Numerical Simulation of Flow-Field Characteristics of a Submerged Pre-Mixed Abrasive Water Jet Impinging on a Wall

Abstract

1. Introduction

2. Physics Model

3. Mathematical Model

3.1. Discrete Phase Model

3.2. Turbulence Model

4. Numerical Simulation

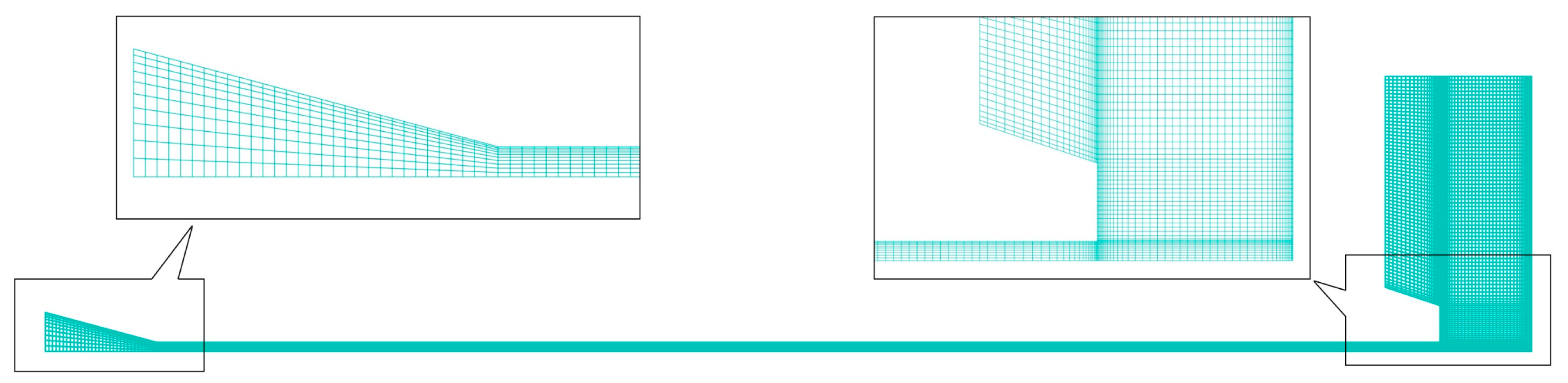

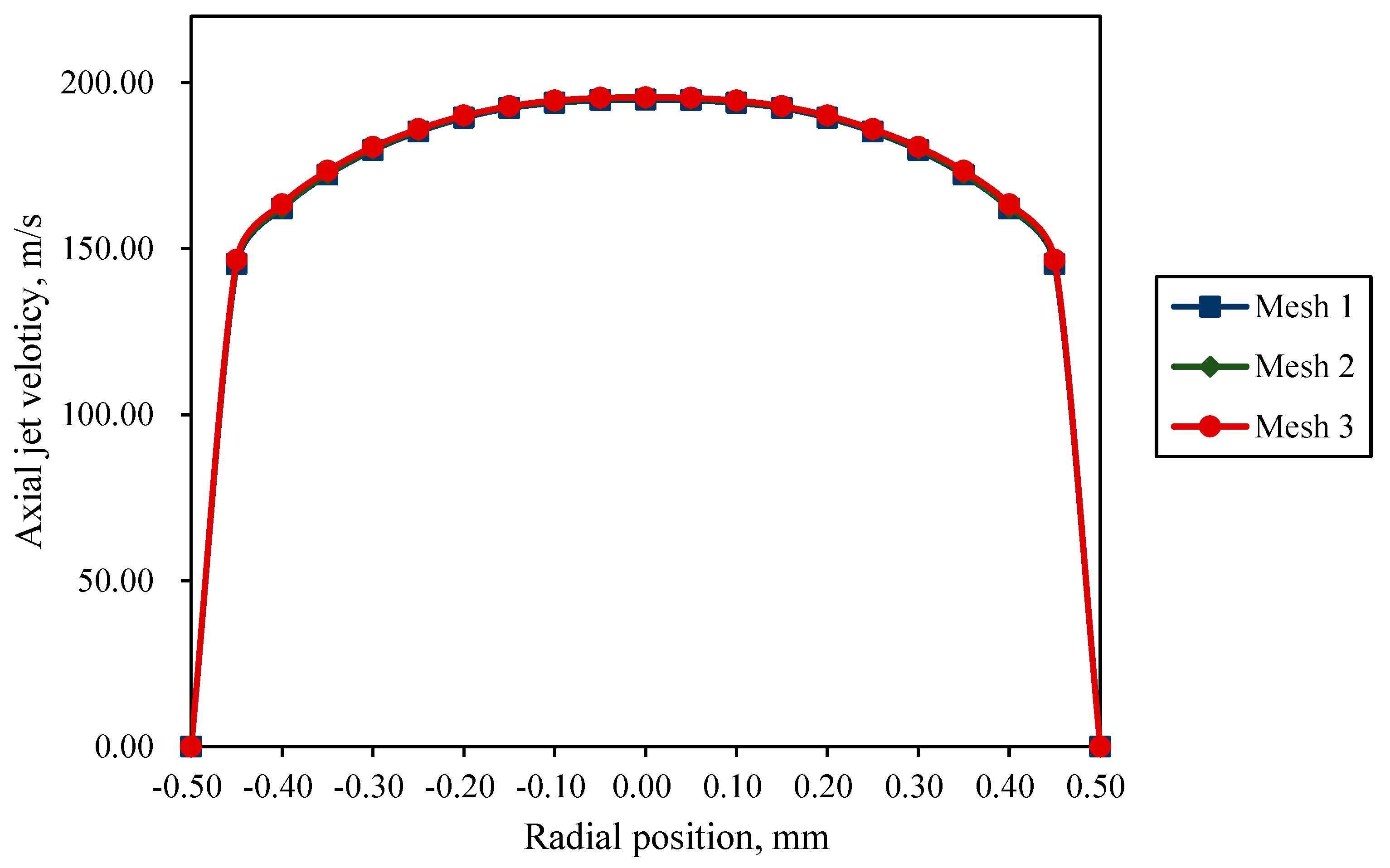

4.1. Mesh Generation

4.2. Computational Strategy

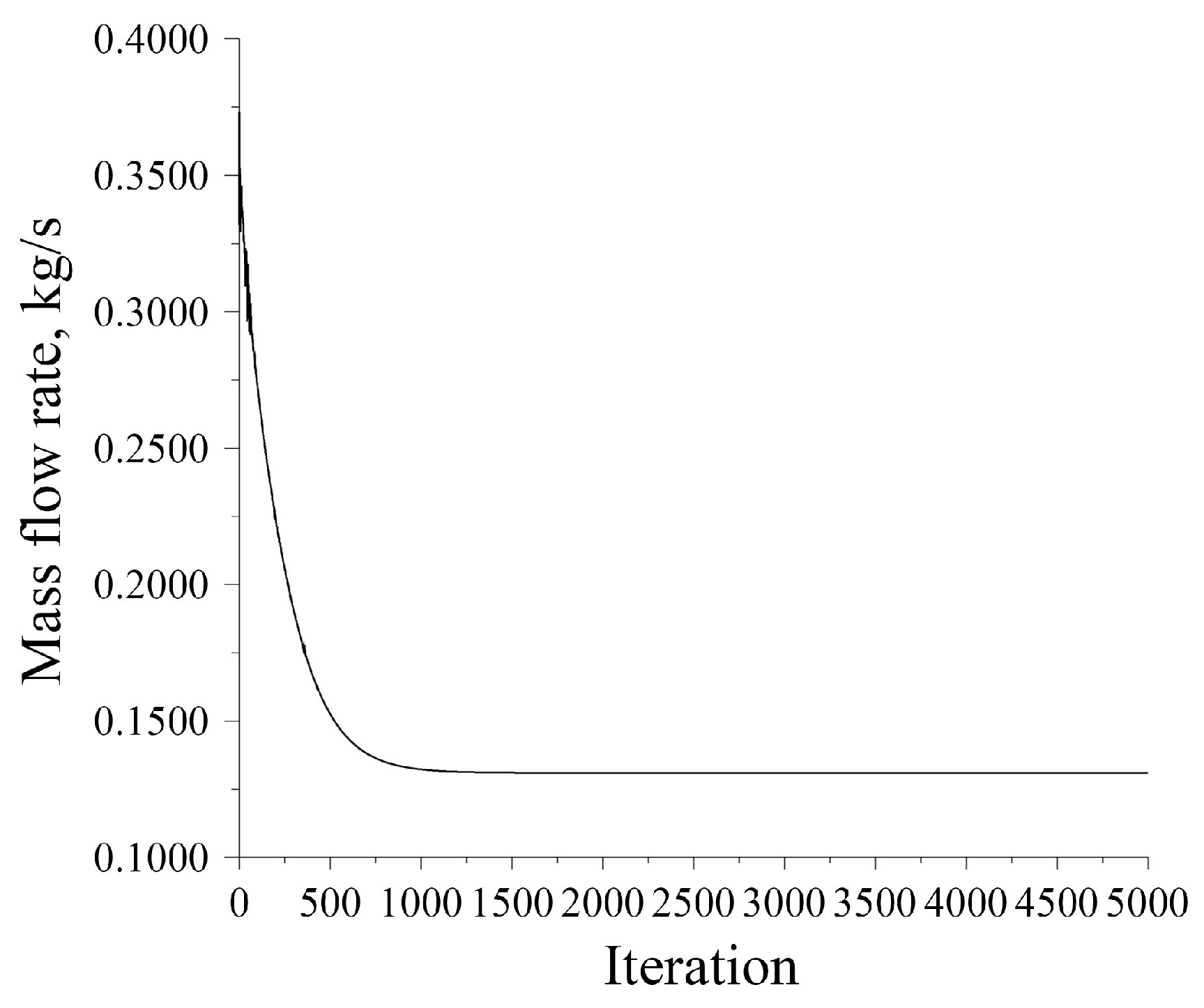

4.3. Experimental Validation of Numerical Simulations

- (1)

- Prepare a collection bucket with a steel plate placed at its bottom to prevent jet penetration. Add water to a depth of 30 cm within the collection bucket. Weigh the entire assembly (including water, steel plate, and collection bucket) using an electronic balance and record the initial mass as M1.

- (2)

- After charging the abrasive tank with abrasive, initiate the pre-mixed abrasive-water-jet experiment system. Adjust the discharge pressure of the plunger pump in the high-pressure generator to 30 MPa. When the discharge pressure stabilizes, promptly redirect the handheld cutting spray gun into the collection bucket with its nozzle outlet submerged below the water surface to form a submerged pre-mixed abrasive water jet. After sustaining continuous jetting for 3 min, withdraw the gun. Upon cessation of jetting, reweigh the entire assembly and record the final mass as M2. The differential mass (M2 − M1) represents the total weight of the abrasive–water mixture injected into the collection bucket by the pre-mixed abrasive water jet. Dividing this value by time t (where t = 3 min) yields the mass flow rate of the pre-mixed abrasive water jet: (M2 − M1)/t.

4.4. Simulation Results and Analysis

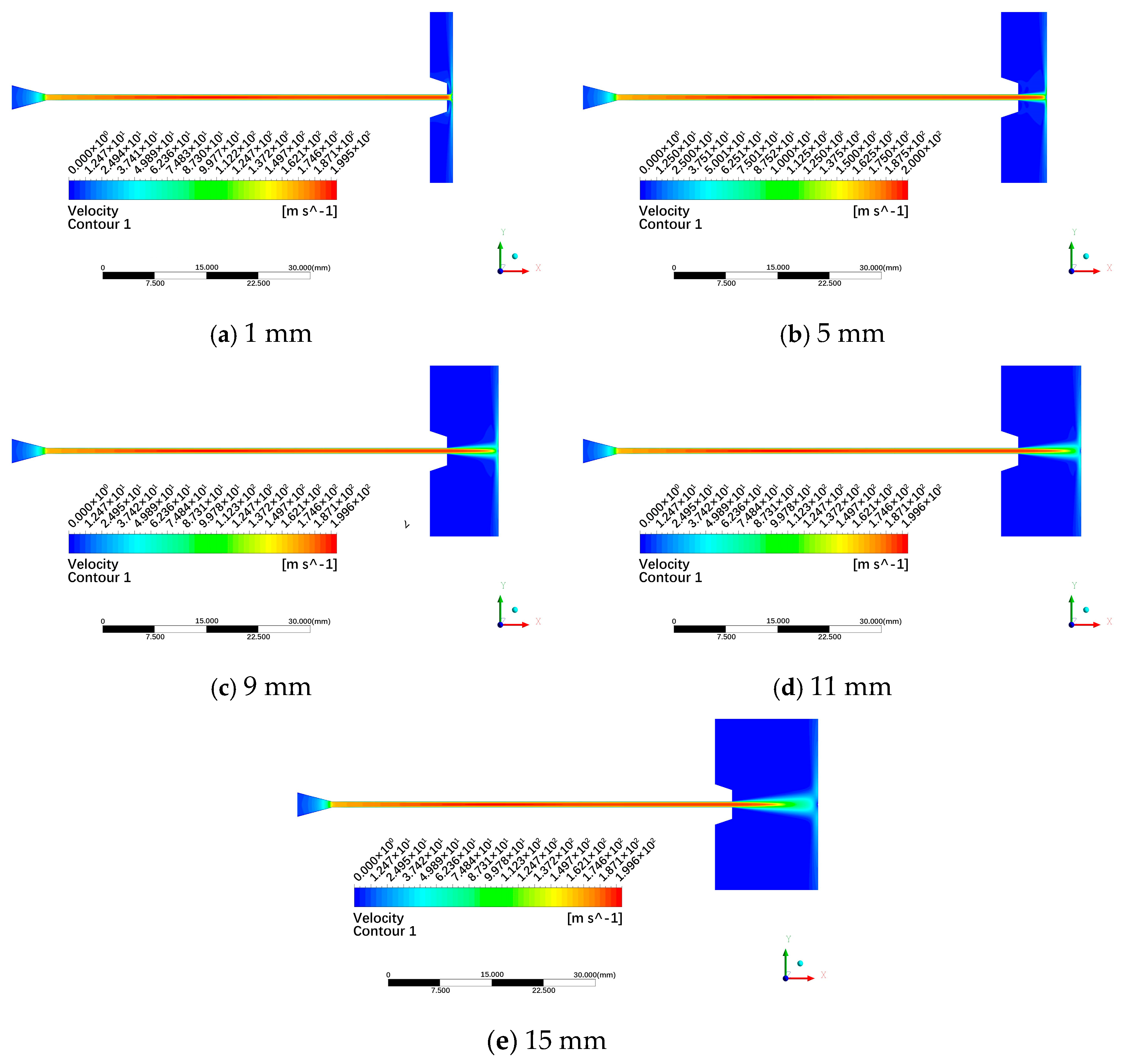

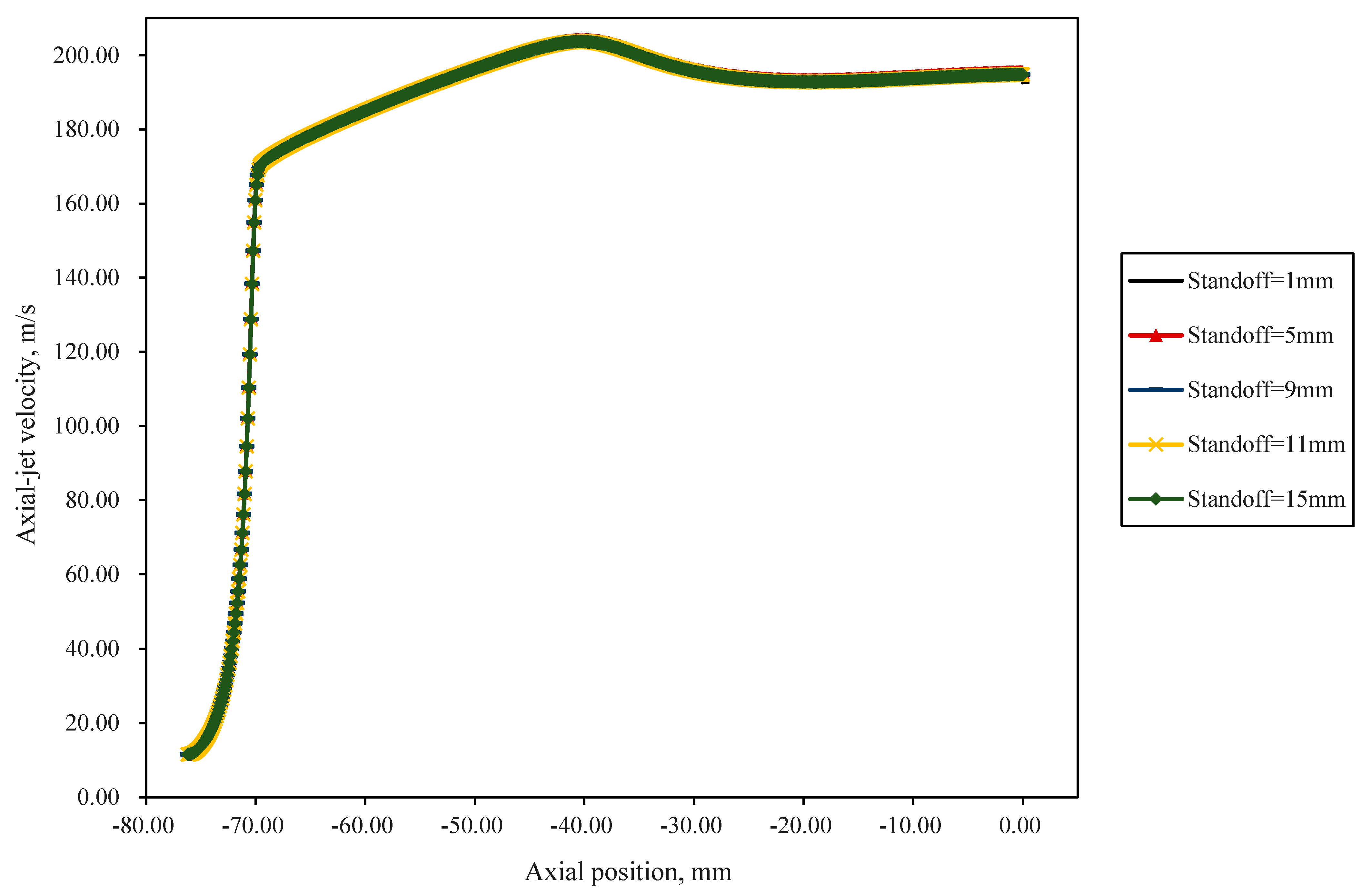

4.4.1. Influence of Standoff Distance on the Flow-Field Characteristics of the Submerged Pre-Mixed Abrasive Water Jet

- (1)

- Velocity distribution

- (2)

- Pressure distribution

- (3)

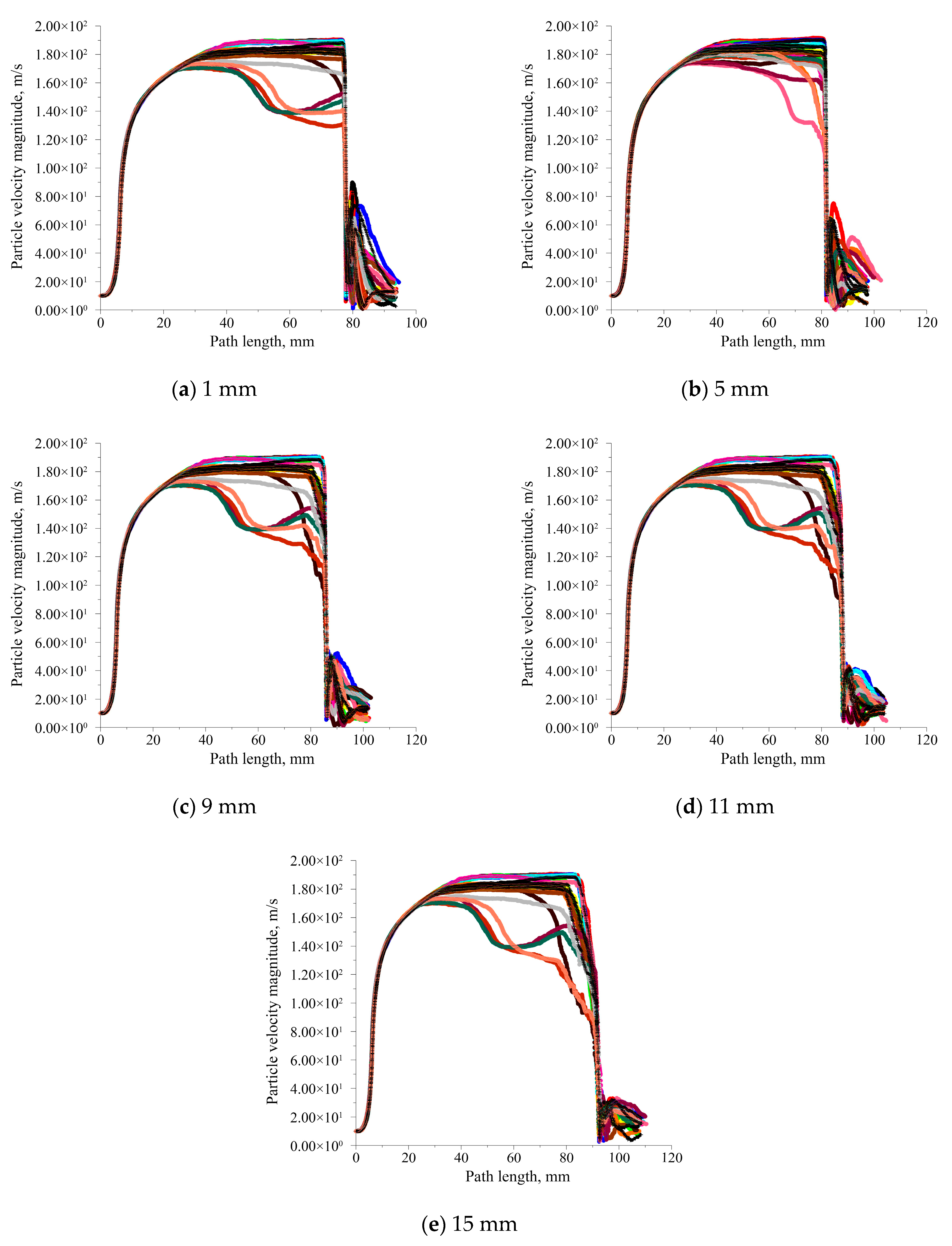

- Motion behavior of abrasive particles

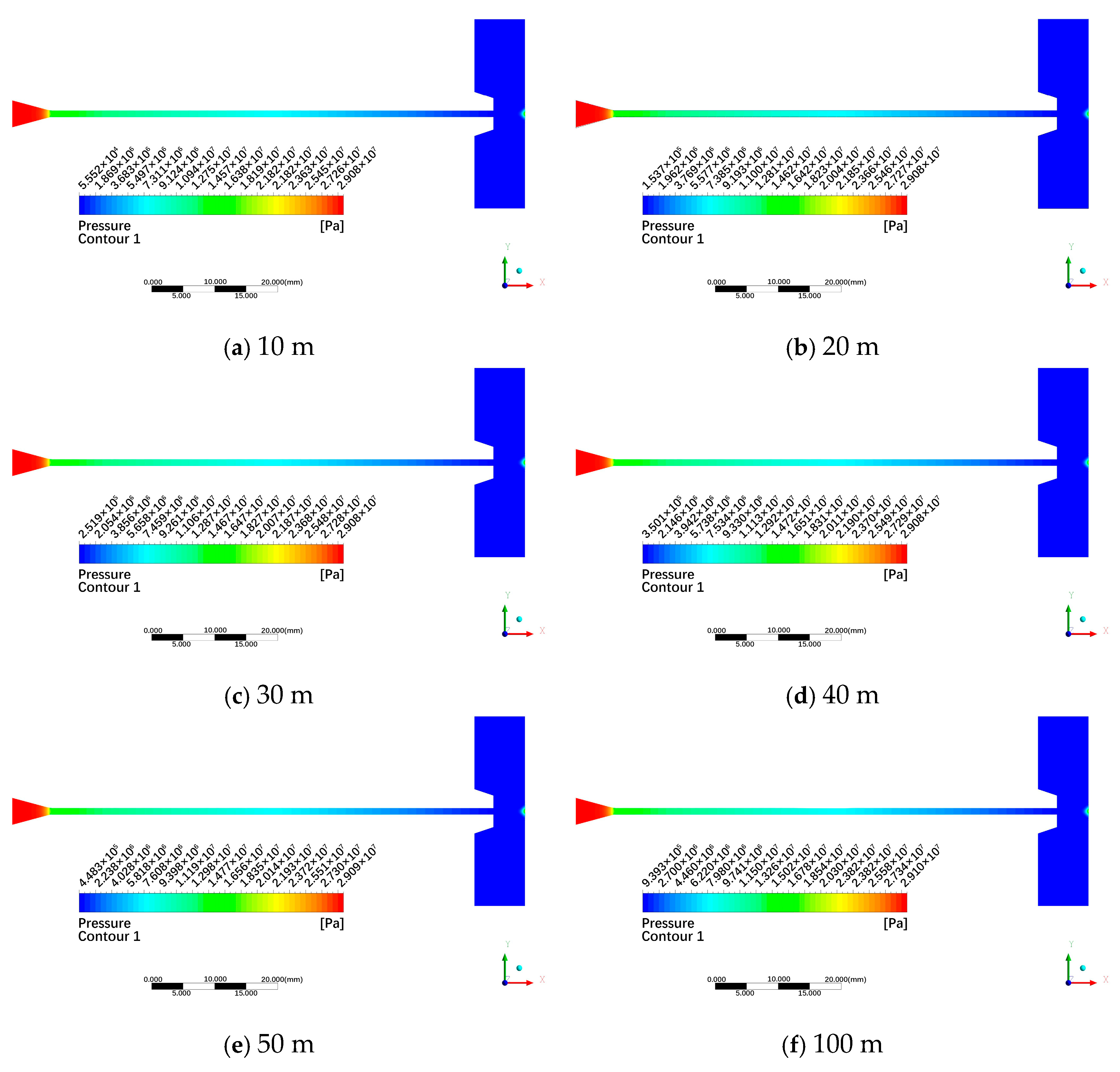

4.4.2. Influence of Submergence Depth on the Flow-Field Characteristics of the Submerged Pre-Mixed Abrasive Water Jet

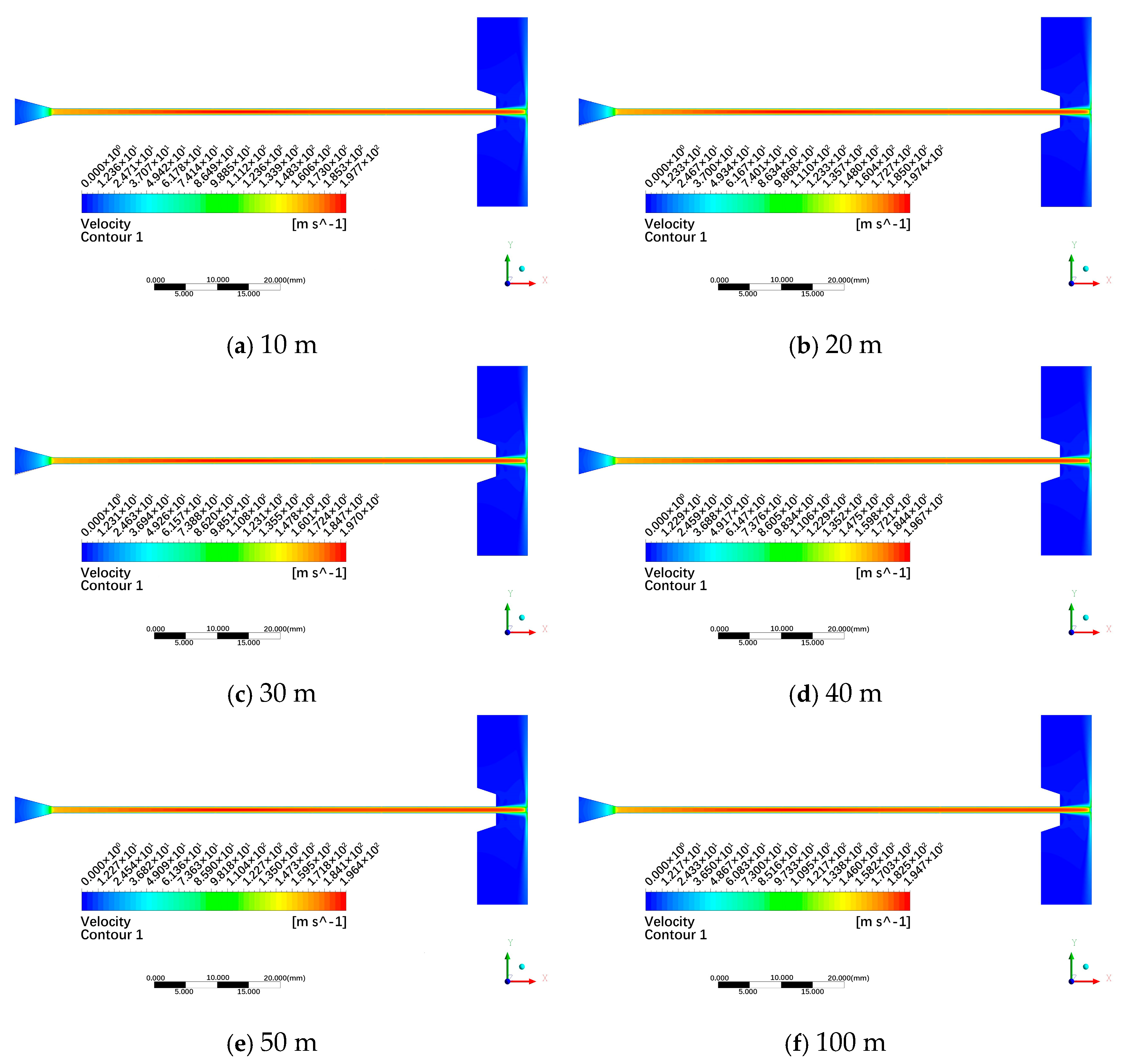

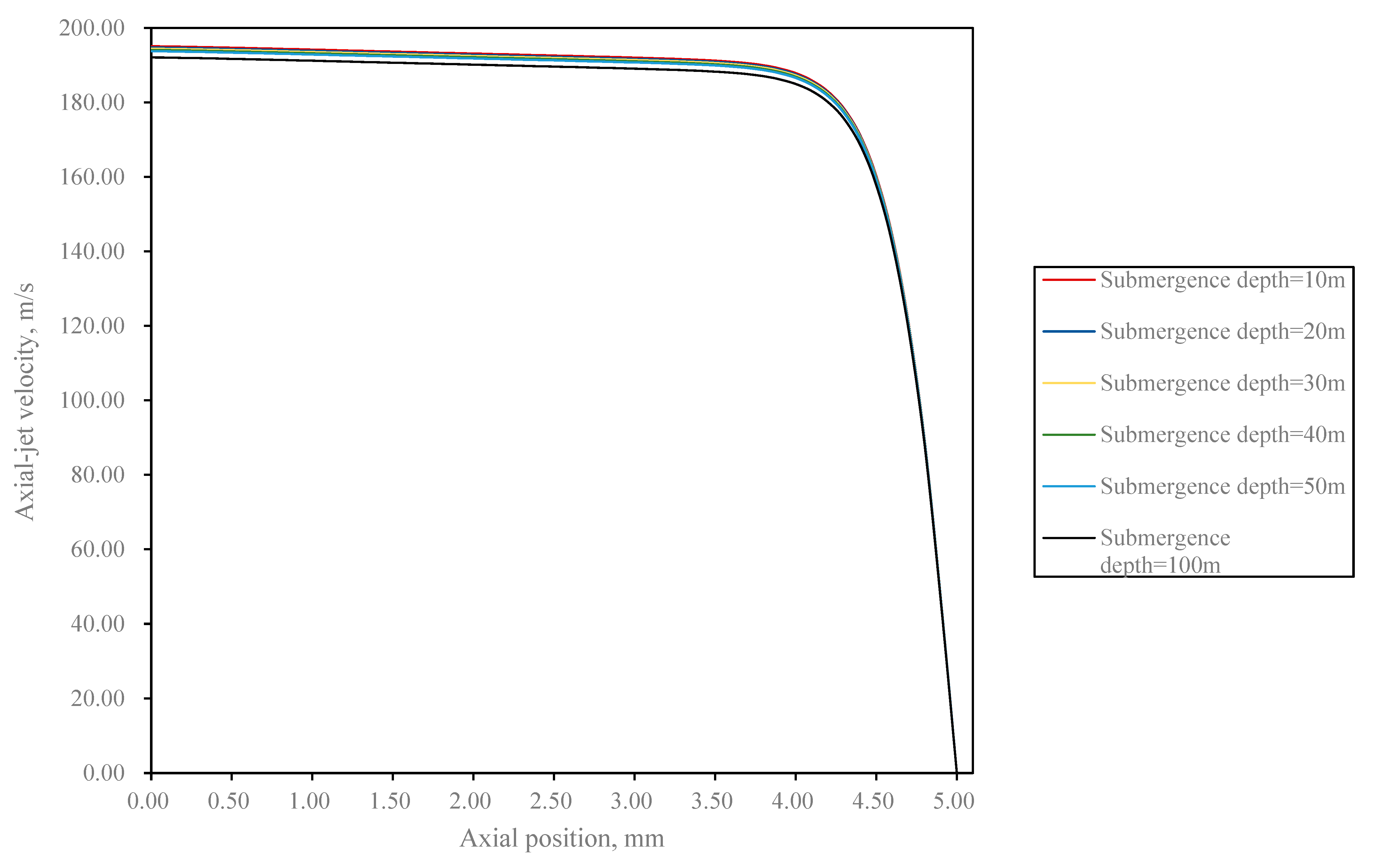

- (1)

- Velocity distribution

- (2)

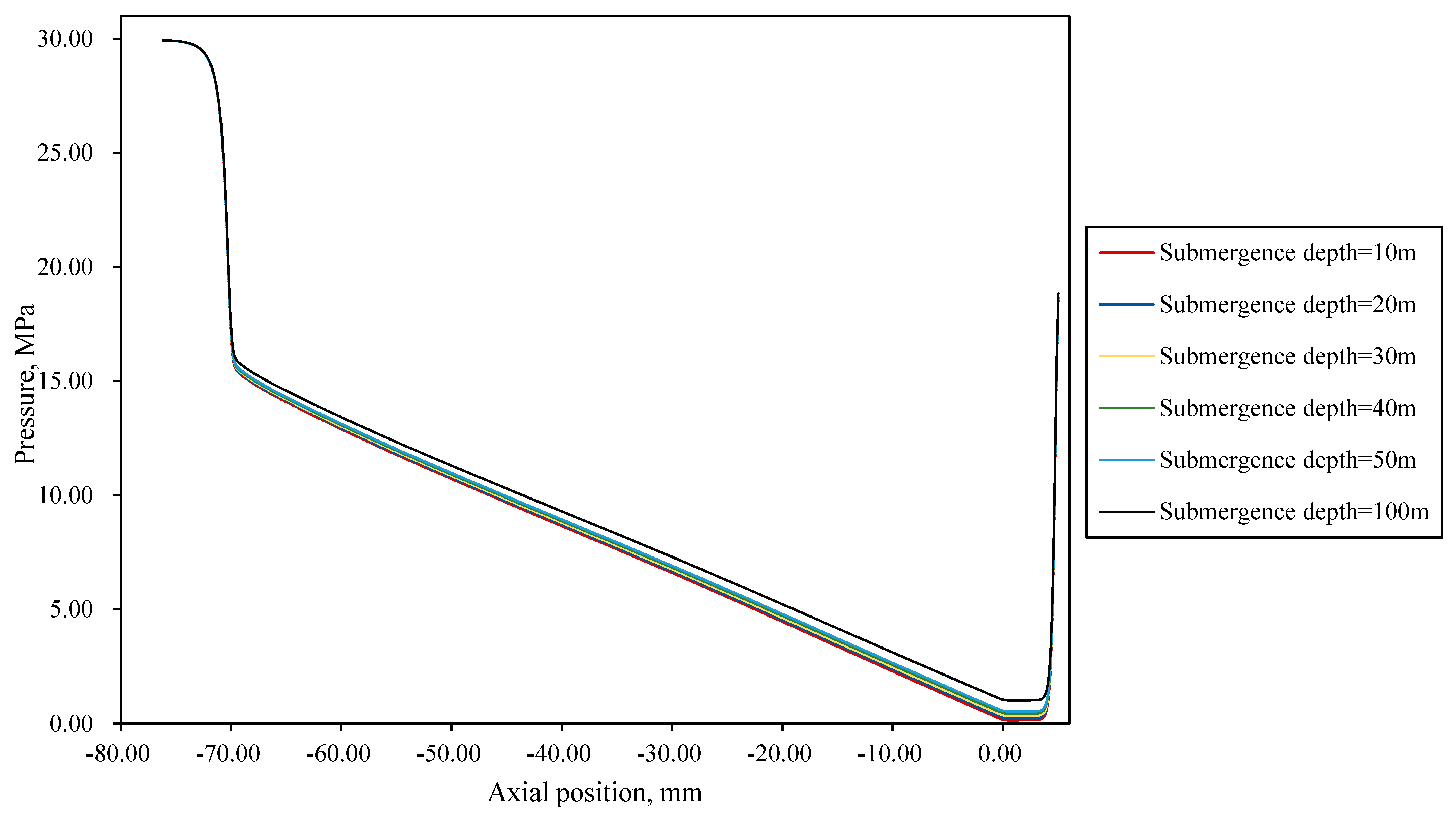

- Pressure Distribution

- (3)

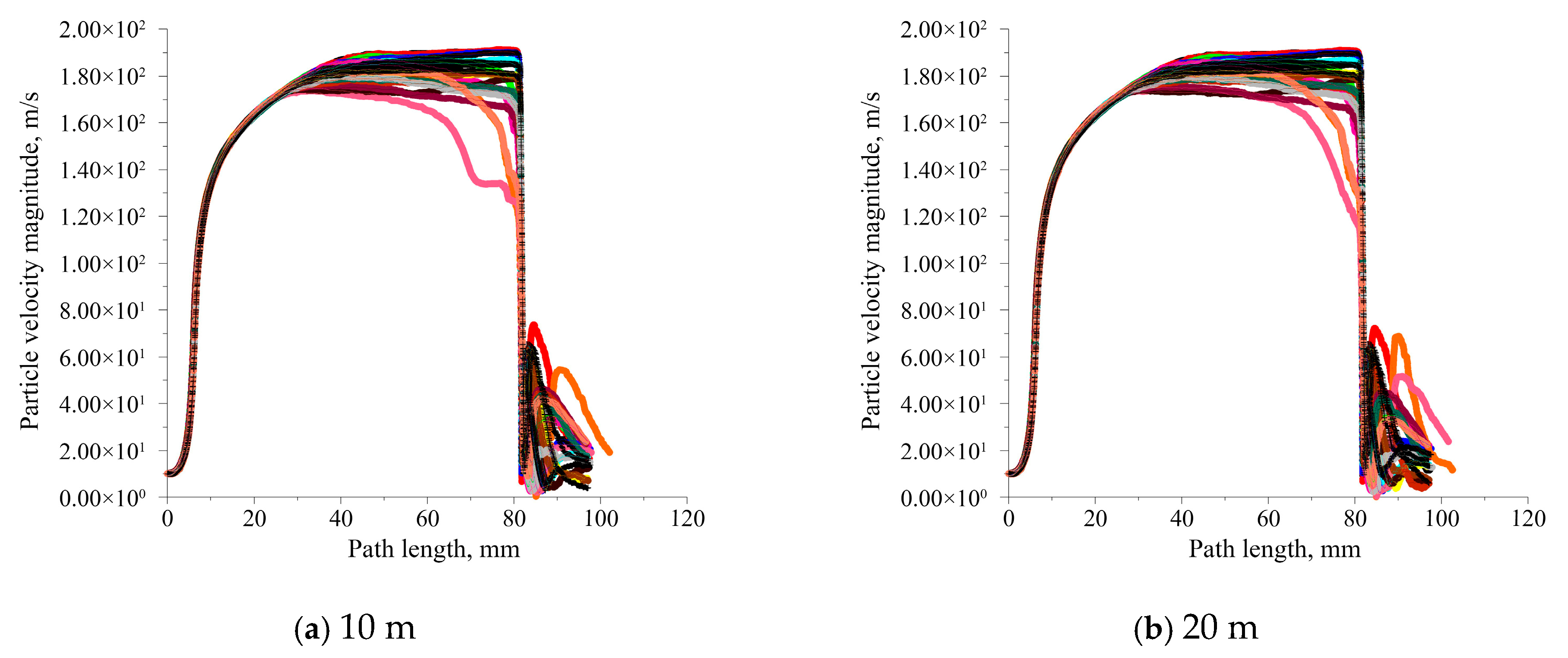

- Motion behavior of abrasive particles

5. Conclusions

- (1)

- A “water cushion layer” forms when the submerged pre-mixed abrasive water jet (SPAWJ) impinges on a wall, which is detrimental to the erosive action of abrasive particles on the target material. Tilting the nozzle appropriately facilitates the rapid dispersion of water and abrasive particles, which is beneficial for cutting.

- (2)

- The axial-jet velocity increases rapidly in the convergent section of the nozzle, continues to accelerate over a certain distance after entering the cylindrical section, reaches its maximum value inside the nozzle, and then decelerates to a steady value before exiting the nozzle. In addition, the standoff distance has minimal impact on the flow-field characteristic inside the nozzle.

- (3)

- In the external flow field of nozzles, beyond the length of the jet core section along the centerline, the decay rate of the axial-jet velocity decreases more slowly with increasing axial distance.

- (4)

- Jet pressure peaks at the nozzle inlet and decreases progressively along the jet direction within the nozzle. Upon exiting the nozzle, the jet pressure approaches ambient levels. When impinging on the wall surface, rapid decay of axial-jet velocity generates significant stagnation pressure. The stagnation pressure at the centerline of the submerged pre-mixed abrasive water jet decreases with increasing standoff distance for different standoff-distance models.

- (5)

- Considering the effects of standoff distance on jet velocity and abrasive particle dynamics, a standoff distance of 5 mm is determined to be optimal for submerged pre-mixed abrasive-water-jet (SPAWJ) pipe-cutting operations.

- (6)

- When the submergence depth is less than 100 m, its effect on the flow-field characteristics (such as velocity distribution, pressure variation pattern, and abrasive particle dynamics) of a submerged pre-mixed abrasive water jet (SPAWJ) impinging on a wall surface remains minimal. Consequently, for underwater oil pipelines operating at depths not exceeding 100 m, the influence of submergence depth can be disregarded during cutting operations.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wu, T.; Chen, Y.; Deng, Z.; Shen, L.; Xie, Z.; Liu, Y.; Zhu, S.; Liu, C.; Li, Y. Oil pipeline leakage monitoring developments in China. J. Pipeline Sci. Eng. 2023, 3, 100129. [Google Scholar] [CrossRef]

- Wu, Y. Research on High Pressure Abrasive Jet Underwater Cutting Technology. Master’s Thesis, Harbin Engineering University, Harbin, China, 2023. [Google Scholar] [CrossRef]

- Zhou, C.; Jiao, X.; Gao, H. Abrasive water jet technology and its application to cutting of underwater structure. Weld. Join. 2015, 5, 1–6. [Google Scholar]

- Yan, H.; Shi, S.; Liu, J.; Xu, L. Risk assessment of cutting methods for underwater structures removal of abandoned platform. China Offshore Platf. 2021, 36, 26–30. [Google Scholar] [CrossRef]

- Deng, S.; Dai, F.; Pang, C.; Leng, X.; Sun, G.; Wang, Y. Discussion on safety application of abrasive water jet cutting technology in coal mine production. Min. Saf. Environ. Prot. 2023, 50, 115–118. [Google Scholar] [CrossRef]

- Qiang, C. Study on Cutting Mechanism and Performance Optimization of Tungsten Steel by Liquid Nitrogen Assisted Abrasive Water Jet. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2023. [Google Scholar]

- Deng, L. Research on Underwater Cutting Performance of High-Pressure Abrasive Jet System. Ph.D. Thesis, Harbin Engineering University, Harbin, China, 2024. [Google Scholar] [CrossRef]

- Li, Z.; Li, B.; Wang, G.; Qiao, Z.; Sun, H.; Lei, Z. Global simulation of post-mixed abrasive water jet based on abrasive kinetic energy and concentration. J. Vib. Shock. 2023, 44, 76–85. [Google Scholar] [CrossRef]

- Zhao, W. Study on the System Pressure Characteristics of ASJ and Its Control Technology. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 2021. [Google Scholar]

- Xu, Q. Numerical Simulation and Experimental Research on External Flow Field of Abrasive Water Suspension Jet. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2019. [Google Scholar]

- Li, L. Two phase numerical simulation of continuous abrasive water jet system based on EDEM. IOP Conf. Ser. Earth Environ. Sci. 2020, 546, 042055. [Google Scholar] [CrossRef]

- Tang, J.; Zhang, J.; Liu, W.; Chen, C.; Zhang, H.; Cui, J. Two-way coupled CFD-DEM model of a pre-mixed abrasive water jet and its application to the investigation of abrasive motion characteristics. Powder Technol. Int. J. Sci. Technol. Wet Dry Part. Syst. 2024, 438, 119650. [Google Scholar] [CrossRef]

- Chen, C. Study on Energy Distribution Characteristics and Transfer Mechanism of Pre-Mixed Abrasive Jet. Ph.D. Thesis, Chongqing University, Chongqing, China, 2024. [Google Scholar] [CrossRef]

- Li, L. Study on the Microscopic Failure Mechanism of Abrasive Suspension Water Jet Cutting Carbon Fiber Reinforced Plastics and Optimization of Cutting Quality. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 2024. [Google Scholar] [CrossRef]

- Wang, X.; Ge, Z.; Liu, W.; Ge, R.; Wang, M.; Ge, B. Experimental Study on Rock-Breaking Mechanism of Submerged Abrasive Jet Assisted by an Air Sheath. Rock Mech. Rock Eng. 2025, 1–13. [Google Scholar] [CrossRef]

- Wang, G.; Yao, S.; Chi, Y.; Zhang, C.; Wang, N.; Chen, Y.; Lu, R.; Li, Z.; Zhang, X. Improvement of titanium alloy TA19 fatigue life by submerged abrasive waterjet peening: Correlation of its process parameters with surface integrity and fatigue performance. Chin. J. Aeronaut. 2024, 37, 377–390. [Google Scholar] [CrossRef]

- Ravi, R.R.; Srinivasu, D. An experimental investigation into the influence of water column height in submerged mode of abrasive waterjet trepanning on the hole quality. J. Manuf. Process. 2024, 117, 170–192. [Google Scholar] [CrossRef]

- Zeng, S. Study on the Characteristics of Flow Field Inside and Outside the Nozzle of High Pressure Abrasive Water Jet Under Submerged Conditions. Master’s Thesis, Chongqing Jiaotong University, Chongqing, China, 2018. [Google Scholar]

- Wang, C.; Shen, Y.; Liu, Z.; Zhao, Y.; Zhu, Y. Numerical simulation of straight cone nozzle abrasive water jets submerged. J. Daqing Pet. Inst. 2011, 35, 51–54. [Google Scholar] [CrossRef]

- Huang, N.; Xue, S.; Chang, X.; Pang, J. Research on Under-water Cutting Technology of Abrasive Water Jet with CFD. Hydraul. Pneum. Seals 2011, 11, 22–25. [Google Scholar]

- Cui, H. Numerical Simulation and Its Applications on Flow Field of Liquid-Solid Two-Phase Flow for Pre-Mixed Abrasive Water Jet. Master’s Thesis, Liaoning Technical University, Fuxin, China, 2008. [Google Scholar]

- Wang, J.; Zhang, S. Under-water cutting explosive equipment technology of pre-mixed abrasive water jet. J. PLA Univ. Sci. Technol. (Nat. Sci. Ed.) 2011, 12, 393–396. [Google Scholar]

- Qiang, Z.; Wu, M.; Miao, X.; Sawhney, R. CFD research on particle movement and nozzle wear in the abrasive water jet cutting head. Int. J. Adv. Manuf. Technol. 2018, 95, 4091–4100. [Google Scholar] [CrossRef]

- Chen, Z.; Heng, Y.; Xiong, P.; Jiang, Q.; Luo, X.; Shen, Q. Influence of particle properties on the performance and wear of centrifugal pumps based on CFD-DPM. J. Xihua Univ. (Nat. Sci. Ed.) 2024, 43, 87–96. [Google Scholar] [CrossRef]

- Yang, S.; Huang, D.; Zeng, S. Influence of environmental flow velocity on the flow field characteristics of underwater abrasive water jet. J. Vib. Shock. 2019, 38, 139–152. [Google Scholar] [CrossRef]

- Zhu, H.; Lin, Y.; Xie, L. Fluent 12: Fluid Analysis and Engineering Simulation; Tsinghua University Press: Beijing, China, 2011; pp. 179–188. [Google Scholar]

- Guan, J.; Deng, S.; Duan, J.; Chen, X.; Yu, Y. Analysis of rule influences of geometric structural parameters on wear of abrasive water jet nozzle. Mach. Tool Hydraul. 2017, 45, 5. [Google Scholar]

- Yang, H. Research on Numerical Simulation Method and Vortex Control Technology for Wall Turbulence of Hydraulic Torque Converter. Ph.D. Thesis, Jilin University, Jilin, China, 2024. [Google Scholar] [CrossRef]

- Zhang, L. Study on Numerical Calculation and Internal Flow Characteristics of Submerged Impinging Jet. Master’s Thesis, Jiangsu University, Zhenjiang, China, 2022. [Google Scholar] [CrossRef]

- Dai, T. Numerical Simulation and Equipment Design of Self-excited Oscillation Cavitation. Master’s Thesis, China Three Gorges University, Yichang, China, 2024. [Google Scholar] [CrossRef]

- Yu, J.; Liu, J.; Wang, G.; Luo, S.; Wang, J. Correction of Realizable k-ε model for high pressure submerged water jets. Sci. Technol. Eng. 2021, 12, 5024–5030. [Google Scholar] [CrossRef]

- Lin, X.; Lu, Y.; Tang, J.; Zhang, W.; Cheng, Y. Numerical simulation of abrasive particles acceleration process in pre-mixed abrasive water jet. J. Vib. Shock. 2015, 34, 19–24. [Google Scholar] [CrossRef]

- Wei, X. The Study on Flow Field Characteristics of High Pressure Water Jet Under Submerged Condition. Master’s Thesis, Chongqing Jiaotong University, Chongqing, China, 2017. [Google Scholar]

| Standoff distance/mm | 1 | 5 | 9 | 11 | 15 |

| Number of mesh elements | 16,168 | 23,908 | 31,108 | 34,708 | 41,908 |

| Pressure/MPa | Mass Flow Rate/kg/s | ||

|---|---|---|---|

| 30 | First trial | Second trial | Mean Value |

| 0.161682 | 0.162093 | 0.161688 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guan, J.; Duan, J.; Zhang, P.; He, S.; Chen, S.; Wang, J.; Xiao, J. Numerical Simulation of Flow-Field Characteristics of a Submerged Pre-Mixed Abrasive Water Jet Impinging on a Wall. Processes 2025, 13, 3647. https://doi.org/10.3390/pr13113647

Guan J, Duan J, Zhang P, He S, Chen S, Wang J, Xiao J. Numerical Simulation of Flow-Field Characteristics of a Submerged Pre-Mixed Abrasive Water Jet Impinging on a Wall. Processes. 2025; 13(11):3647. https://doi.org/10.3390/pr13113647

Chicago/Turabian StyleGuan, Jinfa, Jimiao Duan, Peili Zhang, Sichen He, Shiming Chen, Jian Wang, and Jun Xiao. 2025. "Numerical Simulation of Flow-Field Characteristics of a Submerged Pre-Mixed Abrasive Water Jet Impinging on a Wall" Processes 13, no. 11: 3647. https://doi.org/10.3390/pr13113647

APA StyleGuan, J., Duan, J., Zhang, P., He, S., Chen, S., Wang, J., & Xiao, J. (2025). Numerical Simulation of Flow-Field Characteristics of a Submerged Pre-Mixed Abrasive Water Jet Impinging on a Wall. Processes, 13(11), 3647. https://doi.org/10.3390/pr13113647