Dilation Potential Analysis of Low-Permeability Sandstone Reservoir under Water Injection in the West Oilfield of the South China Sea

Abstract

1. Introduction

2. Experimental Material and Scheme

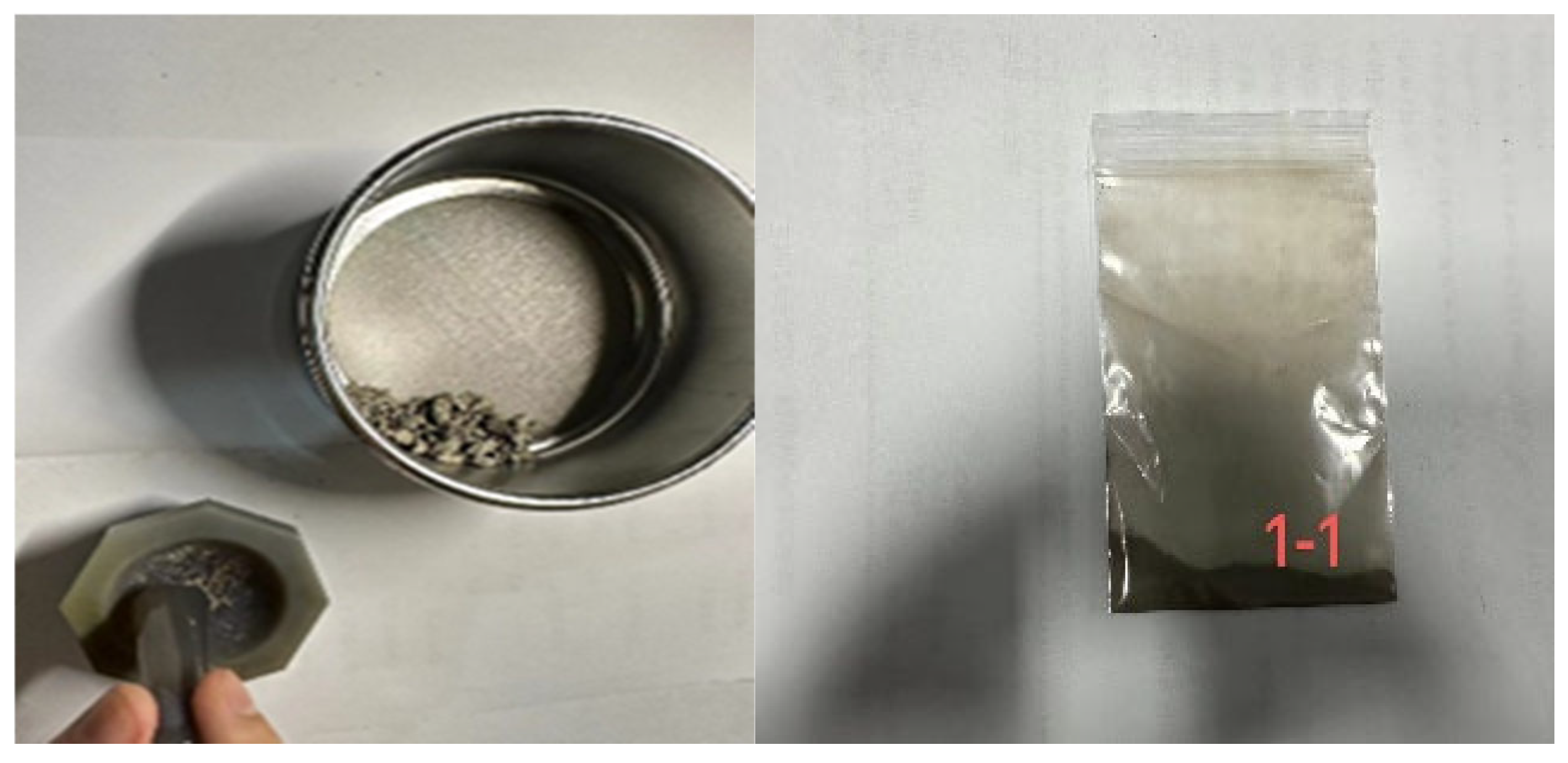

2.1. X-ray Diffraction Experiment

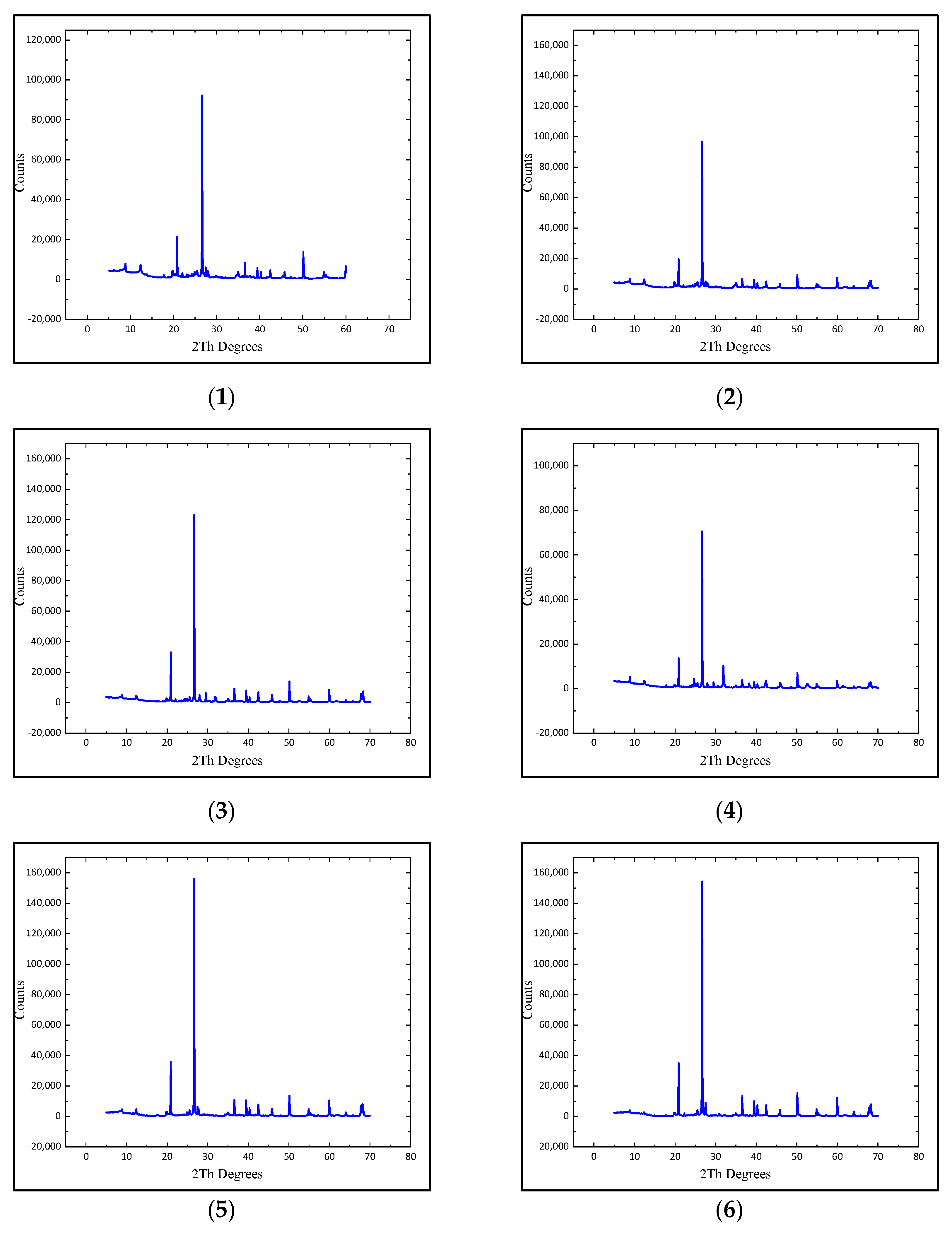

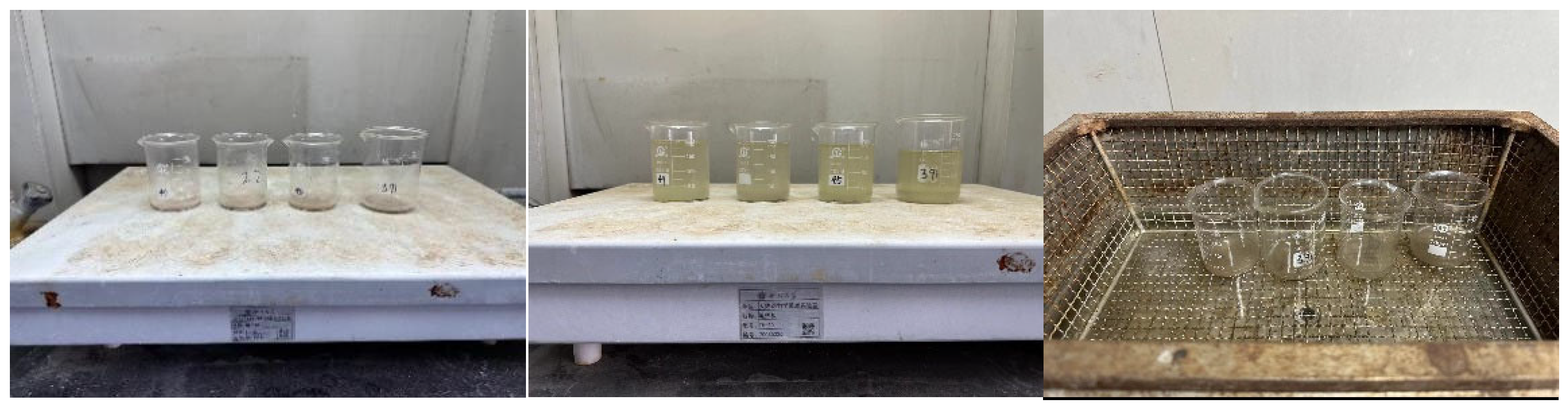

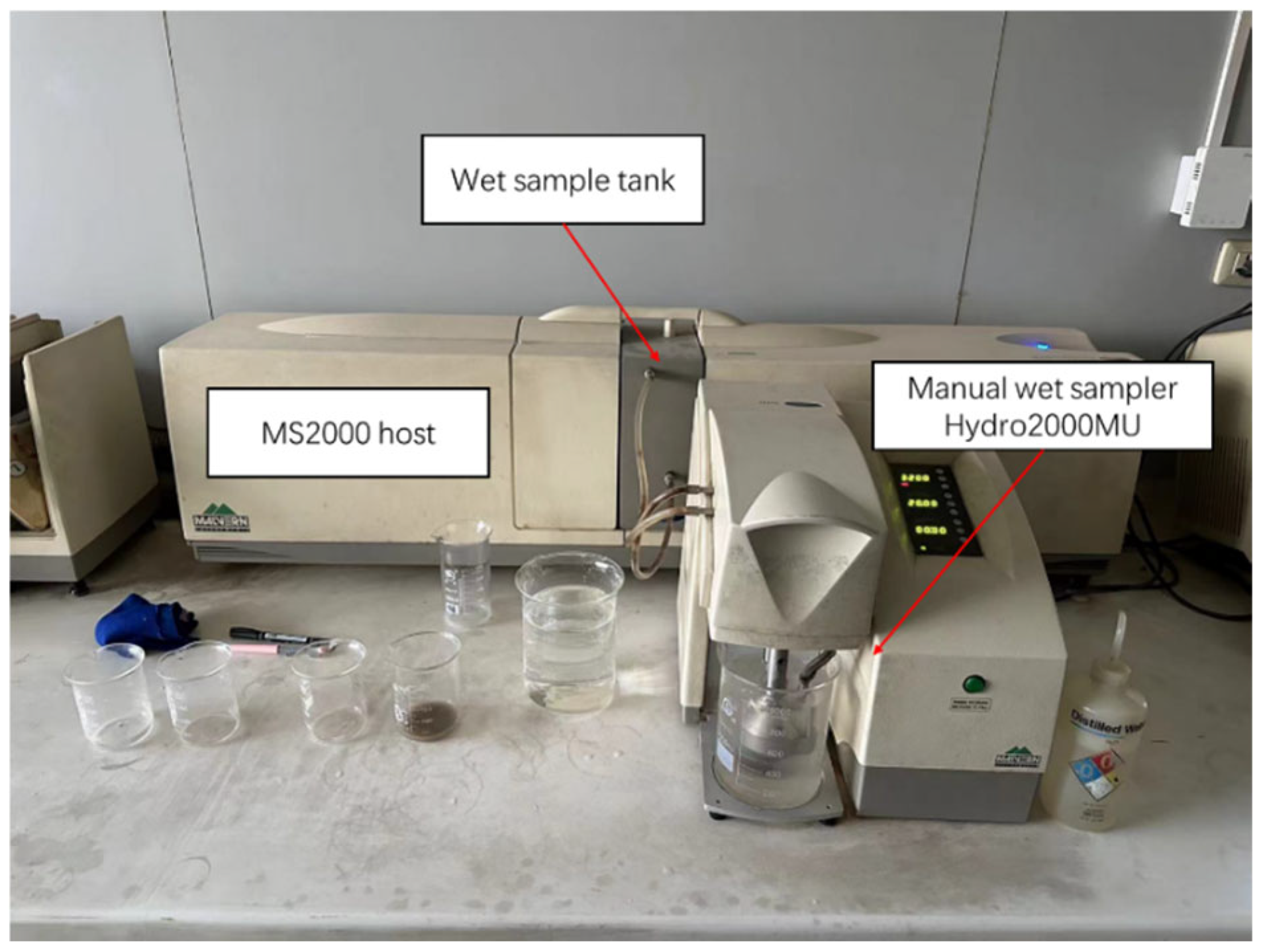

2.2. Laser Particle Size Analysis

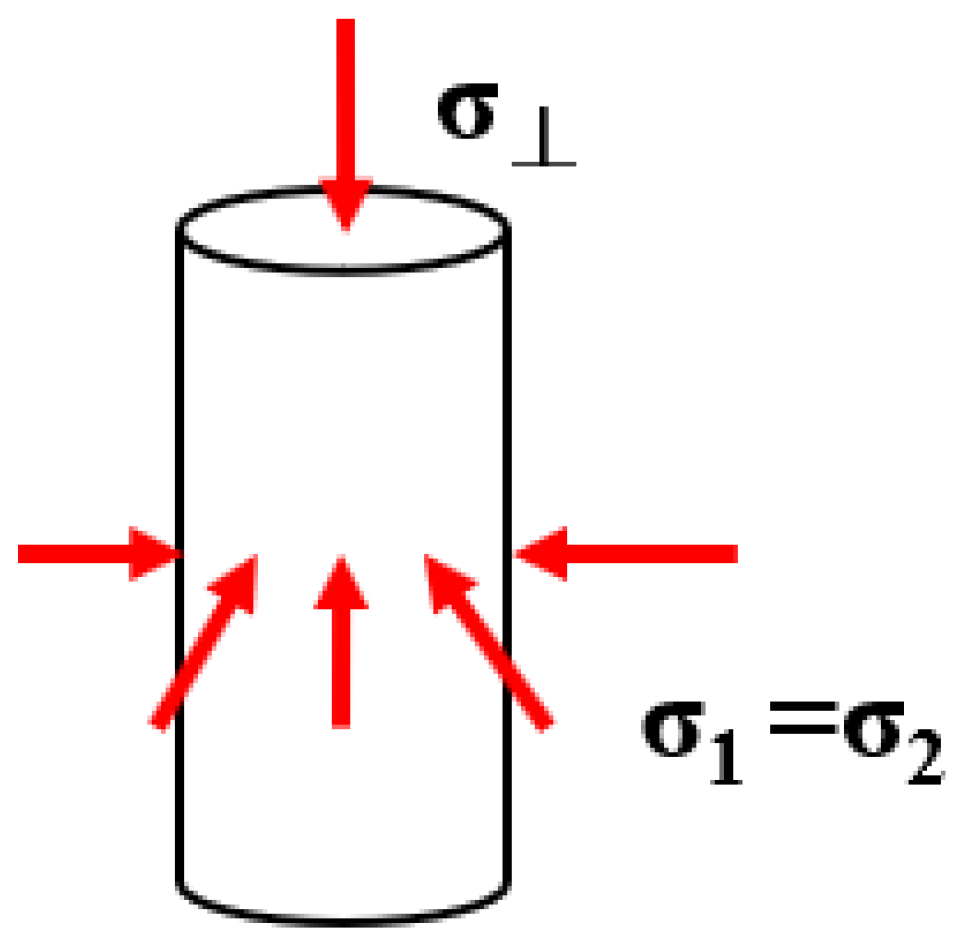

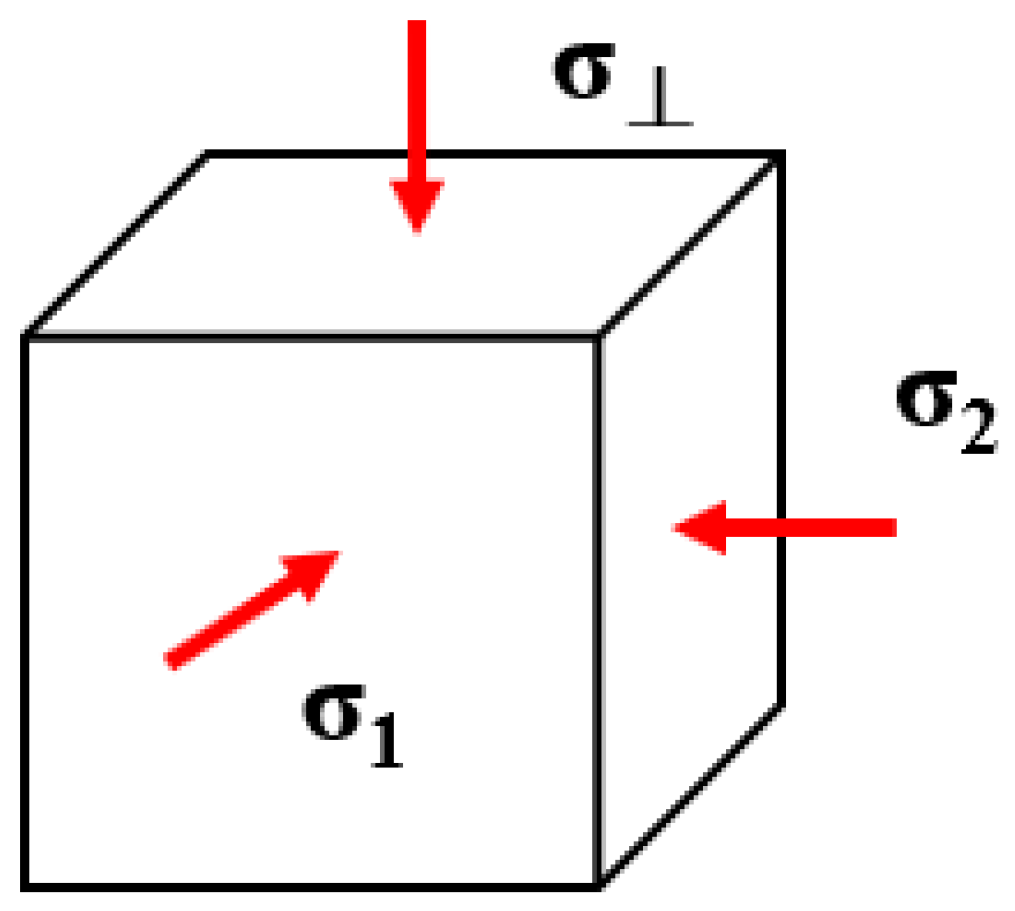

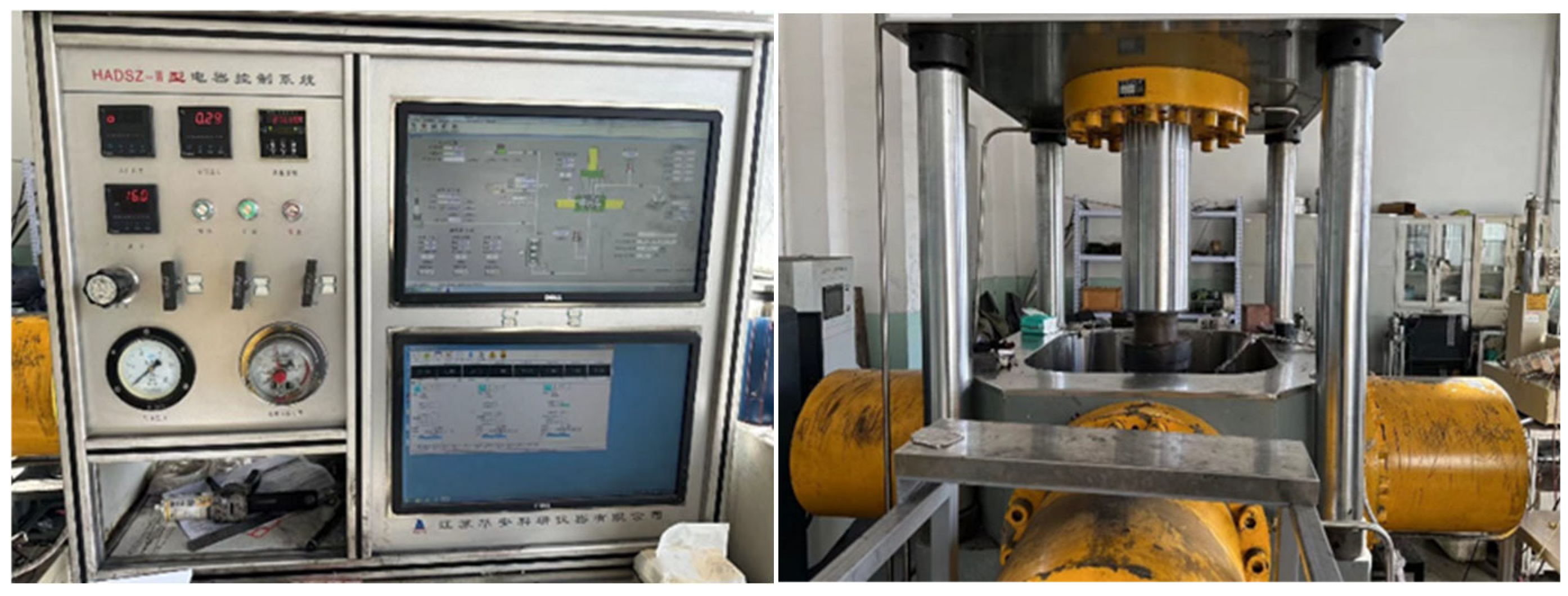

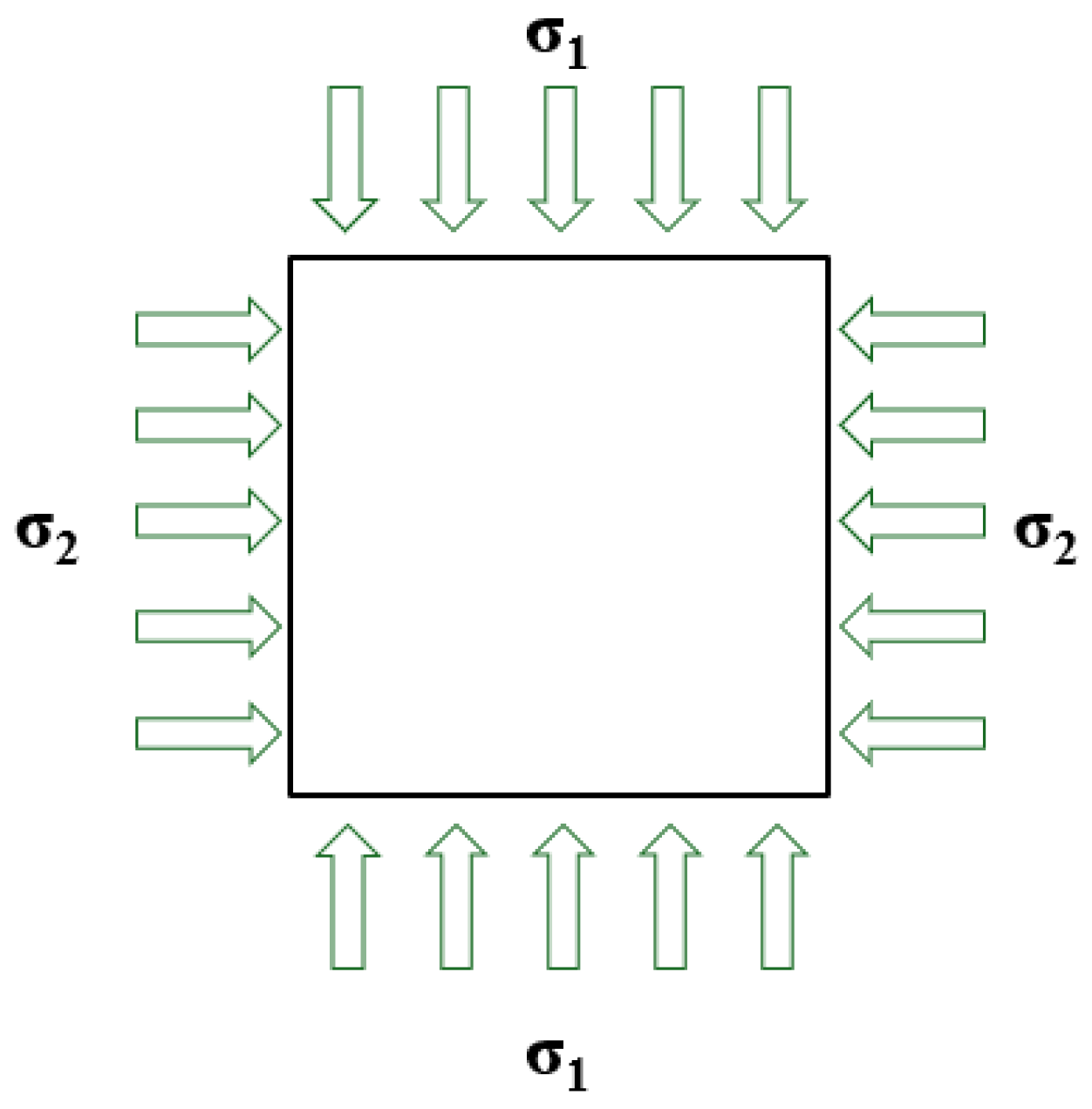

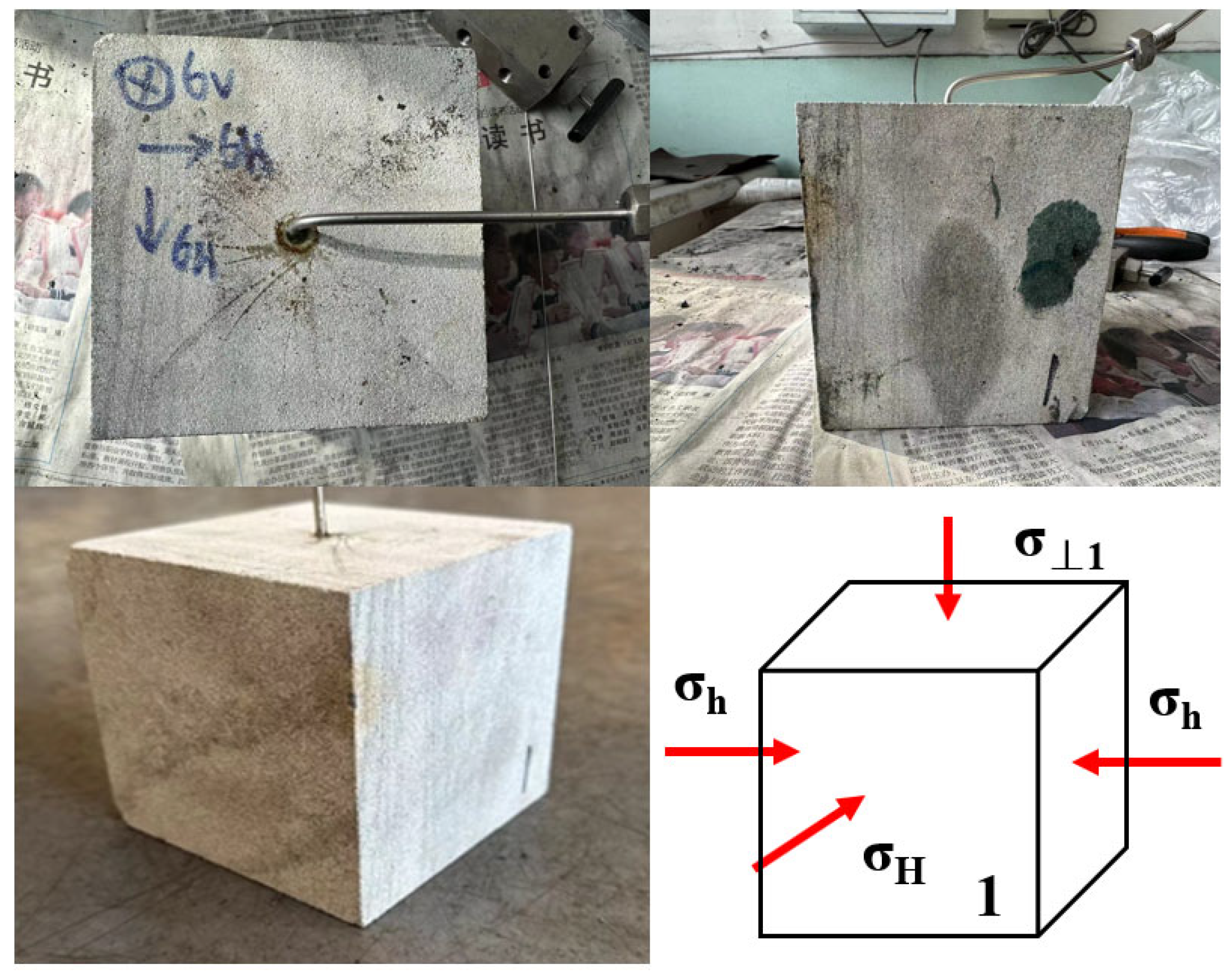

2.3. Physical Simulation Experiment of Water Injection Dilation in True Triaxial Rock Mechanics

3. Results

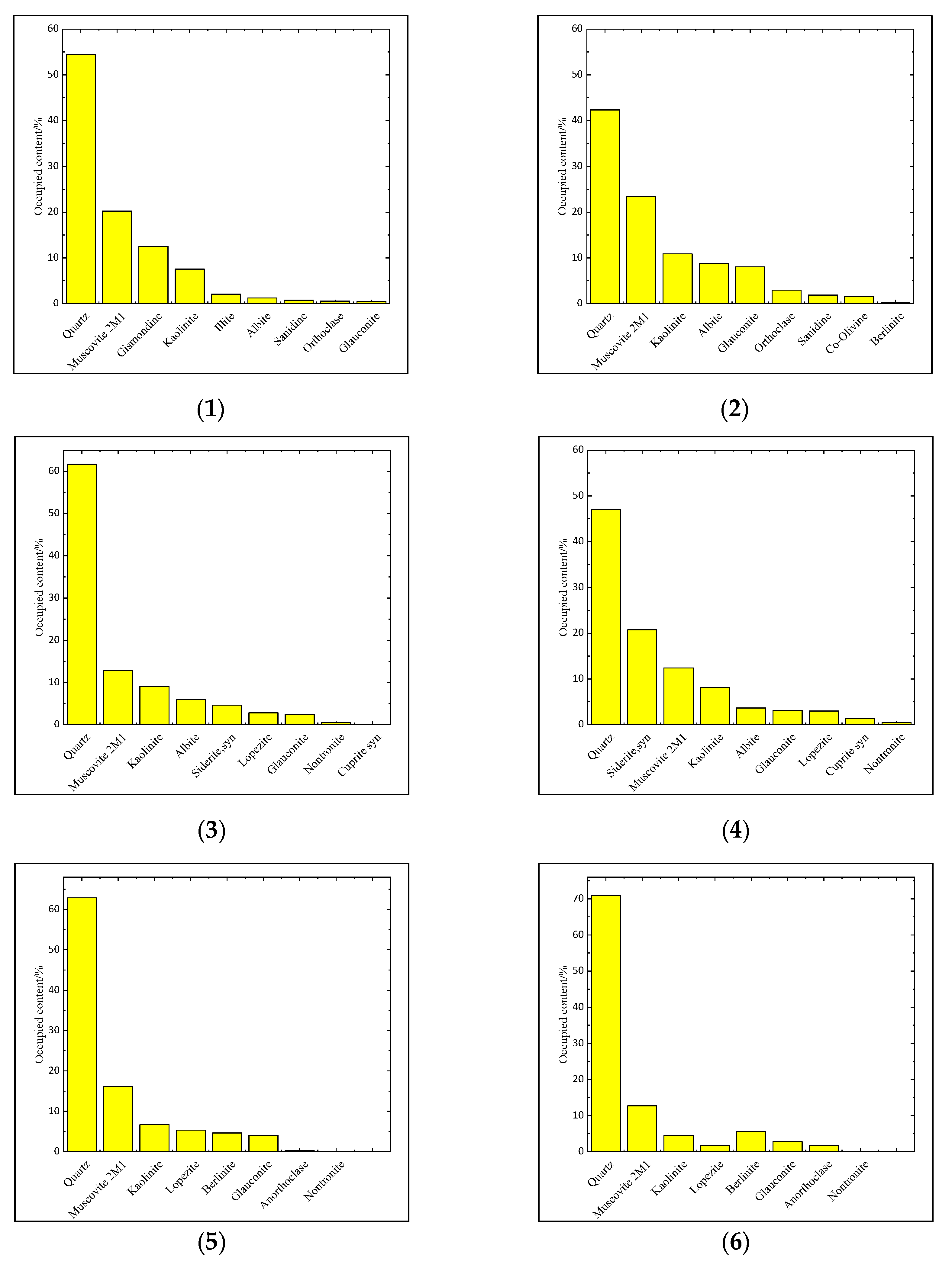

3.1. X-ray Diffraction Experiment

3.2. Laser Particle Size Analysis Results

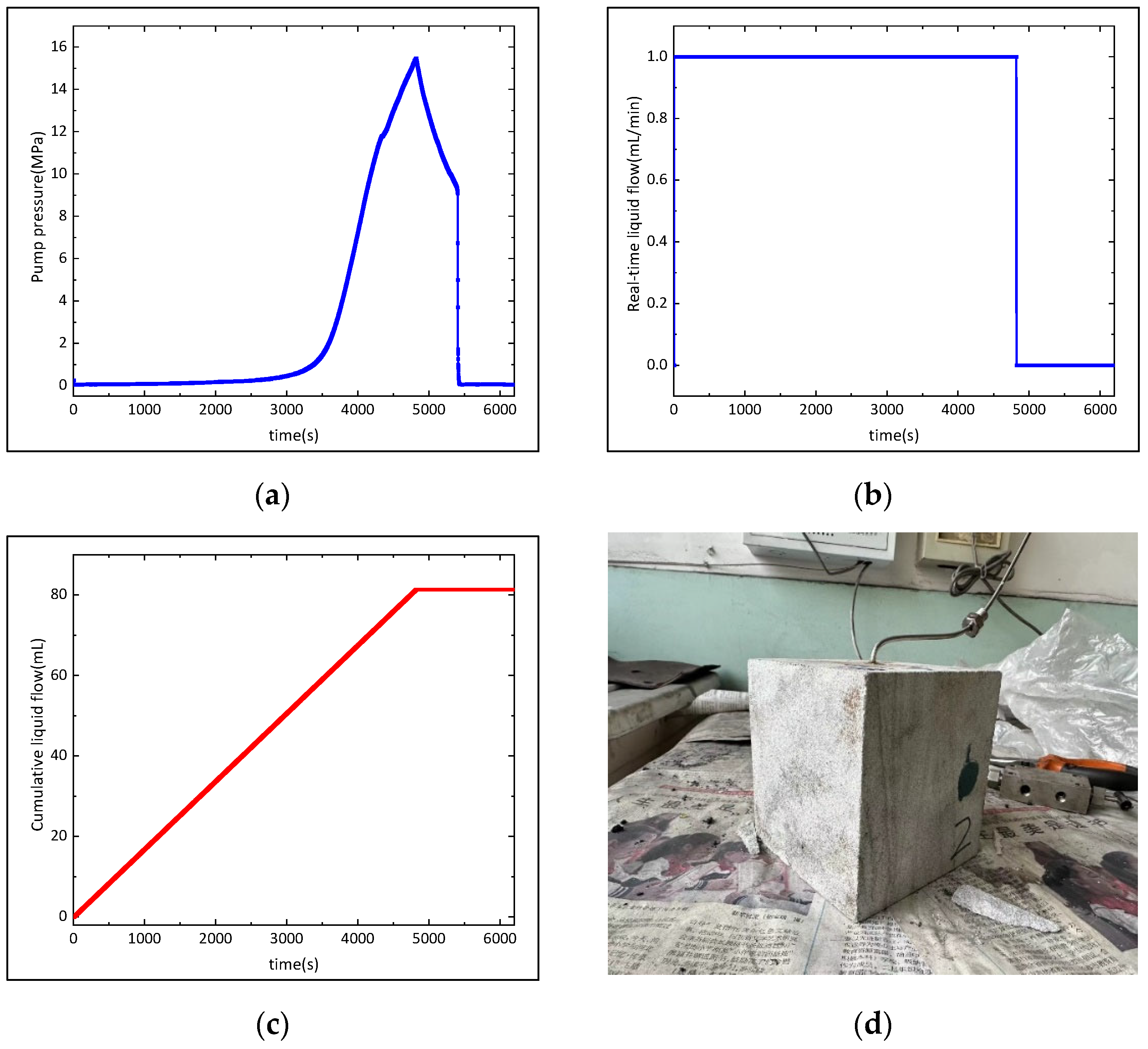

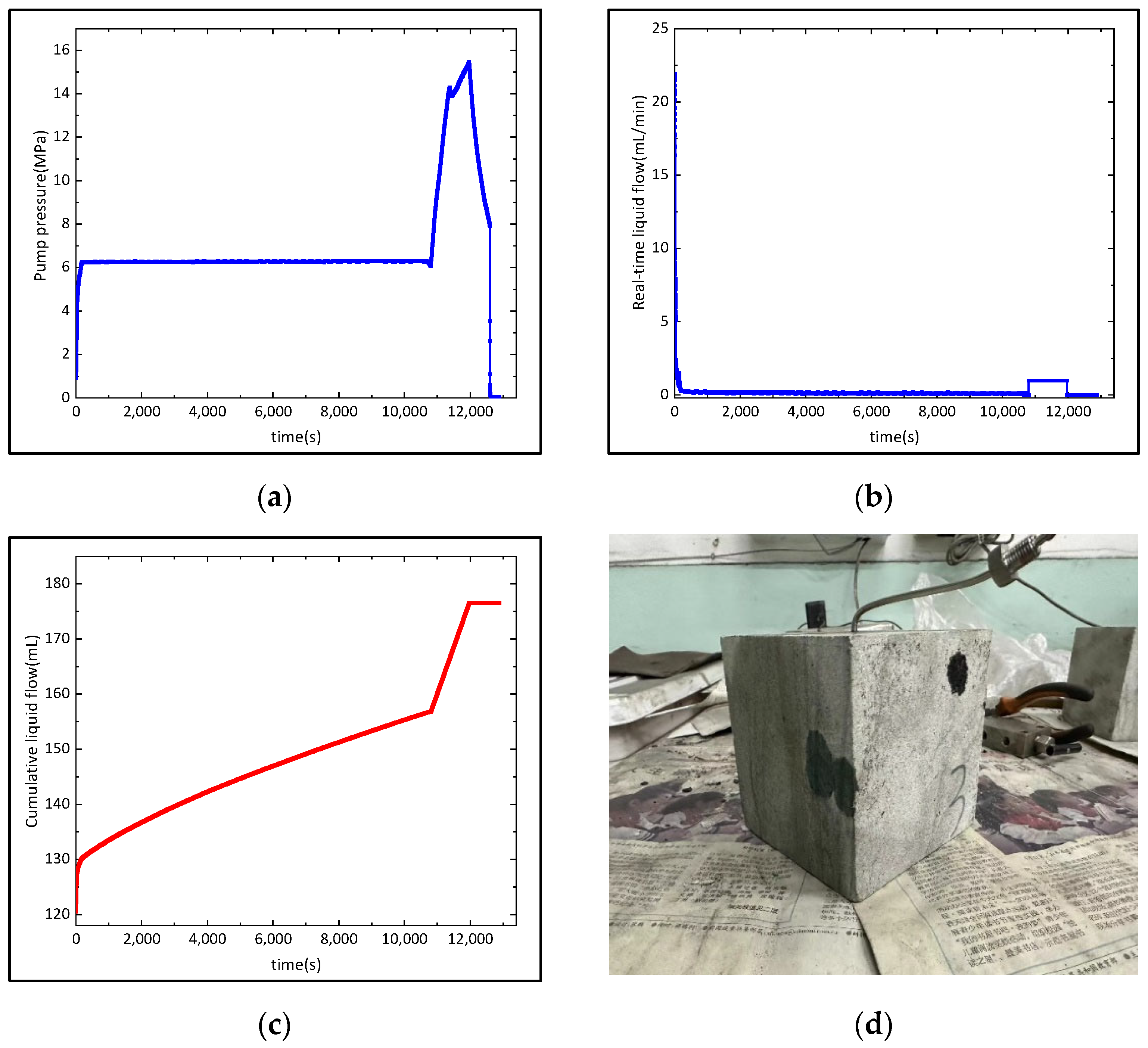

3.3. Physical Simulation Experiment of Water Injection Dilation in True Triaxial Rock Mechanics

4. Feasibility Analysis of Water Injection Dilation

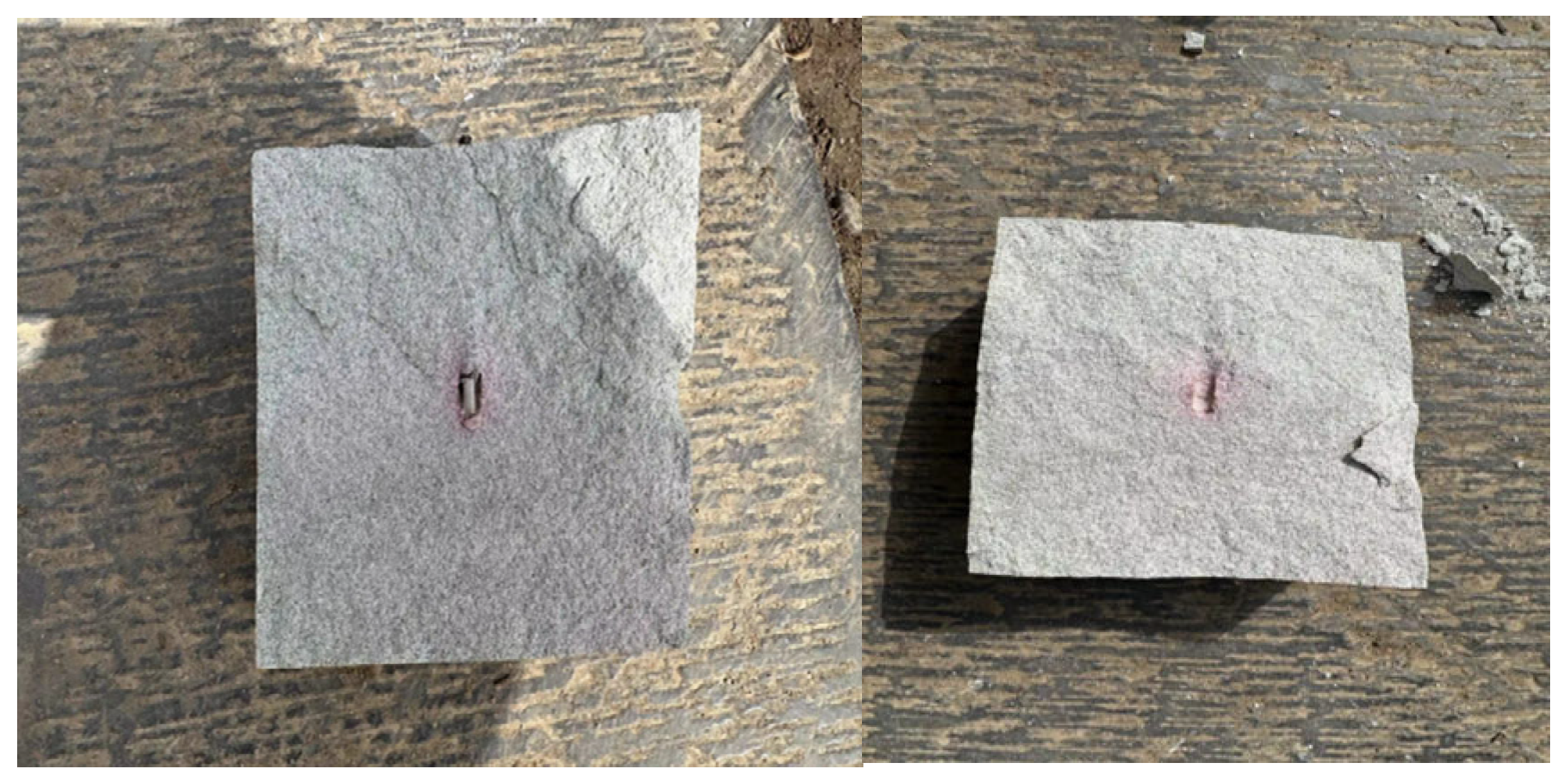

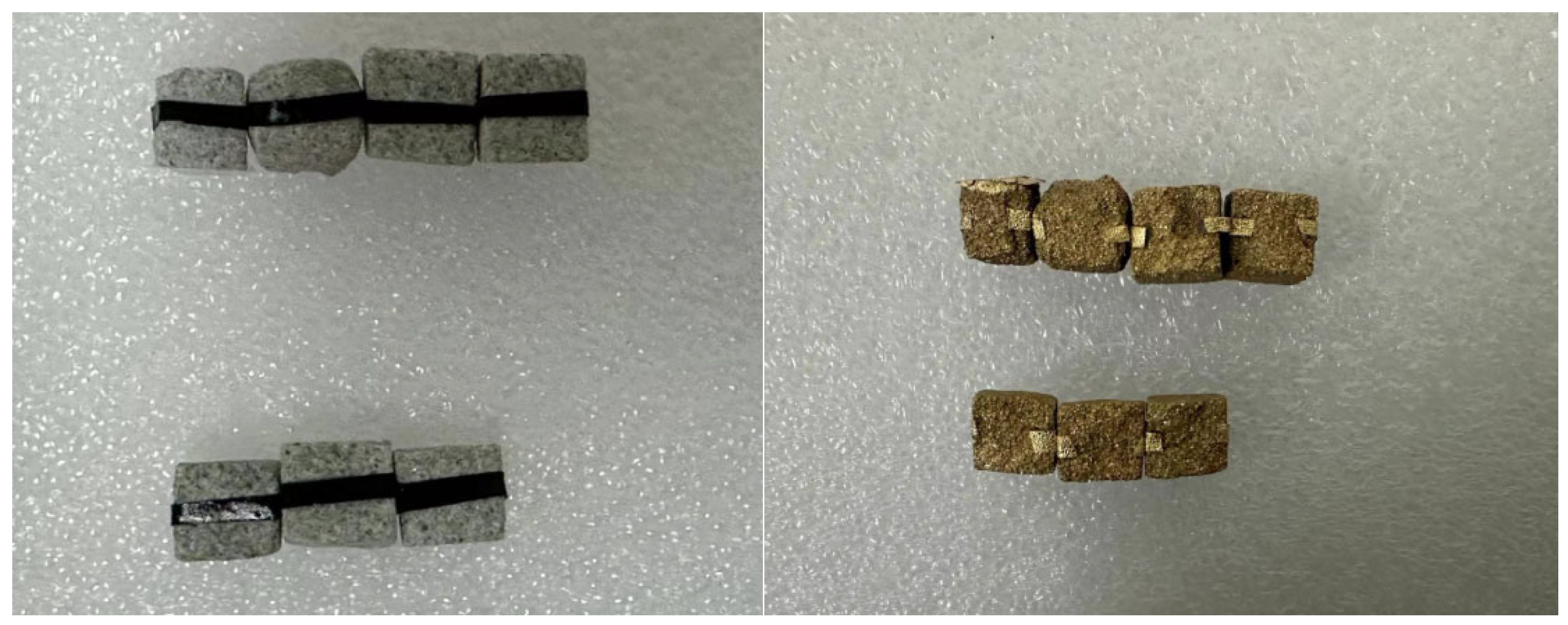

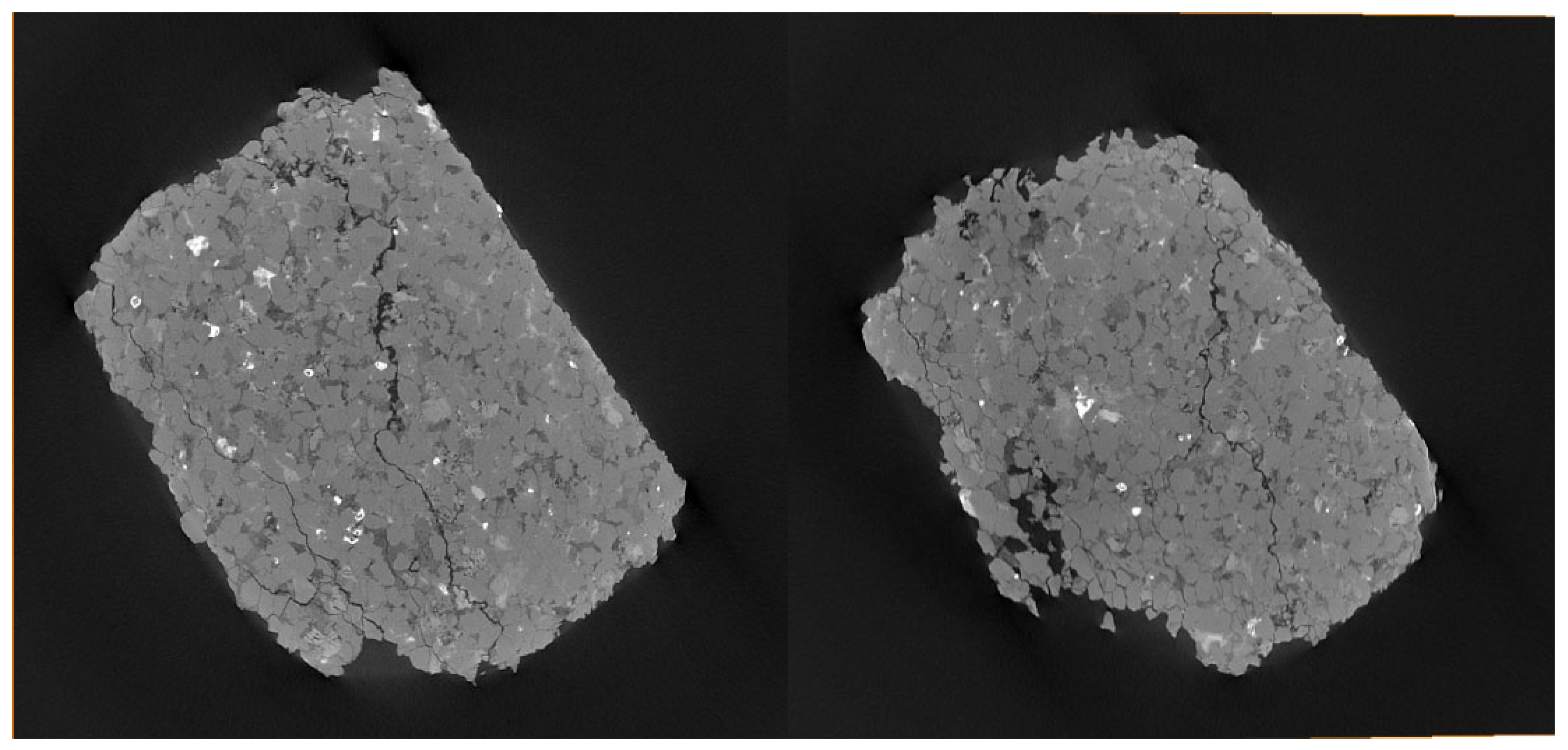

4.1. Surface Analysis of Samples

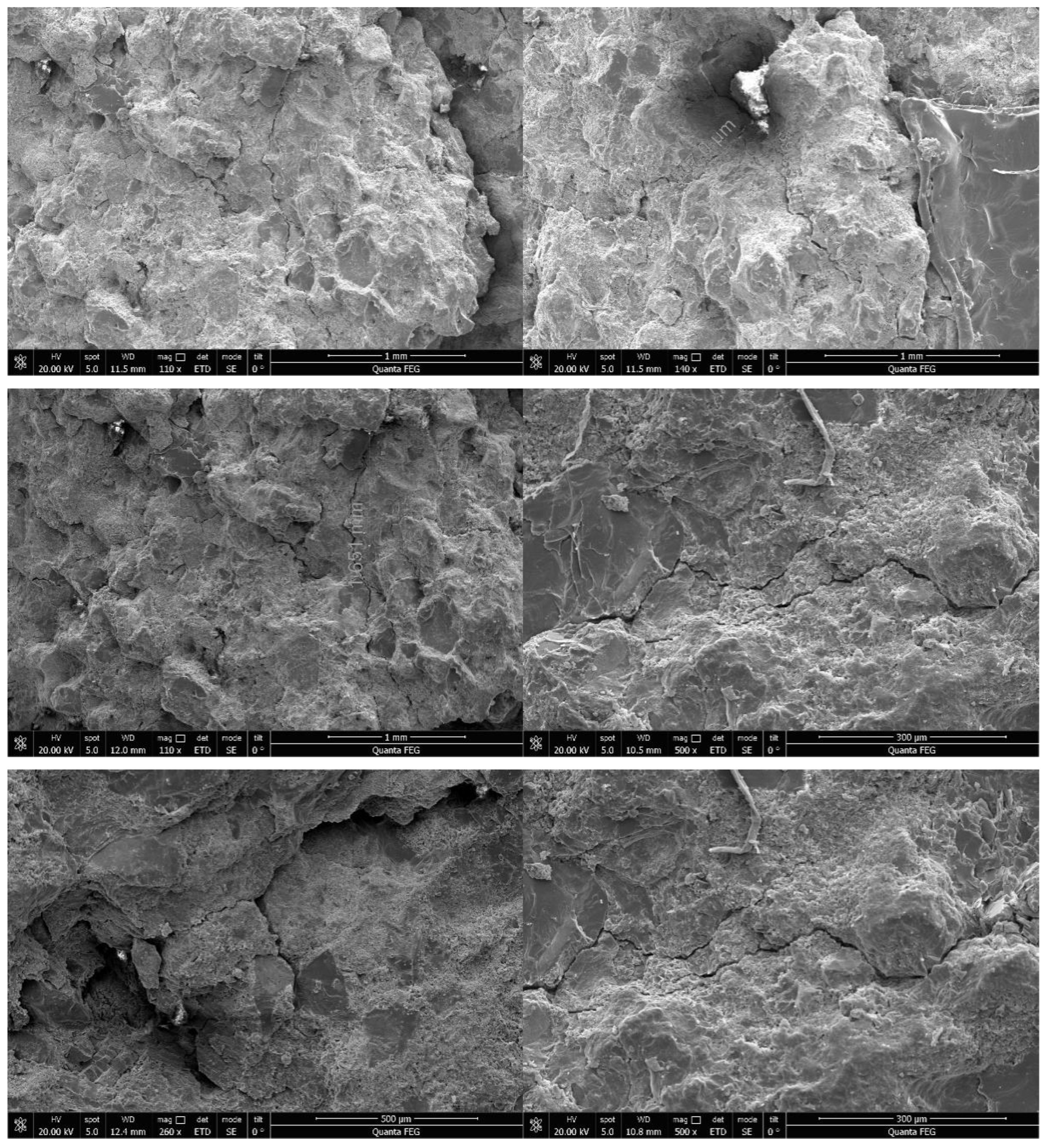

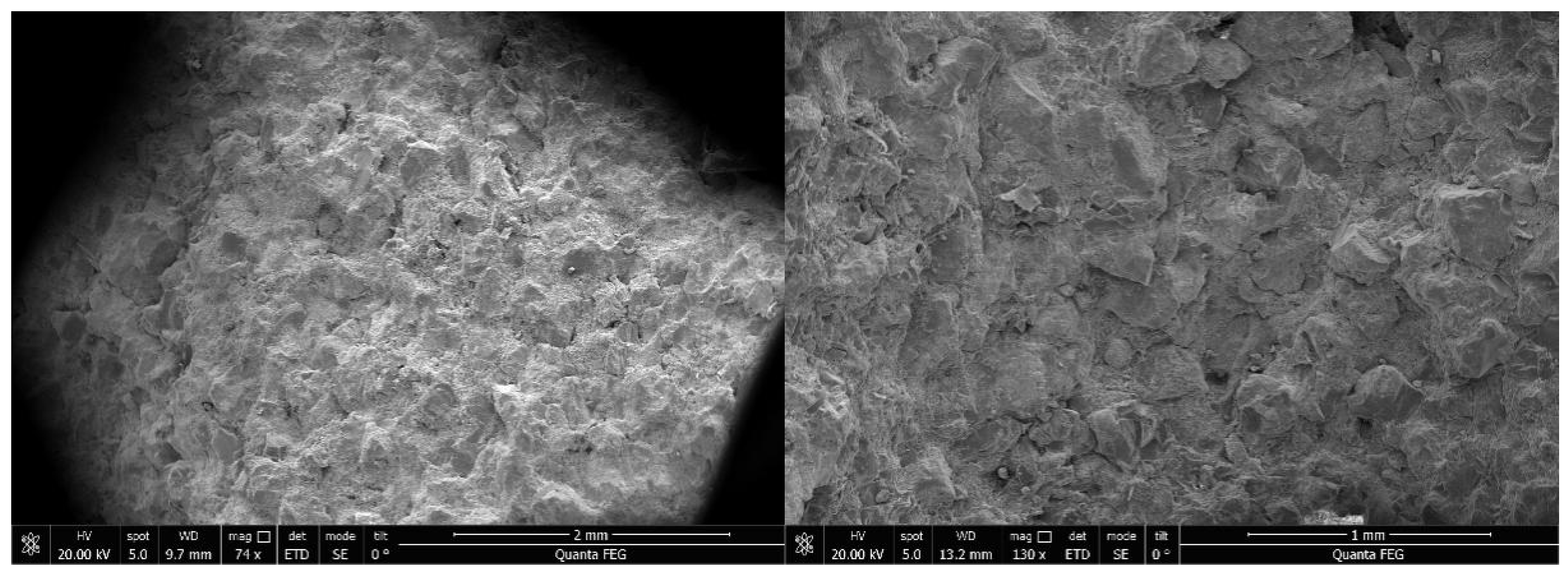

4.2. SEM Analysis of Samples

4.3. Three-Dimensional X-ray Microscope Analysis of Samples

5. Conclusions

- (1)

- The XRD experiments showed that the minerals in the target reservoir section were mainly quartz and muscovite, and the content was more than 80%. The quartz particles were mostly angular, strongly hydrophilic, and had high dilatation potential. The brittleness analysis of the six groups of samples showed that their brittleness was above 0.65, and the average brittleness was 0.82. Previous scholars have found that the higher the content of brittle minerals in tight sandstone, the higher the brittleness, the easier it is to form fracture zones, and the more favorable the formation of complex fracture zones in water injection dilation development.

- (2)

- The laser particle size analysis experiment showed that the particle size of the target reservoir was mainly between 10 μm and 100 μm, and it could be classified as coarse silt according to the particle size division. According to Folk and Ward, the normal distribution standard deviation was used to judge the sorting grade of the target reservoir, which was found to be suitable for the development of an offshore target reservoir by the water injection dilation technology.

- (3)

- The true triaxial rock mechanics physical simulation experiment of water injection and dilatation showed that there were red areas (dilatation spread areas) on the surface of the sample after water injection, and no obvious cracks appeared in the sample. Electron microscope scans of the red zone of the rock cross-section and different water injection blocks after the test found that there were evident cracks in the block from near the wellbore but no cracks in the block far from the wellbore. At the same time, the 3D X-ray microscope and scanning results confirmed each other, where the more obvious the red area, the greater the fracture probability, while the principal wellbore (no red area) had almost no obvious fracture zone.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Correction Statement

Abbreviations

| Variable Symbol | Variable Notes | Unites |

| B | Sample brittleness index | - |

| ϕ5 | 5% volume fraction | % |

| ϕ16 | 16% volume fraction | % |

| ϕ84 | 84% volume fraction | % |

| ϕ95 | 95% volume fraction | % |

| σ | Standard deviation | - |

| σ⊥ | vertical principal stress | MPa |

| σ⊥1 | Sample 1 vertical principal stress | Mpa |

| σ1 | Maximum horizontal principal stress | MPa |

| σ2 | Minimum horizontal principal stress | MPa |

| σCm | proportion of clay mineral | % |

| σH | Sample 1 maximum horizontal principal stress | MPa |

| σh | Sample 1 minimum horizontal principal stress | MPa |

| σQ | Proportion of quartz | % |

References

- Shentu, J.; Lin, B.; Lu, J. Research on risk assessment and prevention methods of shallow water flow hazards in deep-water and shallow areas. Pet. Sci. Bull. 2021, 3, 451–464. [Google Scholar]

- Liu, W.H.; Yi, F.; Zhao, X.; He, R.; Li, C.; Liu, Y. Plugging removal and injection enhancement technology for the water injection wells in Bohai oilfield. Oil Drill. Prod. Technol. 2004, 26, 53–56. [Google Scholar]

- Huang, R.Z. Initiation and dilation of hydraulic fracturing. Pet. Explor. Dev. 1982, 8, 65–77. [Google Scholar]

- Samieh, A.M.; Wong, R.C.K. Modelling the Responses of Athabasca Oil Sand in Triaxial Compression Tests at Low Pressure. Can. Geotech. J. 1998, 35, 395–406. [Google Scholar] [CrossRef]

- Wong, R.C.K. Strain-Induced Anisotropy in Fabric and Hydraulic Parameters of Oil Sand in Triaxial Compression. Can. Geotech. J. 2003, 40, 489–500. [Google Scholar] [CrossRef]

- Yuan, Y.; Yang, B.; Xu, B. Fracturing in the oil sand reservoirs. In Proceedings of the Canadian Unconventional Resources Conference, Calgary, AB, Canada, 15–17 November 2011. SPE-149308-MS. [Google Scholar] [CrossRef]

- Yuan, Y.; Xu, B.; Yang, B. Geomechanics for the thermal stimulation of heavy oil reservoirs. In Proceedings of the SPE Heavy Oil Conference and Exhibition, Kuwait City, Kuwait, 12–14 December 2011. SPE 150293 2011. [Google Scholar]

- Wong, R.C.K.; Barr, W.E.; Kry, P.R. Stress-Strain Response of Cold Lake Oil Sand. Can. Geotech. J. 1993, 30, 220–235. [Google Scholar] [CrossRef]

- ASTM D7181-11; Method for Consolidated Drained Triaxial Compression Test for Soils. ASTM International: West Conshohocken, PA, USA, 2003. [CrossRef]

- ASTM D7012-14e1; Standard Test Methods for Compressive Strength and Elastic Moduli of Intact Rock Core Specimens under Varying States of Stress and Temperatures. ASTM International: West Conshohocken, PA, USA, 2014.

- Xu, B.; Yuan, Y.; Wong, R.C.K. Modeling of the hydraulic fractures in unconsolidated oilsands reservoirs. In Proceedings of the 44th US Rock Mechanics Symposium and 5th U.S.—Canada Rock Mechanics Symposium, Salt Lake City, UT, USA, 27–30 June 2010. [Google Scholar]

- Xu, B.; Wong, R.C.K. Coupled finite-element simulation of injection well testing in unconsolidated oil sands reservoir. Int. J. Numer. Anal. Methods Geomech. 2013, 37, 3131–3149. [Google Scholar] [CrossRef]

- Xu, B.; Dou, S.; Zhang, J.; Chen, S. Consideration of geomechanics for in-situ bitu-men recovery in Xinjiang, China. In Proceedings of the SPE Heavy Oil Conferenc—Canada, Calgary, AB, Canada, 11–13 June 2013. SPE 165414. [Google Scholar]

- Ulusay, R. The ISRM Suggested Methods for Rock Characterization, Testing and Monitoring: 2007–2014; Springer: Cham, Switzerland, 2015. [Google Scholar]

- Duncan, J.M.; Chang, C.Y. Nonlinear Analysis of Stress and Strain in Soils. J. Soil Mech. ASCE 1970, 96, 1629–1653. [Google Scholar] [CrossRef]

- Rowe, P.W. The Stress-Dilatancy Relation for Static Equilibrium of an Assembly of Particles in Contact. Proc. R. Soc. A Math. Phys. Eng. Sci. 1962, 269, 1339. [Google Scholar]

- Bolton, M.D. The strength and dilatancy of sands. Geotechnique 1986, 36, 65–78. [Google Scholar] [CrossRef]

- Lin, B.T.; Chen, S.; Pan, J.J.; Jin, Y.; Zhang, L.; Huiwen, P. Experimental study on dilation mechanism of micro-fracturing in continental ultra-heavy oil sand reservoir, Fengcheng Oilfield. Oil Drill. Prod. Technol. 2016, 38, 359–364. [Google Scholar]

- Lin, B.T.; Jin, Y.; Chen, S.; You, H.; Huang, Y. Prediction on the reservoir dilatation results by squeeze preprocessing in SAGD wells. Oil Drill. Prod. Technol. 2018, 40, 341–347. [Google Scholar]

- Lin, B.T.; Jin, Y. Evaluation of the Influencing Factors of Dilatancy Effects by Squeezing Liquids in SAGD Wells in the Fengcheng Oilfield of Xinjiang Oilfield. Pet. Drill. Tech. 2018, 46, 71–76. [Google Scholar]

- Lin, B.T. Microfracturing mechanisms and techniques in unconsolidated sandstone formations. Pet. Sci. Bull. 2021, 6, 209–227. [Google Scholar]

- Wang, Q.Q.; Lin, B.T.; Jin, Y.; Chen, S.; Pan, J. Effects of SAGD well squeeze dilatation on the circulating preheating and production. Oil Drill. Prod. Technol. 2019, 41, 387–392. [Google Scholar]

- Ding, W.; Fan, T.; Huang, X.; Liu, C. Paleo-structural stress field simulation for middle-lower Ordovician in Tazhong area and favorable area prediction of fractured reservoirs. J. China Univ. Pet. (Ed. Nat. Sci.) 2010, 34, 1–6. [Google Scholar]

- Zhao, A.; Xie, B.; He, X.; Wu, Y. Well logging evaluation of the Lower Permian dolomite reservoir in central Sichuan Basin. Nat. Gas Explor. Dev. 2017, 40, 1–6. [Google Scholar]

- Zhu, X. Distribution laws of geomechanical parameters in Shihezi 1 Member, Fuxian block. Nat. Gas Explor. Dev. 2018, 41, 85–89. [Google Scholar]

- Zhang, A.; Zhang, Y.; Liu, X.; Zhang, P. Test study on water affected to physical mechanics performances of muddy siltstone. Coal Sci. Technol. 2015, 43, 67–71. [Google Scholar]

- Thomas, J. The birth of X-ray crystallography. Nature 2012, 491, 186–187. [Google Scholar] [CrossRef]

- Pan, F.; Wang, Y.H.; Chen, C. X-ray Diffraction Technology; Chemical Industry Press: Beijing, China, 2016. [Google Scholar]

- ASTM UOP905-20; Platinum Agglomeration by X-ray Diffraction. ASTM: West Conshohocken, PA, USA, 2020.

- Shu, X.; Wu, Y.; Cheng, J.; Xia, Y.; Zheng, Y. Masterizer 2000 laser particle size analyzer and its applications. J. Hefei Univ. Technol. 2007, 30, 164–166. [Google Scholar]

- Wang, W.; Li, Y.; Wang, Z.; Nie, Z.; Chen, B.; Yan, Z.; Yan, L.; Shao, C.; Lu, S. Evaluation of rock brittleness and analysis of related factors for tight sandstone reservoirs. China Pet. Explor. 2016, 21, 50–57. [Google Scholar]

- Diao, H. Rock mechanical properties and brittleness evaluation of shale reservoir. Acta Petrol. Sin. 2013, 29, 3300–3306. [Google Scholar]

- Jia, C. Foreland thrust-fold belt features and gas accumulation in Midwest China. Pet. Explor. Dev. 2005, 32, 9–15. [Google Scholar]

- He, Y.; Wang, W. Sedimentary Rocks and Sedimentary Phases; Petroleum Industry Press: Beijing, China, 2006; (In Chinese with English Abstract). [Google Scholar]

- Chen, Q.; Tang, W.; Xue, C.; Yang, Y.; Gao, W.; Yang, J.; Jia, J. The ϕ Value Expresses Granularity and the Unit Problem of the Sorting Coefficient. Acta Sedimentol. Sin. 2022, 1–16. [Google Scholar] [CrossRef]

- Trask, P.D. Mechanical analyses of sediments by centrifuge. Econ. Geol. 1930, 25, 581–599. [Google Scholar] [CrossRef]

- Inman, D.L. Measures for describing the size distribution of sediments. J. Sediment. Res. 1952, 22, 125–145. [Google Scholar]

- Folk, R.L.; Ward, W.C. Brazos river bar: A study in the significance of grain size parameters. J. Sediment. Res. 1957, 27, 3–26. [Google Scholar] [CrossRef]

- GB/T 12763.8; Specifications for Oceanographic Survey—Part 8: Marine Geology and Geophysics Survey. National Standards of People’s Republic of China: Beijing, China, 2008.

| Simulation Experiment Type | Pore Pressure Pretreatment | Fluid Property | Injection Type of Capacity Dilation |

|---|---|---|---|

| Pressure-controlled water injection capacity dilation 1 | Nothing | Hot water | Constant displacement |

| Pressure-controlled water injection capacity dilation 2 | Nothing | Hot water | Constant displacement |

| Pressure-controlled water injection capacity dilation 3 | Constant pressure for 3 h | Hot water | Constant displacement |

| Mineral Composition and Content/% | Sample 1 | Sample 2 | Sample 3 | Sample 4 | Sample 5 | Sample 6 | |

|---|---|---|---|---|---|---|---|

| Non-clay minerals | Quartz | 54.48 | 42.34 | 61.69 | 47.11 | 62.88 | 70.85 |

| Muscovite 2M1 | 20.28 | 23.43 | 12.82 | 12.40 | 16.17 | 12.70 | |

| Gismondine | 12.53 | ||||||

| Albite | 1.25 | 8.79 | 5.95 | 3.65 | |||

| Sanidine | 0.76 | 1.88 | |||||

| Siderite | 4.65 | 20.76 | |||||

| Orthoclase | 0.55 | 2.96 | |||||

| Co-olivine | 1.56 | ||||||

| Berlinite | 0.15 | 4.63 | 5.6 | ||||

| Lopezite | 2.81 | 3.00 | 5.35 | 1.72 | |||

| Cuprite syn | 0.11 | 1.32 | |||||

| Anorthoclase | 0.2 | 1.69 | |||||

| Total | 89.85 | 81.11 | 88.03 | 88.24 | 89.23 | 92.56 | |

| Clay minerals | Kaolinite | 7.62 | 10.87 | 9.03 | 8.16 | 6.67 | 4.53 |

| Illite | 2.06 | ||||||

| Glauconite | 0.47 | 8.02 | 2.46 | 3.14 | 4.04 | 2.79 | |

| Nontronite | 0.48 | 0.46 | 0.06 | 0.11 | |||

| Total | 10.15 | 18.89 | 11.97 | 11.76 | 10.77 | 7.43 | |

| Serial Number | ϕ5 (mm) | ϕ16 (mm) | ϕ84 (mm) | ϕ95 (mm) | σ1 | Sorting Grade |

|---|---|---|---|---|---|---|

| 1 | 0.00126 | 0.00288 | 0.07943 | 0.13804 | 0.04 | Excellent |

| 2 | 0.00191 | 0.00661 | 0.18197 | 0.41687 | 0.11 | Excellent |

| 3 | 0.00166 | 0.00501 | 0.11701 | 0.23988 | 0.06 | Excellent |

| 4 | 0.00145 | 0.00380 | 0.09120 | 0.18897 | 0.05 | Excellent |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, H.; Cao, Y.; Yu, J.; Ma, Y.; Gao, Y.; Wu, S.; Yuan, H.; Zou, M.; Li, D.; Yan, X.; et al. Dilation Potential Analysis of Low-Permeability Sandstone Reservoir under Water Injection in the West Oilfield of the South China Sea. Processes 2024, 12, 2015. https://doi.org/10.3390/pr12092015

Chen H, Cao Y, Yu J, Ma Y, Gao Y, Wu S, Yuan H, Zou M, Li D, Yan X, et al. Dilation Potential Analysis of Low-Permeability Sandstone Reservoir under Water Injection in the West Oilfield of the South China Sea. Processes. 2024; 12(9):2015. https://doi.org/10.3390/pr12092015

Chicago/Turabian StyleChen, Huan, Yanfeng Cao, Jifei Yu, Yingwen Ma, Yanfang Gao, Shaowei Wu, Hui Yuan, Minghua Zou, Dengke Li, Xinjiang Yan, and et al. 2024. "Dilation Potential Analysis of Low-Permeability Sandstone Reservoir under Water Injection in the West Oilfield of the South China Sea" Processes 12, no. 9: 2015. https://doi.org/10.3390/pr12092015

APA StyleChen, H., Cao, Y., Yu, J., Ma, Y., Gao, Y., Wu, S., Yuan, H., Zou, M., Li, D., Yan, X., & Peng, J. (2024). Dilation Potential Analysis of Low-Permeability Sandstone Reservoir under Water Injection in the West Oilfield of the South China Sea. Processes, 12(9), 2015. https://doi.org/10.3390/pr12092015