Life Cycle Assessment of Waste Glass Geopolymerization for the Production of Sustainable Construction Materials

Abstract

1. Introduction

2. Materials and Methods

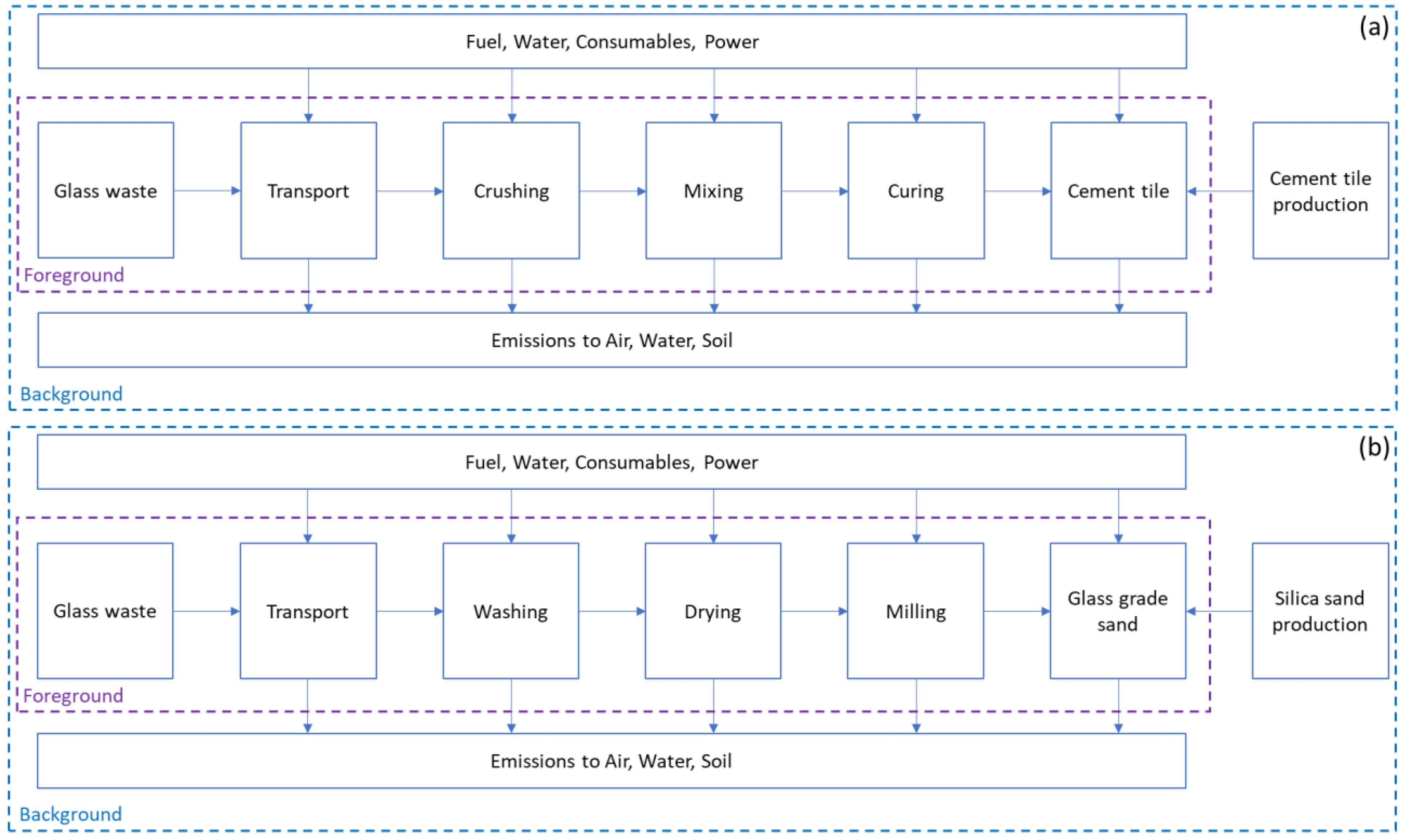

2.1. Goal and Scope

2.2. Mass Balances and Assumptions

2.3. Geopolymerization Process Modeling

2.4. Recycling Process Modeling

3. Results and Discussion

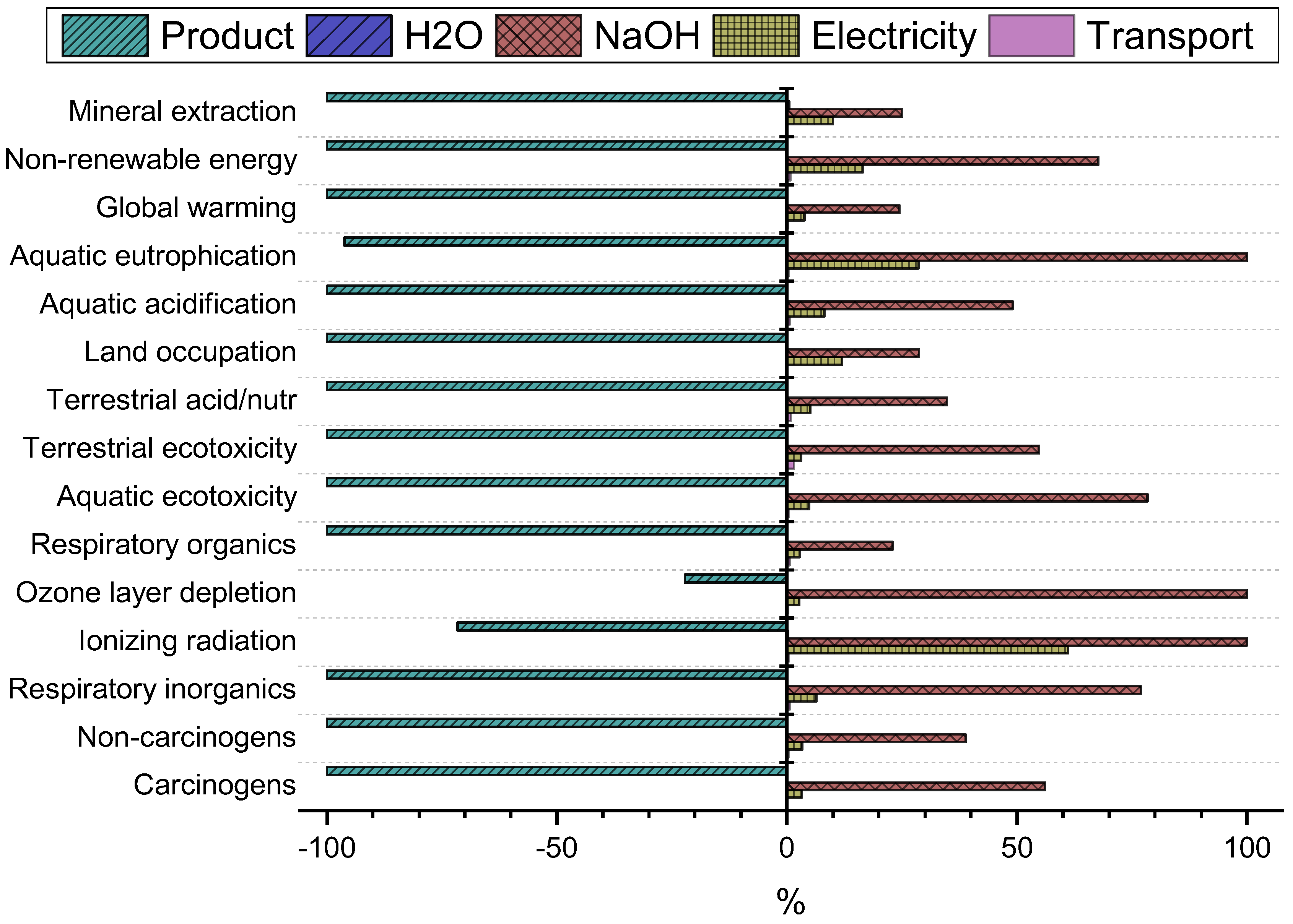

3.1. Characterization

3.2. Damage Assessment

3.3. Normalization

4. Interpretation

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mota, B.; Gomes, M.I.; Carvalho, A.; Barbosa-Povoa, A.P. Towards supply chain sustainability: Economic, environmental and social design and planning. J. Clean. Prod. 2015, 105, 14–27. [Google Scholar] [CrossRef]

- Santoyo-Castelazo, E.; Azapagic, A. Sustainability assessment of energy systems: Integrating environmental, economic and social aspects. J. Clean. Prod. 2014, 80, 119–138. [Google Scholar] [CrossRef]

- Jitmaneeroj, B. Reform priorities for corporate sustainability: Environmental, social, governance, or economic performance? Manag. Decis. 2016, 54, 1497–1521. [Google Scholar] [CrossRef]

- Pahlevani, F.; Sahajwalla, V. From waste glass to building materials—An innovative sustainable solution for waste glass. J. Clean. Prod. 2018, 191, 192–206. [Google Scholar]

- Eurostat. Generation of Waste by Waste Category, Hazardousness and NACE Rev. 2 Activity; Dispon. en ligne; Eurostat: Luxembourg, 2016. [Google Scholar]

- Bignozzi, M.C.; Saccani, A.; Barbieri, L.; Lancellotti, I. Glass waste as supplementary cementing materials: The effects of glass chemical composition. Cem. Concr. Compos. 2015, 55, 45–52. [Google Scholar] [CrossRef]

- Bisikirske, D.; Blumberga, D.; Vasarevicius, S.; Skripkiunas, G. Multicriteria analysis of glass waste application. Environ. Clim. Technol. 2019, 23, 152–167. [Google Scholar] [CrossRef]

- Khale, D.; Chaudhary, R. Mechanism of geopolymerization and factors influencing its development: A review. J. Mater. Sci. 2007, 42, 729–746. [Google Scholar] [CrossRef]

- Komnitsas, K.; Zaharaki, D. Geopolymerisation: A review and prospects for the minerals industry. Miner. Eng. 2007, 20, 1261–1277. [Google Scholar] [CrossRef]

- Rao, F.; Liu, Q. Geopolymerization and its potential application in mine tailings consolidation: A review. Miner. Process. Extr. Metall. Rev. 2015, 36, 399–409. [Google Scholar] [CrossRef]

- You, S.; Ho, S.W.; Li, T.; Maneerung, T.; Wang, C.-H. Techno-economic analysis of geopolymer production from the coal fly ash with high iron oxide and calcium oxide contents. J. Hazard. Mater. 2019, 361, 237–244. [Google Scholar] [CrossRef] [PubMed]

- Youssef, N.; Lafhaj, Z.; Chapiseau, C. Economic analysis of geopolymer brick manufacturing: A french case study. Sustainability 2020, 12, 7403. [Google Scholar] [CrossRef]

- Hauschild, M.Z.; Rosenbaum, R.K.; Olsen, S.I. Life Cycle Assessment; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Manthos, G.; Zagklis, D.; Zafiri, C.; Kornaros, M. Comparative life cycle assessment of anaerobic digestion, lagoon evaporation, and direct land application of olive mill wastewater. Bioresour. Technol. 2023, 388, 129778. [Google Scholar] [CrossRef]

- Turner, L.K.; Collins, F.G. Carbon dioxide equivalent (CO2-e) emissions: A comparison between geopolymer and OPC cement concrete. Constr. Build. Mater. 2013, 43, 125–130. [Google Scholar] [CrossRef]

- Habert, G.; De Lacaillerie, J.B.D.; Roussel, N. An environmental evaluation of geopolymer based concrete production: Reviewing current research trends. J. Clean. Prod. 2011, 19, 1229–1238. [Google Scholar] [CrossRef]

- Petrillo, A.; Cioffi, R.; Ferone, C.; Colangelo, F.; Borrelli, C. Eco-sustainable geopolymer concrete blocks production process. Agric. Agric. Sci. Procedia 2016, 8, 408–418. [Google Scholar] [CrossRef]

- Salas, D.A.; Ramirez, A.D.; Ulloa, N.; Baykara, H.; Boero, A.J. Life cycle assessment of geopolymer concrete. Constr. Build. Mater. 2018, 190, 170–177. [Google Scholar] [CrossRef]

- Curran, M.A. Life Cycle Assessment Handbook: A Guide for Environmentally Sustainable Products; John Wiley & Sons: Hoboken, NJ, USA, 2012; ISBN 1118099729. [Google Scholar]

- Kazmi, D.; Williams, D.J.; Serati, M. Waste glass in civil engineering applications—A review. Int. J. Appl. Ceram. Technol. 2020, 17, 529–554. [Google Scholar] [CrossRef]

- PRé Sustainability B.V., Simapro 8, 2010. Available online: https://simapro.com (accessed on 30 November 2024).

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Jolliet, O.; Margni, M.; Charles, R.; Humbert, S.; Payet, J.; Rebitzer, G.; Rosenbaum, R. IMPACT 2002+: A new life cycle impact assessment methodology. Int. J. Life Cycle Assess. 2003, 8, 324–330. [Google Scholar] [CrossRef]

- Humbert, S.; Margni, M.; Jolliet, O. IMPACT 2002+: User guide. Draft Version Q 2012, 2. [Google Scholar]

- Blengini, G.A.; Busto, M.; Fantoni, M.; Fino, D. Eco-efficient waste glass recycling: Integrated waste management and green product development through LCA. Waste Manag. 2012, 32, 1000–1008. [Google Scholar] [CrossRef] [PubMed]

- Henao Rios, L.M.; Hoyos Triviño, A.F.; Villaquirán-Caicedo, M.A.; de Gutiérrez, R.M. Effect of the use of waste glass (as precursor, and alkali activator) in the manufacture of geopolymer rendering mortars and architectural tiles. Constr. Build. Mater. 2023, 363, 129760. [Google Scholar] [CrossRef]

- Rivera, J.F.; Cuarán-Cuarán, Z.I.; Vanegas-Bonilla, N.; Mejía de Gutiérrez, R. Novel use of waste glass powder: Production of geopolymeric tiles. Adv. Powder Technol. 2018, 29, 3448–3454. [Google Scholar] [CrossRef]

- Jeswani, H.K.; Saharudin, D.M.; Azapagic, A. Environmental sustainability of negative emissions technologies: A review. Sustain. Prod. Consum. 2022, 33, 608–635. [Google Scholar] [CrossRef]

- Hong, J.; Chen, W.; Wang, Y.; Xu, C.; Xu, X. Life cycle assessment of caustic soda production: A case study in China. J. Clean. Prod. 2014, 66, 113–120. [Google Scholar] [CrossRef]

- Rathee, M.; Singh, N. Reviewing geopolymer concrete: A possible sustainable structural material of future. Environ. Dev. Sustain. 2024, 1–55. [Google Scholar] [CrossRef]

- Osman, A.I.; Chen, L.; Yang, M.; Msigwa, G.; Farghali, M.; Fawzy, S.; Rooney, D.W.; Yap, P.-S. Cost, environmental impact, and resilience of renewable energy under a changing climate: A review. Environ. Chem. Lett. 2023, 21, 741–764. [Google Scholar] [CrossRef]

- Munir, Q.; Abdulkareem, M.; Horttanainen, M.; Kärki, T. A comparative cradle-to-gate life cycle assessment of geopolymer concrete produced from industrial side streams in comparison with traditional concrete. Sci. Total Environ. 2023, 865, 161230. [Google Scholar] [CrossRef] [PubMed]

- Mir, N.; Khan, S.A.; Kul, A.; Sahin, O.; Lachemi, M.; Sahmaran, M.; Koç, M. Life cycle assessment of binary recycled ceramic tile and recycled brick waste-based geopolymers. Clean. Mater. 2022, 5, 100116. [Google Scholar] [CrossRef]

- Bianco, I.; Tomos, B.A.D.; Vinai, R. Analysis of the environmental impacts of alkali-activated concrete produced with waste glass-derived silicate activator—A LCA study. J. Clean. Prod. 2021, 316, 128383. [Google Scholar] [CrossRef]

- Weidema, B.; Goedkoop, M.; Meijer, E.; Harmens, R. LCA-based assessment of the Sustainable Development Goals. Development update and preliminary findings of the Project “Linking the UN Sustainable Development Goals to life cycle impact pathway frameworks”. PRé Sustain. 2020, 2, 1–55. [Google Scholar]

- Samuel, R.; Puppala, A.J.; Radovic, M. Sustainability benefits assessment of metakaolin-based geopolymer treatment of high plasticity clay. Sustainability 2020, 12, 10495. [Google Scholar] [CrossRef]

- Kamseu, E.; Alzari, V.; Nuvoli, D.; Sanna, D.; Lancellotti, I.; Mariani, A.; Leonelli, C. Dependence of the geopolymerization process and end-products to the nature of solid precursors: Challenge of the sustainability. J. Clean. Prod. 2021, 278, 123587. [Google Scholar] [CrossRef]

- Shehata, N.; Mohamed, O.A.; Sayed, E.T.; Abdelkareem, M.A.; Olabi, A.G. Geopolymer concrete as green building materials: Recent applications, sustainable development and circular economy potentials. Sci. Total Environ. 2022, 836, 155577. [Google Scholar] [CrossRef]

- Umer, M.; Ahmad, J.; Mukhtar, H. Innovative valorization of biomass waste-derived sodium silicate for geopolymer concrete synthesis: Sustainability assessment and circular economy potential. J. Clean. Prod. 2024, 452, 142181. [Google Scholar] [CrossRef]

- Colglazier, W. Sustainable development agenda: 2030. Science 2015, 349, 1048–1050. [Google Scholar] [CrossRef]

| Avoided products | ||

| Cement tile | 1068 | kg |

| Materials/fuels | ||

| Sodium hydroxide | 56 | kg |

| Tap water | 200 | kg |

| Transport, freight, lorry | 5 | tkm |

| Electricity/heat | ||

| Electricity, medium voltage | 87.5 | MJ |

| Avoided products | ||

| Silica sand | 850 | kg |

| Materials/fuels | ||

| Oxygen, liquid | 0.49 | kg |

| Tap water | 830 | kg |

| Transport, freight, lorry | 20 | tkm |

| Diesel | 0.425 | kg |

| Electricity/heat | ||

| Heat, district or industrial, natural gas | 103.59 | MJ |

| Electricity, medium voltage | 25 | kWh |

| Damage Category | Unit | Maximum Absolute Value |

|---|---|---|

| Mineral extraction | MJ surplus | 0.20 |

| Non-renewable energy | MJ primary | 14 × 102 |

| Global warming | kg CO2 eq | 27 |

| Aquatic eutrophication | kg PO4 P-lim | 13 × 10−3 |

| Aquatic acidification | kg SO2 eq | 0.7 |

| Land occupation | m2 org.arable | 1.4 |

| Terrestrial acid/nutr | kg SO2 eq | 3.3 |

| Terrestrial ecotoxicity | kg TEG soil | 36 × 102 |

| Aquatic ecotoxicity | kg TEG water | 11 × 102 |

| Respiratory organics | kg C2H4 eq | 3.2 × 10−2 |

| Ozone layer depletion | kg CFC-11 eq | 4.5 × 10−5 |

| Ionizing radiation | Bq C-14 eq | 10 × 102 |

| Respiratory inorganics | kg PM2.5 eq | 16 × 10−2 |

| Non-carcinogens | kg C2H3Cl eq | 3.0 |

| Carcinogens | kg C2H3Cl eq | 1.3 |

| Damage Category | Unit | Transport | Electricity | NaOH | H2O | Product | Total |

|---|---|---|---|---|---|---|---|

| Human health | DALY | 7.08 × 10−7 | 7.52 × 10−6 | 8.97 × 10−5 | 3.67 × 10−8 | −1.2 × 10−4 | −2.2 × 10−5 |

| Ecosystem quality | PDF*m2*yr | 0.5 | 1.3 | 17.7 | 0.01 | −34 | −14.5 |

| Climate change | kg CO2 eq | 0.7 | 10 | 65 | 0.1 | −265 | −189 |

| Resources | MJ primary | 11 | 235 | 962 | 1 | −1421 | −212 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Manthos, G.; Zagklis, D.; Georgopoulos, C.; Zafiri, C.; Kornaros, M. Life Cycle Assessment of Waste Glass Geopolymerization for the Production of Sustainable Construction Materials. Processes 2025, 13, 331. https://doi.org/10.3390/pr13020331

Manthos G, Zagklis D, Georgopoulos C, Zafiri C, Kornaros M. Life Cycle Assessment of Waste Glass Geopolymerization for the Production of Sustainable Construction Materials. Processes. 2025; 13(2):331. https://doi.org/10.3390/pr13020331

Chicago/Turabian StyleManthos, Georgios, Dimitris Zagklis, Christos Georgopoulos, Constantina Zafiri, and Michael Kornaros. 2025. "Life Cycle Assessment of Waste Glass Geopolymerization for the Production of Sustainable Construction Materials" Processes 13, no. 2: 331. https://doi.org/10.3390/pr13020331

APA StyleManthos, G., Zagklis, D., Georgopoulos, C., Zafiri, C., & Kornaros, M. (2025). Life Cycle Assessment of Waste Glass Geopolymerization for the Production of Sustainable Construction Materials. Processes, 13(2), 331. https://doi.org/10.3390/pr13020331