Aerodynamic Optimization of a 10 kW Radial Inflow Turbine with Splitter Blades

Abstract

:1. Introduction

2. Calculation Model

2.1. 1D Design

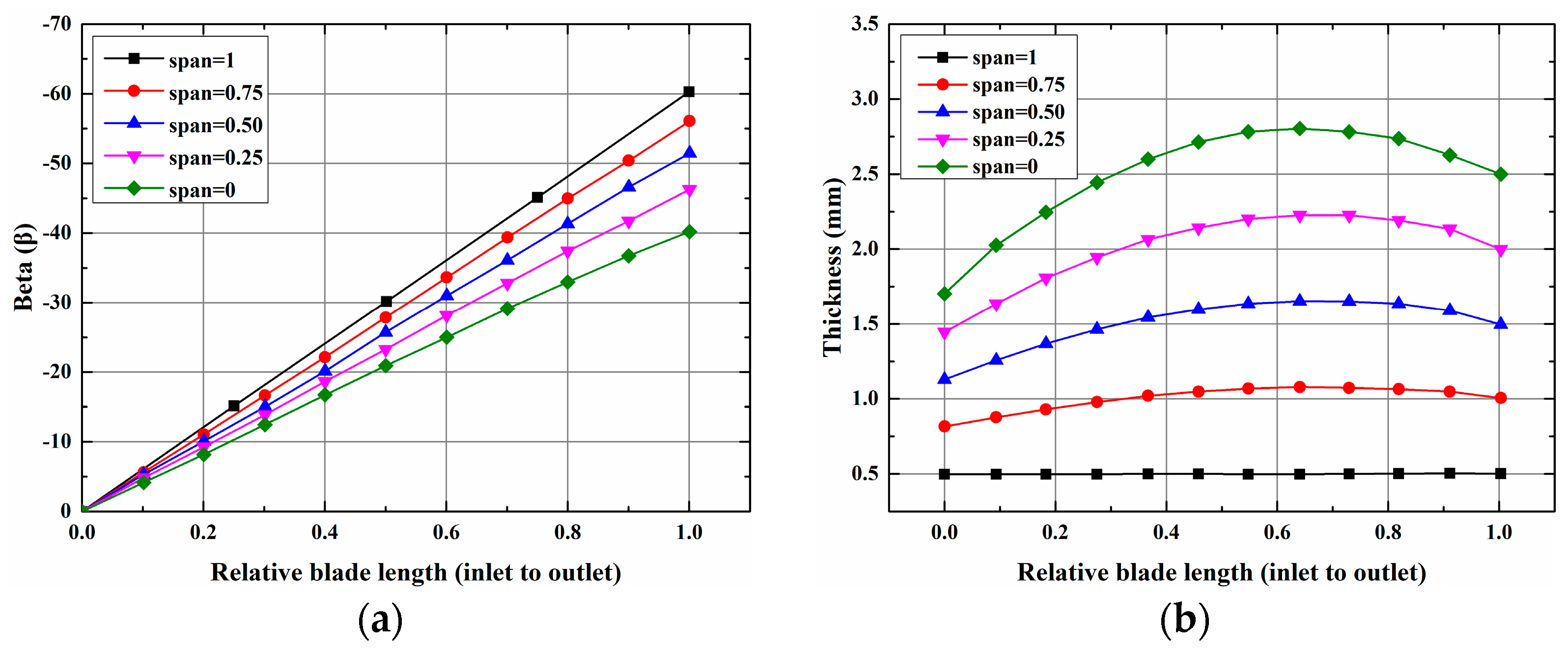

2.2. Geometric Structure

2.3. Performance Index

- Total pressure loss coefficient.

- 2.

- Energy loss coefficient.

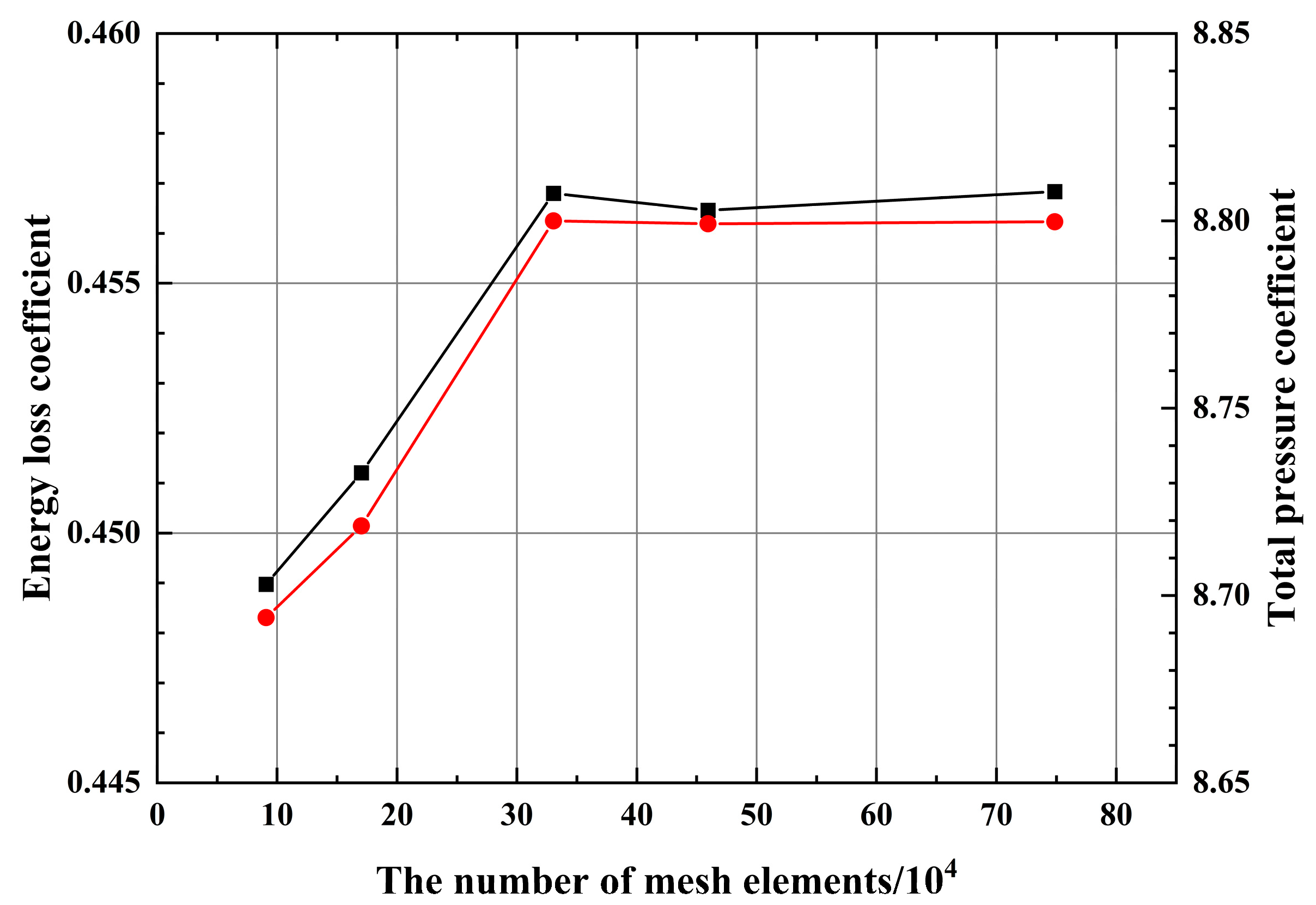

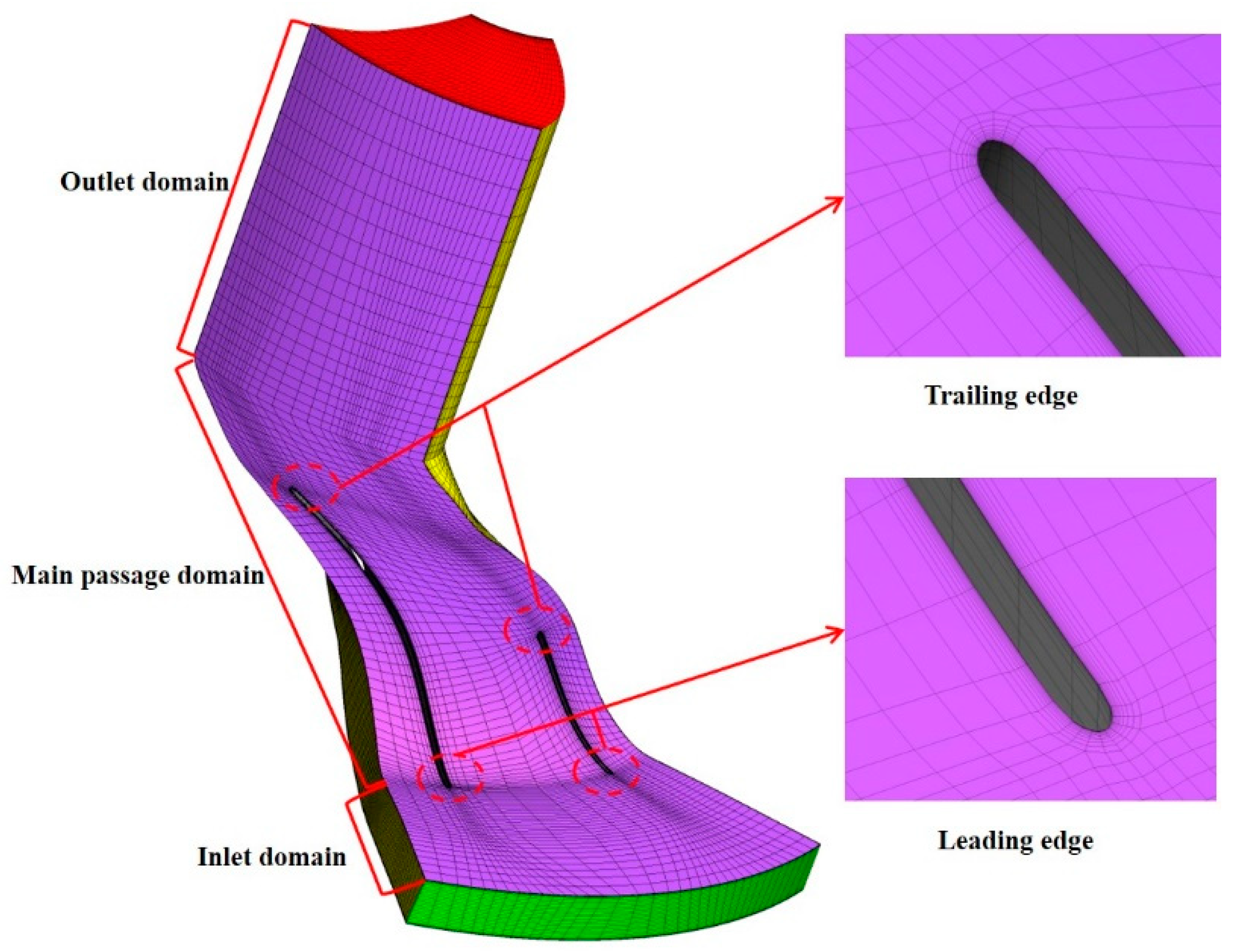

2.4. Grid and Boundary Conditions

3. Results and Discussion

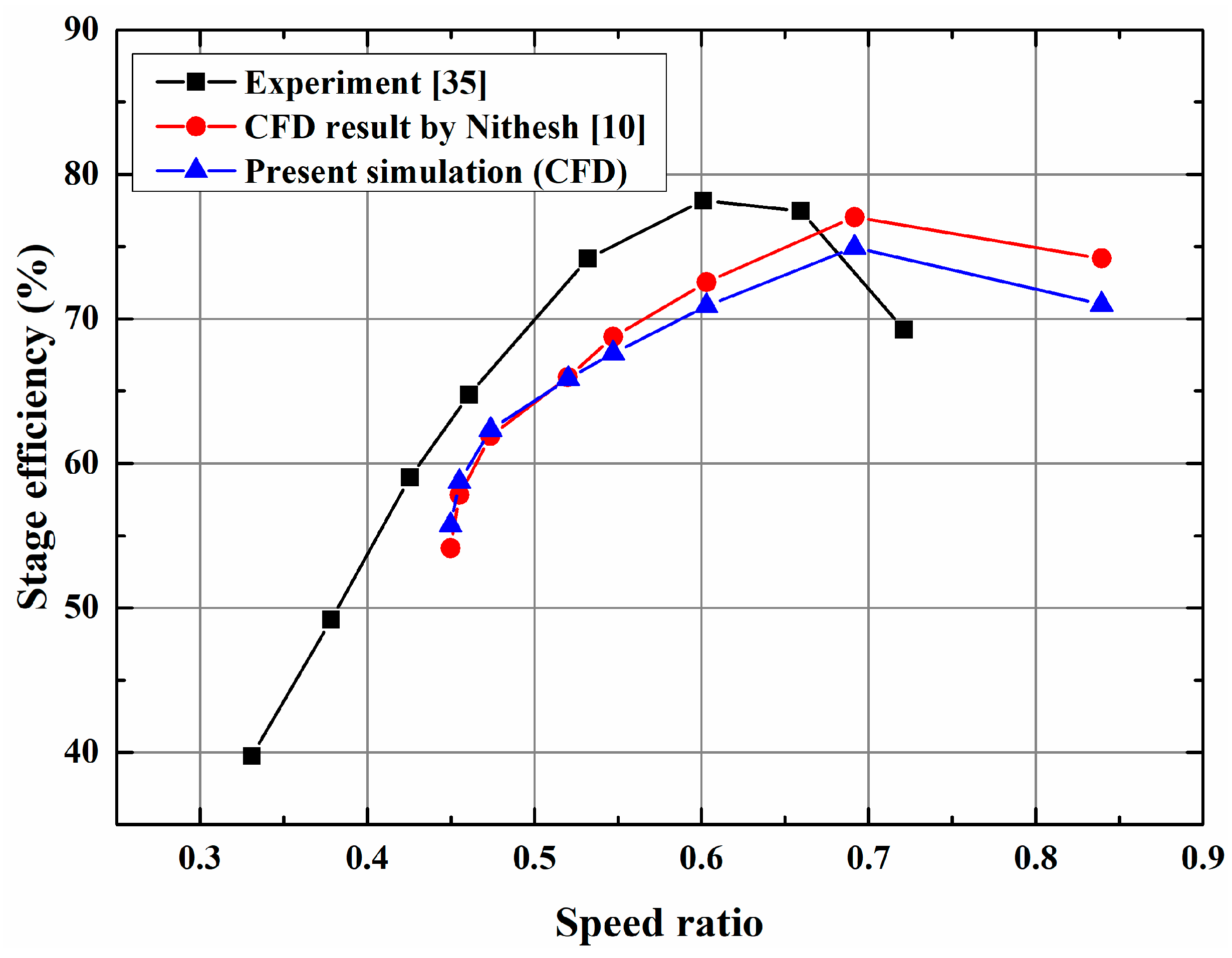

3.1. The Validation of the Numerical Approach

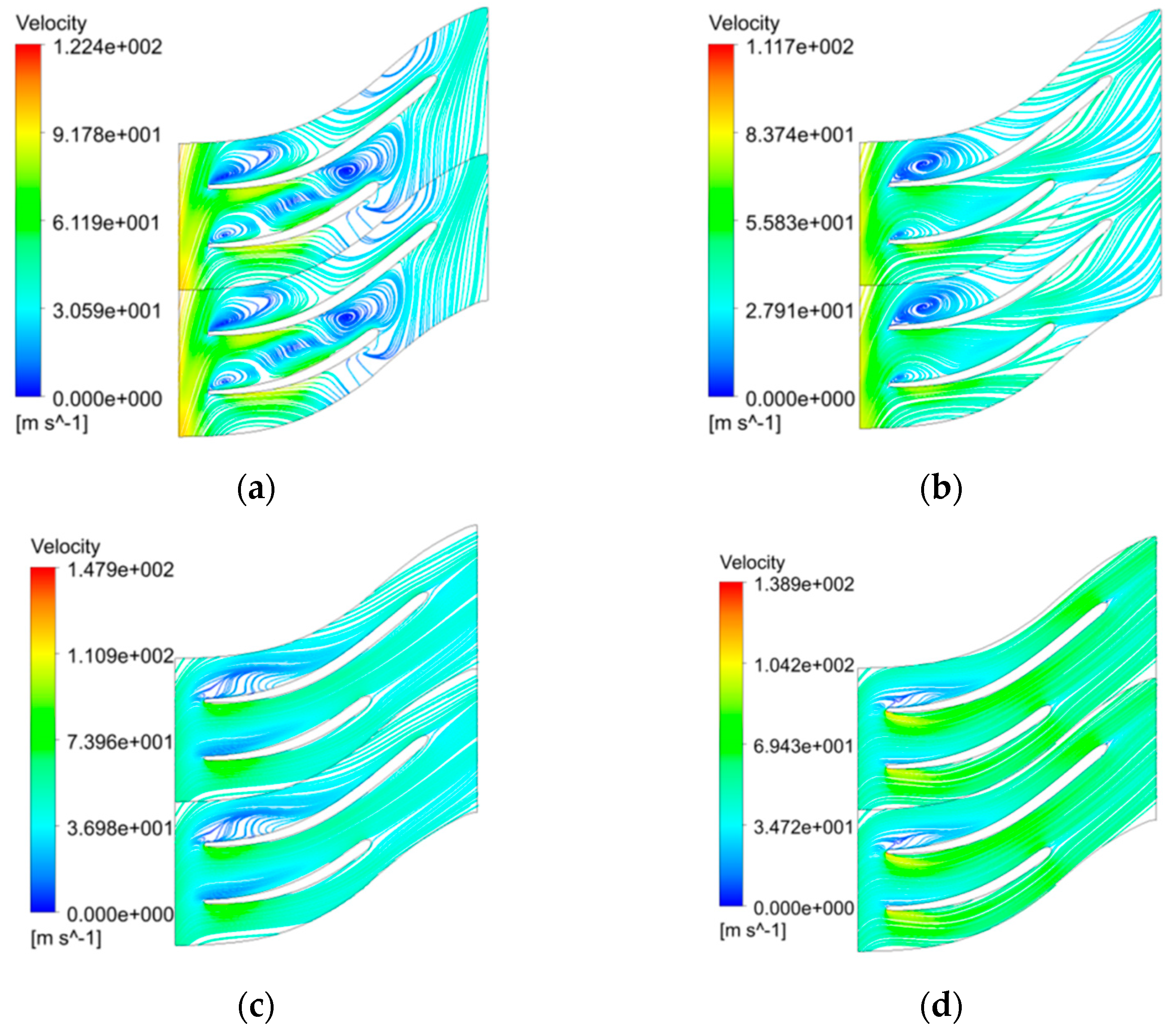

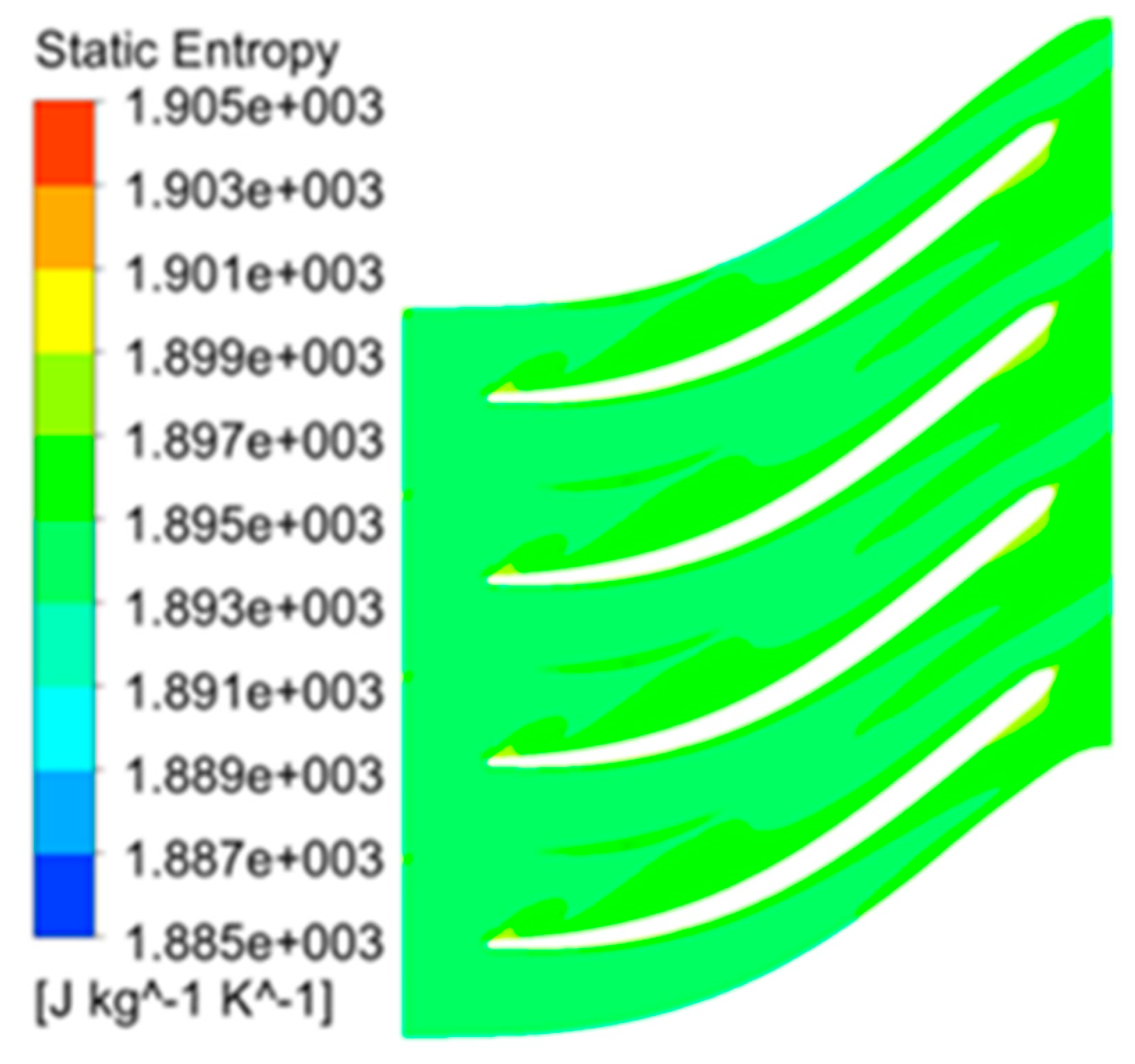

3.2. Influence of Splitter Blades on Flow Field of Impeller Passage

3.3. Influence of Splitter Blades on Impeller Load Distribution

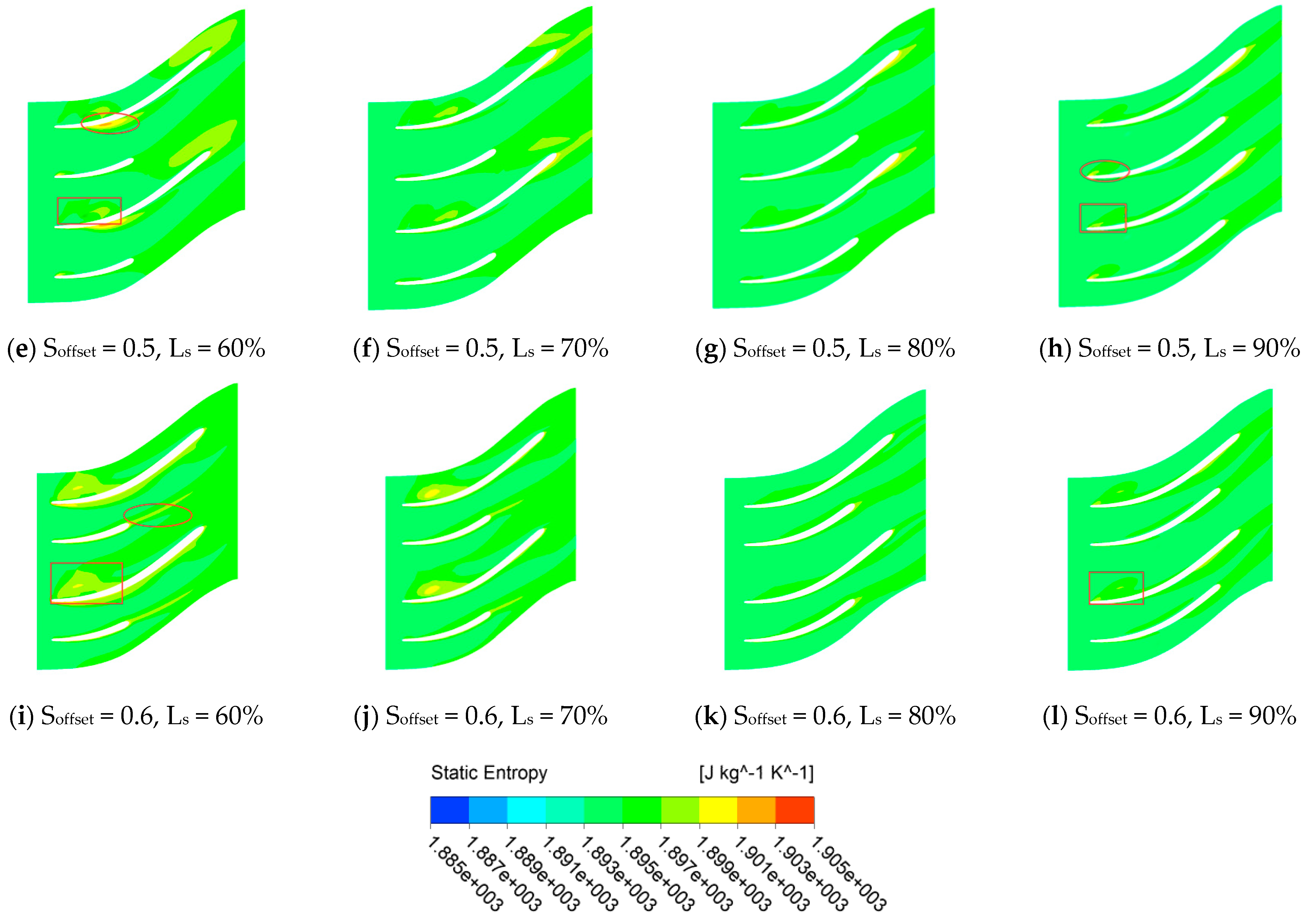

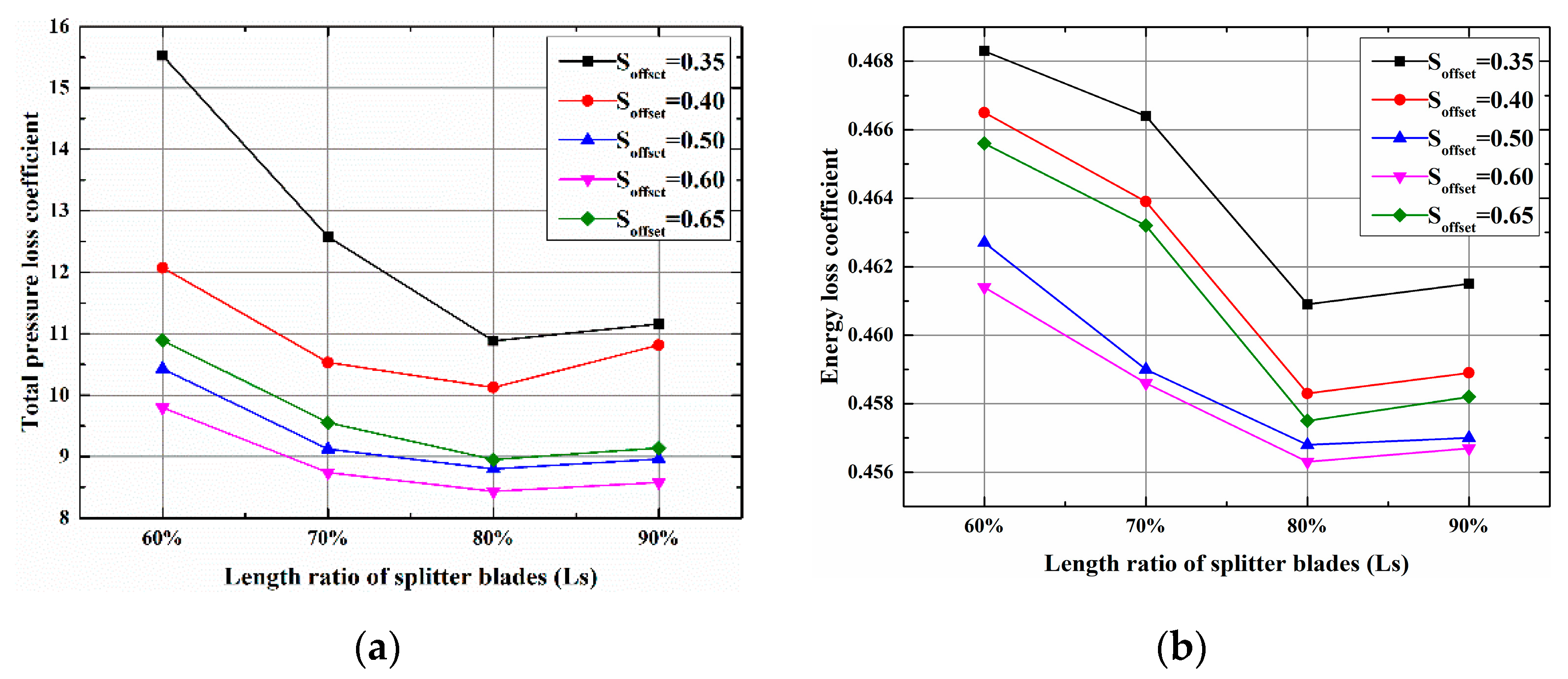

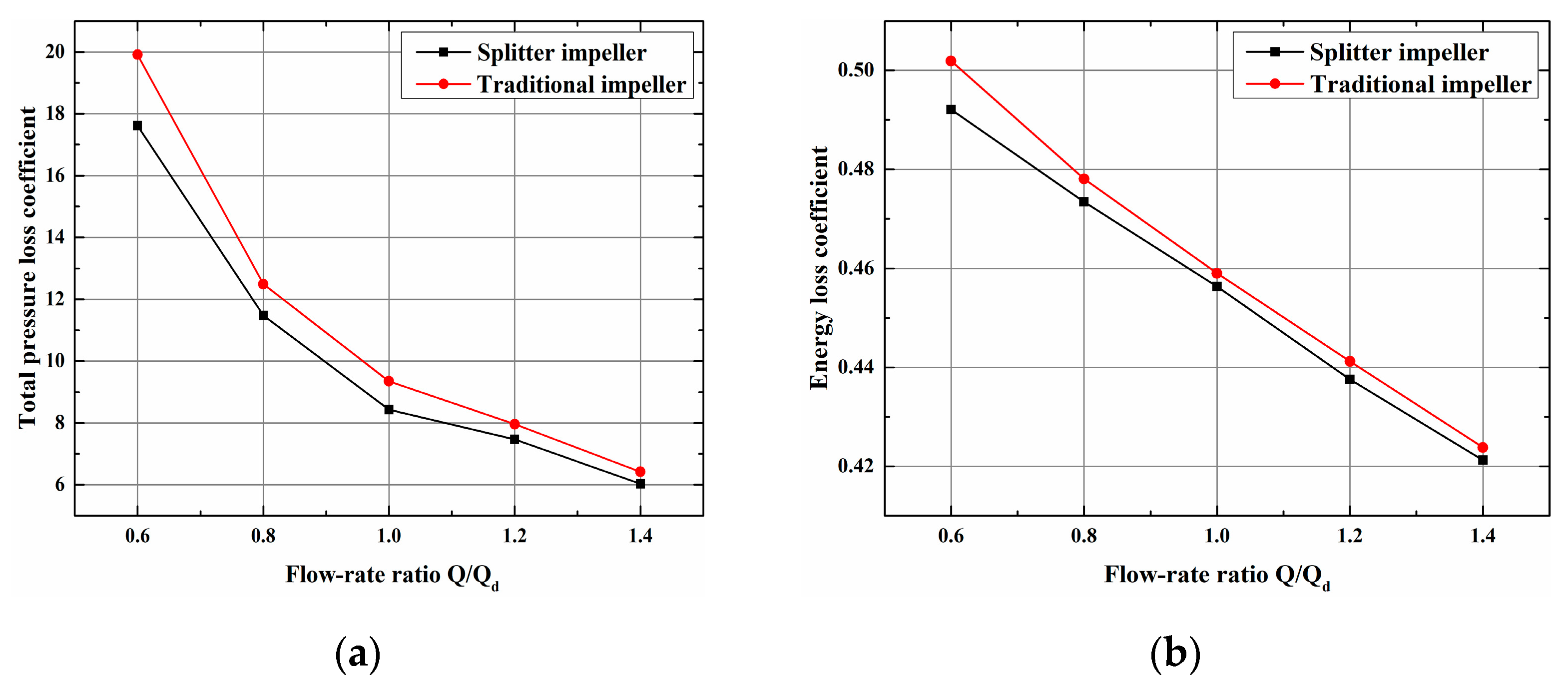

3.4. Influence of Splitter Blades on Flow Losses Inside the Passages

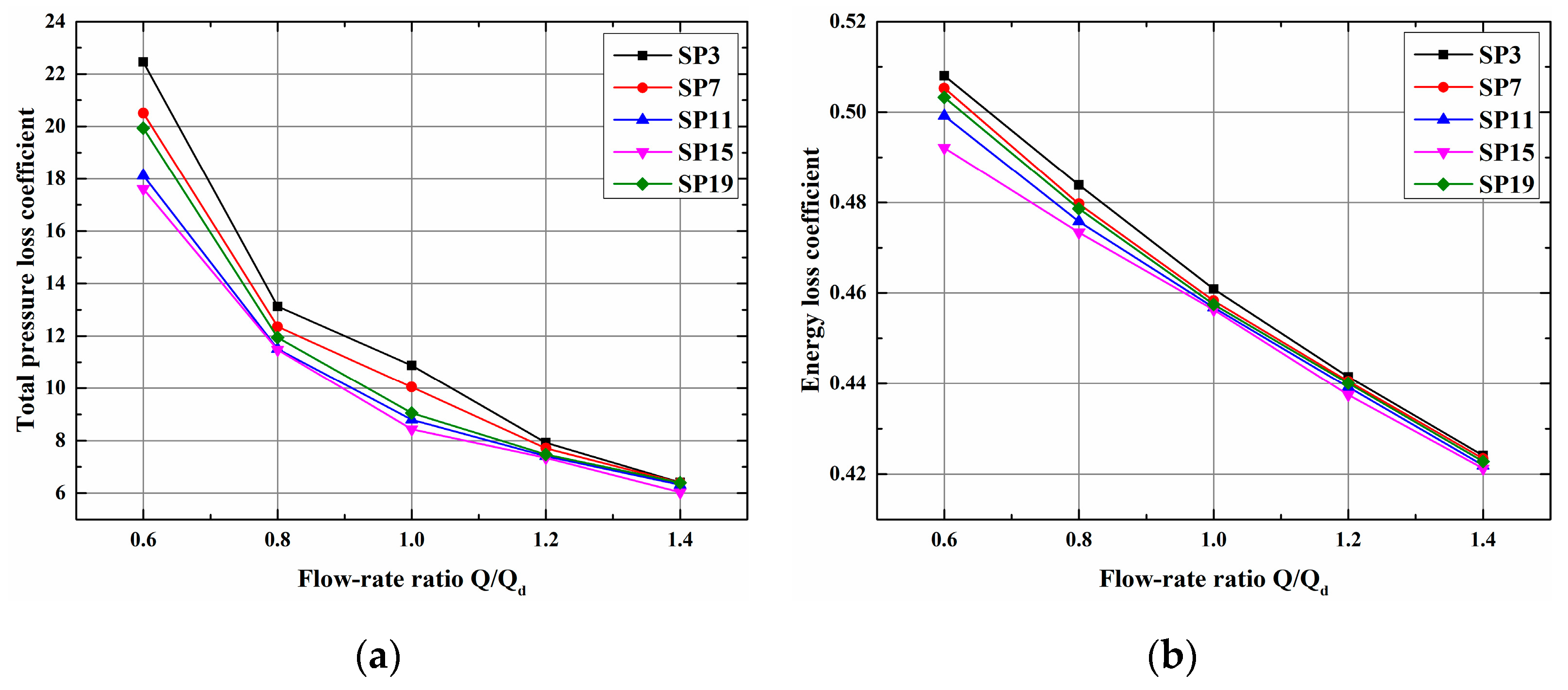

3.5. Performance Comparison of Splitter Impellers under Off-Design Conditions

3.6. Performance Comparison between Splitter Impeller and Traditional Impeller

4. Conclusions

- The splitter length exerts apparent effects on the impeller performance and internal flow. When the splitter blades are shorter, it easily leads to inlet obstruction and energy dissipation. The splitter blades’ ability to share the load is weak. With the increase in splitter length, the flow field can be optimized. Furthermore, the splitter blades’ ability to share the load correspondingly improves. Nevertheless, with further increases in splitter length, the flow field deteriorated again, which decreased the impeller performance. Thus, the splitter blades cannot be excessively short or long. As for the calculation case in this study, when Ls is about 80%, the flow field distribution inside the impeller is optimum.

- The circumferential distribution of blades also has a relatively large impact on the impeller performance and internal flow. The circumferential offset influences the distribution of the passage, and the differences in passage distribution lead to different flow states inside the passages and greater differences in their aerodynamic characteristics. With comprehensive consideration of the streamline distribution, static entropy distribution, and performance curves, the offset of splitter blades in the ORC turbine shall be reasonable within the range of 0.5–0.6, wherein there exists the optimal value.

- The length and circumferential offset of the splitter blades exert comprehensive effects on the impeller performance of the ORC radial inflow turbine. There exists an optimal impeller scheme for the 10 kW ORC turbine considered in this study. In other words, the optimal impeller performance exists when the circumferential offset of the splitter blades is about 0.6 and the blade length is about 80% of the main blade length, and this impeller still has the best performance under off-design conditions. In addition, the performance of this impeller is also better than that of the traditional impeller. This studies only considers the impeller, and does not consider the interaction between the volute and the impeller and nozzle. In future work, the simulation of the whole turbine should be considered, and an experimental platform can be built for research.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Bz | extensional length of rotor (mm) | Greek symbols | |

| diameter (mm) | efficiency | ||

| relative diameter | absolute flow angle (°) | ||

| specific diameter | relative flow angle (°) | ||

| h | specific enthalpy (kJ/kg) | pressure ratio | |

| i | incident angle (°) | stator velocity coefficient | |

| L | blade height (mm) | rotor velocity coefficient | |

| L | blade height relative | reaction degree | |

| m | mass flow rate (kg/s) | ||

| n | rotational speed (rpm) | Abbreviations | |

| N | blade number of rotor | 0 | stator inlet |

| Ns | specific speed | 1 | rotor inlet/stator outlet |

| total pressure (MPa) | 2 | rotor outlet | |

| P | pressure (MPa) | sh | shroud |

| total temperature (K) | h | hub | |

| T | temperature (K) | ||

| t | obstruction coefficient | Subscripts | |

| w | relative speed (m/s) | PS | pressure surface |

| inlet Mach number | SS | suction surface | |

References

- Yamaguchi, H.; Zhang, X.; Fujima, K.; Enomoto, M.; Sawada, N. Solar energy powered Rankine cycle using supercritical CO2. Appl. Therm. Eng. 2006, 26, 2345–2354. [Google Scholar] [CrossRef]

- Dai, Y.; Wang, J.; Gao, L. Parametric optimization and comparative study of organic Rankine cycle (ORC) for low grade waste heat recovery. Energy Convers. Manag. 2009, 50, 576–582. [Google Scholar] [CrossRef]

- Hettiarachchi, H.M.; Golubovic, M.; Worek, W.M.; Ikegami, Y. Optimum design criteria for an organic Rankine cycle using low-temperature geothermal heat sources. Energy 2007, 32, 1698–1706. [Google Scholar] [CrossRef]

- Quoilin, S.; Van Den Broek, M.; Declaye, S.; Dewallef, P.; Lemort, V. Techno-economic survey of Organic Rankine Cycle (ORC) systems. Renew. Sustain. Energy Rev. 2013, 22, 168–186. [Google Scholar] [CrossRef] [Green Version]

- Astofi, M. An Innovative Approach for the Techno-Economic Optimization of Organic Rankine Cycles. Ph.D. Thesis, Politecnico di Milano, Milano, Italy, 2014. [Google Scholar]

- Landelle, A.; Tauveron, N.; Haberschill, P.; Revellin, R.; Colassibm, S. Performance Evaluation and Comparison of Experimental Organic Rankine Cycle Prototypes from Published Data. Energy Procedia 2017, 105, 1706–1711. [Google Scholar] [CrossRef]

- Kang, S.H. Design and experimental study of ORC (organic Rankine cycle) and radial turbine using R245fa working fluid. Energy 2012, 41, 514–524. [Google Scholar] [CrossRef]

- Quoilin, S.; Lemort, V. Technological and economical survey of organic Rankine cycle systems. In Proceedings of the 5th European Conference Economics and Management of Energy in Industry, Algarve, Portugal, 14–17 April 2009. [Google Scholar]

- Harinck, J.; Pasquale, D.; Pecnik, R.; Buijtenen, J.V.; Cplonna, P. Performance improvement of a radial orc turbine by means of automated CFD design. In Proceedings of the 10th European Conference on Turbomachinery Fluid Dynamics and Thermodynamics, Lappeenranta, Finland, 15–19 April 2013; Lappeenranta University of Technology: Lappeenranta, Finland; pp. 763–775. [Google Scholar]

- Nithesh, K.; Chatterjee, D. Numerical prediction of the performance of radial inflow turbine designed for ocean thermal energy conversion system. Appl. Energy 2016, 167, 1–16. [Google Scholar] [CrossRef]

- Glassman, A.J. Computer Program for Design Analysis of Radial-Inflow Turbines; NASATechnical Report TN D-8164; NASA: Washington, DC, USA, 1976. [Google Scholar]

- Aungier, R.H. Preliminary Aerodynamic Design of Axial-Flow Turbine Stages; ASME Press: New York, NY, USA, 2006. [Google Scholar]

- Carrillo, R.A.M.; Nascimento, M.A.R.; Gutieŕrez Velásquez, E.I.; Moura, N.R. Radial Inflow Turbine One and Tri-Dimensional Design Analysis of 600 kW Simple Cycle Gas Turbine Engine. In Proceedings of the ASME Turbo Expo 2010: Power for Land, Sea, and Air, Glasgow, UK, 14–18 June 2010; pp. 477–486. [Google Scholar]

- Fiaschi, D.; Manfrida, G.; Maraschiello, F. Thermo-fluid dynamics preliminary design of turbo-expanders for ORC cycles. Appl. Energy 2012, 97, 601–608. [Google Scholar] [CrossRef]

- Fiaschi, D.; Manfrida, G.; Maraschiello, F. Design and performance prediction of radial ORC turboexpanders. Appl. Energy 2015, 138, 517–532. [Google Scholar] [CrossRef]

- Sauret, E.; Rowlands, A.S. Candidate radial-inflow turbines and high-density working fluids for geothermal power systems. Energy 2011, 36, 4460–4467. [Google Scholar] [CrossRef]

- Li, Y.; Ren, X.D. Investigation of the organic Rankine cycle (ORC) system and the radial-inflow turbine design. Appl. Therm. Eng. 2016, 96, 547–554. [Google Scholar] [CrossRef]

- Wang, H.; Peterson, R.; Herron, T. Design study of configurations on system COP for a combined ORC (organic Rankine cycle) and VCC (vapor compression cycle). Energy 2011, 36, 4809–4820. [Google Scholar] [CrossRef]

- Pasquale, D.; Ghidoni, A.; Rebay, S. Shape optimization of an organic rankine cycle radial turbine nozzle. J. Eng. Gas Turbines Power 2013, 135, 042308. [Google Scholar] [CrossRef]

- Shuai, S.; Deng, Q.; Feng, Z. Aerodynamic Optimization of the Radial Inflow Turbine for a 100 kW-Class Micro Gas Turbine Based on Metamodel-Semi-Assisted Method; ASME Paper GT2013-94580; ASME: New York, NY, USA, 2013. [Google Scholar]

- Barr, L.; Spence, S.; Thornhill, D.; Eynon, P. A Numerical and Experimental Performance Comparisonof an 86 mm Radial and Back Swept Turbine. In Proceedings of the ASME Turbo Expo 2009: Power for Land, Sea, and Air, Orlando, FL, USA, 8–12 June 2009. [Google Scholar]

- Miyamoto, H.; Nakashima, Y.; Ohba, H. Effects of splitter blades on the flows and characteristics in centrifugal impellers. JSME Int. J. Transf. Power Combust. Phys. Prop. 1992, 35, 238–246. [Google Scholar] [CrossRef] [Green Version]

- Miyamoto, H.; Nakashima, Y.; Yasunaga, Y.; Shiramoto, K. Study on flow of centrifugal impeller (1st report, Flow measurement in unshrouded impeller passage). Trans. Jpn. Soc. Mech. Eng. 1989, 55, B1137. (In Japanese) [Google Scholar] [CrossRef]

- Moussavi, S.A.; Benisi, A.H.; Durali, M. Effect of splitter leading edge location on performance of an automotive turbocharger compressor. Energy 2017, 123, 511–520. [Google Scholar] [CrossRef]

- Xu, C.; Amano, R. Centrifugal compressor performance improvements through compressor splitter location. J. Energy Resour. Technol. 2017, 140, 051201. [Google Scholar] [CrossRef]

- Ye, L.; Yuan, S.; Zhang, J.; Yuan, Y. Effects of Splitter Blades on the Unsteady Flow of a Centrifugal Pump. In Proceedings of the ASME 2012 Fluids Engineering Division Summer Meeting Collocated with the ASME 2012 Heat Transfer Summer Conference and the ASME 2012, International Conference on Nanochannels, Microchannels, and Minichannels, Rio Grande, Puerto Rico, USA, 8–12 July 2012; pp. 435–441. [Google Scholar]

- Gölcü, M.; Pancar, Y.; Sekmen, Y. Energy saving in a deep well pump with splitter blade. Energy Convers. Manag. 2006, 47, 638–651. [Google Scholar] [CrossRef]

- Gui, L.; Gu, C.; Chang, H. Influences of splitter blades on the centrifugal fan performance; 89-GT-33. In Proceedings of the ASME, the Gas Turbine and Aeroengine Congress and Exposition, Toronto, ON, Canada, 4–8 June 1989. [Google Scholar]

- Tjokroamlnata, W.; Tan, C.; Hawthorne, W. A design study of radial inflow turbines with splitter blades in three-dimensional flow. In Proceedings of the ASME 1994 International Gas Turbine and Aeroengine Congress and Exposition, Cincinnati, OH, USA, 24–27 May 1994. [Google Scholar]

- Walkingshaw, J.; Spence, S.; Filsinger, D.; Thornhill, D. A Numerical and Experimental Assessment of the Use of a Turbine Utilizing Splitter Blades for an Automotive Variable Geometry Turbocharger. In Proceedings of the ASME Turbo Expo 2014: Turbine Technical Conference and Exposition, Düsseldorf, Germany, 16–20 June 2014. [Google Scholar]

- Aungier, R.H. Turbine Aerodynamics: Axial-Flow and Radial-Inflow Turbine Design and Analysis; ASME Press: New York, NY, USA, 2006. [Google Scholar]

- Li, Y.; Lu, G. Radial Turbines and Centrifugal Compressors, 1st ed.; China Machine Press: Beijing, China, 1987. [Google Scholar]

- Selig, M.S.; Coverstone-Carroll, V.L. Application of a Genetic Algorithm to Wind Turbine Design. J. Energy Resour. Technol. 1996, 118, 22–28. [Google Scholar] [CrossRef] [Green Version]

- Qin, X.; Chen, L.; Sun, F.; Wu, C. Optimization for a steam turbine stage efficiency using a genetic algorithm. Appl. Therm. Eng. 2003, 23, 2307–2316. [Google Scholar] [CrossRef]

- Naga Srinivasa, P.R. Flow Studies in Radial Inflow Turbines. Ph.D. Thesis, Indian Institute of Technology Madras, Chennai, India, 1993. [Google Scholar]

| Type | Name | Symbol | Unit | Range |

|---|---|---|---|---|

| Thermodynamic parameters | Total inlet pressure | MPa | 0.45–0.8 | |

| Total inlet temperature | K | 360–385 | ||

| Pressure ratio | — | 2–6 | ||

| Design parameters | Reaction degree | — | 0.35–0.55 | |

| Absolute inlet angle | Degree | 14–20 | ||

| Relative outlet angle | Degree | 35–40 | ||

| Speed ratio | — | 0.45–0.70 | ||

| Rotor diameter ratio | — | 0.4–0.6 | ||

| Stator velocity coefficient | — | 0.92 | ||

| Rotor velocity coefficient | — | 0.8 |

| Name | Symbol | Constraint Range |

|---|---|---|

| Incidence angle | −10–5° | |

| Inlet Mach number | The smaller, the better; not larger than 1.35 | |

| Relative speed | w2 < w1 | |

| Relative shroud diameter | <0.85 | |

| Relative hub diameter | 0.15–0.35 | |

| Obstruction coefficient of rotor outlet | >0 | |

| Turbine outlet pressure | >1 atm | |

| Relative blade height to rotor inlet | 0.02–0.17; the larger, the better |

| Name | Symbol | Unit | Value |

|---|---|---|---|

| Total inlet pressure | MPa | 0.49 | |

| Total inlet temperature | K | 377.15 | |

| Pressure ratio | — | 2.6 | |

| Reaction degree | — | 0.437 | |

| Absolute inlet angle of rotor impeller | degree | 14 | |

| Absolute outlet angle of rotor impeller | degree | 35 | |

| Speed ratio | — | 0.684 | |

| Rotor impeller diameter ratio | — | 0.55 | |

| Mass flow rate | kg/s | 0.7 | |

| Temperature of rotor inlet | K | 370 | |

| Temperature of rotor outlet | K | 355 | |

| Backpressure at rotor outlet | P2 | Pa | 80,675 |

| Rotational speed of rotor impeller | rpm | 30,000 | |

| Blade number of rotor impeller | — | 7 Main + 7 splitter | |

| Outer diameter of rotor | mm | 88 | |

| Blade height of rotor inlet | mm | 5.8 | |

| Relative blade height of rotor inlet | — | 0.066 | |

| Shroud diameter of rotor outlet | mm | 65 | |

| Hub diameter of rotor outlet | mm | 21.4 | |

| Extensional length of rotor impeller | mm | 30.8 | |

| Specific speed | — | 0.49 | |

| Specific diameter | — | 4.08 |

| Impeller Scheme | Offset and Meridian Length of Splitter Blades |

|---|---|

| SP1–SP4 | Soffset = 0.35, Ls = 60%, 70%, 80%, 90% |

| SP5–SP8 | Soffset = 0.40, Ls = 60%, 70%, 80%, 90% |

| SP9–SP12 | Soffset = 0.50, Ls = 60%, 70%, 80%, 90% |

| SP13–SP16 | Soffset = 0.60, Ls = 60%, 70%, 80%, 90% |

| SP17–SP20 | Soffset = 0.65, Ls = 60%, 70%, 80%, 90% |

| Parameter | Value |

|---|---|

| Substance identification number CAS# | 460-73-1 |

| Molar mass | 134.05 kg/mol |

| Three-phase point temperature | 171.05 K |

| Standard boiling point temperature | 288.29 K |

| Critical point temperature | 427.16 K |

| Critical point pressure | 3.651 MPa |

| Critical point density | 516.08 kg/m3 |

| Eccentricity factor | 0.3776 |

| Ozone depression potential (ODP) | 0 |

| Global warming potential (GWP) | 1030 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Zhu, Z.; Li, X.; Zhang, Y.; Gao, W. Aerodynamic Optimization of a 10 kW Radial Inflow Turbine with Splitter Blades. Processes 2021, 9, 1256. https://doi.org/10.3390/pr9071256

Chen Y, Zhu Z, Li X, Zhang Y, Gao W. Aerodynamic Optimization of a 10 kW Radial Inflow Turbine with Splitter Blades. Processes. 2021; 9(7):1256. https://doi.org/10.3390/pr9071256

Chicago/Turabian StyleChen, Yuxuan, Zhicheng Zhu, Xiao Li, Yanping Zhang, and Wei Gao. 2021. "Aerodynamic Optimization of a 10 kW Radial Inflow Turbine with Splitter Blades" Processes 9, no. 7: 1256. https://doi.org/10.3390/pr9071256

APA StyleChen, Y., Zhu, Z., Li, X., Zhang, Y., & Gao, W. (2021). Aerodynamic Optimization of a 10 kW Radial Inflow Turbine with Splitter Blades. Processes, 9(7), 1256. https://doi.org/10.3390/pr9071256