Inferential Online Measurement of 3D Fractal Dimension of Spray Fluidized Bed Agglomerates

Abstract

1. Introduction

2. Agglomerate Formulation and Characterization

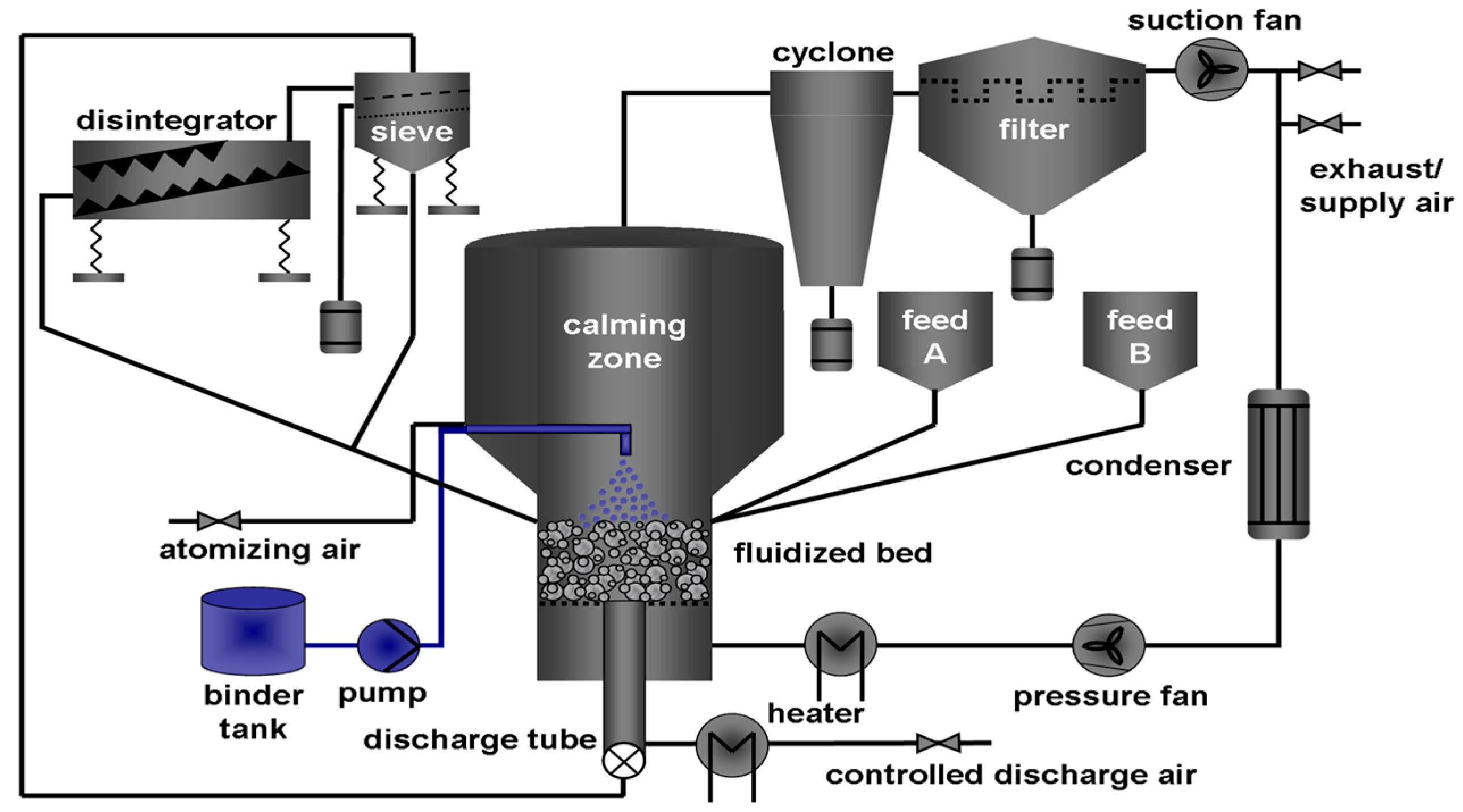

2.1. Spray Fluidized Bed Agglomeration: Process Setup

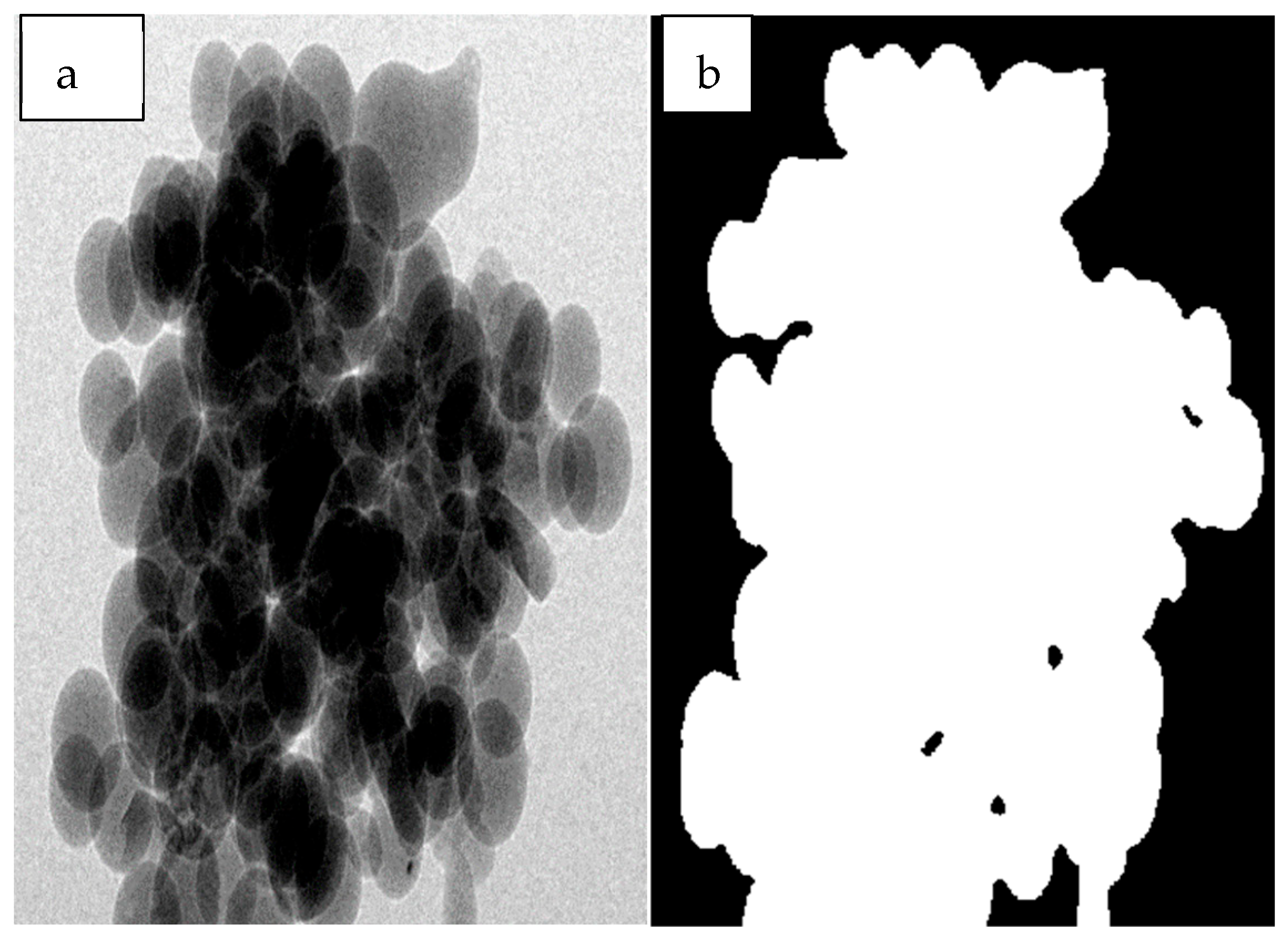

2.2. Offline Data Evaluation: 3D and Image Information from X-Ray Μ-Computed Tomography

2.3. Online Data Source: High-Speed Image Acquisition

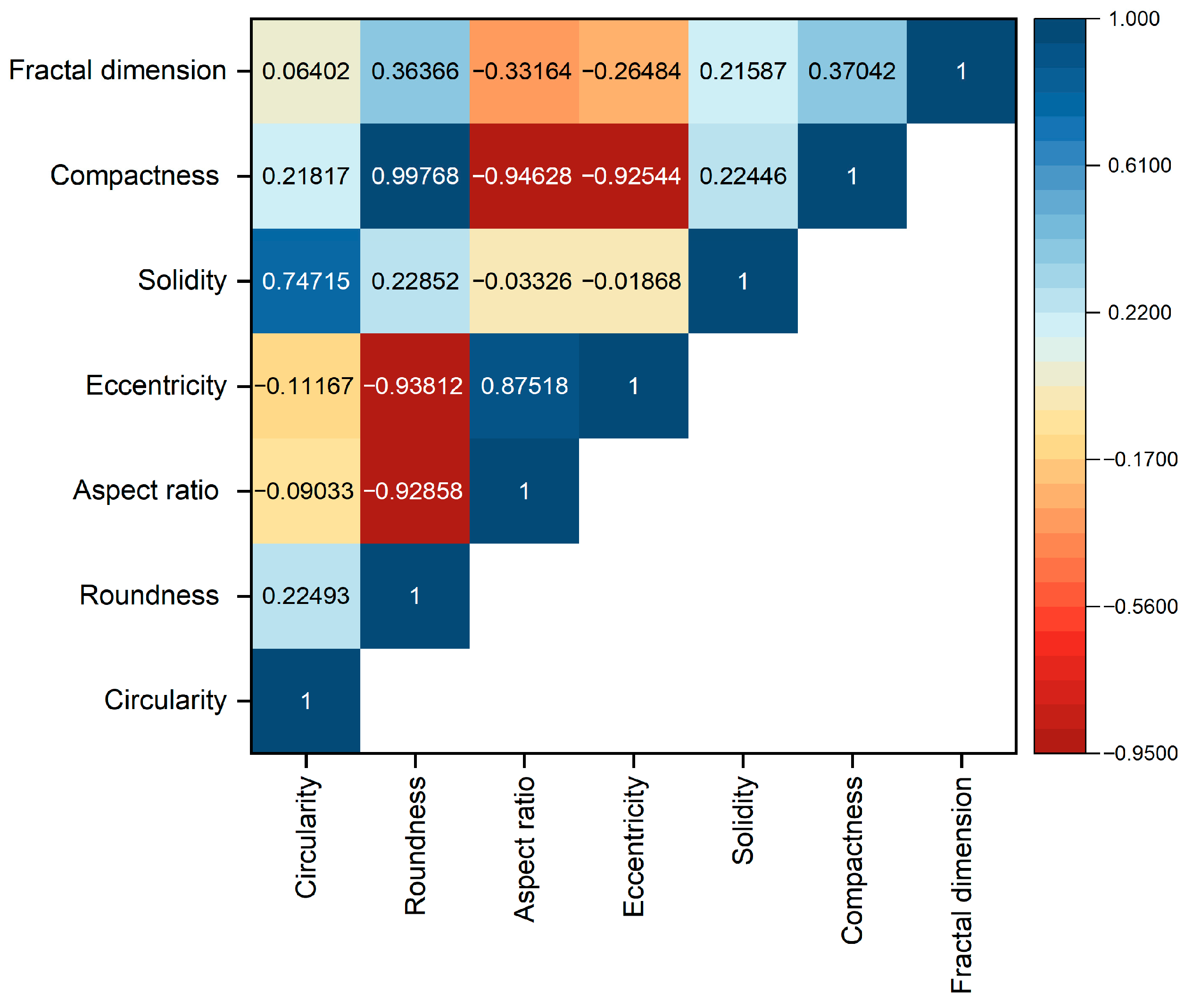

3. Inferential Assessment of Online 3D Fractal Dimension: Development, Results, and Discussion

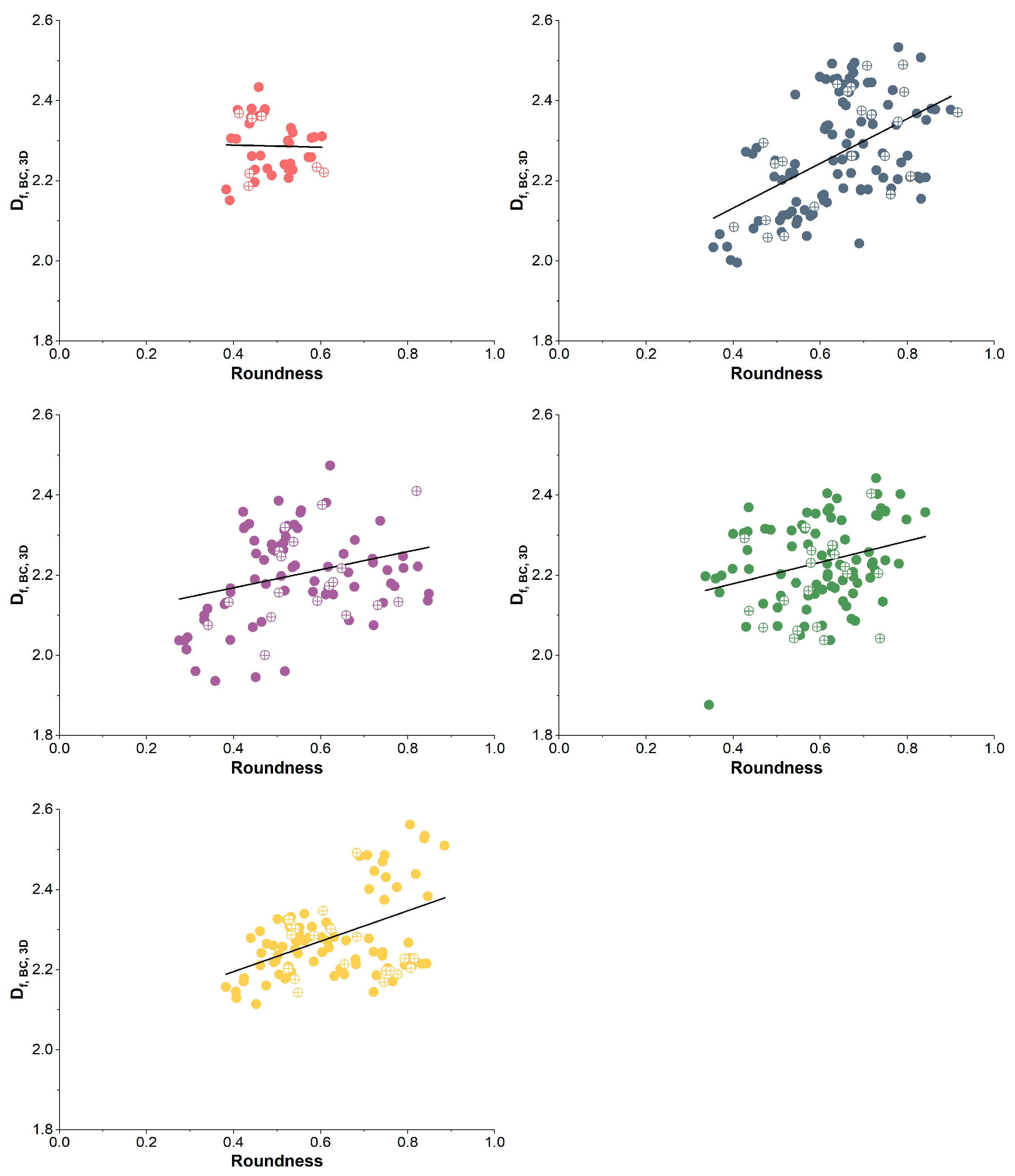

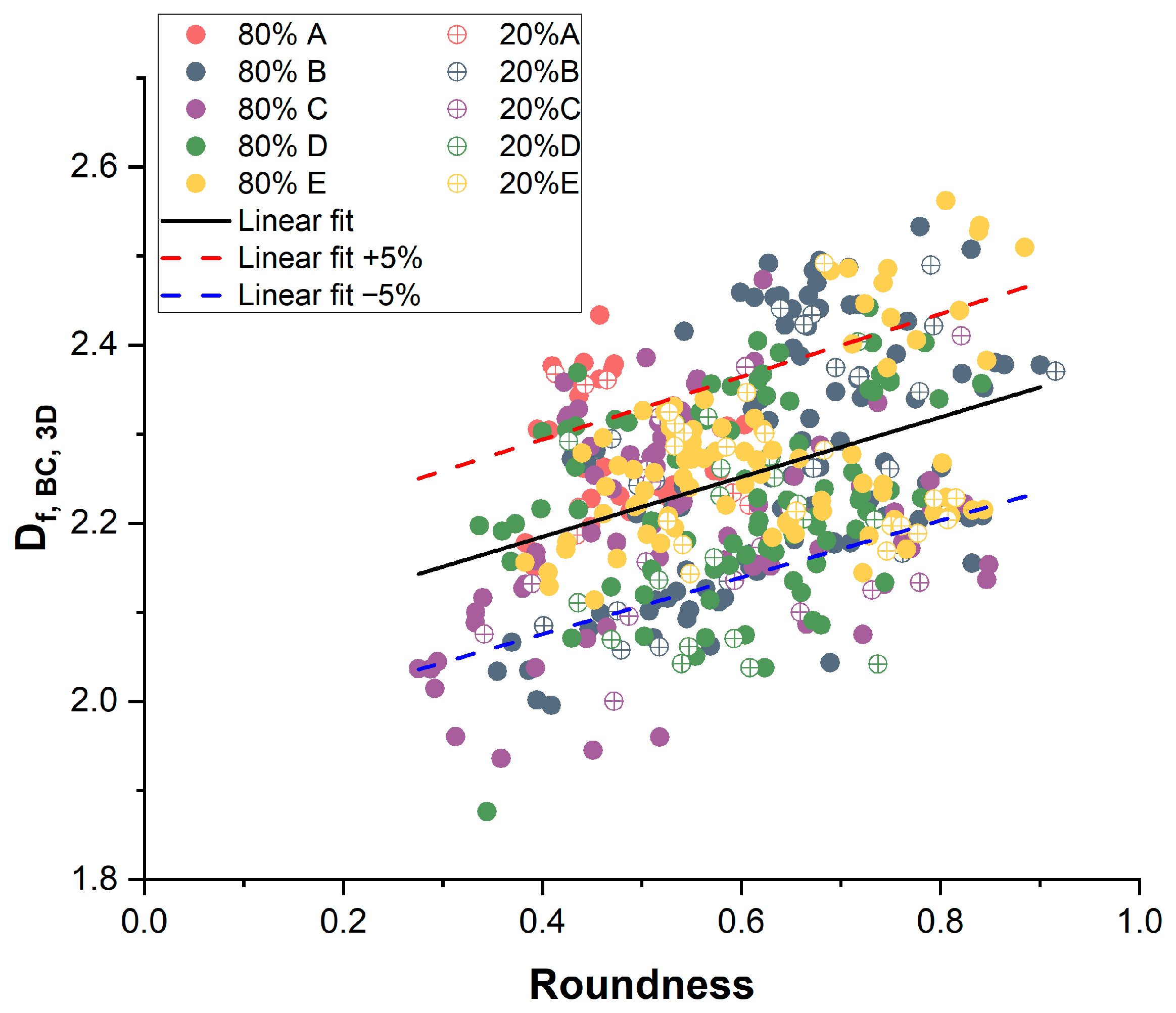

3.1. Correlating Agglomerate Roundness R to 3D Fractal Dimension Using Offline Data

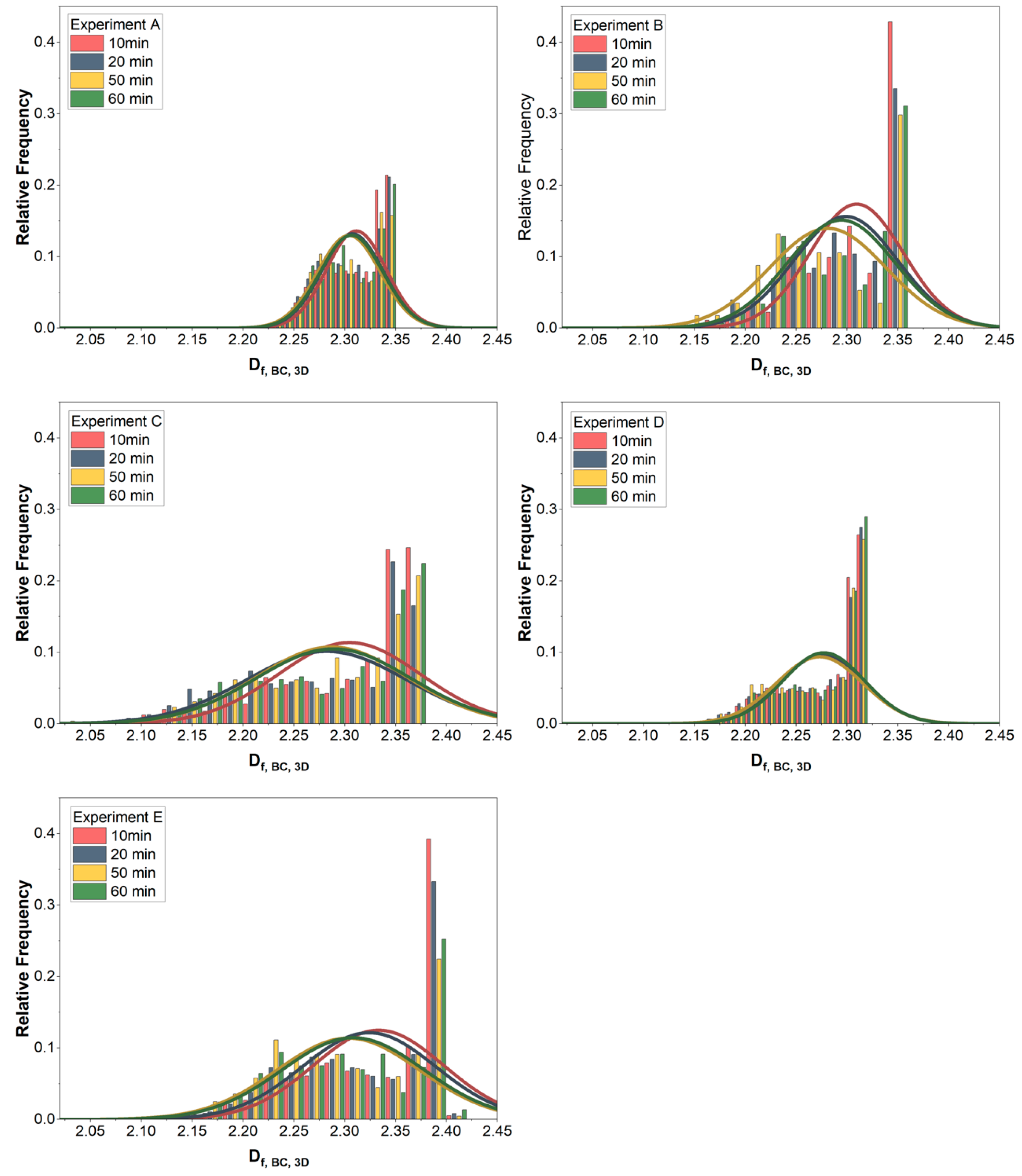

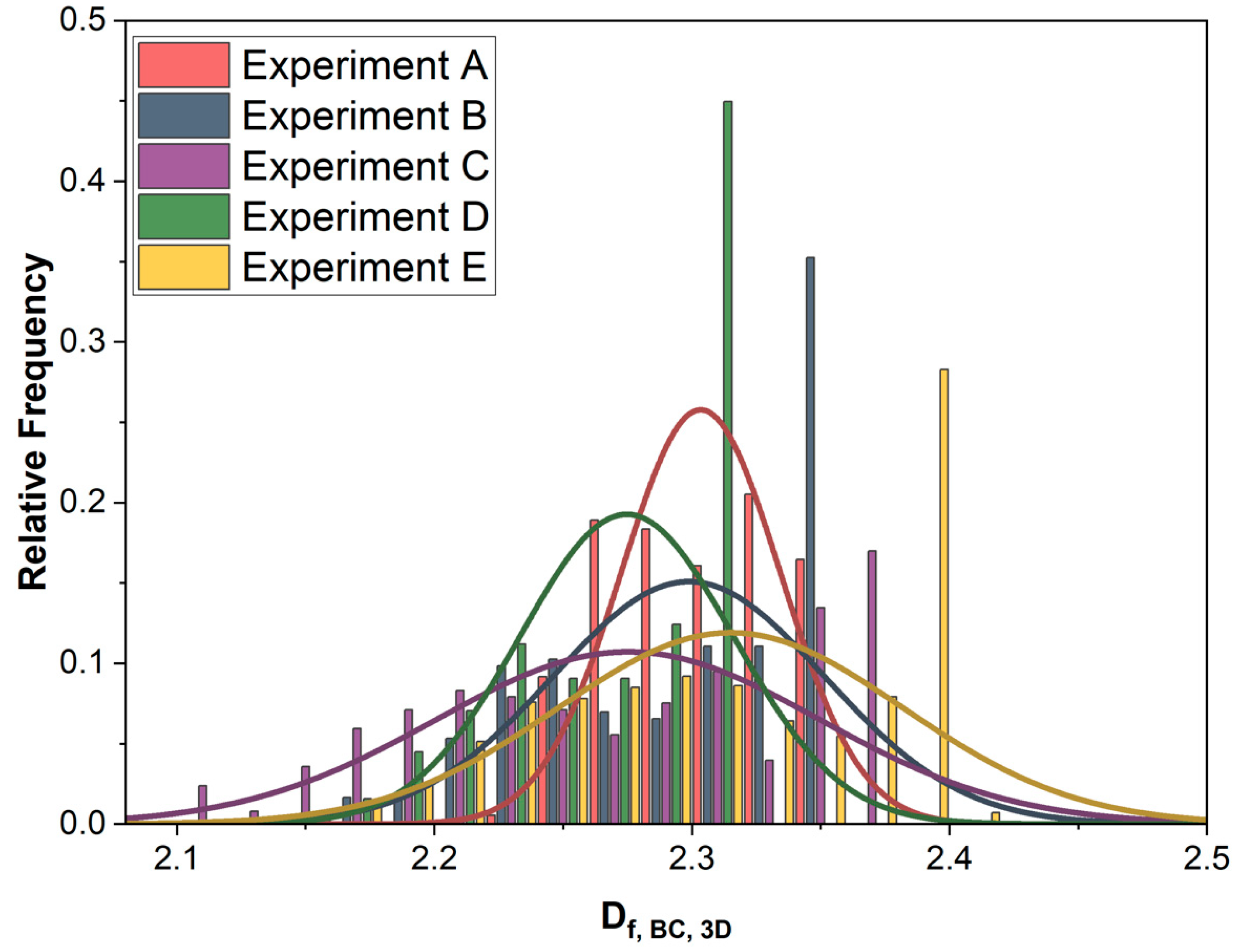

3.2. Fractal Dimension Formation Dynamics and 3D Fractal Dimension Distribution from Online Data

4. Conclusions and Outlook

- By sensitivity analysis, the geometric shape factor of the roundness of the single agglomerate was identified as the most suitable proxy variable for inferential correlation to the 3D fractal dimension of a single agglomerate.

- Inferential evaluation can be performed at about 5 ms per agglomerate on average, about one order of magnitude faster than by box-counting (200 ms on average) due to the avoidance of an iterative process.

- Evaluating online measurement data, new insights into the dynamics of the structure formation of spray agglomerated materials were obtained, especially with respect to the evolution of the property distribution (multi-modal and non-normal). This general information can be used for the rational design of agglomerated products and optimized process operation [27,28,29].

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Palzer, S. Agglomeration of pharmaceutical, detergent, chemical and food powders—Similarities of materials and processes. Powder Technol. 2011, 206, 2–17. [Google Scholar] [CrossRef]

- Dadkhah, M.; Peglow, M.; Tsotsas, E. Characterization of the internal morphology of agglomerates produced in a spray fluidized bed by X-ray tomography. Powder Technol. 2012, 228, 349–358. [Google Scholar] [CrossRef]

- Gao, S.; Li, Q.; Luo, J. Fractal characteristic of recycled aggregate and its influence on physical property of recycled aggregate concrete. Rev. Adv. Mater. Sci. 2021, 60, 663–677. [Google Scholar] [CrossRef]

- Elhmali, H.T.; Serpa, C.; Radojevic, V.; Stajcic, A.; Petrovic, M.; Jankovic-Castvan, I.; Stajcic, I. Correlation between agglomerates Hausdorff dimension and mechanical properties of denture poly(methyl methacrylate)-based composites. Fractal Fract. 2024, 8, 314. [Google Scholar] [CrossRef]

- Bahramian, A. The mutual effects between the interparticle forces and mechanical properties on fluidization of TiO2 nanoparticle agglomerates in a conical fluidized bed: Nanoindentation and pressure fluctuation analysis. J. Nanoparticle Res. 2019, 21, 196. [Google Scholar] [CrossRef]

- Khadilkar, A.B.; Rozelle, P.L.; Pisupati, S.V. Investigation of fluidized bed agglomerate growth process using simulations and SEM-EDX characterization of laboratory-generated agglomerates. Chem. Eng. Sci. 2018, 184, 172–185. [Google Scholar] [CrossRef]

- Furuvik, N.C.I.S.; Wang, L.; Jaiswal, R.; Thapa, R.; Eikeland, M.S.; Moldestad, B.M.E. Experimental study and SEM-EDS analysis of agglomerates from gasification of biomass in fluidized beds. Energy 2022, 252, 124034. [Google Scholar] [CrossRef]

- De Temmerman, P.-J.; Van Doren, E.; Verleysen, E.; Van der Stede, Y.; Abi Daoud Francisco, M.; Mast, J. Quantitative characterization of agglomerates and aggregates of pyrogenic and precipitated amorphous silica nanomaterials by transmission electron microscopy. J. Nanobiotechnol. 2012, 10, 24. [Google Scholar] [CrossRef] [PubMed]

- LaRocca, A.; Bonatesta, F.; Fay, M.W.; Campanella, F. Characterization of soot in oil from a gasoline direct injection engine using Transmission Electron Microscopy. Tribol. Int. 2015, 86, 77–84. [Google Scholar] [CrossRef]

- Farber, L.; Tardos, G.; Michaels, J.N. Use of X-ray tomography to study the porosity and morphology of granules. Powder Technol. 2003, 132, 57–63. [Google Scholar] [CrossRef]

- Pashminehazar, R.; Kharaghani, A.; Tsotsas, E. Three dimensional characterization of morphology and internal structure of soft material agglomerates produced in spray fluidized bed by X-ray tomography. Powder Technol. 2016, 300, 46–60. [Google Scholar] [CrossRef]

- Campello, S.L.; dos Santos, W.P.; Machado, V.F.; Mota, V.F.; Gomes, A.S.L.; de Souza, R.E. Micro-structural information of porous materials by optical coherence tomography. Microporous Mesoporous Mat. 2014, 198, 50–54. [Google Scholar] [CrossRef]

- Dong, Y.; Lin, H.; Abolghasemi, V.; Gan, L.; Zeitler, J.A.; Shen, Y.-C. Investigating intra-tablet coating uniformity with spectral-domain Optical Coherence Tomography. J. Pharm. Sci. 2017, 106, 546–553. [Google Scholar] [CrossRef] [PubMed]

- Koukoulas, T.; Broughton, W.R.; Williams, J.; Rahatekar, S. Optical characterisation of polymeric nanocomposites using tomographic, spectroscopic and Fraunhofer wavefront assessment. Proc. Opt. Syst. Des. 2012, 8550, 855039. [Google Scholar]

- Windows-Yule, C.R.K.; Buist, K.A.; Taghizadeh, K.; Finotello, G.; Nicusan, A.L. A multidisciplinary perspective on the present and future of particle imaging. Particuology 2025, 101, 3–17. [Google Scholar] [CrossRef]

- Silva, A.F.T.; Burggraeve, A.; Denon, Q.; Van der Meeren, P.; Sandler, N.; Van Den Kerkhof, T.; Hellings, M.; Vervaet, C.; Remon, J.P.; Almeida Lopes, J.; et al. Particle sizing measurements in pharmaceutical applications: Comparison of in-process methods versus off-line methods. Eur. J. Pharm. Biopharm. 2013, 85, 1006–1018. [Google Scholar] [CrossRef] [PubMed]

- Naidu, V.R.; Deshpande, R.S.; Syed, M.R.; Wakte, P.S. Real-time imaging as an emerging process analytical technology tool for monitoring of fluid bed coating process. Pharm. Dev. Technol. 2017, 23, 596–601. [Google Scholar] [CrossRef] [PubMed]

- Otto, E.; Dürr, R.; Kienle, A. Stability of combined continuous granulation and agglomeration processes in a fluidized bed with sieve-mill-recycle. Processes 2023, 11, 473. [Google Scholar] [CrossRef]

- Ajalova, A.; Ma, W.; Hoffmann, T.; Tsotsas, E. Continuous spray fluidized bed agglomeration: Influence of gas inlet temperature and binder content on growth and morphology. Powder Technol. 2025, 464, 121260. [Google Scholar] [CrossRef]

- Arasan, S.; Akbulut, S.; Hasiloglu, A.S. The relationship between the fractal dimension and shape properties of particles. KSCE J. Civil Eng. 2011, 15, 1219–1225. [Google Scholar] [CrossRef]

- Walsh, J.J.; Watterson, J. Fractal analysis of fracture patterns using the standard box-counting technique: Valid and invalid methodologies. J. Struct. Geol. 1993, 15, 1509–1512. [Google Scholar] [CrossRef]

- Wang, R.; Singh, A.K.; Kolan, S.R.; Tsotsas, E. Fractal analysis of aggregates: Correlation between the 2D and 3D box-counting fractal dimension and power law fractal dimension. Chaos Solitons Fractals 2022, 160, 112246. [Google Scholar] [CrossRef]

- Turchiuli, C.; Castillo-Castaneda, E. Agglomerates structure characterization using 3D-image reconstruction. Part. Part. Syst. Charact. 2009, 26, 25–33. [Google Scholar] [CrossRef]

- Groppe, P.; Reichstein, J.; Carl, S.; Cuadrado Collados, C.; Niebuur, B.-J.; Zhang, K.; Apeleo Zubiri, B.; Libuda, J.; Kraus, T.; Retzer, T.; et al. Catalyst supraparticles: Tuning the structure of spray-dried Pt/SiO2 supraparticles via salt-based colloidal manipulation to control their catalytic performance. Small 2024, 20, 2310813. [Google Scholar] [CrossRef] [PubMed]

- Mahr, C.; Stahl, J.; Gerken, B.; Krause, F.F.; Schowalter, M.; Grieb, T.; Mädler, L.; Rosenauer, A. Characterization of structure and mixing in nanoparticle hetero-aggregates using convolutional neural networks: 3D-reconstruction versus 2D-projection. Ultramicroscopy 2024, 265, 114020. [Google Scholar] [CrossRef] [PubMed]

- Markl, D.; Hannesschläger, G.; Sacher, S.; Leitner, M.; Khinast, J.G. Optical coherence tomography as a novel tool for in-line monitoring of a pharmaceutical film-coating process. Eur J Pharm Sci. 2014, 55, 58–67. [Google Scholar] [CrossRef] [PubMed]

- Koerfer, R.; Simutis, R. Advanced process control for fluidized bed agglomeration. Inform. Technol. Contr. 2008, 37, 285–293. [Google Scholar]

- Hogg, R. Agglomeration models for process design and control. Powder Technol. 1992, 69, 69–76. [Google Scholar] [CrossRef]

- Vesjolaja, L.; Glemmestad, B.; Lie, B. Double-Loop Control Structure for Rotary Drum Granulation Loop. Processes 2020, 8, 1423. [Google Scholar] [CrossRef]

- Barreirós, F.M.; Ferreira, J.M.; Figueiredo, M.M. Calculating shape factors from particle sizing data. Part. Part. Syst. Charact. 1996, 13, 368–373. [Google Scholar] [CrossRef]

| Parameter | A | B | C | D | E |

|---|---|---|---|---|---|

| Inlet gas temperature/°C | 80 | 90 | 100 | 90 | 90 |

| Binder weight fraction/w-% | 4 | 4 | 4 | 2 | 6 |

| Particle feed rate/g min−1 | 145 | 158 | 182 | 166 | 155 |

| Exp. | Individual Correlation | Normalized Residual Sum of Squares (80%) Individual Correlations | Normalized Residual Sum of Squares (20%) Individual Correlations | Normalized Residual Sum of Squares (20%) Equations (3) and (4) | Normalized Residual Sum of Squares (20%) Equation (5) |

|---|---|---|---|---|---|

| A | Df, BC, 3D = −0.0251 R + 2.299 | 0.0045 | 0.0054 | 0.0063 | 0.0116 |

| B | Df, BC, 3D = 0.557 R + 1.909 | 0.0137 | 0.0127 | 0.0143 | 0.0136 |

| C | Df, BC, 3D = 0.2256 R + 2.078 | 0.0116 | 0.0101 | 0.0102 | 0.0127 |

| D | Df, BC, 3D = 0.2664 R + 2.072 | 0.01 | 0.0126 | 0.0123 | 0.0149 |

| E | Df, BC, 3D = 0.3796 R + 2.043 | 0.0078 | 0.0108 | 0.0101 | 0.0091 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Men, J.; Ajalova, A.; Tsotsas, E.; Bück, A. Inferential Online Measurement of 3D Fractal Dimension of Spray Fluidized Bed Agglomerates. Processes 2025, 13, 2316. https://doi.org/10.3390/pr13072316

Men J, Ajalova A, Tsotsas E, Bück A. Inferential Online Measurement of 3D Fractal Dimension of Spray Fluidized Bed Agglomerates. Processes. 2025; 13(7):2316. https://doi.org/10.3390/pr13072316

Chicago/Turabian StyleMen, Jialin, Aisel Ajalova, Evangelos Tsotsas, and Andreas Bück. 2025. "Inferential Online Measurement of 3D Fractal Dimension of Spray Fluidized Bed Agglomerates" Processes 13, no. 7: 2316. https://doi.org/10.3390/pr13072316

APA StyleMen, J., Ajalova, A., Tsotsas, E., & Bück, A. (2025). Inferential Online Measurement of 3D Fractal Dimension of Spray Fluidized Bed Agglomerates. Processes, 13(7), 2316. https://doi.org/10.3390/pr13072316