Combined Solar Air Source Heat Pump and Ground Pipe Heating System for Chinese Assembled Solar Greenhouses in Gobi Desert Region

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Greenhouse

2.2. Greenhouse Thermal Calculation

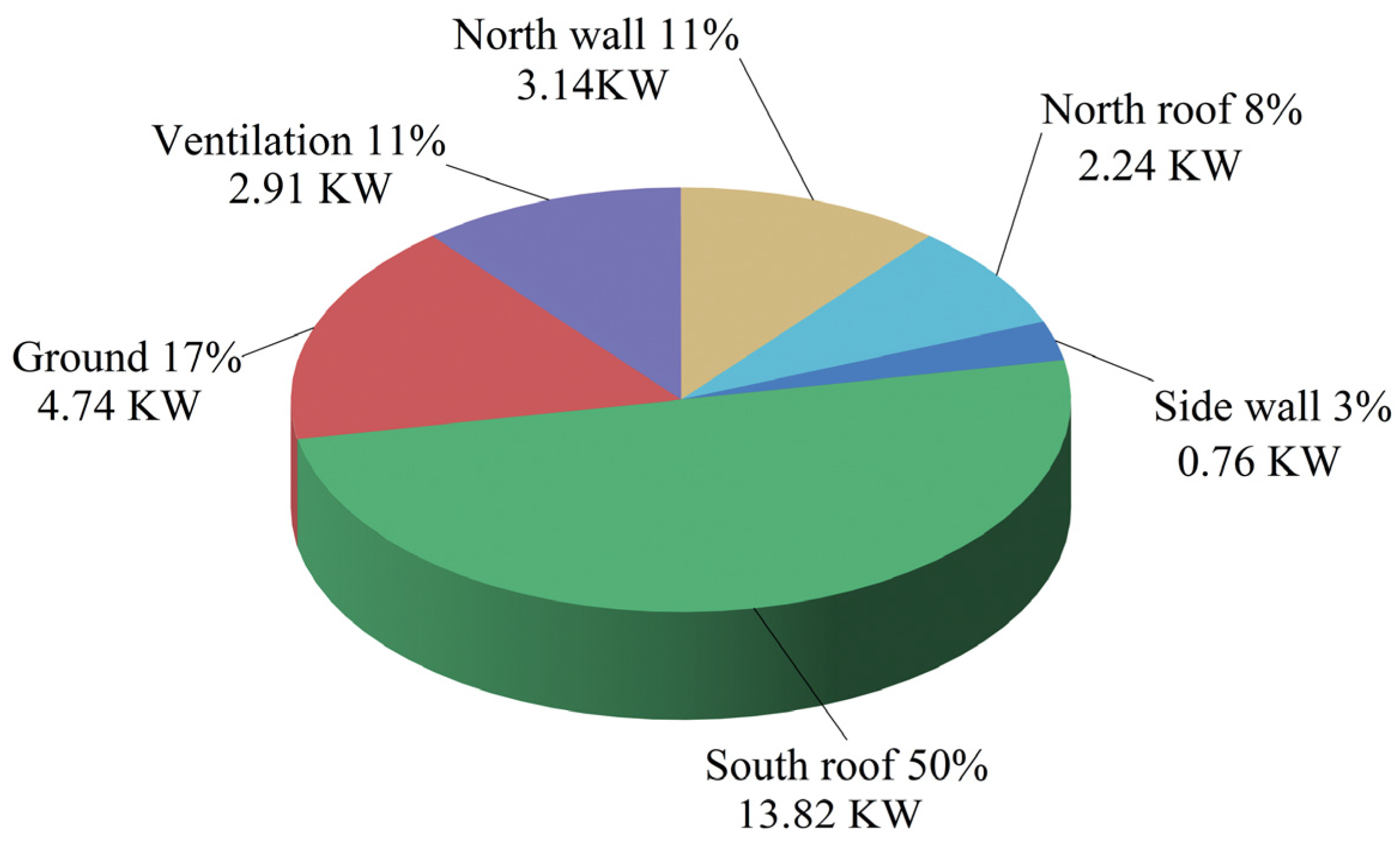

2.2.1. Heat Loss Calculation of Greenhouse at Night

| System Parameter Configuration | Reference Value and Units | System Parameter Configuration | Reference Value and Units |

|---|---|---|---|

| Total nighttime heat loss from greenhouse () | W | Greenhouse ground thermal conductivity () | 0.47 W m−2 °C−1 [31] |

| Greenhouse nighttime envelope heat loss () | W | South roof cover area () | 960.0 m2 |

| Greenhouse nighttime ground heat loss () | W | North wall area () | 280.0 m2 |

| Greenhouse nighttime infiltration heat loss () | W | North roof cover area () | 200.0 m2 |

| Demand for night-time heating of greenhouses () | MJ | Side wall area () | 68.2 m2 |

| Heat released by the system per unit of time () | MJ | Greenhouse enclosure edge ground area () | 504.0 m2 |

| Heat stored in the system per unit of time () | MJ | Air temperature inside the greenhouse () | 20.0 °C [30] |

| Running time of air source heat pumps () | h | Air temperature outside the greenhouse () | −15.0 °C [30] |

| Running time of water pumps () | h | Soil temperature inside the greenhouse () | 15.0 °C [31] |

| Inlet water temperature of buried pipes () | °C | Soil temperature outside the greenhouse () | −5.0 °C [31] |

| Outlet water temperature of buried pipes () | °C | Greenhouse ventilation frequency () | 0.1 h−1 [37] |

| Heat pump air temperature at air inlet () | °C | Wind speed impact factor () | 1.16 [32] |

| Heat pump air temperature at the air outlet () | °C | Daylight greenhouse volume () | 2880.0 m2 |

| Maximum temperature of indoor environment on day () | °C | Specific heat capacity of air () | 1005.0 |

| Minimum temperature of the indoor environment on a daily basis () | °C | Theoretical hours of night heating () | 14.0 |

| Total system heat storage () | W | Specific heat capacity of water () | 4200.0 J kg−1 °C−1 |

| Total system heat release () | W | Air source heat pump air inlet air velocity () | 2.0 m s−1 |

| Air source heat pump operation power consumption () | MJ | Air source heat pump air inlet area () | 0.36 m2 |

| Electricity consumption for pump operation () | MJ | Air density () | 1.29 kg m−3 |

| Total power consumption for system operation () | MJ | water density () | 1000.0 kg m−3 |

| Total system running time () | h | Water flow inside buried pipes () | 4.0 m3 s−1 |

| Standard coal consumption for heating the system () | kg | Air source heat pump rated input power () | 6.3 KW |

| Quality of standard coal consumed for heating in coal-fired boilers () | kg | Rated input power of water pump () | 1.5 KW |

| Mass of standard coal consumed for heating in gas boilers () | kg | Combustion value per kg of standard coal () | 29,307.6 KJ [38] |

| Mass of standard coal consumed for electric heating () | kg | Thermoelectric Conversion Rate () | 36% [39,40] |

| South roof thermal conductivity () | 0.72 W m−2 °C−1 [30,31,41] | Thermal efficiency of coal-fired boilers () | 70% [39,40] |

| Side walls thermal conductivity () | 0.56 W m−2 °C−1 [30,31,41] | Thermal efficiency of gas boilers () | 85% [39,40] |

| North wall thermal conductivity () | 0.56 W m−2 °C−1 [30,31,41] | Electric heating thermal efficiency () | 95% [39,40] |

| North roof thermal conductivity () | 0.56 W m−2 °C−1 [30,31,41] | Natural gas discount factor () | 1.10 [39,40] |

2.2.2. Calculation of Greenhouse Heating Demand at Night

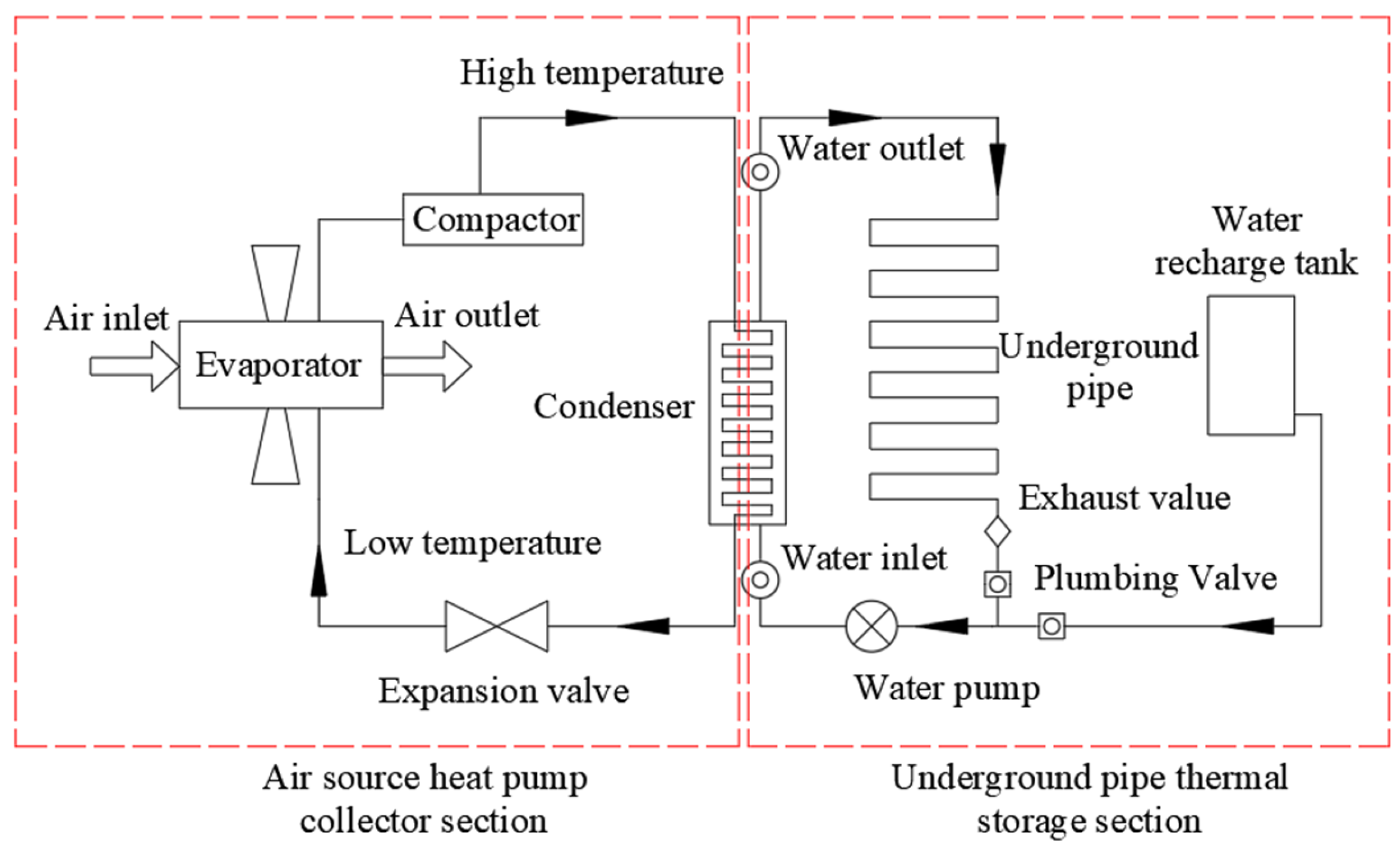

2.3. System Design of the Air Source Heat Pump Combined with Underground Pipe

2.3.1. Parameter Design

2.3.2. System Principle

2.3.3. System Operational

2.4. System Heat Storage and Release Calculation

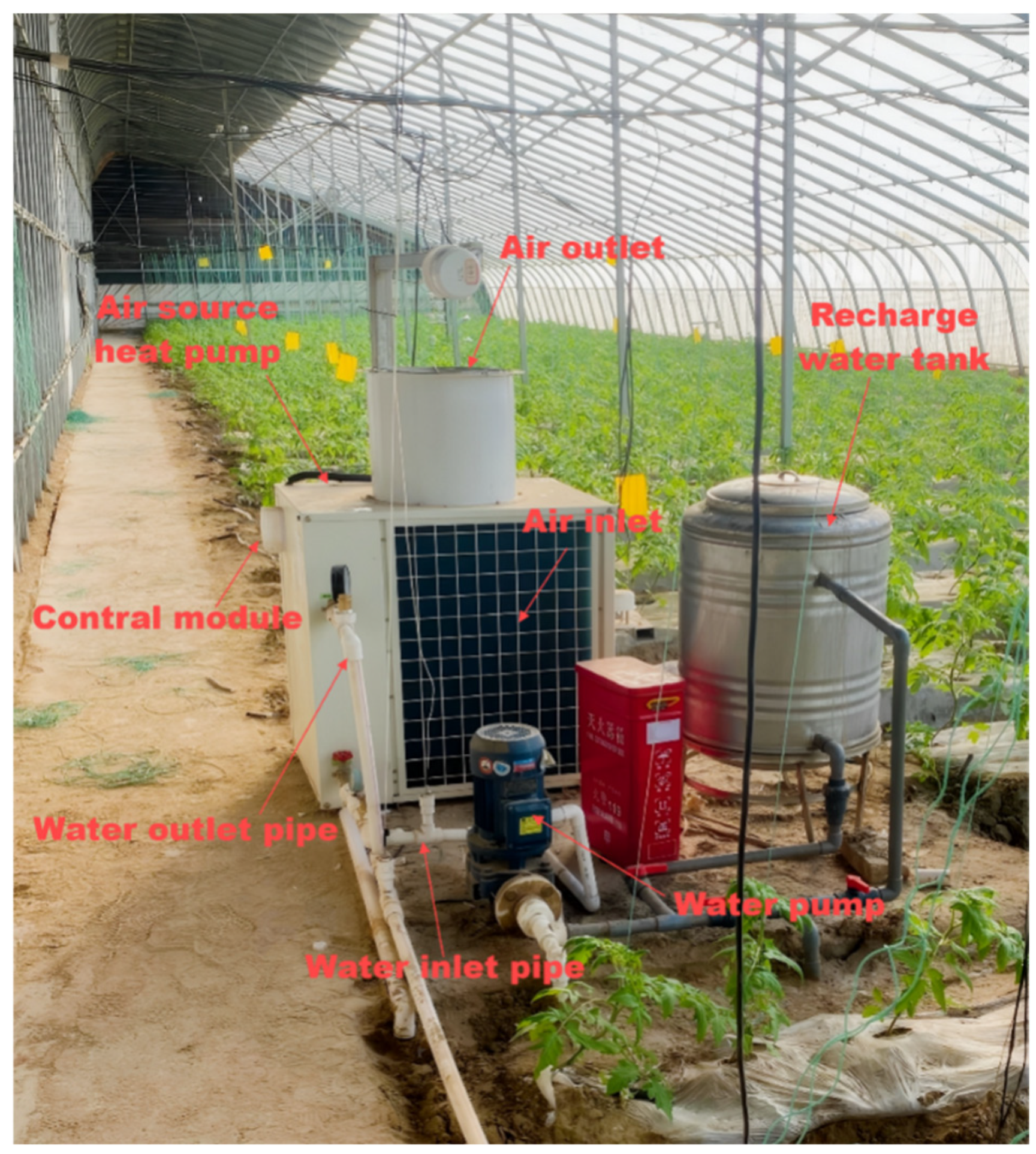

2.5. Experimental Method

2.5.1. Selection and Arrangement of Test Device

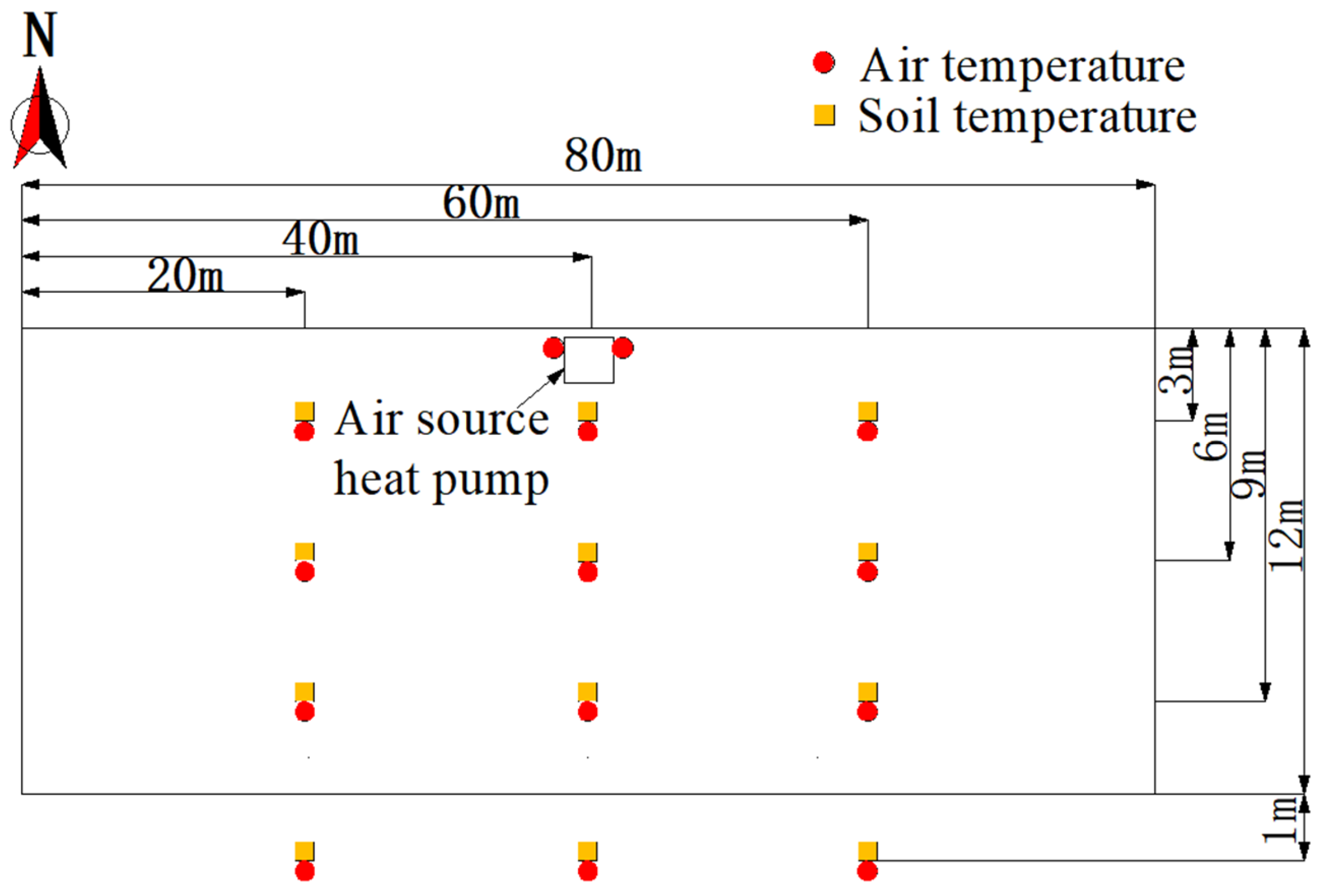

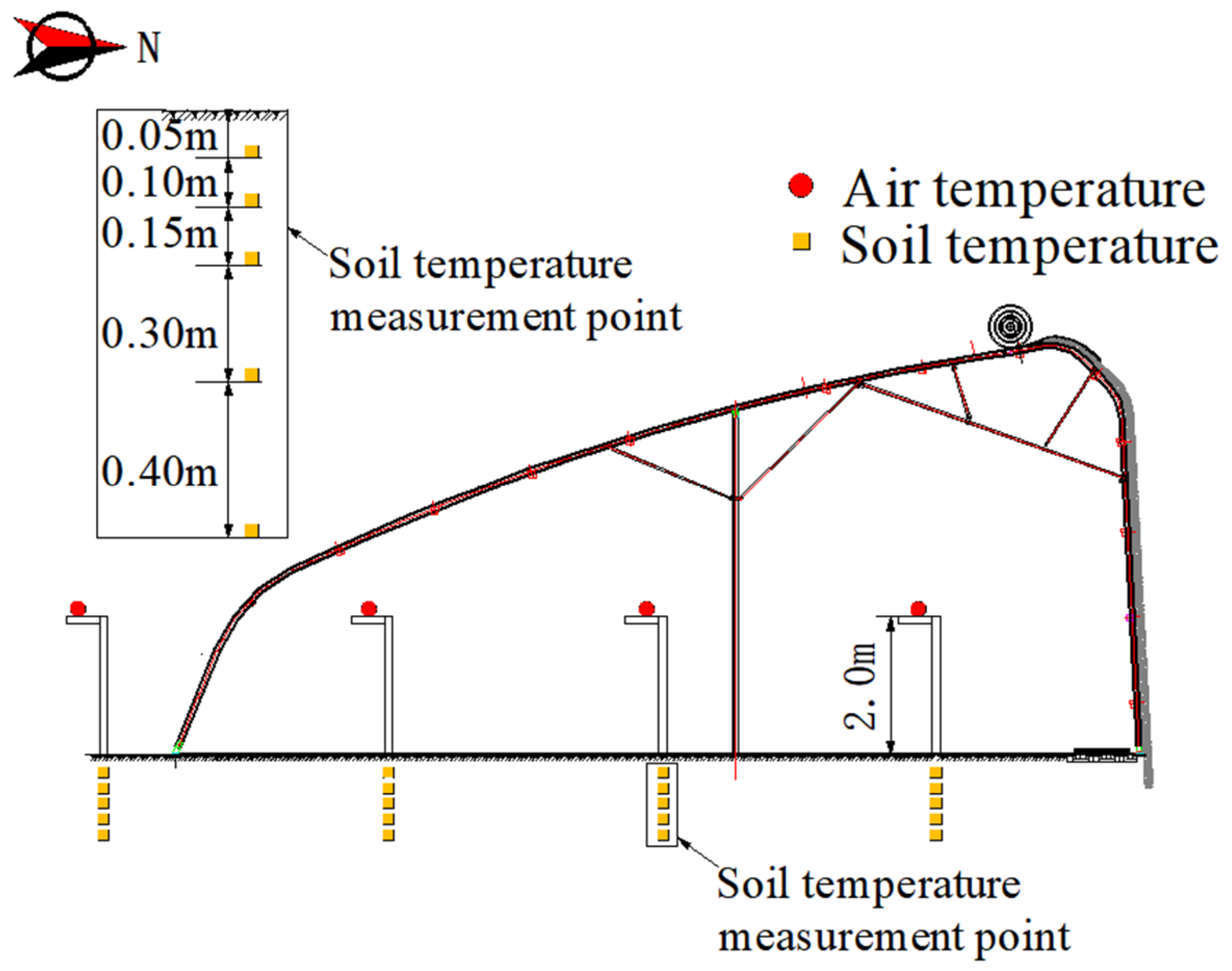

2.5.2. Arrangement of Testing Points

2.6. Calculation of Greenhouse Temperature Fluctuation

2.7. System Performance Coefficient Calculation

2.8. Energy Saving and Environmental Protection Calculation

3. Results and Discussion

3.1. Analysis of Night Heating Demand in Greenhouse

3.2. Analysis of Heat and Moisture Characteristics of Heating Greenhouse

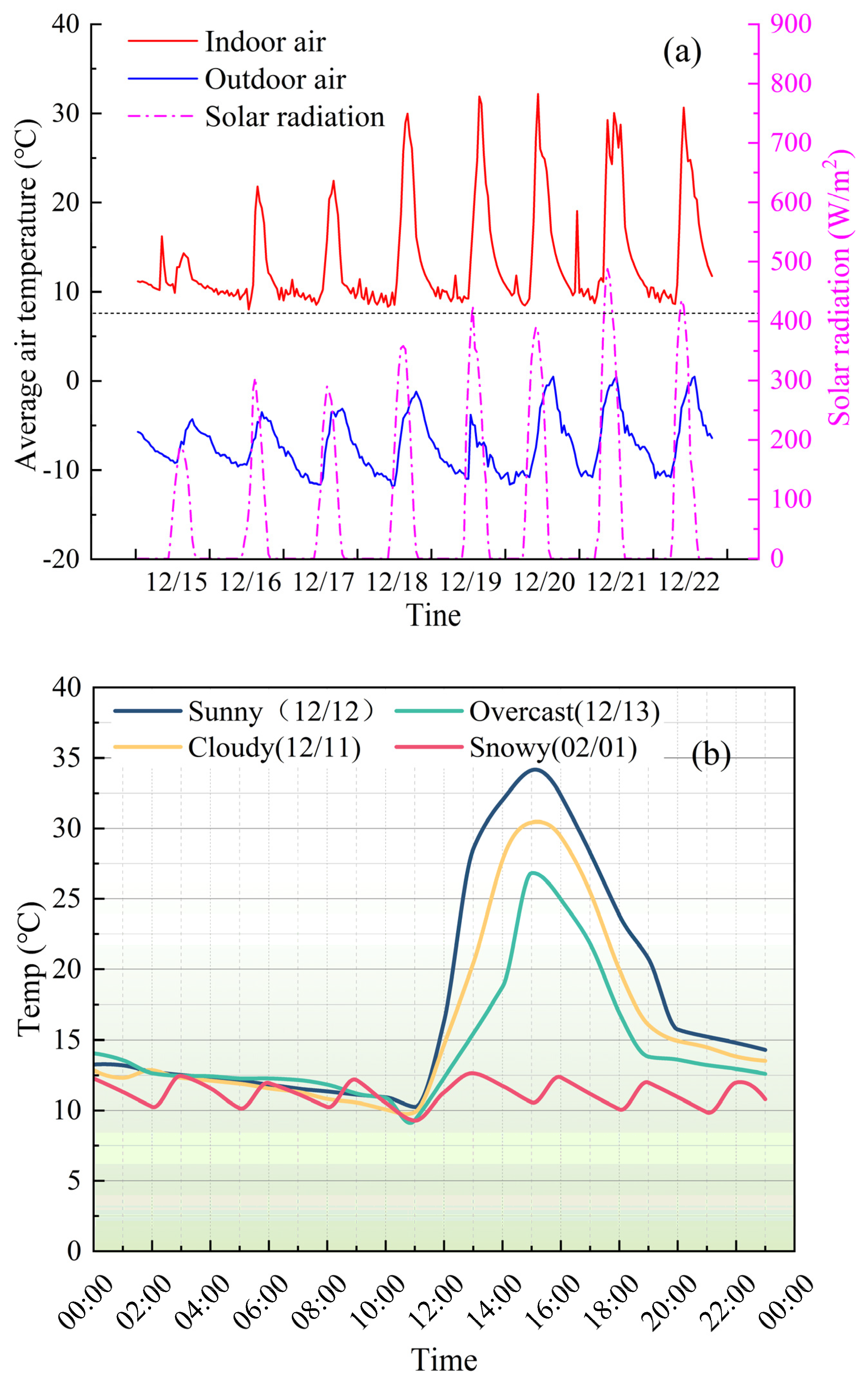

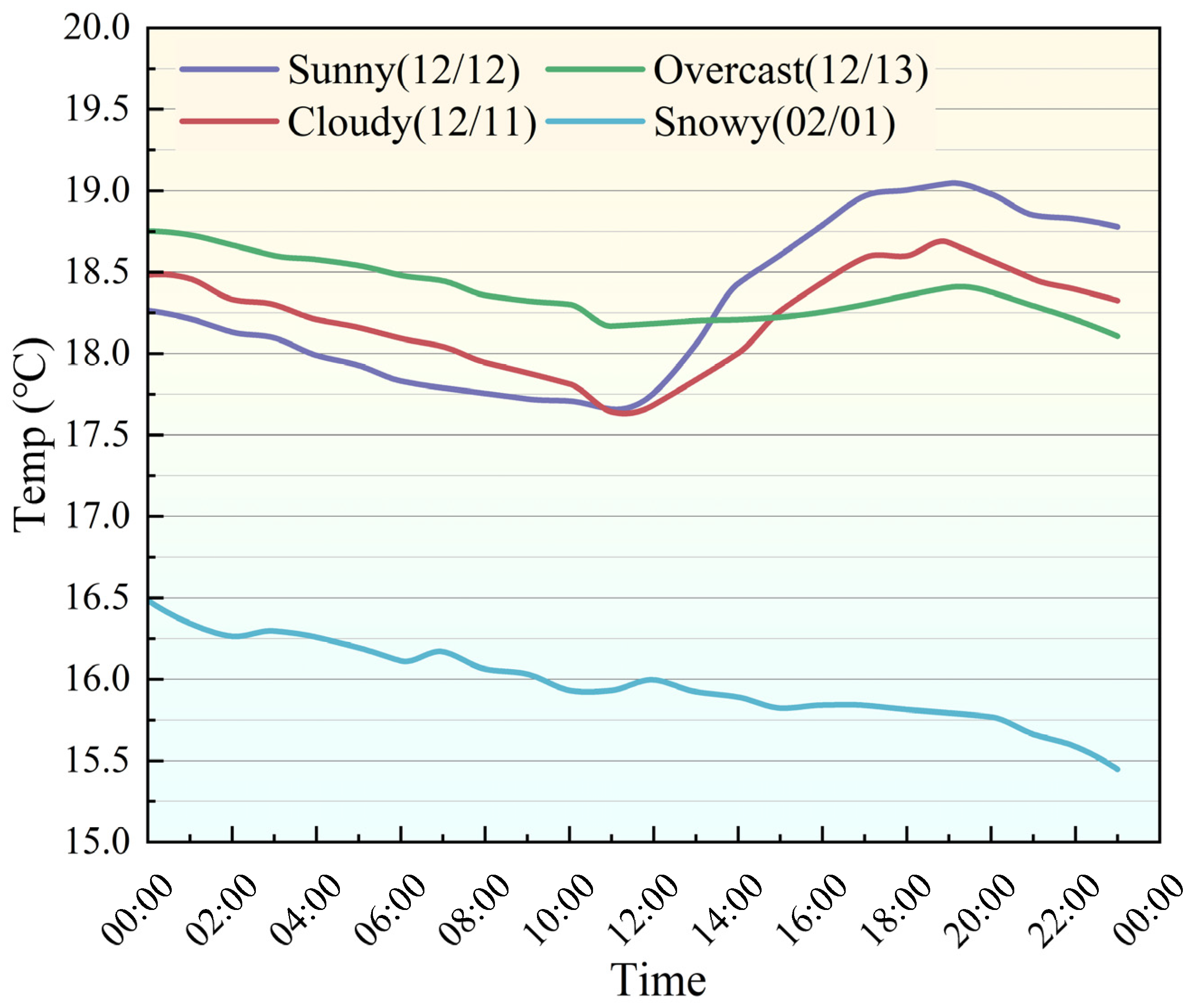

3.2.1. Air Temperature Change

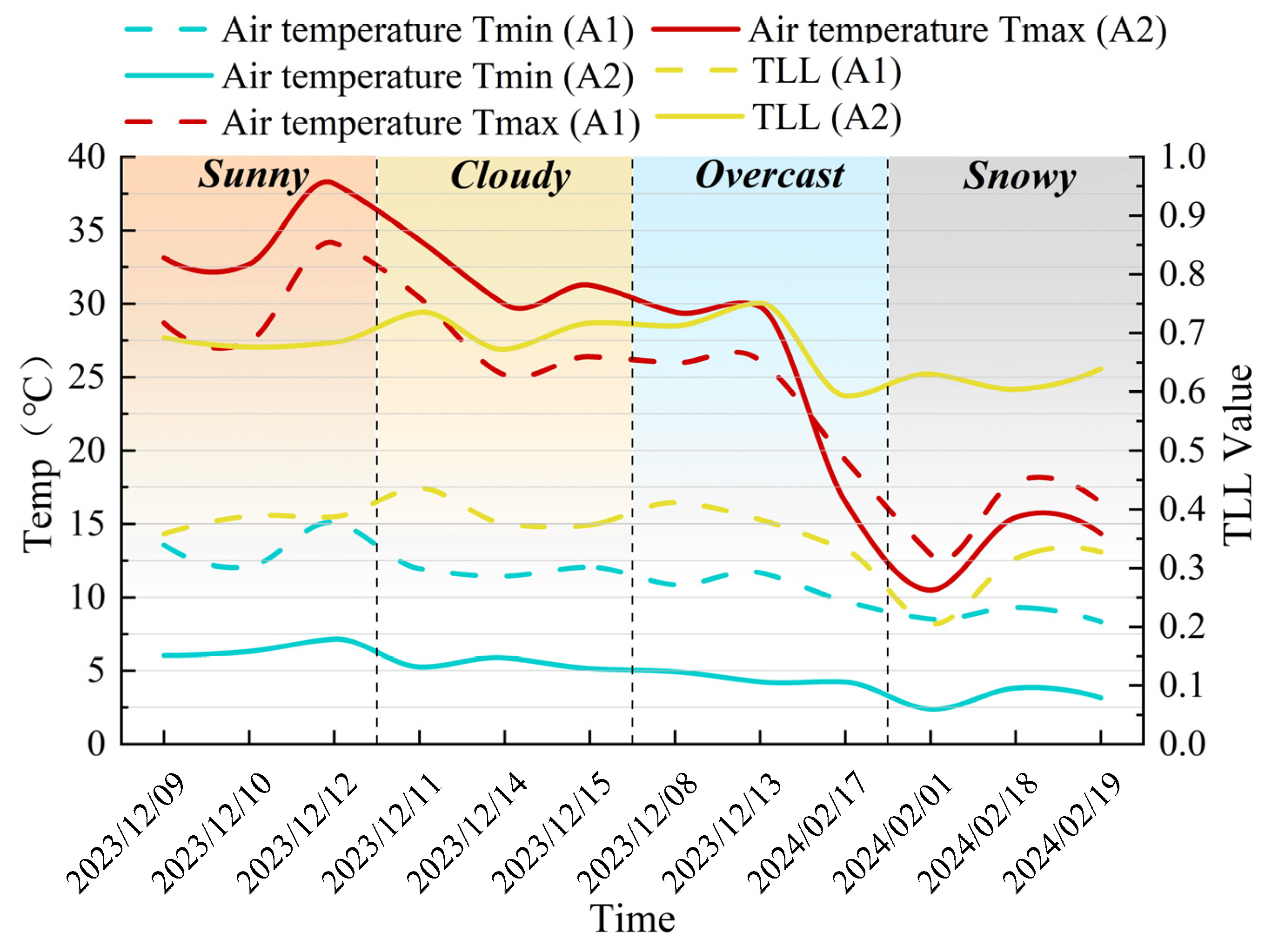

3.2.2. Analysis of Greenhouse Temperature Fluctuation

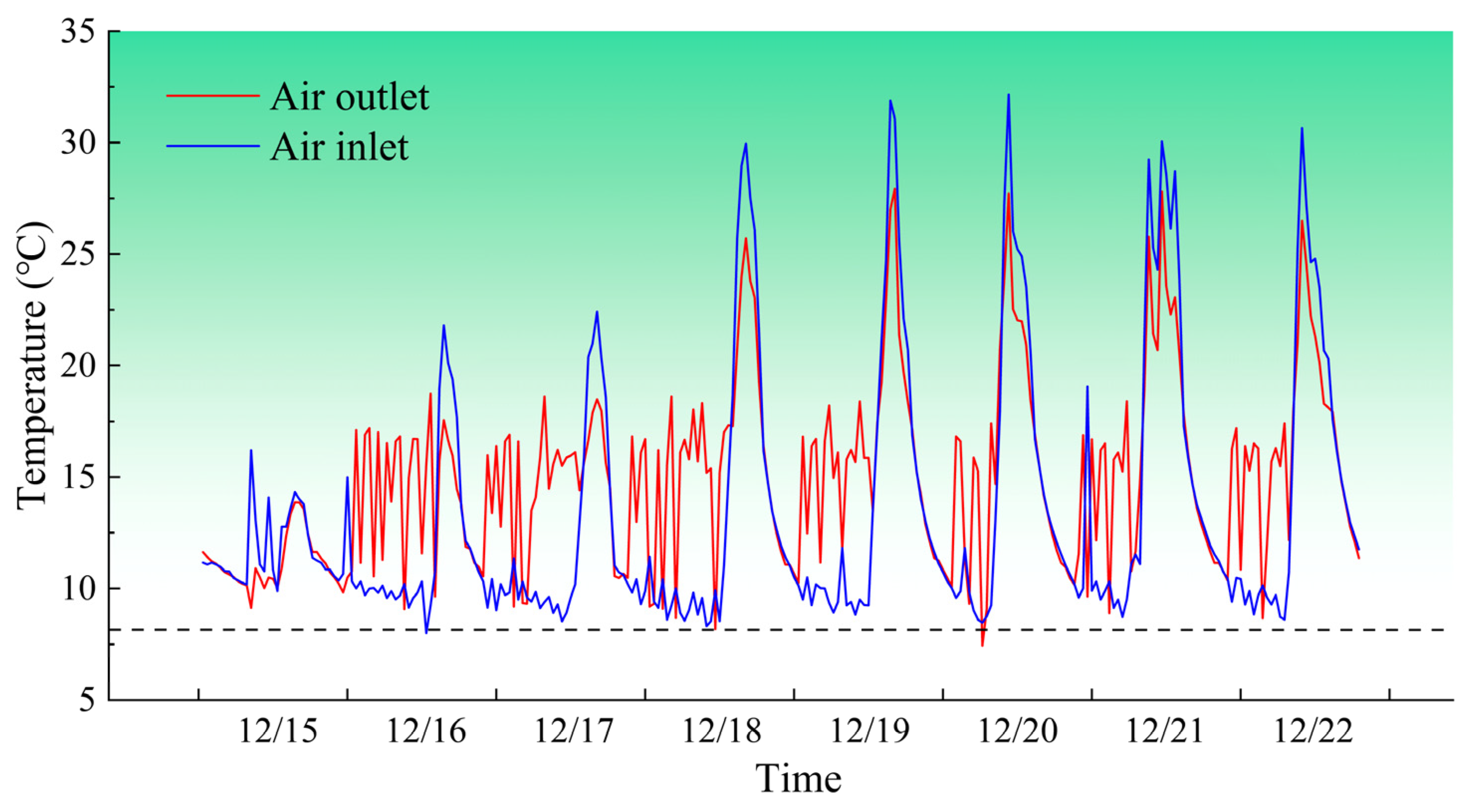

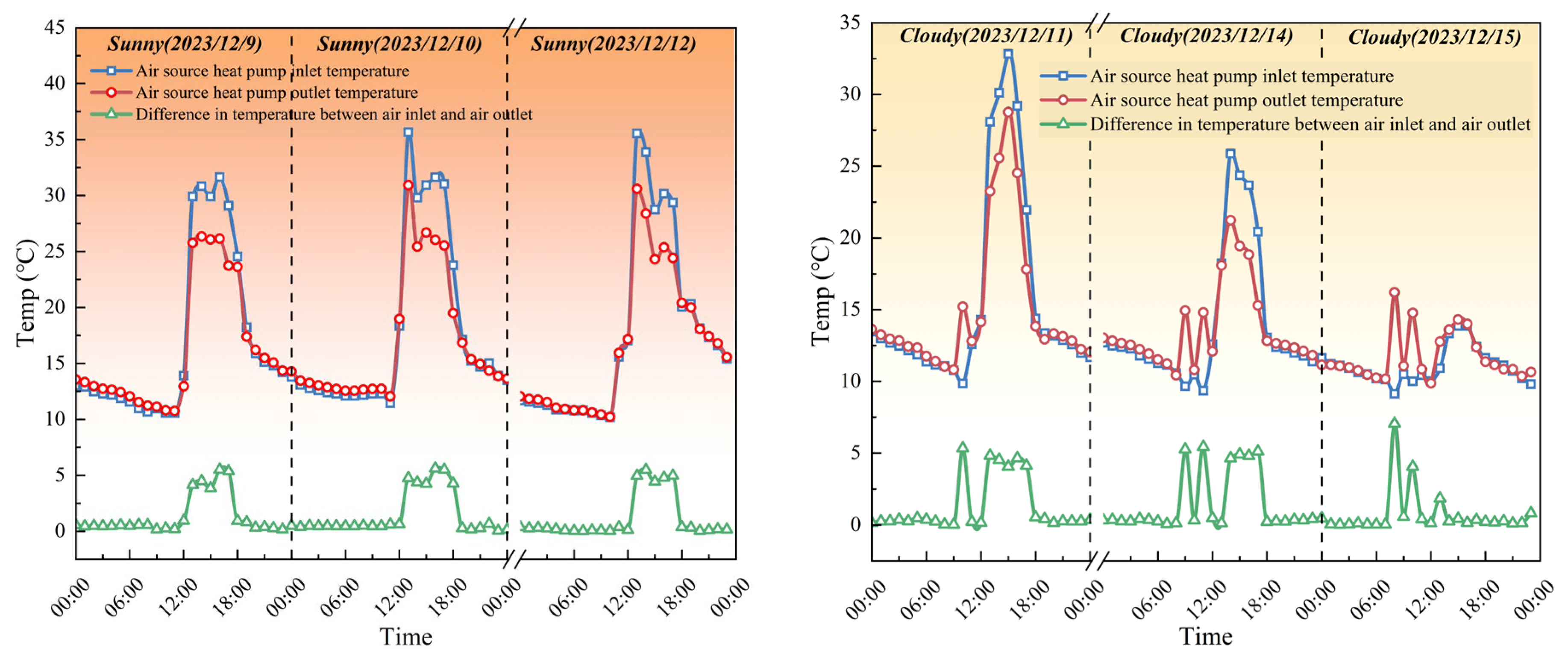

3.2.3. Temperature Analysis at the Heat Exchange Port of the System

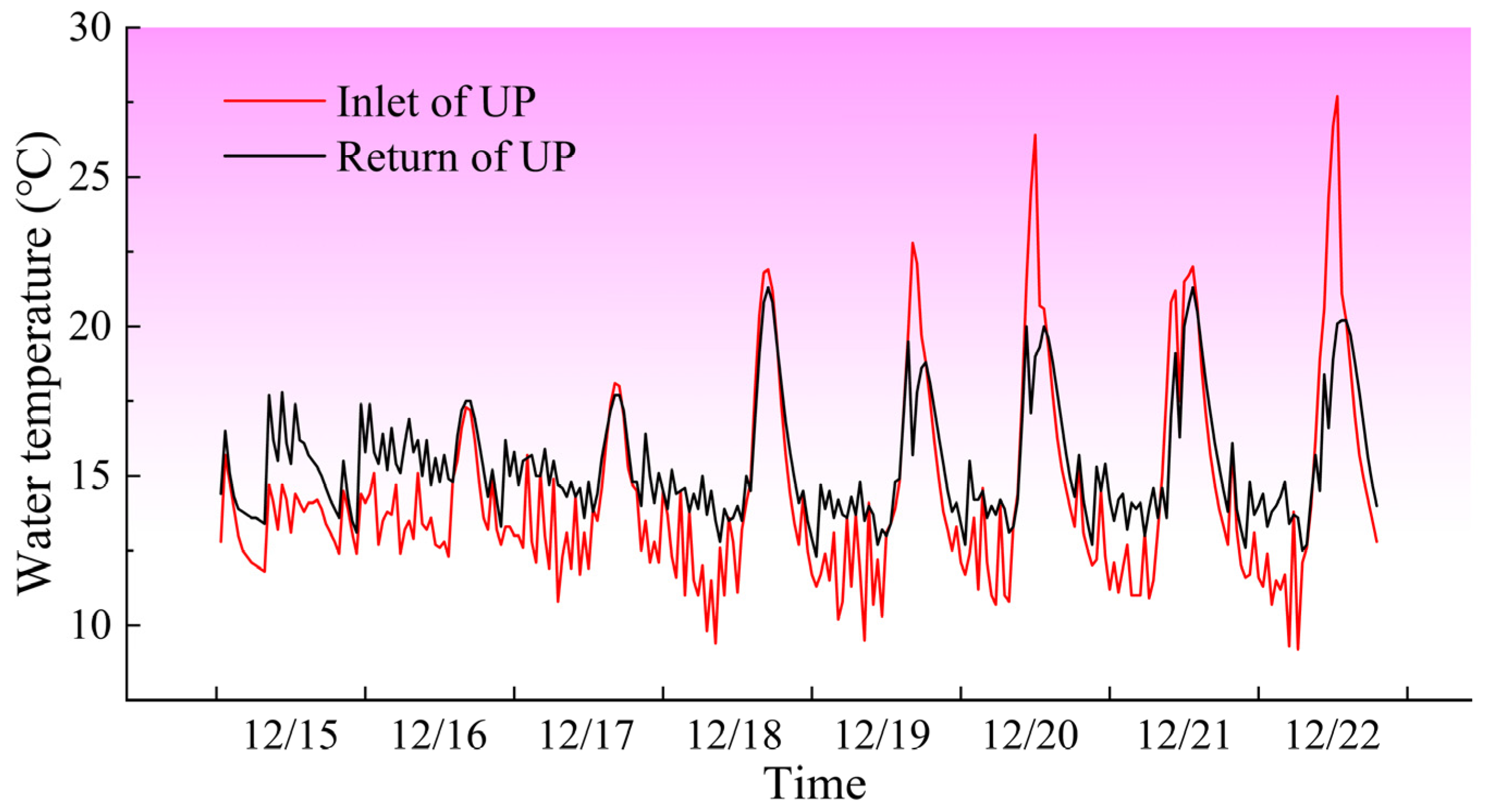

3.2.4. Ground Temperature Change

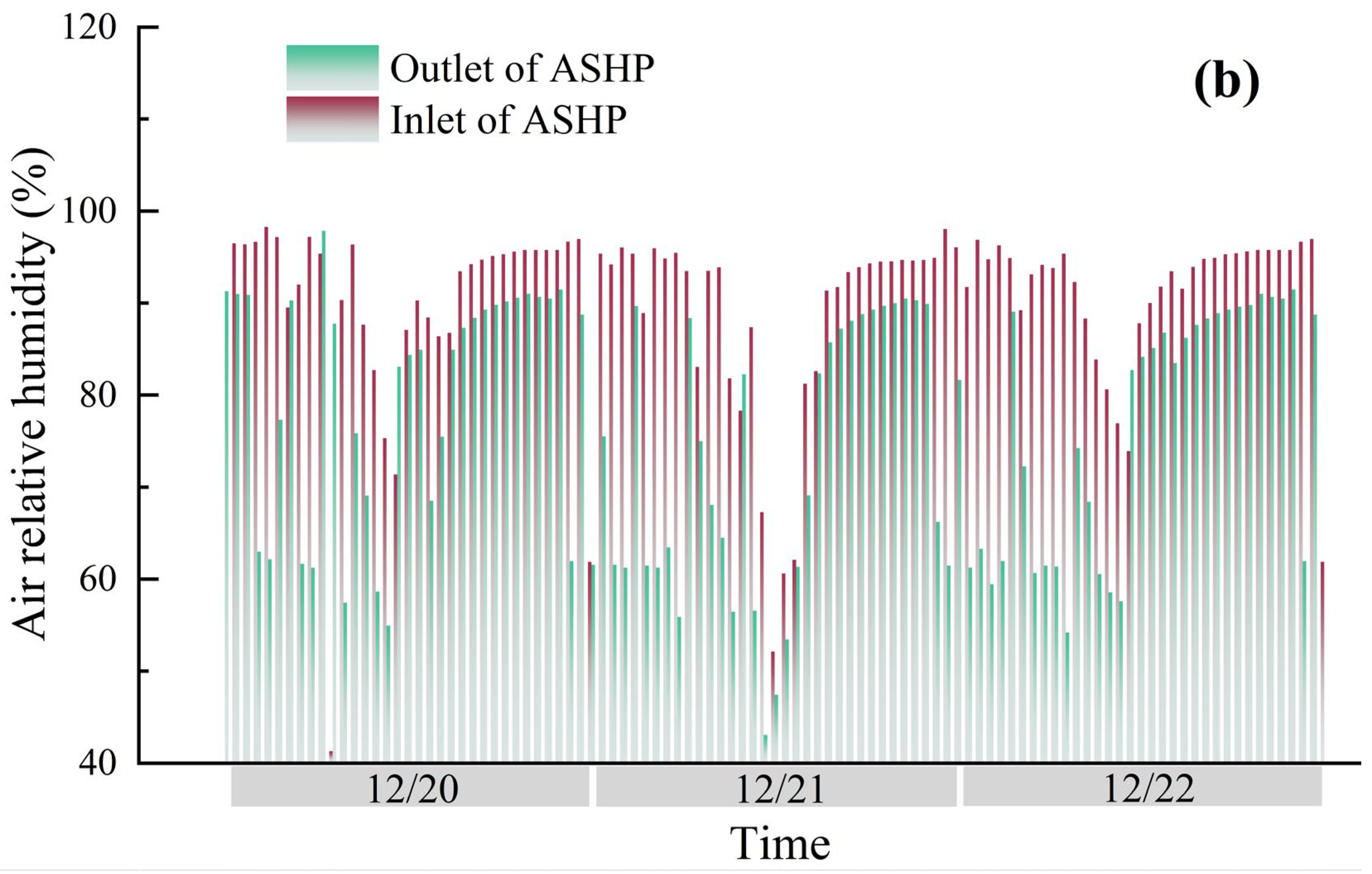

3.2.5. Air Humidity Analysis

3.3. Energy Saving Analysis of ASHP–UP System

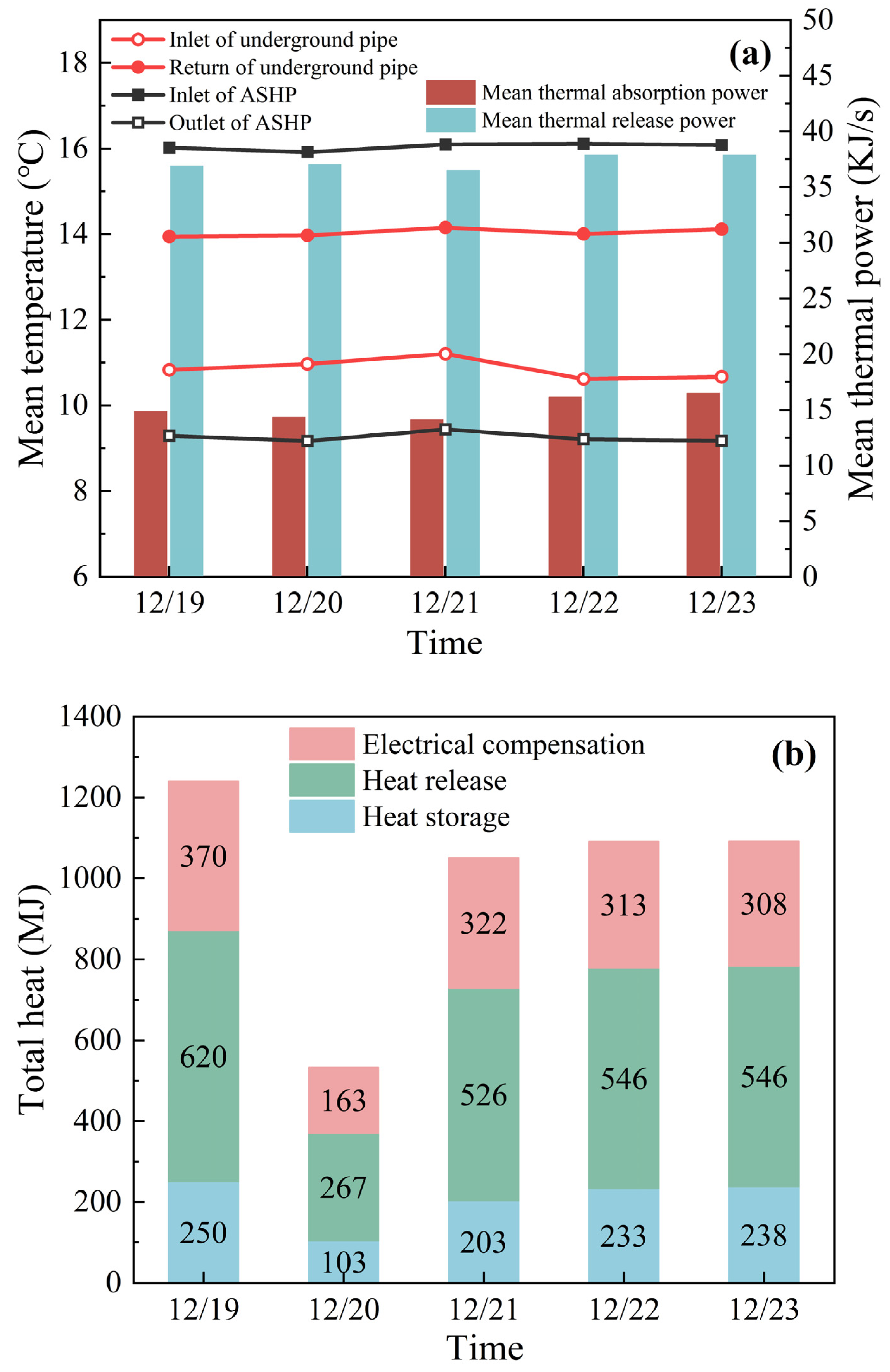

3.3.1. System Heat Absorbed and Released Capacity

3.3.2. System COP Analysis

3.4. Analysis of Energy Saving Rate and Environmental Protection

3.5. Economic and Sustainability Analysis

4. Conclusions

- (1)

- Following the implementation of the ASHP–UP heating system, the minimum nighttime temperature of the greenhouse stabilized between 10 °C and 12 °C. The relative humidity of the air can be reduced by 8%, thereby providing an optimal thermal and humidity environment for crop growth. Under snowy weather conditions, the greenhouse internal temperatures were able to be maintained in the range of 10 to 12 °C throughout the day, mainly due to the lower ambient temperatures outside and the lower intensity of solar radiation. In this case, the greenhouse climate control system was operated solely in exothermic mode to maintain a stable internal temperature.

- (2)

- The ASHP–UP system greatly reduced indoor temperature fluctuations in all types of weather. The greatest reduction in TLL values was observed in sunny climates, where the greenhouse temperature varied the most throughout the day. However, the system’s ability to store heat during the day, which helps lower the daily maximum temperature, and its exothermic function to raise the minimum temperature at night, led to a significant reduction in TLL values on sunny days.

- (3)

- Throughout the system’s operation, the average heat release power fluctuated between 36.5 kJ s−1 and 37.5 kJ s−1, demonstrating satisfactory heating performance.

- (4)

- By calculating the temperature difference between the system’s inlet and outlet, the average coefficients of performance (COP) for heat storage and release were found to be 4.33 and 4.81, respectively. In comparison to traditional heating methods, such as coal-fired, gas-fired, and electric heating systems, energy consumption was reduced by 84.7%, 81.3%, and 79.1%, respectively.

- (5)

- When compared to coal-fired, gas-fired, and electric heating systems, as well as conventional heat storage methods, greenhouse gas emissions were reduced by 8.24 t, 6.52 t, and 5.67 t, respectively. An analysis of comprehensive costs and profitability indicated that the system demonstrates high sustainability, with a payback period of approximately four years.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dong, J.; Gruda, N.; Li, X.; Cai, Z.; Zhang, L.; Duan, Z. Global vegetable supply towards sustainable food production and a healthy diet. Clean. Prod. 2022, 369, 133212. [Google Scholar] [CrossRef]

- Li, T.; Qi, M.; Meng, S. Sixty Years of Facility Horticulture Development in China: Achievements and Prospects. Acta Hortic. Sin. 2022, 49, 2119–2130. (In Chinese) [Google Scholar]

- Qi, F.; Wei, X.; Zhang, Y. Development status and future research emphase on greenhouse horticultural equipment and its relative technology in China. Trans. Chin. Soc. Agric. Eng. 2017, 33, 24. (In Chinese) [Google Scholar]

- Guo, B.; Zhou, B.; Zhang, Z.; Li, K.; Wang, J.; Papadakis, G. A Critical Review of the Status of Current Greenhouse Technology in China and Development Prospects. Appl. Sci. 2024, 14, 5952. Available online: https://www.mdpi.com/2076-3417/14/13/5952 (accessed on 10 December 2024). [CrossRef]

- Shi, Y.; Wang, X.; Wei, M.; Li, Q.; Liu, F.; Hou, J. Temperature variation, heat storage and heat release characteristics of soil wall in solar greenhouse. Trans. Chin. Soc. Agric. Eng. 2016, 32, 214–221. (In Chinese) [Google Scholar]

- Li, J.; Li, H.; Sun, G.; Wang, J. Performance testing and analysis of flexible composite walls in assembled solar greenhouse. Trans. Chin. Soc. Agric. Eng. 2024, 40, 179–187. (In Chinese) [Google Scholar]

- Bao, E.; Cao, Y.; Zou, Z.; Shen, T.; Zhang, Y. Research progress of thermal storage technology in energy-saving solar greenhouse. Trans. Chin. Soc. Agric. Eng. 2018, 34, 1–14. (In Chinese) [Google Scholar]

- Wang, H.; Zu, G.; Yang, F.; Li, D.; Tian, L. Design of multi-functional solar greenhouses in high latitude areas. Trans. Chin. Soc. Agric. Eng. 2020, 36, 170–178. (In Chinese) [Google Scholar]

- Zhang, X.; Zhang, W.; Yang, X.; Wang, L.; Ma, H.; Fan, Q. Survey of Research Methods on Agricultural Greenhouse Environment Control. Control. Eng. China 2017, 24, 8–15. (In Chinese) [Google Scholar]

- Zohra, F.; Dahmani, M. Optimization of greenhouse climate with solar heating systems. In Proceedings of the International Renewable Energy DAYS’2024, Algiers, Algeria, 28–30 May 2024; Available online: https://www.researchgate.net/publication/386553155 (accessed on 11 December 2024).

- Chaigneau, M.; Nienborg, B. Sustainable Heat Supply for Greenhouses with Heatpumps. In Proceedings of the International Sustainable Energy, Ho Chi Minh City, Vietnam, 10–11 November 2023; Available online: https://www.tib-op.org/ojs/index.php/isec/article/view/1162 (accessed on 22 December 2024).

- Ozcan, Z.; Bilir, L.; Caglar, B. Modelling and analysis of heat pump integrated Photovoltaics-Wind systems for an agricultural greenhouse in Turkey. Appl. Therm. Eng. 2024, 248, 123364. Available online: https://www.sciencedirect.com/science/article/abs/pii/S1359431124010329 (accessed on 25 December 2024). [CrossRef]

- Sun, W.; Yang, Q.; Fang, H.; Zhang, Y.; Guan, D.; Lu, W. Application of heating system with active heat storage-release and heat pump in solar greenhouse. Trans. Chin. Soc. Agric. Eng. 2013, 29, 168–177. (In Chinese) [Google Scholar]

- Sun, W.; Zhang, Y.; Yang, Q.; Fang, H.; Lu, W.; Hu, Y. Thermodynamic analysis of active heat storage-release associated with heat pump heating system in greenhouse. Trans. Chin. Soc. Agric. Eng. 2014, 30, 179–188. (In Chinese) [Google Scholar]

- Wang, Y.; Zhang, X.; Zhao, H.; Miao, R. Application analysis of centralized straw methane gas supply project in sunlight greenhouse. Acta Energiae Solaris Sin. 2017, 38, 913–919. (In Chinese) [Google Scholar]

- Chai, L.; Ma, C.; Zhang, X.; Qu, M.; Chen, Q.; Yu, F. Experimental investigation and performance analysis on ground source heat pump system for greenhouse cooling. Trans. Chin. Soc. Agric. Eng. 2008, 24, 150–154. (In Chinese) [Google Scholar]

- Marsh, L.S.; Singh, S. Economics of greenhouse heating with a mine air-assisted heat pump. Trans. ASAE 1994, 37, 1959–1963. [Google Scholar] [CrossRef]

- Tong, Y.; Kozai, T.; Nishioka, N.; Ohyama, K. Greenhouse heating using heat pumps with a high coefficient of performance (COP). Biosyst. Eng. 2010, 106, 405–411. [Google Scholar] [CrossRef]

- Bot, G.; Van De Braak, N.; Challa, H.; Hemming, S.; Rieswijk, T.; van Straten, G.; Verlodt, I. The solar greenhouse: State of the art in energy saving and sustainable energy supply. Acta Hortic. 2005, 691, 501. [Google Scholar] [CrossRef]

- Amirirad, A.; Kumar, R.; Fung, A.-S. Performance characterization of an indoor air source heat pump water heater for residential applications in Canada. Int. J. Energy Res. 2018, 42, 1316–1327. [Google Scholar] [CrossRef]

- Yang, S.H.; Rhee, J.Y. Utilization and performance evaluation of a surplus air heat pump system for greenhouse cooling and heating. Appl. Energy 2013, 105, 244–251. [Google Scholar] [CrossRef]

- Yu, W.; Wang, T.; Liu, W.; Bai, Y.; Tong, G. Soil Temperature in Solar Greenhouse with Buried Hot Water Pipes. J. Shenyang Agric. Univ. 2014, 45, 321–325. (In Chinese) [Google Scholar]

- Dong, P.; Lu, Q.; Chen, Q.; Zhang, Z.; Xu, H.; Yao, L. Influencing Factors of Greenhouse Buried Pipeline Temperature Field—Based on Fluent. J. Agric. Mech. Res. 2015, 37, 239–244. (In Chinese) [Google Scholar]

- Yu, T.; Wang, D.; Wang, Y. Research on Heat Storage Effect of Horizontal Underground Pipe in Solar Greenhouse in Cold Area. J. Agric. Mech. Res. 2022, 44, 248–258. (In Chinese) [Google Scholar]

- Guo, Z.; Wang, D.; Wang, X.; Liu, L.; Meng, K.; Wei, C. Simulation Study on Effect of Buried Pipe Heating on Distribution of Soil Temperature and Moisture in Vegetable Greenhouse. J. Shenyang Agric. Univ. 2022, 53, 73–82. (In Chinese) [Google Scholar]

- Zhen, Q.; Du, J.; Ta, N.; Yan, C.; Sun, Y. Numerical Analysis of the Influence of Solar Greenhouse Heating Channels and Soil Heat Transfer Intensity in Cold and Arid Areas. J. Agric. Mech. Res. 2024, 46, 257–263. (In Chinese) [Google Scholar]

- Bao, L.; Geng, J.; Zhu, S.; Li, R.; Dong, S. Study on Operation Characteristics of Ground Pipe and Air Source Heat Pump System in Greenhouse. J. Agric. Mech. Res. 2020, 42, 258–264. (In Chinese) [Google Scholar]

- Bao, L.; Cui, J.; Li, Y.; An, H. Heat Storage Performance of Air Source Heat Pump-underground Buried Pipe Heat Exchange System. Sci. Technol. Eng. 2022, 22, 10688–10697. (In Chinese) [Google Scholar]

- Wang, C.; Fang, H.; Zhang, Y.; Sang, S.; Cao, K. Energy consumption analysis of simply soft insulated wall-assembled Chinese solar greenhouse. Trans. Chin. Soc. Agric. Eng. 2023, 39, 190–197. (In Chinese) [Google Scholar]

- Luo, Q.; Cheng, R.; Zhang, Y.; Fang, H.; Li, D.; Zhang, J.; Song, G. Optimization of active heat storage and release system in solar greenhouse. Trans. Chin. Soc. Agric. Eng. 2020, 36, 234–241. (In Chinese) [Google Scholar]

- Zhou, B.; Zhang, Y.; Fang, H.; Yang, Q.; Ao, H. Performance experiment and design of simply assembled Chinese solar greenhouse equipped with heating and dehumidification system. Trans. Chin. Soc. Agric. Eng. 2016, 32, 226–232. (In Chinese) [Google Scholar]

- JB/T 10297-2001; Greenhouse Heating System Design Specification. Chinese Academy of Agricultural Mechanization Sciences Environmental Engineering Equipment Research and Development Center: Beijing, China, 2003. (In Chinese)

- Xia, T.; Li, Y.; Sun, Z.; Wan, X.; Sun, D.; Wang, L.; Liu, X.; Li, T. Performance study of an active solar water curtain heating system for Chinese solar greenhouse heating in high latitudes regions. Appl. Energy 2023, 332, 120548. [Google Scholar] [CrossRef]

- Xu, W.; Guo, H.; Ma, C. An active solar water wall for passive solar greenhouse heating. Appl. Energy 2022, 308, 118270. [Google Scholar] [CrossRef]

- Ahamed, M.-S.; Guo, H.; Tanino, K. Development of a thermal model for simulation of supplemental heating requirements in Chinese-style solar greenhouses. Comput. Electron Agric. 2018, 150, 235. [Google Scholar] [CrossRef]

- Jolliet, O.; Danloy, L.; Gay, J.B.; Munday, G.L.; Reist, A. HORTICERN: An improved static model for predicting the energy consumption of a greenhouse. Agric. Meteorol. 1991, 55, 265–294. [Google Scholar] [CrossRef]

- Deng, L.; Huang, L.; Zhang, Y.; Li, A.; Gao, R.; Zhang, L.; Lei, W. Analytic model for calculation of soil temperature and heat balance of bare soil surface in solar greenhouse. Sol. Energy 2023, 249, 312–326. [Google Scholar] [CrossRef]

- Ma, Q.; Li, M.; Wang, L.; Hu, X.; Song, W.; Wei, X. Heat storage and release characteristics of the combined heat storage system for prefabricated solar greenhouses with flexible material wall. Trans. Chin. Soc. Agric. Eng. 2024, 40, 183–193. (In Chinese) [Google Scholar]

- Zhang, Y.; Ni, X.; Zhang, K.; Xu, Y. Cooling performance for tomato root zone with intelligent ecological planting matrix temperature control system driven by photovoltaic in greenhouse. Trans. Chin. Soc. Agric. Eng. 2020, 36, 212–219. (In Chinese) [Google Scholar]

- Feng, S.; Hu, W.; Li, D. Heating Mode and Equipment Selection during Agricultural Construction. Tianjin Agric. Sci. 2017, 23, 78–81. (In Chinese) [Google Scholar]

- Tian, D.; Song, W.; Wang, P.; Cheng, J.; Liang, C.; Zhao, S. Soil heat storage and release characteristics of the plastic tunnel with external thermal insulation. Trans. Chin. Soc. Agric. Eng. 2022, 38, 189–196. (In Chinese) [Google Scholar]

- Xiao, J.; Wang, Q.; Wang, X.; Hu, Y.; Cao, Y.; Li, J. An earth-air heat exchanger integrated with a greenhouse in cold-winter and hot-summer regions of northern China: Modeling and experimental analysis. Appl. Therm. Eng. 2023, 232, 120939. [Google Scholar] [CrossRef]

- Mirzazade, A.A.; Haghighi, P.A.; Biglari, F. Performance analysis of domed roof integrated with earth-to-air heat exchanger system to meet thermal comfort conditions in buildings. Renew Energy 2021, 168, 1265–1293. [Google Scholar] [CrossRef]

- Ma, C.-W. Studies on the vinyl-house house heating by the underground heat exchange system. Trans. Chin. Soc. Agric. Eng. 1985, 1, 54–65. (In Chinese) [Google Scholar]

- Baddadi, S.; Bouadila, S.; Ghorbel, W.; Guizani, A. Autonomous greenhouse microclimate through hydroponic design and refurbished thermal energy by phase change material. J. Clean. Prod. 2019, 211, 360–379. [Google Scholar] [CrossRef]

- Sethi, V.; Sumathy, K.; Lee, C.; Pal, D. Thermal modeling aspects of solar greenhouse microclimate control: A review on heating technologies. Sol. Energy 2013, 96, 56–82. [Google Scholar] [CrossRef]

- Ihoume, I.; Tadili, R.; Arbaoui, N.; Bazgaou, A.; Idrissi, A.; Benchrifa, M.; Fatnassi, H. Performance study of a sustainable solar heating system based on a copper coil water to air heat exchanger for greenhouse heating. Sol. Energy 2022, 232, 128–138. [Google Scholar] [CrossRef]

- Yu, W.; Liu, W.; Bai, Y.-K.; Ding, X. Simulating thermal environment in a two-span solar greenhouse using CFD. Trans. Chin. Soc. Agric. Eng. 2023, 39, 215–222. (In Chinese) [Google Scholar]

- Yuan, Q.; Lu, W.; Wang, J.; Chen, R.; Li, Y.; Yu, X.; He, C.; Sun, M.; Yan, Y. Effects of irrigation strategies of accumulated solar radiation on cucumber growth under different soil textures in the solar greenhouse. Trans. Chin. Soc. Agric. Eng. 2023, 39, 98–105. (In Chinese) [Google Scholar]

- Sun, X.; Guo, K.; Zou, Z.; Zhang, Y. System investigation of a solar combined with air-source heat pump system for greenhouse heating. Acta Energ. Solaris Sin. 2016, 37, 658–665. (In Chinese) [Google Scholar]

- Zhou, S.; Zhang, Y.; Cheng, R.; Yang, Q.; Fang, H.; Zhou, B.; Lu, W.; Zhang, F. Evaluation on heat preservation effects in micro-environment of large-scale greenhouse with active heat storage system. Trans. Chin. Soc. Agric. Eng. 2016, 32, 218–225. (In Chinese) [Google Scholar]

- Sun, X.; Hui, L.; Sheng, W.; Liu, T.; Zhao, X. Study on the Potential of SO3 Emission Reduction from Coal Power Industry in China Through the Analysis of Whole Smoke treatment Process. Proc. CSEE 2024, 1–11. (In Chinese) [Google Scholar]

- Yao, Y.; Dai, J.; Luo, W.; Sun, G. Simulation analysis of distribution of energy consumption for year round cucumber production in multi-span greenhouse in China. Trans. Chin. Soc. Agric. Eng. 2011, 27, 273–279. (In Chinese) [Google Scholar]

- Wang, Z.; Lian, L. Comprehensive fuzzy evaluation of indoor thermal environment in cold area. J. Journal of Harbin Institute of Technology. 2004, 36, 752–755. (In Chinese) [Google Scholar] [CrossRef]

- Fang, K.; He, B.; Yang, M.; Wang, Z. Application of fuzzy comprehensive evaluation method to CENS. J. Harbin Inst. Technol. 2011, 43, 30–36. (In Chinese) [Google Scholar]

- Shang, L.; Liu, S.; Shan, Q.; Zhang, L.; Sun, N.; Wei, W. Comprehensive evaluation of low carbon performance of typical carbon dioxide utilization technologies. Chem. Ind. Eng. Prog. 2022, 41, 1199–1208. (In Chinese) [Google Scholar]

| Installations | Parametric | Numerical Value |

|---|---|---|

| Air source heat pump | Rated heat capacity/kW | 30 |

| Rated input power/kW | 6.3 | |

| Water pump | Flux/m3h−1 | 10 |

| Power/kW | 1.5 | |

| Ground heat exchanger | Horizontal spacing/m | 0.9 |

| Main water pipe diameter/mm | 63 | |

| Branch water pipe diameter/mm | 32 | |

| Water supply tank | Diameter/m | 0.4 |

| High degree/m | 1.0 |

| Date | Weather | Run Model | Heat Storage and Heat Release Value MJ | Heat Storage and Heat Release System Runtime h | Heat Storage and Heat Release Electricity Consumption MJ | Heat Storage and Heat Release COP |

|---|---|---|---|---|---|---|

| 9 December 2023 | Sunny | HS | 596/- | 5.0/- | 140/- | 4.26/- |

| 10 December 2023 | Sunny | HS | 556/- | 4.7/- | 132/- | 4.21/- |

| 12 December 2023 | Sunny | HS | 534/- | 4.5/- | 126/- | 4.24/- |

| 11 December 2023 | Cloudy | HS + HR | 458/136 | 3.8/1.0 | 106/28 | 4.32/4.87 |

| 14 December 2023 | Cloudy | HS + HR | 394/278 | 3.2/2.0 | 90/56 | 4.38/4.96 |

| 15 December 2023 | Cloudy | HS + HR | 356/382 | 3.0/2.8 | 84/79 | 4.24/4.83 |

| 8 December 2023 | Overcast | HS | 485/- | 4.0/- | 112/- | 4.32/- |

| 13 December 2023 | Overcast | HS + HR | 424/214 | 3.5/1.6 | 98/45 | 4.33/4.75 |

| 17 February 2024 | Overcast | HR | -/956 | -/7.2 | -/202 | -/4.74 |

| 1 February 2024 | Snowy | HR | -/1138 | -/8.5 | -/238 | -/4.78 |

| 18 February 2024 | Snowy | HR | -/990 | -/7.5 | -/210 | -/4.71 |

| 19 February 2024 | Snowy | HR | -/1052 | -/7.8 | -/218 | -/4.82 |

| Equipment Type | Thermal Efficiency | Standard Coal (t) | Energy Conservation Rate (%) | Amount of Carbon Emission Reduction (t) |

|---|---|---|---|---|

| ASHP–UP system | 4.56 | 0.60 | - | 1.50 |

| Coal-fired boiler | 0.70 | 3.91 | 84.7 | 9.74 |

| Gas-fired boiler | 0.85 | 3.22 | 81.4 | 8.02 |

| Electric boiler | 0.95 | 2.88 | 79.2 | 7.17 |

| Objectives | h1 | h2 | h3 | h4 |

|---|---|---|---|---|

| k1/kg | 1759.36 | 5790.36 | 2896.91 | 5596.58 |

| k2/kg | 16.32 | 35.36 | 1.60 | 51.91 |

| k4/kg | 9.23 | 19.89 | 12.41 | 29.36 |

| k5/kg | 1.02 | 16.59 | 3.12 | 3.24 |

| Pollutants | Types of Pollutants | |||

|---|---|---|---|---|

| CO2 | SO2 | NOx | Soot | |

| CO2 | 1 | 5/6 | 3/4 | 4/5 |

| SO2 | 6/5 | 1 | 4/5 | 5/6 |

| NOx | 4/3 | 5/4 | 1 | 6/5 |

| Soot | 5/4 | 6/5 | 5/6 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, G.; Wu, L.; Guo, S.; Yue, Q.; Sun, X.; Shi, H. Combined Solar Air Source Heat Pump and Ground Pipe Heating System for Chinese Assembled Solar Greenhouses in Gobi Desert Region. Processes 2025, 13, 334. https://doi.org/10.3390/pr13020334

Zhang G, Wu L, Guo S, Yue Q, Sun X, Shi H. Combined Solar Air Source Heat Pump and Ground Pipe Heating System for Chinese Assembled Solar Greenhouses in Gobi Desert Region. Processes. 2025; 13(2):334. https://doi.org/10.3390/pr13020334

Chicago/Turabian StyleZhang, Gaoshang, Letian Wu, Shenbo Guo, Qiuxing Yue, Xiaoli Sun, and Huifeng Shi. 2025. "Combined Solar Air Source Heat Pump and Ground Pipe Heating System for Chinese Assembled Solar Greenhouses in Gobi Desert Region" Processes 13, no. 2: 334. https://doi.org/10.3390/pr13020334

APA StyleZhang, G., Wu, L., Guo, S., Yue, Q., Sun, X., & Shi, H. (2025). Combined Solar Air Source Heat Pump and Ground Pipe Heating System for Chinese Assembled Solar Greenhouses in Gobi Desert Region. Processes, 13(2), 334. https://doi.org/10.3390/pr13020334