1. Introduction

Coiled tubing interventions have become increasingly important in current oilfield operations, notably for well stimulation and remediation in mature and complex reservoirs. Among these interventions, matrix acidizing remains one of the most commonly utilized methods for improving hydrocarbon recovery in carbonate and sandstone formations [

1]. However, increasingly harsh reservoir conditions, including high-pressure, high-temperature (HPHT) conditions, coupled with corrosive gases such as H

2S and CO

2 offer significant issues for fluid design, operational execution, and mechanical integrity of downhole tools [

2]. Acid stimulation in these conditions necessitates equipment that can handle combined mechanical, chemical, and thermal loads, with a focus on bottom hole assemblies (BHAs), which hold jetting nozzles responsible for precise acid deposition in specific zones [

2,

3]. Tungsten carbide has long been the material of choice for high-velocity acid jetting nozzles due to its remarkable hardness, wear resistance, and ability to withstand extreme temperatures and pressures [

4,

5]. Its mechanical strength enables structural stability in the face of erosive and corrosive flow while also sustaining nozzle geometry and jet efficiency [

5]. Despite these advantages, various limitations prevent the practical use of tungsten carbide nozzles in field operations. The material’s inherent brittleness and the need for specialist equipment drive up procurement and machining costs [

6]. Over time, this combination causes severe erosion, pitting, and surface wear, which gradually alters nozzle geometry, reduces jetting performance, and necessitates regular nozzle replacement. within the operating intervention routine conditions of Superior Abu Dhabi, where an average of twelve stimulation activities are conducted per campaign monthly, standard tungsten carbide nozzles have a much shorter service life. Because of the high price, limited local stock, and difficult machining needs of tungsten carbide components, this leads to frequent replacements, increased operational expenses, and logistical delays. To overcome these issues, academics around the world have looked into a variety of methods. Some have concentrated on improved surface coatings, including nitriding, boriding, and thermal spray coatings, to improve base alloy erosion and corrosion resistance [

7,

8,

9,

10]. Others have investigated other hard materials, such as ceramics, cermets, and martensitic stainless steels, using specific heat treatments to increase hardness and chemical stability [

8]. Additional techniques include using corrosion inhibitors to lower acid aggressiveness [

11]. While each strategy offers some benefit, and given the ongoing issues connected with tungsten carbide nozzles, we took the initiative to investigate a fundamentally alternative strategy by fully modifying the nozzle material rather than depending just on coatings. Specifically, we focused on using the same basic materials as the tool body itself, AISI 4140 and 4145 steels, which are readily available in the local market and have outstanding machinability and mechanical strength. Several tests were carried out on both uncoated and surface-treated forms of these alloys to determine their capacity to tolerate the combined effects of high-velocity acid jetting, erosive particle impacts, and extended exposure to stimulating fluids under HPHT and corrosive conditions [

9,

10].

The current study seeks to find and validate a feasible, cost-effective alternative to tungsten carbide for jetting nozzles in coiled tubing acid stimulation. This study takes a multiphase, interdisciplinary approach that includes material selection, laboratory evaluation, field implementation, and predictive modeling [

12]. The selected materials, 4140 and 4145 low-alloy chromium–molybdenum steels, have high tensile strength, good ductility, and excellent hardenability, allowing them to withstand the intense fluid dynamic forces and cyclic loading encountered during high-velocity acid jetting operations [

13]. Their inherent machinability enables rapid prototyping of complex nozzle shapes, addressing one of the most significant drawbacks of tungsten carbide nozzles, which need specialist machining and long lead times. When combined with thermochemical treatments such as nitriding or QPQ (Quench–Polish–Quench), both 4140 and 4145 steels form a compound layer with high surface hardness and increased resistance to erosive and corrosive media, such as hydrochloric acid and the mixed acid systems commonly used in matrix acidization [

9,

10,

14,

15]. While high-chromium martensitic stainless steels like AISI 420 (X105CrMo17) provide superior bulk corrosion resistance, they have lower fracture toughness and ductility and are more prone to brittle failure at high strain rates, making them unsuitable for components subjected to both erosive flow and mechanical impact [

16]. Furthermore, martensitic stainless steels have much reduced machinability, which increases the production complexity and cost of specific nozzle designs. In contrast, nitrided AISI 4140 and 4145 can provide a balanced combination of mechanical strength, surface hardness, and chemical resistance, delivering wear and corrosion performance equivalent to or superior to many stainless steels while maintaining a harder and more machinable core structure [

9,

10,

17].

Their local availability and established heat treatment infrastructure make them economically and logistically advantageous, especially in areas where tungsten carbide procurement takes a long time and is expensive. For these reasons, AISI 4140 and 4145, when properly surface-engineered, offer a technically and economically viable alternative to tungsten carbide for jetting nozzle applications in coiled tubing acid stimulation operations [

9,

18].

Recognizing the inherent unpredictability of downhole corrosion and erosion, a machine learning (ML) framework is built to improve predictive capability. Operational and experimental data, such as acid concentration, flow rates, temperature, exposure time, and grain size, were utilized to train a Gradient Boosting model that can predict corrosion and wear patterns in candidate materials. This AI-driven approach allowed for proactive material selection, decreased trial-and-error field testing, and maximized nozzle deployment in certain operational conditions. Furthermore, the ML framework may be used for other downhole components, such as packers, seals, valves, and tubing strings, that are subjected to similar conditions, suggesting greater relevance for predictive materials engineering in oilfield operations.

The primary goal of this research is to show that a low-cost, readily available, and easily machinable alloy could closely match tungsten carbide under abrasive and corrosive acid stimulation conditions. The study indicates that AISI 4145, when paired with specific surface treatments and validated by integrated laboratory, field, and AI-driven analysis, provides dependable jetting performance while preserving structural integrity and lowering operational costs and downtime. This work not only solves technical issues with nozzle durability but also provides a scalable, cost-effective system for selecting, validating, and predicting the performance of downhole materials under demanding operating conditions [

19].

Finally, this study bridges the gap between laboratory research and field applications, providing a realistic, long-term alternative to tungsten carbide. By combining rigorous material science, controlled experimentation, full-scale field trials, and advanced predictive analytics, this study creates a solid framework for material optimization in coiled tubing acid stimulation operations, increasing operational efficiency, reducing non-productive time, and improving the economic viability of mature field redevelopment. The findings highlight the possibility of merging metallurgical innovation with AI-enabled predictive modeling to improve material selection procedures in the oilfield industry, resulting in a repeatable strategy for high-performance, cost-effective, and dependable downhole solutions.

2. Materials and Methods

This section describes in detail the experimental and analytical processes used to analyze, qualify, and field-validate viable alternatives to tungsten carbide for use in jetting nozzles during coiled tubing acid stimulation operations. The experimental design attempted to closely simulate downhole circumstances in order to ensure that the findings were applicable in the actual case. All candidate materials underwent rigorous multiphase testing due to extreme service conditions, including high-pressure, high-temperature (HPHT) acid exposure, corrosive gases like hydrogen sulfide (H

2S) and carbon dioxide (CO

2), and the abrasive flow regime typical of matrix acidizing operations [

20].

The first stage entailed screening prospective materials based on essential parameters such as thermal and chemical stability, resistance to corrosion and erosion, mechanical robustness, acid compatibility, ease of fabrication, and local availability. Locally sourced oilfield alloys, particularly AISI 4140 and 4145 steels, were selected for their balanced mechanical strength, ductility, machinability, and compatibility with surface treatments and thermochemical modifications that improve performance in corrosive and erosive environments [

2,

3]. AISI 4140 and 4145 steels were chosen as candidate materials due to their mechanical strength, chemical adaptability through surface modification, and demonstrated operational reliability in HPHT conditions, rather than their application in other oilfield components [

13,

21]. The following phase involved extensive laboratory testing under simulated HPHT circumstances, which replicated downhole environments with high-temperature acidic fluids and sour gas exposure. The test methods comprised static and dynamic corrosion assessments, pitting analysis, mass-loss evaluations, volumetric wear testing under high-velocity flow, and surface degradation characterization [

12,

22]. A wide range of acid concentrations, exposure times, pressures, temperatures, and flow regimes were used to imitate field variability, allowing us a thorough understanding of each material’s mechanical and chemical resistance. During these tests, some candidate materials were eliminated owing to mechanical failure, such as the 4140 material, quick degradation, or poor corrosion tolerance, while promising alloys were refined further with surface treatments to improve durability [

22].

The next step was to turn laboratory-validated alloys into working nozzle components, which were then deployed in real-world acid stimulation operations using coiled tubing. Field trials assessed performance under operational loads, multiphase fluid exposure, temperature cycling, and dynamic flow scenarios. Key performance metrics included wear resistance, corrosion behavior, jetting efficiency, and structural integrity under repetitive operational stress [

22]. Nozzle imaging, work records, and post-job inspections offered both quantitative and qualitative data, assuring that effective materials performed consistently throughout numerous stimulation cycles [

12,

22].

The overall methodology was divided into five interdependent phases:

- (1)

Material screening and selection;

- (2)

Laboratory-based corrosion and erosion testing;

- (3)

Material performance validation;

- (4)

Full-scale field trials in active stimulation campaigns;

- (5)

Corrosion rate prediction using advanced machine learning algorithms.

Each phase was methodically developed to measure a specific aspect of material performance, allowing for a multidimensional assessment that includes empirical data, field validation, and predictive analytics.

The approach began with identifying and procuring three prospective materials, which included high-alloy steels, low-metal composites, and coated alloy versions. Each material was chosen using characteristics such as corrosion resistance, acid compatibility, structural durability, cost-effectiveness, availability, and machinability. These candidates completed a thorough laboratory examination in controlled conditions that closely reflect downhole stimulation conditions. The testing techniques included both static and dynamic immersion in high-concentration hydrochloric acid (HCl) at extreme temperatures and pressures, followed by surface characterization of the jetting nozzle including pitting and volumetric wear.

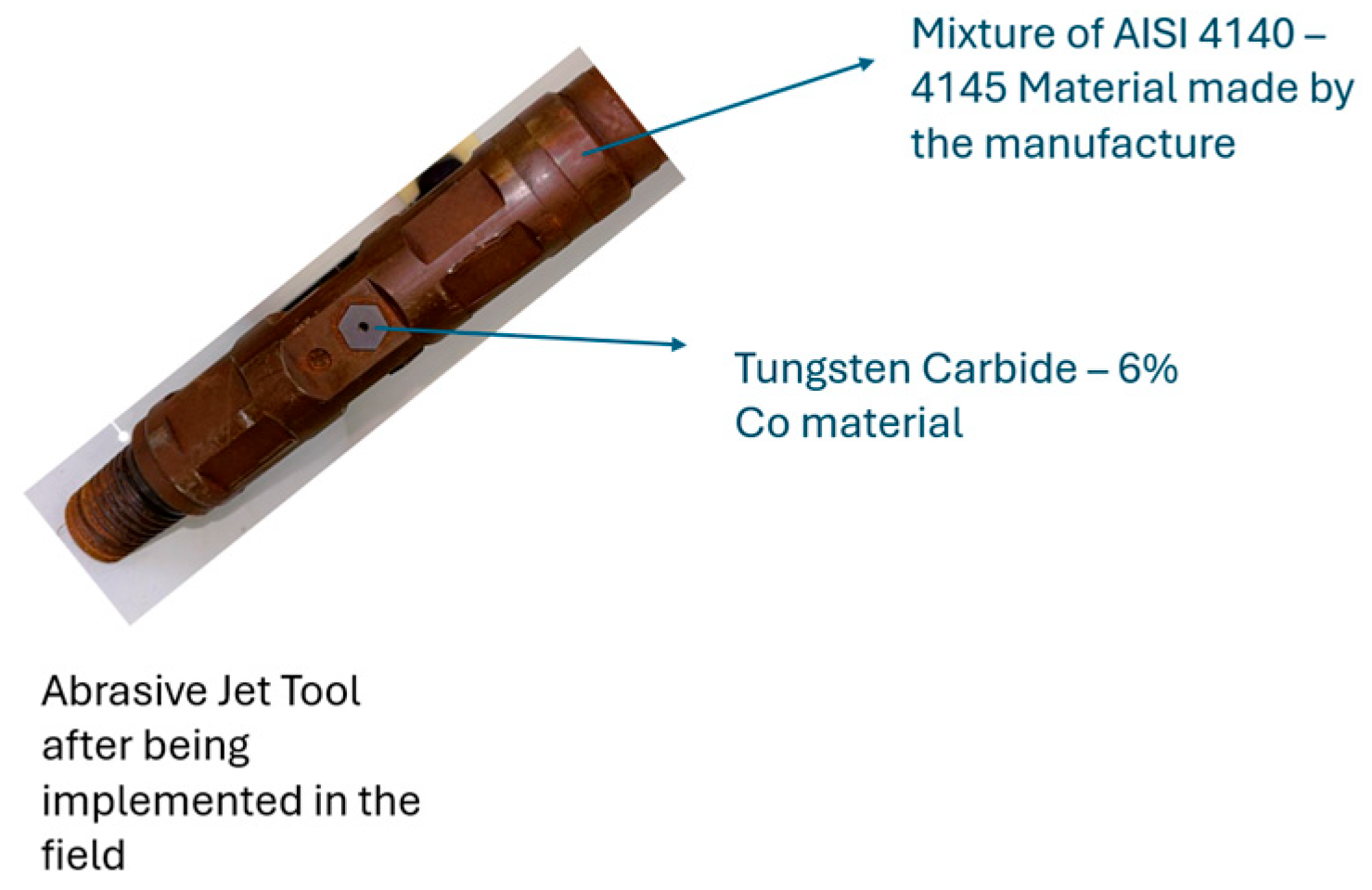

Figure 1 illustrates an abrasive jet tool after field deployment, showcasing its construction from a manufacturer-specified blend of AISI 4140 and 4145 alloy steels for the tool body, as well as jetting nozzles composed of tungsten carbide with 6% cobalt binder [

23]. Tungsten carbide has long been the industry standard for coiled tubing acid stimulation due to its outstanding hardness, erosion resistance, and longevity in high-pressure, high-temperature (HPHT), and corrosive acidifying environments. However, its high cost, production complexity, and vulnerability to acid-induced deterioration provide operational and economic barriers. The primary goal of this research is to identify alternative nozzle materials, such as uncoated 4140 and 4145 steels and QPQ-coated 4145, that can closely matching tungsten carbide in terms of corrosion resistance, erosion tolerance, and field service life while significantly lowering costs and improving manufacturing accessibility. This study seeks to develop a practical, cost-effective alternative that retains jetting efficiency and operating dependability under extreme acid stimulation conditions.

The second phase focused on erosion resistance under jetting conditions. A custom-built, closed-loop recirculating flow system was created to simulate the high-velocity, sand-laden acid streams found in real stimulation operations where the corrosion tester runs under dynamic flow conditions, allowing for precise simulation of acid injection rates as they occur at the jetting nozzle during downhole stimulation. The machine is fully pressurized and thermally controlled to match actual reservoir temperatures, resulting in precise replication of jetting impact, shear stress, and chemical reaction at the nozzle contact. This allows for a more realistic examination of material deterioration under actual field settings. Also, nozzle prototypes were tested for dimensional stability and wear resistance.

The third phase concentrated on mechanical validation utilizing ASTM-compliant tests such as Rockwell, flexural strength testing, and thermal expansion coefficient evaluation via dilatometry.

Field validation was the fourth phase. Based on laboratory results, the top two materials were selected and turned into actual nozzle geometries with CNC machining processes. These nozzles were integrated into coiled tubing bottom hole assemblies and used in five real-world acid stimulation operations in a sour carbonate reservoir with measured HPHT conditions. After-job retrieval and inspection of the nozzles allowed for a direct comparison of pre- and post-operation integrity, such as jet shape retention, material pitting, cracking, and chemical residue analysis.

In the last phase, a machine learning model was created to forecast corrosion rates under various operational conditions. Scikit-learn, a Python version 3.10 library, was used to assemble and process both laboratory and field generated datasets. The model combined regression-based methods (such as Random Forest and Ridge Regression) with advanced ensemble learners. The input variables were fluid composition, exposure length, temperature, flow rate, and gas concentrations, whereas the output was corrosion rate (mm/year). Model performance was validated using conventional metrics including R2 score, MAE, and RMSE.

This methodology combines controlled laboratory evaluations, dynamic flow simulations, real-world field testing, and AI-driven prediction models to provide a robust, reproducible, and scalable framework for selecting and deploying advanced materials in corrosive, high-temperature downhole environments. Each of these phases is explained in depth in the following subsections to ensure complete reproducibility and to seek future research and engineering implementation in similar operating settings.

2.1. Material Screening and Selection

The fundamental concept for selecting specific metal alloys stemmed from the present field-proven performance of the jetting tool body, which is made up of a mix of AISI 4140 and AISI 4145 alloy steel [

24].

Recognizing the durability of this mixed-material tool body under the extreme service conditions encountered by jetting nozzles, the material selection technique naturally began by separating and assessing the core metallic constituents independently. The goal was to understand their independent behavior under corrosive and erosive conditions, and to check if an optimized, standalone, or composite configuration could be engineered for nozzle fabrication, providing comparable or superior performance to tungsten carbide while ensuring lower costs, better machinability, and shorter delivery times.

The first phase of the screening included the use of AISI 4140 steel, a low-alloy chromium–molybdenum composite, as shown in

Table 1, known for its good balance of mechanical strength, toughness, and ease of heat treatment. This steel is widely used in the oil industry for components that require moderate wear and corrosion resistance. Despite its mechanical strength and resilience to some corrosive situations, 4140 has a low alloy content, which may limit its long-term performance in direct acid contact unless it is additionally surface-treated. However, due to its outstanding machinability, widespread availability in the local market, and low procurement cost, 4140 was selected as this study’s baseline material. The 4140 samples were machined into normal test coupons as well as prototype nozzles for full-exposure testing.

The goal of integrating this material early in the selection process was not only to establish a cost-effective performance baseline but also to observe important failure modes that could occur under acidic and erosive flow conditions. In this phase, it was critical to determine how quickly pitting, uniform corrosion, or material loss would occur, as well as how the microstructure would react to prolonged acid interaction and high-velocity jet impingement.

Following the establishment of the basic response from 4140, the investigation moved on to AISI 4145, a higher-grade alloy steel from the same family with better tensile strength, impact resistance, and dynamic loading performance. The 4145 material is commonly used in downhole drilling instruments, such as collars and drill stem components, due to its strong fatigue resistance and heat treatability.

This material has higher hardenability and superior wear resistance than 4140 owing to its improved microstructure and regulated alloy composition, as highlighted in

Table 2. One of the primary reasons for including 4145 in this study was its documented track record in similar oilfield service situations as well as its compatibility with traditional machining methods. Furthermore, 4145 steel is locally available and heat-treated domestically, allowing for quick-turnaround nozzle manufacturing, cost control, and logistical flexibility, all of which are increasingly relevant in today’s operational scenarios where lead time reduction is critical. In its uncoated form, 4145 was exposed to the same laboratory test matrices as 4140, including acid compatibility, erosion resistance, and thermal stress testing, to see whether the raw alloy could be used as a viable nozzle material.

Prior to surface treatment, all nozzle blanks made from AISI 4140 and 4145 steels underwent a regulated heat treatment sequence to standardize their mechanical qualities and assure consistent surface response during thermochemical processing. The components were first austenitized at 845–870 °C before being quenched in oil to generate a martensitic microstructure. A tempering step at 540–595 °C was then used to relieve internal tensions and tune the core hardness to 32 HRC, resulting in an ideal blend of strength, toughness, and machinability. After final machining, a stress-relief heat treatment at 180–200 °C for 1 h was used to reduce residual tensions from manufacturing and prevent deformation during subsequent nitriding.

The final stage of material screening comprised applying a Quench–Polish–Quench (QPQ) surface treatment to AISI 4145 steel, which produced a high-alloy, surface-hardened version, which was performed in three consecutive stages: first was salt bath nitriding at 565–580 °C for 90 min, which produced a compound layer consisting of ε-Fe

2–3N and γ′-Fe

4N phases and an underlying nitrogen diffusion zone; second was mechanical polishing, which removed surface residues and improved surface finish, reducing initiation sites for fatigue or localized corrosion; and third was post-oxidation in a hot salt bath. The microhardness of the treated layer was 60–80 µm thick, with a diffusion layer of 200–300 µm. The final surface hardness was 68 HRC (

Table 3).

This thermochemical treatment was selected due to its dual functionality: it maintains the base steel’s fundamental mechanical qualities and machinability while greatly enhancing surface hardness, wear resistance, and chemical stability. QPQ-coated 4145 specimens were manufactured and tested as the final candidate in the material screening program, with the goal of achieving a synergistic balance between mechanical robustness and chemical inertness under the harsh conditions encountered during coiled tubing acid stimulation operation, namely, high-pressure, high-velocity acid jetting, prolonged exposure to corrosive fluids, and abrasive flow regimes [

25]. The treated surface was specifically engineered to prevent acid penetration, metal ion leaching, erosion, and localized damage caused by turbulent flow and entrained particulates, hence increasing the nozzles’ operational life in difficult downhole settings.

Table 3 in this study describes uncoated AISI 4140 steel, uncoated AISI 4145 steel, and AISI 4145 steel treated with a Quench–Polish–Quench (QPQ) thermochemical surface treatment; these were investigated as potential substitutes for conventional tungsten carbide nozzles. Tungsten carbide with 6% cobalt binder, with density of 14.5 g/cm

3, hardness of 80.5 HRA, and fine grain size of 1.2 µm, is the baseline reference material due to its widespread use in coiled tubing acid stimulation operations. The choice of 4140 and 4145 steels, even in their uncoated forms, was not arbitrary but rather directly related to field relevance, as the majority of abrasive jetting instruments currently used in acid stimulation are made from a combination of 4140 and 4145 alloys.

These steels have already been shown to endure high-pressure, high-temperature, and corrosive service conditions in downhole environments, validating their inclusion in the evaluation matrix as viable and accessible choices. Prior to testing, each steel grade’s chemical composition and microstructural and mechanical properties were thoroughly investigated. Uncoated steel baselines included the standard compositions of 4140 and 4145.

The QPQ-coated 4145 nozzle was created by subjecting 4145 steel to a controlled nitriding–polishing cycle, which refined the grain size to 45 µm, improved the hardness to 68 HRC, and enhanced bending toughness to 1980 N/mm2, allowing for comparison with the benchmark tungsten carbide nozzle.

2.2. Laboratory-Based Corrosion

A crucial part of the material evaluation process was the laboratory corrosion testing stage, which replicated the extremely corrosive and high temperature environment that jetting nozzles experience during coiled tubing acid stimulation. In this phase, three candidate materials, AISI 4140, AISI 4145, and QPQ-treated AISI 4145, were subjected to inhibited 28% HCl at HPHT conditions in order to evaluate their acid resistance. The results were compared with the conventional WC-Co material [

28,

29]. To guarantee consistency between laboratory results and practical applications, each material was machined into prototype nozzles that were identical to those used in field operations in order to replicate real downhole conditions, including temperatures between 94 °C and 160 °C, fluid dynamics, and pressure cycles typical of sour carbonate reservoirs. The corrosion tests were conducted in an HPHT chamber outfitted with precise heat, pressure control systems, and dynamic conditions. The configuration enhanced the erosion–corrosion effects seen in jetting tools by simulating turbulent flow through dynamic acid circulation [

30]. Gravimetric analysis, a standardized technique for quantifying material loss in corrosive conditions, was used to calculate corrosion rates. A high-precision digital balance Precisa PB/XB 220A Precision Balance (+0.1 mg), located in Precisa Gravimetrics AG manufacturer, in Moosmattstrasse 32, Dietikon, Switzerland, was used to record the initial dry weights. Following exposure times of twelve hours, the samples were taken out, neutralized in accordance with ASTM G1 protocols, dried, and weighed again to calculate the overall mass loss [

31,

32].

The weight loss ∆m was then used to compute the corrosion rate in grams per meter square (g/m2) in 12 h then converted to mm/year using the usual equation:

This method enabled a quantitative comparison of material degradation under various temperatures to establish the heat sensitivity and activation energy of corrosion mechanisms. Over 150 corrosion tests were carried out across the three material categories to ensure statistical validity and reproducibility of the results. Special attention was devoted to the behavior of materials at the upper end of the temperature spectrum, as this range closely corresponds to extreme bottomhole conditions where acid reactivity and corrosion acceleration are most noticeable.

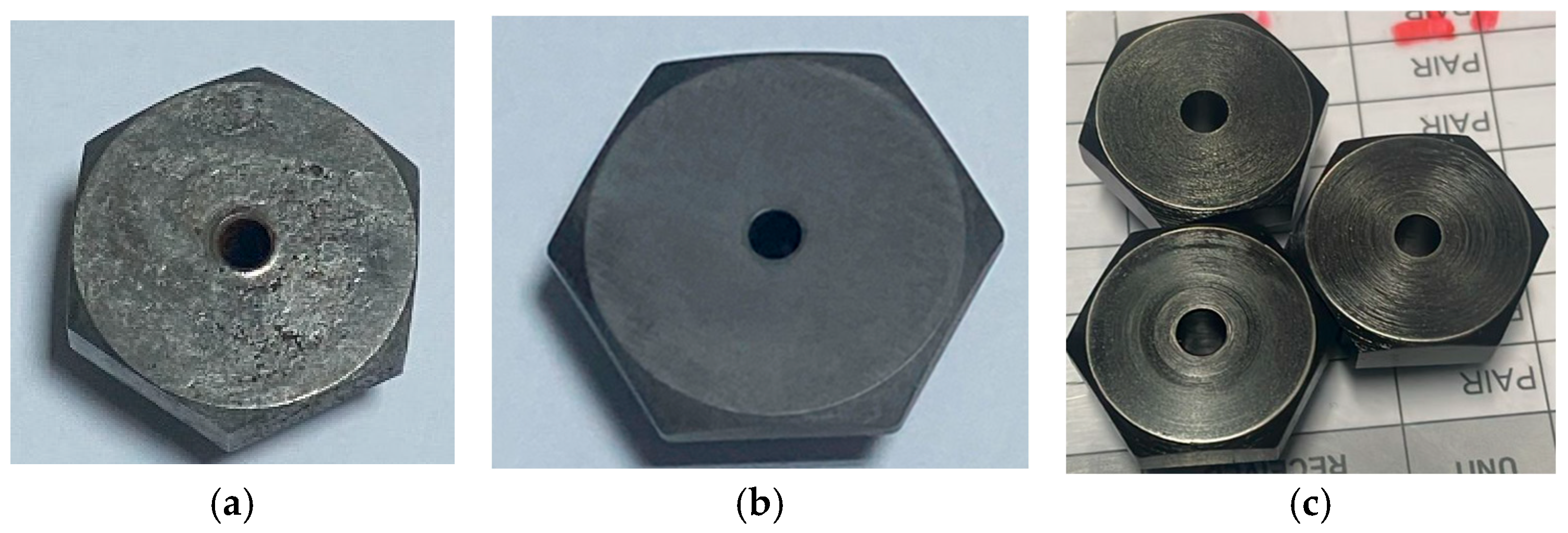

Following completion of each corrosion test, a thorough post-exposure review was conducted. The nozzles in

Figure 2 were initially visually examined for signs of surface degradation, discoloration, and mechanical deformation.

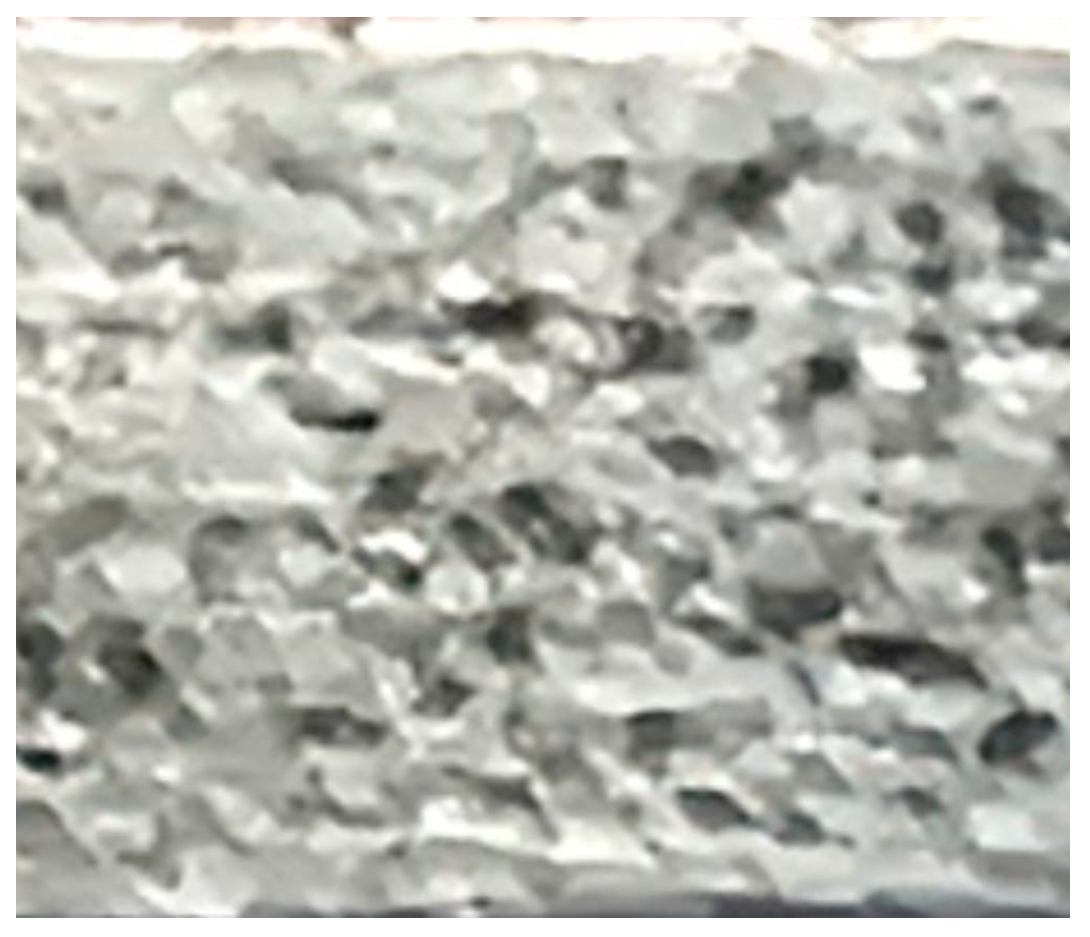

The surface morphology at the micro- and nano-scales was then analyzed using optical microscopy. These analyses focused on detecting incipient pit development, microcrack nucleation, intergranular corrosion, and localized surface thinning, all of which are precursors to catastrophic failure in downhole components as demonstrated in

Figure 3, where a microscope detected severe pitting and irregularities within the 4140 tested materials under reservoir simulated conditions. The goal of micro-analysis was to assess the elemental composition and whether protective passivation layers were degraded. This level of microscopic analysis was required to uncover failure modes that gravimetric methods could not detect.

In conclusion, the laboratory corrosion testing program used in this research was distinguished by its rigorous simulation of real-world service conditions, adherence to defined measurement techniques, and detailed multi-scale analysis of corrosion behavior [

33]. The combination of gravimetric weight loss calculation, visual and microscopic investigation, and multi-temperature exposure trials offered a solid data foundation for comparing the three potential materials.

Figure 4 illustrates microstructural details of nitrocarburized layers, as reported in [

34].

The data clearly revealed that the QPQ-coating for 4145 steel demonstrated in

Figure 4 provides exceptional corrosion resistance in extreme acidic environments, confirming its integrity as a dependable, cost-effective alternative to tungsten carbide in coiled tubing jetting nozzles.

2.3. Material Performance Validation

Material performance validation was designed to evaluate not only the material’s intrinsic strength and surface stability but also its ability to maintain dimensional integrity and jetting efficiency under realistic acid stimulation operating conditions. While corrosion resistance is frequently the primary concern in materials exposed to harsh chemical environments, erosion-induced changes in nozzle shape, particularly at the orifice level, can be as damaging to the efficiency of coiled tubing jetting treatment [

33,

35]. This is essential in matrix acidizing operations, where jet trajectory, velocity, and flow design are critical for deep acid penetration and effective reservoir contact. Thus, this phase of the inquiry focused heavily on both surface degradation mechanisms and fluid dynamics preservation via high-velocity flow paths [

36,

37].

Following laboratory corrosion testing, each of the tested nozzles, made of AISI 4140, 4145, and QPQ-coated 4145, had a post-exposure physical inspection. The goal was to visually and microscopically examine surface quality, detect early signs of mechanical pitting, and evaluate any changes in orifice diameter of the nozzle that would affect jetting behavior, as highlighted in

Figure 3. Visual examinations allow for the detection of fine surface changes like as discoloration, matte finish development, and erosive mark, which are early indicators of mechanical stress. Laboratory engineers focused on edge rounding, flow-induced channeling, and micro-pitting at the throat and orifice diameter, as in

Figure 5.

However, the maintenance of nozzle geometry, particularly orifice diameter, edge profile, and internal tapering, was critical to the mechanical performance evaluation. Given the nature of acid jetting tools, even tiny dimensional variations can result in considerable adjustments in flow velocity, jet form, and acid dispersion, affecting the treatment’s reach and effectiveness [

38]. The photo in

Figure 5 shows how orifice distortion, whether caused by erosion or pitting, resulted in diverging spray patterns, turbulent eddies, or shorter penetration distances, all of which are known to limit stimulation efficiency and acid–rock contact.

Prior to field application, a thorough mechanical evaluation was performed to ensure the integrity of the chosen materials under operating conditions. To analyze nozzle durability under high-pressure acid jetting, key parameters were tested, including tensile and yield strength, hardness, impact toughness, and erosion-wear resistance. Hardness was assessed using the Rockwell technique, and erosion resistance was determined using high-velocity jet and dynamic experiments that simulated downhole acid flow. The results in

Table 3 compare AISI 4140, AISI 4145, and QPQ-treated 4145 alloys to create a mechanical performance baseline [

37].

This study found that corrosion resistance alone is insufficient; material viability is dependent on retaining geometry, resisting abrasion, and withstanding thermal and impact fatigue. This comprehensive mechanical evaluation guarantees that selected materials exhibit both chemical stability and mechanical robustness, which is crucial for dependable performance and reduced non-productive time in coiled tubing acid stimulation operations [

38].

2.4. Full-Scale Field Trials in Active Stimulation Campaigns

Following extensive laboratory corrosion and erosion testing, a full-scale field trial program was carried out to evaluate material performance under realistic downhole stimulation conditions. These trials were included in live acid stimulation campaigns for HPHT gas wells with high CO

2 and H

2S levels. Field operations mimicked laboratory characteristics such as 28% emulsified HCl, dynamic flow regimes, and bottomhole temperatures of up to 160 °C, allowing for direct comparisons of corrosion, erosion, and jetting efficiency [

39,

40,

41].

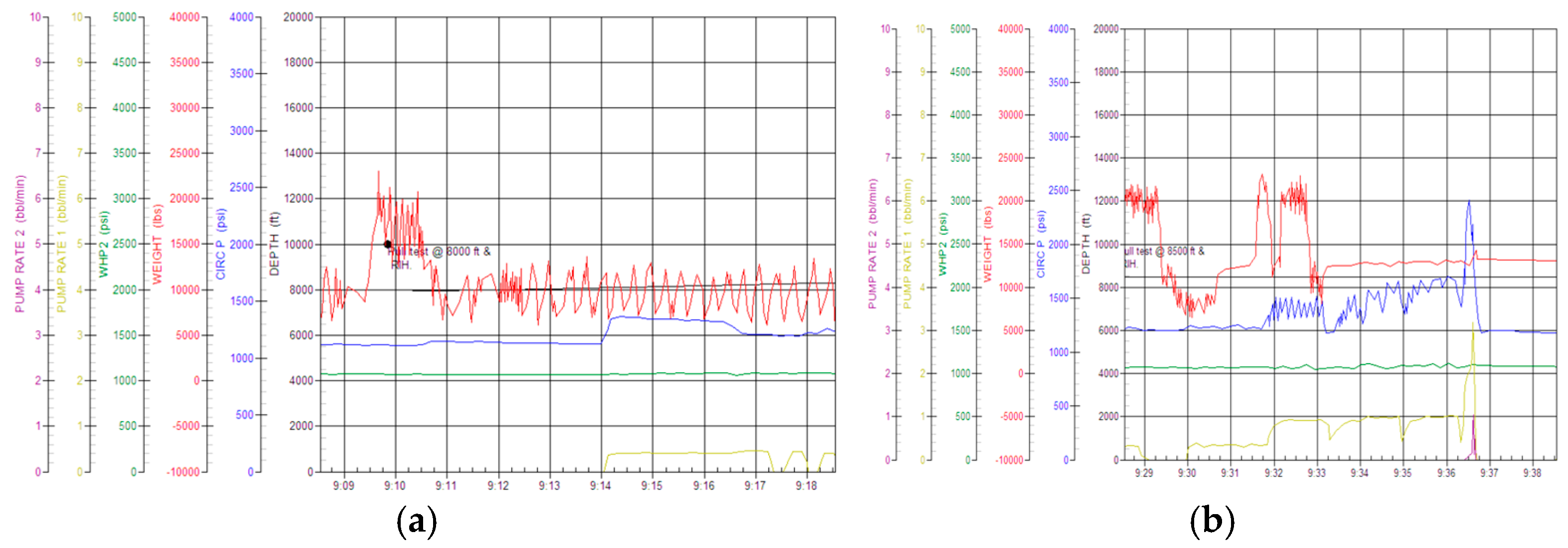

The initial trial used AISI 4140, which was selected for its machinability and cost-effectiveness. Despite experiencing high mass loss (≈244 g/m

2 over 12 h at 160 °C) in lab experiments, it was used in a coiled tubing acidizing intervention to achieve a tight carbonate interval. During the operation in

Figure 6, pressure drop variations and jet asymmetry were detected, indicating nozzle deterioration and ultimately failure. This resulted in unpredictable flow behavior, a significant increase and fluctuation in pumping rate (from 0.7 to 3 bpm), and, ultimately, low stimulation efficiency.

Following post-job retrieval and inspection, it was discovered that the 4140 nozzle had suffered severe mechanical and chemical degradation: the internal orifice was eroded beyond specification, the flow trajectory was distorted, and most importantly, the threaded section of the nozzle had completely washed out. Due to thread wash-out, two nozzles were completely lost and degraded. This structural failure reflected the significant corrosion rate and pitting reported in lab gravimetric measurements, confirming the material’s unsuitability for long-term acid jetting applications. Furthermore, borehole imaging and coiled tubing Cerberus Modeling Software for coiled tubing, version 15.0, from National Oil Varco, located in Texas, TX, USA demonstrated inefficient acid distribution and inadequate zone coverage, implying that nozzle deterioration had a direct impact on job performance.

Figure 7 illustrates the jetting nozzle status after implementing 4140 nozzles in the field.

Following this failure, the next candidate material examined was AISI 4145, a higher-strength, heat-treated alloy steel noted for its superior hardenability and mechanical robustness. In laboratory corrosion testing, 4145 outperformed 4140, with weight loss decreased by around 40% and corrosion rates maintaining below acceptable industry limits for temporary downhole exposure. The post-lab microscopic examination similarly revealed limited pits and smoother surfaces. In the field, the 4145 nozzle was used on a similar gas producer well with nearly identical operational conditions: high-rate coiled tubing pumping of 28% emulsified acid at HPHT [

25]. As demonstrated in

Figure 5 and

Figure 8, the x-axis presents the time in hours and the Y-axis illustrates all operational factors.

During the stimulation, the nozzle performed far better than the 4140 where jetting patterns remained consistent throughout the pumping phase, presented in light yellow as pumping rate 2 in

Figure 8, and no anomalies in pressure readings were noted.

While corrosion losses had occurred, notably around the orifice’s intake and exit zones, the nozzle’s structural integrity and threading remained intact, as shown in

Figure 9b. Visual and microscopic inspections confirmed that the field-induced wear patterns closely matched those observed in lab tests, demonstrating the corrosion simulator’s predictive reliability. However, despite acceptable performance, the level of degradation observed indicated that, while better, 4145 still lacked the resilience and longevity required to compete with tungsten carbide nozzles, particularly for extended acidizing applications or serial reuse.

The final and most successful field trial used AISI 4145 steel treated with a Quench–Polish–Quench (QPQ) nitriding treatment, which creates a dense nitride layer and diffusion zone for improved surface hardness and corrosion resistance (

Figure 4). Laboratory testing demonstrated low mass loss (<90 g/m

2), negligible surface pitting, and excellent geometry retention at high acid concentrations and temperatures. Microscopic examination revealed the absence of pit start or microcracks, indicating excellent long-term stability [

42,

43].

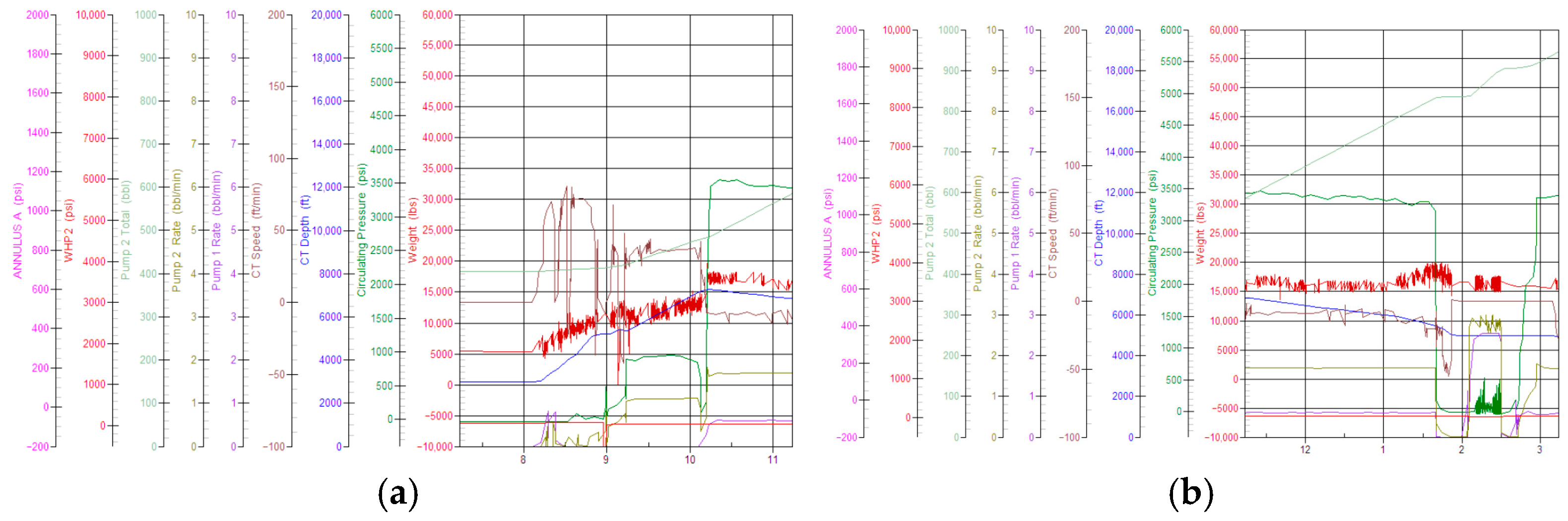

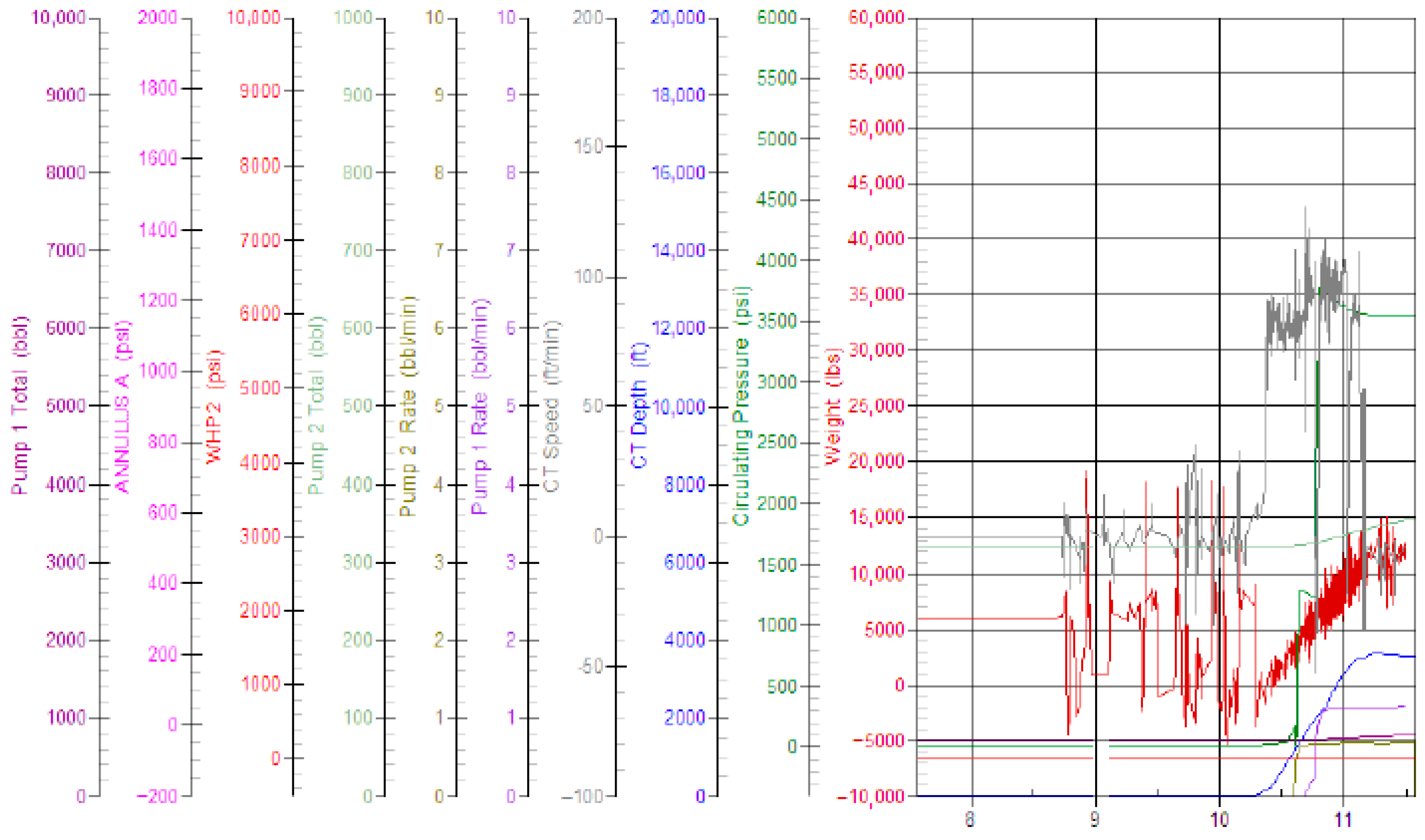

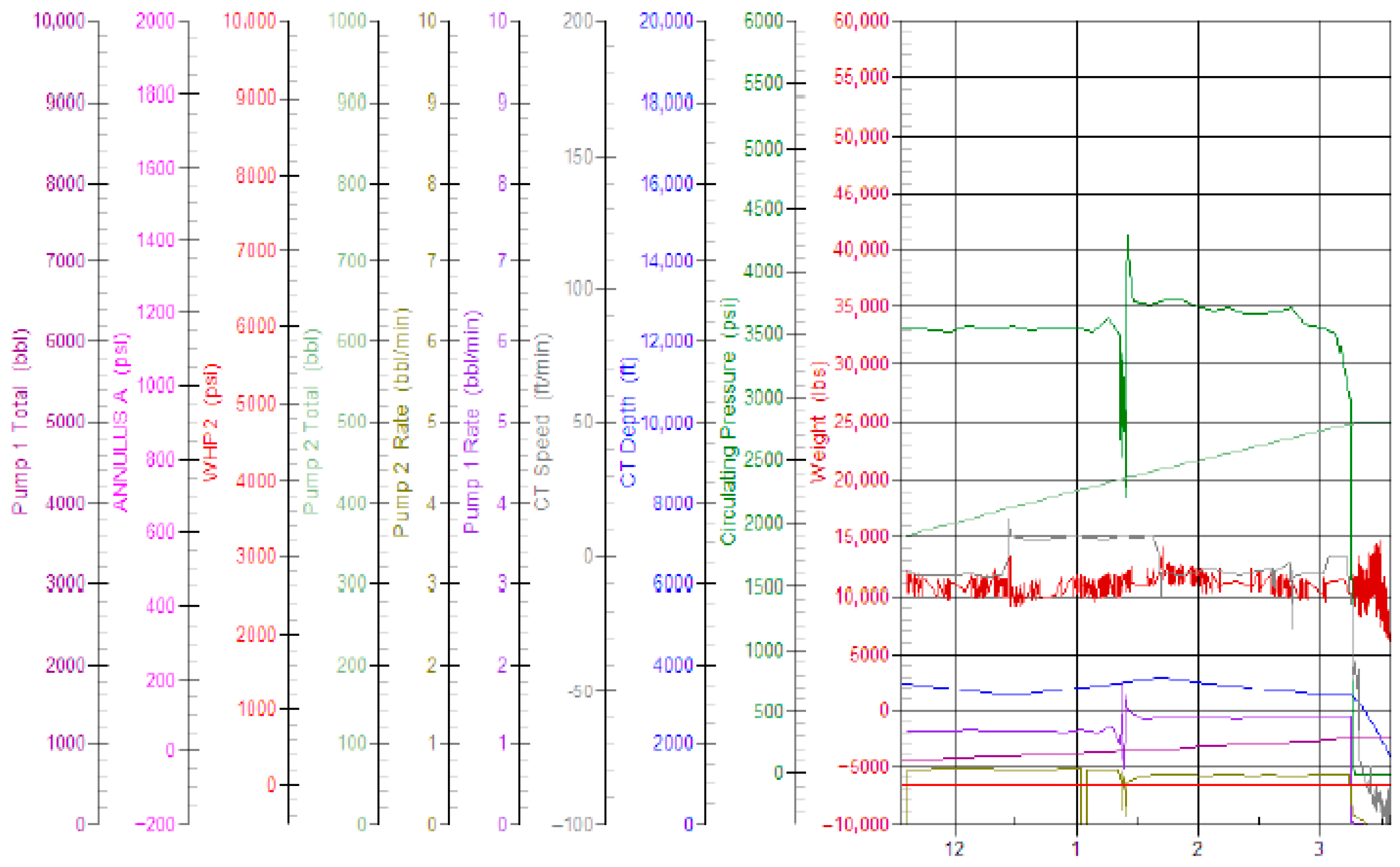

The field deployment of the QPQ-coated 4145 nozzle in a gas well at 163 °C corroborated the laboratory results, as show in

Figure 10 and

Figure 11. A comparative study of all trials revealed a good correlation between lab and field results: AISI 4140 failed prematurely, AISI 4145 showed moderate improvement, and the QPQ-coated 4145 proved to have exceptional durability and stability. The QPQ-treated nozzle maintained consistent pressure and flow with no deviations, demonstrating that it is a cost-effective, machinable, and high-performance alternative to tungsten carbide for coiled tubing acid stimulation [

11].

Figure 12 illustrates the way the jetting tool with QPQ-coated nozzles performs in reservoirs containing H

2S and CO

2. The coated nozzles exhibited good stability and durability to both corrosive and erosive conditions throughout the stimulation process. Post-operation inspections, which included both visual and microscopic investigation, indicated no abnormalities or structural damage, as previously stated. The lack of pitting, cracking, or dimensional abnormalities demonstrated that the QPQ coating effectively conserved nozzle geometry and performance, ensuring consistent jetting efficiency even after extended exposure to extreme downhole environments. This result demonstrates the strength of the QPQ-coated alloy as a long-lasting alternative for tungsten carbide [

44].

These experiments demonstrated the need for integrating laboratory simulations with field deployment to guarantee that material qualifying is both predictive and practical. The effective use of QPQ-coated 4145 as a jetting nozzle material represents a substantial improvement in material selection, offering a dependable alternative to tungsten carbide in acidic conditions where corrosive chemicals, high velocity, and mechanical wear all coexist.

2.5. Corrosion Rate Prediction Using Advanced Machine Learning Algorithms

Integrating artificial intelligence (AI) and machine learning (ML) into oilfield engineering is no longer an experiment; rather, it is a realistic extension of established laboratory and field workflows that significantly accelerates decision-making. In the context of material qualification for acid jetting nozzles, ML provides the ability to synthesize large, heterogeneous datasets (lab gravimetry, metallography, flow-loop measurements, and job logs) and produce robust, quantitative forecasts of corrosion and erosion outcomes across many combinations of operational conditions that would be prohibitively expensive to test experimentally [

32]. The primary goal is to create and validate a strong, data-driven framework for predicting the corrosion rate of different jetting nozzle materials used in coiled tubing acid stimulation operations, allowing for more reliable future material selection or modification before costly laboratory and field testing. The work aims to accurately forecast material performance under harsh downhole conditions by integrating real HPHT gravimetric corrosion data with key operational factors, such as the following [

45]:

Acid concentration (15–28% HCl).

Temperature (170–280 °F).

Pressure (9–345 bar).

Grain size (0.6–1.6 µm).

Material type/coating (4140, 4145, 4145 + QPQ).

Advanced machine learning algorithms, such as Ridge Regression, Random Forest, and Gradient Boosting, are used. This strategy avoids unnecessary testing, shortens material qualification schedules, and supports the selection of cost-effective, locally accessible alternatives to tungsten carbide while providing resistance to acid, erosion, and wear [

46].

In our program, we created a structured AI pipeline that combines traditional regression baselines with modern ensemble learners and a domain-aware model called Three-Vector Regression (TVR) [

47].

The training dataset combined results from all laboratory and field campaigns and consisted of structured rows for each exposure/run with features including material specification as identification (4140, 4145, 4145 + QPQ), detailed composition descriptors (Cr, Mo, C content), microstructural metrics (grain size, hardness, measured prior to test), fluid descriptors (acid type: HCl vs. emulsified HCl, concentration%), thermodynamic conditions (temperature °C, pressure psi), and flow parameters (injection rate). Additional meta-features included surface treatment descriptors (QPQ parameters: nitriding time, compound layer thickness), preceding heat treatment status, and nozzle orifice geometry descriptors (starting diameter, taper angle).

All categorical features were one-hot encoded or target-encoded, while continuous features were scaled and, where physically important, converted (log for concentration, reciprocal for exposure duration in some tests) to linearize relationships.

2.5.1. Model Selection and Based Parameters

We trained and compared four major algorithms: Linear Regression (LR) as a transparent baseline, Support Vector Machines (SVMs) with an RBF kernel for medium-sized, nonlinear separations, Gradient Boosting (GB) (XGBoost/LightGBM implementations) for high performance on structured tabular data, and a Random Forest (RF) ensemble for robust, low-variance predictions and built-in feature importance estimates. All categorical features were one-hot encoded or target-encoded, while continuous features were scaled and, where physically important, converted (log for concentration, reciprocal for exposure duration in some tests) to linearize relationships [

48].

TVR applies independent sub-models to each vector (such as Ridge Regression for the Material Vector and Gradient Boosting for the Operational Vector) and learns a higher-level regressor from the three sub-predictions. The objective for TVR is to preserve physical grouping (so that the model recognizes that material attributes interact differently with operational factors), increase interpretability, and avoid overfitting when sample counts per material/coating are restricted [

48].

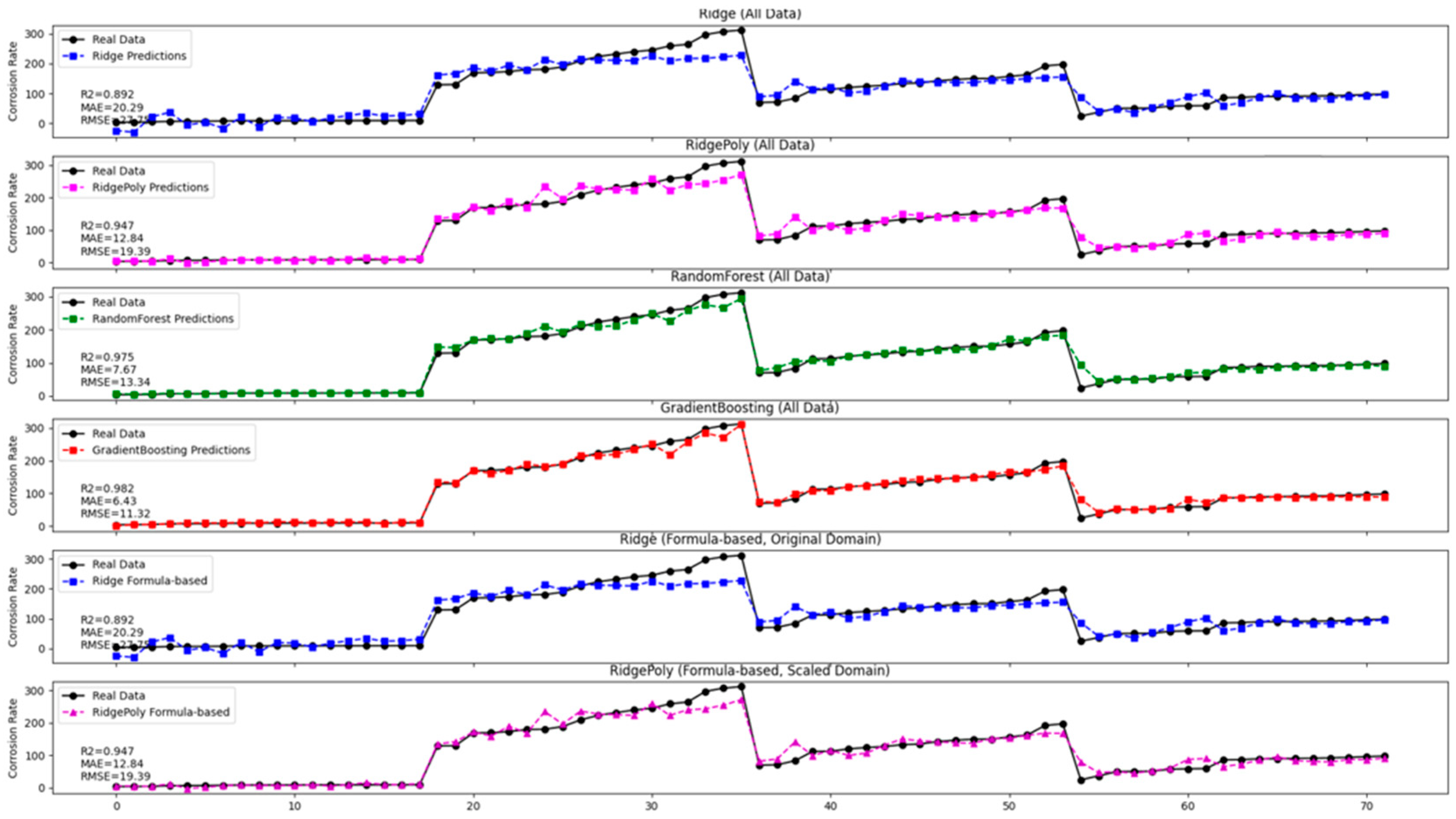

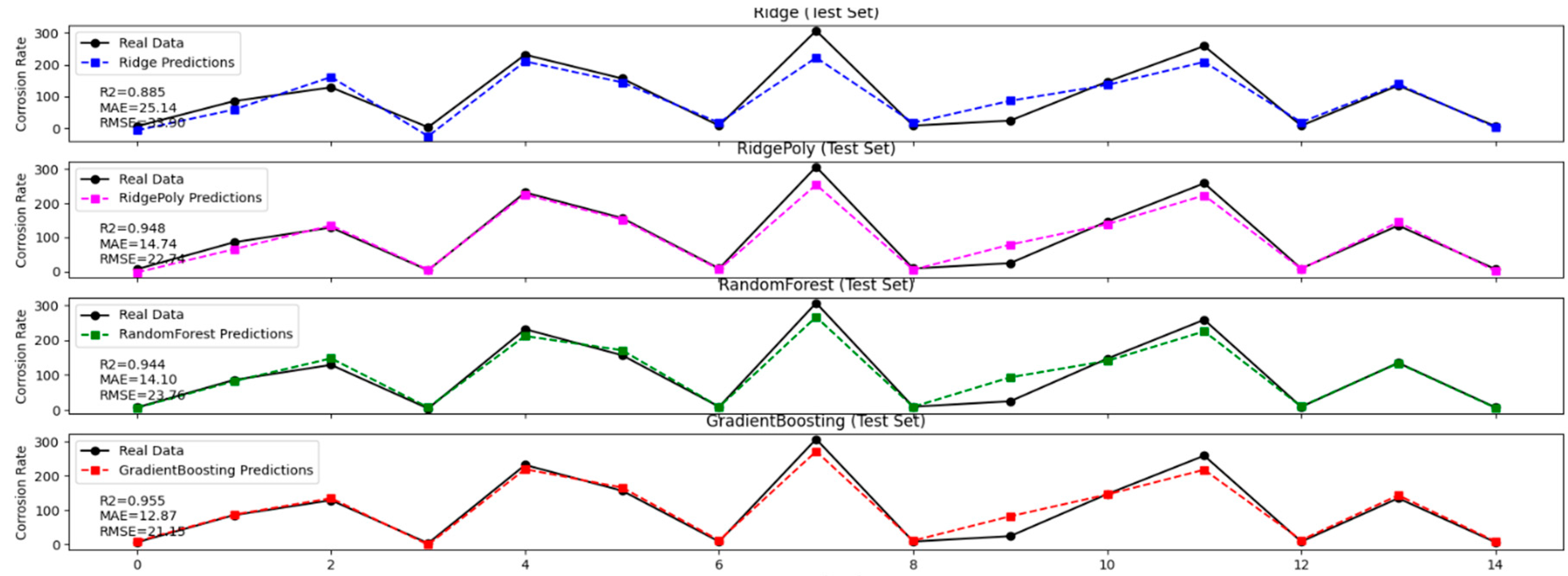

Training, validation, and hyperparameter optimization: We employed an 80/20 train/test split stratified by material type and job origin, as well as repeated K-fold cross-validation (K = 5, 10 repeats) on training folds, to adjust hyperparameters using GridSearchCV and Bayesian optimization for GB/RF. The performance measurements were R2, MAE, RMSE, and calibration diagnostics (residual plots by material and temperature bucket), and all these measures are highlighted in Table 8.

To avoid data leakage, we ensured that all runs from a single field job existed entirely in either train or test splits (no mixed-job leakage).

2.5.2. Model Explanation and Uncertainty Quantification

For production, we coupled point predictions with prediction intervals (quantile regression forests or bootstrapped ensembles) and used SHAP values to explain each feature’s contribution to the prediction. This enabled engineers to notice, for example, that at 150 °C and 28% HCl, grain size and QPQ layer thickness were the most important elements lowering projected corrosion for coated 4145. We also identified high-uncertainty forecasts (large prediction intervals) and recommended targeted lab studies before field deployment.

2.5.3. Practical Workflow and Decision Support

The ML pipeline was intended as a decision-support tool, not as an automated alternative for experimentation. The typical workflow was as follows:

- (1)

Enter planned job parameters (temperature, pressure, acid recipe, grain parameters, …).

- (2)

Obtain predicted corrosion rate and confidence band for candidate material as per built model.

- (3)

View feature-level explanations (why a material performs well/poorly).

- (4)

Reject the material or schedule focused lab tests for the exact parameter window.

This strategy significantly decreased the amount of full-scale lab/field permutations in our program.

4. Discussion

4.1. Field and Laboratory Result Correlation

A comparison of laboratory and field findings demonstrated an important association between HPHT corrosion rates and real nozzle durability during acid stimulation operations. Materials having significant lab corrosion rates, such as AISI 4140, degraded rapidly and failed prematurely in the field, demonstrating their unsuitability for downhole application. AISI 4145 demonstrated moderate improvement, leading to reduced corrosion and pitting resistance but only short-term field endurance [

57].

In contrast, QPQ-coated AISI 4145 performed excellently, with negligible corrosion, no erosion or dimensional change in lab tests, and consistent geometric integrity and jetting efficiency in the field. The coating efficiently protected against acid attack and wear, providing durability similar to tungsten carbide at a lower cost and faster manufacturing time. The high correlation between lab and field results validates the HPHT testing technique as a credible indicator for evaluating materials utilized in challenging downhole conditions.

4.2. Comparative Material Performance

The comparative examination of AISI 4140, AISI 4145, and QPQ-coated AISI 4145 nozzles revealed a clear performance hierarchy based on alloy composition and surface treatments. Under HPHT acid exposure (28% HCl, 94–160 °C, up to 345 bar), AISI 4140 showed the maximum mass loss and severe pitting due to its low alloy content and susceptibility to chloride corrosion, whereas AISI 4145 showed modest improvement with reduced corrosion and greater pitting resistance [

56,

57].

QPQ-coated AISI 4145 displayed superior performance in laboratory and field circumstances, with little weight loss, excellent pitting resistance, and stable geometry, attaining durability comparable to tungsten carbide. These findings support a substantial link between lab corrosion rates and field durability, establishing HPHT testing as a predictive technique for material quality. This study highlights QPQ-treated 4145 as a low-cost, locally machinable alternative to tungsten carbide and offers future investigations into multilayer coatings and AI-based predictive corrosion modeling.

4.3. Influence of Parameters on Models

In addition to evaluating the test set, we also computed predictions on all data to see how well each model fits the entire dataset. Below in

Table 9 are the key findings for each model on which each was built and trained [

46].

For Ridge coefficients:

Scaled Domain In scaled feature space, the intercept is reported as 0.0 (since fit intercept = False).

The coefficients for each scaled feature are as follows:

Intercept (scaled) = 0.0;

Acid concentration: 28.649425603989613;

Temperature: 29.3353881829566;

Pressure: 33.90318840870961;

Grain size: 80.17750222057201;

Type: Type1: −36.62652115457015;

Type: Type2: 73.49620504565877;

Type: Type3: 19.187363113006914;

Type: Type4: −14.953447771363082.

However, the original domain is restored by applying the appropriate transformation, and we obtain the following intercept and coefficients for use on unscaled features:

Intercept (original) = −127.82458593952053;,

Acid concentration: 358.1178200498701;,

Temperature: 0.3411091649181;

Pressure: 3.082108037155419;

Grain size: 1.8305365803783564;

Type: Type1: −36.62652115457015;

Type: Type2: 73.49620504565877;

Type: Type3: 19.187363113006914;

Type: Type4: −14.953447771363082.

Hence, for original-feature inputs (

xacid,

xtemp,

xpress,

xgrain, . . .), the predicted corrosion rate is as follows:

where the type indicators appear with their respective coefficients if that type is present (1) or not present (0).

For the RidgePoly polynomial formula (scaled domain):

For the polynomial (degree 2) Ridge model, the scaled intercept is 38.2640, and the coefficients for each polynomial term are as follows (abbreviated):

Acid concentration: 4.251267082534386;

Temperature: 7.887681174424277;

Pressure: 10.618166594926109;

Grain size: 17.41647984486332;

Type: Type1: −16.279347705746357. . .;

Acid Concetration2: 4.251267082534372;

Acid Concentration × Temperature: −0.3741091131420305. . . (and so on for every interaction and squared term). To predict in scaled space, one must scale the input features to [0, 1], compute these interaction terms, then apply these coefficients plus the intercept of 38.2640.

Formula-based prediction:

Once a Ridge model (in scaled space) is trained, we can transform its coefficients back to the original domain using the min and max of each feature (as shown above). The final equation for Ridge is thus fully interpretable in real units.

For the Ridge + Polynomial Features pipeline, the model is effective:

where

is the scaled input vector and φk(x˜) are polynomial terms (e.g., x2, x1x2, . . .) in scaled space. Converting it all the way back to original-feature space is more complex because each polynomial term must be unscaled carefully [

55].

While this study effectively proved the potential of QPQ-coated 4145 steel as a low-cost, high-performance alternative to tungsten carbide for coiled tubing stimulation nozzles, several areas require more exploration to broaden the findings’ applicability and dependability. Future research should focus on long-term field monitoring over a wider range of reservoirs, particularly under harsh HPHT conditions and in wells with greater concentrations of H2S and CO2 to validate material durability throughout lengthy operational lifespans.

Additional research is needed to optimize the process parameters of QPQ treatment to improve corrosion and wear resistance under varying acid compositions and flow regimes. Investigating hybrid or multilayer coatings that combine steel substrate toughness with sophisticated ceramic or nanostructured overlays may also result in improved performance. Furthermore, the integration of advanced computational modeling and AI-driven predictive analytics should be broadened to cover larger datasets from various field applications, allowing for real-time corrosion and wear prediction in changing operational settings.

Finally, future research should look into the economic and environmental implications of deploying coated 4145 materials on a large scale, assuring compliance with industry sustainability goals and cost-cutting measures in oilfield operations over several materials involved in coiled tubing and downhole intervention.

5. Conclusions

The findings of this study demonstrate a paradigm shift in nozzle material selection for coiled tubing acid stimulation operations, achieving what was previously thought impossible: the development of an alternative to tungsten carbide with four times less strength and corrosion resistance, which has dominated the industry for decades. After a rigorous, multiphase qualification process that included HPHT laboratory corrosion testing, erosion-wear evaluation, full-scale field trials, and AI-driven predictive analytics, the QPQ-coated 4145 alloy emerged as a game-changing solution capable of withstanding extreme acidic environments during acid stimulation operation with unrivaled durability, cost-efficiency, and operational reliability. In addition to the material breakthrough, including artificial intelligence and machine learning into the corrosion assessment workflow has transformed how material qualifying is conducted in the oilfield. Training models such as Random Forest, Gradient Boosting, and a Three-Vector Regression ensemble on real-world operational datasets, such as acid chemistry, temperature, pressure, grain size, and metallurgical composition, allowed for accurate prediction of corrosion rates prior to field deployment. This predictive capability not only shortens the certification cycle but also improves decision-making, avoids wasteful trials, and assures that only the most durable materials are chosen for deployment in high-risk areas.

Below are conclusions related to each topic evaluated during this study:

Material innovation: Under extreme acid stimulation conditions, QPQ-coated 4145 alloy displayed corrosion and erosion resistance comparable to tungsten carbide, and it can be implemented across all coiled tubing operations after confirming laboratory experiments results depending on reservoir variables.

Operational reliability: Full-scale field studies confirmed laboratory findings, with the coated alloy preserving nozzle geometry, jetting efficiency, and thread integrity across long acid pumping cycles.

Cost and logistics advantage: Compared to tungsten carbide, QPQ-coated 4145 is seven times less expensive, easier to manufacture, and more widely accessible, allowing for faster manufacturing and replacement cycles while reducing non-productive time.

AI-powered predictive insight: Machine learning models accurately predicted corrosion rates (within ±3% for QPQ-coated 4145), allowing for proactive material selection based on specific operational conditions.

Decision-making enhancement: The AI framework enables engineers to virtually evaluate material compatibility prior to costly physical tests, eliminating underperforming alloys and focusing resources on potential possibilities.

Scalability and future application: The methodology can be applied to additional downhole components that are subjected to corrosive fluids, potentially changing material selection across many oilfield domains.

This study not only provides a viable alternative to tungsten carbide but also pioneers a data-driven, AI-enhanced strategy to material qualifying in the oil and gas industry, specifically in coiled tubing and downhole intervention. By combining metallurgical innovation and predictive analytics, it paves the way for a new stage of intelligent, performance-optimized, and cost-effective downhole component design.