Bonding Effectiveness of Veneering Ceramic to Zirconia after Different Grit-Blasting Treatments

Abstract

1. Introduction

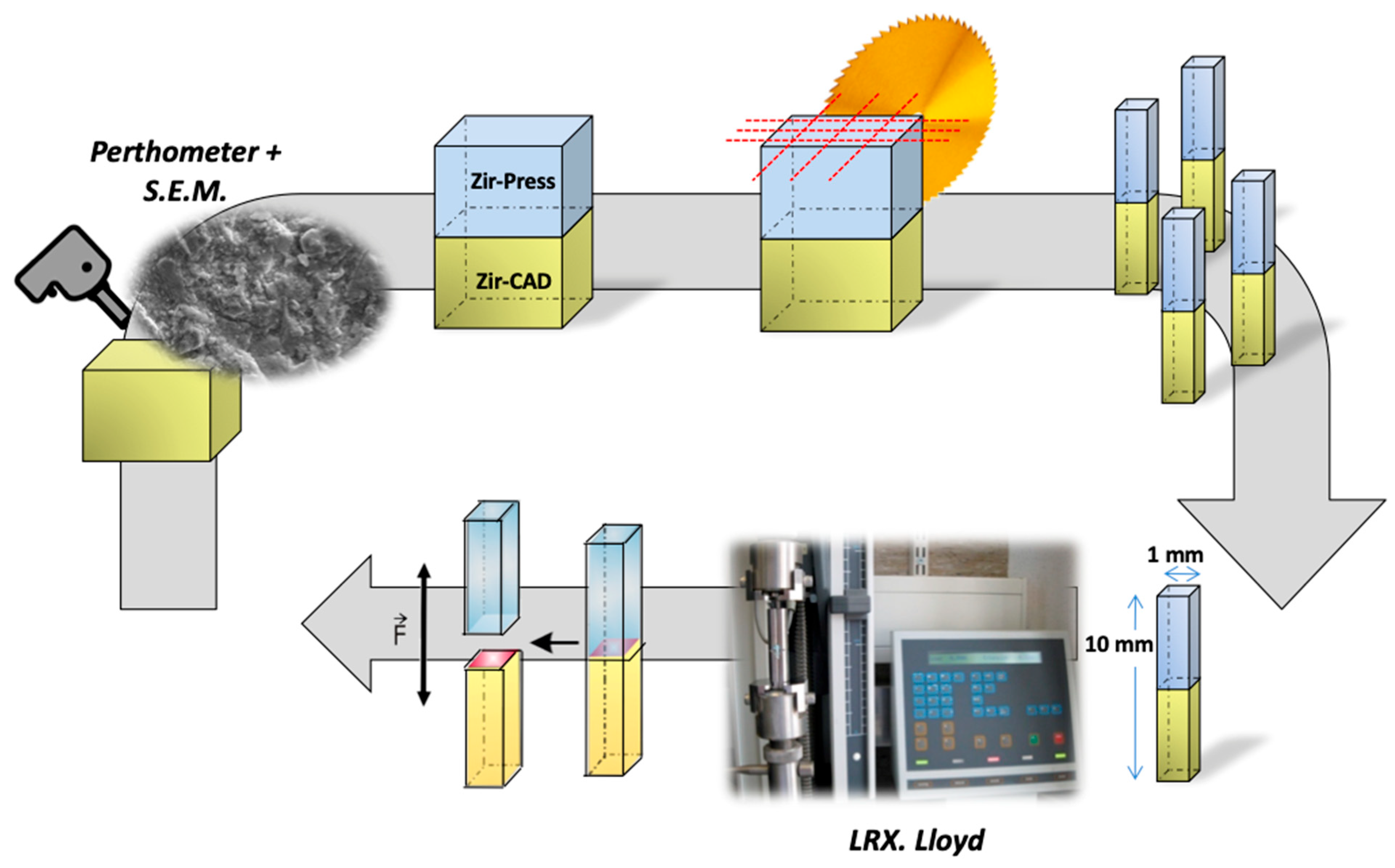

2. Materials and Methods

2.1. Specimen Preparation

2.1.1. Surface Treatment

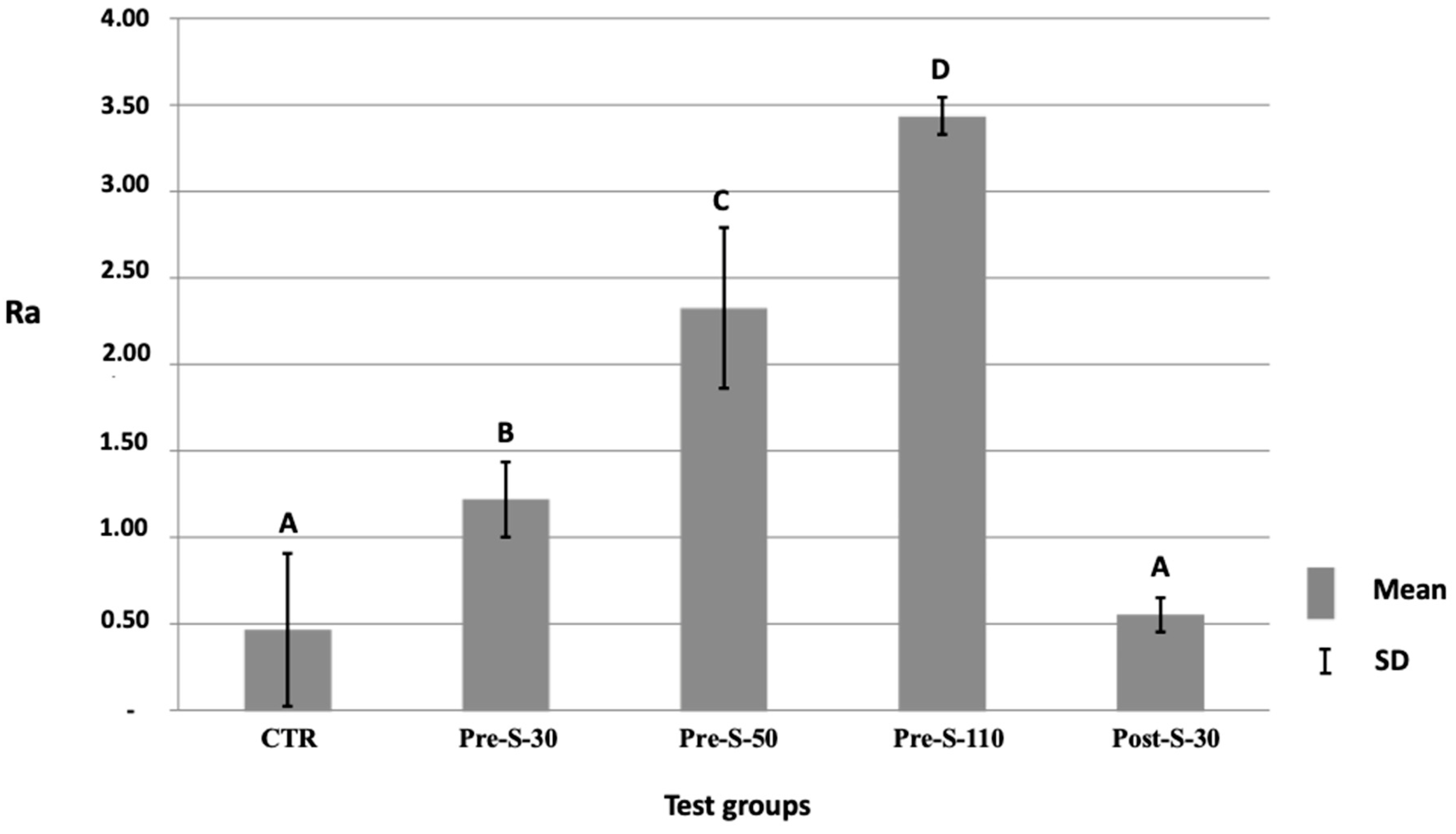

2.1.2. Surface-Roughness Evaluation

2.1.3. Over-Pressing Technique

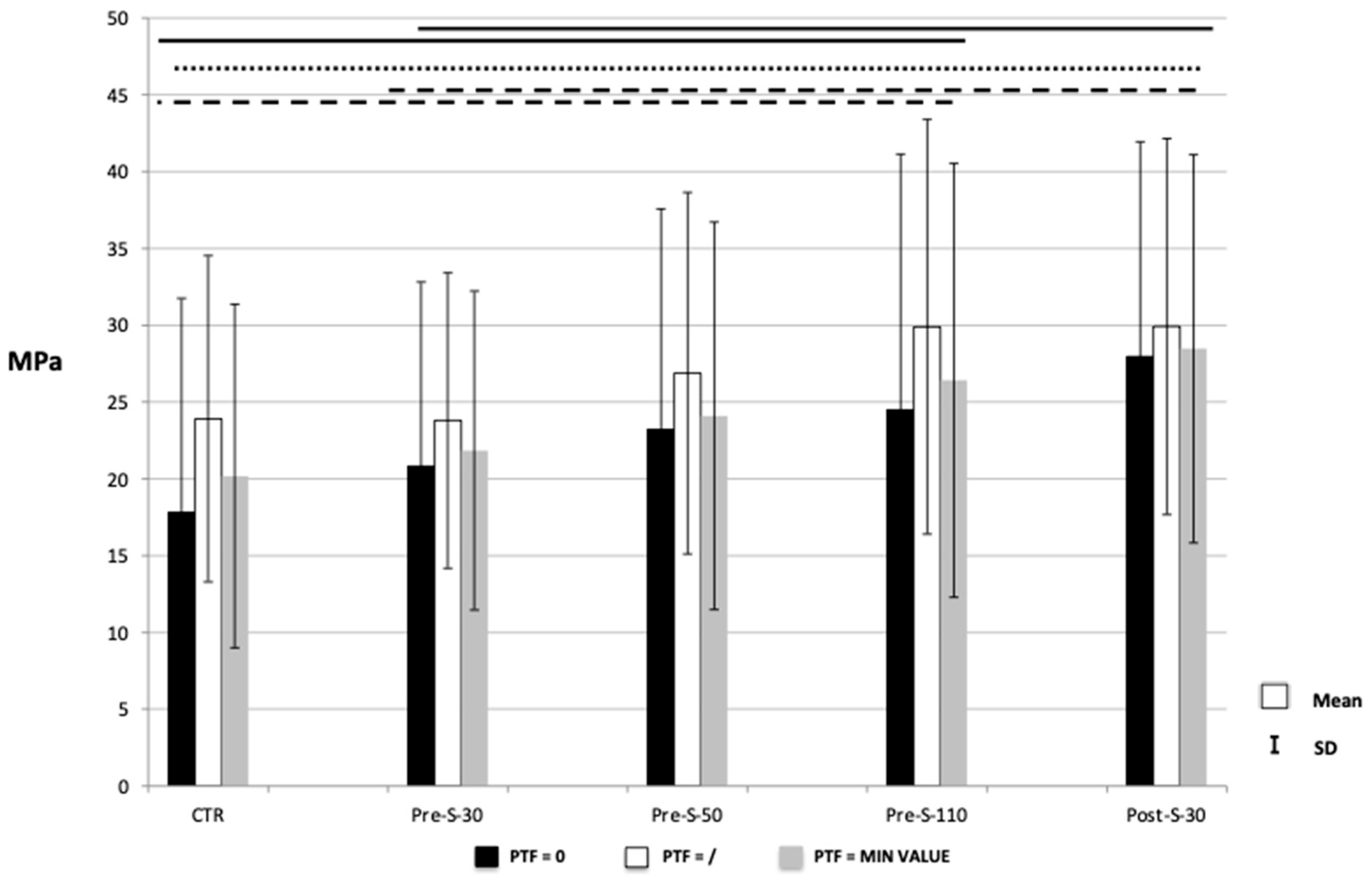

2.2. Micro-Tensile Bond-Strength Test

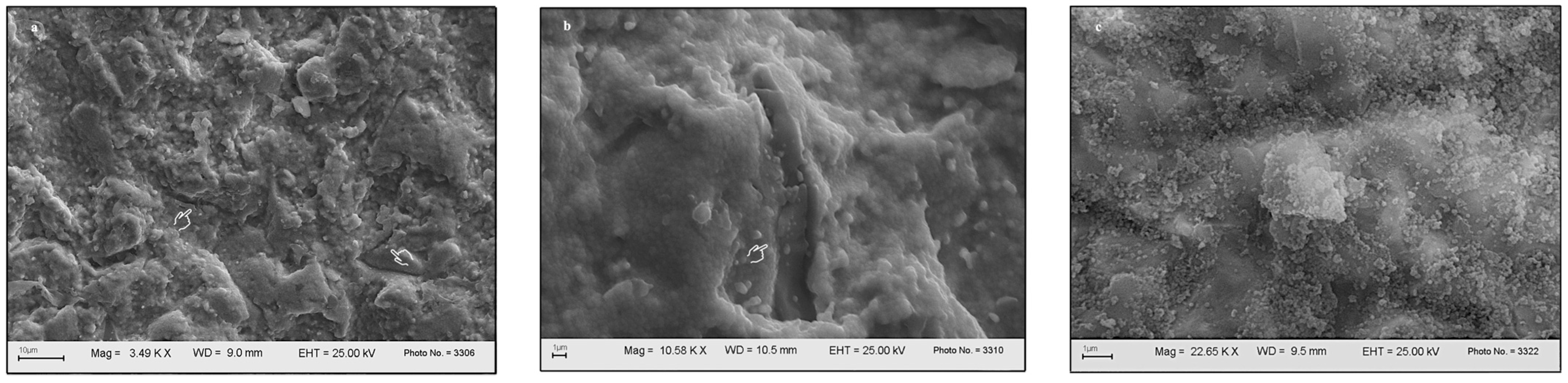

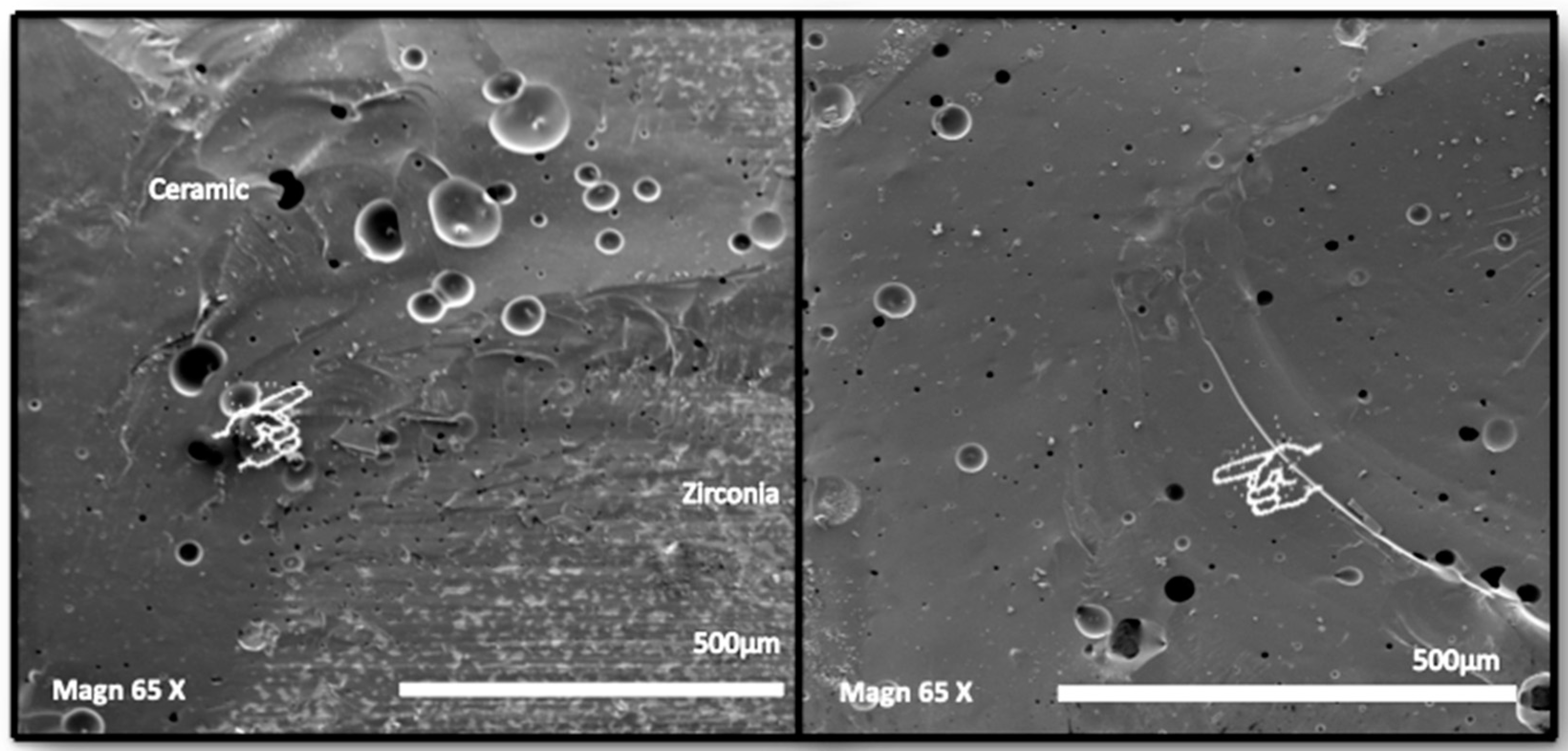

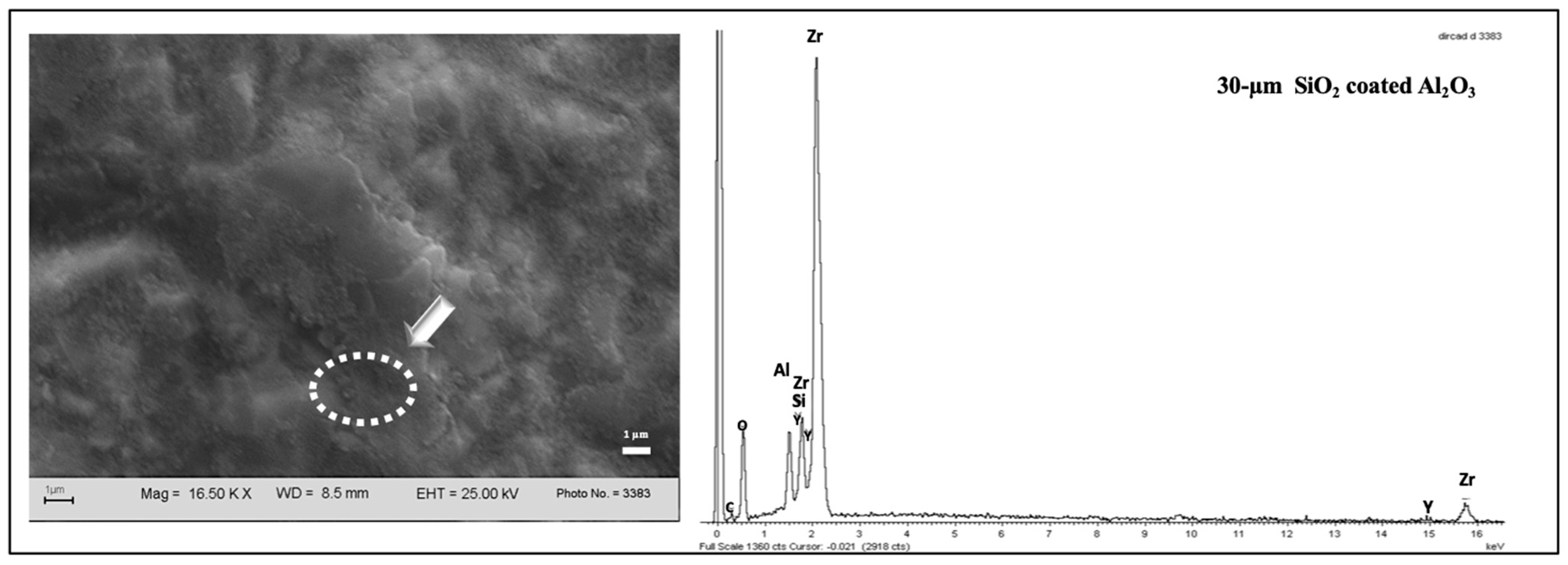

2.3. Microstructural Analysis by Stereomicroscopy and Scanning Electron Microscopy

2.4. Statistical Analysis

3. Results

4. Discussion

5. Conclusions

- A trend of increased surface roughness proportional to the size of the airborne particles employed was observed when grit-blasting was carried out before sintering.

- Grit-blasting with silica-coated alumina particles after sintering may improve the micro-tensile bond strength of veneering ceramic to zirconia.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Laumbacher, H.; Strasser, T.; Knüttel, H.; Rosentritt, M. Long-term clinical performance and complications of zirconia-based tooth- and implant-supported fixed prosthodontic restorations: A summary of systematic reviews. J. Dent. 2021, 111, 103723. [Google Scholar] [CrossRef] [PubMed]

- Pjetursson, B.E.; Sailer, I.; Merino-Higuera, E.; Spies, B.C.; Burkhardt, F.; Karasan, D. Systematic review evaluating the influence of the prosthetic material and prosthetic design on the clinical outcomes of implant-supported multi-unit fixed dental prosthesis in the posterior area. Clin. Oral Implants Res. 2023, 34, 86–103. [Google Scholar] [CrossRef] [PubMed]

- Pjetursson, B.E.; Valente, N.A.; Strasding, M.; Zwahlen, M.; Liu, S.; Sailer, I. A systematic review of the survival and complication rates of zirconia-ceramic and metal-ceramic single crowns. Clin. Oral Implants Res. 2018, 29, 199–214. [Google Scholar] [CrossRef] [PubMed]

- Prause, E.; Hey, J.; Sterzenbach, G.; Beuer, F.; Adali, U. Survival and success of veneered zirconia crowns. Int. J. Comput. Dent. 2023, 26, 247–255. [Google Scholar] [PubMed]

- Aboushelib, M.N.; De Jager, N.; Kleverlaan, C.J.; Feilzer, A.J. Microtensile bond strength of different components of core veneered all-ceramic restorations. Dent. Mater. 2005, 21, 984–991. [Google Scholar] [CrossRef] [PubMed]

- Heintze, S.D.; Rousson, V. Survival of zirconia and metal supported fixed dental prostheses: A systematic review. Int. J. Prosthod. 2010, 23, 493–502. [Google Scholar]

- Sailer, I.; Pjetursson, B.E.; Zwahlen, M.; Hämmerle, C.H. A systematic review of the survival and complication rates of all-ceramic and metal-ceramic reconstructions after an observation period of at least 3 years: Part II: Fixed dental prostheses. Clin. Oral Implants Res. 2007, 183, 86–96. [Google Scholar] [CrossRef] [PubMed]

- Soleimani, F.; Jalali, H.; Mostafavi, A.S.; Zeighami, S.; Memarian, M. Retention and clinical performance of zirconia crowns: A comprehensive review. Int. J. Dent. 2020, 15, 8846534. [Google Scholar] [CrossRef] [PubMed]

- Mühlemann, S.; Benic, G.I.; Fehmer, V.; Hämmerle, C.H.F.; Sailer, I. Clinical quality and efficiency of monolithic glass ceramic crowns in the posterior area: Digital compared with conventional workflows. Int. J. Comput. Dent. 2018, 21, 215–223. [Google Scholar] [PubMed]

- Aboushelib, M.N.; Kleverlaan, C.J.; Feilzer, A.J. Microtensile bond strength of different components of core veneered all-ceramic restorations. Part 3: Double veneer technique. J. Prosthodont. 2008, 17, 9–13. [Google Scholar] [CrossRef] [PubMed]

- Poggio, C.E.; Ercoli, C.; Rispoli, L.; Maiorana, C.; Esposito, M. Metal-free materials for fixed prosthodontic restorations. Cochrane Database Syst. Rev. 2017, 12, CD009606. [Google Scholar] [CrossRef] [PubMed]

- Koenig, V.; Vanheusden, A.J.; Le Goff, S.O.; Mainjot, A.K. Clinical risk factors related to failures with zirconia-based restorations: An up to 9-year retrospective study. J. Dent. 2013, 41, 1164–1174. [Google Scholar] [CrossRef] [PubMed]

- Isgrò, G.; Pallav, P.; Van der Zel, J.M.; Feilzer, A.J. The influence of the veneering porcelain and difference surface treatments on the biaxial flexural strength of a heat-pressed ceramic. J. Prosthet. Dent. 2003, 90, 465–473. [Google Scholar] [CrossRef] [PubMed]

- Sailer, I.; Makarov, N.A.; Thoma, D.S.; Zwahlen, M.; Pjetursson, B.E. All-ceramic or metal-ceramic tooth-supported fixed dental prostheses (FDPs)? A systematic review of the survival and complication rates. Part I: Single crowns (SCs). Dent. Mater. 2015, 31, 603–623. [Google Scholar] [CrossRef] [PubMed]

- Pjetursson, B.E.; Sailer, I.; Makarov, N.A.; Zwahlen, M.; Thoma, D.S. All-ceramic or metal-ceramic tooth-supported fixed dental prostheses (FDPs)? A systematic review of the survival and complication rates. Part II: Multiple-unit FDPs. Dent. Mater. 2015, 31, 624–639. [Google Scholar] [CrossRef] [PubMed]

- Swain, M.V. Unstable cracking (chipping) of veneering porcelain on all-ceramic dental crowns and fixed partial dentures. Acta Biomater. 2009, 5, 1668–1677. [Google Scholar] [CrossRef]

- D’Souza, N.L.; Jutlah, E.M.; Deshpande, R.A.; Somogyi-Ganss, E. Comparison of clinical outcomes between single metal-ceramic and zirconia crowns. J. Prosthet. Dent. 2024, in press. [Google Scholar] [CrossRef] [PubMed]

- Monaco, C.; Llukacej, A.; Baldissara, P.; Arena, A.; Scotti, R. Zirconia-based versus metal-based single crowns veneered with overpressing ceramic for restoration of posterior endodontically treated teeth: 5-year results of a randomized controlled clinical study. J. Dent. 2017, 65, 56–63. [Google Scholar] [CrossRef] [PubMed]

- Kim, B.K.; Shim, J.S.; Lee, K.W. The influence of ceramic surface treatments on the tensile bond strength of composite resin to all-ceramic coping materials. J. Prosthet. Dent. 2005, 94, 357–362. [Google Scholar] [CrossRef] [PubMed]

- Nishigori, A.; Yoshida, T.; Bottino, M.C.; Platt, J.A. Influence of zirconia surface treatment on veneering porcelain shear bond strength after cyclic loading. J. Prosthet. Dent. 2014, 112, 1392–1398. [Google Scholar] [CrossRef] [PubMed]

- Guazzato, M.; Quach, L.; Albakry, M.; Swain, M.V. Influence of surface and heat treatments on the flexural strength of Y-TZP dental ceramic. J. Dent. 2005, 1, 9–18. [Google Scholar] [CrossRef] [PubMed]

- Monaco, C.; Tucci, A.; Esposito, L.; Scotti, R. Adhesion mechanisms at the interface between Y-TZP and veneering ceramic with and without modifier. J. Dent. 2014, 42, 1473–1479. [Google Scholar] [CrossRef]

- Harding, A.B.; Norling, B.K.; Teixeira, E.C. The effect of surface treatment of the interfacial surface on fatigue-related microtensile bond strength of milled zirconia to veneering porcelain. J. Prosthodont. 2012, 21, 346–352. [Google Scholar] [CrossRef]

- Liu, Y.C.; Hsieh, J.P.; Chen, Y.C.; Kang, L.L.; Hwang, C.S.; Chuang, S.F. Promoting porcelain-zirconia bonding using different atmospheric pressure gas plasmas. Dent. Mater. 2018, 8, 1188–1198. [Google Scholar] [CrossRef] [PubMed]

- Worpenberg, C.; Stiesch, M.; Eisenburger, M.; Breidenstein, B.; Busemann, S.; Greuling, A. The effect of surface treatments on the adhesive bond in all-ceramic dental crowns using four-point bending and dynamic loading tests. J. Mech. Behav. Biomed. Mater. 2023, 139, 105686. [Google Scholar] [CrossRef] [PubMed]

- Aktas, G.; Sahin, E.; Vallittu, P.; Ozcan, M.; Lassila, L. Effect of coloring green stage zirconia on the adhesion of veneering ceramics with different thermal expansion coefficients. Int. J. Oral Sci. 2013, 5, 236–241. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Fischer, J.; Grohmann, P.; Stawarczyk, B. Effect of zirconia surface treatments in the shear strength of zirconia/veneering ceramic composites. Dent. Mater. J. 2008, 24, 448–454. [Google Scholar] [CrossRef] [PubMed]

- El Zohairy, A.A.; De Gee, A.J.; de Jager, N.; Ruijven, L.J.; Feilzer, A.J. The influence of specimen attachment and dimension on the microtensile strength. J. Dent. Res. 2004, 83, 420–424. [Google Scholar] [CrossRef] [PubMed]

- Rosentritt, M.; Schneider-Feyrer, S.; Kurzendorfer, L. Comparison of surface roughness parameters Ra/Sa and Rz/Sz with different measuring devices. J. Mech. Behav. Biomed. Mater. 2024, 150, 106349. [Google Scholar] [CrossRef] [PubMed]

- Ayad, M.F.; Fahmy, N.Z.; Rosenstiel, S.F. Effect of surface treatment on roughness and bond strength of a heat- pressed ceramic. J. Prosthet. Dent. 2008, 99, 123–130. [Google Scholar] [CrossRef] [PubMed]

- EN 623-4:2005; Advanced Technical Ceramics. Monolithic Ceramics. General and Textures Properties. Part 4: Determination of Surface Roughness. European Standard: Brussels, Belgium, 2004.

- Hjerppe, J.; Närhi, T.O.; Vallittu, P.K.; Lassila, L.V. Surface roughness and the flexural and bend strength of zirconia after different surface treatments. J. Prosthet. Dent. 2016, 166, 577–583. [Google Scholar] [CrossRef] [PubMed]

- Machado, P.S.; Pereira, G.K.R.; Zucuni, C.P.; Guilardi, L.F.; Valandro, L.F.; Rippe, M.P. Influence of zirconia surface treatments of a bilayer restorative assembly on the fatigue performance. J. Prosthodont. Res. 2021, 65, 162–170. [Google Scholar] [CrossRef] [PubMed]

- Thammajaruk, P.; Buranadham, S.; Guazzato, M.; Swain, M.V. Influence of ceramic-coating techniques on composite-zirconia bonding: Strain energy release rate evaluation. Dent. Mater. 2022, 38, e31–e42. [Google Scholar] [CrossRef] [PubMed]

- Sun, R.; Suansuwan, N.; Kilpatrick, N.; Swain, M. Characterisation of tribochemically assisted bonding of composite resin to porcelain and metal. J. Dent. 2000, 28, 441–445. [Google Scholar] [CrossRef]

- Kern, M.; Wegner, S.M. Bonding to zirconia ceramic: Adhesion methods and their durability. Dent. Mater. 1998, 14, 64–71. [Google Scholar] [CrossRef] [PubMed]

- Ozcan, M.; Vallittu, P.K. Effect of surface conditioning methods on the bond strength of luting cement to ceramics. Dent. Mater. 2003, 19, 725–731. [Google Scholar] [CrossRef] [PubMed]

- Wegner, S.M.; Kern, M. Long-term resin bond strength to zirconia ceramic. J. Adhes. Dent. 2000, 2, 139–147. [Google Scholar] [PubMed]

- Inokoshi, M.; Van Meerbeek, B. Adhesively luted zirconia restorations: Why and how? J. Adhes. Dent. 2014, 16, 294. [Google Scholar] [PubMed]

- Nakamura, T.; Wakabayashi, K.; Zaima, C.; Hisataka, N.; Soichiro, K.; Hirofumi, Y. Tensile bond strength between tooth-colored porcelain and sandblasted zirconia framework. J. Prosthodont. Res. 2009, 53, 116–119. [Google Scholar] [CrossRef] [PubMed]

- Liu, D.; Matinlinna, J.P.; Tsoi, J.K.; Pow, E.H.; Miyazaki, T.; Shibata, Y.; Kan, C.W. A new modified laser pretreatment for porcelain zirconia bonding. Dent. Mater. 2013, 29, 559–565. [Google Scholar] [CrossRef]

- He, M.; Zhang, Z.; Zheng, D.; Ding, N.; Liu, Y. Effect of sandblasting on surface roughness of zirconia-based ceramics and shear bond strength of veneering porcelain. Dent. Mater. J. 2014, 33, 778–785. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.J.; Lim, H.P.; Park, Y.J.; Vang, M.S. Effect of zirconia surface treatments on the shear bond strength of veneering ceramic. J. Prosthet. Dent. 2011, 105, 315–322. [Google Scholar] [CrossRef] [PubMed]

- Bielen, V.; Inokoshi, M.; De Munck, J.; Zhang, F.; Vanmeensel, K.; Minakuchi, S.; Vleugels, J.; Naert, I.; Van Meerbeek, B. Bonding Effectiveness to Differently Sandblasted Dental Zirconia. J. Adhes. Dent. 2015, 17, 235–242. [Google Scholar] [PubMed]

- Inokoshi, M.; Poitevin, A.; De Munck, J.; Minakuchi, S.; Van Meerbeek, B. Bonding effectiveness to different chemically pre-treated dental zirconia. Clin. Oral Investig. 2014, 18, 1803–1812. [Google Scholar] [CrossRef] [PubMed]

- Al-Dohan, H.M.; Yaman, P.; Dennison, J.B.; Razzoog, M.E.; Lang, B.R. Shear strength of core-veneer interface in bi-layered ceramics. J. Prosthet. Dent. 2004, 91, 349–355. [Google Scholar] [CrossRef] [PubMed]

- Aboushelib, M.N.; Kleverlaan, C.J.; Feilzer, A.J. Microtensile bond strength of different components of core veneered all-ceramic restorations. Part II: Zirconia veneering ceramics. Dent. Mater. 2006, 22, 857–863. [Google Scholar] [CrossRef] [PubMed]

- Nagaoka, N.; Yoshihara, K.; Tamada, Y.; Yoshida, Y.; Van Meerbeek, B.V. Ultrastructure and bonding properties of tribochemical silica-coated zirconia. Dent. Mater. J. 2019, 38, 107–113. [Google Scholar] [CrossRef] [PubMed]

- Kern, M. Bonding to oxide ceramics-laboratory testing versus clinical out-come. Dent. Mater. 2015, 31, 8–14. [Google Scholar] [CrossRef] [PubMed]

- Chaiyabutr, Y.; McGowan, S.; Phillips, K.M.; Kois, J.C.; Giordano, R.A. The effect of hydrofluoric acid surface treatment and bond strength of a zirconia veneering ceramic. J. Prosthet. Dent. 2008, 100, 194–202. [Google Scholar] [CrossRef] [PubMed]

- Youssef, M.K.; Abdelkader, S.H.; Aly, Y.M. Effect of different interfacial surface treatments on the shear bond strength of veneering ceramic and zirconia core. BMC Oral Health 2023, 5, 363. [Google Scholar] [CrossRef] [PubMed]

| Materials | Composition | Coefficient of Thermal Expansion 10−6 K−1 |

|---|---|---|

| IPS e.max ZirCAD, Ivoclar, Schaan, Liechtenstein | 3Y-TZP, zirconium oxide (87–95 vol%), yttrium oxide (4–6 vol%), hafnium oxide (1–5 vol%), and alumina and silica (<1 vol%) | 10.8 ± 0.3 |

| IPS e.max Zir Liner, Ivoclar | Water, butandiol, and chloride | 9.8 ± 0.3 |

| IPS e.max ZirPress, Ivoclar | SiO2 with Li2O, Na2O, K2O, MgO, Al2O3, CaO, ZrO2, P2O5 | 9.8 ± 0.3 |

| Group—Surface Treatment | Working Distance | Working Time |

|---|---|---|

| Pre-S-30: 30-µm SiO2-coated Al2O3 before sintering | 1 cm | 15 s |

| Pre-S-50: 50-µm Al2O3 before sintering | 1.5 cm | 15 s |

| Pre-S-110: 110-µm Al2O3 before sintering | 1.5 cm | 15 s |

| Post-S-30: 30-µm SiO2-coated Al2O3 after sintering | 1 cm | 15 s |

| CTR—no treatment | - | - |

| Group—Surface Treatment | PTF/N | µTBS (MPa) Mean (SD) | Failure Patterns | ||

|---|---|---|---|---|---|

| Cohesive | Mixed | Adhesive | |||

| CTR-No treatment | 12/48 | 20.2 (11.2) B | 13% | 60% | 27% |

| Pre-S-30: 30-µm SiO2-coated Al2O3-pre-sintering | 6/48 | 21.8 (10.4) B | 23% | 70% | 7% |

| Pre-S-50: 50-µm Al2O3-pre-sintering | 5/48 | 24.1 (12.6) B | 27% | 65% | 8% |

| Pre-S-110: 110-µm Al2O3-pre-sintering | 8/48 | 26.4 (14.1) B | 33% | 46% | 21% |

| Post-S-30: 30-µm SiO2-coated Al2O3-post-sintering | 3/48 | 28.5 (12.6) A | 29% | 52% | 19% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zicari, F.; Monaco, C.; Vivan Cardoso, M.; Silvestri, D.; Van Meerbeek, B. Bonding Effectiveness of Veneering Ceramic to Zirconia after Different Grit-Blasting Treatments. Dent. J. 2024, 12, 219. https://doi.org/10.3390/dj12070219

Zicari F, Monaco C, Vivan Cardoso M, Silvestri D, Van Meerbeek B. Bonding Effectiveness of Veneering Ceramic to Zirconia after Different Grit-Blasting Treatments. Dentistry Journal. 2024; 12(7):219. https://doi.org/10.3390/dj12070219

Chicago/Turabian StyleZicari, Francesca, Carlo Monaco, Marcio Vivan Cardoso, Davide Silvestri, and Bart Van Meerbeek. 2024. "Bonding Effectiveness of Veneering Ceramic to Zirconia after Different Grit-Blasting Treatments" Dentistry Journal 12, no. 7: 219. https://doi.org/10.3390/dj12070219

APA StyleZicari, F., Monaco, C., Vivan Cardoso, M., Silvestri, D., & Van Meerbeek, B. (2024). Bonding Effectiveness of Veneering Ceramic to Zirconia after Different Grit-Blasting Treatments. Dentistry Journal, 12(7), 219. https://doi.org/10.3390/dj12070219