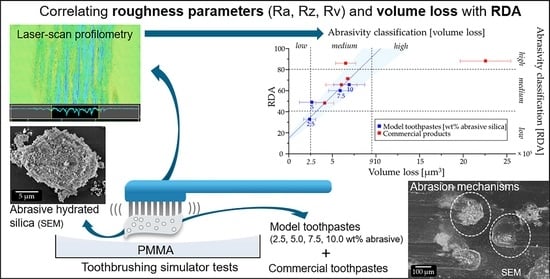

Toothpaste Abrasion and Abrasive Particle Content: Correlating High-Resolution Profilometric Analysis with Relative Dentin Abrasivity (RDA)

Abstract

1. Introduction

2. Materials and Methods

2.1. Model Toothpastes

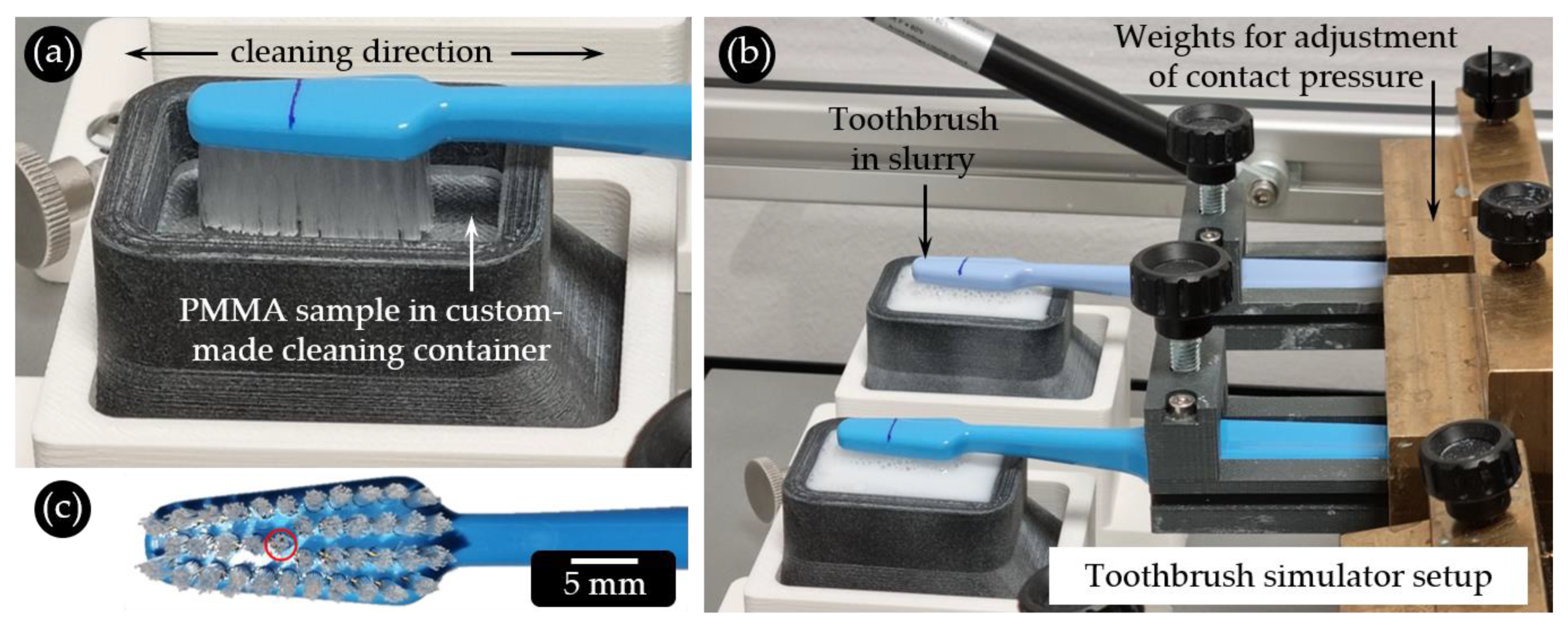

2.2. Abrasion Tests

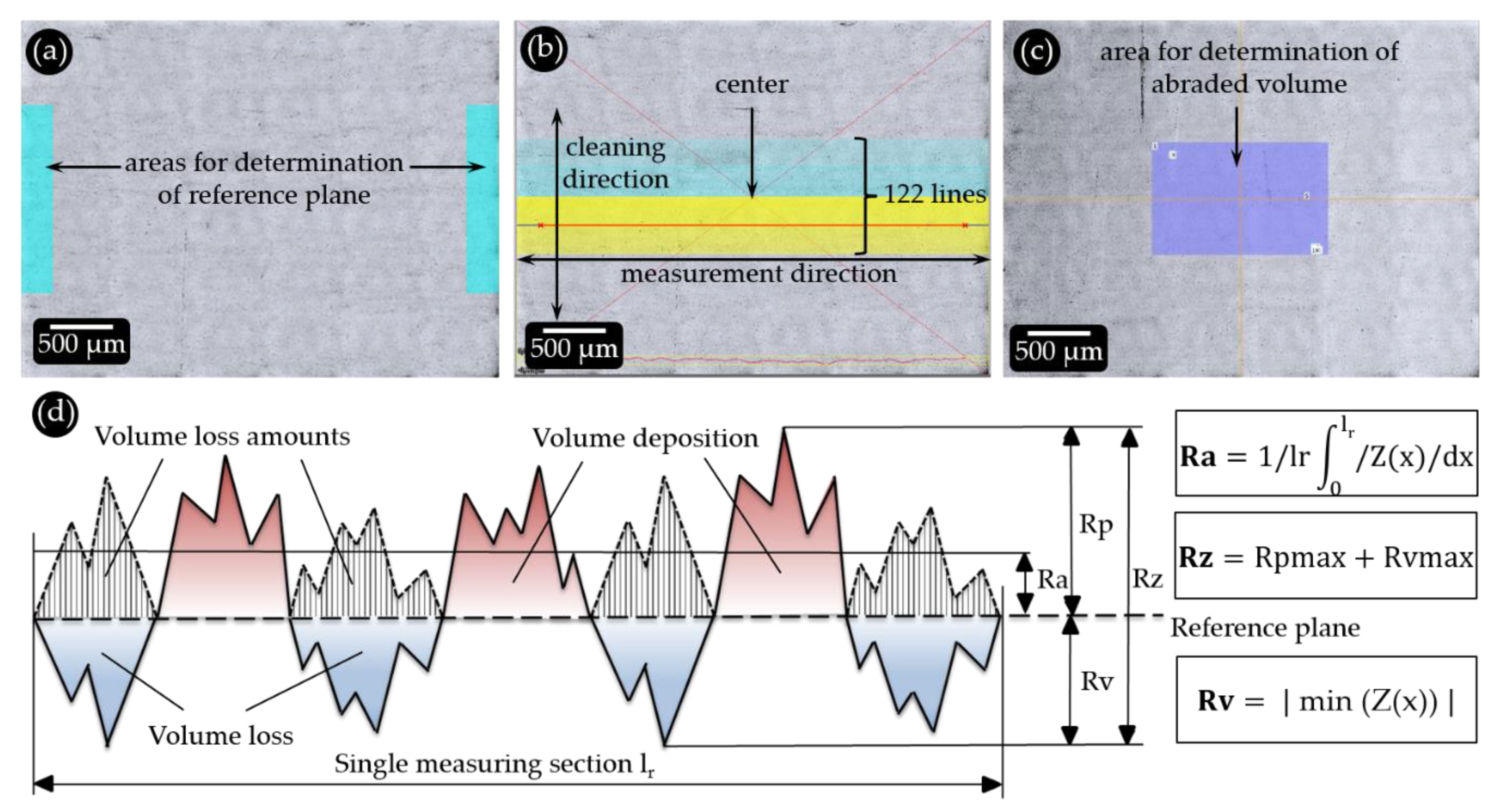

2.3. Profilometric Recording of Abrasion

2.4. Profilometric Analysis of Abrasion

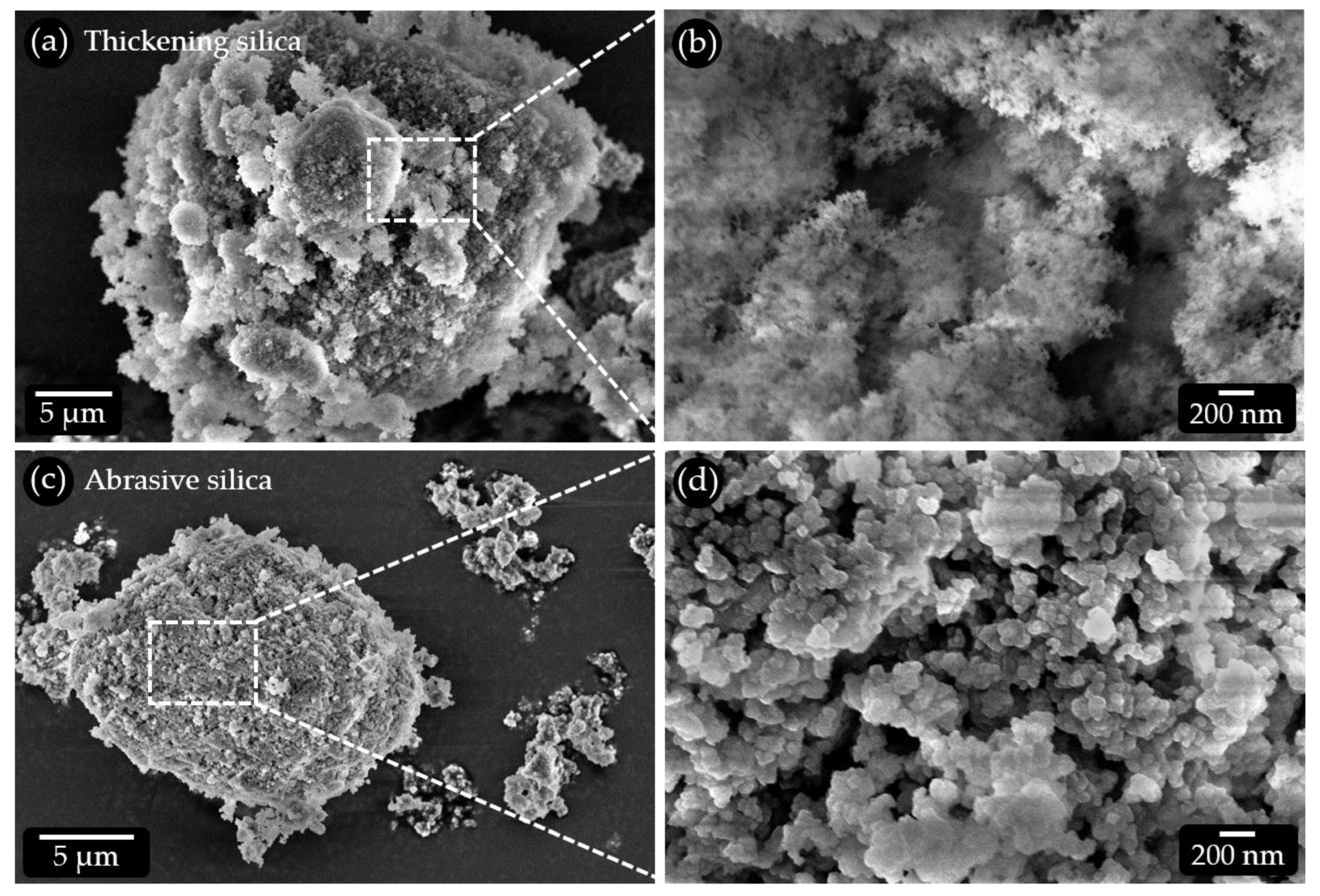

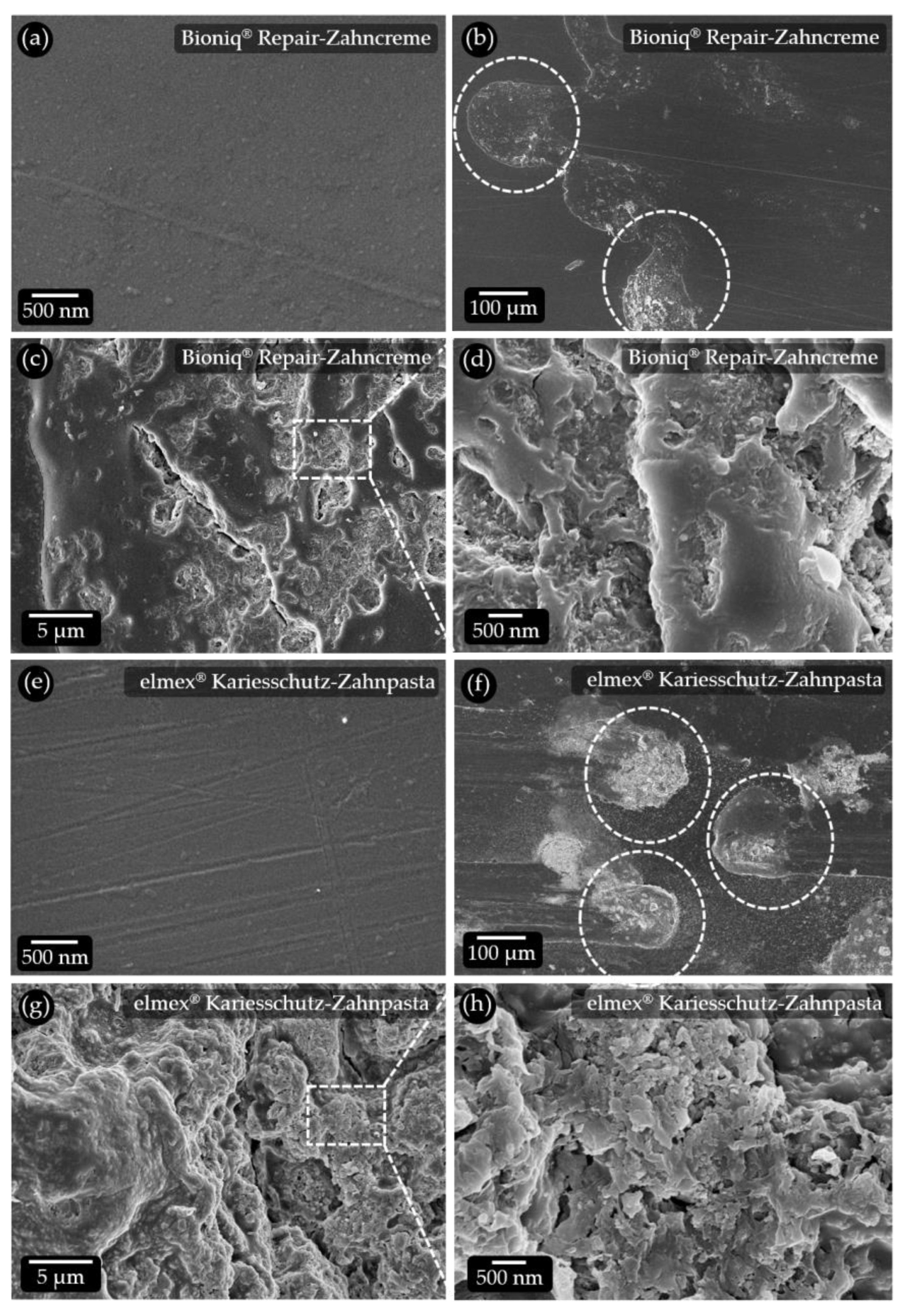

2.5. SEM Analysis of Hydrated Silica Particles and Abrasion Test Samples

2.6. Determination of Radioactive/Relative Dentine Abrasion (RDA)

3. Results and Discussion

3.1. Model Toothpastes and Substrate Material

3.2. Microstructure of the Used Hydrated Silica Particle Qualities

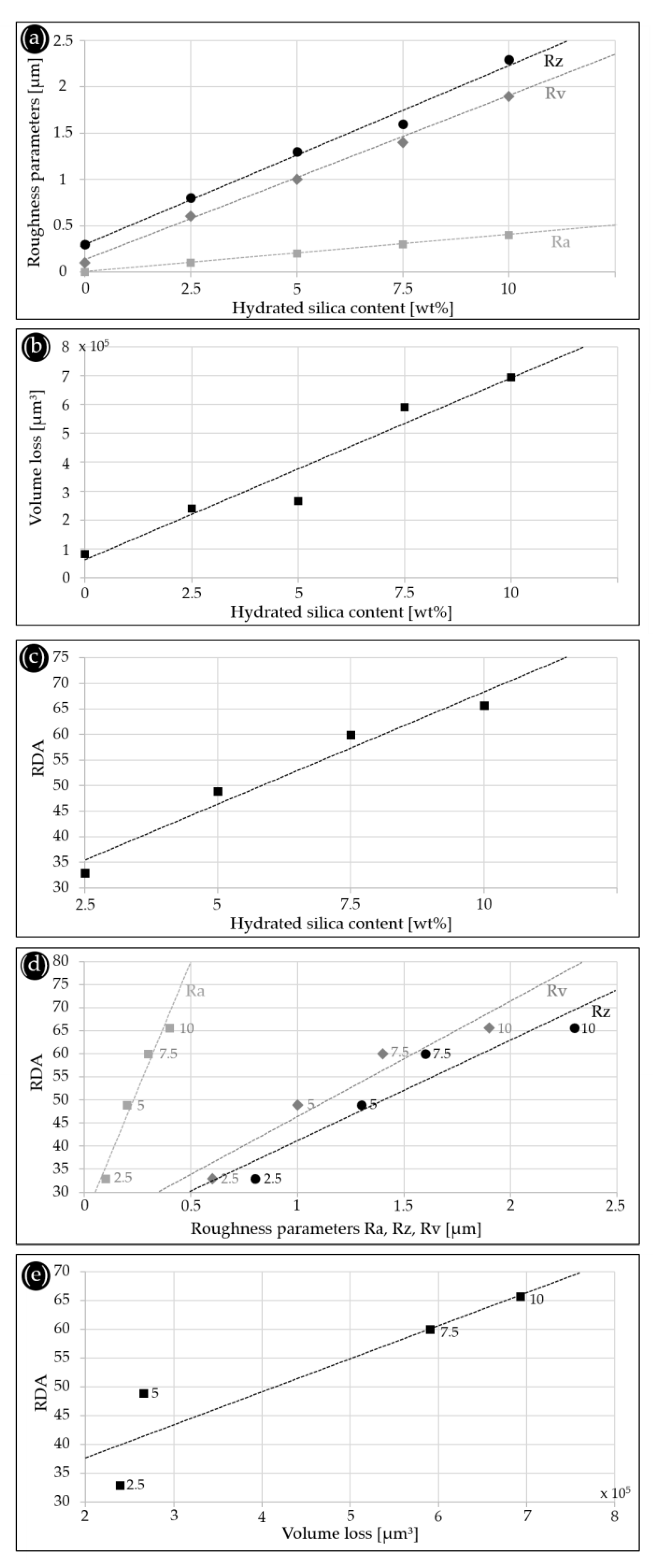

3.3. Abrasivity of Model Toothpastes Obtained by Profilometric Analysis and RDA

3.4. Abrasivity of Commercial Toothpastes Obtained by Profilometric Analysis and RDA

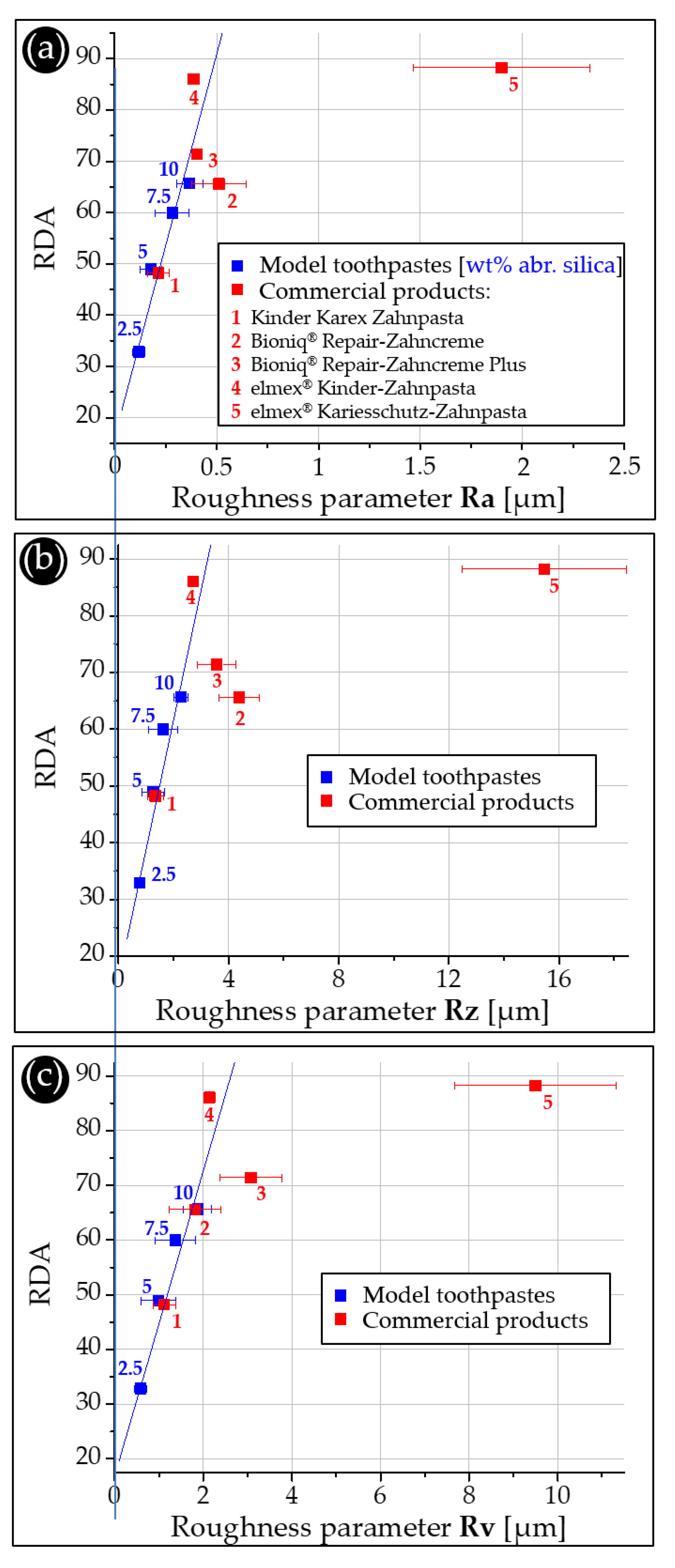

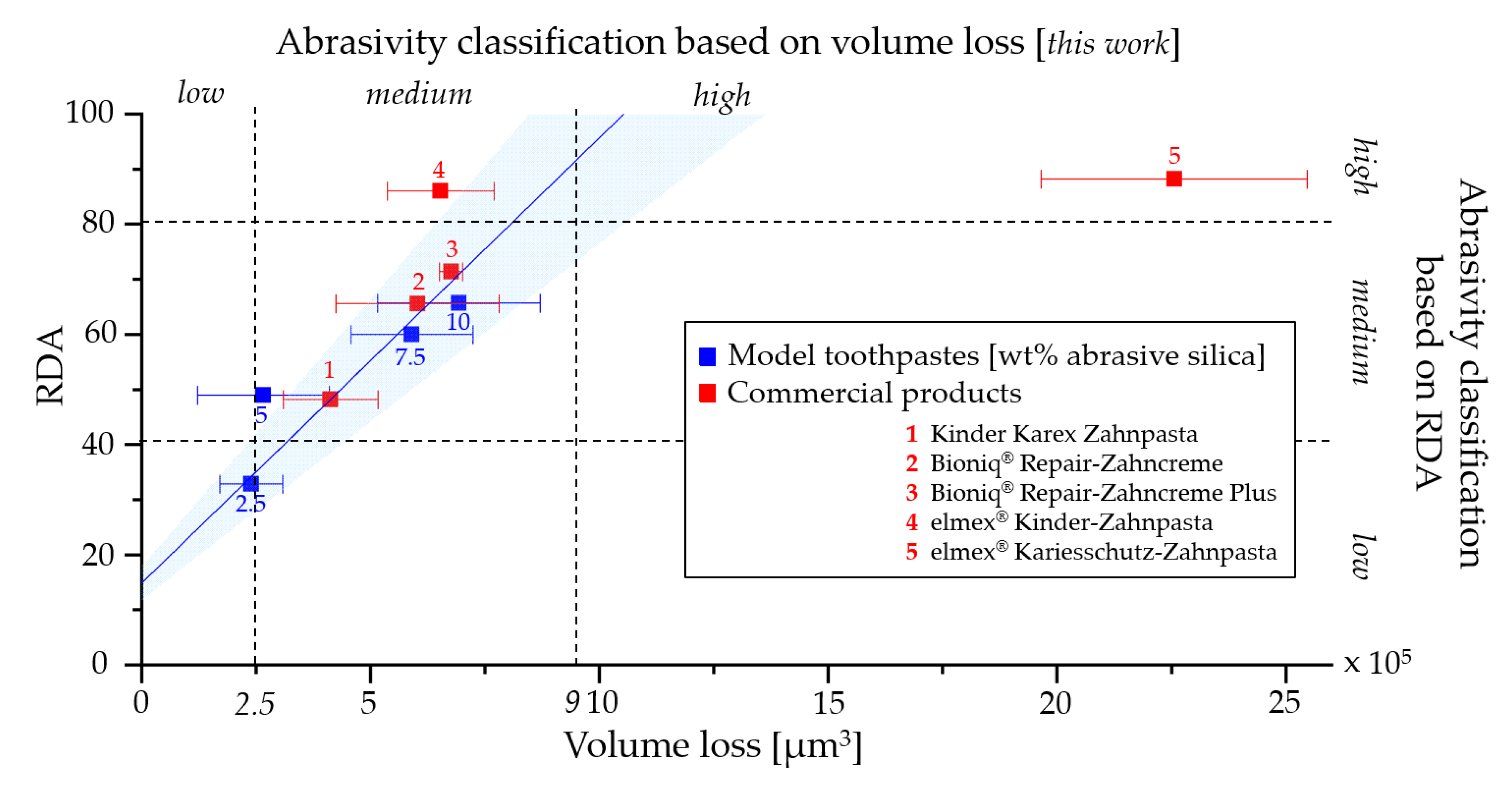

3.5. Correlation of Profilometric Analysis and RDA Values

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Meyer, F.; Enax, J.; Epple, M.; Amaechi, B.T.; Simader, B. Cariogenic biofilms: Development, properties, and biomimetic preventive agents. Dent. J. 2021, 9, 88. [Google Scholar] [CrossRef]

- Valm, A.M. The structure of dental plaque microbial communities in the transition from health to dental caries and periodontal disease. J. Mol. Biol. 2019, 431, 2957–2969. [Google Scholar] [CrossRef]

- Slot, D.E.; Wiggelinkhuizen, L.; Rosema, N.A.; Van der Weijden, G.A. The efficacy of manual toothbrushes following a brushing exercise: A systematic review. Int. J. Dent. Hyg. 2012, 10, 187–197. [Google Scholar] [CrossRef] [PubMed]

- Tellefsen, G.; Liljeborg, A.; Johannsen, A.; Johannsen, G. The role of the toothbrush in the abrasion process. Int. J. Dent. Hyg. 2011, 9, 284–290. [Google Scholar] [CrossRef]

- Loveren, C.v. Toothpastes. Monogr. Oral Sci. 2013, 23. [Google Scholar]

- Joiner, A. Whitening toothpastes: A review of the literature. J. Dent. 2010, 38 (Suppl 2), e17–e24. [Google Scholar] [CrossRef]

- Walsh, T.; Worthington, H.V.; Glenny, A.M.; Marinho, V.C.; Jeroncic, A. Fluoride toothpastes of different concentrations for preventing dental caries. Cochrane Database Syst. Rev. 2019, 3, CD007868. [Google Scholar] [CrossRef]

- González-Cabezas, C.; Hara, A.T.; Hefferren, J.; Lippert, F. Abrasivity testing of dentifrices—Challenges and current state of the art. Monogr. Oral. Sci. 2013, 23, 100–107. [Google Scholar] [PubMed]

- Doerfer, C.E.; Hefferren, J.; González-Cabezas, C.; Imfeld, M.; Addy, T. Methods to determine dentifrice abrasiveness. J. Clin. Dent. 2010, 21, S1–S16. [Google Scholar]

- DIN EN ISO 11609:2017-09; Dentistry—Dentifrices—Requirements, Test Methods and Marking (ISO 11609:2017). German version EN ISO 11609:2017; ISO: Geneva, Switzerland, 2017.

- Fabritius-Vilpoux, K.; Enax, J.; Herbig, M.; Raabe, D.; Fabritius, H.-O. Quantitative affinity parameters of synthetic hydroxyapatite and enamel surfaces in vitro. Bioinspir. Biomim. Nan. 2019, 8, 141–153. [Google Scholar] [CrossRef]

- Liljeborg, A.; Tellefsen, G.; Johannsen, G. The use of a profilometer for both quantitative and qualitative measurements of toothpaste abrasivity. Int. J. Dent. Hyg. 2010, 8, 237–243. [Google Scholar] [CrossRef]

- Johannsen, G.; Tellefsen, G.; Johannsen, A.; Liljeborg, A. The importance of measuring toothpaste abrasivity in both a quantitative and qualitative way. Acta Odontol. Scand. 2013, 71, 508–517. [Google Scholar] [CrossRef]

- DIN EN ISO 4287:2010-07; Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Terms, Definitions and Surface Texture Parameters (ISO 4287:1997 + Cor 1:1998 + Cor 2:2005 + Amd 1:2009). German version EN ISO 4287:1998 + AC:2008 + A1:2009; ISO: Geneva, Switzerland, 2010.

- Stovell, A.G.; Newton, B.M.; Lynch, R.J. Important considerations in the development of toothpaste formulations for children. Int. Dent. J. 2013, 63 (Suppl 2), 57–63. [Google Scholar] [CrossRef] [PubMed]

- Viscio, D.; Gaffar, A.; Fakhry-Smith, S.; Xu, T. Present and future technologies of tooth whitening. Compend. Contin. Educ. Dent. 2000, 28, 36–43. [Google Scholar]

- Schneiderman, E.; Colon, E.; White, D.J.; John, S.S. A profilometry-based dentifrice abrasion method for V8 brushing machines part II: Comparision of RDA-PE and radiotracer RDA measures. J. Clin. Dent. 2015, 26, 61–65. [Google Scholar]

- White, D.J.; Schneiderman, E.; Colon, E.; St. John, S. A profilometry based dentifrice abrasion method for V8 brushing machines Part I: The RDA-PE method and correlation to conventional RDA. J. Clin. Dent. 2015, 26, 1–6. [Google Scholar]

- Fabritius-Vilpoux, K.; Enax, J.; Mayweg, D.; Meyer, F.; Herbig, M.; Raabe, D.; Fabritius, H.-O. Ultrastructural changes of bovine tooth surfaces under erosion in presence of biomimetic hydroxyapatite. Bioinspir. Biomim. Nan. 2021, 10, 132–145. [Google Scholar] [CrossRef]

- Enax, J.; Epple, M. Die Charakterisierung von Putzkörpern in Zahnpasten. Dtsch. Zahnärztliche Z. 2018, 73, 100–108. [Google Scholar]

- Delgado, A.J.; Olafsson, V.G. Acidic oral moisturizers with pH below 6.7 may be harmful to teeth depending on formulation: A short report. Clin. Cosmet. Investig. Dent. 2017, 9, 81–83. [Google Scholar] [CrossRef] [PubMed]

- NF T45-036; NF ISO 19246:2016-10-14; Rubber Compounding Ingredients—Silica—Oil absorption of Precipitated Silica. Edition 2016-10-14; ISO: Geneva, Switzerland, 2016.

- Bizhang, M.; Riemer, K.; Arnold, W.H.; Domin, J.; Zimmer, S. Influence of Bristle Stiffness of Manual Toothbrushes on Eroded and Sound Human Dentin—An In Vitro Study. PLoS ONE 2016, 11, e0153250. [Google Scholar]

- Hamza, B.; Svellenti, L.; Körner, P.; Attin, T.; Wegehaupt, F.J. Effect of tapered-end and round-end bristles on the abrasive dentine wear applying increasing brushing forces. Acta Odontol. Scand. 2022, 80, 465–469. [Google Scholar] [CrossRef]

- Hamza, B.; Tanner, M.; Körner, P.; Attin, T.; Wegehaupt, F.J. Effect of toothbrush bristle stiffness and toothbrushing force on the abrasive dentine wear. Int. J. Dent. Hyg. 2021, 19, 355–359. [Google Scholar] [CrossRef]

- Hamza, B.; Martinola, L.; Körner, P.; Gubler, A.; Attin, T.; Wegehaupt, F.J. Effect of brushing force on the abrasive dentin wear using slurries with different abrasivity values. Int. J. Dent. Hyg. 2023, 21, 172–177. [Google Scholar] [CrossRef]

- Turssi, C.P.; Messias, D.C.; Hara, A.T.; Hughes, N.; Garcia-Godoy, F. Brushing abrasion of dentin: Effect of diluent and dilution rate of toothpaste. Am. J. Dent. 2010, 23, 247–250. [Google Scholar]

- Epple, M.; Enax, J. Moderne Zahnpflege aus chemischer Sicht. Chem. Unserer. Zeit. 2018, 52, 218–228. [Google Scholar] [CrossRef]

- Ganss, C.; Klimek, J.; Brune, V.; Schürmann, A. Effects of Two Fluoridation Measures on Erosion Progression in Human Enamel and Dentine in situ. Caries Res. 2004, 38, 561–566. [Google Scholar] [CrossRef] [PubMed]

- Zeitz, C.; Faidt, T.; Grandthyll, S.; Hähl, H.; Thewes, N.; Spengler, C.; Schmauch, J.; Deckarm, M.J.; Gachot, C.; Natter, H.; et al. Synthesis of Hydroxyapatite Substrates: Bridging the Gap between Model Surfaces and Enamel. ACS Appl. Mater. Interfaces 2016, 8, 25848–25855. [Google Scholar] [CrossRef]

- Butera, A.; Pascadopoli, M.; Pellegrini, M.; Trapani, B.; Gallo, S.; Radu, M.; Scribante, A. Biomimetic hydroxyapatite paste for molar-incisor hypomineralization: A randomized clinical trial. Oral Dis. 2022; Epub ahead of print. [Google Scholar] [CrossRef]

- Limeback, H.; Enax, J.; Meyer, F. Biomimetic hydroxyapatite and caries prevention: A systematic review and meta-analysis. Can. J. Dent. Hyg. 2021, 55, 148–159. [Google Scholar]

- Meyer, F.; Enax, J.; Amaechi, B.T.; Limeback, H.; Fabritius, H.-O.; Ganss, B.; Pawinska, M.; Paszynska, E. Hydroxyapatite as remineralization agent for children’s dental care. Front. Dent. Med. 2022, 3, 859560. [Google Scholar] [CrossRef]

- Hamza, B.; Atti, T.; Cucuzza, C.; Gubler, A.; Wegehaupt, F.J. RDA and REA values of commercially available toothpastes utilizing diamond powder and traditional abrasives. Oral. Health Prev. Dent. 2020, 18, 807–814. [Google Scholar]

- Sarembe, S.; Ufer, C.; Kiesow, A.; Limeback, H.; Meyer, F.; Fuhrmann, I.; Enax, J. Influence of the Amount of Toothpaste on Cleaning Efficacy: An In Vitro Study. Eur. J. Dent. 2022; Epub ahead of print. [Google Scholar] [CrossRef]

| Formulation Ingredients [INCI Denom. (Standard Denom.)/Trade Name (Manufacturer)] | 1 [wt%] | 2 [wt%] | 3 [wt%] | 4 [wt%] | Function |

|---|---|---|---|---|---|

| Water (Aqua) | 57.0 | 54.6 | 52.2 | 49.9 | Excipient |

| Cellulose Gum (Sodium carboxymethyl cellulose)/ WALOCEL™ CRT 2000 PA Sodium Carboxymethylcellulose (DDP Specialty Products Germany GmbH & Co. KG, Walsrode, Germany) | 1.7 | 1.6 | 1.5 | 1.3 | Thickening |

| Hydrated Silica (Amorphous silicon dioxide)/ SYLODENT® SM 850C (GRACE GmbH, Worms, Germany) | 2.5 | 5.0 | 7.5 | 10.0 | Abrasive |

| Hydrogenated Starch Hydrolysate (hydrolyzed starch)/ Meritol 160 Pharma (Tereos Starch & Sweeteners Belgium NV, Aalst, Belgium) | 15.0 | Humectant, consistency | |||

| Glycerin (Propan-1,2,3-triol, Glycerol)/ MERCOL® V995 EP RSPO/MB, Non-GMO (cosmetic grade)/GLYCERIN 99.5%, (CREMER OLEO GmbH & Co. KG, Hamburg, Germany) | 11.3 | Humectant, consistency | |||

| Hydrated Silica (Amorphous silicon dioxide)/ SYLODENT® SM 880T, (GRACE GmbH, Worms, Germany) | 9.5 | Thickening | |||

| 1,2-Hexanediol (DL-hexane-1,2-diol), Caprylyl Glycol (Octane-1,2-diol)/ SymDiol® 68 (Symrise AG, Holzminden, Germany) | 1.0 | Preservation, humectants, consistency | |||

| Silica (Highly dispersed silica, synthetic radio-amorphous silica)/ HDK® N20 PYROGENE KIESELSÄURE HYDROPHIL (Wacker Chemie AG, Munich, Germany) | 1.0 | Consistency, thickening | |||

| Sodium Methyl Cocoyl Taurate (Ethanesulfonic acid, 2-(methylamino)-, N-coco acyl derivs., sodium salts)/ ADINOL™ CT95SD-PW-(RB) (Croda Europe Limited, Cowick Hall, Snaith, UK) | 1.0 | Surfactant, cleaning | |||

| Formulation Properties | 1 | 2 | 3 | 4 |

|---|---|---|---|---|

| Abrasive hydrated silica content [wt%] | 2.5 | 5.0 | 7.5 | 10.0 |

| Dynamic shear viscosity [Pa·s] (n = 3) | 45.1 ± 0.6 | 51.0 ± 2.7 | 53.0 ± 0.7 | 56.7 ± 1.2 |

| pH of virgin formulation | 6.5 | 6.4 | 6.4 | 6.3 |

| pH of slurry (25 g toothpaste + 40 mL distilled water) | 6.9 | 6.8 | 6.8 | 6.8 |

| Toothpaste | Manufacturer | Active Substance | Abrasive |

|---|---|---|---|

| elmex® Kariesschutz-Zahnpasta | CP GABA GmbH, Hamburg, Germany | Olaflur (amine fluoride) (1400 ppm F−) | Hydrated silica |

| elmex® Kinder-Zahnpasta | CP GABA GmbH, Hamburg, Germany | Olaflur (amine fluoride) (1000 ppm F−) | Hydrated silica |

| Bioniq® Repair-Zahncreme Plus | Dr. Kurt Wolff GmbH & Co. KG, Bielefeld, Germany | Hydroxyapatite (20 wt%) | Hydrated silica (5 wt%), Hydroxyapatite (20 wt%) |

| Bioniq® Repair-Zahncreme | Dr. Kurt Wolff GmbH & Co. KG, Bielefeld, Germany | Hydroxyapatite (20 wt%) | Hydrated silica (5 wt%), Tetrapotassium pyrophosphate, Hydroxyapatite (20 wt%) |

| Kinder Karex Zahnpasta | Dr. Kurt Wolff GmbH & Co. KG, Bielefeld, Germany | Hydroxyapatite (10 wt%) | Hydrated silica (5 wt%), Hydroxyapatite (10 wt%) |

| Sampled Formulations | Ra [µm] | Rz [µm] | Rv [µm] | Volume loss [µm3] | RDA | Predicted RDA |

|---|---|---|---|---|---|---|

| Model Toothpastes Hydrated Silica [wt%] | ||||||

| 0.0 | 0.0 ± 0.0 | 0.3 ± 1.9 | 0.1 ± 0.0 | 0.8 ×105 ± 0.3 ×105 | - | - |

| 2.5 | 0.1 ± 0.0 | 0.8 ± 0.2 | 0.6 ± 0.2 | 2.4 ×105 ± 0.7×105 | 33 ± 3 | 41 |

| 5.0 | 0.2 ± 0.0 | 1.3 ± 0.4 | 1.0 ± 0.4 | 2.7 ×105 ± 1.4 ×105 | 49 ± 4 | 42 |

| 7.5 | 0.3 ± 0.1 | 1.6 ± 0.5 | 1.4 ± 0.4 | 5.9 ×105 ± 1.3 ×105 | 60 ± 6 | 62 |

| 10.0 | 0.4 ± 0.1 | 2.3 ± 0.4 | 1.9 ± 0.4 | 6.9 ×105 ± 1.8 ×105 | 66 ± 6 | 68 |

| Commercial toothpastes | ||||||

| Bioniq® Repair-Zahncreme Plus | 0.4 ± 0.0 | 3.6 ± 0.71 | 3.1 ± 0.7 | 6.8 ×105 ± 0.3 ×105 | 71 ± 9 | 67 |

| Bioniq® Repair-Zahncreme | 0.5 ± 0.2 | 4.4 ± 1.7 | 1.8 ± 0.6 | 6.0 ×105 ± 1.8 ×105 | 66 ± 4 | 62 |

| elmex® Kariesschutz-Zahnpasta | 1.9 ± 0.5 | 15.5 ± 5.2 | 9.5 ± 1.8 | 22.6 ×105 ± 2.9 ×105 | 88 ± 17 | 162 |

| elmex® Kinder-Zahnpasta | 0.4 ± 0.1 | 2.7 ± 0.4 | 2.1 ± 0.4 | 6.5 ×105 ± 1.2 ×105 | 86 ± 9 | 65 |

| Kinder Karex Zahnpasta | 0.2 ± 0.1 | 1.3 ± 0.4 | 1.1 ± 0.3 | 4.1 ×105 ± 1.0 ×105 | 48 ± 5 | 51 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Enax, J.; Meyer, F.; Schulze zur Wiesche, E.; Fuhrmann, I.C.; Fabritius, H.-O. Toothpaste Abrasion and Abrasive Particle Content: Correlating High-Resolution Profilometric Analysis with Relative Dentin Abrasivity (RDA). Dent. J. 2023, 11, 79. https://doi.org/10.3390/dj11030079

Enax J, Meyer F, Schulze zur Wiesche E, Fuhrmann IC, Fabritius H-O. Toothpaste Abrasion and Abrasive Particle Content: Correlating High-Resolution Profilometric Analysis with Relative Dentin Abrasivity (RDA). Dentistry Journal. 2023; 11(3):79. https://doi.org/10.3390/dj11030079

Chicago/Turabian StyleEnax, Joachim, Frederic Meyer, Erik Schulze zur Wiesche, Ines Christin Fuhrmann, and Helge-Otto Fabritius. 2023. "Toothpaste Abrasion and Abrasive Particle Content: Correlating High-Resolution Profilometric Analysis with Relative Dentin Abrasivity (RDA)" Dentistry Journal 11, no. 3: 79. https://doi.org/10.3390/dj11030079

APA StyleEnax, J., Meyer, F., Schulze zur Wiesche, E., Fuhrmann, I. C., & Fabritius, H.-O. (2023). Toothpaste Abrasion and Abrasive Particle Content: Correlating High-Resolution Profilometric Analysis with Relative Dentin Abrasivity (RDA). Dentistry Journal, 11(3), 79. https://doi.org/10.3390/dj11030079