Reasonable Coal Pillar Width and Control Technology for Gob-Side Entry Driving in Deep Irregular Working Face

Abstract

1. Introduction

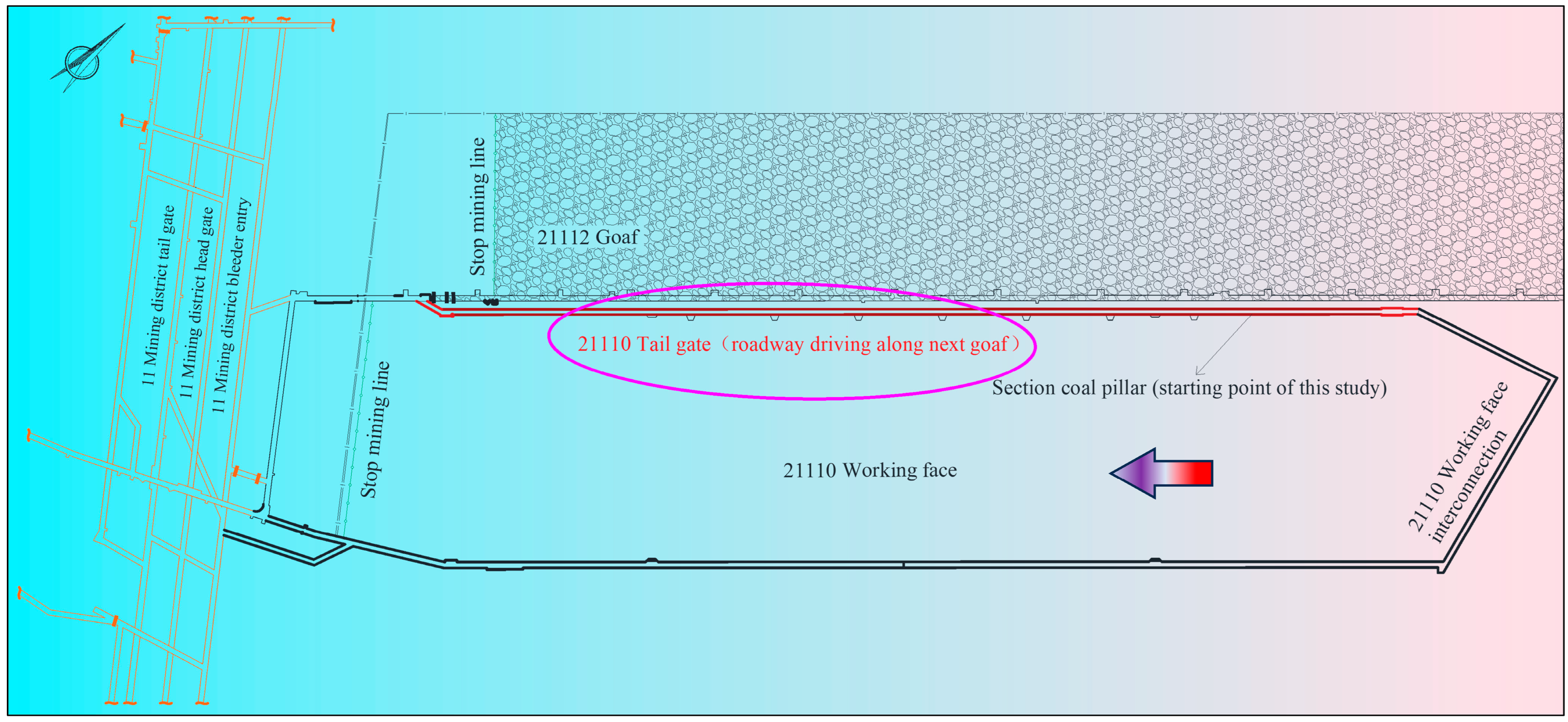

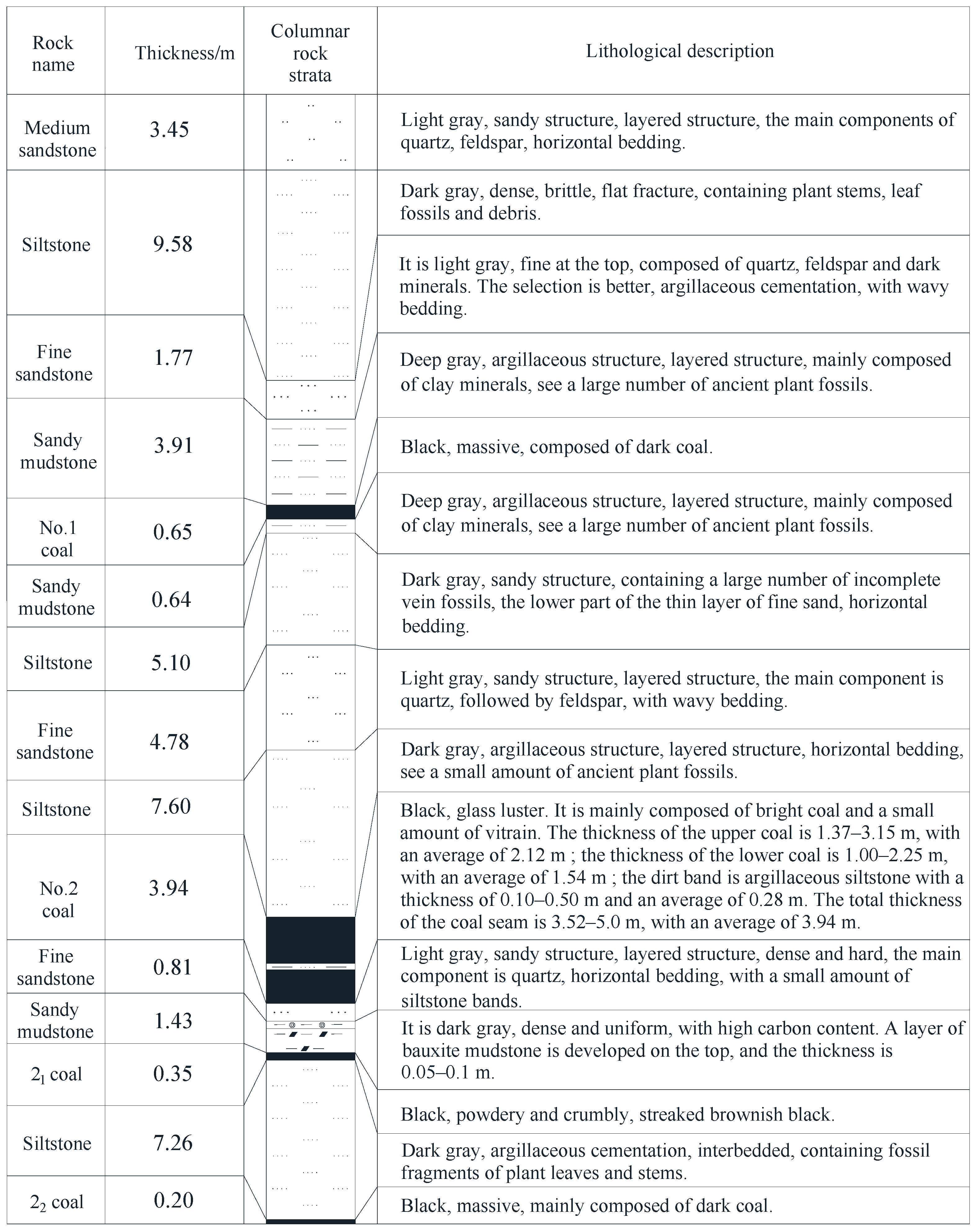

2. Engineering Overview

2.1. Geological Profile

2.2. Characteristics of Mineral Pressure Manifestation

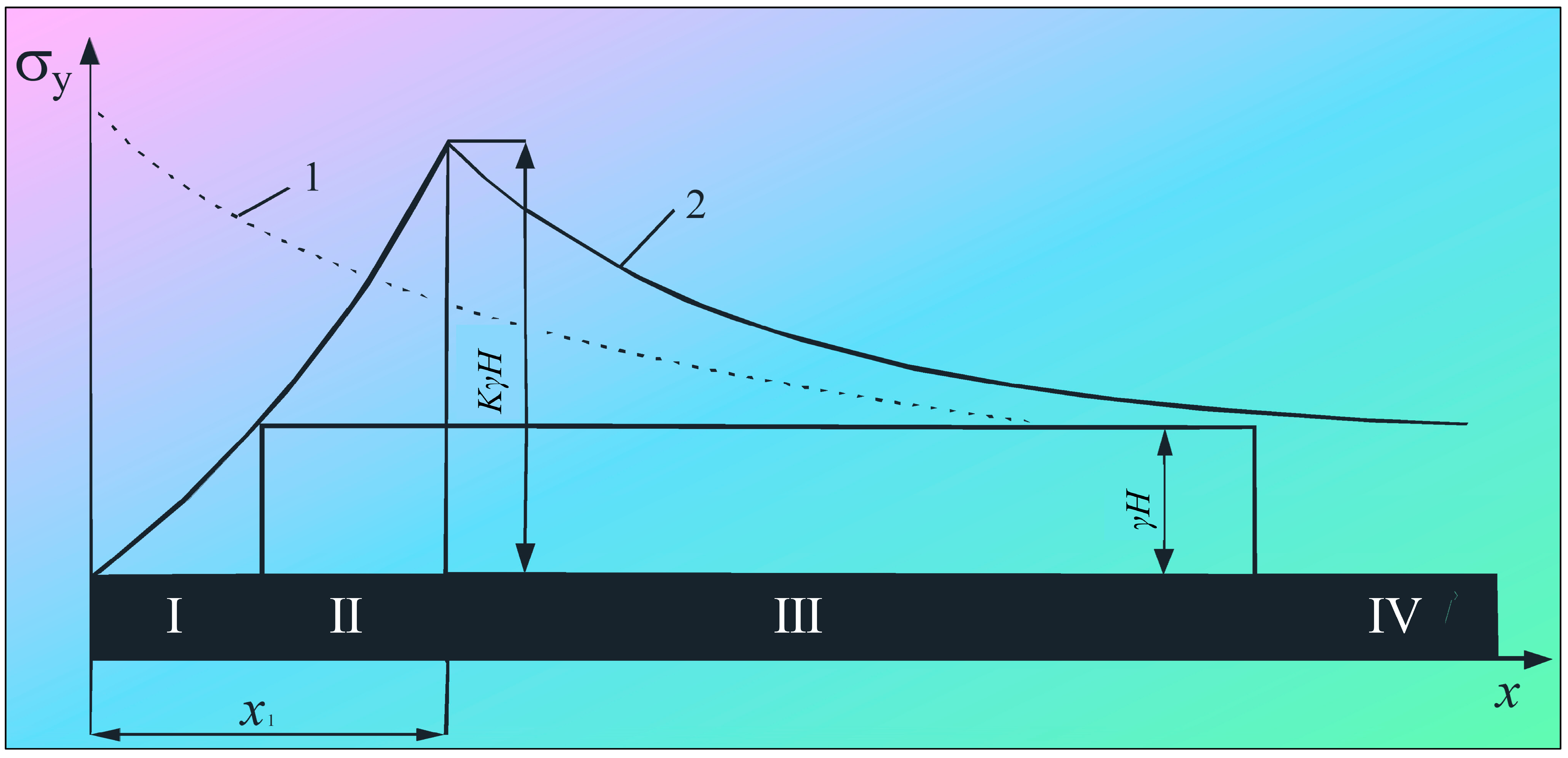

3. Theoretical Calculation of Reasonable Coal Pillar Width

4. Numerical Simulation of Reasonable Coal Pillar Width

4.1. Numerical Model Establishment and Simulation Scheme

4.2. Simulation Results Analysis

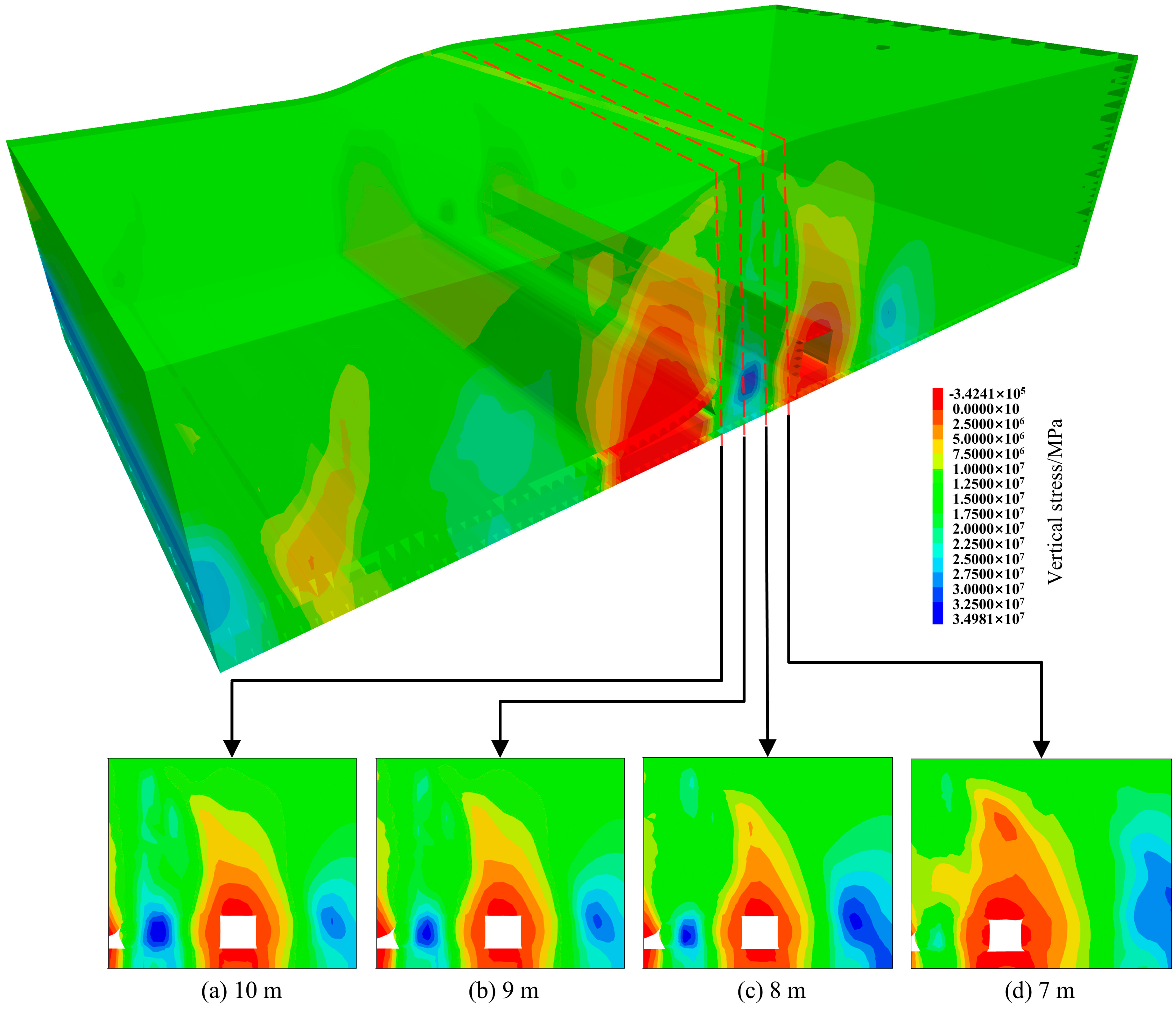

4.2.1. Vertical Stress Distribution Law for Different Coal Pillar Widths

- (1)

- As the 21110 working face is mined, the surrounding rock of the roof and floor experiences deformation, breaking the equilibrium state of the in situ stress field in the coal measures and causing the rock stress field to be redistributed during mining. To reach the equilibrium state again, a lateral support stress is formed on the coal pillar side.

- (2)

- Stress concentration occurs in the gob-side entry driving. With the progressive widening of the coal pillar, the area of stress concentration transitions from the solid coal pillar to the coal pillar. Consequently, the coal pillar experiences greater vertical stress compared to the solid coal pillar.

- (3)

- When the coal pillar width is 7 m, the stress experienced is less than that experienced by the solid coal pillar. The primary concentration of support stress is concentrated in the solid coal pillar. There is no high stress zone inside the coal pillar, resulting in poor load-bearing capacity and difficult maintenance of the roadway; As the coal pillar is widened to 8 m, the stress is transferred to it, forming stress-bearing areas. This mitigates stress concentration in solid coal. At this point, the roadway possesses strong control capabilities, facilitating the stabilization of the surrounding rock.

- (4)

- As the width of the coal pillar continues to increase to 9~10 m, the supporting stress and stress range of the coal pillar rapidly increases. The coal pillar endures a peak stress that surpasses the stress in the solid coal pillar. This results in stress concentration within the coal pillar, which is detrimental to the management of the roadway’s surrounding rock.

4.2.2. Distribution Pattern of Plastic Zone with Different Coal Pillar Widths

4.3. Determination of Coal Pillar Width

5. Support Parameters and Schemes for Gob-Side Entry Driving

5.1. Borehole Observation of Surrounding Rock in Gob-Side Entry Driving

5.2. Design of Support Parameters for Surrounding Rock in Gob-Side Entry Driving

5.2.1. Verification of Support Parameters Based on the Unit Anchor Cable Suspension Principle

- (1)

- Roof bolts through the suspension action, and rib bolts through the reinforcement of the rib body, to achieve the condition of support effect, should meet:

- (2)

- Verification of anchor bolt spacing based on the weight that the anchor bolt can suspend

5.2.2. Calculation Based on the Natural Pressure Arch Principle

- (1)

- Roof bolt parameters

- 1.

- Roof bolt length:

- 2.

- Anchorage length:

- 3.

- Bolt spacing:

- (2)

- Rib bolt parameters

- Rib bolt length:

In the formula:—Anchorage length is taken as 659 mm;—The rib bolt hole diameter is taken as 29 mm;—The resin adhesive bonding strength with rock is taken as 20 kg/cm2;- 2.

- Bolt spacing:

In the formula:—The number of ribs per row is taken as 10;—The anchor rod anchoring force is taken as 12 t;—The rib bolt spacing is 1 m;

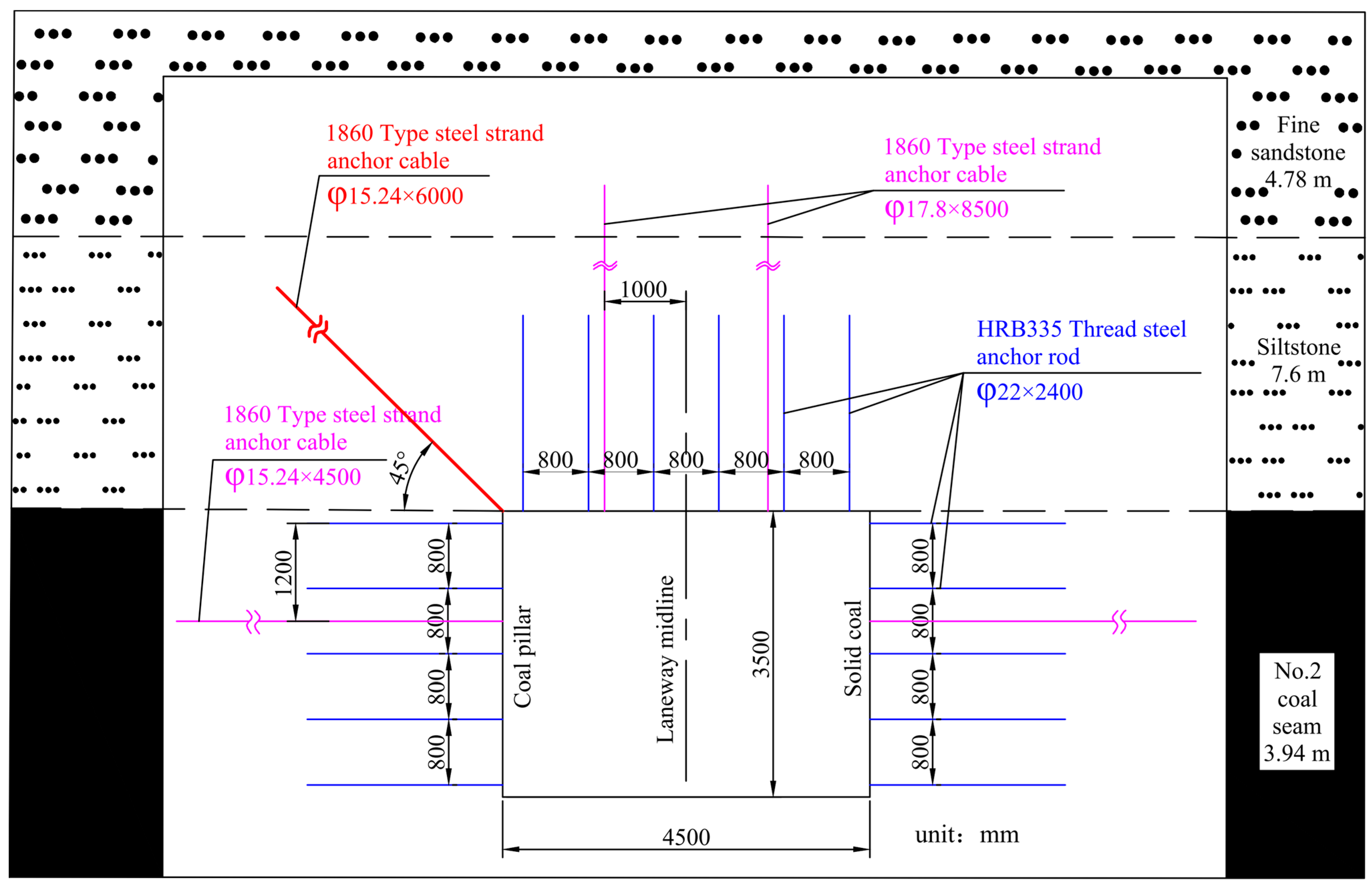

5.3. Optimization Scheme for Gob-Side Entry Driving Support

- (1)

- Roof support. Roof bolts: Each row of the roadway roof is lined with six equally robust, fully threaded steel rock bolts, each measuring 22 mm × 2400 mm, equipped with S2360 and Z2360 resin cartridges. The full-length anchoring force is a minimum of 15 t, while the torque is a minimum of 300 N·m. The arrangement of roof bolts in rows should have a spacing of 800 mm × 800 mm on the vertical roof plane.

- (2)

- Rib support. Rib bolts: On either side of the roadway, there are 10 completely threaded 20 mm × 2400 mm HRB335 steel rock bolts, each fitted with a roll of S2360 and a Z2360 resin cartridge, ensuring a minimum anchoring force of 12 tons and torque of 250 N·m; the distance between each rib bolt measures 800 mm × 800 mm.

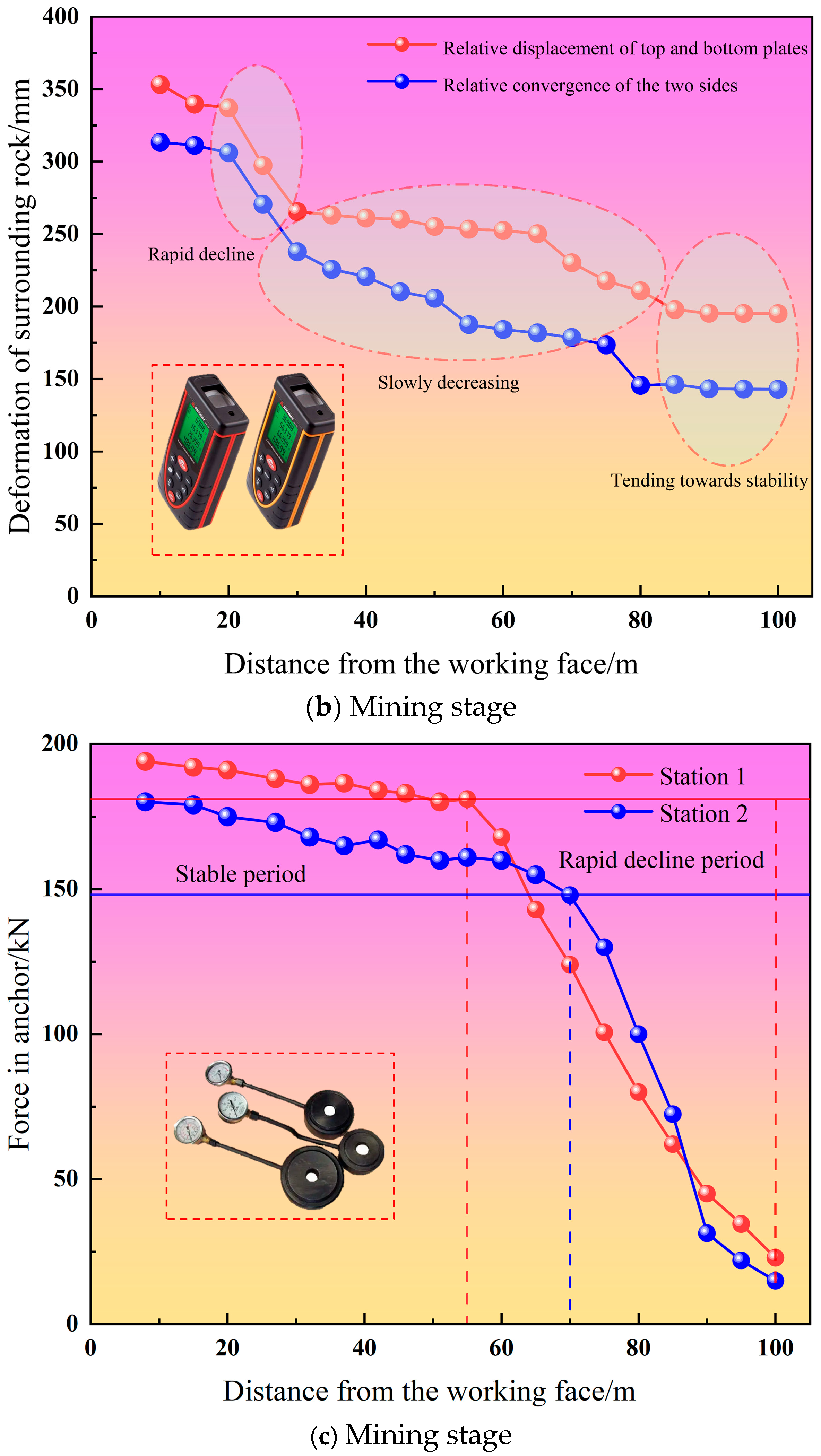

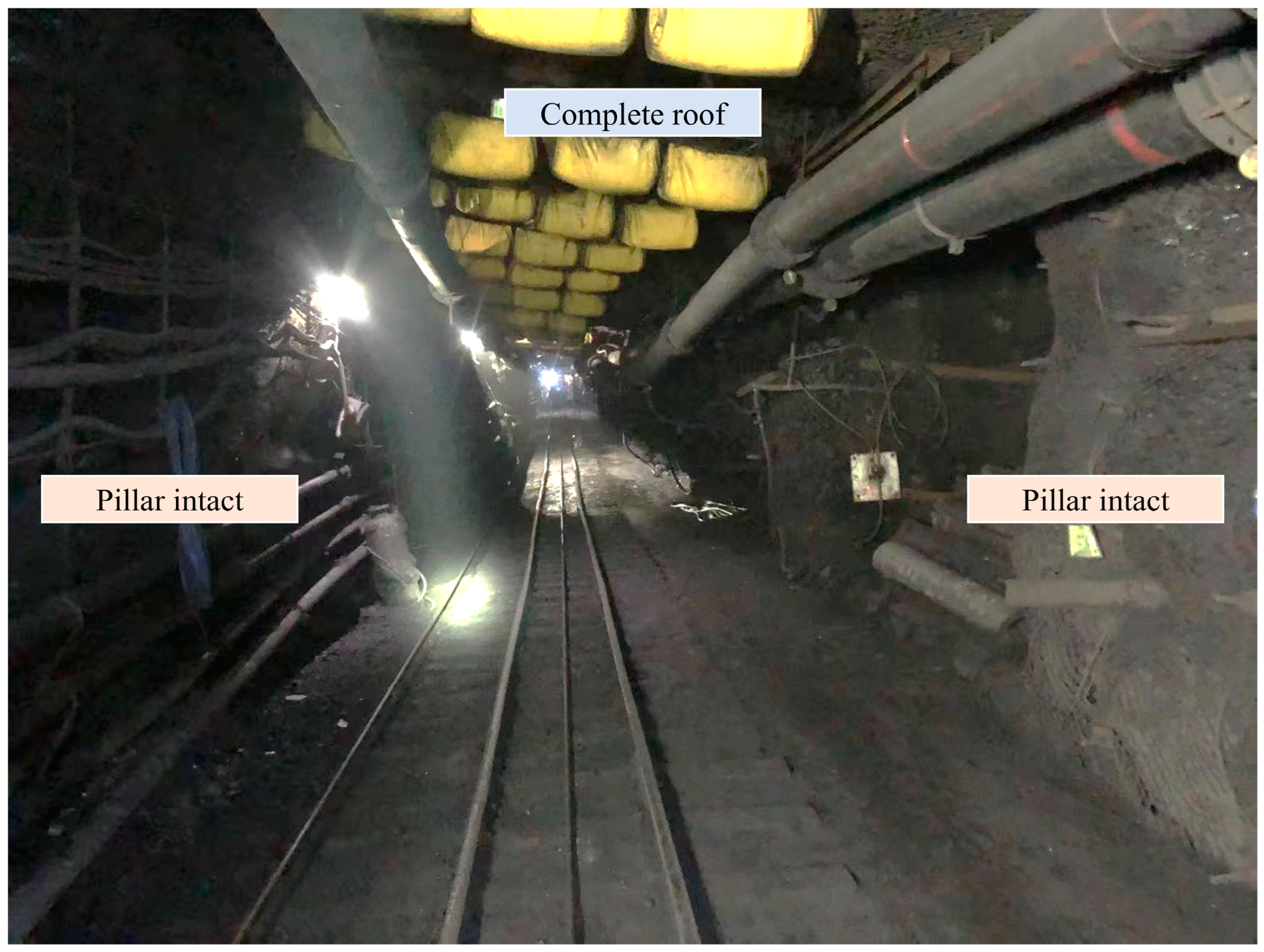

6. On Site Mining Pressure Observation and Control Effect Analysis

7. Conclusions

- (1)

- According to the limit equilibrium theory, a reasonable value range for the coal pillar in gob-side entry driving is 7.9~9.8 m. The results of the numerical simulation demonstrate that, when the width of the coal pillar is 7.0 m, 8.0 m, 9.0 m, and 10.0 m, the stress and plastic zone of the roadway’s surrounding rock show significant differential distribution characteristics. Moreover, when the coal pillar width is 8.0 m, this is beneficial to the stability of the surrounding rock in gob-side entry driving. Therefore, a reasonable width for the coal pillar is 8.0 m.

- (2)

- The borehole observation results show that, within a sector area 2.1 m away from the mining coal pillar, 1.4 m from the left shoulder corner, 3.5 m from the roadway roof, 1.8 m from the right shoulder corner, and 1.7 m from the solid coal pillar, significant transverse and longitudinal fissures have developed inside the surrounding rock. The depth of the surrounding rock damage at the coal pillar side shoulder nest position is significant and exhibits asymmetric distortion characteristics. Therefore, it is proposed that the coal pillar side shoulder nest position be considered a key area for track roadway support, and the extent of the anchor cable on the left shoulder corner of the trackway roof and the roof should not be less than 4.5 m and 5.2 m, respectively.

- (3)

- Engineering practice has shown that the relative displacement of the roof and floor during the excavation of the roadway consistently exceeds that of the sides or ribs, with a maximum deformation of 185 mm for the roof and floor and 133 mm for the ribs, and with a maximum difference of 52 mm. The maximum deformation of the roof and floor during the mining period of the roadway is 353 mm, and the maximum deformation of the ribs is 313 mm. The mining pressure manifestation is normal. Through engineering practice, it is proven that setting up an 8.0 m coal pillar and adopting asymmetric coupling support technology effectively ensures the stability of the surrounding rock, achieving safe production of coal resources at the working face.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kang, H.; Gao, F.; Xu, G.; Ren, H. Mechanical behaviors of coal measures and ground control technologies for China’s deep coal mines—A review. J. Rock Mech. Geotech. Eng. 2023, 15, 37–65. [Google Scholar] [CrossRef]

- Ranjith, P.; Zhao, J.; Ju, M.; De Silva, R.; Rathnaweera, T.; Bandara, A. Opportunities and Challenges in Deep Mining: A Brief Review. Engineering 2017, 3, 546–551. [Google Scholar] [CrossRef]

- Tao, M.; Cheng, W.; Nie, K.; Zhang, X.; Cao, W. Life cycle assessment of underground coal mining in China. Sci. Total Environ. 2022, 805, 150231. [Google Scholar] [CrossRef]

- Liu, X.; Li, L.; Yang, Y. Development status of coal mining in China. J. S. Afr. Inst. Min. Metall. 2023, 123, 19–27. [Google Scholar] [CrossRef]

- Ren, S.; Zheng, D.; Qu, Y.; Qin, R.; Jiao, X.; Bai, J. Development Assessment of the Coal Industry of China Based on the Minimum Deviation Comprehensive Weight Evaluation Model. Adv. Civ. Eng. 2021, 2021, 5248324. [Google Scholar] [CrossRef]

- Huang, P.; Zhang, Q.; Xie, J.; Li, J.; Zhang, Q.; Li, M.; Simao, F. Multiscale study on coal pillar strength and rational size under variable width working face. Front. Environ. Sci. 2024, 12, 1338642. [Google Scholar] [CrossRef]

- Du, B.; Liu, C.; Yang, J.; Wu, F. Abutment pressure distribution pattern and size optimization of coal pillar under repeated mining: A case study. Arab. J. Geosci. 2020, 13, 1261. [Google Scholar] [CrossRef]

- Chen, A. Width Design of Small Coal Pillar of Gob-Side Entry Driving in Soft Rock Working Face and Its Application of Zaoquan Coal Mine. Adv. Civ. Eng. 2021, 2021, 9999957. [Google Scholar] [CrossRef]

- Jiang, L.; Yang, Z.; Li, G. Research on the Reasonable Coal Pillar Width and Surrounding Rock Supporting Optimization of Gob-Side Entry under Inclined Seam Condition. Adv. Civ. Eng. 2021, 2021, 7145821. [Google Scholar] [CrossRef]

- Xu, Q.; Bai, J.; Yan, S.; Wang, R.; Wu, S.; Chu, T. Numerical Study on Soft Coal Pillar Stability in an Island Longwall Panel. Adv. Civ. Eng. 2021, 2021, 8831778. [Google Scholar] [CrossRef]

- Kang, H.; Yang, J.; Jiang, P.; Gao, F.; Li, W.; Li, J.; Chen, H. Theory, technology and application of grouted bolting in soft rock roadways of deep coal mines. Int. J. Miner. Metall. Mater. 2024, 31, 1463–1479. [Google Scholar] [CrossRef]

- Jiang, Z.; Guo, W.; Xie, S. Coal Pillar Size Determination and Surrounding Rock Control for Gob-Side Entry Driving in Deep Soft Coal Seams. Processes 2023, 11, 2331. [Google Scholar] [CrossRef]

- Wang, E.; Xie, S. Determination of coal pillar width for gob-side entry driving in isolated coal face and its control in deep soft-broken coal seam: A case study. Energy Sci. Eng. 2022, 10, 2305–2316. [Google Scholar] [CrossRef]

- Wang, D.; He, F.; Wu, Y.; Xu, X.; Zhang, J.; Lv, K.; Li, L.; Zhai, W.; Song, J. Study on surrounding rock failure mechanism and rational coal pillar width of the gob-side coal roadway under influence of intense dynamic pressure. Energy Sci. Eng. 2023, 11, 1716–1733. [Google Scholar] [CrossRef]

- Wang, M.; Li, X.; Su, J.; Liu, W.; Fang, Z.; Wang, S.; Kang, J.; Yu, W. A study on the reasonable width of narrow coal pillars in the section of hard primary roof hewing along the air excavation roadway. Energy Sci. Eng. 2024, 12, 2746–2765. [Google Scholar] [CrossRef]

- Chen, Y.; Sun, J.; Pang, D.; Zhang, R. Deformation and Failure Law of Roadway along Goaf and Reserve Width of Section Coal Pillar. Geofluids 2022, 2022, 9947113. [Google Scholar] [CrossRef]

- Huang, W.; Liu, S.; Gao, M.; Hou, T.; Wang, X.; Zhao, T.; Sui, L.; Xie, Z. Improvement of Reinforcement Performance and Engineering Application of Small Coal Pillars Arranged in Double Roadways. Sustainability 2023, 15, 292. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, X.; Fan, G.; Zhang, D.; Cui, J. Pillar size optimization design of isolated island panel gob-side entry driving in deep inclined coal seam-case study of Pingmei No. 6 coal seam. J. Geophys. Eng. 2018, 15, 816–828. [Google Scholar] [CrossRef]

- Zhu, L.; Liu, C.; Gu, W.; Yuan, C.; Wu, Y.; Liu, Z.; Song, T.; Sheng, F. Research on Floor Heave Mechanisms and Control Technology for Deep Dynamic Pressure Roadways. Processes 2023, 11, 467. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, B.; Li, X.; Liu, C.; Wang, C.; Wang, F.; Chen, D. Research on roof damage mechanism and control technology of gob-side entry retaining under close distance gob. Eng. Fail. Anal. 2022, 138, 106331. [Google Scholar] [CrossRef]

- He, M.; Wang, Q. Rock dynamics in deep mining. Int. J. Min. Sci. Technol. 2023, 33, 1065–1082. [Google Scholar] [CrossRef]

- Ma, Q.; Zhang, Y.; Gao, L.; Li, Z.; Song, G.; Zheng, Y. The Optimization of Coal Pillars on Return Air Sides and the Reasonable Horizon Layout of Roadway Groups in Highly Gassy Mines. Sustainability 2022, 14, 9417. [Google Scholar] [CrossRef]

- Jawed, M.; Sinha, R. Design of rhombus coal pillars and support for Roadway Stability and mechanizing loading of face coal using SDLs in a steeply inclined thin coal seam-a technical feasibility study. Arab. J. Geosci. 2018, 11, 415. [Google Scholar] [CrossRef]

- Chang, Q.; Ge, S.; Shi, X.; Sun, Y.; Wang, H.; Li, M.; Wang, Y.; Wu, F. Determination of Narrow Coal Pillar Width and Roadway Surrounding Rock Support Technology in Gob Driving Roadway. Sustainability 2022, 14, 4848. [Google Scholar] [CrossRef]

- Xu, Y.; Pan, K.; Zhang, H. Investigation of key techniques on floor roadway support under the impacts of superimposed mining: Theoretical analysis and field study. Environ. Earth Sci. 2019, 78, 436. [Google Scholar] [CrossRef]

- Wang, B.; Dang, F.; Gu, S.; Huang, R.; Miao, Y.; Chao, W. Method for determining the width of protective coal pillar in the pre-driven longwall recovery room considering main roof failure form. Int. J. Rock Mech. Min. Sci. 2020, 130, 104340. [Google Scholar] [CrossRef]

- Ghasemi, E.; Shahriar, K. A new coal pillars design method in order to enhance safety of the retreat mining in room and pillar mines. Saf. Sci. 2012, 50, 579–585. [Google Scholar] [CrossRef]

- Wei, G. Study on the width of the non-elastic zone in inclined coal pillar for strip mining. Int. J. Rock Mech. Min. Sci. 2014, 72, 304–310. [Google Scholar] [CrossRef]

- Yin, S.; Zheng, X.; Wang, E.; Kang, Q.; Zhang, X. Non-uniform failure and differential pressure relief technology of roadway under irregular goafs in deep close-distance coal seams. Sci. Rep. 2023, 13, 18527. [Google Scholar] [CrossRef]

- Yin, S.; Zuo, A.; Ma, L.; Ren, Y.; Shi, S. Study on surrounding rock stability of gob-side entry driving with narrow coal pillar in medium thick coal seam. Coal Eng. 2022, 54, 90–96. [Google Scholar]

- Wang, E.; Yin, S.; Zhao, Q.; Kang, Q.; Zheng, X. Control Effect Analysis and Engineering Application of Anchor Cable Beam-Truss Structure on Large-Deformation Roadway in Deep Coal Mine. Shock Vib. 2024, 2024, 2987574. [Google Scholar] [CrossRef]

- Zhao, W.; Long, G.; Li, J. Analysis of stress distribution law of surrounding rock of rectangular roadway with different specifications based on complex variable function. Conserv. Util. Miner. Resour. 2024, 44, 111–123. [Google Scholar] [CrossRef]

- Wang, E.; Yin, S.; Kang, Q.; Zhao, X.; Lan, Q.; Sheng, H.; Liang, H. Coupling control technology of anchoring and unloading in deep intense-mining and large-deformation roadway: A case study. Sci. Rep. 2024, 14, 12075. [Google Scholar] [CrossRef]

- Sha, X.; Chen, C.; Li, J. Numerical simulation of the impact of geostress on the stability and rockburst susceptibility of large cross–section roadways at julong copper mine. Conserv. Util. Miner. Resour. 2024, 44, 52–57. [Google Scholar] [CrossRef]

- Li, P.; Jiang, G.; Li, H. Study on failure characteristics and control technology of surrounding rock in deep soft rock roadway of a coal mine. Conserv. Util. Miner. Resour. 2024, 44, 58–64. [Google Scholar] [CrossRef]

| Rock Formation | Bulk Modulus (GPa) | Shear Modulus (GPa) | Internal Friction Angle (°) | Density (kg/m3) | Cohesion (MPa) | Tensile Strength (MPa) |

|---|---|---|---|---|---|---|

| Fine sandstone | 6.98 | 5.3 | 36 | 2590 | 3.4 | 2.5 |

| Siltstone | 7.11 | 6.3 | 25 | 2602 | 3.0 | 2.1 |

| No. 2 coal | 2.6 | 1.5 | 31 | 1400 | 0.8 | 0.4 |

| Carbonaceous mudstone | 7.5 | 6.3 | 29 | 2200 | 2.9 | 2.2 |

| Coal Pillar Width | Vertical Stress | Plastic Zone |

|---|---|---|

| 7 m | There is no high stress zone inside the coal pillar, resulting in poor load-bearing capacity and difficult maintenance of the roadway. | Relatively high damage to the surrounding rock, which is obviously insufficient to support the stability of the roadway. |

| 8 m | At this point, the roadway possesses strong control capabilities, facilitating the stabilization of the surrounding rock. | There are areas inside the coal pillar that have not been damaged, and the coal pillar may be stable. |

| 9~10 m | This results in stress concentration within the coal pillar, which is detrimental to the management of the roadway’s surrounding rock. | While a wider coal pillar might make the road safer, it would waste coal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, S.; Zhao, X.; Wang, E.; Yan, Y.; Han, K.; Ma, J.; Wang, Y. Reasonable Coal Pillar Width and Control Technology for Gob-Side Entry Driving in Deep Irregular Working Face. Processes 2025, 13, 127. https://doi.org/10.3390/pr13010127

Yin S, Zhao X, Wang E, Yan Y, Han K, Ma J, Wang Y. Reasonable Coal Pillar Width and Control Technology for Gob-Side Entry Driving in Deep Irregular Working Face. Processes. 2025; 13(1):127. https://doi.org/10.3390/pr13010127

Chicago/Turabian StyleYin, Shuaifeng, Xubo Zhao, En Wang, Yitao Yan, Kanglei Han, Jun Ma, and Yibo Wang. 2025. "Reasonable Coal Pillar Width and Control Technology for Gob-Side Entry Driving in Deep Irregular Working Face" Processes 13, no. 1: 127. https://doi.org/10.3390/pr13010127

APA StyleYin, S., Zhao, X., Wang, E., Yan, Y., Han, K., Ma, J., & Wang, Y. (2025). Reasonable Coal Pillar Width and Control Technology for Gob-Side Entry Driving in Deep Irregular Working Face. Processes, 13(1), 127. https://doi.org/10.3390/pr13010127