Probing Internal Damage in Grey Cast Iron Compression Based on Acoustic Emission and Particle Flow

Abstract

1. Introduction

2. Analysis Steps

2.1. Material Selection and Preparation

2.2. Compression Experiments and Acoustic Emission Detection

2.3. Metallographic Analysis

2.4. Discrete Meta-Analytical Models

3. Results and Discussion

3.1. Results of the Experiment

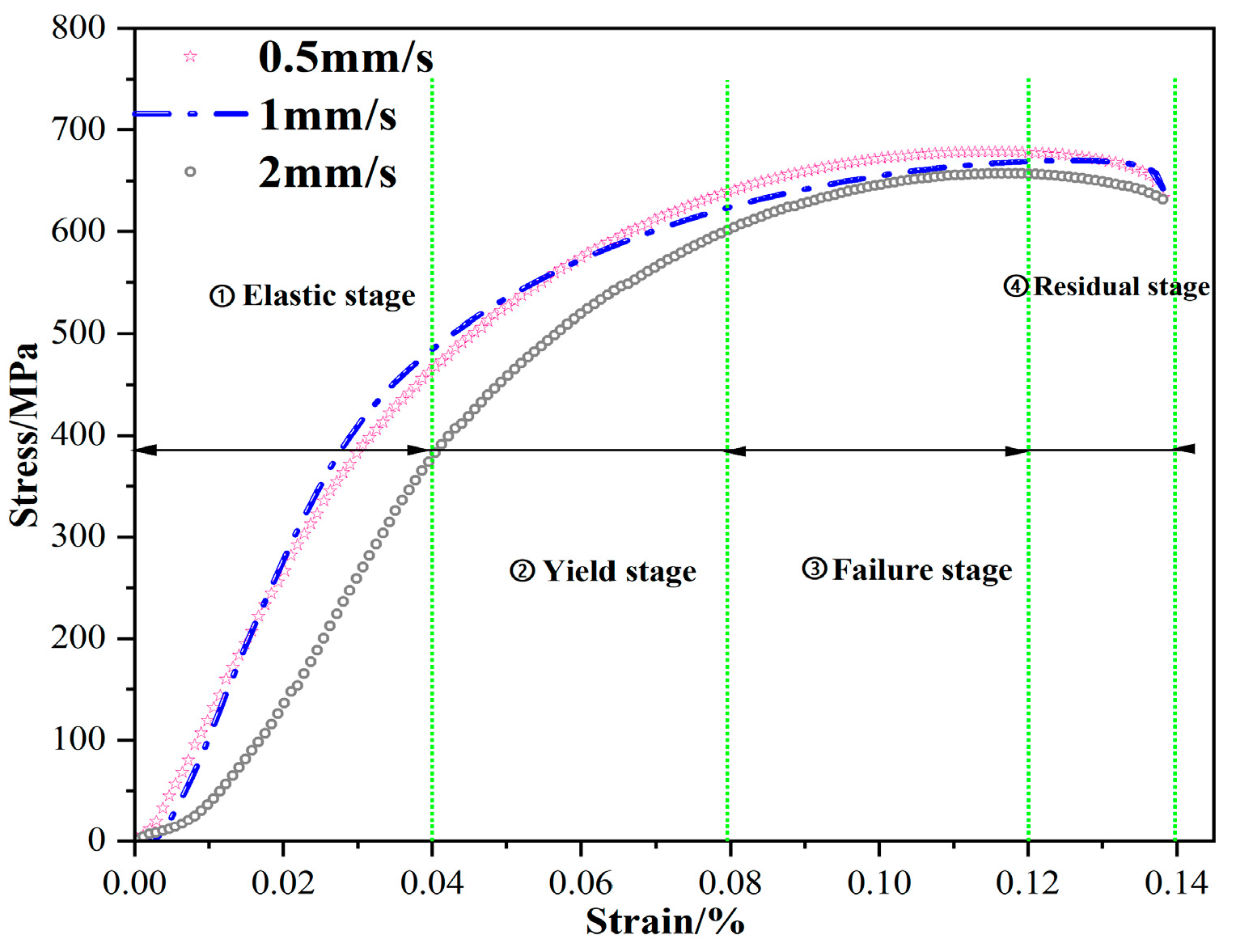

3.1.1. Engineering Stress–Strain Curve Analysis

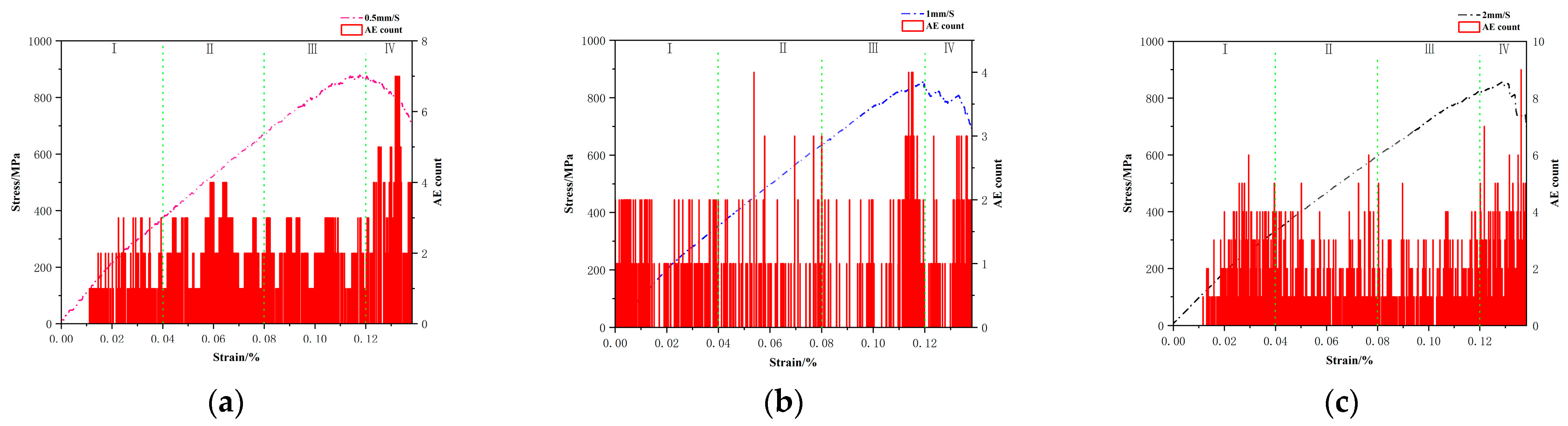

3.1.2. Damage Analysis of Cast Iron HT150 Based on Acoustic Emission Parameters

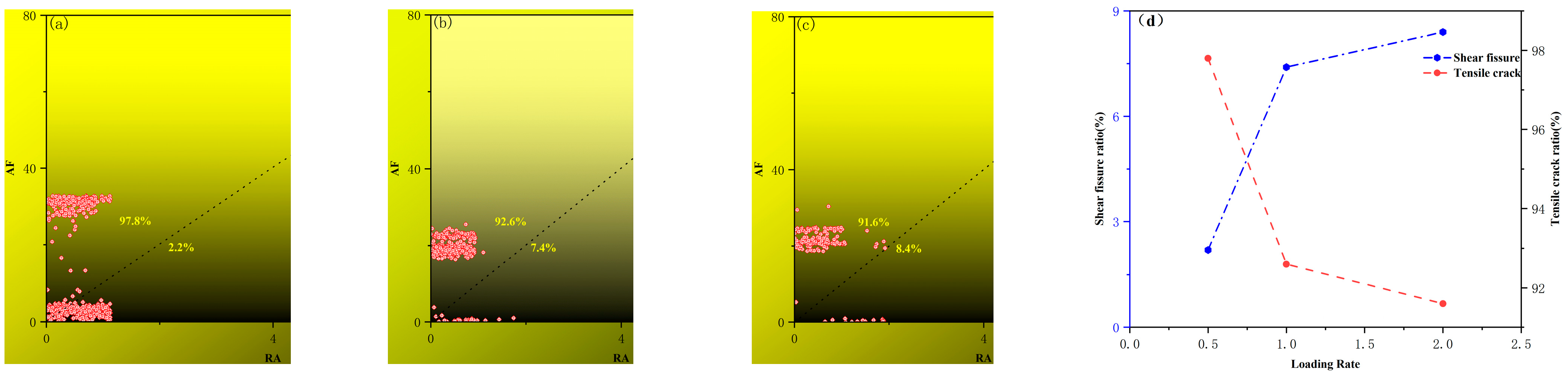

3.1.3. Failure of Pattern Recognition

3.2. Results of Discrete Element Analysis

3.2.1. Numerical Simulation of Stress Curves and Analysis of Damage Results

3.2.2. A Closer Look at Evolution

4. Conclusions

- With the increase in loading rate, the compressive strength of the specimen decreases, and the damage displays 45 degrees diagonal columnar splitting, mainly dominated by tensile damage.

- In the PFC2D simulation of the compression process, the acoustic emission increases before the stress peak and gradually decreases after reaching the maximum value, in agreement with the experimental data

- The uniaxial compressive stress–strain curves are divided into four stages, elastic, yield, damage, and residual, and the strong and weak force chains at different strains are analysed, and it is found that the strength of the force chain varies the most near the main crack line.

- The essence of cast iron deformation and failure lies in the dissipation and release of internal energy. Utilising acoustic emission energy to monitor the energy release law throughout the entire damage process is a reasonable approach. Data analysis has revealed that the trends in bonding energy monitored by the GBM align with the energy collected through acoustic emission, effectively capturing the variation in acoustic emission energy observed in experiments.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- König, T.; Kimpel, T.; Kürten, D.; Kailer, A.; Dienwiebel, M. Influence of atmospheres on the friction and wear of cast iron against chromium plated steel at high temperatures. Wear 2023, 522, 204695. [Google Scholar] [CrossRef]

- Gómez, T.; Cuesta, I.; Alegre, J. Mechanical Property Prediction Based on Casting Process Simulation for Structural Parts in the Wind Gearbox Sector. Int. J. Met. 2023, 17, 3032–3052. [Google Scholar] [CrossRef]

- Hamilton, J.D.; Sorondo, S.; Li, B.; Qin, H.; Rivero, I.V. Mechanical behavior of bimetallic stainless steel and gray cast iron repairs via directed energy deposition additive manufacturing. J. Manuf. Process. 2023, 85, 1197–1207. [Google Scholar] [CrossRef]

- Chaus, A.S.; Čaplovič, Ľ.; Pokrovskii, A.I.; Sobota, R. Microstructure and ProPerties evaluation of ductile cast iron subjected to Hot Plastic deforMation and aMbient teMPerature coMPression. Arch. Metall. Mater. 2023, 68, 639–647. [Google Scholar] [CrossRef]

- Fan, L.; Hu, H.; Tang, X.; He, J.; Chen, W. Influence of microscopic effects on the static tensile strength of gray cast iron ht200 specimens. Adv. Mater. Sci. Eng. 2021, 2021, 6629413. [Google Scholar] [CrossRef]

- Du, K.; Li, X.; Tao, M.; Wang, S. Experimental study on acoustic emission (AE) characteristics and crack classification during rock fracture in several basic lab tests. Int. J. Rock Mech. Min. Sci. 2020, 133, 104411. [Google Scholar] [CrossRef]

- Li, S.; Wu, Y.; Li, W.; Li, P. Shear test on damage evolution of brick masonry based on acoustic emission technique. Constr. Build. Mater. 2021, 273, 121782. [Google Scholar] [CrossRef]

- Ma, S.; Liu, K.; Guo, T.; Yang, J.; Li, X.; Yan, Z. Experimental and numerical investigation on the mechanical characteristics and failure mechanism of cracked coal & rock-like combined sample under uniaxial compression. Theor. Appl. Fract. Mech. 2022, 122, 103583. [Google Scholar] [CrossRef]

- Song, Q.; Shi, J.; Chen, X. Acoustic Emission Characterization Analysis of Quasi-Static and Fatigue Compression Properties of Aluminum Foam. Processes 2023, 11, 998. [Google Scholar] [CrossRef]

- Park, H.; Hong, K.; Kang, J.S.; Um, T.; Knapek, M.; Minárik, P.; Sung, Y.-E.; Máthis, K.; Yamamoto, A.; Kim, H.-K. Acoustic emission analysis of the compressive deformation of iron foams and their biocompatibility study. Mater. Sci. Eng. C 2019, 97, 367–376. [Google Scholar] [CrossRef]

- Brown, J.A.; Vendra, L.J.; Rabiei, A. Bending properties of Al-steel and steel-steel composite metal foams. Metall. Mater. Trans. A 2010, 41, 2784–2793. [Google Scholar] [CrossRef]

- Ma, Q.; Tan, Y.-l.; Liu, X.-s.; Zhao, Z.-h.; Fan, D.-y.; Purev, L. Experimental and numerical simulation of loading rate effects on failure and strain energy characteristics of coal-rock composite samples. J. Cent. South Univ. 2021, 28, 3207–3222. [Google Scholar] [CrossRef]

- Zheng, J.; Jin, X.; Tian, K.; Zhou, Y. Acoustic emission and damage characteristics of anthracite under different conditions. Mater. Technol. 2021, 55, 213–218. [Google Scholar] [CrossRef]

- Xu, X.; Chen, L.; Gao, F.; Zhang, Z. Studies on loading rate effects and energy mechanism of granite. Chin. J. Solid Mech. 2015, 36, 154–163. [Google Scholar] [CrossRef]

- Mori, T.; Inuzuka, T.; Ismail, M.A.M.; Shaalan, H. AE Measurement via Rock Triaxial Compression Test and Rock Failure Simulation using PFC Analysis. In Proceedings of the ISRM International Symposium-Asian Rock Mechanics Symposium, Singapore, 29 October–3 November 2018; p. ISRM–ARMS10-2018-2155. [Google Scholar]

- Mirgal, P.; Singh, R.K.; Banerjee, S. Acoustic and fracture energy correlation in mode I fracture with concrete damage plasticity model and three-point bend experiment. J. Mater. Civ. Eng. 2023, 35, 04023002. [Google Scholar] [CrossRef]

- Saadat, M.; Taheri, A. Modelling micro-cracking behaviour of pre-cracked granite using grain-based distinct element model. Rock Mech. Rock Eng. 2019, 52, 4669–4692. [Google Scholar] [CrossRef]

- GB/T 228. 1-2010; Metallicmaterials—Tensiletesting—Partl: Method of Testat Room Temperature. Standards Press of China: Beijing, China, 2010.

- Liu, W.; Zhou, W.; Li, H. Acoustic emission characteristics of Pykrete under uniaxial compression. Cold Reg. Sci. Technol. 2022, 202, 103645. [Google Scholar] [CrossRef]

- ISO 945-1:2008; Microstructure of Cast Irons. Standards Press of China: Beijing, China, 1987.

- Tian, J.; Ye, F.; Li, Z.; Xu, Y. Investigation on Microstructure and Mechanism of In-situ Producing Grey Cast Iron Matrix Composite. Hot Work. Technol. 2013, 42, 97–99. [Google Scholar] [CrossRef]

- Xing, J.; Wang, Q. Study of Bainite/Martensite Structure in Grey Cast Iron. Hot Work. Technol. 2006, 35, 12–13. [Google Scholar] [CrossRef]

- Lei, B.; Zuo, J.; Coli, M.; Yu, X.; Li, Y.; Liu, H. Investigation on failure behavior and hydraulic fracturing mechanism of Longmaxi shale with different bedding properties. Comput. Geotech. 2024, 167, 106081. [Google Scholar] [CrossRef]

- Tian, W.; Yang, S.; Huang, Y.; Yin, P.; Zhu, Z.; Sun, B. Meso-fracture mechanism of granite specimens under high temperature and confining pressure by numerical simulation. Chin. J. Rock Mech. Eng 2022, 41, 1810–1819. [Google Scholar] [CrossRef]

- Lachart, P.; Tonn, B.; Stolz, E.; Esderts, A.; Masendorf, R. Prediction of Cross-Section-Dependent ADI Microstructures by Experimental Heat Treatment Simulation. Int. J. Met. 2024, 1–12. [Google Scholar] [CrossRef]

- Ljustina, G.; Larsson, R.; Fagerström, M. A FE based machining simulation methodology accounting for cast iron microstructure. Finite Elem. Anal. Des. 2014, 80, 1–10. [Google Scholar] [CrossRef]

- Li, X.; Li, Y.; Yang, C.; Zhang, L.; Li, Z.; Huang, T. Acoustic emission response characteristics and numerical simulation of soil failure under uniaxial compression. J. Appl. Geophys. 2024, 222, 105310. [Google Scholar] [CrossRef]

- Niu, Z.; Wang, X.; Zhang, L.; Wang, J.; Chang, Z.; Qian, C.; Chen, X. Investigation into the Failure Characteristics and Mechanism of Rock with Single Elliptical Defects under Ultrasonic Vibrations. Fractal Fract. 2024, 8, 261. [Google Scholar] [CrossRef]

- Song, X.; Yuan, Q.; Wang, S.; Dong, Z.; Hao, Y. Analysis on mechanical properties and mesoscopic acoustic emission characteristics of prefabricated fracture cemented paste backfill under different loading rates. Environ. Sci. Pollut. Res. 2023, 30, 24687–24707. [Google Scholar] [CrossRef] [PubMed]

- Li, K.; Zhang, F. Study on the Meso-Failure Mechanism of Granite under Real-Time High Temperature by Numerical Simulation. Appl. Sci. 2024, 14, 4575. [Google Scholar] [CrossRef]

- He, C.-S.; Wang, W.-W.; Tang, Y.-X.; Xue, Y.-J. Experimental Study on the Static Behavior and Recovery Properties of CFRP/SMA Composites. Sustainability 2023, 15, 13078. [Google Scholar] [CrossRef]

- Chai, F.; Ma, Z.; Han, X.; Hu, X.; Chang, Z.; Zhou, J. Effect of strain rates on mechanical behavior, microstructure evolution and failure mechanism of extruded-annealed AZ91 magnesium alloy under room-temperature tension. J. Mater. Res. Technol. 2023, 27, 4644–4656. [Google Scholar] [CrossRef]

- Liu, X.; Liu, Z.; Li, X.; Gong, F.; Du, K. Experimental study on the effect of strain rate on rock acoustic emission characteristics. Int. J. Rock Mech. Min. Sci. 2020, 133, 104420. [Google Scholar] [CrossRef]

- Yu, X.; Zuo, J.; Mao, L.; Xu, X.; Lei, B.; Zhao, S. Uncovering the progressive failure process of primary coal-rock mass specimens: Insights from energy evolution, acoustic emission crack patterns, and visual characterization. Int. J. Rock Mech. Min. Sci. 2024, 178, 105773. [Google Scholar] [CrossRef]

- Wan, L.; Jiang, T.; Wu, Q.; Dong, J.; Yu, Z. Critical slowing down characteristics of acoustic emission for fracture instability of sandstone down-slope rock bridge under cyclic wetting and drying. Theor. Appl. Fract. Mech. 2024, 131, 104372. [Google Scholar] [CrossRef]

- Liu, K.-D.; Zhou, Y.; Zhang, X.-P.; Fu, S.-J.; Liu, Q.-S.; Dong, P.; Yao, K.-W.; Wang, D.-B. Study on mechanical properties and acoustic emission characteristics of deep diorite under uniaxial compression. Heliyon 2024, 10, e24482. [Google Scholar] [CrossRef] [PubMed]

- Lai, X.; Fang, X.; Shan, P.; Gu, H.; Zhan, S.; Liu, X. Analysis of mechanical response mechanism and energy evolution characteristics of saturated coal with a single pre-existing hole. Geomech. Geophys. Geo-Energy Geo-Resour. 2024, 10, 103. [Google Scholar] [CrossRef]

- Huang, L.; Li, B.; Li, C.; Wu, B.; Wang, J. Research on anisotropic characteristics and energy damage evolution mechanism of bedding coal under uniaxial compression. Energy 2024, 301, 131659. [Google Scholar] [CrossRef]

- Wang, Y.; Zheng, X.; Jiao, H.; Cheng, F.; Zhao, H. Energy evolution mechanism and energy yield criterion in granite’s failure process. Explos. Shock Waves 2016, 36, 876–882. [Google Scholar] [CrossRef]

- Liu, W.; Yan, E.; Dai, H.; Du, Y.; Xiao, W.; Zhao, S. Study on characteristic strength and energy evolution law of Badong formation mudstone under water effect. Chin. J. Rock Mech. Eng. 2020, 39, 311–326. [Google Scholar] [CrossRef]

- Yu, H.; Liu, S.; Jia, H.; Wang, S. Mechanical response and energy dissipation mechanism of closed single fractured sandstone under different confining pressures. J. Min. Saf. Eng. 2020, 37, 385–393. [Google Scholar] [CrossRef]

- Xia, Z.; Yuan, H.; Li, H.; Yu, X.; Fang, X.; Huang, S. Energy Transfer and Damage Evolution Process Research of Ore Rock-Filling Body under the Blasting Load. Minerals 2022, 12, 1362. [Google Scholar] [CrossRef]

| Grade | C | Si | Mn | P≤ | S≤ | Cr< |

|---|---|---|---|---|---|---|

| HT150 | 3.3–3.5 | 2.0–2.4 | 0.5–0.8 | 0.2 | 0.12 | 0.12 |

| Smooth Joint Parameters | Normal Stiffness (sj_kn/Gpa) | Shear Stiffness (sj_ks/ Gpa) | Friction Coefficient (sj_fric) | Normal Strength (sj_coh/N) | Cohesive Force (sj_ten/N) |

|---|---|---|---|---|---|

| Count | 6.1 × 1013 | 6.1 × 1013 × 0.2 | 0.8 | 178 × 106 | 178 × 106 × 0.3 |

| Micro-Parameters | Values | ||

|---|---|---|---|

| Pearlite | Graphite Flake | Matrix | |

| Micro-properties of grey cast iron | |||

| Density (kg/m−3) | 2700 | 2560 | 2600 |

| Elasticity modulus (emod/Gpa) | 55 × 109 | 65 × 109 | 50 × 109 |

| Stiffness ratio (kratio) | 0.2 | 0.2 | 0.2 |

| Friction coefficient (fric) | 0.55 | 0.55 | 0.55 |

| Parallel bond elastic modulus (pb_emod/Gpa) | 55 × 109 | 65 × 109 | 50 × 109 |

| Parallel bond stiffness ratio (kratio) | 0.3 | 0.2 | 0.25 |

| Tensile strength of cement (pb_ten/N) | 23.14 × 105 | 18.2 × 105 | 20.15 × 105 |

| Cementation and cohesion (pb_coh/N) | 165 × 105 | 140 × 105 | 155 × 105 |

| Internal friction angle of cement (pb_fa/o) | 40 | 50 | 30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Lei, Z.; Xu, S.; Sun, H.; Li, B.; Qiao, Z. Probing Internal Damage in Grey Cast Iron Compression Based on Acoustic Emission and Particle Flow. Processes 2024, 12, 1893. https://doi.org/10.3390/pr12091893

Li Z, Lei Z, Xu S, Sun H, Li B, Qiao Z. Probing Internal Damage in Grey Cast Iron Compression Based on Acoustic Emission and Particle Flow. Processes. 2024; 12(9):1893. https://doi.org/10.3390/pr12091893

Chicago/Turabian StyleLi, Zhen, Zhao Lei, Sheng Xu, Hengyang Sun, Bin Li, and Zhizhong Qiao. 2024. "Probing Internal Damage in Grey Cast Iron Compression Based on Acoustic Emission and Particle Flow" Processes 12, no. 9: 1893. https://doi.org/10.3390/pr12091893

APA StyleLi, Z., Lei, Z., Xu, S., Sun, H., Li, B., & Qiao, Z. (2024). Probing Internal Damage in Grey Cast Iron Compression Based on Acoustic Emission and Particle Flow. Processes, 12(9), 1893. https://doi.org/10.3390/pr12091893