Double-Layer Reactive Power Optimal Configuration Method for Large-Scale Offshore Wind Farms Based on an Adaptively Improved Gravitational Search Algorithm

Abstract

1. Introduction

- (1)

- A double-layer “configuration-control” framework model for RP is designed, minimizing full-cycle costs and boosting system stability via upper-level optimization and lower-level coordinated control.

- (2)

- The upper level sets up an optimization configuration model to minimize equipment and operational costs. The lower level formulates an RP optimization model, considering system losses, voltage fluctuations, and RP capacity margins, aiming to minimize a weighted index of these factors.

- (3)

- To overcome the local optima issue in traditional GSA, a random factor is added to mass calculation. Elite strategies are used to selectively combine gravitational forces based on fitness, with more randomness for superior particles. Control parameters are introduced for adaptive particle position updates, resulting in an adaptively improved GSA.

- (4)

- The improved algorithm is used to solve the bi-level optimization model for RP and voltage in large offshore WFs. Simulation analysis in MATLAB on a large offshore WF validates the effectiveness of the improved GSA and the bi-level optimization model.

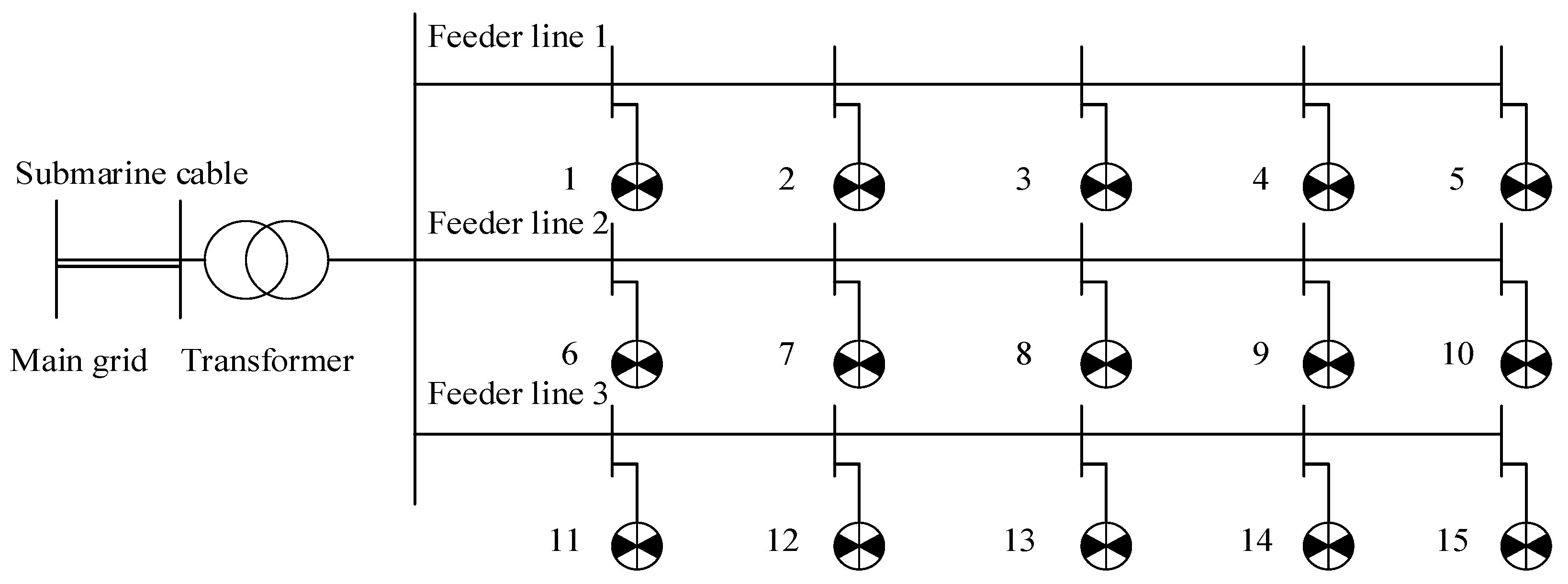

2. System Model of Offshore WF

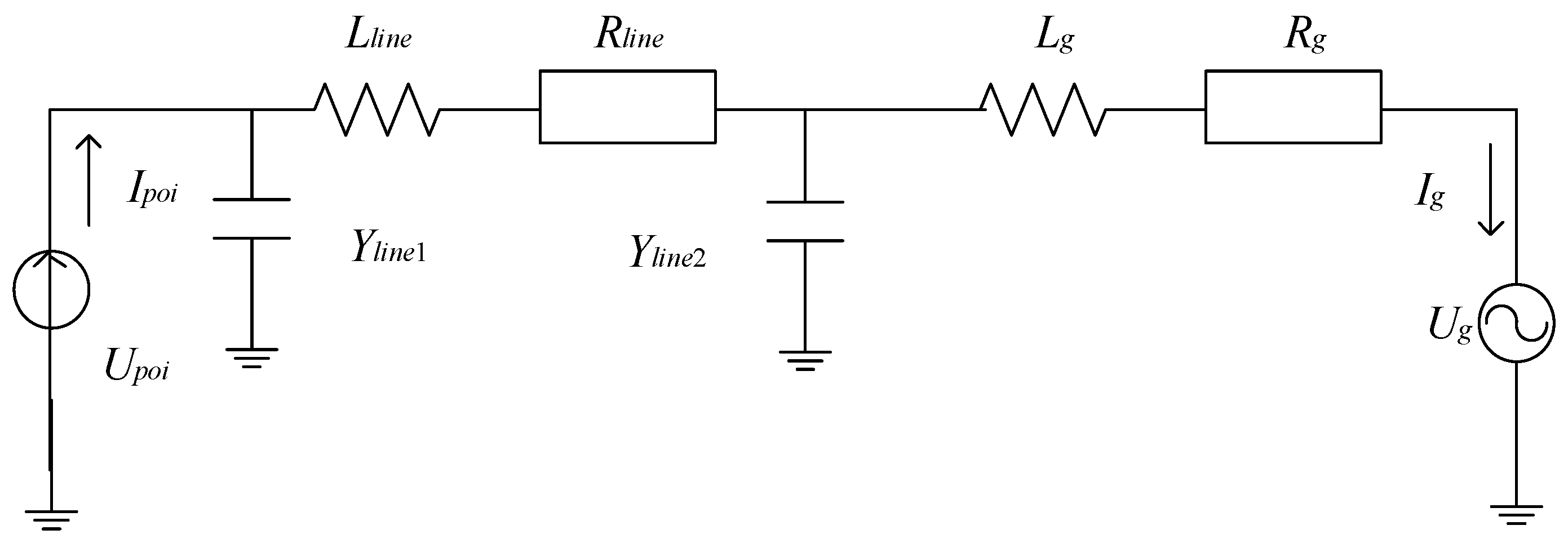

2.1. Parametric Model of Submarine Cable

2.2. Model of RP Compensation Device

2.3. Model of RP Limit for Wind Turbine

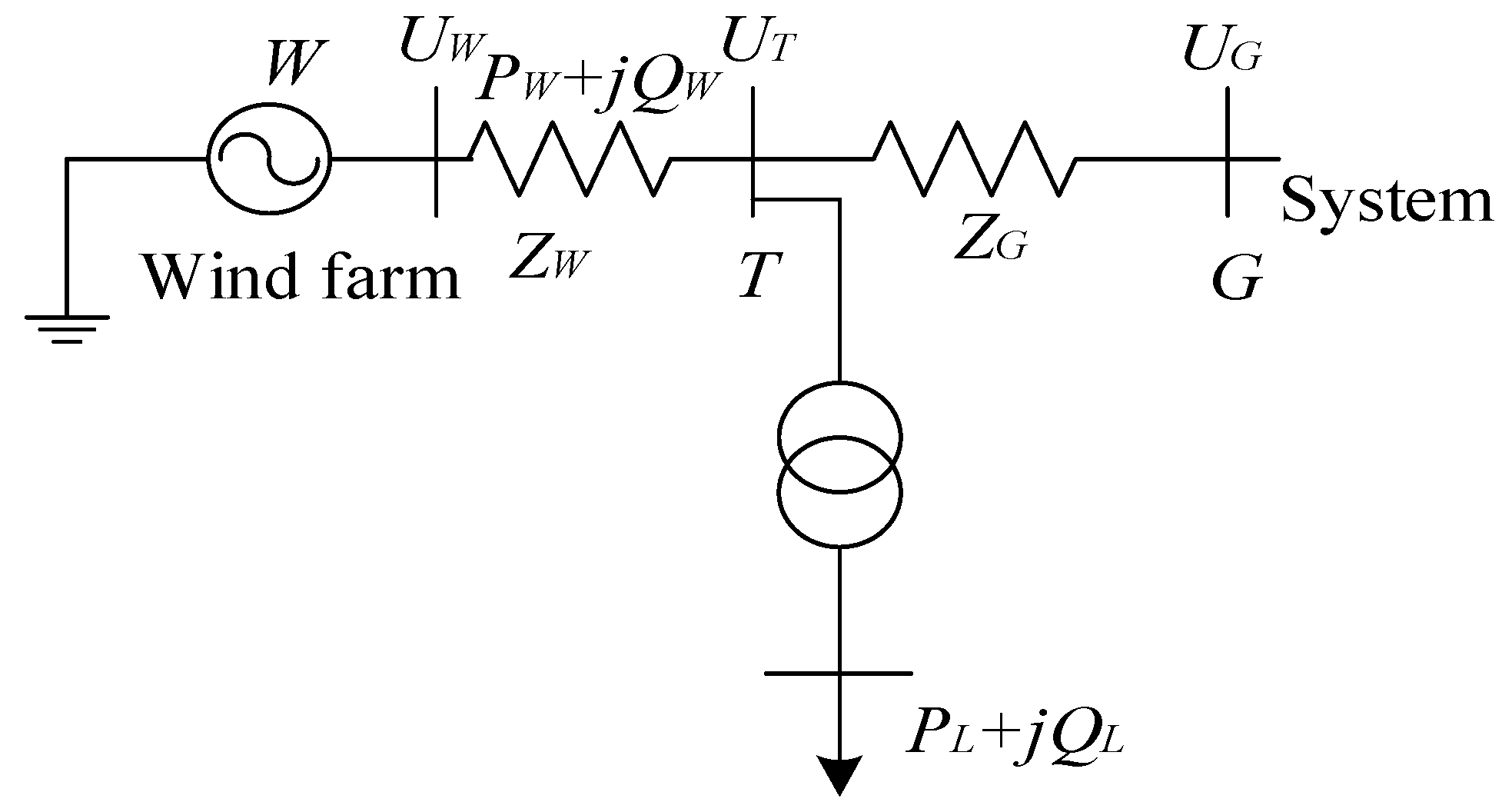

2.4. Grid-Connected Model of Wind Turbine

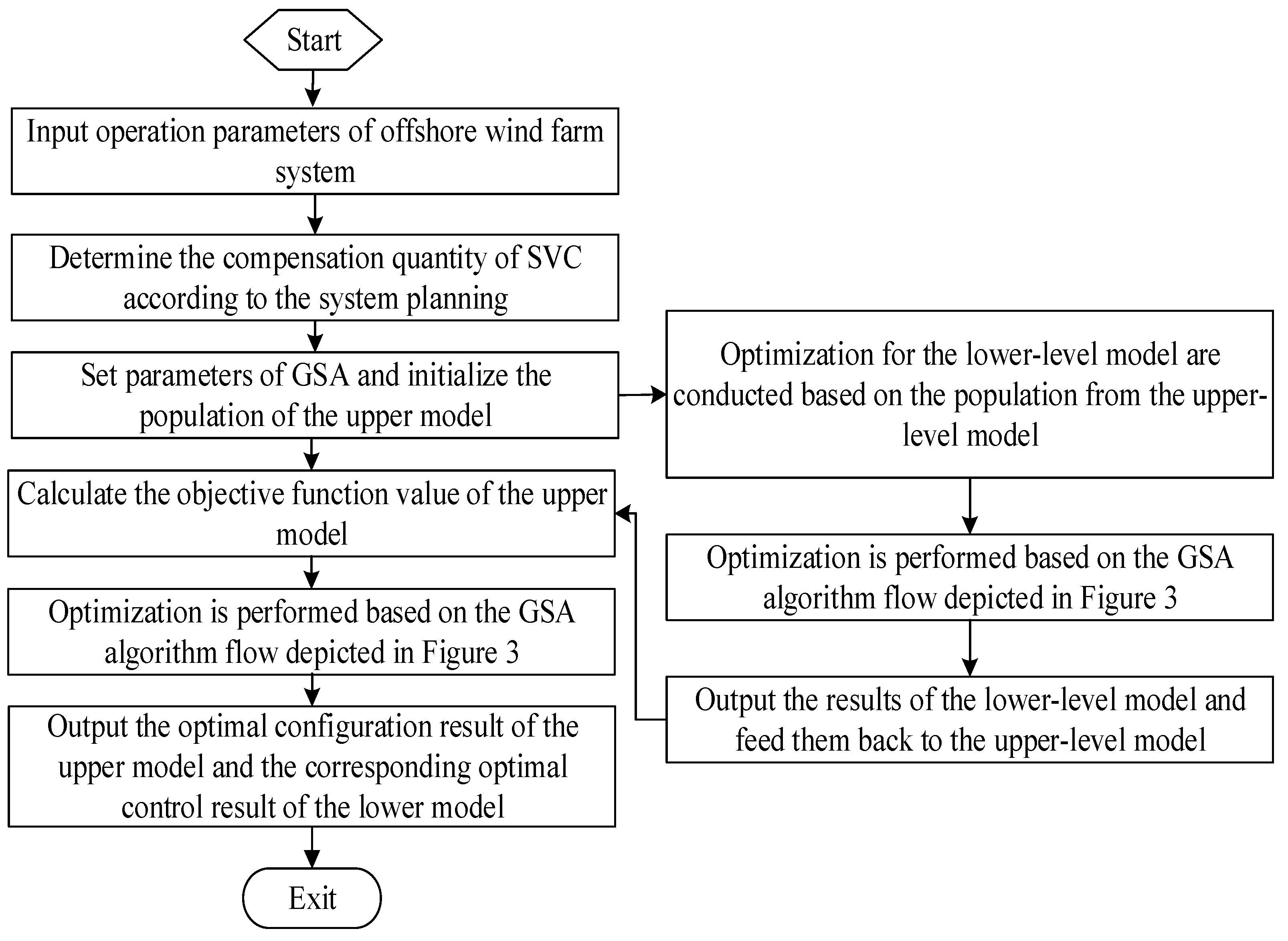

3. Double-Layer “Configuration-Control” Optimization Framework for RP

3.1. Upper RP Optimization Configuration Model

3.2. Lower RP Optimization Control Model

3.3. Normalization of Objective Function Index

3.4. The Constraints

4. The Improved GSA for Double-Layer Framework Model

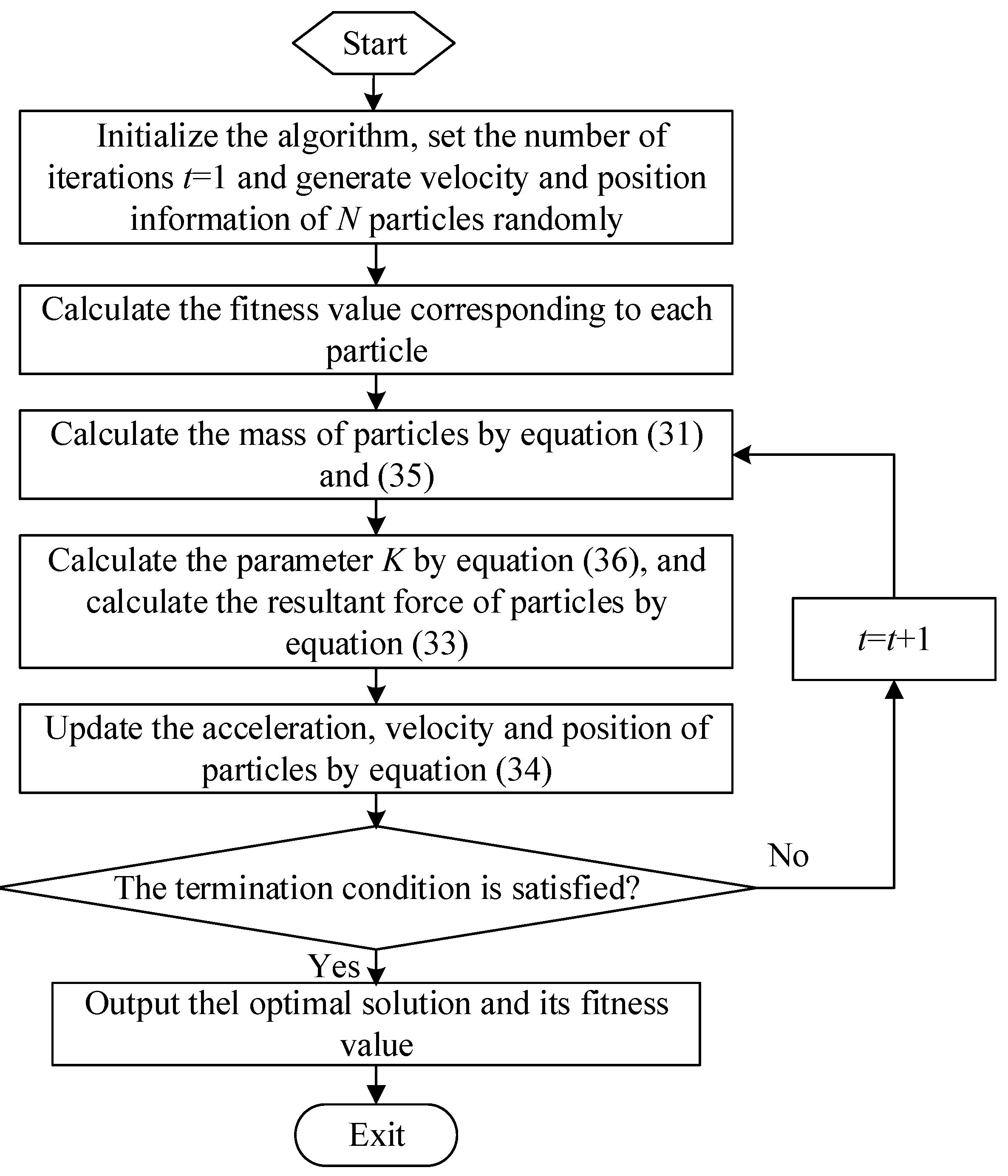

4.1. The Basic GSA

4.2. The Improved GSA

5. Numerical Test and Analysis

5.1. Basic Data and Simulation Conditions

5.2. Simulation Results and Analysis

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| WF | wind farms |

| RP | reactive power |

| GSA | gravitational search algorithm |

| WT | wind turbines |

| AC | alternating current |

| pu | per unit |

| POI | point of interconnection |

| DFIGs | doubly-fed induction generators |

| GWEO | grey wolf equilibrium optimizer |

| STATCOM | static synchronous compensators |

| MMC | modular multilevel converter |

| VSG | virtual synchronous generator |

| CVaR | conditional value at risk |

| MAS | multi-agent system |

| PMU | phasor measurement unit |

| SVC | static var compensator |

| TSC | thyristor switched capacitor |

| TCR | thyristor controlled reactor |

| GA | genetic algorithm |

| PSO | and particle swarm optimization |

References

- Nishikata, S.; Tatsuta, F. Study on Output Power of Wind Farm Composed of Current-Source Series-Connected Wind Turbines. IEEE Trans. Sustain. Energy 2025, 16, 1827–1836. [Google Scholar] [CrossRef]

- Wei, S.; Wang, H.; Fu, Y.; Li, F.; Huang, L. Electrical System Planning of Large-Scale Offshore Wind Farm Based on $N+$ Design Considering Optimization of Upper Power Limits of Wind Turbines. J. Mod. Power Syst. Clean Energy 2023, 11, 1784–1794. [Google Scholar] [CrossRef]

- Fu, Y.; Liu, Y.; Huang, L.-L.; Ying, F.; Li, F. Collection System Topology for Deep-Sea Offshore Wind Farms Considering Wind Characteristics. IEEE Trans. Energy Convers. 2022, 37, 631–642. [Google Scholar] [CrossRef]

- Xiang, F.; Liao, S.; Zhang, H.; Luo, L. Sub-Synchronous Oscillation Phenomenon Analysis of Grid-Connected Direct Drive-Doubly Fed Hybrid Wind Farms via VSC-HVdc System. IEEE Access 2025, 13, 37966–37978. [Google Scholar] [CrossRef]

- Mu, G.; Wu, F.; Zhang, X.; Fu, Z.; Xiao, B. Analytic Mechanism for the Cumulative Effect of Wind Power Fluctuations from Single Wind Farm to Wind Farm Cluster. CSEE J. Power Energy Syst. 2022, 8, 1290–1301. [Google Scholar] [CrossRef]

- Ma, Y.; Xie, K.; Zhao, Y.; Yang, H.; Zhang, D. Bi-Objective Layout Optimization for Multiple Wind Farms Considering Sequential Fluctuation of Wind Power Using Uniform Design. CSEE J. Power Energy Syst. 2022, 8, 1623–1635. [Google Scholar] [CrossRef]

- Wang, X.; Yang, R.; Shi, Z.; Cai, X.; Shi, X.; Chen, Y. Coordinated Low Voltage Ride-Through of MMC-HVDC Transmission System and Wind Farm with Distributed Braking Resistors. IEEE Access 2022, 10, 87860–87869. [Google Scholar] [CrossRef]

- Wu, C.; Zhang, X.-P.; Sterling, M. Wind power generation variations and aggregations. CSEE J. Power Energy Syst. 2022, 8, 17–38. [Google Scholar] [CrossRef]

- Raza, M.W.; Raza, M.; Badia, J.G.; Prieto-Araujo, E.; Gomis-Bellmunt, O. Fault Handling Capabilities of Grid-Forming Wind Turbines in Offshore Wind Farms Connected with MMC HVDC System. IEEE Access 2024, 12, 36404–36414. [Google Scholar] [CrossRef]

- Stock, A.; Amos, L.; Alves, R.; Leithead, W. Design and Implementation of a Wind Farm Controller Using Aerodynamics Estimated from LIDAR Scans of Wind Turbine Blades. IEEE Control. Syst. Lett. 2021, 5, 1735–1740. [Google Scholar] [CrossRef]

- Dong, H.; Zhao, X. Reinforcement Learning-Based Wind Farm Control: Toward Large Farm Applications via Automatic Grouping and Transfer Learning. IEEE Trans. Ind. Inform. 2023, 19, 11833–11845. [Google Scholar] [CrossRef]

- Xiang, W.; Tu, R.; Han, M.; Wen, J. Hybrid AC/DC Collection and HVDC Transmission Topology for Large-scale Offshore Wind Farms. CSEE J. Power Energy Syst. 2025, 11, 949–959. [Google Scholar] [CrossRef]

- Zou, M.; Wang, Y.; Zhao, C.; Xu, J.; Guo, X.; Sun, X. Integrated Equivalent Model of Permanent Magnet Synchronous Generator Based Wind Turbine for Large-scale Offshore Wind Farm Simulation. J. Mod. Power Syst. Clean Energy 2023, 11, 1415–1426. [Google Scholar] [CrossRef]

- Sheng, Y.; Li, C.; Jia, H.; Liu, B.; Coombs, T.A. Investigation on FRT Capability of PMSG-Based Offshore Wind Farm Using the SFCL. IEEE Trans. Appl. Supercond. 2021, 31, 1–4. [Google Scholar] [CrossRef]

- Du, C.; Du, X.; Tong, C.; Li, Y.; Zhou, P. Stability Analysis for DFIG-Based Wind Farm Grid-Connected System Under All Wind Speed Conditions. IEEE Trans. Ind. Appl. 2023, 59, 2430–2445. [Google Scholar] [CrossRef]

- Mei, M.; Kou, P.; Xu, Y.; Zhang, Z.; Tian, R.; Liang, D. Improving Floating Offshore Wind Farm Flow Control with Scalable Model-Based Deep Reinforcement Learning. IEEE Trans. Autom. Sci. Eng. 2025, 22, 18255–18268. [Google Scholar] [CrossRef]

- Lei, Z.; Gao, S.; Zhang, Z.; Yang, H.; Li, H. A Chaotic Local Search-Based Particle Swarm Optimizer for Large-Scale Complex Wind Farm Layout Optimization. IEEE/CAA J. Autom. Sin. 2023, 10, 1168–1180. [Google Scholar] [CrossRef]

- Jadidi, S.; Badihi, H.; Zhang, Y. Hybrid Fault-Tolerant and Attack-Resilient Cooperative Control in an Offshore Wind Farm. IEEE Trans. Sustain. Energy 2024, 15, 1365–1379. [Google Scholar] [CrossRef]

- Dakic, J.; Cheah-Mane, M.; Gomis-Bellmunt, O.; Prieto-Araujo, E. HVAC Transmission System for Offshore Wind Power Plants Including Mid-Cable Reactive Power Compensation: Optimal Design and Comparison to VSC-HVDC Transmission. IEEE Trans. Power Deliv. 2021, 36, 2814–2824. [Google Scholar] [CrossRef]

- Bulut, N.E.; Dandil, E.; Yuzgec, U.; Duysak, A. CMACGSA: Improved Gravitational Search Algorithm Based on Cerebellar Model Articulation Controller for Optimization. IEEE Access 2025, 13, 20847–20870. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, S.; Zhou, M.; Yu, Y. A multi-layered gravitational search algorithm for function optimization and real-world problems. IEEE/CAA J. Autom. Sin. 2021, 8, 94–109. [Google Scholar] [CrossRef]

- Li, X.; Yang, H.; Li, J.; Wang, Y.; Gao, S. A Novel Distributed Gravitational Search Algorithm with Multi-Layered Information Interaction. IEEE Access 2021, 9, 166552–166565. [Google Scholar] [CrossRef]

- Fan, Y.; Zhang, S.; Yang, H.; Xu, D.; Wang, Y. An Improved Future Search Algorithm Based on the Sine Cosine Algorithm for Function Optimization Problems. IEEE Access 2023, 11, 30171–30187. [Google Scholar] [CrossRef]

- Zandavi, S.M.; Chung, V.Y.Y.; Anaissi, A. Stochastic Dual Simplex Algorithm: A Novel Heuristic Optimization Algorithm. IEEE Trans. Cybern. 2021, 51, 2725–2734. [Google Scholar] [CrossRef] [PubMed]

- Noroozi, M.; Mohammadi, H.; Efatinasab, E.; Lashgari, A.; Eslami, M.; Khan, B. Golden Search Optimization Algorithm. IEEE Access 2022, 10, 37515–37532. [Google Scholar] [CrossRef]

- Zhu, J.; Mo, X.; Xia, Y.; Guo, Y.; Chen, J.; Liu, M. Fully-Decentralized Optimal Power Flow of Multi-Area Power Systems Based on Parallel Dual Dynamic Programming. IEEE Trans. Power Syst. 2022, 37, 927–941. [Google Scholar] [CrossRef]

- Golla, M.; Reddy, D.V.S.; Thangavel, S.; Padhy, N.P. An Improved Control Strategy for Active Power Injection and Power Quality Enhancement in a Low-Voltage Weak-Grid Integrated PV and Battery System. IEEE Trans. Consum. Electron. 2025, 71, 476–487. [Google Scholar] [CrossRef]

- Mahdavi, M.; Siano, P. Impact of Demand-Side Behavior on Line Switching and Reactive Power Management Considering Reconfiguration and Capacitor Costs. IEEE Can. J. Electr. Comput. Eng. 2025, 48, 155–166. [Google Scholar] [CrossRef]

| Parameter | Value | Parameter | Value | Parameter | Value |

|---|---|---|---|---|---|

| Rated mechanical power | 5 MW | Stator resistance | 1.5 mΩ | Line resistance | 0.132 Ω/km |

| Rated voltage | 950 V | Stator reactance | 2.0 Ω | Line reactance | 0.130 Ω/km |

| Rated frequency | 50 Hz | Rotor resistance | 1.5 mΩ | Transformer no-load loss | 14 kW |

| Rated speed | 1170 r/min | Rotor reactance | 2.0 Ω | Transformer load loss | 30 kW |

| Rated slip | 0.2 | Mutual reactance | 1.7 Ω | Rated capacity | 100 MVA |

| Method | Basic GSA | GA | PSO | The Proposed Method |

|---|---|---|---|---|

| Configuration quantity | 6 | 5 | 5 | 5 |

| Configuration capacity (Mvar) | 30 | 25 | 25 | 25 |

| Configuration point | 2, 5, 8, 10, 11, 15 | 3, 5, 6, 10, 15 | 2, 5, 10, 12, 15 | 5, 6, 10, 13, 15 |

| Annual cost (million RMB) | 1.671 | 1.256 | 1.381 | 1.215 |

| Method | System Network Loss (pu) | Voltage Deviation (pu) | RP Margin (pu) |

|---|---|---|---|

| Basic GSA | 0.0251 | 0.0278 | 0.8714 |

| GA | 0.0156 | 0.0147 | 0.8025 |

| PSO | 0.0187 | 0.0175 | 0.8329 |

| The proposed method | 0.0124 | 0.0098 | 0.7566 |

| Method | Iteration Times of Upper Model | Mean Iteration Times of Lower Model | Total Calculation Time (min) |

|---|---|---|---|

| Basic GSA | 127 | 115 | 121.75 |

| GA | 78 | 75 | 73.18 |

| PSO | 84 | 81 | 79.56 |

| The proposed method | 73 | 70 | 71.24 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Wang, J.; Zhang, F.; Wang, F. Double-Layer Reactive Power Optimal Configuration Method for Large-Scale Offshore Wind Farms Based on an Adaptively Improved Gravitational Search Algorithm. Processes 2025, 13, 3408. https://doi.org/10.3390/pr13113408

Li Y, Wang J, Zhang F, Wang F. Double-Layer Reactive Power Optimal Configuration Method for Large-Scale Offshore Wind Farms Based on an Adaptively Improved Gravitational Search Algorithm. Processes. 2025; 13(11):3408. https://doi.org/10.3390/pr13113408

Chicago/Turabian StyleLi, Yu, Jianbao Wang, Feng Zhang, and Fei Wang. 2025. "Double-Layer Reactive Power Optimal Configuration Method for Large-Scale Offshore Wind Farms Based on an Adaptively Improved Gravitational Search Algorithm" Processes 13, no. 11: 3408. https://doi.org/10.3390/pr13113408

APA StyleLi, Y., Wang, J., Zhang, F., & Wang, F. (2025). Double-Layer Reactive Power Optimal Configuration Method for Large-Scale Offshore Wind Farms Based on an Adaptively Improved Gravitational Search Algorithm. Processes, 13(11), 3408. https://doi.org/10.3390/pr13113408