Integrating Machine Learning into Asset Administration Shell: A Practical Example Using Industrial Control Valves

Abstract

1. Introduction

2. Conceptual Foundations

2.1. Asset Administration Shell

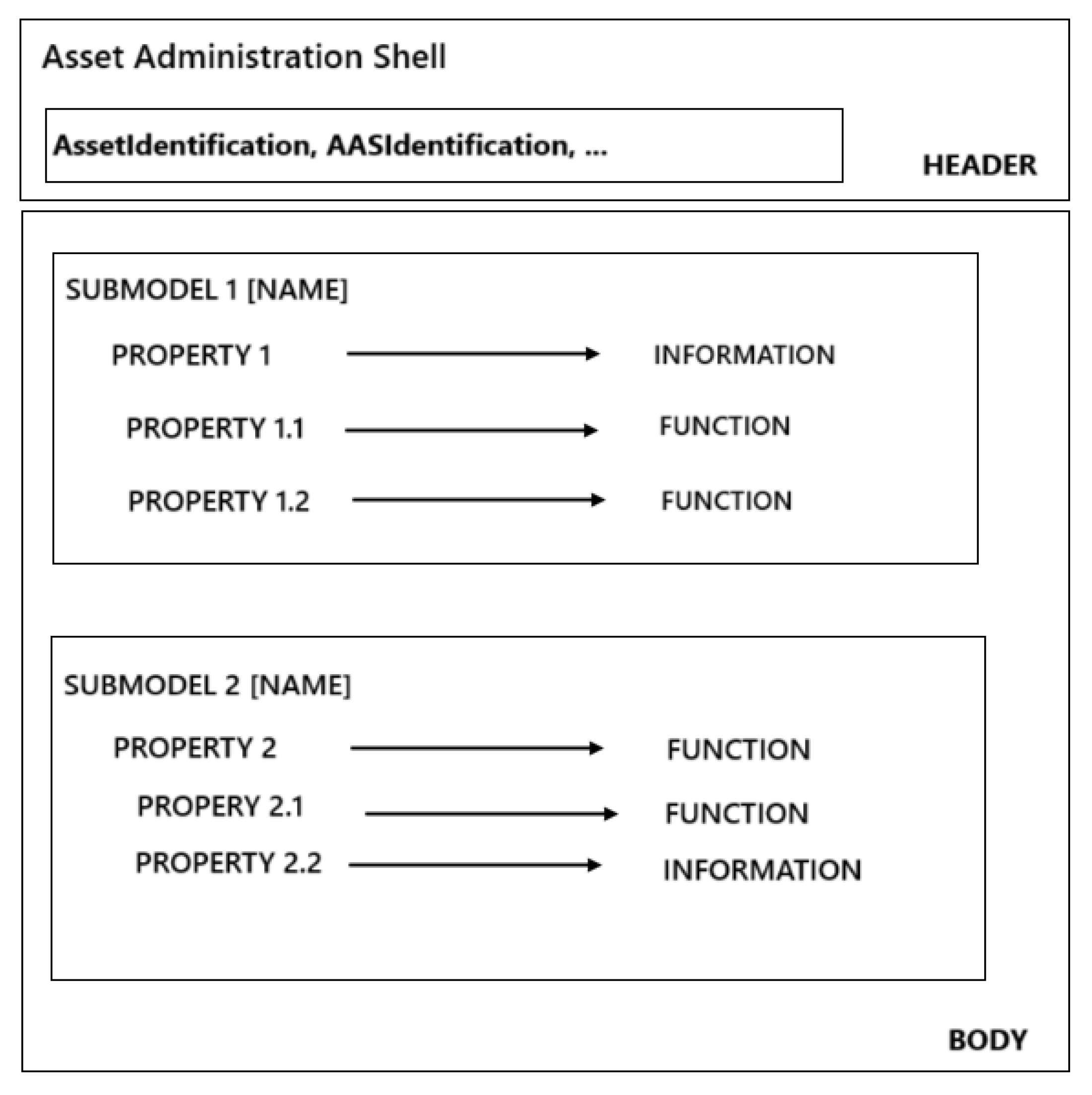

2.1.1. Asset Modeling

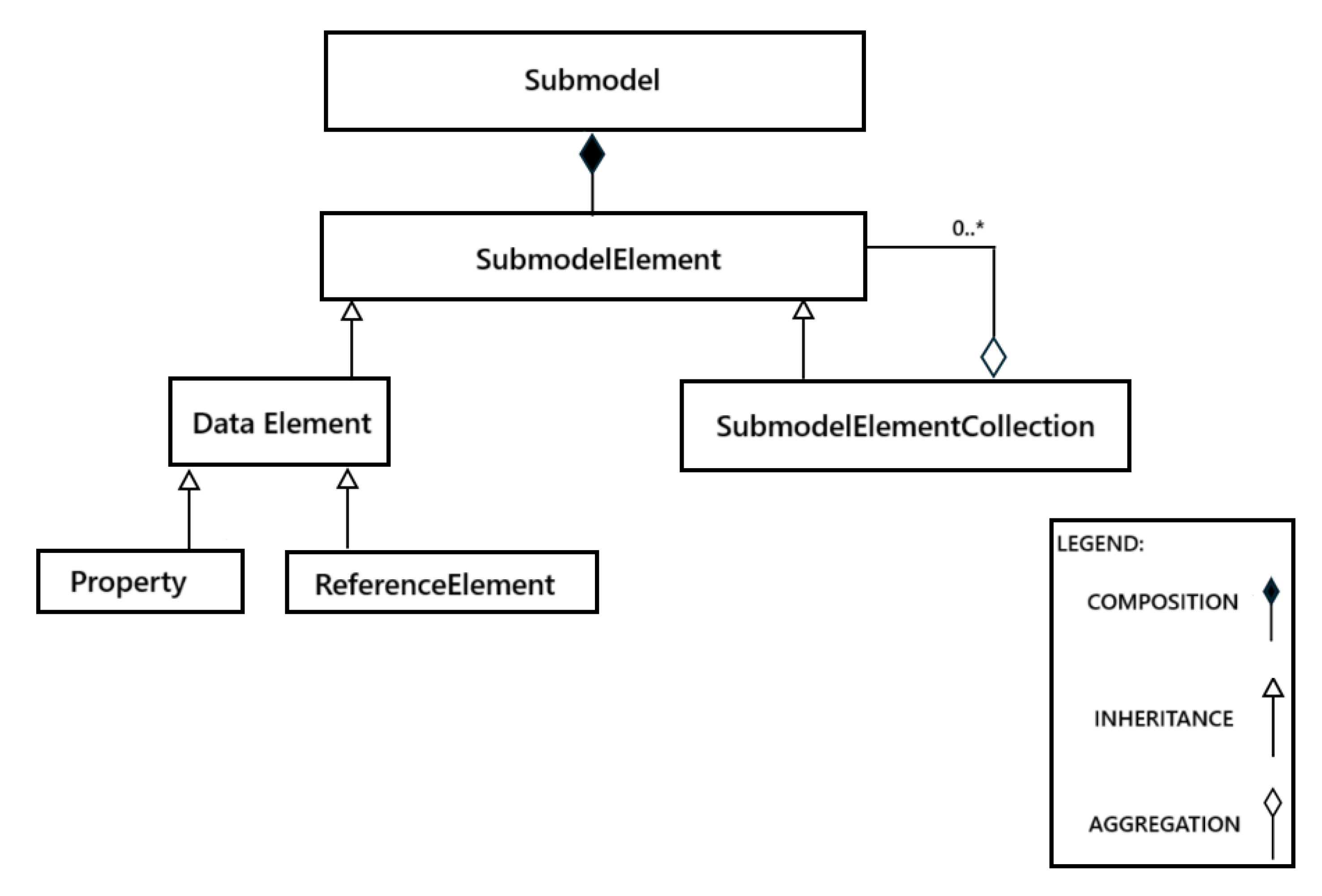

2.1.2. AAS Metamodel

2.1.3. Entities in the AAS Metamodel

2.1.4. Submodel

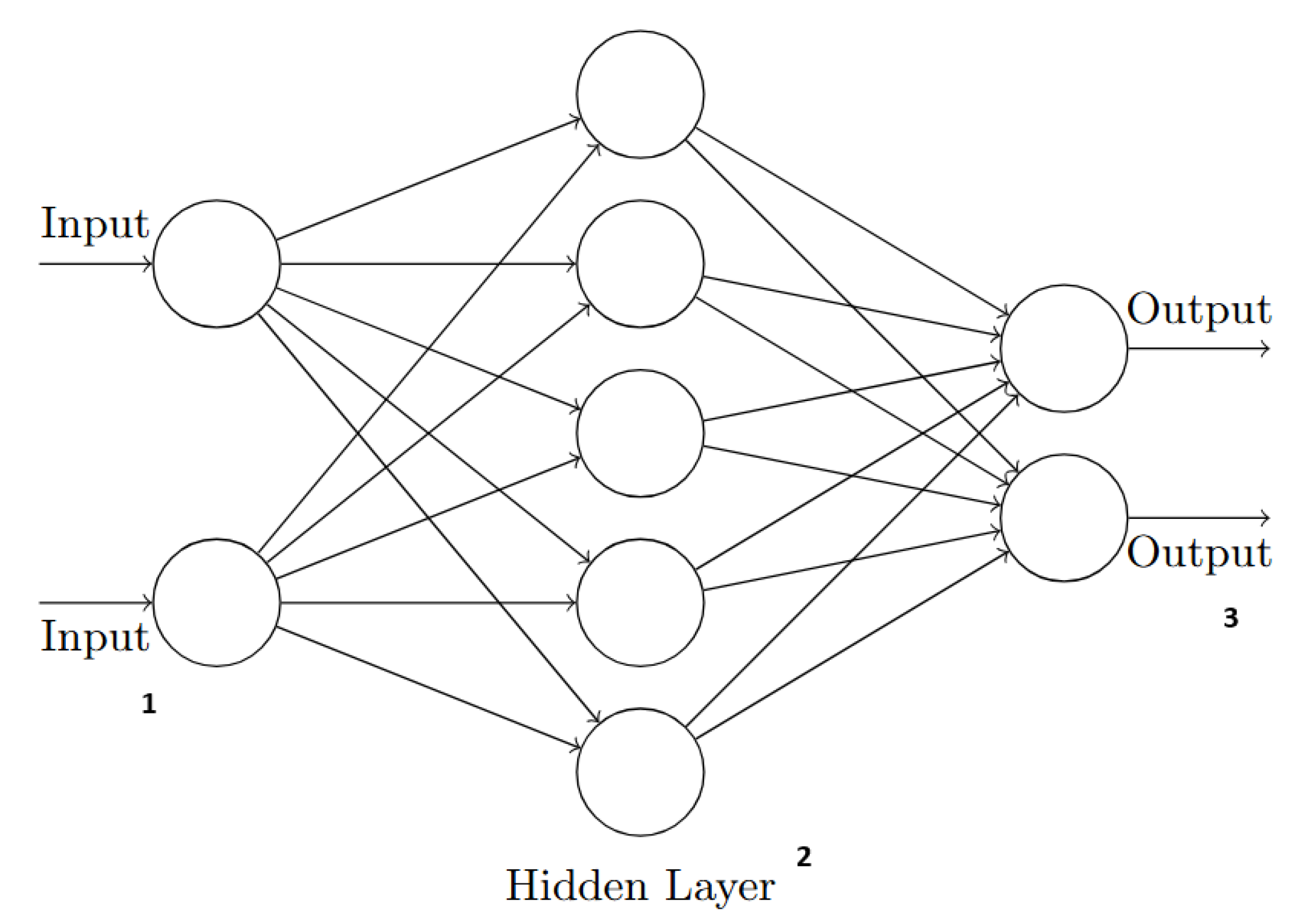

2.2. Neural Networks

- Sample: a sample is a single unit of data. For example, when you are trying to categorize images of fruits, each image is a sample. Each sample contains all the information of a particular example.

- Label: a label can be understood as a tag or an annotation that is given to data, which is the output of the model. In a classification problem, it can be considered the target of interest.

- Feature: a feature is an identifying characteristic, typically referred to as an attribute, of a specific sample. For instance, in a photo of a dog, a feature might be the dog’s size.

- Dimension: a dimension is the quantity of features possessed by a sample. For instance, a picture of 100 pixels in width and 100 pixels in height therefore comprises 10,000 dimensions (one corresponding value per pixel). More generally, a dimension is the total number of variables or attributes that are utilized in representing the sample.

- Input layer: Input layer: The input layer of a neural network is the first stage in the learning process, where the network is given input data and passes the data on to further layers for learning and processing.

- Hidden layer: The hidden layers are located between the input and output layers and work behind the scenes. Although the hidden part in Figure 3 consists of only one layer of neurons to simplify the illustration, there are usually multiple layers in practice. They help the network understand the data better through multiple complex calculations and find useful patterns. This is where most of the “learning” in the network occurs.

- Output layer: The output layer is the final layer of a neural network, which makes predictions about the data produced as a result of the knowledge acquisition that the network achieved while training. The layer output may be in the form of an output label (classification task) or a number (regression task).

- Learning rate: This is the parameter that determines how fast the neural network learns while training.

- Epoch: This refers to a single complete training cycle, where the neural network processes the training dataset once.

- Batch: This is a small subset of data from the training set, used solely to alter the weights of the network.

- Training set: This is the collection of data on which the neural network is trained, where the model learns to recognize patterns and relations.

- Test set: This is the dataset that is used to verify how well the network makes predictions after it has been trained. The idea is to determine whether the model has learned adequately and can use its knowledge on new, unseen data.

- Validation set: This is the subset of the dataset that is utilized in the measurement of a model’s performance while training.

- Split ratio: This specifies the relative allocation of data to the training, validation, and test datasets.

3. Related Works

4. Example of Use: Representing ML Models with AAS for an Industrial Control Valve

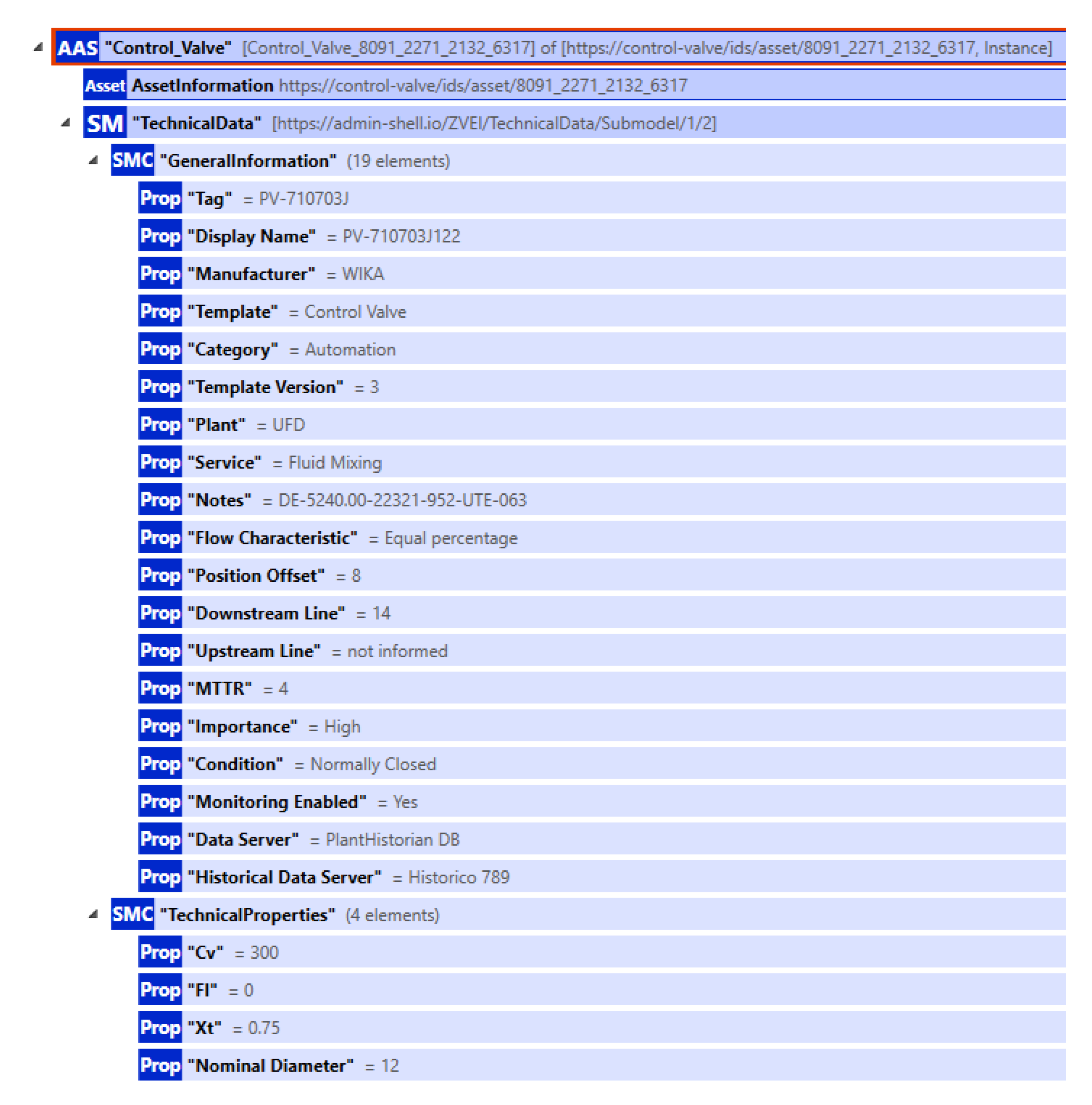

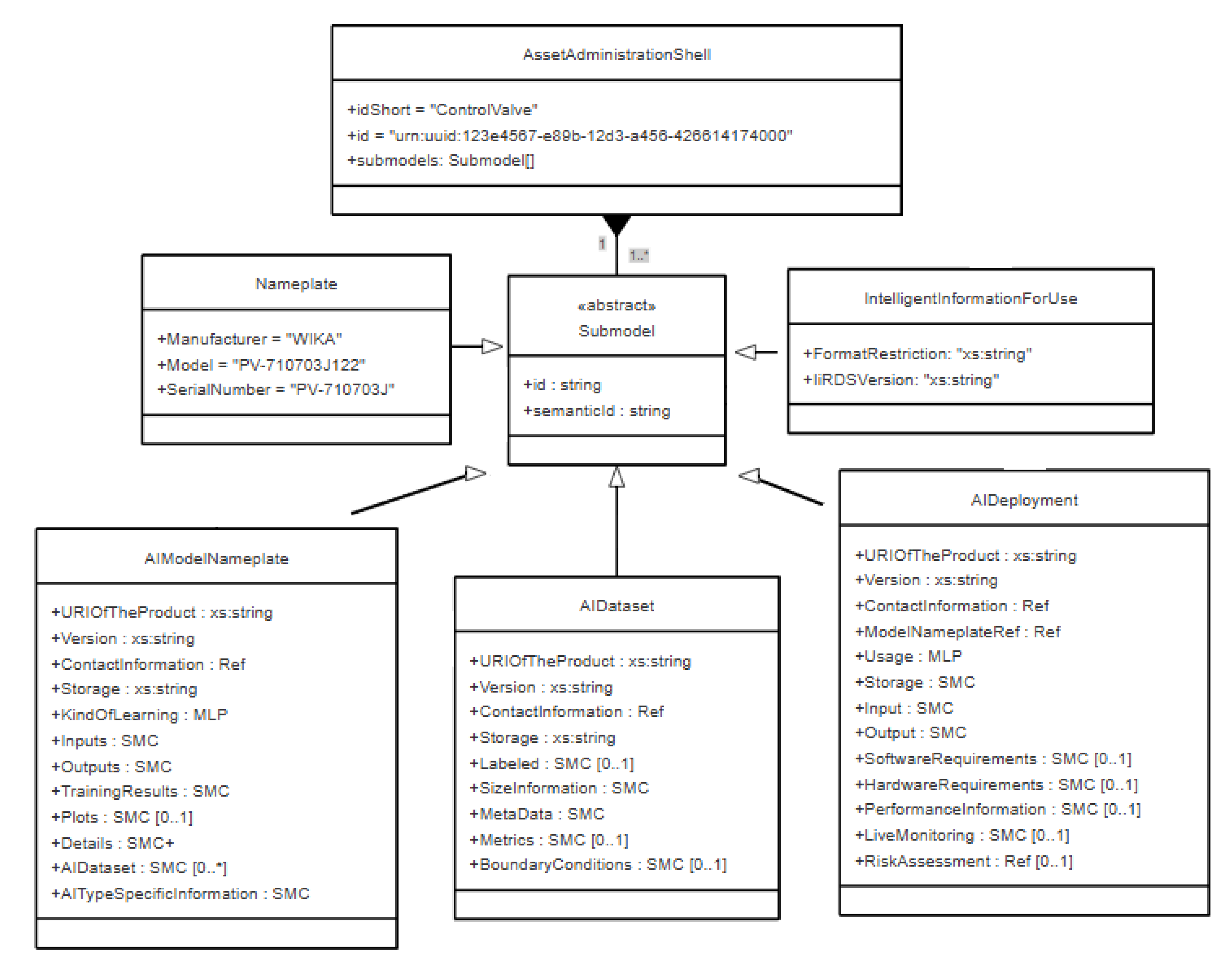

4.1. Control Valve AAS

4.2. IDTA Specifications

- AIModelNameplate (IDTA-02060-1.0): This submodel specifies the identity of an AI model, which is the same as a nameplate, to explicitly present essential metadata. This promotes transparency and increases the model communication, as well as explaining what it can and cannot do, how it came about, and how its boundaries are part and parcel of interoperability/regulatory compliance.

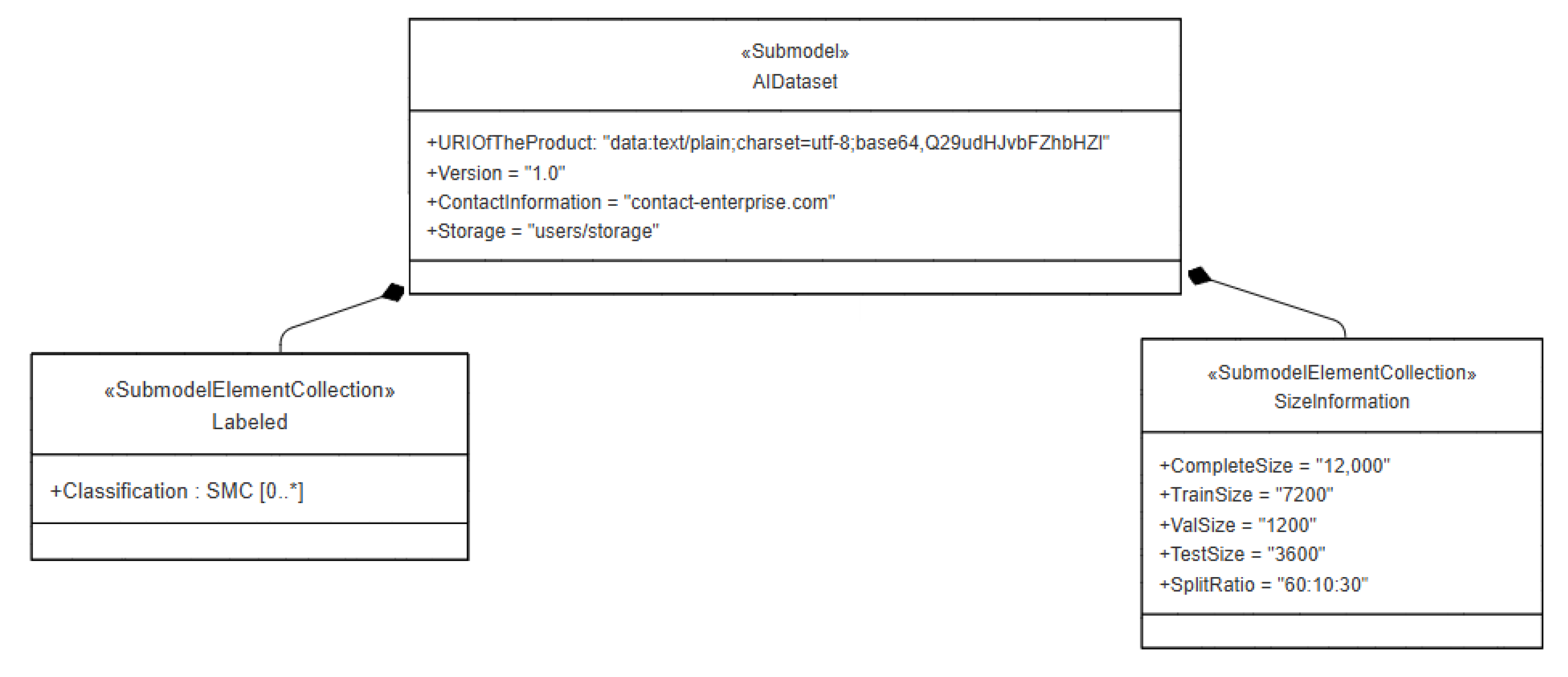

- AIDataset (IDTA-02058-1.0): The submodel presents the data that was used in the development or operation of an AI system, as well as technical details regarding the dataset, its origin, and its restrictions. It enables data provenance, ensures the re-usability of data, allows for data quality checks for training, validation, and testing; these are all crucial aspects of the documentation and governance of AI models.

- AIDeployment (IDTA-02059-1.0): This submodel aims to determine the structure and properties of the AI model to be deployed in an industrial environment, making it more applicable for use in the real world. It supports the use of these models in real applications and in the final stage of the AI lifecycle.

- IntelligentInformationUse (IDTA-02063-1.0): The submodel defines the framework used to deliver intelligent information for industrial assets. This comprises more than just traditional manuals, using multimedia content, operational context, and dynamic data to provide a safety-oriented experience directed to the user. By embedding contextual, personalized, and on-demand information, the goal is to improve the asset operations’ effectiveness and safety.

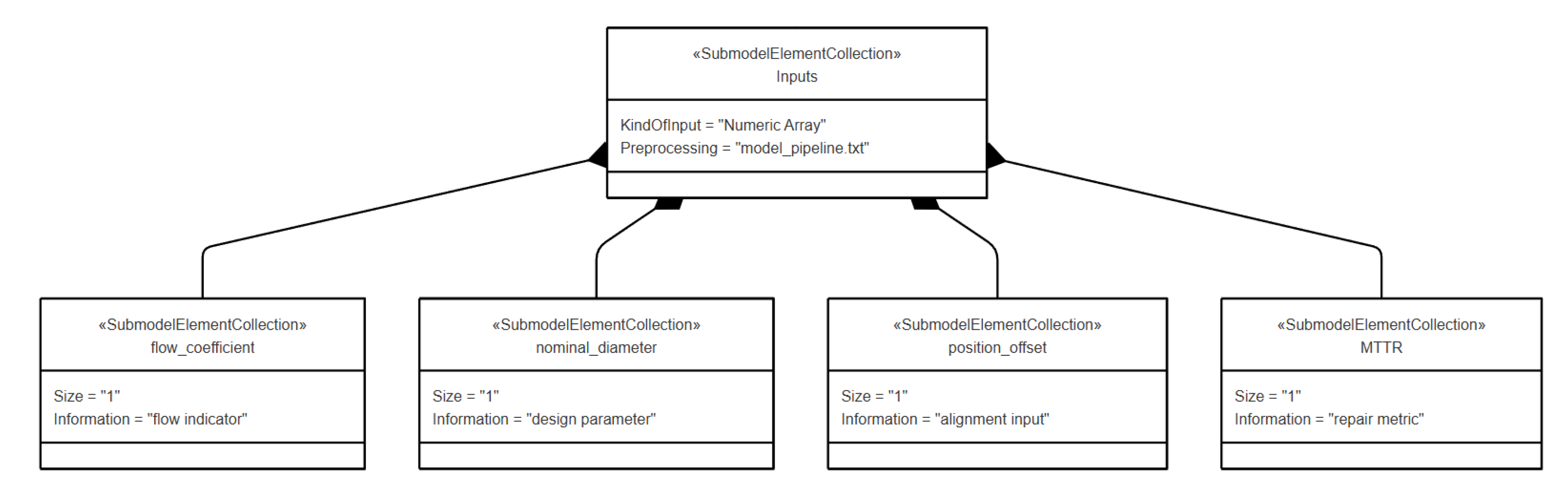

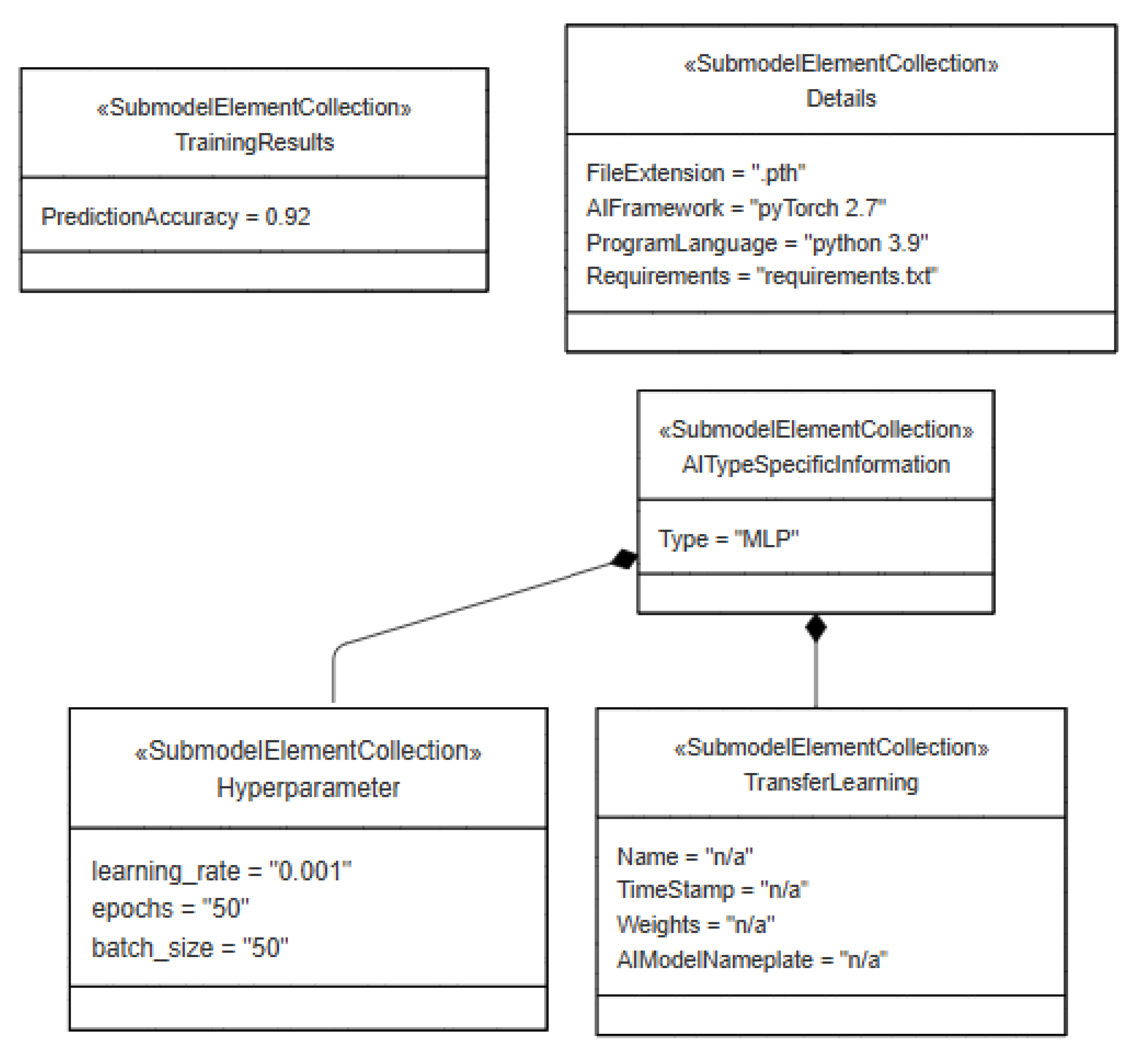

4.3. AAS ML Model for Control Valve Prediction

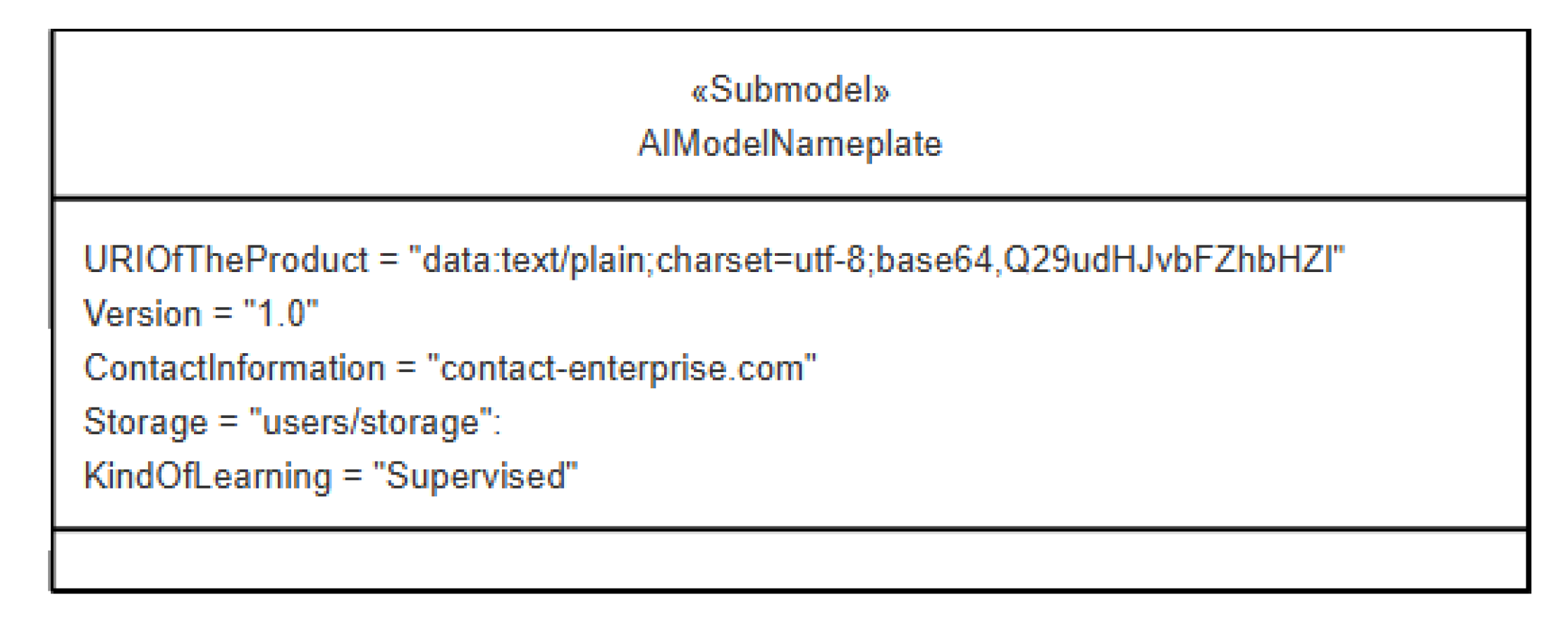

4.3.1. AIModelNameplate Submodel

4.3.2. AIDataset Submodel

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AM | Asset Management |

| ISO | International Organization for Standardization |

| CPS | Cyber–Physical Systems |

| AAS | Asset Administration Shell |

| DT | Digital Twin |

| ML | Machine Learning |

| RAMI | Reference Architectural Model for Industries |

| I4.0 | Industry 4.0 |

| OPC-UA | Open Platform Communication–Unified Architecture |

| SMC | Submodel Element Collection |

| IDTA | Industrial Digital Twin Association |

| NN | Neural Networks |

References

- ISO 55000:2014; Asset Management—Overview, Principles and Terminology. Technical report; International Organization for Standardization: Geneva, Switzerland, 2014.

- Somia Alfatih, M.; Leong, M.S.; Hee, L.M. Definition of engineering asset management: A review. Appl. Mech. Mater. 2015, 773, 794–798. [Google Scholar] [CrossRef]

- Lee, E.A. Cyber-physical systems—Are computing foundations adequate. In Proceedings of the Position Paper for NSF Workshop on Cyber-Physical Systems: Research Motivation, Techniques and Roadmap, Austin, TX, USA, 16–17 October 2006; Volume 2, pp. 1–9. [Google Scholar]

- Lee, E.A. Cyber physical systems: Design challenges. In Proceedings of the 2008 11th IEEE International Symposium on Object and Component-Oriented Real-Time Distributed Computing (ISORC), Orlando, FL, USA, 5–7 May 2008; pp. 363–369. [Google Scholar]

- Biard, G.; Nour, G.A. Industry 4.0 Contribution to Asset Management in the Electrical Industry. Sustainability 2021, 13, 369. [Google Scholar] [CrossRef]

- Zhang, K.; Shi, Y.; Karnouskos, S.; Sauter, T.; Fang, H.; Colombo, A.W. Advancements in industrial cyber-physical systems: An overview and perspectives. IEEE Trans. Ind. Inform. 2022, 19, 716–729. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y. Digital twin in industry: State-of-the-art. IEEE Trans. Ind. Inform. 2018, 15, 2405–2415. [Google Scholar] [CrossRef]

- Wang, S.; Wan, J.; Li, D.; Zhang, C. Implementing smart factory of industrie 4.0: An outlook. Int. J. Distrib. Sens. Netw. 2016, 12, 3159805. [Google Scholar] [CrossRef]

- Bousdekis, A.; Lepenioti, K.; Apostolou, D.; Mentzas, G. A review of data-driven decision-making methods for industry 4.0 maintenance applications. Electronics 2021, 10, 828. [Google Scholar] [CrossRef]

- Miragliotta, G.; Sianesi, A.; Convertini, E.; Distante, R. Data driven management in Industry 4.0: A method to measure Data Productivity. IFAC-PapersOnLine 2018, 51, 19–24. [Google Scholar] [CrossRef]

- Zhao, R.; Yan, R.; Chen, Z.; Mao, K.; Wang, P.; Gao, R.X. Deep learning and its applications to machine health monitoring. Mech. Syst. Signal Process. 2019, 115, 213–237. [Google Scholar] [CrossRef]

- Lee, J.; Bagheri, B.; Jin, C. Introduction to cyber manufacturing. Manuf. Lett. 2016, 8, 11–15. [Google Scholar] [CrossRef]

- Idowu, S.; Strüber, D.; Berger, T. Asset management in machine learning: A survey. In Proceedings of the 2021 IEEE/ACM 43rd International Conference on Software Engineering: Software Engineering in Practice (ICSE-SEIP), Madrid, Spain, 25–28 May 2021; pp. 51–60. [Google Scholar]

- Idowu, S.; Strüber, D.; Berger, T. Asset management in machine learning: State-of-research and state-of-practice. ACM Comput. Surv. 2022, 55, 1–35. [Google Scholar] [CrossRef]

- Zhao, Z.; Chen, Y.; Bangash, A.A.; Adams, B.; Hassan, A.E. An empirical study of challenges in machine learning asset management. Empir. Softw. Eng. 2024, 29, 98. [Google Scholar] [CrossRef]

- Amershi, S.; Begel, A.; Bird, C.; DeLine, R.; Gall, H.; Kamar, E.; Nagappan, N.; Nushi, B.; Zimmermann, T. Software engineering for machine learning: A case study. In Proceedings of the 2019 IEEE/ACM 41st International Conference on Software Engineering: Software Engineering in Practice (ICSE-SEIP), Montreal, QC, Canada, 25–29 May 2019; pp. 291–300. [Google Scholar]

- Tao, F.; Xiao, B.; Qi, Q.; Cheng, J.; Ji, P. Digital twin modeling. J. Manuf. Syst. 2022, 64, 372–389. [Google Scholar] [CrossRef]

- Cavalieri, S.; Gambadoro, S. Digital Twin of a Water Supply System Using the Asset Administration Shell. Sensors 2024, 24, 1360. [Google Scholar] [CrossRef]

- Jones, D.; Snider, C.; Nassehi, A.; Yon, J.; Hicks, B. Characterising the Digital Twin: A systematic literature review. CIRP J. Manuf. Sci. Technol. 2020, 29, 36–52. [Google Scholar] [CrossRef]

- IDTA. Specification of the Asset Administration Shell—Part 1: Metamodel; Technical Report; Industrial Digital Twin Association: Frankfurt am Main, Germany, 2024. [Google Scholar]

- Resman, M.; Pipan, M.; Šimic, M.; Herakovič, N. A new architecture model for smart manufacturing: A performance analysis and comparison with the RAMI 4.0 reference model. Adv. Prod. Eng. Manag. 2019, 14, 153–165. [Google Scholar] [CrossRef]

- Amelete, S.; Vaillancourt, R.; Abdul-Nour, G.; Gauthier, F. Asset management, industry 4.0 and maintenance in electrical energy distribution. In Proceedings of the Advances in Production Management Systems. Artificial Intelligence for Sustainable and Resilient Production Systems: IFIP WG 5.7 International Conference, APMS 2021, Nantes, France, 5–9 September 2021; Proceedings, Part V; Springer: Berlin/Heidelberg, Germany, 2021; pp. 199–208. [Google Scholar]

- IDTA 02058-1-0; Artificial Intelligence Dataset. Industrial Digital Twin Association: Frankfurt am Main, Germany, 2025.

- DTA 02059-1-0; Artificial Intelligence Deployment. Industrial Digital Twin Association: Frankfurt am Main, Germany, 2025.

- Industrial Digital Twin Association. IDTA 02060-1-0 Artificial Intelligence Model Nameplate. Submodel Template of the Asset Administration Shell. 2025. Available online: https://industrialdigitaltwin.org/wp-content/uploads/2025/02/IDTA-02060-1-0_Submodel_AIModelNameplate.pdf (accessed on 4 May 2025).

- IDTA 02063-1-0; Intelligent Information for Use. Industrial Digital Twin Association: Frankfurt am Main, Germany, 2025.

- Krishnamenon, M.; Tuladhar, R.; Azghadi, M.R.; Loughran, J.G.; Pandey, G. Digital Twins and their significance in Engineering Asset Management. In Proceedings of the 2021 International Conference on Maintenance and Intelligent Asset Management (ICMIAM), Ballarat, Australia, 12–15 December 2021; pp. 1–6. [Google Scholar]

- Cirillo, F.; Solmaz, G.; Berz, E.L.; Bauer, M.; Cheng, B.; Kovacs, E. A standard-based open source IoT platform: FIWARE. IEEE Internet Things Mag. 2019, 2, 12–18. [Google Scholar] [CrossRef]

- Bader, S.R.; Maleshkova, M. The semantic asset administration shell. In Proceedings of the Semantic Systems. The Power of AI and Knowledge Graphs: 15th International Conference, SEMANTiCS 2019, Karlsruhe, Germany, 9–12 September 2019; Proceedings 15; Springer: Berlin/Heidelberg, Germany, 2019; pp. 159–174. [Google Scholar]

- Tantik, E.; Anderl, R. Integrated data model and structure for the asset administration shell in industrie 4.0. Procedia Cirp 2017, 60, 86–91. [Google Scholar] [CrossRef]

- Sakurada, L.; Leitao, P.; De la Prieta, F. Towards the digitization using asset administration shells. In Proceedings of the IECON 2021—47th Annual Conference of the IEEE Industrial Electronics Society, Toronto, ON, Canada, 13–16 October 2021; pp. 1–6. [Google Scholar]

- Rongen, S.; Nikolova, N.; van der Pas, M. Modelling with AAS and RDF in Industry 4.0. Comput. Ind. 2023, 148, 103910. [Google Scholar] [CrossRef]

- Ochoa, W.; Larrinaga, F.; Pérez, A. Architecture for managing AAS-based business processes. Procedia Comput. Sci. 2023, 217, 217–226. [Google Scholar] [CrossRef]

- Angelopoulos, A.; Michailidis, E.T.; Nomikos, N.; Trakadas, P.; Hatziefremidis, A.; Voliotis, S.; Zahariadis, T. Tackling faults in the industry 4.0 era—A survey of machine-learning solutions and key aspects. Sensors 2019, 20, 109. [Google Scholar] [CrossRef]

- Yuan, C.; Agaian, S.S. A comprehensive review of binary neural network. Artif. Intell. Rev. 2023, 56, 12949–13013. [Google Scholar] [CrossRef]

- IDTA. Downloads—IDTA—industrialdigitaltwin.org. 2025. Available online: https://industrialdigitaltwin.org/en/content-hub/downloads (accessed on 4 May 2025).

- Brereton, R.G.; Lloyd, G.R. Support vector machines for classification and regression. Analyst 2010, 135, 230–267. [Google Scholar] [CrossRef]

- Goodfellow, I.; Bengio, Y.; Courville, A.; Bengio, Y. Deep Learning; MIT Press: Cambridge, UK, 2016; Volume 1. [Google Scholar]

- Bishop, C.M. Neural Networks for Pattern Recognition; Oxford University Press: Oxford, UK, 1995. [Google Scholar]

- Islam, M.; Chen, G.; Jin, S. An overview of neural network. Am. J. Neural Netw. Appl. 2019, 5, 7–11. [Google Scholar] [CrossRef]

- Bishop, C.M.; Nasrabadi, N.M. Pattern Recognition and Machine Learning; Springer: Berlin/Heidelberg, Germany, 2006; Volume 4. [Google Scholar]

- Martínez-Galán, P.; Crespo, A.; de la Fuente, A.; Guillén, A. A new model to compare intelligent asset management platforms (IAMP). IFAC-PapersOnLine 2020, 53, 13–18. [Google Scholar] [CrossRef]

- Teoh, Y.K.; Gill, S.S.; Parlikad, A.K. IoT and Fog-Computing-Based Predictive Maintenance Model for Effective Asset Management in Industry 4.0 Using Machine Learning. IEEE Internet Things J. 2023, 10, 2087–2094. [Google Scholar] [CrossRef]

- Bao, Y.; Zhang, X.; Zhou, T.; Chen, Z.; Ming, X. Application of industrial internet for equipment asset management in social digitalization platform based on system engineering using fuzzy DEMATEL-TOPSIS. Machines 2022, 10, 1137. [Google Scholar] [CrossRef]

- Sleiti, A.K.; Kapat, J.S.; Vesely, L. Digital twin in energy industry: Proposed robust digital twin for power plant and other complex capital-intensive large engineering systems. Energy Rep. 2022, 8, 3704–3726. [Google Scholar] [CrossRef]

- Rauh, L.; Reichardt, M.; Schotten, H.D. AI asset management: A case study with the asset administration shell (AAS). In Proceedings of the 2022 IEEE 27th International Conference on Emerging Technologies and Factory Automation (ETFA), Stuttgart, Germany, 6–9 September 2022; pp. 1–8. [Google Scholar]

- Open Source. GitHub-Eclipse-Aaspe/Package-Explorer: AASXPackage Explorer—github.com. 2025. Available online: https://github.com/eclipse-aaspe/package-explorer (accessed on 4 May 2025).

- Lima, F. Control Valve AASExample—gist.github.com. 2025. Available online: https://gist.github.com/FelipeLM1/eb0a30a63f0fa3fe6553b6c2098ea076 (accessed on 4 May 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marques, J.G.; Medeiros, F.L.; de Medeiros, P.L.F.F.; Leitão, G.B.P.; de Souza, D.C.; Silva, D.R.C.; Guedes, L.A. Integrating Machine Learning into Asset Administration Shell: A Practical Example Using Industrial Control Valves. Processes 2025, 13, 2100. https://doi.org/10.3390/pr13072100

Marques JG, Medeiros FL, de Medeiros PLFF, Leitão GBP, de Souza DC, Silva DRC, Guedes LA. Integrating Machine Learning into Asset Administration Shell: A Practical Example Using Industrial Control Valves. Processes. 2025; 13(7):2100. https://doi.org/10.3390/pr13072100

Chicago/Turabian StyleMarques, Julliana Gonçalves, Felipe L. Medeiros, Pedro L. F. F. de Medeiros, Gustavo B. Paz Leitão, Danilo C. de Souza, Diego R. Cabral Silva, and Luiz Affonso Guedes. 2025. "Integrating Machine Learning into Asset Administration Shell: A Practical Example Using Industrial Control Valves" Processes 13, no. 7: 2100. https://doi.org/10.3390/pr13072100

APA StyleMarques, J. G., Medeiros, F. L., de Medeiros, P. L. F. F., Leitão, G. B. P., de Souza, D. C., Silva, D. R. C., & Guedes, L. A. (2025). Integrating Machine Learning into Asset Administration Shell: A Practical Example Using Industrial Control Valves. Processes, 13(7), 2100. https://doi.org/10.3390/pr13072100