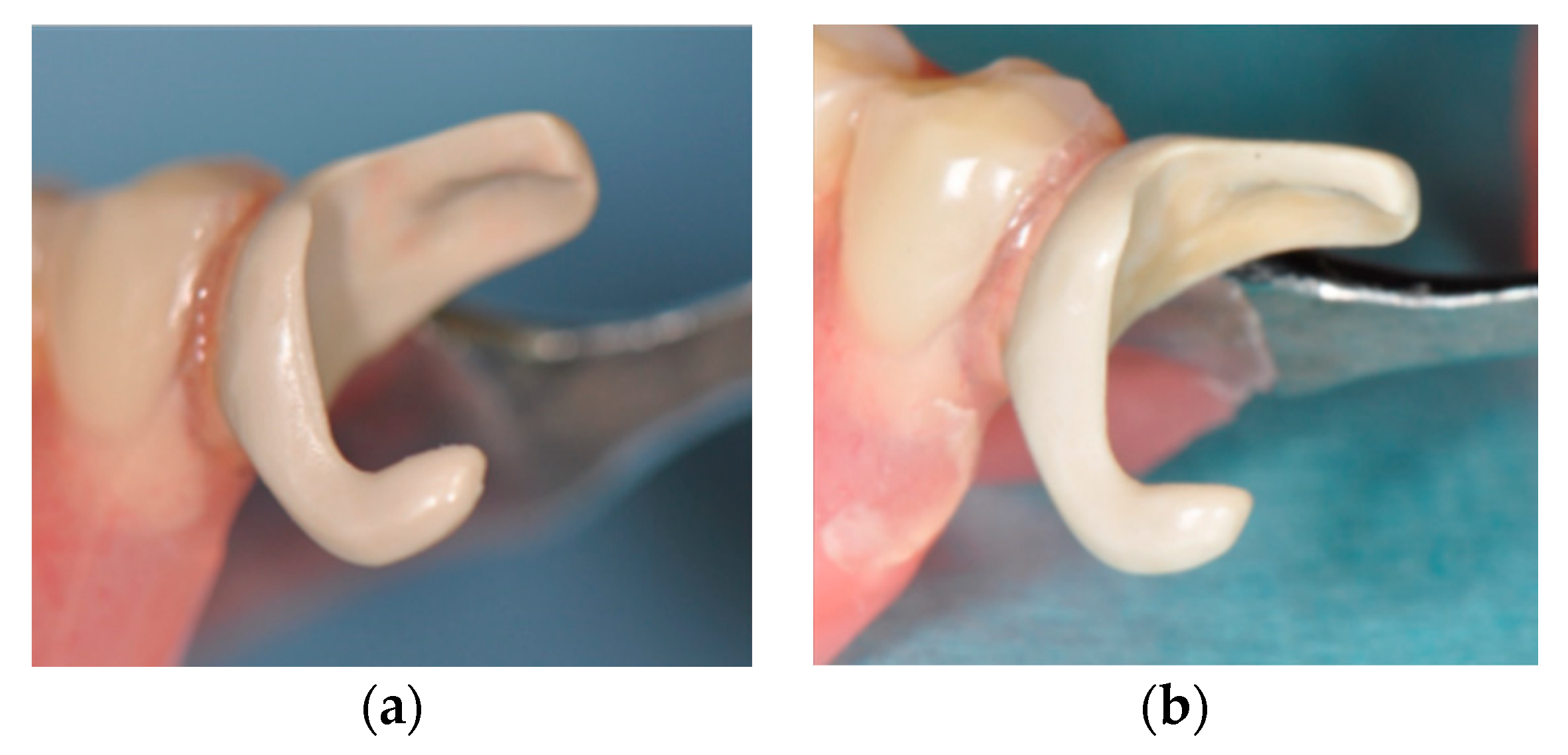

2. Case Presentation

3. Discussion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Faurschou, A.; Menné, T.; Johansen, J.D.; Thyssen, J.P. Metal allergen of the 21st century—A review on exposure, epidemiology and clinical manifestations of palladium allergy of palladium allergy. Contact Dermat. 2011, 64, 185–195. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Cai, H.; Suo, L.; Xue, Y.; Wang, J.; Wan, Q. A systematic review of the survival and complication rates of inlay-retained fixed dental prostheses. J. Dent. 2017, 59, 2–10. [Google Scholar] [CrossRef] [PubMed]

- Fueki, K.; Ohkubo, C.; Yatabe, M.; Arakawa, I.; Arita, M.; Ino, S.; Kanamori, T.; Kawai, Y.; Kawara, M.; Komiyama, O.; et al. Clinical application of removable partial dentures using thermoplastic resin-part I: Definition and indication of non-metal clasp dentures. J. Prosthodont. Res. 2014, 58, 3–10. [Google Scholar] [CrossRef] [PubMed]

- Fueki, K.; Ohkubo, C.; Yatabe, M.; Arakawa, I.; Arita, M.; Ino, S.; Kanamori, T.; Kawai, Y.; Kawara, M.; Komiyama, O.; et al. Clinical application of removable partial dentures using thermoplastic resin. Part II: Material properties and clinical features of non-metal clasp dentures. J. Prosthodont. Res. 2014, 58, 71–84. [Google Scholar] [CrossRef] [PubMed]

- Taguchi, Y.; Shimamura, I.; Sakurai, K. Effect of buccal part designs of polyamide resin partial removable dental prosthesis on retentive force. J. Prosthodont. Res. 2011, 55, 44–47. [Google Scholar] [CrossRef] [PubMed]

- Zoidis, P.; Papathanasiou, I.; Polyzois, G. The Use of a Modified Poly-Ether-Ether-Ketone (PEEK) as an Alternative Framework Material for Removable Dental Prostheses. A Clinical Report. J. Prosthodont. 2016, 25, 580–584. [Google Scholar] [CrossRef] [PubMed]

- Stock, V.; Schmidlin, P.R.; Merk, S.; Wagner, C.; Roos, M.; Eichberger, M.; Stawarczyk, B. PEEK Primary Crowns with Cobalt-Chromium, Zirconia and Galvanic Secondary Crowns with Different Tapers—A Comparison of Retention Forces. Materials 2016, 9, 187. [Google Scholar] [CrossRef] [PubMed]

- Najeeb, S.; Zafar, M.S.; Khurshid, Z.; Siddiqui, F. Applications of polyetheretherketone (PEEK) in oral implantology and prosthodontics. J. Prosthodont. Res. 2016, 60, 12–19. [Google Scholar] [CrossRef] [PubMed]

- Rahmitasari, F.; Ishida, Y.; Kurahashi, K.; Matsuda, T.; Watanabe, M.; Ichikawa, T. PEEK with Reinforced Materials and Modifications for Dental Implant Applications. Dent. J. 2017, 5, 35. [Google Scholar] [CrossRef] [PubMed]

- Hahnel, S.; Wieser, A.; Lang, R.; Rosentritt, M. Biofilm formation on the surface of modern implant abutment materials. Clin. Oral Implants Res. 2015, 26, 1297–1301. [Google Scholar] [CrossRef] [PubMed]

- Beyli, M.S.; von Fraunhofer, J.A. An analysis of causes of fracture of acrylic resin dentures. J. Prosthet. Dent. 1981, 46, 238–241. [Google Scholar] [CrossRef]

- Silthampitag, P.; Chaijareenont, P.; Tattakorn, K.; Banjongprasert, C.; Takahashi, H.; Arksornnukit, M. Effect of surface pretreatments on resin composite bonding to PEEK. Dent. Mater. J. 2016, 35, 668–674. [Google Scholar] [CrossRef] [PubMed]

- Ogasawara, T.; Tsuda, T.; Takeda, N. Stress-strain behavior of multi-walled carbon nanotube/PEEK composites. Compos. Sci. Technol. 2011, 71, 73–78. [Google Scholar] [CrossRef]

- Young, F.A.; Williams, K.R.; Draughn, R.; Strohaver, R. Design of prosthetic cantilever bridgework supported by osseointegrated implants using the finite element method. Dent. Mater. 1998, 14, 37–43. [Google Scholar] [CrossRef]

- Morris, H.F.; Asgar, K.; Brudvik, J.S.; Winkler, S.; Roberts, E.P. Stress-relaxation testing. Part IV: Clasp pattern dimensions and their influence on clasp behavior. J. Prosthet. Dent. 1983, 50, 319–326. [Google Scholar] [PubMed]

- Chrystie, J.A. Principles of clasp retention: A review. Aust. Dent. J. 1988, 33, 96–100. [Google Scholar] [CrossRef] [PubMed]

- Osada, H.; Shimpo, H.; Hayakawa, T.; Ohkubo, C. Influence of thickness and undercut of thermoplastic resin clasps on retentive force. Dent. Mater. J. 2013, 32, 381–389. [Google Scholar] [CrossRef] [PubMed]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ichikawa, T.; Kurahashi, K.; Liu, L.; Matsuda, T.; Ishida, Y. Use of a Polyetheretherketone Clasp Retainer for Removable Partial Denture: A Case Report. Dent. J. 2019, 7, 4. https://doi.org/10.3390/dj7010004

Ichikawa T, Kurahashi K, Liu L, Matsuda T, Ishida Y. Use of a Polyetheretherketone Clasp Retainer for Removable Partial Denture: A Case Report. Dentistry Journal. 2019; 7(1):4. https://doi.org/10.3390/dj7010004

Chicago/Turabian StyleIchikawa, Tetsuo, Kosuke Kurahashi, Lipei Liu, Takashi Matsuda, and Yuichi Ishida. 2019. "Use of a Polyetheretherketone Clasp Retainer for Removable Partial Denture: A Case Report" Dentistry Journal 7, no. 1: 4. https://doi.org/10.3390/dj7010004

APA StyleIchikawa, T., Kurahashi, K., Liu, L., Matsuda, T., & Ishida, Y. (2019). Use of a Polyetheretherketone Clasp Retainer for Removable Partial Denture: A Case Report. Dentistry Journal, 7(1), 4. https://doi.org/10.3390/dj7010004